Page 1

®

INDUSTRIAL

SEWING

FINEST QUALITY

ST

YLE

S

63400AF

63400BF

LEWIS

•

COLUMBIA

MACHINES

CLASS

63400

STREAMLINED

CATALOG

No.

HIGH

SPEED

LOCKSTITCH

WITH

121AF

FEEDING

CHICAGO

PRESSER

MACHINE

FOOT

Page 2

(Supplement

Catalog

to

No.

Catalog

INSTRUCTIONS

FOR

121

AF

No.

121

M)

ADJUSTING

LIST

Streamlined

63400

First

AND

OF

CLASS

Styles

AF

OPERATING

PARTS

63400

Lockstitch

63400

Edition

BF

Union

Rights

Copyright

by

Special

Reserved

1971

Machine

in

All

MACHINE COMPANY

INDUSTRIAl

Printed

SEWING

CHICAGO

in

2

MACHINES

U.S.

Co.

Countries

A.

July,

1971

Page 3

IDENTIFICATION

OF

MACIDNES

Each

the

machine.

numbers

Example:

only

minor

Style

number.

Styles

which

differs

"Class

This

junction

not

used

Opposite

number,

NOTE:

Adjusting

those

ions

B.

in

included

or

are

Union

Style

have

"Style

changes

of

machines

63400".

catalog

therewith.

on

Styles

the

description

When

ordering

column.

and

Catalog

in

additional

Special

machine

numbers

one

or

more

63400

Example:

are

AF".

made

"Style

similar

from

the

style

is a supplement

Only

63400

those

A

illustration

and

amount

repairparts

operating

No.

121

M

this

catalog

instructions

is

identified

are

classified

letters

Special

suffixed,

Style

in a standard

63400

in

AFZ".

construction

number,

APPLICATION

to

Catalog

parts

and B are

page.

which

illustrated

parts

required.

always

instructions

for

Styles

are

that

the

63400

ones

pertain

by a Style

as

standard

but

never

numbers

machine. a "Z"

are

grouped

in

that

OF

are

are

use

for

A

that

it

contains

CATALOG

No.

121

used

and

on

listed

identified

the

part

Styles

63400

and B respectively.

are

different

specifically

number

and

contain

is

M

and

Styles

number

AF

from

to

Styles

on a name

special.

contain

the

suffixed

the

letter

to

under a class

no

letters.

should

63400

at

the

by

be

AF

back

detail

listed

and

BF

are

The

Styles

63400

plate

Standard

letter

"Z".

the

Standard

number

Example:

used

and

of

in

BF.

this

number.

in

the

similar

only

instruct-

63400

AF

and

on

Style

"Z".

When

con-

but

book.

part

second

to

A

and

BF.

This

herein.

this

from

It

class.

the

handwheel

High

Speed

Medium

Button

matic

matic

for

Stitch

Lubricating

Head

Take-up

Equipped

Work

63400

Space

AF

work,

stitches

recommended

63400

BF

weight

Specify

Maximum

catalog

can

also

Reference

operator's

is

toward

Streamlined

and

Heavy

Regulator,

Oiling.

Lever

with

Feeding

to

Right

For

miscellaneous

1

9/64

per

For

miscellaneous

work.

stitches

recommended

applies

be

the

Duty.

System.

Needle

and

of

inch

inch,

speed

1

13/64

specifically

applied

to

direction.

position

operator.

Long

Drop

Stitch

Needle

Presser

Needle

needle

thread

5500

inch

per

inch,

with

while

STYLES

Arm

Feed,

Length

Head

Oil

Bearing

Bar

Foot

Bar

plain

bar

travel.

size,

R.

P.

plain

needle

thread

speed

to

the

discretion

such

as

seated

OF

MACHINES

Lockstitch

Rotary

Indicator.

Siphon,

Adjustable

Driving

and

Rotary

11

1/8

Inches.

seaming

Type

needle

M.

seaming

bar

travel.

size,

5500

R.

Standard

to

some

right.

at

left,

the

Hook,

Adjustable

Feed

Link,

Feed

Needle

operations

180

type

and

operations

Type

needle

P.M.

Styles

Special

front.

machine.

Machines,

Horizontal

One

Reservoir

Hook

Eccentric,

Timing

Thread

on

light

GXS

or

180

size

and

on

medium

180

GXS

type

and

of

machines

Styles

back,

etc

Operating

One

Needle,

Hook

Enclosed

Oil

Control.

Needle

on

Lower

Tension,

and

medium

GYS

needle.

edge

guide.

and

or

180

size

and

as

of

machines

.•

are

dir2ction

Shaft,

Bearin

Main

Maximum

Maximum

medium

GYS

edge

listed

in

given

of

Light.

Push

AutoAuto-

gs

Shaft.

weight

Specify

heavy

needle.

guide.

3

Page 4

NEEDLES

Each

denotes

number,

sured

the

size

needles

Needle

The

description

Type

180

180

No.

GXS

GYS

To

sample

on

label.

Selection

used.

stitch

formation.

Union

the

kind

stamped

in

thousandths

number

packaged

Type

have

needle,

A

complete

Thread

Special

of

on

needle

shank,

the

of

an

represent

and

sold

180

GXS

and

sizes

Round

groove,

shank,

wide

chromium

Round

groove,

shank,

wide

plated -sizes

needle

or

orders

the

type

order

of

the

proper

should

pass

point,

needle

inch

the

by

Union

or

180

available

round

angle

plated

round

angle

029,

promptly

and

would

needle

freely

has

both a type

length,

shank,

across

complete

Special.

GYS

are

are

point,

groove,

-

sizes

point,

groove,

032,

size

number

read:

size

through

and a size

groove,

denotes

the

eye.

symbol,

finish

largest

Collectively,

which

recommended

listed

below.

Description

lockstitch,

struck

029, 032, 036,

lockstitch,

struck

036,

and

040, 044,

accurately

should

"1000

should

the

Needles,

be

needle

number.

and

diameter

is

for

Styles

and

Sizes

short

groove,

040,

short

groove,

049,

filled,

be

forwarded.

Type

determined

eye

in

order

other

the

given

length,

deep

044, 049,

length,

deep

054,

an

180

by

The

type

details.

of

the

type

on

the

63400

ball

spot,

The

blade,

number

label

AF

eye,

ball

054,

ball

eye,

spot,

chromium

060.

empty

Use

GXS,

the

to

package,

description

Size

size

of

produce a good

number

size

mea-

and

of

and

BF.

single

point,

060.

single

".

036

thread

all

a

11

•

The

size

the

size

The

of

thread.

above,

than

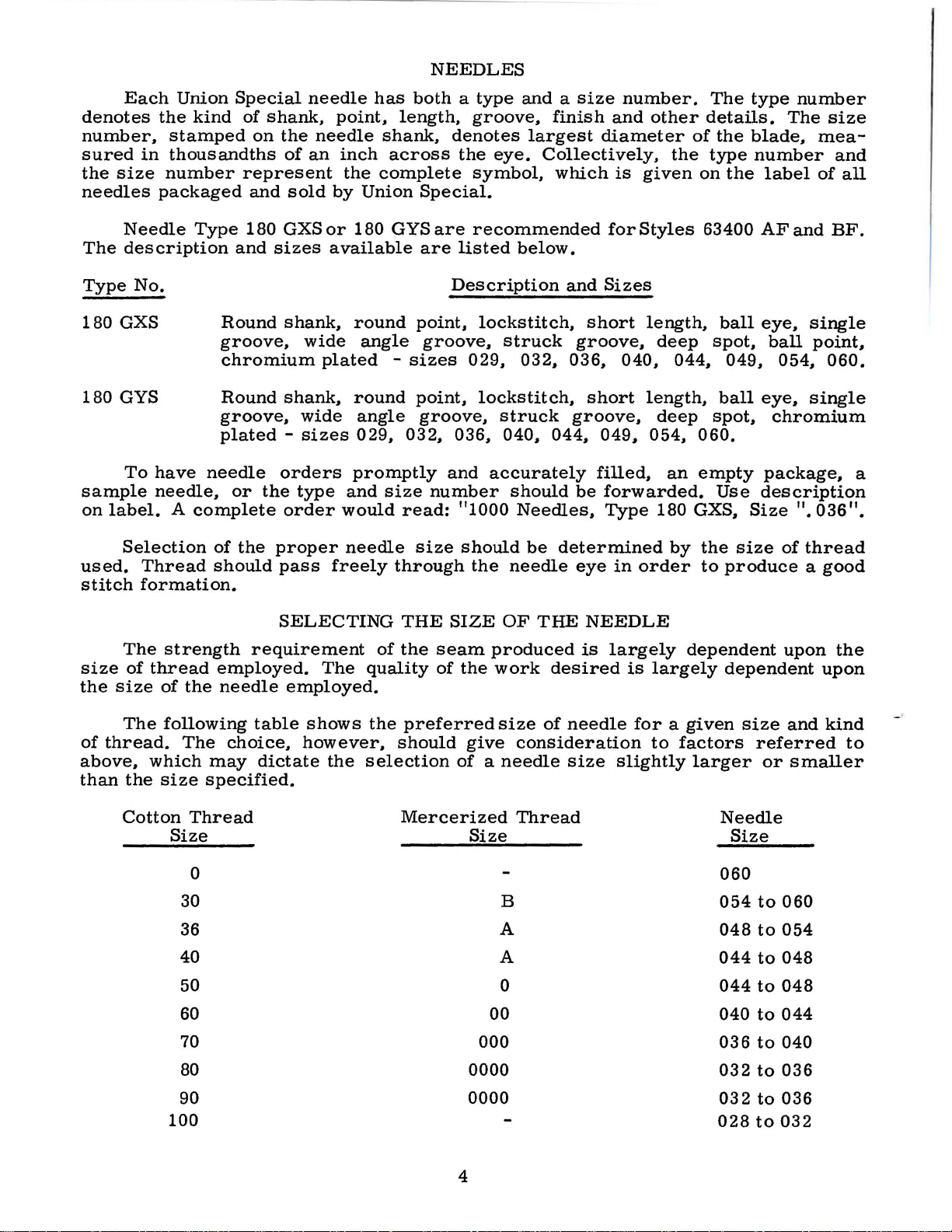

Cotton

of

the

thread

which

size

strength

employed.

of

the

needle

following

The

choice,

may

specified.

Thread

Size

0

30

36

40

50

60

70

80

SELECTING

requirement

The

employed.

table

shows

however,

dictate

the

THE

of

the

quality

the

preferred

should

selection

Mercerized

SIZE

seam

of

produced

the

work

OF

size

give

of a needle

Size

B

A

A

0

00

000

0000

THE

NEEDLE

is

largely

desired

of

needle

consideration

size

slightly

Thread

dependent

is

largely

for a given

to

factors

larger

upon

dependent

size

and

referred

or

Needle

Size

060

054

to

060

048

to

054

044

to

048

044

to

048

040

to

044

to

to

040

036

036

032

the

upon

_,

kind

to

smaller

90

0000

100

4

032

028

to

to

036

032

Page 5

IDENTIFYING

PARTS

Where

Parts

which

too

distinguish

Part

numbers

appear.

IMPORTANT!

OF

MACHINE

The

arrangement

replacement

An

exploded

Styles

The

position.

their

view

listed

plate

part

being

presents a sector

On

the

construction

small

for a complete

FOR

parts

view

in

this

the

page

numbers.

shown.

one

part

represent

ON

ALL

WHICH

of

for

Styles

plate

catalog

opposite

descriptions

permits,

catalog

from

the

another

same

ORDERS,

PART

IS

ORDERING

this

catalog

63400

at

the

back,

and

Styles

of

the

machine,

the

illustration

and

each

stamping

that

part.

PLEASE

ORDERED.

OF

REPAIR

is

to

facilitate

AF

and

BF.

covers

63400 A

parts

the

number

part

is

stamped

are

is

similar

regardless

INCLUDEPART

PARTS

easy

the

differences

and B covered

being

will

be

found a listing

of

pieces

with

identified

in

appearance.

of

the

and

in

aligned

as

required

its

part

number.

by

letter

catalog

in

symbols

which

NAMEANDSTYLE

accurate

between

Catalog

in

of

their

the

in

the

ordering

the

Standard

No. 121 M.

assembled

parts

particular

they

of

with

Numbers

the

position

in

ordering

exploded

Sub-assemblies.

or a solid

can

be

furnished

description

Success

Union

Special

Company,

to

the

most

Maximum

Genuine

parts

are

guarantee

in

of

the

parts.

view

line

of

plate

box

the

in

the

Needles

its

subsidiaries

approved

efficiency

needles

stamped

of

the

the

first

part

Always

carries

which

on

the

for

repairs,

main

USE

operation

and

are

with

highest

column

in

the

illustration.

use

the

a

reference

are

sold

picture

are

sub-assembly.

GENUINE

of

these

and

Repair

and

authorized

scientific

durability

packaged

the

Union

quality

in

are

reference

part

number

number

complete,

plate.

Component

indicated

NEEDLES

machines

Parts

as

distributors.

principles,

are

assured.

with

labels

Special

materials

TERMS

numbers

Reference

listed

for

or

by

by

indenting

AND

REPAIR

can

furnished

and

are

marked

trade

and

mark.

workmanship.

numbers

each

separate

parts

their

be

by

They

made

~

only,

and

should

in

the

second

part

available

part,

of

sub-assemblies,

descriptions

PARTS

secured

the

Union

are

designed

with

Each

utmost

trade

merely

never

are

only

Special

.

Genuine

mark

indicate

be

used

column.

for

The

sale.

in a bracket

which

under

with

the

genuine

Machine

according

precision.

repair

is

your

Prices

are

forwarded

otherwise

are

strictly

f.

o.

directed.

b.

shipping

A

charge

net

cash

is

and

point.

made

subject

Parcel

to

cover

5

to

change

Post

the

shipments

postage

without

and

notice.

are

All

insured

insurance.

shipments

unless

Page 6

INSTALLING

CAUTION!

on

handwheel.

Before

carefully

packing

A

attaching

packed.

box,

bag

screw,

miscellaneous

the

Insert

upper

hinge

frame

Included

ing

one

bobbin

its

clamp

and

screw,

essential

spring,

when

When

Using

leaving

both

factory,

After

the

following

PREPARATION

of

assembly

one

attachments

studs

eyelet

also

with

winder

one

four

isolator

setting

unpacking,

hands

each

the

machine

steps

parts,

extra

in

(A,

bobbin,

to

holes

Fig.

the

STANDARD

each

machine,

assembly,

knee

lifter

pads

up

the

machine.

DO

on

bed

Union

should

OF

MACHINE

consisting

bed

provided

2A).

is a box

the

machine

assembly

and

clips,

NOT

lift

machine

casting,

Special

and

accessories

be

followed:

FOR

of

one

two

hinge

plate,

for

is

packed

them

ACCESSORIES

of

STANDARD

mounting

and

its

and

one

out

of

lift

gently.

machine

is

have

INSTALLATION

frf3_me

studs

thread

and

with

in

rear

of

ACCESSORIES--contain-

frame,

rubber

machine

pad,

rest

box

sewed

been

two

each

cloth

one

bed

pin.

by

placing

off,

inspected

removed

eyelet,

screws

machine.

plate.

oil

drain

positioning

These

one

from

one

eyelet

for

holding

Assemble

jar

spring

parts

hand

and

the

and

are

Lockstitch

the

bed

On a

cut-out

through

over

the

nuts

right

retaining

lightly.

Place

1/16

inch

taining

of

the

Tip

shown.

must

not

plate

sui~abl

with

left

hinge

hinge

sewing

clearance

plate

board

machine

All

end

bind.

machines

is

FLUSH

.

e

tableboard,

the

hinge

pad

pad;

plate

smartly

and

tighten

back

play

TABLE

are

with

installed

the

top

of

in

the

MACHINE MOUNTING

lugs

and

tighten

insert

(21393 R)

head

in

between

upward

locking

against

of

the

place

to

the

round

to

the

frame

the

with a hammer

cross

machine

rear

securely.

head

outside

mounting,

cloth

nuts

securely.

rest

pin,

shaft

(Fig.

wood

front

plate

should

TOPS

table

machine

FRAME

mounting

1).

Assemble

screw

of

edge

to

and

assemble

be

tops,

prepared

mounting

INSTALLATION

Insert

pan

and

and

frame

bed

and

section,

after

the

(21393

the

countersunk

positioning

tighten

being

frame

insure a good

the

knee

taken

up

by

with

frame.

securely.

as

shown,

sure

sides,

grip

press

the

cone

cut-out,

N)

in

spring

there

on

the

assembly

bearings,

so

the

machine

wood

screw

(63474

Assemble

and

snug

is

rap

the

underside

that

A)

up

about

re-

as

but

6

Page 7

MACHINE

MOUNTING

FRAME

INSTALLATION

(Continued)

Before

lifter

maximum

in

raises

located

in

the

pulley

the

under

121

al

"THREAD

rod

the

head.

approximately

The

directly

operation.

mechanism

of

belt

to

"Winding

M.

These

Thread

requirements.

the

machine

should

lift

bobbin

the

wind

machines

machine

CONTROL".

be

of

the

This

winder

in

The

to

winder,

the

the

adjusted.

presser

may

5/16

front

base

be

moved

when

bobbin.

Bobbin",

are

as

has

been

is

put

The

bar

be

done

inch.

should

of

the

sewing

of

the

winder

closer

in

operation,

Regulation

under

equipped

indicated

enlarged

Needle

into

production,

left

stop

and

its

by

setting

BOBBIN

be

secured

machine

has

to

and

OPERATOR'S

BELTS

to

use

THREADING

in

Fig.

for

is

threaded

screw

parts

WINDER

to

two

or

farther

should

operation

either

2A.

clarity

from

the

(22597

do

not

the

stop

the

table

belt

elongated

exert

#1

Check

and

left

bell

crank

F)

interfere

screw

top

and

will

bear

attaching

away

of

INSTRUCTIONS,

"Vee"

spring

from

only

the

bobbin

or

threading

described

to

right.

(21665

should

with

so

that

so

that

against

belt

enough

winder

round

under

J)

be

set

moving

the

its

pulley

holes,

as

pressure

in

belts.

with

paragraph

of

the

so

that

parts

presser

will

the

belt

which

needed.

against

is

described

Catalog

dimension-

knee

the

with-

bar

be

when

allow

The

No.

on

6347

'

21393N

6

} 16630

660-

168

Fig.

1

\ '-651-16

"'-213

93S

6

3476

61477

C

7

Page 8

OILING

CAUTION!

the

reservoir

Fill

oil

is

be

added

straight

in

the

Oil

left

in

The

of

the

arrow

the

flow

It

long

period,

parts.

Run

machine

speed

Oil

has

main

at

maximum

when

mineral

main

may

the

oil

quantity

machine

must

reservoir

reservoir.

be

reservoir

be

level

needle

oil

drained

of

just

of a Saybolt

oil

below

(counterclockwise)

of

oil.

is

recommended

be

lubricated

After

operation

oiling,

slowly

can

replace

for

then

been

filled

at

before

plug

when

is

in

yellow

This

from

cover.

supplied

the

increases

that a new

by

head

several

be

expected

drained

screw

needle

band

viscosity

is

equivalent

main

reservoir

to

the

cloth

the

machine,

removing

cover

minutes

from

starting

(B,

is

in

marked

hook

plate.

oil

as

to

without

the

main

to

operate.

Fig.

2A)

yellow

"LOW".

of

90

to

Union

by

is

controlled

Turning

flow

and

or

one

the

head

no

further

distribute

damage.

reservoir

and

check

band

marked

Use a stainless

to

125

seconds

Special

removing

plug

by

the

dial

in a clockwise

that

has

cover

and

hand

oil

to

before

oil

level

"FULL".

at

100°

specification

screw

dial

located

in

the

direction

direction

been

out

oiling

oiling

the

will

various

shipment

at

gauge

Oil

water-white

Fahrenheit

located

on

decreases

of

service

all

the

be

required.

parts.

should

No.

on

the

front

of

for

moving

and

(C);

175.

the

the

a

Full

WR

AP

THREAD

ROTARY

2

1/2

TURNS

THEN

POST

THREAD

EYELET

TENSION

AROUND

DISC

CLOCKWISE

TENSION

Fi

g. 2A

8

Page 9

The

adjusting

63400 A and B covered

instructions

INSTRUCTIONS

for

Styles

in

Catalog

TO

No.

SET

121 M,

THE

FOR

63400

FEED

MECHANICS

AF

and

BF

with

the

additions

TIMING

are

the

same

as

follows:

as

for

Styles

NOTE:

needle

the

screws

gauge.

needle

Hold

the

mark

eccentric

on

screws

sure

lower

ing.

ADJUSTING

feed

in

both

feed

should

above

stroke.

plunger

right

While

wheel

regulating

slot

plunger

ting

and

stitch

The

be

set

To

reset

and

oil

gauge.

through

Turn

bar

the

lower

"9"

on

the

bed

in

that

main

The

feed

slots

directions,

as

well

rise

the

To

(located

and

rear

holding

in

operating

of

feed

down,

direction

in

opposite

length.

feed

eccentric

at

"9

".

the

large

handwheel

lines

there

of

throat

change

finger

plug

Loosen

the

the

is

at

the

main

casting

the

shaft.

FEED

eccentric.

shaft

the

adjustable

up

lower

is

Recheck

dog

must

the

throat

as

in

approximately

plate

the

in

of

needle

plunger

is

turn

to

increase

direction

Release

timing

feed

MECHANISM

direction

timing,

screw

the

hole

handwheel

securely

with

wall.

no

across

the

stitch

the

felt

handwheel

located

lower

below

top

of

until

the

Retighten

sprocket,

end

the

be

centered

plate

line

at

the

length,

bed

bar)

down,

to

drop

Continuing

the

to

decrease

plunger.

its

the

feed

timing

play

hook

and

the

of

3/64

top

base

in

turn

until

in

stitch

line

remove

below

sprocket

the

until

and

the

stroke.

turn

timing

driving

line

the

being

in

the

tim-

in

the

leveled

line

feed.

inch

of

its

press

to

the

firmly.

handstitch

into

the

to

hold

opera-

length

the

to

oil

of

It

.

Stitch

uations

ed

through

next

to

Adjust

threads

lengths

on

the

the

the

handwheel.

the

are

visible

are

indicator

window

ADJUSTING

presser

above

indicated

dial

and

in

the

spring

the

by grad-

are vie

belt

guard

THE

regulator

bed

casting.

w-

FEEDING

(A,

Fig.

9

PRESSER

16A)

so

Fi

g.

16A

FOOT

that

approximately

thr

ee (3)

Page 10

ADJUSTING

THE

FEEDING

PRESSER

FOOT

(Continued)

Back

flat

on

adjusting

Tighten

the

lock

off

throat

lines

nut

stop

on

screw

plate

the

(D).

(B)

and

presser

in

feed

foot

feeding

dog

bottom,

presser

down,

adjust

line

foot.

up

With

stop

with

the

nut

the

centerline

(C.

presser

Fig.

foot

16A)

of

the

resting

until

needle.

the

Loosen

presser

lifter

above

machine

screw

or

the

required

the

the

adjust

needle

lever.

Set

left,

lock

guide

needle

Remove

bar

the

the

back

in

the

the

nut

to

stop

slot

screw

(G),

presser

throat

lifter

proper

to

reset

and

before

nut

nut

will

depress

plate

against

lever

setting

lock

the

presser

tightening

(A.

(C)

so

not

(E.

Fig.

bar

seat

the

the

stop

presser

bar

Fig.

that

touch

16A)

presser

connection

(See

rest

pin.

bell

crank

for

the

screw

bar

guide

connection.

screw

18C)

when

the

and

the

needle.

Fig.

in

presser

foot

(A.

Fig.

loosening

(61468

presser

in

place.

(E).

presser

presser

lifter

Fig.

16B).

(F.

be

Lock

10

16B

bar

lever

16B)

This

F).

By

bar

connection

Release

Fig.

sure

spring

foot

in

guide

and

so

is

the

lock

turning

1)

allowing a 1/16

the

presser

(B)

is

pushed

position

(F),

while

retighten

its

top

accomplished

nut

and

the

stop

is

accomplished.

pressure

foot

of

the

feeding

forward.

with

lock

holding

screw

surface

relocating

screw

on

presser

inch

is

in

presser

nut

down

(E).

Release

is 5 1/8

by

tipping

the

to

the

Retighten

spring

space

alignment

the

rear

(D).

between

foot

Replace

inch

stop

right

with

and

of

on

the

as

the

Page 11

ADJUSTING

THE

FEEDING

PRESSER

FOOT

(Continued)

presser

between

stop

screw

of

1164

Lift

Should

loosen

18C)

as

spring

the

inch

feeding

adjustment

screw

required

top

(F)

on

(B)

in

throat

in

and

of

the

feeding

presser

be

bottom

to

obtain

adjusting

yoke

plate

(E)

foot

so

when

foot

and

necessary,

of

presser

proper

nut

and

top

that

foot

check

remove

foot

position.

(A)

on

of

presser

is

lifted

to

shank

presser

spring

foot

with

see

if

the

presser

to

Retighten

foot,

(B)

with

bottom

bottom

reposition

feed

screw.

slides

dog

foot

and

the

down.

is

parallel

leveling

adjust

feed

rearward a maximum

from

dog

to

the

spring

to

45164

down.

throat

machine

(G,

inch

Adjust

plate.

Fig.

and

Set

to

top

Set

1

I 64 ,;.nch

thread

the

thread

spring

check

thread

Thread

thread

tension

Set

spring

bottom

ine

is

at

Set

light

being

as

sure

Fig.

needle

of

cloth

tension

running

not

spring

pull-up

machine

2 112

dis

check

overthrows

of

speed.

needle

possible

plate

clearance

pull-up

threaded

times

c.

spring

checkspring

check

thread

post

from

bracket,

1 I 2

bracket

as

clockwise

and

bobbin

to

spring

18C

THREAD

pull-upbracket4

(See

Fig.

eyelet

between

the

(See

inch

shown.

tension

threadline

motionwhen

produce a good

is

so

rotary

with

Fig.

above

(See

around

so

thread

acting

16A).

there

it

tension

the

18D).

bottom

Fig.

Wind

that

slightly

tension

properly.

is

and

check

18E).

needle

rotary

check

mach-

stitch

CONTROL

19/32

the

to

Set

of

at

as

inchfrombottom

a

Fig.

(underside)

Fig.

18E

18D

ofbracket

may

to

feed

When

have

the

sewing

to

be

bottom

various

changed

ply

materials,

to

faster

get

good

and

vice-versa.

the

ply

matching.

pressure

11

of

Increasing

the

feeding

the

foot

presser

pressure

spring

will

tend

Page 12

12

Page 13

The

are

used

Use

catalog.

parts

on

Styles

Catalog

illustrated

63400

No.

121 M

on the

AF

and

BF,

(Styles

opposite

but

63400 A or

page

not

used

and

on

B)

described

Styles

for

all

on

this

not

page,

illustrated

63400 A or B respectively.

parts

represent

or

the

described

parts

in

that

this

Reference

descriptions,

Ref.

No.

1

3

5

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

33A

34

35

36

37

38

39

39A

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57 73 c

Part

No.

63457

63457

2

61257

51257

4

63957

21390

6

7

8 57

57 WD

57

22564

63471

63471

90

12935

63992

HS24 C

22513

63970

29475

660-269

63992

22560

63492

63492

63453

61492

61492

61492

63492

61292

61405

61424

63420

63420

63430

22785

22560

63430

56330

63430

63430

22799

22798

56330

56330

56330

56330

604

52930

51430

61377

41071

563

30

63430

61405

61424 AB-063

63459

22570

AP

s

AB

A

AS

AJ

AG

AF

AC

F

Q

G

AD

v

AB

B

numbers

indicate

M

L

G

G

A

BE

we

WB

B

A

A

A

A

BE

A

G

A

B

N

T

s

H

C-4

c

AA

AA-063

J

H

u

B

T

w

that

are

they

are

Lock

Stop

Nut

Presser

Presser

Presser

Nipper

Screw,

Nipper

Nipper

Screw--------------------------------------------------------

Nipper

Nipper

Screw,

Screw,

Tension

Screw-----------------------------------------------------------Screw,

Thread

Rotary

Quad

Tension

Tension

Tension

Take-up

Felt

Rotary

Tension

Tension

Tension

eed Dog, 22

F

hroat

T

Presser

Pr

esser

Yoke---------------------------------------------------------

Presser

Presser Foot

Presser Foot Bottom,

Hin

Screw,

Hin

flin

Regulating Screw---------------------------Link Hin

Scr

Cha

N

Washer

Lock

Compressi

Regulating

F

eed Dog,

Throat

P

ress

Screw-------------------------------------------------------Screw--------------------------------------------------------

inside a bracket

component

Nut

---------------------------------------------------------

---------------------------------------------------------

Spring

Bar------------------------------------------------------

Bar

Spring Assembly

for

Spring------------------------------------------------Spring Plate

Base

Spring

for

nipper

for

tension

Post

for

thread

Pull-up

Needle

Ring ----------------------------------------------------

Set

\Vas

Tension

Plate, . 063 inch

Foot,

Foot, for

Screw---------------------------------------------------Screw----------------------------------------------------

Bu

shing

63420

J - -

63420

1-I----------------------------------------------------- 1

ge

Pin

for

ge

Spring ----------------------------------------------

ge P

in---------------------------------------------

ew, f

in

Cutting

ut

---------------------------------------------------------Nut

22 t e e

Plate, . 063

er

Bar Gui

parts

Regulator

Bushin

Socket

Post

Screw

Post

Release

Spring ----------------------------------------------her

Release

Spring-----------------------------------------------Nut

Foot

g,

lower

nipper

Bracket--------------------------------------------

Tension

teeth

for

spring---------------------------------------

-------------------------------------------------Mounting Bracket

spring assembly----------------------------------

assembly

Eyelet

pull-up

Socket

------------------------------------------------

------------------------------------------------P 'n

-------------------------------------------------Disc

Washer---------------------------------------

--------------------------------------------------

per

wide

nar

r ow

Link, marked

-------------------------------------------------Bottom,

---------------------------------------------------

Screw----------------------------------------------

hinge spring

ge

Screw----------------------------------------------

or chain cut

Knife,

------------------------------------------------------

----------------------------------------------------on

Spring -------------------------------------------

Nut

--------------

th

per i

inch needle hole, for

de------------------------------------------------

or

box

on

the

of a complete

Description

and

Bushing-------------------------------

---------------------------------------

- -

-----------------------------------------

-------------------------------------------

--------------------------------

---------------------------------------

----------------------------------------

bracket-----------------------------------

Assemb

inch,

needle

feed

tin

nch, for

ly

-----------------------------------

-------------------------------------------

------------------------------------------

------------------------------------------

for

wide

hol

combination

feed com

m a r k

marked "BU",

----------------------------------------

g knife

ma

r ked "D"

feed

e,

for

bination

"C"

--------------------------------

ed

"BV", for

---------------------------------

--------------------------------

-

---------------------------------

narr

ow f

picture

part

or

combination

wide

----------------------------

--------------------------

for

eed

narrow feed com

assembly.

feed

pre

presser

combination-------------

plate

combination

sser foot

-

and

have

---------------

foot

-----------------

binati

--------

o.

No.

-

on

-------

------

indented

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

---1

1

1

1

- - 1

1

1

1

1

1

1

1

1

1

1

1

13

Page 14

BOOST

PRODUCTION

WITH

WORK

UNION

THESE

AIDS

SPECIAL

FROM

PNEUMATIC

conventional Class

scissor-action

posi

live

AIR

FABRIC

signed

to

remove curls

knit materials as fabric passes

area. Style

CHAIN-CUTTER-lor

mechanism

cut.

Style

2899

lor

UNCURLER-This

Class

39500

from

2899

B-1

39500

and

that

A-1

machines, uses air jets

top

and bottom plies of

39600

is

a durable

makes a clean

"--"

unit,

through

use on

de·

flat

sewing

PNEUMATIC

operated

machines

simply by knee-touch ing an actuating

CHAIN

CUTTER-

small pneumatic chain cutter that is available

lor

Installat ion as an accessory

:16200

Flalseamers. Style 2899A-6

FOOT

fool

lifter

lor

allows

use on Class

the operator to raise the

The above photo

LIFTER-The

shows

unit

on

39500

loot

switch

Class

air-

the

.

KNIFE

GRINDER

kn

ives, is simple and easy to operate, elimi-

type

nates defective g11rments caused

sharpens

straight

by

dull knives.

®

u

II

NISTQUALITY

MACHINE

ELECTRONIC

wheel

to

insurmg better

move the needle

NEEDLE

control,

uniform quality and increased

up

or

down

POSITIONERS

AMCO

or

angle

..• this allows

HEAT

DISPELLER-

unit (arrow) is an effective means

oil temperature where heavy duty service re-

quires i

t.

Style

el

iminate

the

operator

necessi

the

production.

Union Special's auxiliary

2899

E-1

ty

of

to

reaching

keep both hands on

lor

lor

reducing

the

hand·

the

work,

Page 15

Helpful,

cient

types

machine

Promotion

Sales

esting,

obligation

illustrated

authoritative

of

equipment

sewed article

are the

Department.

bulletins

following:

information

for

is

available

Among

that

on

the

making

are available

from

virtually

Union

the

many

most

effi

Special's

inter-

without

any

-

HERE

ARE

HELPFUL

No.

240,

"Men's,

No.

249,

"Rainwear"

No.

250,

"Men's

No.

251,

"Service

No.

252,

"Men's

No.

253,

"Overalls, Coveralls, and Dungarees"

No.

254,

"Men's

No.

256,

"Knit

No.

259,

"Men's

No.

260,

"Work

No.

262,

"Cotton,

No.

263,

"Men's

No.

264,

"Men's

No.

265,

"Women's

No.

266,

"Women's

No.

267,

"Corsets, Girdles, Brassieres"

No.

268,

"Children's

No.

269, "Mattresses,

Upholstery"

No.

271,

"Awnings,

No.

273,

"Curtains & Drapes"

No.

610,

"Kiipp-it"

No.

710,

"MCS

No.

730,

"MCS

Hemmer"

No.

740,

"MCS

No.

750,

"Fusing

No.

1100,

No.

1105,

"Columbia

ing

Machines"

No.

1500,

Women's,

Dress

Shirts

Shorts

Knit

Outerwear"

Sports

Gloves"

Bags"

"Lewis

stitch,

"Button

Blindstitch,

"Alteration

Burlap,

Clothing"

Women's,

ForMation

Automatic

Automatic

Presses"

Blindst

Machines"

Children's

Shirts"

and

Pants"

and Pajamas"

Underwear"

Shirts"

Jute,

and

Children's

Wear"

Wear

And

High

Wear"

Slip

Covers,

Canopies, Tents,

Unit"

Dual

Underfront

Rib-Knit

itch,

Chainstitch,

Sewers-

Ticket

Saddle

Stitch,

Department

Footwear"

Multiwall

Jackets"

Fashion"

Furniture

Tarps"

Cuff

Machine"

Lock-

Tackers"

and

Tie

Machines"

Paper

Shirt

Clos-

BULLETINS

TO

SEWING

HELP

PROBLEMS

YOU

and

CATALOGS

SOLVE

®

Page 16

,..o

...

...

'

0

WORLD'S

,..&lf

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

and

facilities throughout the world. These offices

aid

you

in

the selection of the right sewing

equipment for your particular operation. Union

Special representatives

tory trained

promptly

tion, there

and

and

is

a Union Special Representative

serve you. Check with

ATLANTA,

BOSTON, MASS.

CHICAGO,

DALLAS,

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

GA.

ILL.

TEXAS

YORK, N.

Y.

PA.

efficiently. Whatever your loca-

are

and

service men

able

to serve your needs

him

today.

MONTREAL, CANADA

TORONTO, CANADA

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUnG

ART, GERMANY

service

will

are

fac-

to

ENGLAND

ENGLAND

400

Representatives

MACHINE

N.

FRANKLIN

industrial

and

cities

distributors

throughout

COMPANY

ST.,

CHICAGO,

in

the

all

Important

world.

ILL.

60610

Loading...

Loading...