Page 1

®

INDUSTRIAL

SEWING

FINEST QUALITY

STYLES

63400AB

LEWIS

•

COLUMBIA

MACHINES

CLASS

63400

STREAMLINED

ATALOG

No.

121AB

HIGH

SPEED

TOP

CHICAGO

LOCKSTITCH

DRIVEN

WITH

GRIP-FEED

MACHINE

Page 2

Page 3

Catalog

(Supplement

No.

to

Catalog

INSTRUCTIONS

FOR

121

AB

No.

121

M)

ADJUSTING

Streamlined

Union

Rights

LIST

CLASS

63400

First

Copyright

Special

Reserved

AND

OF

Style

Edition

by

in

OPERATING

PARTS

63400

Lockstitch

AB

1970

Machine

All

Countries

Co.

August.

MACHINE

INDUSTRIAL

CHICAGO

Printed

1970

COMPANY

SEWING

in

MACHINES

U.S.

3

A.

Page 4

IDENTIFICATION

OF

MACHINE

Each

the

machine.

numbers

Example:

only

minor

Style

which

"Class

junction

on

certain

number,

NOTE:

Catalog

are

that

number.

Styles

This

Style

Opposite

Adjusting

the

pertain

Union

Style

have

"Style

differs

63400".

catalog

therewith.

63400 B

63400 B

description

When

column.

No. 121 M

ones

one

changes

Example:

of

machines

from

parts

the

ordering

and

that

specifically

Special

63400

are

is a supplement

Only

are

illustration

operating

for

are

machine

numbers

or

more

AB".

made

"Style

similar

the

those

illustrated

are

shown

and

amount

repair

Style

different

to

are

Special

style

APPLICATION

instructions

63400

Style

is

identified

classified

letters

in a standard

63400

in

number,

parts

in

pages,

required.

parts

from

63400

suffixed,

Style

ABZ".

construction

to

Catalog

which

and

listed

phantom

parts

always

B.

The

Style

AB.

by a Style

as

standard

but

never

numbers

machine, a "Z"

are

in

that

OF

CATALOG

No. 121 M

are

used

at

the

to

help

are

use

the

for

Style

only

instructions

63400

contain

grouped

it

contains

on

back

locate

identified

part

63400

B,

or

number

and

contain

is

and

Style

of

this

the

number

AB

are

on a name

special.

the

suffixed

under a class

no

should

63400 AB,

63400

by

detail

listed

are

included

additional

Standard

the

letter

to

letters.

be

book.

AB

similar

in

used

For

number,

in

plate

Style

letter

"Z".

the

but

parts.

the

to

this

instructions

"Z"

Whe

Standard

number

Example:

in

con-

not

used

clarity,

part

second

those

catalog

on

.

in

The

It

can

also

Reference

operator's

is

toward

High

One

Hook

Enclosed

Control,

Bearings

Main

63400

denotes

number,

sured

the

needles

Speed

Needle,

Shaft,

Shaft,

AB

as

vinyls,

1

13/64

SeamSpec.

speed

Each

in

size

catalog

be

to

position

the

Streamlined

Automatic

Automatic

for

For

5500

Union

the

kind

stamped

thousandths

number

packaged

applies

applied

direction,

operator.

Light,

Push

Take-up

Maximum

miscellaneous

foam

inch

301-SSa-1.

R.

Special

of

specifically

with

while

Long

Medium

Button

Lubricating

Head

Lever

Work

laminates,

needle

P.

M.

needle

shank,

on

the

of

an

represent

and

sold

discretion

such

bar

needle

as

seated

STYLE

Arm

and

Stitch

Oiling,

and

Space

seaming

travel.

Type

point,

inch

the

by

Union

has

to

the

to

some

right,

at

the

OF

Lockstitch

Heavy

Regulator,

System,

Needle

Needle

to

Right

operations

wash

shank,

across

complete

and

Top

180 GXS

NEEDLES

both a type

length,

denotes

Special.

Standard

Special

left,

the

front,

machine.

MACHINE

Machine,

Duty,

Bearing

Bar

wear,

driven

or

groove,

symbol,

Drop

Stitch

Head

Driving

of

Needle

and

grip-feed

180GYSneedle.

and a size

largest

eye.

Collectively,

Style

Operating

Length

Oil

Adjustable

on

material

finish

which

Styles

back,

with

Feed,

Siphon,

Link,

Bar

hard

and

diameter

of

to

number.

is

machine

of

machines

etc.,

direction

Top

Rotary

Indicator,

Adjustable

Feed

Feed

11

1/8

handle

made

independently

Maximum

other

the

given

as

are

given

Driven

Hook,

One

Eccentric,

Timing

Inches.

materials,

of

natural

The

details.

of

the

type

on

the

listed

in

of

recommended

type

blade,

herein

this

class

from

handwheel

Grip-

adjustable.

number

label

Feed,

Horizontal

Reservoir

Hook

Needle

on

Lower

such

fibers.

number

The

size

mea-

of aft

the

Oil

a J

.-.....__.

-....,--...

4

Page 5

NEEDLES

(Continued)

Needle

description

180

GYS

To

have

sample

on

label.

needle,

Selection

used.

stitch

Thread

formation.

The

size

of

thread

the

size

of

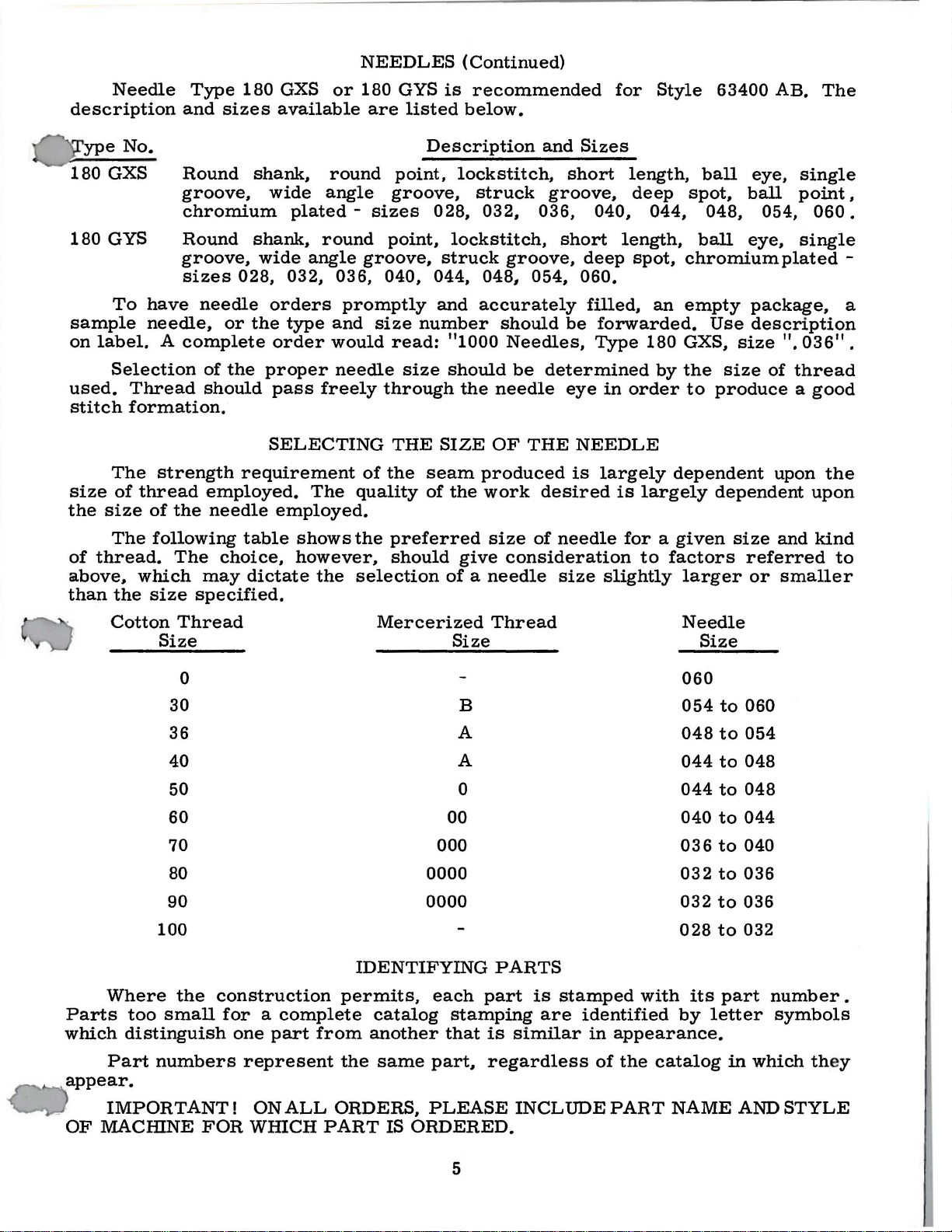

The

following

of

thread.

above,

than

the

which

size

Type

and

Round

groove,

chromium

Round

groove,

sizes

needle

A

complete

of

should

strength

employed.

the

needle

The

may

specified.

180

GXS

sizes

available

shank,

wide

plated -sizes

shank,

wide

028, 032,

orders

or

the

type

order

the

proper

pass

SELECTING

requirement

employed.

table

choice,

dictate

or

180 GYS

round

angle

round

angle

groove,

036, 040,

promptly

and

would

needle

freely

of

The

quality

shows

the

however,

the

selection

are

listed

point,

groove,

point,

size

read:

size

through

THE

the

preferred

should

is

recommended

below.

Description

lockstitch,

struck

028,

032,

lockstitch,

struck

044,

number

and

048,

accurately

should

"1000

should

the

needle

SIZE

seam

of

produced

the

work

OF

size

give

of a needle

and

Sizes

short

groove,

036,

040,

short

groove,

deep

054, 060.

filled,

be

forwarded.

Needles,

be

determined

THE

Type

eye

in

NEEDLE

is

largely

desired

of

needle

consideration

size

slightly

for

Style

length,

deep

spot,

044, 048,

length,

spot,

chromiumplated

an

empty

180 GXS,

by

the

order

to

dependent

is

largely

for a given

to

factors

larger

63400

ball

eye,

ball

AB.

single

point

054,

ball

eye,

single

package,

Use

description

size

".

036

size

of

thread

produce a good

upon

dependent

size

upon

and

referred

or

smaller

The

060.

11

the

kind

to

,

-

a

•

Parts

which

_......_.

~

.appear.

Cotton

Size

30 B

36

40

50 0

60

70

80

90

100

Where

too

small

distinguish

Part

numbers

Thread

0

the

construction

for a complete

one

represent

part

Mercerized

IDENTIFYING

permits,

catalog

from

another

the

same

Thread

Size Size

A

A

00

000

0000

0000

028

PARTS

each

part,

part

stamping

that

is

regardless

is

stamped

are

similar

with

identified

in

appearance.

of

the

catalog

by

Needle

060

054

to

048

to

044

to

044

to

040

to

036

to

032

to

032

to

to

its

part

letter

in

060

054

048

048

044

040

036

036

032

number

symbols

which they

.

IMPORTANT!

OF

MACHINE

FOR

ON

ALL

WHICH

ORDERS,

PART

IS

PLEASE

ORDERED.

INCLUDEPART

5

NAME

ANDSTYLE

Page 6

The

arrangement

replacement

parts

for

ORDERING

of

this

Style

63400

catalog

AB.

OF

is

to

REPAIR

facilitate

PARTS

easy

and

accurate

ordering

o

Exploded

Style

plate

listed

presents a sector

position.

their

view

part

being

Numbers

the

position

in

ordering

exploded

Sub-

assemblies,

or a solid

can

be

furnished

description

view

in

this

On

the

numbers.

shown.

in

of

the

parts.

view

line

of

plate

box

the

plates

catalog

page

opposite

descriptions

the

first

part

Always

carries

which

on

the

for

repairs,

main

USE

at

the

back,

and

Style

of

the

machine,

the

and

column

in

the

illustration.

use

the

a

reference

are

sold

picture

are

plate.

indicated

sub-assembly.

GENUINE

NEEDLES

cover

63400 B

parts

illustration

the

number

are

reference

Reference

part

number

number

complete,

Component

the

covered

being

will

or

by

indenting

AND

differences

in

aligned

be

found a listing

of

pieces

numbers

numbers

listed

for

by

in

each

separate

parts

their

REPAIR

between

Catalog

as

in

required

only,

and

should

the

second

part

available

part,

of

sub-

descriptions

PARTS

the

No. 121 M.

their

of

in

assembled

the

parts

the

particular

merely

never

column.

for

are

in a bracket

assemblies,

under

Standard

Each

with

indicate

be

used

Each

sale.

which

the

Success

Union

Special

Company,

to

the

most

Maximum

Genuine

parts

are

guarantee

Prices

are

forwarded

otherwise

in

the

Needles

its

subsidiaries

approved

efficiency

needles

stamped

of

the

highest

are

strictly

f.

o.

directed.

operation

and

scientific

and

durability

are

packaged

with

the

quality

net

b.

shipping

A

charge

of

Repair

and

authorized

Union

cash

is

these

Parts

principles,

are

with

Special

in

materials

TERMS

and

subject

point.

made

Parcel

to

machine

as

furnished

distributors.

and

assured.

labels

marked

trade

and

to

Post

cover

6

can

be

secured

by

the

They

are

made

~.

mark.

workmanship.

change

without

shipments

the

postage

are

with

Each

and

only

Union

Special

designed

utmost

trade

notice.

are

insured

insurance.

with

according

precision

Genuine

mark

All

shipment

genuine

Machine

repair

is

your

unless

.

-----

Page 7

INSTALLING

CAUTION!

n

handwheel.

Before

carefully

packing

A

attaching

miscellaneous

Insert

the

upper

Includedalsowith

ing

one

its

clamp

and

screw,

essential

packed.

box,

bag

of

screw,

hinge

frame

bobbin

spring,

when

When

Using

leaving

the

PREPARATION

assembly

attachments

winder

four

setting

both

factory,

After

following

one

studs

eyelet

one

isolator

unpacking,

hands

each

the

machine

steps

parts,

extra

in

(A,

eachmachine

assembly,

knee

up

bobbin,

to

the

holes

pads

the

provided

Fig.

STANDARD

lifter

and

machine.

DO

NOT

on

bed

casting,

Union

should

OF

consisting

bed

2A).

the

assembly

clips,

Special

and

be

MACillNE

two

plate,

is a box

machine

lift

machine

lift

gently.

machine

accessories

followed:

FOR

of

one

hinge

is

for

them

ACCESSORIES

of

STANDARDACCESSORIES--contain-

mounting

and

its

and

one

INSTALLATION

frame

studs,

packed

machine

with

in

rear

rubber

out

of

is

have

thread

and

of

frame,

pad,

rest

box

sewed

been

two

each

cloth

one

bed

pin.

by

placing

off,

inspected

removed

eyelet,

screws

machine.

plate.

oil

positioning

for

drain

These

one

hand

from

one

eyelet

holding

Assemble

jar

and

spring

parts

are

and

the

Lockstitch

the

bed

On a suitable

cut-out

through

over

the

nuts

1/16

taining

of

shown.

must

right

retaining

lightly.

Place

inch

the

board

Tip

not

plate

with

the

left

hinge

hinge

sewing

clearance

plate

and

machine

All

end

bind.

machines

is

FLUSH

MACHINE MOUNTING

tableboard,

hinge

pad

pad;

plate

head

smartly

tighten

back

play

are

with

lugs

to

and

tighten

insert

(21393 R)

in

the

between

upward

locking

against

of

the

cross

TABLE

installed

the

top

place

the

rear

securely.

round

to

the

head

outside

frame

cloth

with a hammer

nuts

rest

shaft

in

of

the

machine

(Fig.

wood

front

mounting,

plate

securely.

pin,

should

TOPS

table

machine

FRAME

mounting

1).

Assemble

screw

of

edge

to

and

assemble

be

tops,

Insert

pan

and

insure a good

taken

prepared

mounting

INSTALLATION

frame

bed

and

section,

after

and

the

up

(21393

the

countersunk

positioning

tighten

being

frame

the

knee

by

with

frame.

securely.

as

shown,

sure

sides,

grip

press

the

cone

cut-

N)

in

spring

there

on

the

assembly

bearings,

out,

so

the

machine

wood

and

rap

screw

(63474

Assemble

snug

is

the

underside

that

A)

up

about

re-

as

but

7

Page 8

MACIDNE

MOUNTING

FRAME

INSTALLATION

(Continued)

Before

lifter

rod

should

maximumlift

in

the

head.

raises

located

in

the

pulley

the

under

approximately

The

bobbin

directly

operation.

mechanism

of

the

belt

to

"Winding

121 M.

These

Thread

enlarged

for

the

machine

be

of

the

This

winder

in

The

to

winder,

wind

the

the

machines

machine

clarity.

adjusted.

presserbar

may

be

5/16

should

front

base

be

of

of

moved

when

bobbin.

Bobbin",

are

as

Needle

is

put

into

The

and

done

inch.

be

the

sewing

the

winder

closer

in

operation,

Regulation

under

equipped

indicated

is

threaded

production,

left

stop

itsparts

by

setting

BOBBIN

secured

machine

has

to

or

and

OPERATOR'S

BELTS

to

use

THREADING

in

Fig.

from

the

screw

donot

the

stop

WINDER

to

the

belt

two

elongated

farther

should

operation

either

2A.

#1

Threading

left

bell

(22597

crank

F)

(21665

should

be

J)

set

interferewithmovingpartswith-

screw

table

and

will

away

exert

of

the

INSTRUCTIONS,

"Vee"

to

right.

so

top

so

bear

attaching

from

only

enough

bobbin

or

round

at

check

that

that

against

holes,

belt

winder

the

its

pulley

the

as

needed.

pressure

in

belts.

spring

of

the

so

that

presser

will

belt

which

against

is

described

Catalog

has

knee

the

ba

be

when

allow

The

No

been

.

2

284

6347

6Q-16

6

63474A

63476C

-

Fi

g. 1

8

Page 9

OILING

CAUTION!

the

reservoir

Fill

il

is

e

added

straight

in

the

Oil

The

in

the

wise

direction

NOTE:

It

long

period,

parts.

Run

machine

speed

must

main

at

maximum

reservoir

when

mineral

main

may

reservoir.

be

quantity

direction

The

top

twice

is

recommended

daily.

be

After

oiling,

slowly

operation

Oil

has

be

level

needle

is

oil

of a Saybolt

drained

of

oil

of

the

arrow

decreases

driven

lubricated

replace

for

can

then

been

filled

when

in

This

from

at

plug

yellow

drained

before

needle

is

main

supplied

(counterclockwise)

the

flow

grip-feed

that a new

by

head

several

be

expected

from

starting

screw

(B,

is

band

marked

viscosity

equivalent

reservoir

to

the

hook

of

oil.

mechanism

machine,

removing

cover

minutes

without

the

to

Fig.

in

yellow

of

to

is

or

the

as

no

to

distribute

main

reservoir

operate.

2A)

and

band

"LOW".

90

to

125

Union

by

Special

removing

controlled

increases

must

one

head

be

that

cover

further

damage.

before

check

marked

oil

"FULL".

Use a stainless

seconds

specification

plug

screw

by

dial

(E).

the

oil

flow

manually

has

and

hand

oil

to

been

oiling

oiling

the

oiled

out

various

level

at

100°

Turning

of

will

shipment

at gauge

Oil

water-white

Fahrenheit

No.

(D,

Fig.

the

and

in a clock-

at

(F,

Fig.

service

all

the

moving

be

required.

parts.

and

(C);

should

175.

2A) .

dial

2A)

for

Full

a

Fi

g.

2A

9

Page 10

(a)

presser

The

63400 B

TO

Remove

end

connecting

and

a v o i d c

main

stitch

covered

CHANGE

the

of

the

withdraw

feed

to

INSTRUCTIONS

adjusting

STITCH

snap

top-

hinge

hip p in g teeth

foot

dog

the

instructions

in

Catalog

ring

grip-

pin.

feed

while

required

pin

feed

(A,

This

dog

setting

LENGTH

from

No. 121

one

drive

Fig. 2 8)

is

to

of

the

or

the

the

length

for

AND

.

FOR

Style

M,

SET

MECHANICS

63400

with

THE

AB

the

additions

TOP-GRIP-FEED

are

the

as

same

follows:

as

for

Style

Loosen

(b)

a

(c)

Turn

wise

retighten

NOTE:

crank

equal

sides,

adjustment

screws

the

(C) a s r e

screws

Turn

(d)

forward

(e)

Replace

snap

NOTE:

the

the

ward

nut

left

hand

screw

to

its

extreme

nut

Be

link

lateral

so

there

be

{B,

top-grip-feed

qui

(B).

handwheel

end

the

ring.

It

may

top-grip-feed

top-grip-feed

position,

{A,

Fig.

thread).

(B)

counterclock-

position

(A).

sure

that

assembly

clearance

is

no

bind.

necessary,

Fig.

of

28)

rocker

r e d .

to

its

travel.

top-grip-feed

be

necessary

drive

drive

tighten

29) {it

the

top

(C)

on

Should

loosen

and

move

Retighten

position

arm

arm

screws

has

and

feed

has

both

arm

the

drive

to

{D),

so

{E).

top-grip-feed

connecting

loosen

presser

for

screws

alignment

foot

drive

hinge

(E,

Fig.

to

feed

Fig.

arm

pin

insert

dog

28

28)

is

{A)

the

at

(D)

and

and

its

at

the

secure

slightly

hinge

extreme

extreme

rotate

pin.

Hold

with

for-

At

this

{f)

With

Fig.

point

the

29

the

presser

operating

synchronized

the

set

29)

advance

required.

direction

feed

desired

{g)

presser

foot

main

screws

to

the

dogs.

Loosen

necessary

foot

feed

{F,

or

conditions.

Fig.

direction.

to

feed

dog.

holding

top-

grip-

retard

Snug-up

and

observe

Repeat

nut

move

{A,

to

dog

is

28)

raised

The

forward

Should

the

top-grip-feed

feed

drive

the

top-grip-feed

screws,

relationship

timing

Retighten

Fig.

set

the

set

at

presser

or

timing

shaft.

rotate

adjustment

screws

29)

and

stitch

10

its

maximum

slightly,

foot

rearward

be

necessary,

drive

While

handwheel

between

securely.

turn

length

length

rotate

feed

holding

drive

as

necessary

screw

of

dog

simultaneously

shaft

shaft

upper

{B)

the

of

travel.

handwheel

should

loosen

head

the

in

clockwise

top-grip-fee·

the

{D,

handwheel

head

{D)

operating

and

lower

to

obtain

in

be

with

two

Fig.

as

a

""""'"-..-

Page 11

TO

CHANGE

STITCH

LENGTH

AND

SET

THE

TOP-GRIP-FEED

(Continued)

comparable

lateral

before.

(h)

As a basic

dog

point

(E,

presser

presser

(G)

(H),

NOTE:

moving

the

( i) Sew

evenly.

can

( f)

clearance

left

to

to

point,

Fig.

which

position

Care

parts

presser

off

sample

Should

be

adjusted

and

(g)

to

setting,

right.

28)

which

foot

as

foot

feed

secures

as

of

foot.

for

the

main

on

The

both

the

feed

presser

last

stitch

sides

tooth

in-line-of-feed.

required.

dog,

the

required

must

the

of

material

the

will

be

presser

plies

allow

from

presser

and

taken

and

come

Retighten

left

retighten

to

foot

INDEPENDENTLY

this

adjustment.

length.

of

foot

of

the

This

forward,

to

foot

feed

assure

and

examine

out

uneven,

to

Recheck

top

feed

feed

top

can

screws

right,

dog

screws

that

satisfy

Retighten

crank

dog

should

and

bottom

be

accomplished

rearward

(E). A minute

can

be

to

the

(G).

that

no

the

needle

to

see

if

the

top

this

settings

nut

link

assembly

line

feeds

or

obtained

connecting

binding

centers

top

and

driven

condition.

covered

(A).

Recheck

up

with

should

by

loosening

lateral

adjustment

by

loosening

rod

grip

condition

the

bottom

grip-feed

Refer

in

paragraph

for

equal

as

described

the

main

match

tooth

screws

positioning

of

screws

feed

hinge

exists

needle

plies

in

hole

come

mechanism

toparagraphs

(h).

feed

of

the

the

of

out

11

Page 12

12

Page 13

The

parts

that

are

Use

Catalog

Reference

dicate

illustrated

used

on

numbers

they

are

on

Style

63400 AB,

No. 121 M

that

component

TOP

DRIVEN

pages

(Style

12

and

but

63400 B)

are

inside a bracket

parts

of a complete

GRIP-FEED

14,

and

not

used

described

on

for

all

on

MECHANISM AND

Style

63400 B.

parts

the picture

part

or

on

this

page

not

illustrated

plates

assembly.

MISCELLANEOUS

and

or

and

page

15

described

have

indented

PARTS

represent

in

this

descriptions,

the

parts

catalog.

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

6

7

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

7

~a

59

Part

No.

63494

29475

22894

22894

22894

63439

22651

63493 A

63439

22525 c

22894

22711

63439

22657

63979 A

63479

63479

22591

63439 R

63439

63479 A

22656

22519 c

51235

51235

63439

63439

22730

51236

51236

22768

51054

63439

53564

22652

63485

63439 E

56335

51235

22519 c

56341 E

56335 J

22738

51330

56334

36263-936

B

AZ

w

u

v

u

CD-3

v

J

X

E-24

666-244

W0-3

c

666-198

D

y

D-12

G

A

269

20

AE

AD

G

B

82

666-149

77

w

G

482

98

D-20

A

H

G

660-310

s

87 u

F

Description

Plug,

Mainshaft

Grip-

Bed

Grip-Feed

Screw,

Guard,

Screw,

Oil

Columbia

Grip-Feed

Felt

Grip-Feed

Screw,

Grip-Feed

Grip-

Grip-Feed

Screw,

Screw,

Washer,

GripNut,

Washer,

Feed

Screw,

Feed

Feed

Screw,

Adjusting

Feed

Screw,

Spacer,

Dowel

Collar,

Screw,

Bushin

Grip-Feed

Grip-Feed

Retaining Ring

Hin

Grip-Feed

Chain

Screw,

Grip-Feed

Hin

Presser

plastic,

Set

Screw------------------------------------------------------Spot

Screw----------------------------------------------------------

Feed

Set

Screw-------------------------------------------------------

Plug

Screw---------------------------------------------------------Set

Screw------------------------------------------------------for

for

for

Shield,

Fell

Wick,

for

Feed

for

for

Feed

for

feed

Crank

Ferrule

for

Crank

Crank

for

Link

Felt

for

for

Pin,

for

Screw----------------------------------------------------------

for grip-feed

g,

Washer--------------------------------------------------------Screw----------------------------------------------------------

ge P i

n-----------------------------------------------------------

Screw----------------------------------------------------------

Cutting Knife--------------------------------------------------

for

ge Pin-----------------------------------------------------------

Foot

for

arm-----------------------------------------------

and

Counterweight

Screw------------------------------------------------------

Driving

----------------------------------------------------------Driven

drive

drive

drive

for

Lining

Yarn----------------------------------

Drive

for

Drive

drive

Drive

Drive

Drive

grip-feed

grip-feed

for

grip-feed

Rocker

for

feed

Link

oil

Stud----------------------------------------------------Stud

feed

Screw,

Crank

Wick-------------------------------------------------------

feed

grip-feed

for gri

grip-feed

for

grip-feed

Rocker

Drive

Drive

grip-

Connecting Rod

Gear----------------------------------------------

Gear

shaft

guard------------------------------------------

shaft

shaft

drive

-----------------------------------------------------

drive

crank

-------------------------------------------------------shield-------------------------------------------------

crank

rocker

------------------------------------------------------

feed

(See

bracket----------------------------------------

shaft

Shaft

shaft

Shaft

shaft

head-------------------------------------------

Shaft

Head-------------------------------------------

Shaft

Shaft

Sleeve----------------------------------------mechanism

rocker

rocker

Arm-----------------------------------------------

stud----------------------------------------------

crank

Assembly-------------------------------------------

Cap-------------------------------------------------

stud

for

feed

Link

Pin--------------------------------------------

mechani

p-feed

rocker

mechanism

Arm

Arm------------------------------------------------

Connection------------------------------------------

connecting rod

Page

Assembly

----------------------------------------------

----------------------------------------------bushing-------------------------------------

Bushing,

Bushing,

-----------------------------------------------

stud------------------------------------------

crank

arm-------------------------------------------

mechanism

mechanism

Shaft

15)

right----------------------------------

bushing,

left-----------------------------------

support-------------------------------

arm--------------------------------------

arm

cap----------------------------------------

stud-----------------------------------

sm

arm shaft---------------------------------

support-------------------------------

-----------------------------------------

Hinge--------------------------------------

------------------------------------------

--------------------------------

left--------------------------------

------------------------------------

support------------------------------

support--------------------

support-----------------------------

hinge-----------~------------------

--------------as

-

------

Amt.

Req.

2

1

1

1

2

1

2

1

1

3

2

1

1

2

1

1

required

1

1

1

2

1

1

1

1

2

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

2

1

1

1

1

1

2

2

2

1

1

1

1

2

1

1

1

13

Page 14

1

------------

25

14

Page 15

PRESSER

FEET,

(WIDE

FEED

SEWING

DOOS AND

THROAT

COMBINATIONS)

PLATES

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Part

No.

61405

61324

61324

61324

61324

63420

22738

61430

61430

63430

1594

61430

63430

61430

61430

56330

61420

22738

61430

61430

61430

1594

61430

61430

61430

61430

61430

AG

D-063

D-073

D-083

D-093

G

BP

BL

N

A

BK

R

BR

BT

F

CG

BP

BL

BM

A

BK

BN

BR

BT

BS

Description

Feed

Dog,

16

teeth

per

inch,

Throat

Throat

Throat

Throat

Presser

Presser

Plate, • 063

Plate,

Plate,

Plate, . 093

Foot

Assembly

Screw------------------------------------------Feed

Section

Presser

Feeding

Hinge

Presser

Feeding

Feed

Spring-------------------------------------------

Yielding

Screw

Feed

Presser

Feedinp

"BM'

Hinge

Presser

Feeding

"BN"

Feed

Spring-------------------------------------------

Yielding

Foot

Section,

Pin----------------------------------------

Foot

Section,

Section

Section

Foot

Assembly

-------------------------------------------

Section

Foot

Section,

------------------------------------------

Pin----------------------------------------

Foot

Section,

------------------------------------------

Section

Section

inch

. 073

inch

. 083

inch

inch

Guide,

Shank

left,

Bottom

right,

Guide,

----------------------------------

Guide,

Shank-------------------------------

left,

Bottom------------------------------

right,

Guide,

----------------------------------

marked

needle

needle

needle

needle

(without

left,

------------------------------

right,

(with

left,

right,

hole

hole

hole

hole

marked

(without

----------------------------(without

marked

16

marked 11B

16

teeth

16

teeth

marked

"BK"--------------

--------------------

--------------------

--------------------

--------------------

teeth)------------------

"B"

--------------

teeth)

teeth

per

teeth)

"C"

per

inch,

per

"c"

marked

marked

-------------

inch)----------

11

--------------

marked

inch,

marked

-------------

"L"

"N"

----

---

Amt.

Req.

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

61405

61424

63420

22738

61430

61430

63430

1594

61430

63430

61430

61430

56330

61420

22738

61430

61430

61430

1594

61430

61430

61430

61430

56330

AK

AK

F

B

CH

BL

p

A

CE

M

CJ

BT

F

CJ

B

CH

BL

CF

A

CE

CG

CJ

BT

F

(NARROW

Feed

Throat

Presser

Screw-------------------------------------------

Feed

Presser

Feeding

Hinge

Presser

Feeding

SEWING

Dog,

16

teeth

Plate,

Foot

Assembly

Section

Foot

Section,

Pin----------------------------------------

Foot

Section,

COMBINATIONS)

per

inch

---------------------------

. 073

inch

needle

(without

Guide,

Shank-------------------------------

Bottom

left,

marked

left

(without

-----------------------------

right,

(without

hole

"K"--------------------------------------------

Feed

Spring------------------------------------------Yielding

Presser

Screw-------------------------------------------

Feeding

Hinge

Presser

Feeding

Feed

Spring-------------------------------------------

Yielding

Section

Foot

Feed

Section

Presser

"D"--------------------------------------------

Pin----------------------------------------

marked

Section

Guide,

Section----------------------------------

Assembly

Guide,

Foot

Shank-------------------------------

Section,

Foot

Bottom

Section,

"E"

------------------------------------

Guide,

Section

right,

(with

left,

left,

right,

right,

----------------------------------

marked

16

marked

16

teeth

----------------------------16

teeth

marked

--------------------

teeth)------------------

"G"

--------------

teeth)

teeth

marked

teeth)

per

per

marked

"F"

-------------

per

inch)----------

"G"---------------

inch,

inch,

"F"

-------------

"M"

marked

-----

1

1

1

4

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

15

Page 16

WORLD'S

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

and

facilities throughout the world. These offices

aid

you

in

the selection of the right sewing

equipment for your particular operation. Union

and

Special representatives

tory trained

promptly

tion, there

and

and

is

a Union Special Representative to

serve you. Check with

ATLANTA,

BOSTON,

CHICAGO,

DALLAS, TEXAS

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

GA.

MASS.

YORK,

ILL.

N.

Y.

PA.

are

efficiently. Whatever your loca-

service men

able

to serve your needs

him

today.

MONTREAL, CANADA

TORONTO,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUnGART,

service

will

are

fac-

CANADA

ENGLAND

ENGLAND

GERMANY

400

Representatives

MACHINE

N.

FRANKLIN

Industrial

and

cities

distributors

throughout

COMPANY

ST.,

CHICAGO,

In

the

all

Important

world.

ILL.

60610

Loading...

Loading...