Page 1

®

I

NDUSTRIAL

SE

WING

NE

ST

QUALITY

STYLES

61800 c

L E W I S • C 0 L U M B_ I A

MACHINES

61800 D

61800 H

62200G

62200H

No.

lOlL

T

hird

Edition

CLASSES

S

TREAMLIN

N

61800, 62200

EE

DLE FEED

LOCKSTITCH

•

.

ED

MACHI ES

CHICAGO

Page 2

Page 3

Catalog

INSTRUCTIONS

No.

FOR

101

L

ADJUSTING

Streamlined,

The

furnished

CLASSES

Vertical

61800

61800

parts

at

LIST

H

listed

list

D

AND

OF

61800,

Hook,

Styles

61800

in

prices

OPERATING

PARTS

62200

Needle

Feed,

c

62200

62200

this

for

catalog

repairs

Lockstitch

G

H

are

only.

Union

Rights

Third

Copyright

Special

Reserved

Edition

by

Machine

in

1960

All

Countries

MACHINE COMPANY

INDUSTRIAL

Printed

SEWING

CHICAGO

in

MACHINES

U.S.

A.

Co.

August,

1967

Page 4

Page 5

FOREWORD

The predominant

se

wing mac

needle

All

parts

A

few

1.

2.

3.

4.

hin

feed

are

of

the

STREAMLINED

Pleasing

and

taupe

SIMPLIFIED

Lubrication

oil

holes

FLEXIBLE

Maximum

lower

PERMANENT

After

hook

replaced

es

in

the

lockstitch

made

outstanding

ruggedness.

finish

main

the

shaft

to

in

appearance.

is

OILING

of

in

upper

COUPLING

gear

shaft.

hook

gear

without

idea

behind

world.

machines

precision

new

DESIGN

freedom

more

these

arm.

life

is

HOOK

has

been

retaining

further

~

The

new

are a decided

gauges

features

this

functional

from

restful

machines

produced

TIMING

to

(See

timed

screws

attention

is

high

speed.

achievement

insuring

are:

difficult-to-clean

the

eyes.

is

automatic

diagram.

by

the

according

secured,

to

complete

design

Fig.

flexible

to

setting

to

build

streamlined.

provides

with

1.)

factory

hook

and

the

along

interchangeability.

recesses;

the

exception

coupling

procedure.

may

timing.

best

vertical

these

greater

new

located

be

removed

industrial

hook.

lines.

stability

neutral

of

three

in

the

and

the

and

5.

RAPID

Precision

possible

It

is

our

enable

Specials.

Classes

Hand

adjustments

anxious

the

61800.

ADJUSTING

62200 G and H call

Union

to

ACCELERATION

methods

top

operating

constant

customers

The

Special

cooperate

following

62200.

INSTRUCTIONS

described

representatives

aim

to

procure

with

with

in

the

speed

to

furnish

pages

attention

use

of

you

to

manufacture

almost

concisely

all

possible

illustrate

for

MECHANICS

to

parts

illustrations.

will

be

plan

and

of

instantaneous.

prepared

advantages

and

describe

coveringthe

important

found

estimate

in

all

~

component

information

from

parts

to

meeting conditional

manufacturing

r e

quirement

parts

the

use

for

61800

s .

MACHJNECOMPANY

makes

that

will

of

Union

styles

C. D and

centers.

in

3

Eng

ineerin

g De

partment

Page 6

IDENTIFICATION

OF

MACHINES

Each

into

the

Union

name

Machines

contains

no

Standard

Standard

This

herein.

this

given

catalog

It

Class..

from

Where

catalog

by

a

letter

number.

appearance.

Each

it

appears.

Special

plate.

similar

letters.

machine

style

identification

applies

can

also

References

the

operator's

construction

A

symbol

part

nulilber

machine

in

Letters

style.

be

part

which

represents

is

identified

construction

suffixed

Letter

to

to

"Z",

specify

APPLICATION

specifically

applied

to

direction

position

to

with

such

while

IDENTIFYING

permits,

too

small

each

for

its

distinguishes

the

by a Style

are

designated

the

Class

however,

machine

OF

CATALOG

the

Standard

discretion

as

right,

seated

PARTS

Union

complete

it

same

part

number

is

reserved

is

to

some

left,

at

the

Special

catalog

from

regardless

number

by a Class

indicate

of

Special

style

of

Special

front,

machine.

part

is

stamping

another

of

which

is

number

the

individual

as a suffix

construction.

machine

machines

back,

stamped

is

identified

part

similar

catalog

stamped

which

to

as

listed

etc

.•

are

with

in

which

the

in

its

in

IMPORTANT!

STYLE

shipments

Post

cover

type

other

largest

between

represent

OF

Prices

shipments

the

Each

Union

number

details.

diameter

the

MACHINE

are

are

postage

shank

the

Selection

thread

used.

produce a good

ON

strictly

forwarded

are

insured

and

Special

denotes

The

size

of

and

complete

of

proper

Thread

stitch

ALL

ORDERS,

FOR

net

WHICH

cash

at

the

unless

insurance.

needle

the

kind

number,

the

blade

the

eye.

symbol.

r1eedle

should

formation.

PART

TERMS

and

are

buyer's

otherwise

NEEDLES

has

both a type

of a shank,

stamped

measured

Collectively,

size

pass

should

freely

PLEASE

IS

ORDERED.

subject

risk

directed.

number

point,

on

in

thousandths

be

through

INCLUDE

to

change

f.

o.

b.

shipping

and a size

length,

the

needle

type

number

determined

the

needle

PART

without

A

charge

groove,

shank,

of

an

and

by

NAME

notice.

point.

is

number.

finish,

denotes

inch

size

the

size

eye

in

AND

Parcel

made

midway

number

of

order

All

to

The

and

the

the

to

For

of

this

which

than

best

machine.

is

three-quarters

results,

backed

use

only

They

are

by a reputation

of a century.

genuine

packaged

for

producing

Union

under

4

Special

our

highest

needles

brand

quality

name,

needles

in

the ope

~

for

ration

more

Page 7

NEEDLES

(Continued)

TYPE

the

tremely

needle

A

036".

machines

is

NUMBERS

Two

standard

Each

To

have

or

complete

The

given

types

heavy

needle

Type

Size

the

covered

the

AND

of

needles

machines,

nature,

is

stocked

Number

Numb

orders

order

Type

description

Type

er

promptly

and

would

numbers

in

SIZES

needle

Size

this

are

use

by

The

finish

The

in

stamped

number

read

of

catalog

of

the

sold

for

needle

Type

Type

kind

largest

thousandths

and

as

the

needle:

Type

182

number

of

and

in

accurately

should

follows:

needles

are

use

180

GA

shank,

other

diameter

of

the

shank

filled,

be

"1000

listed

in

Classes

GL.

is

available.

and

Size

point,

details.

of

an

inch

of

the

given.

needles.

available

below.

For

number:

the

blade

across

each

empty

Use

for

Beside

61800

operations

length,

(measured

the

needle.

package, a sample

description

Type

use

and

groove,

eye)

180

in

the

Type

62200.

of

is

GL,

the

styles

For

an

ex-

on

label.

Size

number

of

Type

No.

180

GL

182

GA

ILLUSTRATIONS

The

accurate

Five

Each

position.

assembled

plate

Lockstitch.

point.

060,

Lockstitch.

chromium

arrangement

ordering

Exploded

presents

Small

machine.

chromium

067.

of

View

a

keyline

short

plated,

long

plated,

ORDERING

and

purpose

Union

plates

sector

views

Special

cover

Description

length,

length,

sizes -044, 048,

of

show

ball

eye,

sizes -032, 036, 040,

REPAIR

of

this

Machine

the

the

machine,

by

blackened

ball

eye,

catalog

Standard

single

single

054,

PARTS

Company

Styles

parts

area

groove,

060,

is

to

aligned

where

deep

044,

groove.

067.

facilitate

replacement

listed

in

in

parts

spot,

048,

deep

easy

parts.

this

catalog.

assembled

fit

in

ball

054,

spot,

and

the

Sub-assemblies

Each

ponent

Union

on

page

part

Special

facing

plate

available.

bears

Machine

illustration.

are

covered

respective

The

Company

reference

part

in

the

Exploded

description,

part

number

5

Views

numbers

the

used

by

and

arrows

amount

when

dotted

required

ordering

line

for

each

plus

is

boxes.

com-

the

found

Page 8

ILLUSTRATIONS

(Continued)

Component

indicated

assembly.

Ref.

No.

55

56

It

will

not

listed.

assembly

Basically,

single

the

is

and

61800

part

description.

needle

standard

changed.

complete

H,

Near

and

the

page

parts

by

indentation

Example:

Part

No.

51239

be

noted

Replacement

should

62200

be

Classes

while

machine

Special

lists

G,

back

numbers

of

L

97

A

in

the

ordered.

the

are

plates

of

sewing

62200

of

this

where

sub-assemblies

of

description

Feed

above

of

61800

Class

the

near

Driving

Joint,

these

and

same.

upper---------------------

Screw-----------------------

example

parts

62200

62200

the

parts

H.

catalog

is a numerical

components

which

underthe

Description

Connecting

that

is

not

are

the

is a two

In

some

back

of

this

applicable

are

can

be

furnished

descriptionfor

Ball

the

shell

recommended.

same

needle;

cases,

revised

to

shown

the

Styles

index

for

except

therefore,

of

accurate

for

and

the

Complete

Class

quantity

edition

61800 c.

parts.

repairs

the

main

Amt.

Req.

1

2

ball

stud

61800

all

parts

requirement

give

separate

61800

Listed

and

complete

ar

sub-

are

sub-

is

for

D,

are

e

a

STYLES

Streamlined

Needle

Stitch

anism,

Mechanism,

Mechanism,

Space

61800 C Single

61800 D Single

61800 H Single

62200 G Two

Feed

Regulator

One

to

medium

foot.

equipped

heavy

size.

shirts.

garments,

weight

Flat

and

ReservoirEnclosedAutomatic

Separate

Upper

Right

and

with

work.

Hinged

Needle

overalls,

jackets.

articles.

OF

Bed

Drop

with

Locking

Left

of

Needle

Needle

heavy

Needle

double

Needle

requiring

bottom

Machine for

work pants.

MACHINES

Lockstitch

Feed,

Reservoir

Head

Machine

weight

Machine

shop

Rotary

Device,

Mechanism

Bar

10

materials;

Machine

action

heavy

presser

coats,

IN

CLASSES

Machines.

Hook,

for

Inches.

for

miscellaneous

for

compensating presser

for

miscellaneous

thread.

foot.

miscellaneous

dungaree

aprons

Vertical

External

Lubricating

Automatic

Manually

equipped

top sti

16-4 cordis

and

Light,

Needle

tching

s ,

corsets

similar

61800

Lubrication

Lubricated,

seaming

with

seaming

AND

Medium

Hook

operations

Shaft,

Thread

System for

operations

hinged

waistbands

foot.

maximum

operations

and

light,

medium

62200

and Heavy

Thumb

Tension

Main Drivin

of Rotary Hoo

Maximum

bottom

to

on

m e

us

able thread

other

foundation

Duty,

Screw

Me

Wor

on

light,

presser

trousers;

dium

on

work

and heavy

ch-

g

k

k

and

62200 H Two

western

similar

usable

Needle

type

items

thread size.

dungarees.

requiring

Machine for

jackets,

the

use

miscellaneous

me

of

dium

heavy

6

weight

thread.

operation

canvas,

16-4 cor d is

s

on

overalls.

upholstery

maximum

and

Page 9

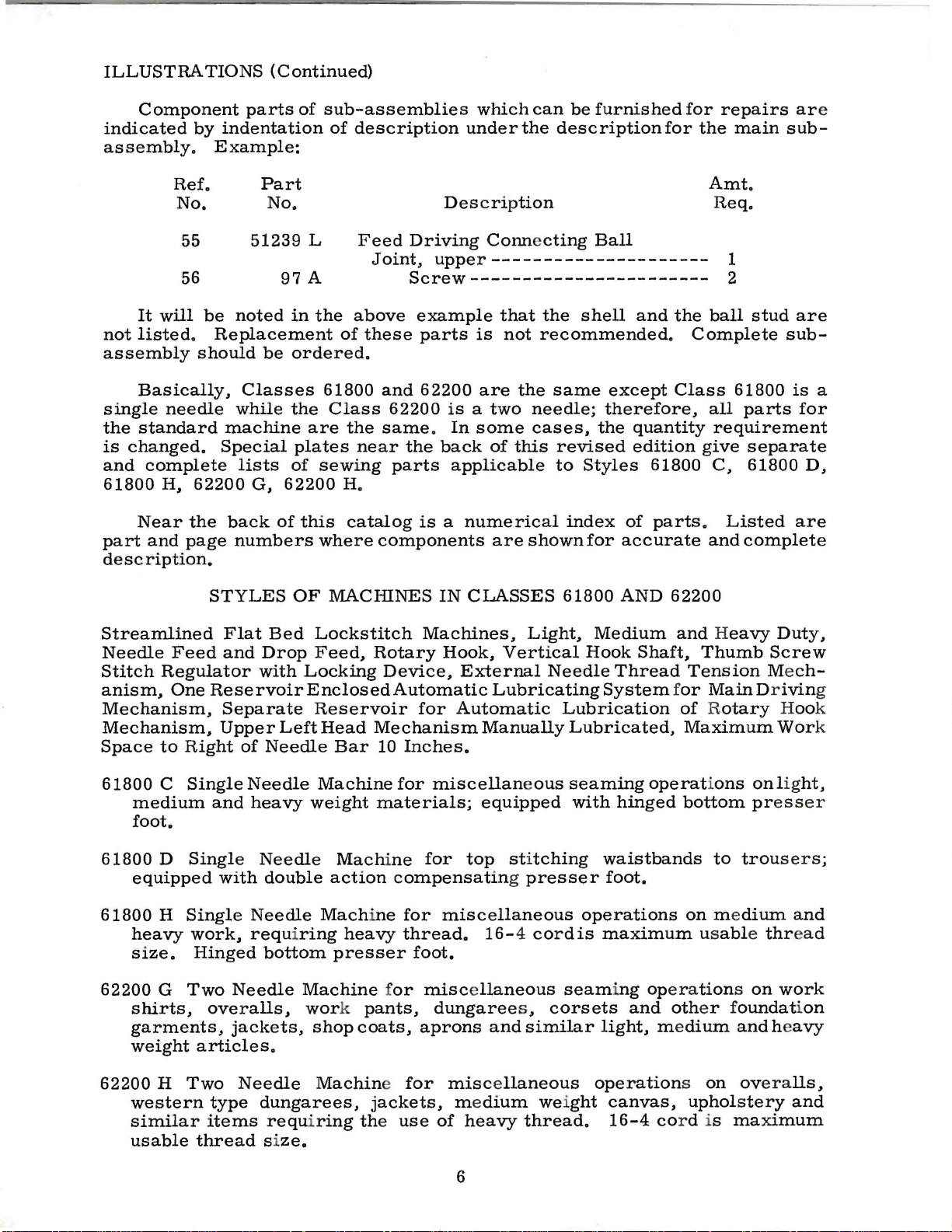

OILING

INSTRUCTIONS

There

62200

cups

are

machines

"C",

"D"

automatically

by a spiral

quired

metering

for

each

screw

reservoir.

the

gears,

feed

bearing

action

stitch

driving

etc.,

and

mechanism

The

level

servoirs

gauges

holes

can

"F"

"A",

mechanism,

and

needle

Use a straight

for

all

oiling

on

operating

lines

of

the

CAUTION!

the

machine

three

which

and

lubricated

oil

screw.

hook

located

The main

regulating

mechanism,

lubricates

also

supplies

through

of

the

readily

,·

"G''

and

"B"

and

the

left

bar

frame

mineral

places.

conditions,

sight

gauges

The

is

shipped

oil

reservoirs

are

"E"

(Fig.

from

The

may

reservoir

these

the

lower

oil

in

be

"H".

"J"

upper

pivot

Lubricate

main

and

filled

1).

its

amount

be

adjusted

at

the

mechanism,

upper

parts

oil

to

shaft.

the

three

observed

The

lubricate

main

pin,

oil

of a Say

and

add

"F",

"G"

reservoir

must

on

the

through

Each

own

the

hook

reservoir

of

oil

for

bottom

which

of

houses

needle

main

by a splash

the

lower

main

at

the

manually

the

shaft

bearing,

respectively.

bolt

machine

oil

to

cuos

and

"H

and

hook

be

filled

Class

oil

is

re-

by

a

the

shaft

feed

re-

lucite

oiled

head

viscosity

at

points

"C",

1

'.

reservoirs

before

of

200

"A",

"D"

and

starting

to

"B"

(or

250

and

"E"

reservoir)

to

operate.

Fig.

seconds

11

J"

twice

to

maintain

1

at

100 °

daily,

is

Fahrenheit

depending

levels

between

drained bef

ore

The

oiling

hook

reservoir.

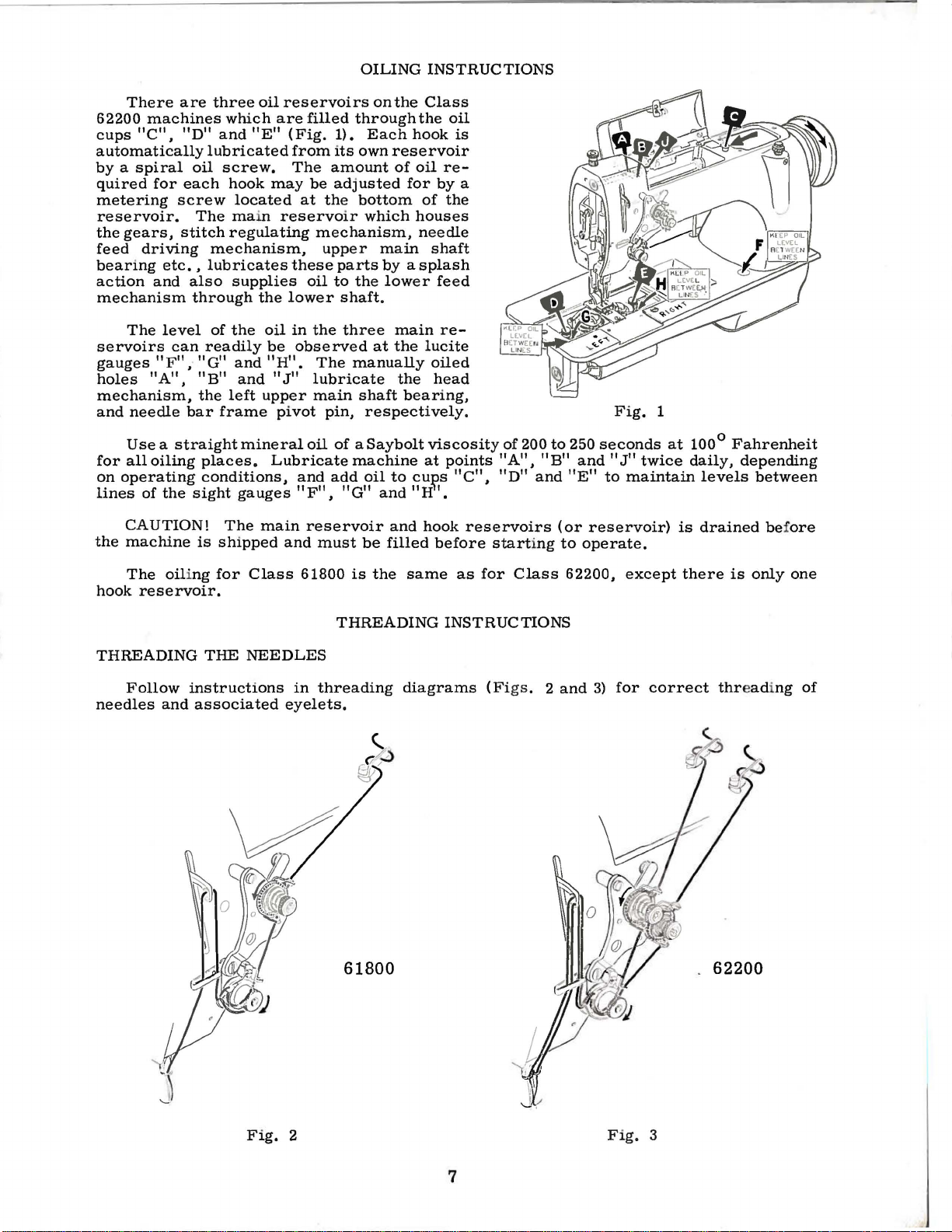

THREADING

Follow

needles

and

for

Class

THE

NEEDLES

instructions

associated

61800

in

threading

eyelets.

is

the

same

THREADING

diagrams

61800

as

for

Class

INSTRUCTIONS

(Figs. 2 and

62200,

3)

except

for

there

correct

is

threading

.

62200

only

one

of

Fig.

2

7

Fig.

3

Page 10

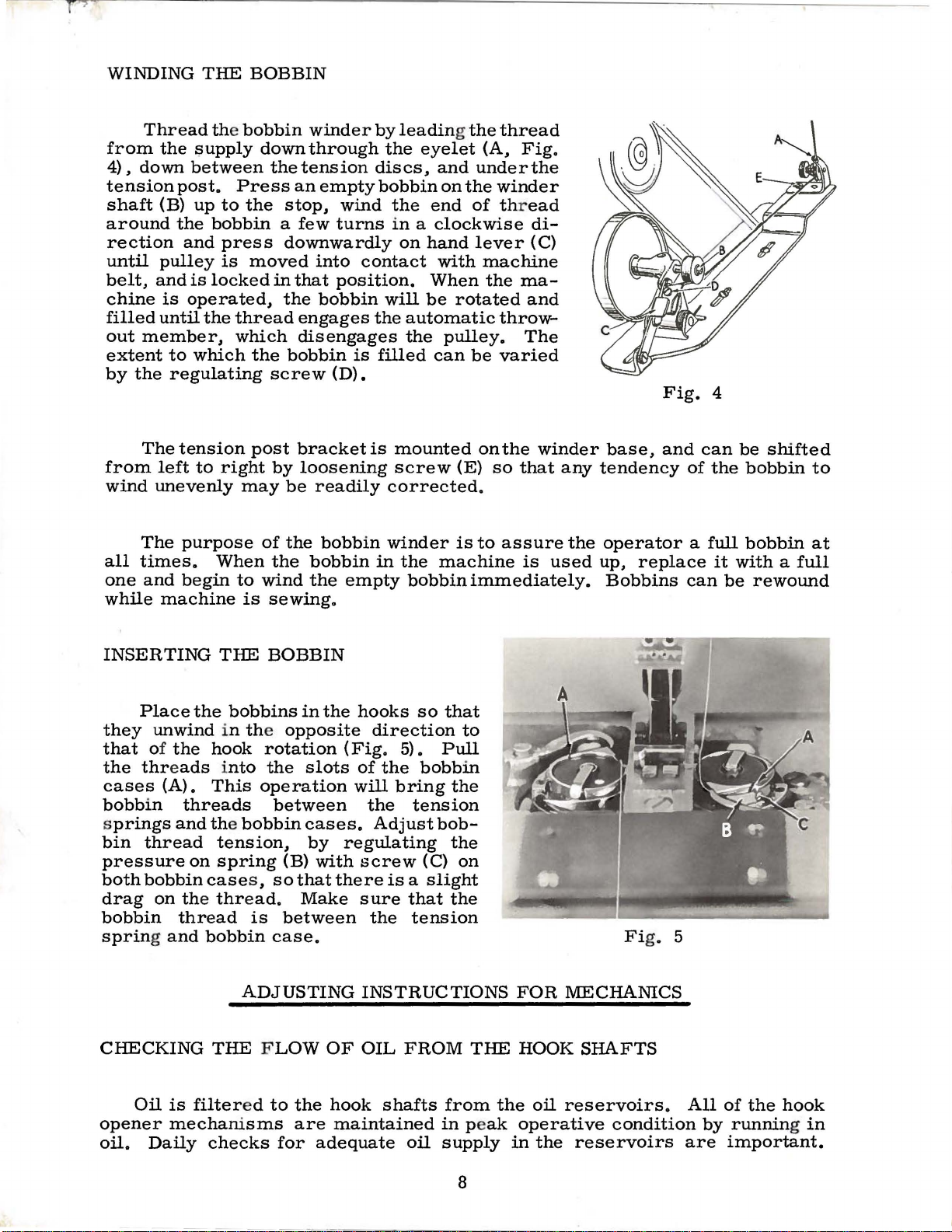

WINDING

THE

BOBBIN

Thread the

from

4),

down

tension

shaft

around

rection

until

belt,

chine

filled

out

member,

extent

by

the

The

from

wind

The

all

times.

one

and

while

the

supply

between

post.

(B)

up

the

bobbin a few

and

pulley

and

is

locked

is

operated,

until

the

to

which

regulating

tension

left

to

unevenly

purpose

When

begin

machine

bobbin

Press

to

the

press

is

moved

thread

which

the

post

right

may

to

is

winder

down

of

wind

through

the

tension

an

empty

stop,

downwardly

into

in

that

the

bobbin

engages

disengages

bobbin

screw

bracket

by

loosening

be

readily

the

bobbin

the

bobbin

the

sewing.

by

the

discs,

bobbin

wind

turns

contact

position.

will

the

is

filled

(D).

is

corrected.

winder

in

empty

leading the

eyelet

and

on

the

end

in a clockwise

on

hand

with

When

be

automatic

the

pulley.

can

mounted

screw

the

machine

bobbinimmediately.

thread

(A,

underthe

the

winder

of thr

lever

machine

the

rotated

throw-

be

varied

on

the

(E)

so

is

to

assure

Fig.

ead

di(C)

ma-

and

The

that

is

winder

any

the

used

Fig.

base,

tendency

operator a full

up,

Bobbins

and

replace

can

of

can

4

the

it

be

shifted

bobbin

bobbin

with a full

be

rewound

to

at

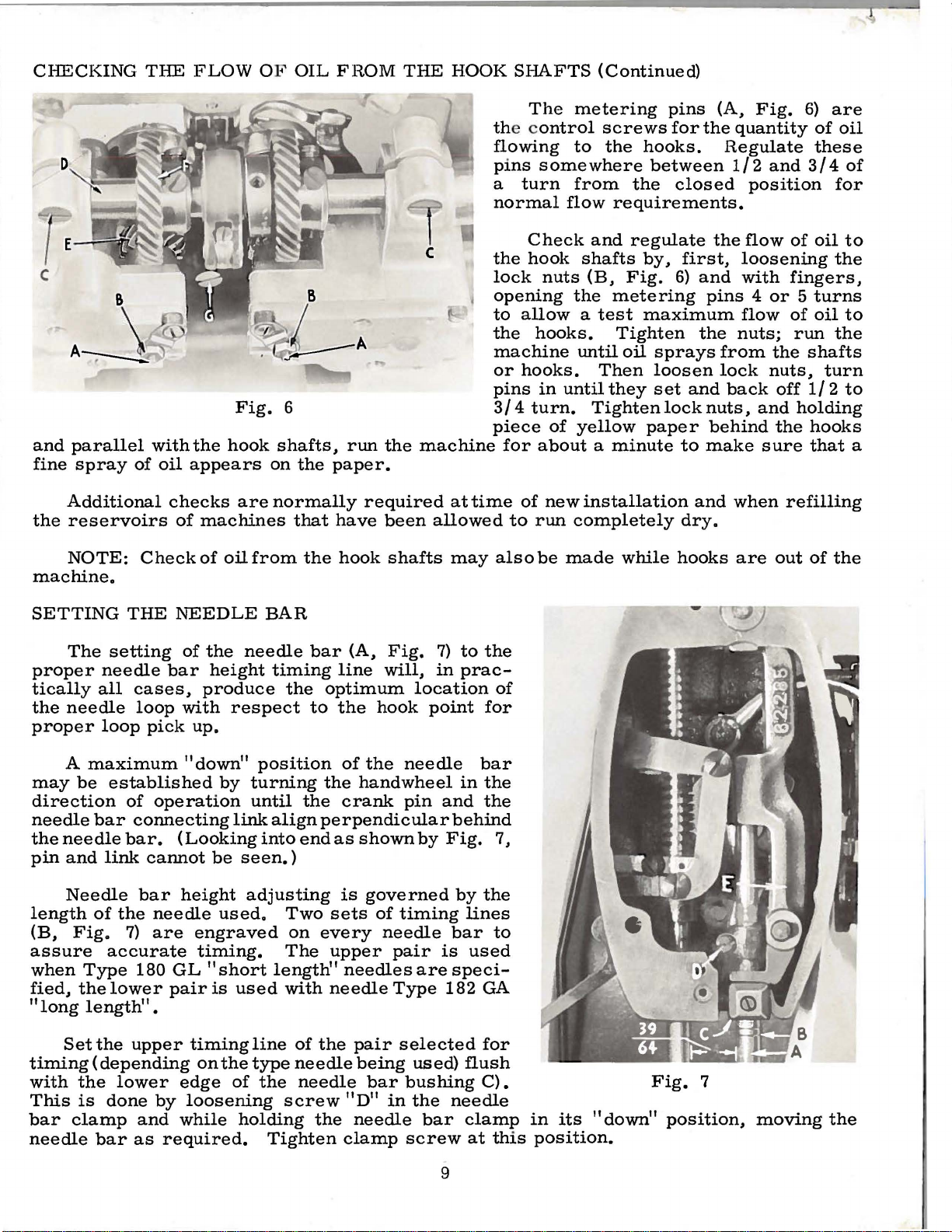

INSERTING

Place

they

that

the

threads into

cases

bobbin

s

prings

bin

thread

pressure

bothbobbincase

drag

bobbin

spring and

CHECKING

Oil

opener

oil.

the

unwind

of

the

hook

(A).

on the

Daily

This

threads

and the

on

thread

bobbin

THE FLOW

is

filter

mechanisms

checks

THE

tension,

spring

thread.

BOBBIN

bobbins

in the

opposite

rotation

the

operation

between

bobbin

(B)

s ,

sothatthereisa

is

between

case.

ADJUSTING

ed

to

for

in

the

slots

cases.

by

with

Make

OF

the

hook

are

maintained

adequate

hooks

(Fig.

of

will

the

regulating

screw

sure

the

INSTRUCTIONS

OIL

so

direction

5).

the

bobbin

bring

tension

Adjust

shafts

bob-

(C)

slight

that

tension

FROM

oil

that

Pull

the

the

on

the

from

in peak

supply

to

THE

FOR

HOOK

the

oil

operative

in

the

Fi

g. 5

MECHANICS

SHAFTS

reservoirs.

condition

reservoirs

All

by

are

of

the

hook

running in

important.

8

Page 11

CHECKING

THE

FLOW

OF

OIL

FROM

THE

HOOK

th

flowing

pins

a

normal

SHAFTS

The

metering

e c

ontrol

to

somewhere

turn

from

flow

(Continued)

pins

screws

the

requirements.

for

hooks.

between

the

closed

(A,

the

quantity

Regulate

1/2

Fig.

position

6)

and

are

of

these

3/4

for

oil

of

and

parallel

fine

spray

Additional

the

reservoirs

NOTE:

machine.

SETTING

The

proper

tically

the

proper

needle

all

needle

loop

with

of

Check

THE

setting

cases,

loop

pick

the

oil

appears

checks

of

machines

of

NEEDLE

of

the

bar

height

produce

with

up.

Fig.

hook

are

oil

from

BAR

needle

respect

6

shafts,

on

the

paper.

normally

that

the

bar

timing

the

optimum

to

run

required

have

hook

(A,

line

the

the

been

shafts

Fig.

will,

hook

c

machine

at

time

allowed

may

7)

to

in

prac-

location

point

Check

the

hook

lock

opening

to

the

machine

or

pins

3/4

piece

the

for

nuts

allow a test

hooks.

hooks.

in

turn.

for

about a minute

of

to

run

also

be

of

and

shafts

(B,

the

until

Then

until

Tighten

of

yellow

new

installation

completely

made

regulate

by.

Fig.

metering

maximum

Tighten

oil

sprays

loosen

they

set

lock

paper

while

the

flow

first,

6)

and

to

dry.

hooks

loosening

and

with

pins 4 or 5 turns

flow

the

nuts;

from

lock

nuts,

behind

make

and

back

and

when

are

the

nuts,

off

the

sure

refilling

out

of

oil

to

the

fingers,

of

oil

to

run

the

shafts

turn

1/2

to

holding

hooks

that

of

the

a

A

maximum

may

be

direction

needle

the

needle

pin

and

Needle

length

(B,

Fig.

assure

when

fied,

"long

timing

with

This

bar

needle

Type

the

length"

Set

the

is

clamp

established

of

operation

bar

connecting

bar.

link

cannot

bar

of

the

needle

7)

are

accurate

180

GL

lower

the

(depending

lower

done

bar

pair

•

upper

by

and

as

required.

"down"

by

link

(Looking

be

seen.

height

used.

engraved

timing.

"short

is

used

timing

on

the

edge

while

of

loosening

holding

position

turning

until

adjusting

line

type

the

align

into

end

)

Two

on

The

length"

with

of

needle

the

needle

screw

Tighten

of

the

needle

the

handwheel

crank

perpendicular

as

is

sets

every

upper

needles

needle

the

pair

being

"D"

the

needle

clamp

pin

shown

governed

of

timing

needle

pair

Type

selected

used)

bar

bushing

in

the

screw

by

are

bar

in

and

behind

Fig.

by

lines

bar

is

used

speci-

182

flush

needle

clamp

at

9

bar

the

the

7,

the

to

GA

for

C).

this

in

its

position.

"down"

Fig.

7

position,

moving

the

Page 12

SETTING

To

to

the

bar

at

r e

move the top

right end

nut

(B, Fig.

(A}

and

F

ig.

of feed until

of

39/64

dle

bar

21227

adjustment.}

quired

8}

and

TIMING

THE

position

presser

the

of the

swing

7}

forward

inch

and

BLis

setting,

re-assemble

NEEDLE

the

needle

bar,

bottom

8}

the

is

the

availablefor

After

of

reservoir

machine.

of

the

the

needle

or

factory

obtained

presser

needle

tighten

BAR

bar

first

backward

cover.

set

its

stroke.

cover

Loosen

feed

driving

bar

specified

between

bar.

measuring

bar

clamp

(Continued}

in

relation

the

needle

Then,

at

clamp

lever

frame

in

(Gauge

meets

nut

(E,

the

line

distance

the

nee-

No.

this

re-

(B,

Fig.

the

Fig.

8

Timing

main

removetheheadcover

shaft.

To

is

change

the

or

synchronization

check

the

andthe

timing

maingearcase

between

between

the

upper

the

reservoirbottom

main

lower

and

shaft

upper

and

main

cover

the

shafts,

(Fig.

lower

9}.

F ig. 9

Make certain

"down" positi

pin

and the needle bar connecting

Timin

butlocated

fl

ats

g between the needle

on

of

the

upp

on

the

er

by

(by a visu

turning the

low

er fe

main

and

al check}

hand

ed

shaft}

lower

wheel

link

bar

and

is

main sha

that

the nee

in dir e

align perpendicul

the

dete

rmin

fts.

feed

ed

ction

lif

by

10

dle

bar

is

of

operation

ar

behind

t eccentric

angular r

in

its

until

the

needle bar.

(not

illustr

elativity

maximum

crank

at e d

between

Page 13

TIMING

(Continued)

Upon

may

be

is

timed

center

(C)

the

taken

which

this

(D)

hub

of

whichis

flexible

to

is

check.

If

timing

to

the

and

location

pling

as

the

hub

timing

coming

case

cover

NOTE:

collar

(F)

operating

Final

after

of

dog

machine

the

holes

entry

needles

as the

the

feed

throat

location

checked

properly,

the

lower

held

coupling

choose

farthest

is

left

far

its

pins

of

the

(E)

is

into

view

ofbottom

There

and

position

check

of

(A,

Fig.

should

dog

plate.

of

the

by

looking

the

main

in

gear

the

correct

away

incorrect,

enough

should

correct

removed

screw

as

reservoir.

should

the

flexible

at

on

timing

is

adjusted

the

needles

10).

enter

is

just

needle

flexible

shaft

(A)

head

(E)

from

to

then

coupling

from

on

the

the

shaft

be

coupling

extreme

by

The

the

feed

passing

bar

into

the

coupling

(D).

willline

has

pin

for

the

two

it

will

be

remove

be

remeshed

pin

the

lower

lower

is

turned

Use

about

right.

can

be

observation

into

the

point

dog

the

in

its

main

It

will

up

two

pins,

the

timing

hub

necessary

it

from

(C)

as

main

no

gasket

1/32

gear

made

feed

of

the

holes

top

of

maximum

reservoir

pin

(C,

also

with

the

located

securing

the

with

shown

main

shaft,

shaft

in

operating

sealing

inch

(A)

when

"down"

at

bottom.

Fig.

be

small

9)

noted

c~sting

180

checking.

screws,

to

move

coupling.

the

idler

in

the

illustration.

the

timing

flat,

direction.

compound

space

this

between

coupling

position,

will

that

apart,

The

the

The

gear

hub

screw

is

If

line

the

end

boss

correct

is

to

lower

gear

to

the

Replace

on

the

gear

the

the

up

of

(B).

care

be

used

main

produce

Ifthe

that

first

any

gaskets.

main

is

timing

machine

with

the

the

pin

Since

must

pin

be

(C)

for

shaft

with

the

the

cou-

is

used

screw

gear

shaft

fixed

in

LOCATING

Having

bar

with

the

feed

dog

with

be

checked.

will

enter

enlarged

if

possible,

To

line

the

main

screw

center

of

(G,

needle

feed,

Loosening

rocker

proper

tighten

shaft

location

clamp

reservoir

To

adjust

of

feed,

(A,

in

needle

Fig.

the

loosen

11)

required

in

THE

FEED

previously

presser

respect

The

feed

the

needle

holes

hole

do

not

enlarge

needles

remove

reservoir

Fig.

9)

the

to

exposing

inthefeeddriving

screw

be

rotated

of

the

screw

bottom

the

the

cover.

feed

feed

andmovethefeed

direction

the

feed

DOG

spaced

bar,

to

the

dog

be

required,

in

the

the

enables

and

dog

rocker

dog

the

position

needles

is

to

be

at

the

the

feed

bottom

to

secure

feed

replace

across

set

rocker

to

center

needle

the

needle

so

center

countersink

bottom

dog

in

cover

the

clamp

the

dog.

the

screws

hole.

of

may

aligned

or

of

the

of

arm.

feed

the

Re-

main

line

(B)

the

just

the

in

the

slightly

the

needle

line

feed

hole.

Fig

of

to

dog

Fi

10

•

feed

the

from

g. 11

that

front.

the

the

Should

top,

needles

an

and,

11

Page 14

TIMING

THE

HOOKS

The correct

The

timing

position

is

placed

Fig.

Visually

respective

maximum

continue

flush

point

with

should

between

of

the

on

hooks.

"down"

to

turn

the

position

the

hook

time

the

flat,

the

12

che

ck

position

Now,

position

until

bottom

be

approximately

of

the

hook

screw

hook

The

time

first

direction

the

to

lockscrew

stitch

possible.

clockwise.

pinion

with

lower

of

one

Fig.

hooks,

produce

Loosen

the

of

turn

of

timing

the

lower

hooks

opener

on

the

opening

screw

visible

.

12

illustrates

it

shortest

(A)

regulator

Lock

the

gears

hook

the

handwheel in

the

needle

1/32

on

finger

hook

finger will

intended

is

recommended

counterclockwise

two

(E,

shaft

needles.

needle

line

inch

their

shaft

as

stitch

(B)

in

position

screws

Fig.

without

bar.

(of

bar

above

shafts

and

the

flat.

be

for

the

hook

the

stitch

length.

also

counterclockwise

6)

so

Make

operating

When

the

pair

bushing.

needle

is

hook

If

the

out

of

the

flat

is

regulato

the

to

by

turning

on

each

the

hooks

turning

sure

their

direction

this

selected)

At

eye.

of

great importan

is

governed

wrong

time

on

turned

regulator

To

do

loosen.

of

the

has

this

hook

with

the

shaft

in

r .

For

this,

lockscrew

the

hook

will

turn

driving gears.

spots

to

been

(B, Fig.

time,

ce.

by the

scr

the

hook

is the

operating

timing

be

turned

turn

the

Turn

as

face

obtain

reached,

the

the

far

(A)

shaft

freely

their

7)

hook

ew

.

as

a

is

The

(Fig.

point

be

is

bent

Adjustment

needle

13)

while

rotated

slightly

and

the

back

to

of

Fi

g. 13

the

needle

and

obtain

the

hooks,

hook

guard

forth

this

point

across

condition.

right

should

is

or

the

Two

and

(tighte

clamp screw

g

hook shaft look

faces. The

and the

if

gear sound

be

approximately . 003 inch apart

just

brushing the needle

the

needl

left,

saddle

hook sa

Aft

the

ear

the ma

e.

The

is

accomplish

scr

ews

ddle

screw

ning the

(F,

s in

er the s addle

retaining screws

s la st)

Fig.

6)

alignment

hook sha

ximum gear life

are

hook needl

(C, Fig.

s a s

back

is correctl

back

screws first and the

the

should

ing

dir e ctly at

ft is

extremely importan

to

be

(A)

as

the

e guar d

ed

by

loosening the

6), and

required

a r e not show

are tightened,

hook

be centered on the

of the dri

gained

shaft

and

.

moving

. (Note:

y locate

drivin

the gea r

vin

g g

minimum

hook

may

n. )

d

g

ear

t

12

Page 15

TIMING

THE

HOOKS

(Continued)

Fig.

hook

need

screw

in

correctly

SETTING

dog

travel.

feed

to

screw

to

only

against

paragraph

Place

teeth

Height

bar

the

desired

in

14

be

removed

be

timed

THE

the

is • 050

adjustment

on

which

the

opposite

When

driving

positioned.

by

using

needle

permanently

timed

screws

(E.

Fig.

Whenever

after

replaced

the

flat

on

1.

Automatically.

position.

FEED

throat

height

plate

inch

the

DOG

bottom

by

direction.

the

gears

the

the

timing

bar

(B.

the

position.

on

the

hook

6).

it

this

initial

on

the

the

hook

HEIGHT

in

the

above

is

the

accomplished

edge

turning

saddles

have

hooks

Fig.

shaft

14).

hook

tighten

shaft

is

necessary

timing.

shaft

the

hook

machine.

throat

of

the

been

may

marks

To

in

its

driven

with

as

plate

by

the

screw

and

the

described

retains

feed

their

correctly

be

timed

on

maintain

properly

the

gear

for

the

hook

timing

The

approximate

(Fig.

turning

dog

clockwise.

the

set

a

its

16)

at

screw

rests.

the

To

Fig

height

(G.

Raise

lower

. 15

of

highest

Fig.

the

it.

the

15)

feed

turn

feed

point

in

of

the

dog

the

ADJUSTING

Place

in

the

the

needle.

against

openerfinger

inch.

finger

setting.

in

the

finger

Re-tighten

the

operating

the

To

make

lever

The

opener

approximately.

THE

opener

While

hook

should

and

screw

finger

screw.

HOOK

finger

direction

in

this

basket

contactthe

this

adjustment.

swing

the

(D)

drive

005

OPENER

(A.

until

position.

(E).

is

Loosen

lever

used

shaft.

inch

FINGER

Fig.

the

cam

totake

away from

finger

the

loosen

to

the

Now

17)

screw

surface

in

is

at

opener

the

proper

up

any

loosen

the

the

machine.

its

finger

(C)

to

onthe

clamp

position

vertical

screw

cam

maximum

should

make

surface

this

basket

screw

to

end

(C)

Turn

point

be

adjustment.

for aleng

(B)

and

obtain

play

and

move

of

the

the

handwheel

oftravel

moved

th

the

the

that

may

the

hook

tightly

of

opener

1/16

open

basket.

from

The

1/16

inch

exist

er

Fig.

16

13

Fig.

17

Page 16

ADJUSTING

The

presser

head

Turning

creases

Only

controls

the

foot

enough

THE

pressure

FOOT

spring

the

amount

thumbscrew

pressure

PRESSURE

regulator

of

in

counterclockwise

while

to

feed

the

(B.

Fig.

pressure

clockwise

work

18)

atop

on

the

turning

uniformly

the

machine

presser

direction

increases

is

required.

foot.

de-

it.

With

presser

mately

presser

rests

CHECK

the

is

on

The

needle

at

the 9 o'clock

the

hand

foot

should

1/16

bar

the

SPRING

take-up

to

guide

throat

thread

Fig.

lifter

rest

1/8

and

plate.

ADJUSTMENT

spring

should

position

19

securely

inch

the

barrel

in

should

presser

be

set

down

as

position

on

the

throat

be

maintained

bar

(A.

Fig.

so

that

shown

screw

behind

This

should

sewing

spring

is

about

check

around

Test

should

returning

released.

screw

slants

first

made

position

screw

position.

locknut

adjustment

of

thread

(A.

Fig.

plate.

between

connection

19).

the

lower

(B.

Fig.

(C)

and

locknut

recommended

be

approximately

trials.

barrel

1/16

spring

the 6 o'clock

check

be

enough

snap

(E)

may

from

sewing

from

the

of

counterclockwise

Maintain

(F).

will

and

which

spring

19).

turn

(F)

should

to

(D)

spring

when

The

be

the

trials.

take-up

no

Final

depend

weight

as

as

take-up

10

pressure.

18)

the

Approxi-

the

the

foot

controls

stop

Loosen

barrel

to

make

position

correct

Ultimately.

be

adjusted

1/8

inch

the

needle

position

tension

tension

spring

spring

set

so

that

to 4 o'clock

This

pressure

to

this

check

upon

of

fabric.

Fig.

(A)

immediately

this

adjustment.

for

the

for

the

take-up

so

that

movement

thread

of

the

(D).

to

insure a good

is

raised

adjusting

the

head

position

adjustment

screw

and

turning

above

adjustment

spring

weight

suggested

pressure

and

18

barrel

first

there

of

the

passes

hook.

There

and

slot

for

is

(E)

the

with

type

POSITIONING

Set

the

in

its

lowest

ADJUSTMENT

By

sewing

Fig.

stitch

age.

of

19).

length

Machine

circle

feed

tack,

front

position

check

should

tack,

at

OF

frame

FOR

trials.

spring

(A.

in

all

THE

Fig.

FRONT

needle

parallel

CONTINUOUS

adjust

pressure

sew

continuously

line

speeds.

12)

of

the

to

feed

EYELET

thread

with

needlethread

required

tack,

eyelet

the

SEWING

and

position

without

and

14

(A.

cloth

plate.

tension

(A).

specifications.

thread

across

Fig.

set

break-

the

20)

(G.

the

line

Fig.

20

Page 17

EXPLODED

VIEWS

PART

NUMERICAL

NO.

AND

DESCRIPTIONS

INDEX

OF

PARTS

15

Page 18

A

'

-

~

27

16

Page 19

MAIN

FRAME

BUSHINGS,

COVERS

AND

PLATES

Ref.

~

1 22569

2

62282

3

62282

4 22569 D

62282

5

62282

6

7 22569 D

62282

8

9

10

11 22569

12

14

15

16 62271 G

17

18

19

20

21

· 22

23

24

25 25

26

27 22539 D

28

29

30 22569 c

31

32

33

34

35

36

37

38

39

40

41

62282

62282

666-117

62292

666-140

61271

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202 F-113

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62282

62282

62285

6228

62284

62290

62236

62232

62232

62232

62232

62232

62232

Part

No.

A

294

G-97

50-568

G

B

4 B

A

B

c

c

A

D

A

F

B

K

B

c

D

E

M

F-125

F-124

F-123

F-122

D

F-120

F-119

F-117

F-115

F-111

F-107

F-103

G-98

G-96

G-94

G-92

G-90

G-88

G-86

G-84

G-80

G-76

N

T

s

R

c

F

Blk.

Description

Screws,

HeadCover------------------------------------------------------

Screws,

Top

Top

Screw,

Top

Top

Gasket,

Screw,

Screw,

Oil

Tension

Oil

Eyelet

Eyelet

Needle

Needle

Screw,

Screw,

Bed

Bed

Bed

Bed

Bed

Bed Sli

B

ed

Tiea

Bed

Bed

Bed

B

ed

B

ed Sli

B

ed Sli

Bed

Bed

Bed

~

B

ed

B

ed Sli

B

ed

Bed

Bed

Bed

Bed

Screws

Oil Sig

Plug

Gasket,

Bottom

Screws

Needle

Needle

Needle

Main

F

eed

Lower

Lower

Lower Main

Lower

Head

Cover----------------------------------------------

Sound

Insulator-----------------------------------------------

Top

Cover

and

Cover,

Cover

Cover

Cover,

Cup--------------------Wick,

Slide,

Slide,

Slide,

Slide,

Slide,

Slide,

Slide,

Slide, left,

Slid

Sl~de,

Slide, left,

Slide, rig

Slide, rig

Slide,

Slide, rig

Slide, rig

Slide, rig

Slide

Slide,

Slide,

Friction

Retaining Sprin

Friction Sli

Screw, Feed

Sha

Lower

Lower

Hinged

Latch

Top

Cover

Hin

ge

right-------------------------------------------------

Top

Cover,

Top

Cover,

Top

Cover,

Release

Mounting

Mounting

Thread

Thread

Top

Top

de,

e,

de,

de, rig

!ide,

de, rig

, right,

Bed

' I I

ht

Gauge---------------------------------------------------

Bottom

Cover

Bottom

'Bar

Feed

Feed

ft Bus

Rocker

Main

Main

Main

Pin

Needle

Sleeve,

Sleeve,

Lead-in

Lead-

Cover,

Cover,

left,

for

left,

for

left,

for

left,

for

left,

for No,

left,

for

left, for N

left,

for

for No,

left,

for

left,

for

for No,

left, for

ht,

ht,

ht,

r ig

ht,

right,

ht,

ht,

ht, for

ht,

r ig

ht,

front--------------------------------------------------

Spr

ing,

de

Slid~

Cover ------------------------------

----------------------------------

Cover--------------------------

Frame Pivot

Hock

Rock

hing

Rock

Shaft

Main

Shaft

Shaft

Main

Shaft Bushing-------------------------------------Shaft Bushing, inside rig

Shaft

Top Cover Hinge----------------------------

-----------------------------------------------

------------------------------------------------Latch

------------------------------------------

-------------------------------------------------

right

-----------------------------------------

for

61800

for

Bushin

Feed

in

for

for

61800

No. 12 gaug

No,

No,

No,

o,

No,

No,

No,

No,

for No,

for

No, 12 gauge

for

No, 16 gauge

for N

os,

for

Nos.

for

No, 40-gauge

for N

o,

No,

for

No,

for No,

for

No, 96 gauge

Bed

g,

Bed

Bed

front ar:d Attachments--------------------------

Rocker

Sha

ft

Shaft

-------------------------------

Sha

ft B

Bushin

Bushing--------------------------------------

Bushing Sleeve, rig

Bushin

--------------------------------------

62200

--------------------------------------

-

------------------------------------

g -

Rock

Eyelet,

Eyelet,

61800

62200--------------------------------------

.-;:ro gauge-----------------------------------

Slide front----------.:.----------------------

Bushin

Bushin

-------------------------------------

Shaft

for

for

and

16 gauge

20 gaug

24 gauge----------------------------------28 gaug

32 gauge------------------------

48 gaug

56 gauge

64 gauge----------------------------------80 gaug

96 gaug

8 gauge

20

28 and

48 gauge--------------------------------56 gaug

64 gauge

80 gauge

Slide,

Slide,

Rock

Pin

ushing -----------------------------------

g Sl

g, rig

Bushin

61800---------------------------------62200----------------------------------

for

61800

for

62200

-------------------------------------No.

8 gauge

e-----------------------------------

-----------------------------------

e----------------------------------e-----------------------------------

e-----------------------------------

-----------------------------------

e----------------------------------e-----------------------------------

----------------------------------

---------------------------------

---------------------------------

and

24 gauges-------------------------

32 g11uges

---------------------------------

e---------------------------------

---------------------------------

---------------------------------

---------------------------------

front

-------------------------------

front------------------------------

Sha

ft

Hole---------------------------

Bush

ing

s------------

g,

left-------------

g, right------------

eeve,

left------------------------------

ht-----------------------------

ht-----------------------------

ht-----------------------------------

g,

left----------------------

---------------------------

---------------------------

62200--------------------

-----------------

Amt.

.

-----------

-

-------

;;:------------

- - -

...

---

-.:~------

--

--------

----

-----------

-

· ...... _:. __________ _

--------------

-

---------------

------

----------

Req.

2

1

1

6

1

1

1

1

1

1

2

1

1

1

1

1

2

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

11

2

1

1

1

3

1

1

1

1

1

1

~

42

43

44

45

46 57

22564

62271

57 WB

15438

B

F

C

WD

Screw-----------------------------------------------------------

Needle

Nipper

Needle

Screw-----------------------------------------------------------

recommended

Thread

Plate---------------------~-------------------------------

Bar

Nipper

Thread

when

sewing with

Base----------------------------------------

Nipper Spring ----------------------------------

"A"

The

use

of

these

parts

is

17

nylon thre

ad.

1

1

l

1

1

Page 20

18

Page 21

--

F!.ef.

No.

1

2

3

4

5

6

6A

7

8

9

10

11

12

13

14

15

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

35

36

37

38

39

40

41

42

43

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

7Q

71

72

73

NOTE:

UPPER

Part

No.

62222

62291

22894

22884

22894

62252

666-137

22533

62251

660-208

62251

62251

62255

62255

22596

666-113

62285

62285

78

22565

62285

95

62285

89

62285

62285

62217

22845

62218

22743

62218

22798

62271

62271

29475

62284

62284

62283

6042

·

55235

22565

62284

95

62283

55235

6042

62283

62283

22560

62283

62283

62283

22570

531

29126

62283

62283

95

62245

28619

62245

62245

62246

62283

62246

22882

62260

22894

62221

22894

62221

62221

22894

Detail

MAIN

A

c

A

AC

A

B

c

A

B

D

A

B

H

D

c

E

A

H

A

A

B

K

L

X

E

c

F

A

E

c

D

B

E

A

F

H

A

E

G

c

A

BP

A

J

A

B

D

A

B

F

A

F

c

G

numbers

SHAFT,

NEEDLE

FEED

DF!.IVE

AND STI

TCH

Description

Upper

Main

Shaft

Main

Shaft

Set

Screw,

Set

Screw,

Spot

Crank

Oil

Screw,

Take-up

Screw,

Pin------------------------------------------------------------

Wick

for

Take-up

Lever

Retaining

Take-up

Take-up

Needle

Needle

Lever

Lever

Bar Dri

Bar

Screw,

O

il Wick,

Needle

Needle

Screw,

Screw,

Needle

Screw,

Needle

Screw,

Needle

Needle

Needle Bar,

Holdin

Needle

Hold

Needle

Needle

Bar

Bar

Needle

Needle

Bar

Needle Bar

Bar

Needle

Bar

Bar

g Scr ew,

Bar

ing

Screw, Needles

Bar

-----------------------------------------------------

Crank

and

Counterwei

Main

Shaft

Main

Shaft

Main

Shaft

62252

A------------------------------------------------

Lever

Stud------------------------------------

ght

Crank----------------------------------------

------------------------------------

Crank----------------------------------------

Crank---------------------------------------

Stud--------------------------------------------------

Ring,

Take-up

-------------------------------------------------------

Sleeve-------------------------------------------------

Lever

Stud---------------------------------

ving Link-----------------------------------------------

Connection

Needle

Frame----------

Frame

Bar

Bar

Frame

Frame

Bar

Frame

F r

ame

for

Needle

Head,

Head,

Stud--------------------------------------------

Bar

Connection

Bar

Connection

Pivot

Pin------------------------------------------Frame Pivot

Frame

Guide

Gui

and

Frame Gui

Rockin

g L i

Frame

Rockin

Rocking L

62200-------------------------------------------------

Rocking Link

g L

Bar Head,

for gauges

-----------------------------------------------

for gauges 8 thru

Stud----------------------------------

Stud-----------------------------------

-

-----------------

·P i

n------------------------------------

de

and

Stud

Stud

--------------------------------------

de

and

nk

Pi n,

-------------------------------

Stud

------------------------------

front------------------------------

Pin,

ink

----------------------------------------

ink

Pin,

rear

------------------------------

for

40

62200--

thru

96

(specify

32

(specify gauge)-------------------Screw-----------------------------------------------------------Needle

Needle

Needle

Needle

Needle

Screw,

Needle

Screw

Feed

Nut,

Washer,

Screw,

Feed Dri

Screw,

Feed

Feed Dri

Feed Driving

Screw,

Screw,

Feed

Bearin

Eccentric, Feed

Stitch Reg

Locking Ball, Sti

Stitch Reg

Locating Stud, Stitch Reg

Stitch Regu

Pi

n, Sti

Stitch Reg

Screw, Stitch

Feed

Set

Thrust

Screw,

Handwhee

Handwheel,

Screw, Han

32

Holder

Holder

Feed

Feed

Feed

Screw,

Washer,

Nut,

Needle

Feed

Rock

Rock

Rock

Needle

Needle

Needle

Rock

Eyelet,

Eyelet,

Shaft

Feed

Sha

for

12

and

16

gaug

for

gauges

and

Lever

Sha

ft

----------------------

Sha

ft

Lev

Feed

Rock

Feed

Feed

ft

Rock

Rock

Rock

Sha

Locking Collar----------------------------------

20

Assembly-----------------------------

er

--------------------------------------

Shaft

Shaft

Shaft

Lever

ft

Lever

es

thru

32--------------------------

Lever--------------------

Lever---------------------------

------------------------------

-------------------------------

Locking Collar----------------------------------------

Dri~ng

Driving

Driving

Dr iving

and

Lever------------------------

Feed

Driving Lever--------------

Feed Dri

Feed Dri

ving Lever Guide Link

Feed

Driving Lever Guide Link Pin------------------------------

Lever Guide Sha

vin

g·

Lever Guide,

Lever_G_uid

Feed DnVlll

Feed Driving

Eccentr

g, F

eed Dri

Screw, Feed

ulat

ing

ulat

ing

lating Sh

tch

Regulating

ula

ting Shaft Connecti

Gear, upper

Screw, Feed

Collar --------------------------------------------------------

Thrust

l, #2

#1

33

are

ving Lev

ving Lever-----------------------------------------

g

ic A

ving Eccentric

Drivi

Driving Eccent

Stud

Loc

tch

Reg

Stud

----------------------------------------

er

---------------------------------------

Pin

ft

- - - -

lower-

~

Le

~

Leve

ssembly

ng

kin

ulating Stud

ulatin

--------------------------------------

up

per-:---

Gu1de, upper

uide

•-------- Eccentric Ass

g S

crew-------------

g S

tud-------------

------------------------------------- 1

-------------

, upper

Assembly'

ric

------------------------------------

aft--------.--------------------

Shaft

Regulat

ing Shaft Connection----------------------------

Dr i

ving Gear, upper

Connecti

---------------------------------------------

on-----------------

on

--------------------------------------

Collar-------------------------

Vee Belt

Vee

dwh

included

-----------------------------------------

or

Round

Belt----------------------------------

eel--------------------------------------------

with detail

number

-

----------------------------

-----------------------------------

-----------------------------

---------------------------.,.""-----------------------

emb,ly•.

----------------------------------

------------------------

31

REGULATING MECHANISM

-

----

-

-----------------------

front-----------------------

---------------------------

gauge)-------------------

--------------------------

-

---------------------

-

-------

-

.:..

--------------------------

.:

----------.------------

-------------------------

150

inch thr

..:

-----------

-'---,

-------------------

-

--------------------

--

-------------

on

all gauges exce

ow----------

-

----------

-

-:

----------------

pt No. 8 gauge .

-----

-

-------

-

- - - -

---

-----

-

---

:-

-:-- 1

----

-

--

..:

--

- - 2

--

- 2

Am

F!.eq.

- 1

- 1

- 1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

t.

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

19

Page 22

20

...

Page 23

LOWER FEED DRIVI

NG

AND HOOK

DRIVING

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

31

32

33

34

35

36

37

38

39

40

41

42

43

45

46

47

48

49

50

51

52

53

54

55

56

57

58

Part

No.

62243 A

s

25

62232 G

22706 A

62243 E

22839 A

22768

62238

29126

A

BL

62238

62206

22894 c

22894 D

51147

95

62260 H

22894 F

62260 G

62282 J

62282 H

22569 c

22597 A

62262

62261

61264

A

HA61 D

9663

22775

A

62234

89

61235

22866

G

62236

666-115

62236 D

95

22706 A

62236 A

62236 E

55235 D

6042 A

55235 E

18

51241

D

22729 c

269

HS35

E

18

51239

L

22729 c

51242 M

18

Descr ipti

Hook

Screw,

Lower

Screw,

Hook

Screw,

Feed

Feed

Collar,

Low

Main

Gasket,

Low

Screw,

Set

Intermediate

Intermediate

Collar,

F eed Dog

Screw,

Screw, Feed Dog Heig

FeedBar-----------------------------------------Scr

Feed

Screw,

Feed

Oil

Collar,

Screw,

Feed

Feed

Nut,

Ball

Nut,

Feed

Nut,

Ball

Washer,

Nut,

Sha

ft D r

iving

Hook

Main

Feed

Sha

Screw,

Feed Lift

Lift

Lift

Feed

Feed Lift

Set

Spot

Lower

Screw,

er

Main

Set

Screw,

Shaft

er Ma

Lower

Screw,

Intermediate

Screw,

F e

ew,

Fee

Bar

F ee d

Rocker---------------------------------------

Wick

Fe

Screw,

Fe

Rocker

Rocker

Locking Stud,

Wa

she

Nut,

Ball

Joint

Screw,

Feed

Driving

Feed

Joint

Screw,

Ball

Sha

Shaft

Driving Shaft --------------------------

ft

Driving

Hook

Eccentric

Eccentric

Lift

Eccentric

Eccentric-----------------------------

Screw,

Screw,

Collar,

Sha

Drivin

Lower

in Sha

Intermediat

Gear

Gear----------------------------------

Collar,

(See Page

edDog------------------------------

d B

Shaft-------------------------------------

Rocker--------------------------------

--------------ed

Rock

Collar, Feed Rocker

ed

Rock

Rock ShaftRock

r,

Driving

Drivin

Joint

Feed

Ball