Page 1

CATALOG

NO.

Adjusting

instructions

and

WH398M

Edition

First

STYLES

398-21

398-22

398-23

398-24

398-25

398-26

398-27

illustrated

—

parts

list

ii

U

398-28

398-29

Finest

Quality

I

398

with

Classic

Pushbutton

Zua

Series

stitch

-

Safety

length

stitch

change

machines

Equipment

Page 2

CATALOG

NO.

WH398M

398

ADJUSTING

ILLUSTRATED

CLASSIC

SERIES

PUSHBUTTON

398-21

398-22

398-23

INSTRUCTIONS

PARTS

-

SAFETY

WITH

STITCH

STYLES

398-24

398-25

398-26

First

Edition

Copyright

LIST

STITCH

LENGTH

1982

AND

FOR

MACHINES

CHANGE

398-27

398-28

398-29

Rights

Union

Reserved

Special

Printed

July,

By

Corporation

in

All

in

U.S.A.

1982

2

Countries

Page 3

CLASS

DESCRIPTION

Small

Stitch

plane.

left

include

automatic

STITCH

SEAM

FEED

MAXIMUM

(Depending

frame,

machines.

Two

needle

fabric

lubrication.

AND

TYPE

SYSTEM

SPEED

on

LUBRICATION

high

speed,

The

independent

and

two

or

trimming

operation)

high

needle

rows

three

mechanism,

capacity,

drive

of

thread

mechanism

stitching

overseaming

adjustable

TECHNICAL

differential

moves

are

produced

looper

DATA

Specification

Spreader

Specification

Main

Push

independent

differential

5500

Enclosed

return

two

stitch

and

differential

button

R.P.M.

automatic

pump

feed,

straight

-

“Double-Lock”

at

avoid

516-SSa-2

furnished

515—SSa-2

stitch

thumbscrew

feed

vertical

the

motion,

for

length

splash

needles

right

feed

control

needle,

in

stitch

needle.

fully

conversion

mechanisms.

adjustment

system

Safety

a

vertical

at

Machines

enclosed

to

for

with

the

with

oil

NEEDLE

(Seam

NEEDLE

The

is

12/64

overedge

or

total

398-21

398-22

398-23

398-24

398-25

GAUGE

width)

GAUGE

12

indicates

(8-1/8

presser

radius

shirts,

(8-3/16

(12-3/16

fabric.

ments

(8-3/16

presser

Same

EXPLANATION.

the

or

3/16

seam.

seam

inch

The

width

Ga.)

foot

curves.

robes

Ga.)

Ga.)

Design

ranging

Ga.)

foot

as

and

Style

total

with

and

from

distance

between

of

3/8

For

matiching

Typical

pajamas.

General

of

sewing

shirts

Same

related

398—24

Example:

seam

inch.

seaming

application

as

except

between

needles.

width

feeds

purpose

parts

and

Style

sewing

On

Style

needles

The

is

the

MACHINE

light

to

and

-

machine

allows

blouses

398-22

parts

12—3/16

See

398-27

graduated

fraction

sum

of

STYLES

medium

throat

setting

for

machine

to

women’s

except

for

crossing

gauge.

machine

the

the

weight

plate

sleeves

seaming

to

fitted

styles

12

in

3/16

represents

two

figures,

fabrics.

allow

and

light

be

used

sportwear

with

heavy

3/16

1/64

stitching

seams.

is

gauge

increments,

i.e.,

side

seaming

to

heavy

on

a

variety

and

jackets.

narrow

the

Short,

tractor

of

width

3/16

on

weight

machine.

thus

of

+

narrow

short

work

of

gar

type

12

3/16

398-26

398-27

(5-1/8

(12-3/16

tion

-

women’s

Ga.)

Ga.)

assembling

sportwear.

For

and

seaming

seaming

medium

operations

to

heavy

on

weight

jeans,

3

fabrics.

work

clothing,

Typical

jackets

applica

and

Page 4

MACHINE

STYLES

(Continued)

398-28

398-29

NOTE:

stamped

is

machi

Saybolt

Union

between

sight

level

Clean

Oil

related

All

cutter.

Each

serial

The

ne.

Oil

viscosity

Special

Machine

tension

gauge

indicator

drain

To

magnetic

must

Same

sewing

Same

machine

UNION

the

in

capacity

Corporation

is

on

changed

be

Style

as

parts

Style

as

styles

SPECIAL

style

number

of

of

filled

disc

front

will

remove

oil

plug

398-27

for

398-21

listed

machine

plate

stamped

is

Class

90

support

of

register

of

periodically

398

125

to

Specification

with

machine.

magnetic

metallic

any

except

crossing

except

can

IDENTIFICATION

carries

located

is

seconds

at

oil

and

between

fitted

heavy

12-3/16

furnished

be

a

the

to

extension

on

LUBRICATION

eight

top

When

plug

to

ounces.

at

No.

spring

cover.

proper

red

on

material

minimize

with

seams.

OF

style

right

100

175.

cap

Before

gauge

back

that

wear.

tractor

gauge.

with

MACHINES

number,

rear

casting

of

Use

degrees

lines.

of

top

operating,

level

machine

may

under

oil

type

“AIR-KLIPP’

which

of

straight

a

F.

cover

is

have

on

machine.

right

at

This

or

reached,

near

accumulated

presser

vacuum

this

rear

mineral

equivalent

is

at

check

bottom

oil

red

class

oil

edge

foot

type

base

oil

filler

level

bulb

crankcase.

in

and

chain

machine

of

with

to

screw

at

oil

on

base.

of

a

Be

thread

five

Before

cloth

and

Turn

tweezers

in

aid

thread,

thread

looper

401

sure

machines

threading

plate

handwheel

No.

threading.

(2)

and

machine

401

(5)

machine

thread,

Thread

Thread

machine

out

in

660-272

looper

front

threaded

is

Fig.

or

machine;

position;

of

operating

and

sequence

in

thread,

needle

sequence

in

rear

(3)

1A,

unlock

direction

threading

thread.

needle

THREADING

properly

four

for

THREADING

presser

upper

pull

until

wire

shown

as

upper

(3)

Push

shown

as

thread

according

thread

DIAGRAMS

foot

looper

needles

39899

No.

Fig.

in

overedge

upper

Fig.

in

and

4

machines.

A

1;

looper

looper

1A;

front

(4)

threading

to

release

thread

are

are

(1)

(1)

bushing,swing

tube

highest

at

furnished

lower

thread,

thread

overedge

needle

diagram

for

up

with

overedge

(4)

tube

thread.

five

position.

machine

rear

down.

looper

Fig.

presser

threads.

looper

needle

thread,

for

1,

arm

Thread

to

(2)

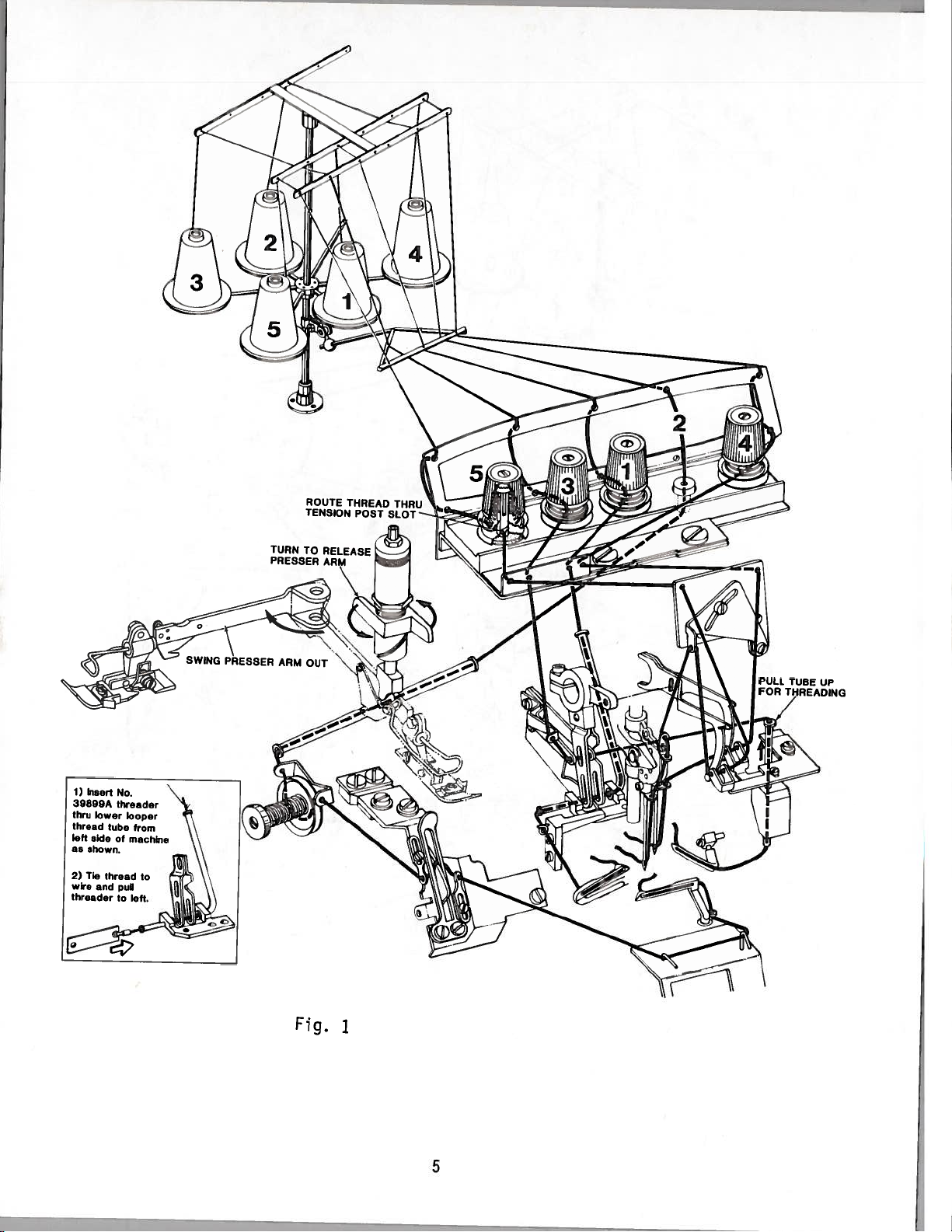

Page 5

TUBE

UP

Fig.

1

5

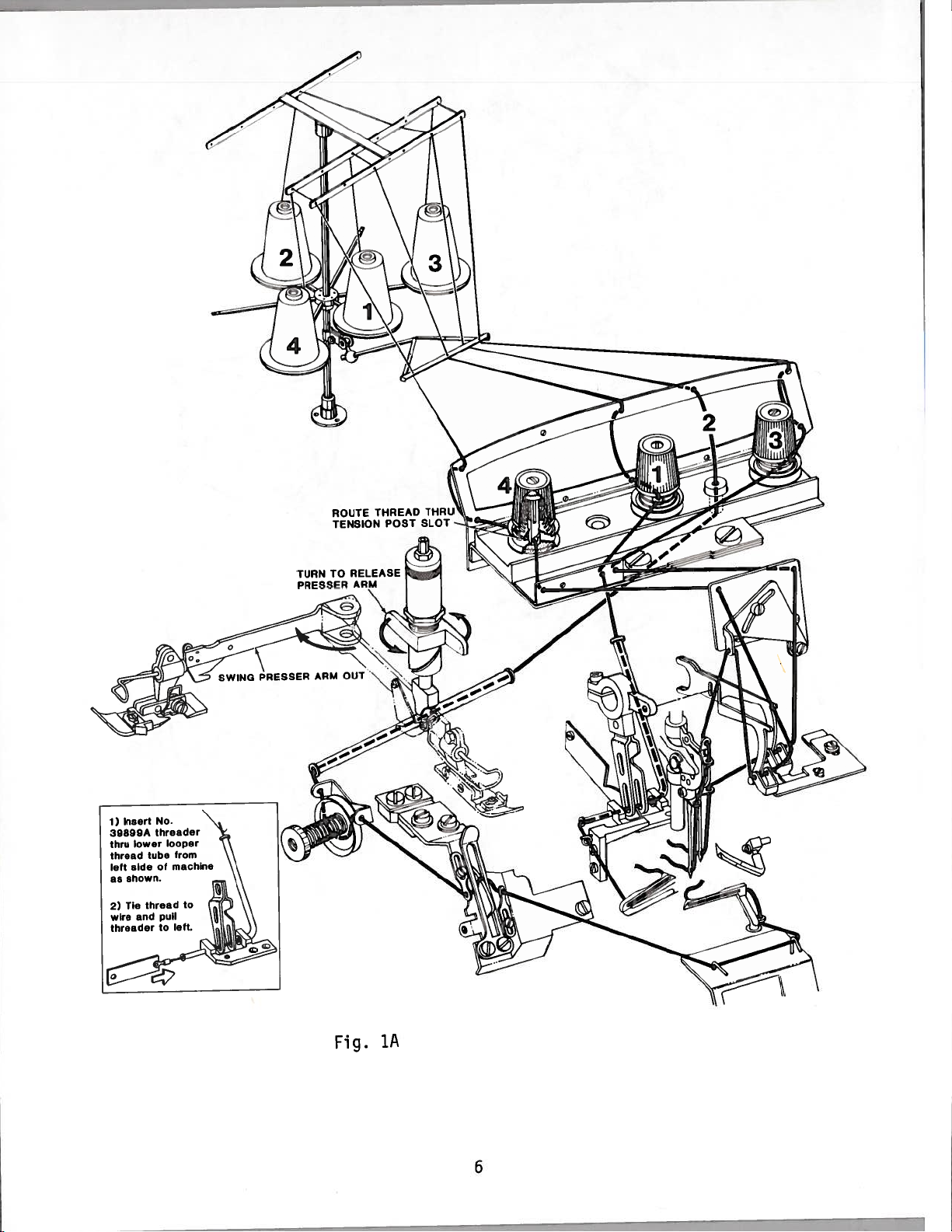

Page 6

TURN

PRESSER

TO

RELEASE

ARM

1A

Fig.

6

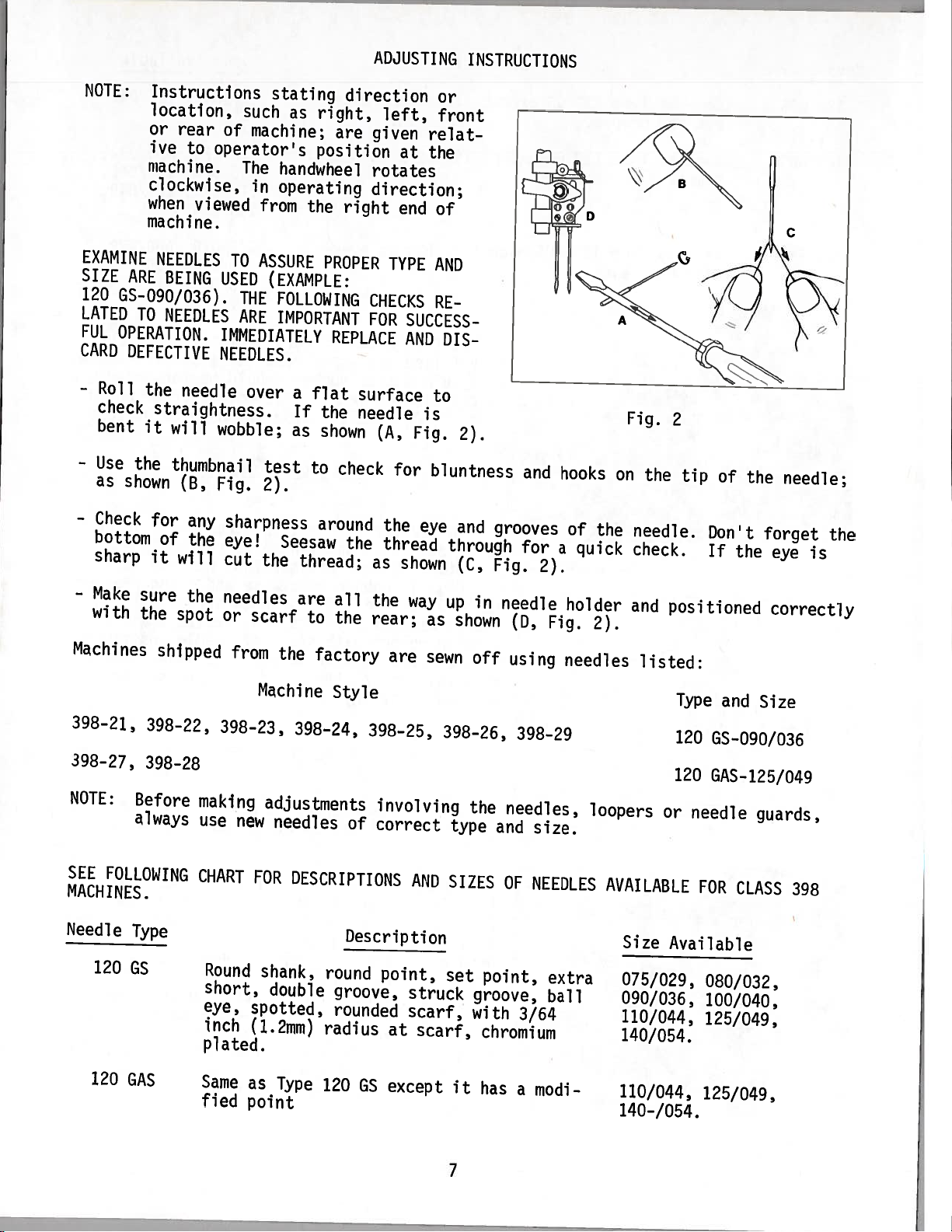

Page 7

-

-

NOTE:

EXAMINE

SIZE

ARE

120

GS-090/036).

LATED

FUL

CARD

-

TO

OPERATION.

DEFECTIVE

Roll

the

check

bent

it

-

Use

the

as

shown

Instructions

location,

or

rear

ive

to

operator’s

machine.

clockwise,

when

viewed

machine.

NEEDLES

BEING

NEEDLES

needle

straightness.

will

thumbnail

(B,

stating

such

as

right,

of

machine;

position

The

handwheel

in

operating

from

the

TO

USED

THE

ARE

ASSURE

(EXAMPLE:

FOLLOWING

IMPORTANT

PROPER

IMMEDIATELY

NEEDLES.

over

wobble;

Fig.

test

2).

a

If

as

flat

the

shown

to

ADJUSTING

direction

left,

are

given

at

rotates

direction;

right

end

TYPE

CHECKS

FOR

REPLACE

surface

needle

(A,

check

for

iNSTRUCTIONS

or

front

relat

the

of

AND

RE

SUCCESS

AND

DIS

to

is

Fig.

2).

bluntness

and

hooks

on

Fig.

the

2

tip

of

the

needle;

-

Check

bottom

sharp

-

Make

with

sure

the

Machines

398-21,

398-27,

NOTE:

398-22,

398-28

Before

always

SEE

FOLLOWING

MACHINES.

Needle

120

Type

GS

for

any

of

the

it

will

the

spot

shipped

sharpness

eye!

cut

needles

or

from

398-23,

making

use

new

CHART

Round

short,

eye,

inch

plated.

around

Seesaw

the

thread;

are

scarf

the

to

factory

Machine

398-24,

adjustments

needles

FOR

DESCRIPTIONS

shank,

double

spotted,

(1.2mm)

the

as

all

the

the

rear;

Style

398-25,

of

Description

round

groove,

rounded

radius

the

eye

thread

shown

way

as

are

sewn

involving

correct

AND

point,

struck

scarf,

at

scarf,

and

through

(C,

up

in

shown

off

398-26,

the

type

SIZES

set

point,

groove,

with

chromium

grooves

for

Fig.

needle

(D,

using

398-29

needles,

and

size.

OF

NEEDLES

3/64

2).

Fig.

extra

ball

of

a

quick

holder

needles

loopers

the

2).

needle.

check.

and

positioned

listed:

Type

120

120

or

needle

AVAILABLE

Size

Available

075/029,

090/036,

110/044,

140/054.

Don’t

If

the

forget

eye

correctly

and

Size

GS-090/036

GAS-125/049

guards,

FOR

CLASS

080/032,

100/040,

125/049,

the

is

398

120

GAS

Same

fled

as

point

Type

120

GS

except

it

has

a

modi-

7

110/044,

140-/054.

125/049,

Page 8

Needle

Type

Description

Sizes

Available

120

120

120

GFS

GHS

GKS

Same

eye

Same

point.

Same

size

as

and

as

as

ball

Type

groove,

Type

Type

eye.

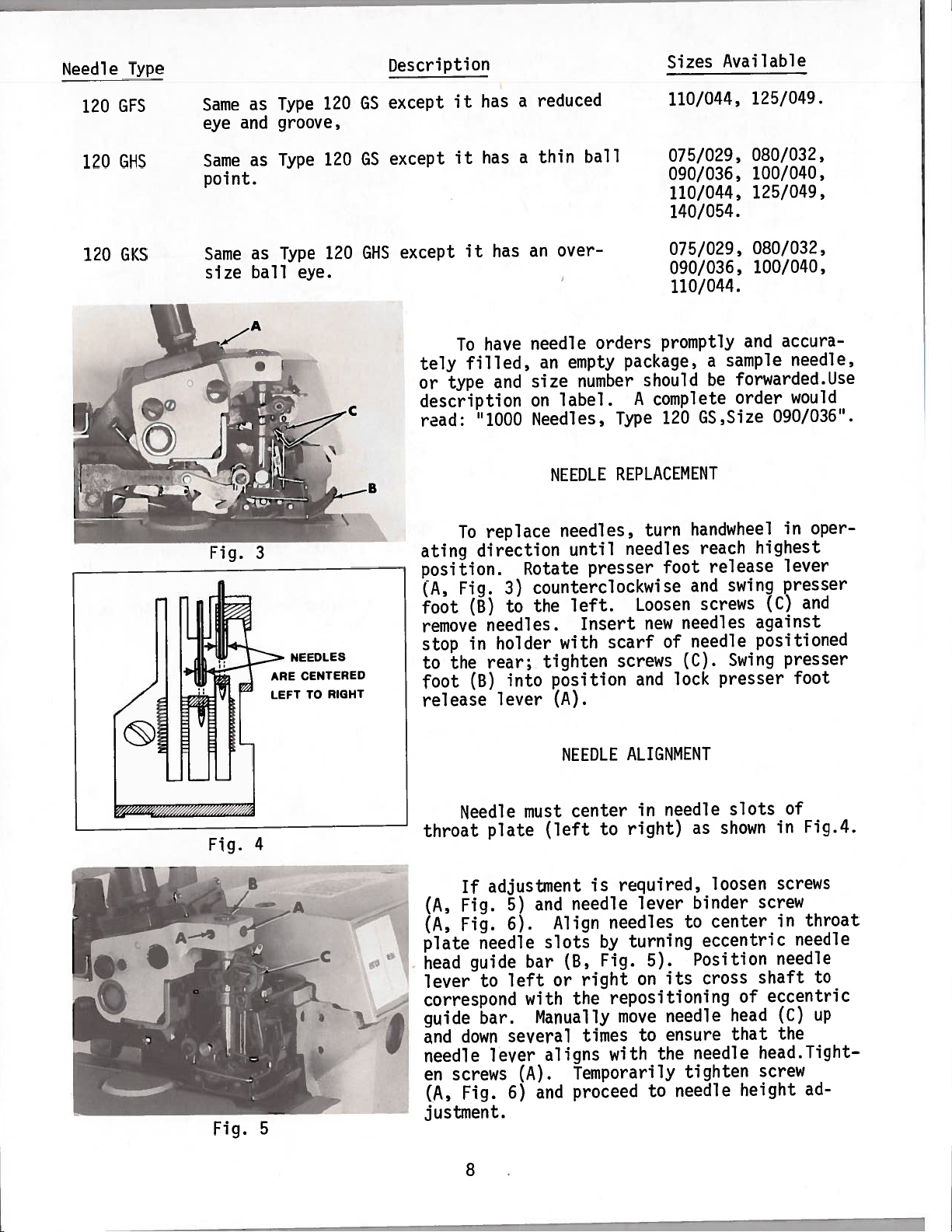

NEEDLES

CENTERED

ARE

TO

LEFT

120

120

120

RIGHT

GS

GS

GHS

except

except

except

tely

or

description

read:

ating

position.

(A,

foot

remove

stop

to

foot

release

it

it

it

To

filled,

type

To

Fig.

the

has

has

has

have

and

“1000

replace

direction

3)

to

(B)

needles.

holder

in

rear;

into

(B)

lever

reduced

a

ball

thin

a

over-

an

needle

an

size

on

orders

empty

number

label.

Needles,

NEEDLE

needles,

until

Rotate

presser

counterclockwise

left.

the

Insert

with

scarf

tighten

position

(A).

110/044,

075/029,

090/036,

110/044,

140/054.

075/029,

090/036,

110/044.

promptly

sample

120

a

be

GS,Size

package,

should

complete

A

Type

REPLACEMENT

handwheel

turn

foot

needles

of

(C).

lock

reach

release

and

screws

needle

presser

swing

Swing

needles

Loosen

new

screws

and

125/049.

080/032,

100/040,

125/049,

080/032,

100/040,

accura

and

needle,

forwarded.Use

order

would

090/036”.

oper

in

highest

lever

presser

and

(C)

against

positioned

presser

foot

Fig.

Fig.

ALIGNMENT

needle

in

right)

to

as

slots

shown

in

of

Fig.4.

throat

Needle

plate

must

NEEDLE

center

(left

4

screw

shaft

eccentric

of

head

that

head.Tight

screw

height

screws

throat

in

needle

needle

(C)

the

ad

to

up

—C

adjustment

If

Fig.

(A,

Fig.

(A,

plate

head

lever

needle

guide

to

correspond

guide

and

bar.

down

needle

en

screws

Fig.

(A,

5)

6).

left

several

lever

6)

and

Align

slots

bar

or

with

Manually

aligns

(A).

and

required,

is

needle

needles

turning

by

Fig.

(B,

right

repositioning

the

move

times

with

Temporarily

proceed

lever

5).

on

to

the

to

binder

to

Position

its

needle

ensure

needle

tighten

needle

loosen

center

eccentric

cross

justment.

5

8

Page 9

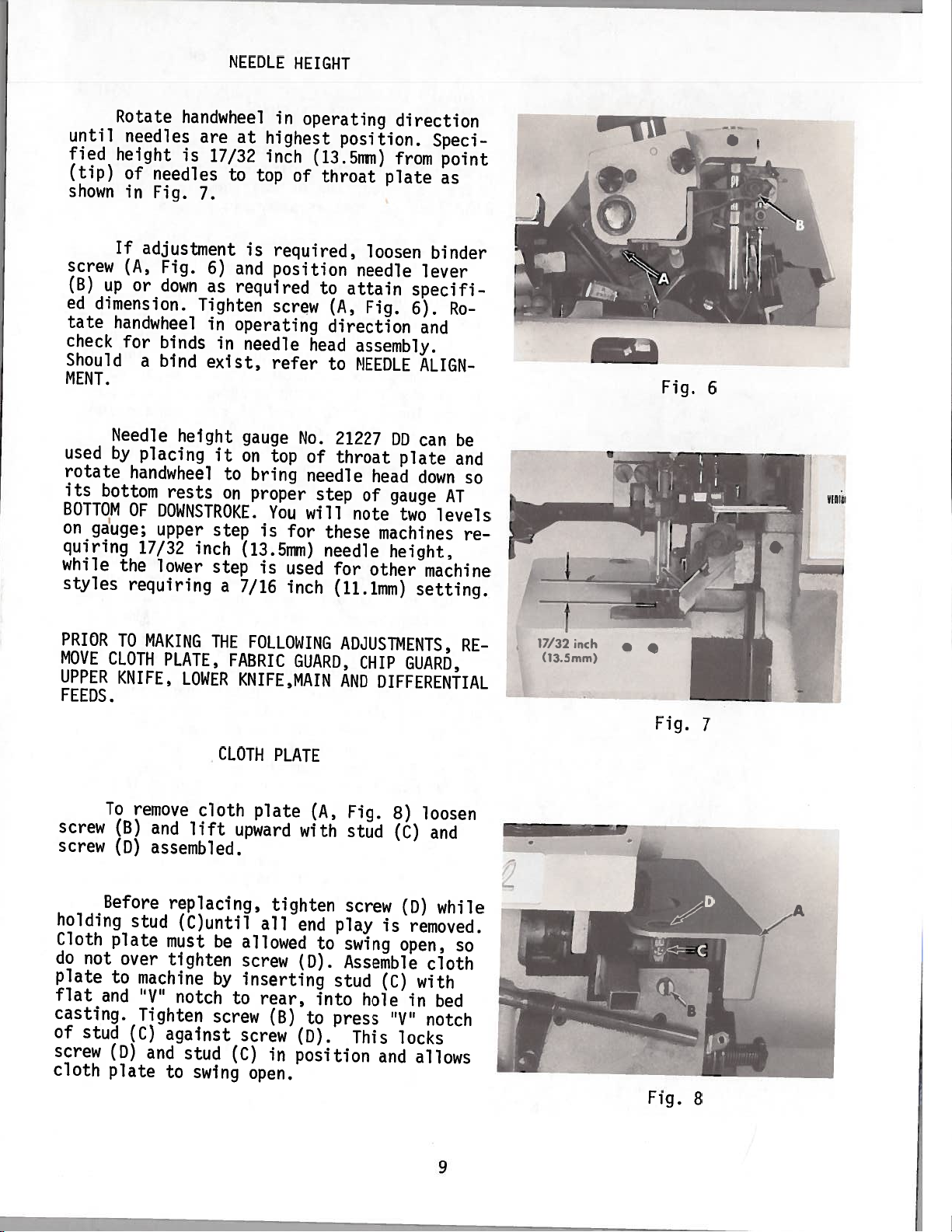

NEEDLE

HEIGHT

Rotate

until

fied

shown

screw

(B)

ed

tate

check

Should

MENT.

used

rotate

its

BOTTOM

on

quiring

while

styles

height

(tip)

If

up

dimension.

handwheel

Needle

by

bottom

gauge;

the

handwheel

needles

of

in

adjustment

(A,

or

for

a

placing

handwheel

OF

17/32

requiring

are

is

needles

Fig.

7.

Fig.

down

Tighten

binds

bind

height

rests

DOWNSTROKE.

upper

inch

lower

17/32

to

6)

as

in

in

exist,

it

to

on

step

step

a

in

at

highest

inch

top

is

required,

and

position

required

screw

operating

needle

refer

gauge

on

top

bring

proper

You

is

for

(13.5mm)

is

used

7/16

inch

operating

(13.5mm)

of

throat

to

(A,

direction

head

to

No.

21227

of

throat

needle

step

will

these

needle

for

(11.1mm)

position.

plate

loosen

needle

attain

Fig.

assembly.

NEEDLE

head

of

note

machines

other

direction

Speci

from

binder

lever

specifi

6).

and

ALIGN

DD

can

plate

down

gauge

two

height,

machine

setting.

point

as

Ro

be

and

so

AT

levels

re

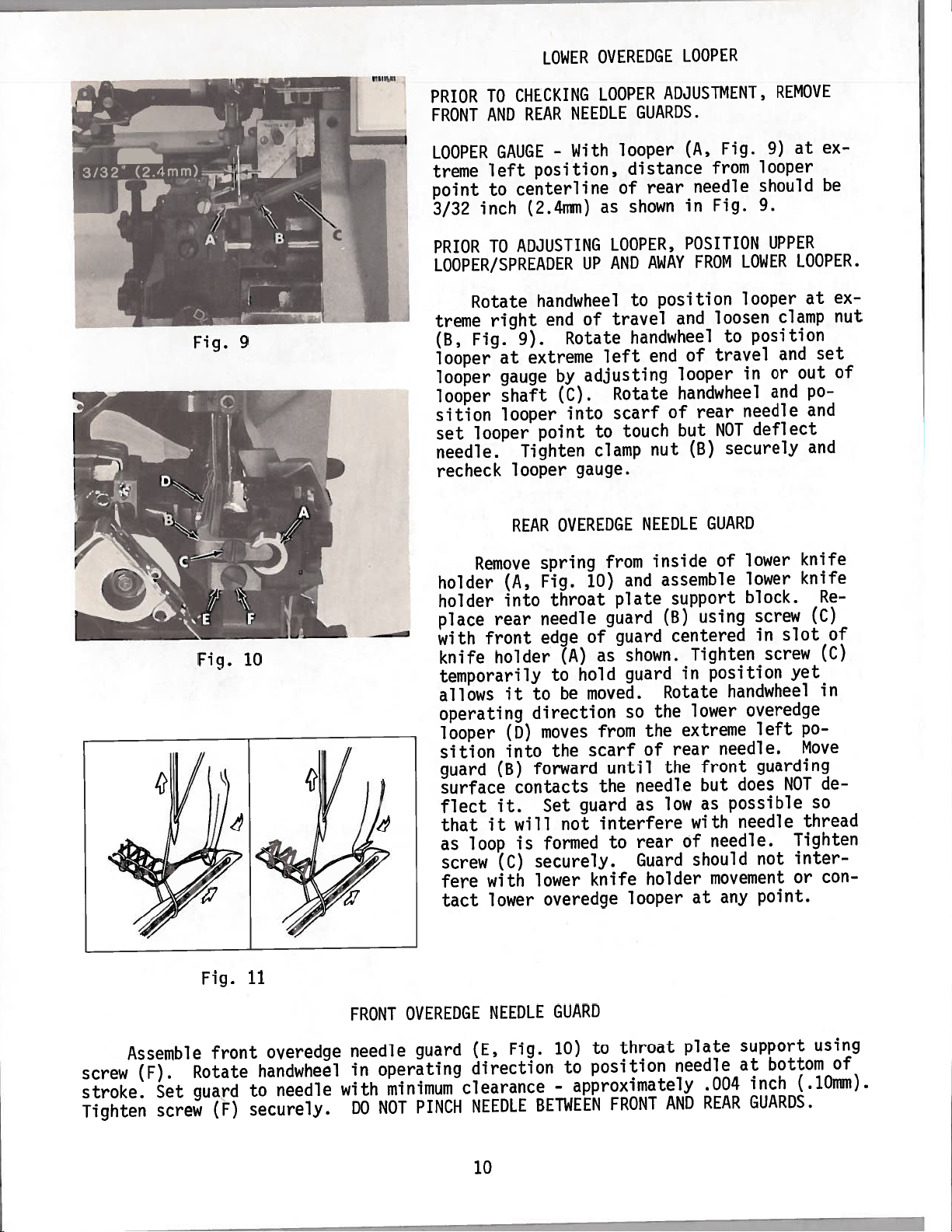

Fig.

6

lTII

I

PRIOR

MOVE

UPPER

FEEDS.

screw

screw

holding

Cloth

do

not

plate

flat

casting.

of

stud

screw

cloth

TO

CLOTH

KNIFE,

To

remove

(B)

(D)

Before

stud

plate

over

to

machine

and

“V’

Tighten

(C)

CD)

plate

MAKING

PLATE,

LOWER

cloth

and

lift

assembled.

replacing,

(C)until

must

tighten

notch

against

and

stud

to

swing

THE

FOLLOWING

FABRIC

KNIFE,MAIN

CLOTH

plate

upward

tighten

all

be

allowed

screw

by

inserting

to

rear,

screw

screw

(C)

open.

(B)

in

GUARD,

PLATE

(A,

with

end

to

(D).

into

to

(D).

position

ADJUSTMENTS,

CHIP

GUARD,

AND

DIFFERENTIAL

Fig.

stud

screw

play

swing

Assemble

stud

press

hole

This

8)

(C)

is

open,

(C)

“V’

locks

and

loosen

and

(D)

while

removed.

cloth

with

in

bed

notch

allows

RE

so

17/32

(13.5mm)

inch

•

1

•

Fig.

7

Fig.

8

9

Page 10

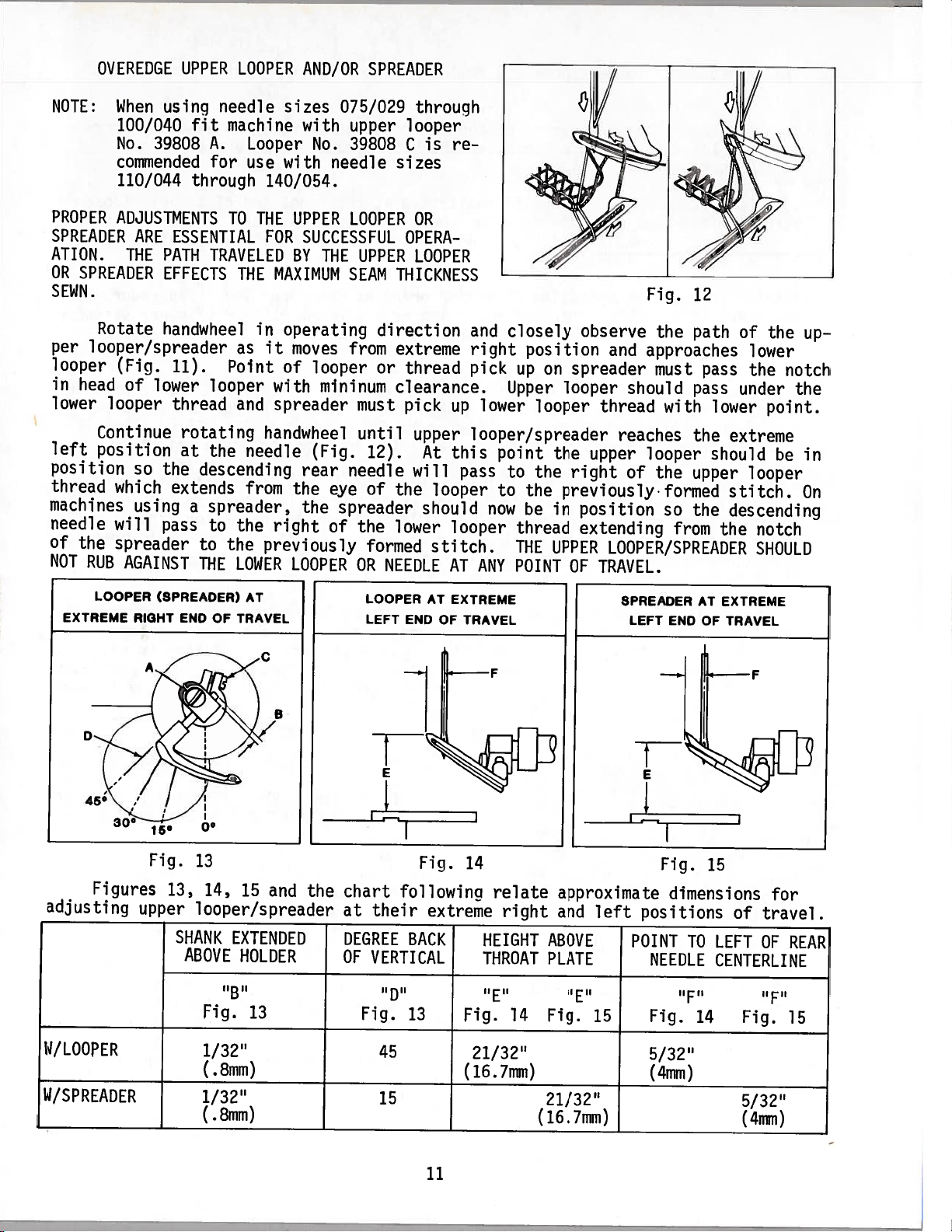

LOWER

OVEREDGE

LOOPER

Fig.

CHECKING

PRIOR

FRONT

LOOPER

treme

point

3/32

PRIOR

TO

REAR

AND

GAUGE

left

centerline

to

inch

(2.4mm)

ADJUSTING

TO

position,

LOOPER/SPREADER

right

at

gauge

shaft

looper

looper

handwheel

end

9).

extreme

point

Tighten

Rotate

treme

Fig.

9

(B,

looper

looper

looper

sition

looper

set

needle.

recheck

REAR

LOOPER

NEEDLE

With

-

as

LOOPER,

AND

UP

travel

of

Rotate

left

adjusting

by

into

Rotate

scarf

(C).

to

clamp

gauge.

OVEREDGE

ADJUSTMENT,

GUARDS.

looper

distance

rear

of

shown

AWAY

position

to

and

handwheel

end

looper

handwheel

of

touch

but

nut

NEEDLE

Fig.

(A,

from

needle

Fig.

in

POSITION

FROM

loosen

to

of

travel

rear

NOT

securely

(B)

GUARD

REMOVE

9)

looper

should

9.

UPPER

LOWER

looper

clamp

position

and

or

in

and

needle

deflect

at

ex

be

LOOPER.

ex

at

nut

set

of

out

po

and

and

Fig.

Fig.

10

11

Remove

holder

holder

place

with

knife

(A,

into

rear

front

holder

temporarily

allows

it

operating

looper

sition

guard

(B)

surface

flect

that

as

screw

fere

tact

it.

it

loop

(C)

with

lower

spring

Fig.

needle

edge

to

direction

moves

(D)

into

forward

contacts

Set

will

is

formed

securely.

lower

overedge

throat

(A)

hold

to

be

the

not

from

10)

guard

of

as

moved.

from

scarf

until

the

guard

interfere

to

knife

and

plate

guard

shown.

guard

so

the

of

needle

as

rear

Guard

looper

inside

assemble

support

(B)

centered

in

Rotate

the

extreme

rear

the

low

of

holder

of

using

Tighten

position

handwheel

lower

needle.

front

but

possible

as

with

needle.

should

movement

any

at

lower

lower

block.

screw

slot

in

screw

overedge

left

guarding

does

needle

not

point.

knife

knife

(C)

yet

po

Move

NOT

so

thread

Tighten

inter

or

Re

of

(C)

in

de

con

GUARD

Fig.

BETWEEN

10)

-

screw

stroke.

Tighten

Assemble

(F).

Set

screw

front

Rotate

guard

(F)

overedge

handwheel

to

needle

securely.

FRONT

needle

in

with

DO

OVEREDGE

guard

operating

minimum

PINCH

NOT

NEEDLE

(E,

direction

clearance

NEEDLE

10

throat

to

position

to

approximately

FRONT

plate

needle

AND

.004

REAR

support

at

bottom

inch

GUARDS.

using

of

(.10mm).

Page 11

OVEREDGE

UPPER

LOOPER

AND/OR

SPREADER

NOTE:

When

100/040

No.

commended

110/044

PROPER

ADJUSTMENTS

SPREADER

ATION.

OR

SPREADER

THE

SEWN.

Rotate

per

looper/spreader

looper

in

lower

head

(Fig.

of

looper

Continue

left

position

position

thread

which

machines

needle

of

NOT

the

RUB

will

spreader

AGAINST

using

39808

ARE

ESSENTIAL

PATH

EFFECTS

handwheel

11).

lower

thread

so

the

extends

using

pass

needle

machine

fit

A.

for

through

TO

TRAVELED

Point

looper

rotating

at

the

descending

a

spreader,

to

to

the

THE

sizes

Looper

use

with

140/054.

THE

FOR

MAXIMUM

THE

in

operating

it

as

of

with

and

spreader

handwheel

needle

from

the

right

previously

LOWER

075/029

with

No.

upper

39808

needle

UPPER

LOOPER

SUCCESSFUL

BY

THE

UPPER

SEAM

direction

moves

looper

from

or

mininum

must

until

(Fig.

rear

the

the

12).

needle

eye

of

spreader

the

of

formed

LOOPER

OR

throuqh

looper

is

re

C

sizes

OR

OPERA

LOOPER

THICKNESS

extreme

thread

clearance.

pick

up

upper

this

At

will

the

pass

looper

should

lower

looper

stitch.

NEEDLE

AT

and

closely

right

pick

lower

position

up

Upper

looper

on

looper

looper/spreader

point

to

now

to

the

the

previouslyformed

the

in

be

thread

THE

UPPER

POINT

ANY

Fig.

observe

and

spreader

the

approaches

must

should

thread

with

reaches

upper

right

position

extending

of

looper

the

so

from

LOOPER/SPREADER

TRAVEL.

OF

12

path

pass

pass

lower

the

should

upper

the

the

of

the

lower

the

notch

under

the

point.

extreme

be

looper

stitch.

descending

notch

SHOULD

up

in

On

LOOPER

EXTREME

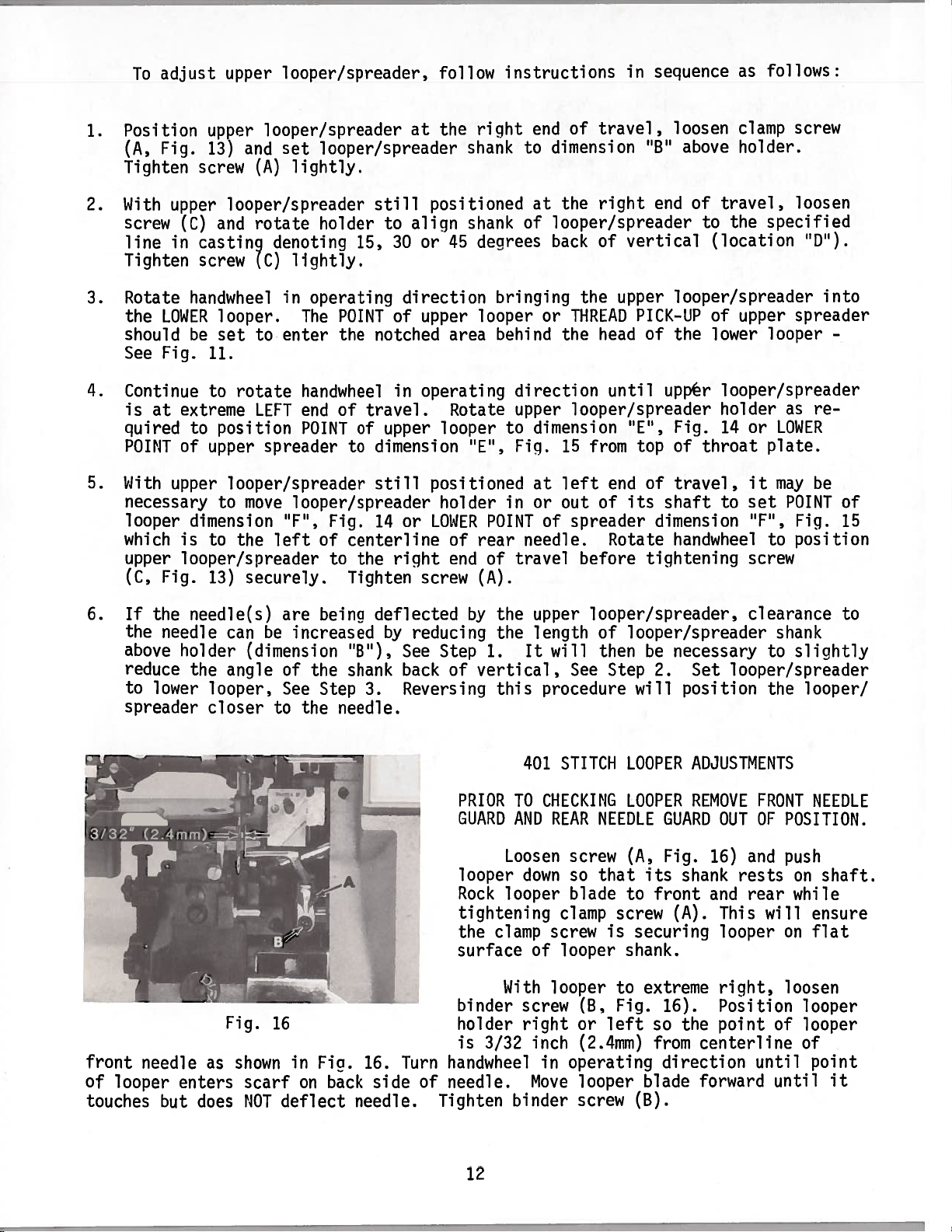

Figures

adjusting

(SPREADER)

RIGHT

Fig.

13,

upper

AT

END

OF

TRAVEL

13

14,

15

looper/spreader

SHANK

ABOVE

EXTENDED

HOLDER

‘‘B’’

Fig.

13

and

the

LOOPER

LEFT

chart

their

at

DEGREE

OF

VERTICAL

Fig.

AT

EXTREME

END

OF

Fig.

following

extreme

BACK

13

TRAVEL

14

relate

right

HEIGHT

THROAT

‘‘E’’

Fig.

14

approximate

and

left

ABOVE

PLATE

Fig.

15

SPREADER

LEFT

END

Fig.

dimensions

positions

POINT

NEEDLE

Fig.

EXTREME

AT

OF

TRAVEL

15

of

TO

LEFT

CENTERLINE

‘‘F’’

14

-F

Fig.

for

travel

OF

REAR

‘‘F’’

15

W/LOOPER

W/SPREADER

1/32”

(.8mm)

1/32”

(.8mm)

45

15

21/32”

(1.6.7mm)

21/32”

(16.7mm)

11

5/32”

(4mm)

5/32”

(4mm)

Page 12

To

adjust

upper

looper/spreader,

follow

instructions

in

sequence

as

follows:

1.

2.

3.

4.

5.

Position

Fig.

(A,

Tighten

With

upper

screw

line

in

Tighten

Rotate

LOWER

the

should

See

Fig.

Continue

is

at

quired

POINT

With

upper

necessary

looper

which

upper

Fig.

(C,

upper

13)

screw

looper/spreader

and

(A)

looper/spreader

and

(C)

castin9

screw

rotate

denoting

(C)

handwheel

looper.

be

set

to

11.

to

rotate

extreme

to

of

position

upper

LEFT

spreader

looper/spreader

to

move

dimension

is

to

the

left

looper/spreader

13)

securely.

set

looper/spreader

lightly.

holder

15,

liqhtly.

in

operating

The

POINT

enter

the

handwheel

of

end

POINT

travel.

of

to

looper/spreader

Fig.

“F”,

of

centerline

to

the

Tighten

at

to

30

positioned

align

or

still

direction

of

upper

notched

operating

in

upper

dimension

still

14

positioned

or

LOWER

right

screw

the

shank

shank

45

area

Rotate

looper

“E”,

holder

of

end

of

right

decirees

bringing

looper

behind

end

diniension

to

at

of

looper/spreader

back

or

travel,

the

right

of

the

THREAD

the

direction

upper

to

Fig.

in

looper/spreader

dimension

15

from

left

at

or

out

of

POINTofspreader

needle.

rear

of

travel

before

(A).

upper

head

until

end

Rotate

‘B’

end

vertical

PICK-UP

of

upp’ér

“E”,

top

of

its

shaft

dimension

tightening

loosen

above

of

to

clamp

holder.

travel,

the

specified

(location

looper/spreader

of

upper

the

lower

looper

looper/spreader

holder

Fig.

of

travel,

14

throat

to

or

plate.

it

set

“F”,

handwheel

to

screw

screw

loosen

“D”).

into

spreader

as

re

LOWER

may

be

POINT

Fig.

position

-

of

15

6.

If

the

above

reduce

to

spreader

front

needle

of looper

touches

the

needle

holder

lower

enters

but

needle(s)

can

the

angle

looper,

closer

Fig.

as

shown

does

are

be

increased

(dimension

of

See

the

to

16

in

scarf

NOT

on

deflect

beina

the

Step

Fig.

“B”),

shank

needle.

back

needle.

deflected

by

See

back

Reversing

3.

16.

Turn

side

reducing

Step

of

PRIOR

GUARD

looper

Rock

tightening

the

surface

binder

holder

is

handwheel

of

needle.

Tighten

by

the

the

1.

vertical,

this

TO

AND

Loosen

looper

clamp

With

3/32 inch

binder

upper

length

It

will

See

procedure

STITCH

401

CHECKING

REAR

screw

down

so

blade

clamp

screw

of

looper

looper

screw

right

(B,

or

(2.4mm)

in

operating

looper

Move

screw

looper/spreader,

of

looper/spreader

then

Step

NEEDLE

that

screw

is

necessary

be

2.

will

position

LOOPER

LOOPER

GUARD

(A,

Fig.

its

shank

to

front

(A).

securing

Set

ADJUSTMENTS

REMOVE

shank.

extreme

to

Fig.

left

so

16).

the

from

direction

blade

(B).

clearance

looper/spreader

the

FRONT

OF

OUT

and

16)

rests

and

rear

This

will

looper

right,

Position

point

centerline

until

forward

shank

to

slightly

looper!

NEEDLE

POSITION.

push

shaft.

on

while

ensure

on

flat

loosen

looper

of

looper

of

point

until

to

it

12

Page 13

ing

enters

(A,

passes

enters

thread,

around

termed

looper

left

travels

Fig.

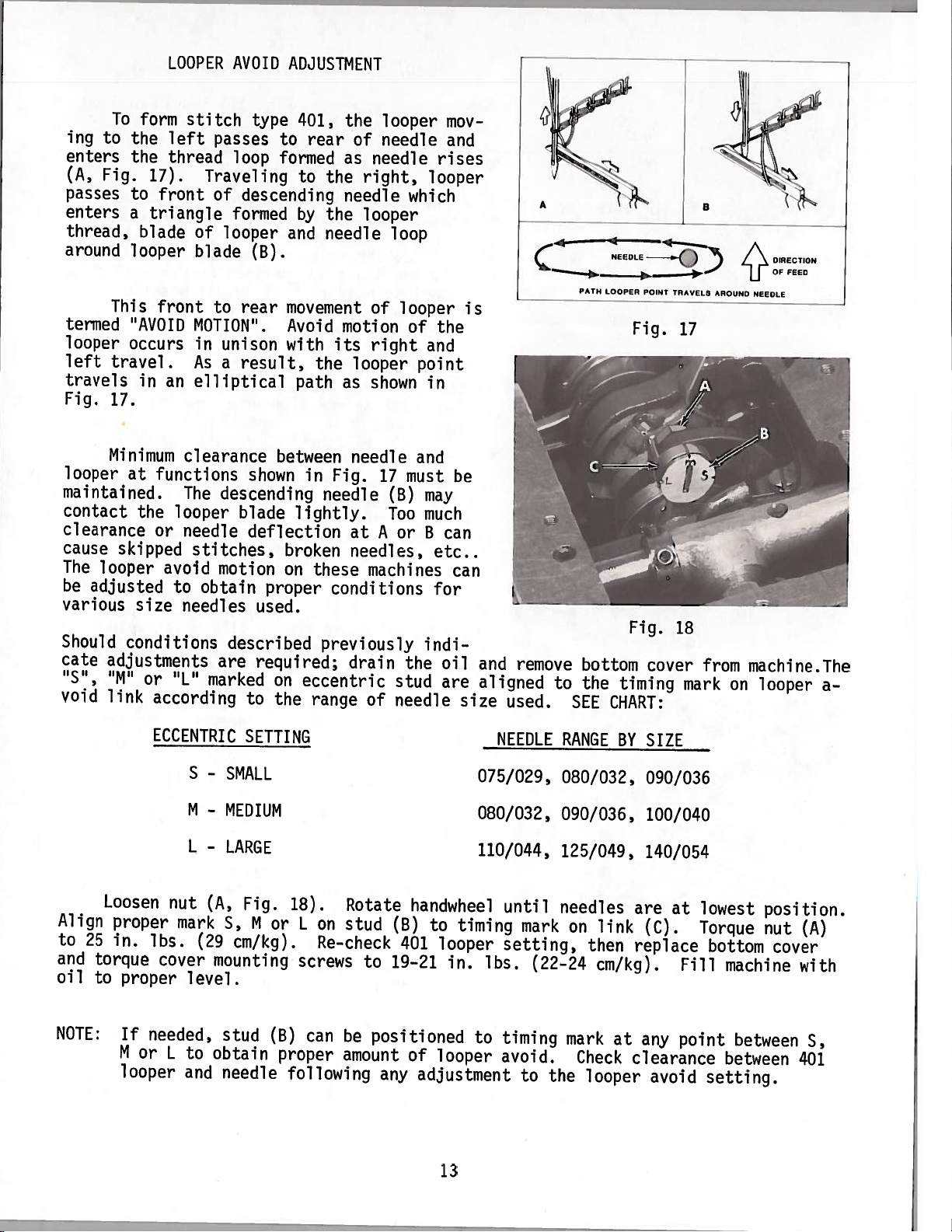

To

to

Fig.

This

occurs

travel.

17.

LOOPER

form

the

left

the

thread

17).

to

front

a

triangle

blade

looper

front

“AVOID

in

an

AVOID

stitch

passes

loop

Traveling

of

descending

formed

of

looper

blade

to

rear

MOTION”.

unison

in

a

As

result,

elliptical

ADJUSTMENT

type

401,

rear

to

formed

to

by

and

(B).

movement

Avoid

with

the

path

the

of

as

the

needle

the

needle

motion

its

looper

as

looper

needle

needle

right,

looper

loop

of

right

shown

looper

which

looper

of

and

point

in

mov

and

rises

the

C

PATH

NEEDLE

LOOPER

POINT

TRAVFLS

AROUND

NEEDLE

DIRECTION

OF

FEED

is

Fig.

17

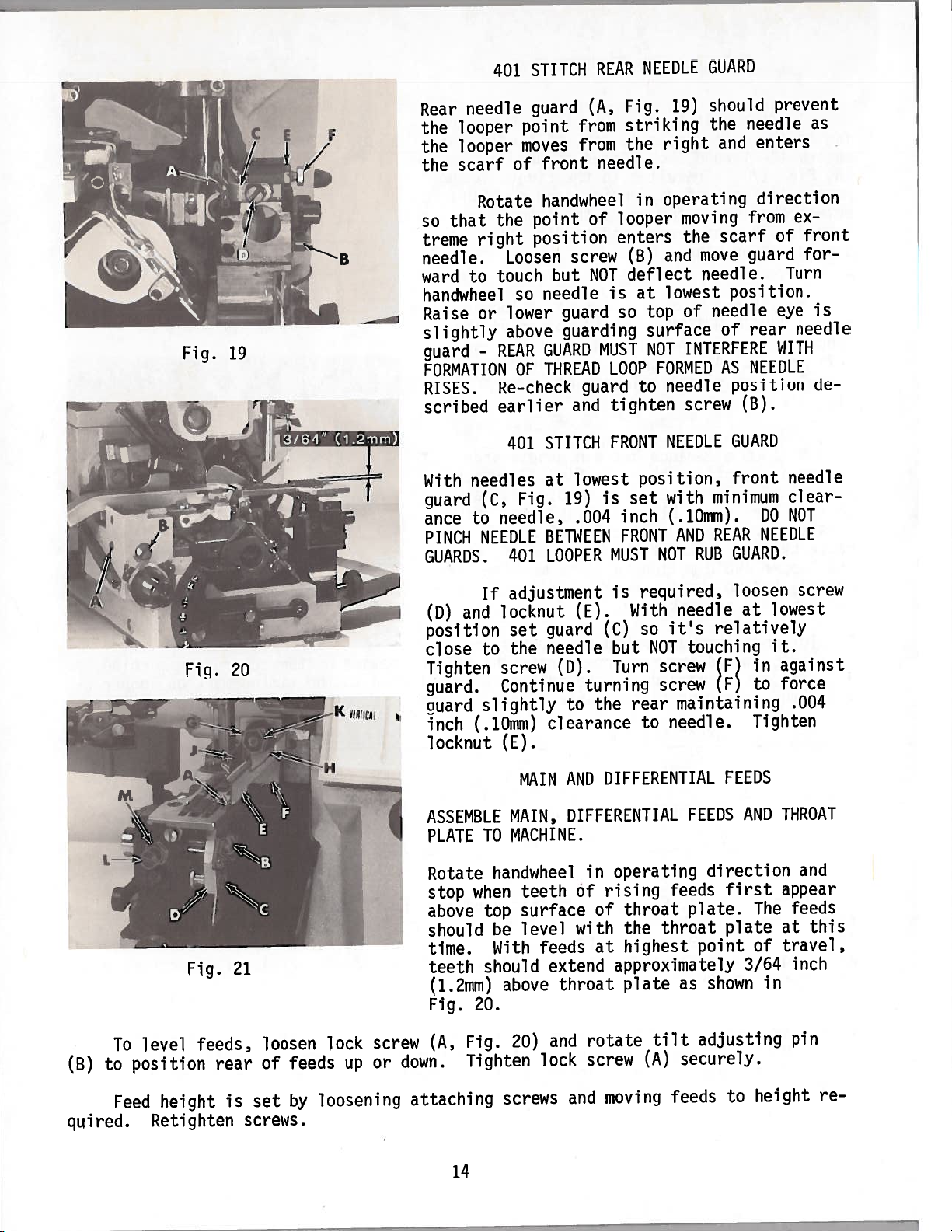

Minimum

looper

maintained.

contact

clearance

cause

The

be

skipped

looper

adjusted

various

Should

cate

void

“S”,

adjustments

“M”

link

Loosen

Align

to

and

oil

25

torque

to

proper

in.

proper

clearance

at

functions

The

looper

the

or

needle

avoid

to

size

needles

conditions

or

“L”

according

ECCENTRIC

nut

mark

lbs.

cover

level.

descending

stitches,

motion

obtain

described

are

marked

S

-

SMALL

M

-

MEDIUM

L

-

LARGE

(A,

5,

(29

mounting

between

shown

blade

deflection

proper

used.

required;

on

to

the

SETTING

Fig.

M

or

cm/kg).

in

lightly.

broken

on

these

previously

eccentric

range

18).

L

on

Re-check

screws

needle

Fig.

17

needle

at

A

needles,

machines

conditions

drain

of

Rotate

stud

to

and

must

(B)

may

Too

much

B

or

indi

the

stud

needle

handwheel

(B)

401

19—21

be

can

etc..

can

for

oil

are

to

looper

in.

and

aligned

size

075/029,

080/032,

110/044,

timing

lbs.

remove

to

used.

NEEDLE

until

mark

setting,

(22—24

bottom

the

SEE

RANGE

080/032,

090/036,

125/049,

needles

link

on

then

cm/kg).

Fig.

cover

timing

CHART:

BY

SIZE

090/036

100/040

140/054

are

(C).

replace

18

mark

at

Fill

from

on

lowest

Torque

bottom

machine

machine.The

looper

a

position.

nut

(A)

cover

with

NOTE:

If

needed,

M

or

looper

stud

L

to

obtain

and

needle

(B)

can

proper

following

be

positioned

amount

any

of

looper

adjustment

to

timing

avoid.

to

the

13

mark

Check

looper

at

any

clearance

avoid

point

between

between

setting.

5,

401

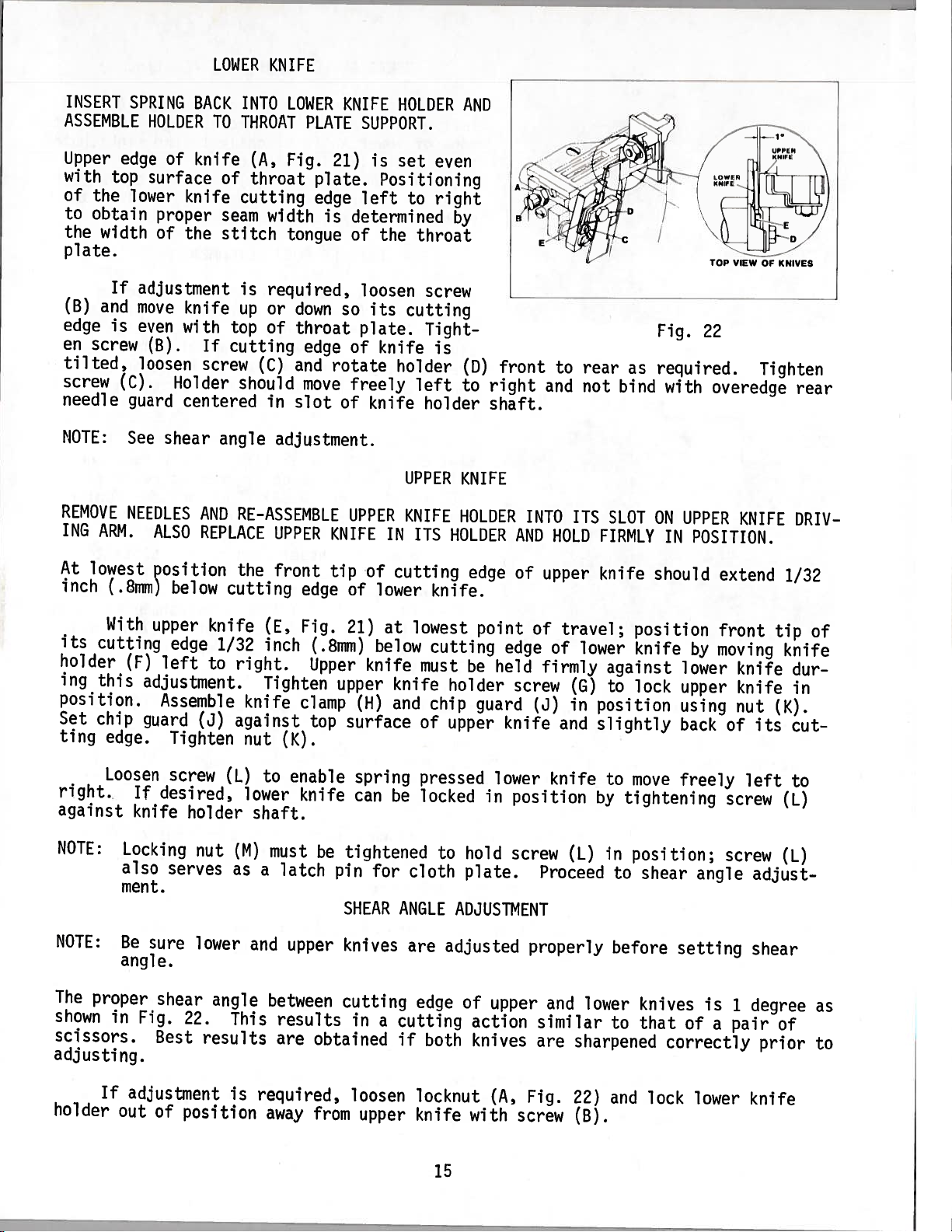

Page 14

—

—

Fig.

19

401

needle

Rear

looper

the

looper

the

scarf

the

Rotate

the

that

so

treme

needle.

ward

right

to

Loosen

touch

handwheel

lower

Raise

slightly

guard

or

-

above

REAR

FORMATION

RISES.

scribed

Re-check

earlier

401

With

needles

guard

ance

PINCH

(C,

to

NEEDLE

GUARDS.

needle,

401

STITCH

guard

point

moves

front

of

handwheel

point

position

but

needle

so

GUARD

THREAD

OF

STITCH

at

Fig.

BETWEEN

LOOPER

REAR

(A,

from

from

needle.

of

screw

NOT

is

guard

guarding

MUST

LOOP

guard

tighten

and

FRONT

lowest

is

19)

.004

MUST

NEEDLE

Fig.

striking

the

in

looper

enters

(B)

deflect

at

top

so

surface

NOT

FORMED

to

position,

set

inch

FRONT

NOT

GUARD

should

19)

the

right

and

operating

moving

scarf

the

move

and

needle.

lowest

needle

of

of

INTERFERE

AS

needle

screw

NEEDLE

minimum

with

(.10mm).

REAR

AND

RUB

prevent

needle

enters

direction

from

of

guard

position.

eye

rear

WITH

NEEDLE

position

(B).

GUARD

front

DO

NEEDLE

GUARD.

as

ex

front

for

Turn

is

needle

de

needle

clear

NOT

(B)

To

to

level

position

Fig.

feeds,

rear

21

loosen

of

feeds

lock

up

screw

or

(D)

position

close

Tighten

guard.

guard

inch

locknut

ASSEMBLE

PLATE

Rotate

stop

above

should

time.

teeth

(1.2mm)

Fig.

(A,

down.

If

locknut

and

to

screw

Continue

slightly

(.10mm)

TO

handwheel

when

top

be

With

should

20.

Fig.

Tighten

adjustment

guard

set

needle

the

CD).

to

clearance

(E).

AND

MAIN

MAIN,

DIFFERENTIAL

MACHINE.

teeth

surface

level

feeds

extend

20)

throat

and

above

lock

required,

is

(C)

but

With

so

NOT

(E).

Turn

turning

rear

the

to

DIFFERENTIAL

operating

in

rising

of

of

throat

at

the

highest

with

approximately

plate

rotate

screw

tilt

(A)

needle

relatively

it’s

touching

screw

screw

maintaining

needle.

FEEDS

direction

feeds

plate.

throat

point

shown

as

adjusting

securely.

loosen

at

(F)

(F)

FEEDS

AND

first

plate

3/64

lowest

it.

against

in

to

force

.004

Tighten

THROAT

appear

feeds

The

at

travel,

of

inch

in

pin

screw

and

this

screws

quired.

Feed

height

Retighten

is

screws.

set

loosening

by

attaching

14

and

moving

feeds

to

height

re

Page 15

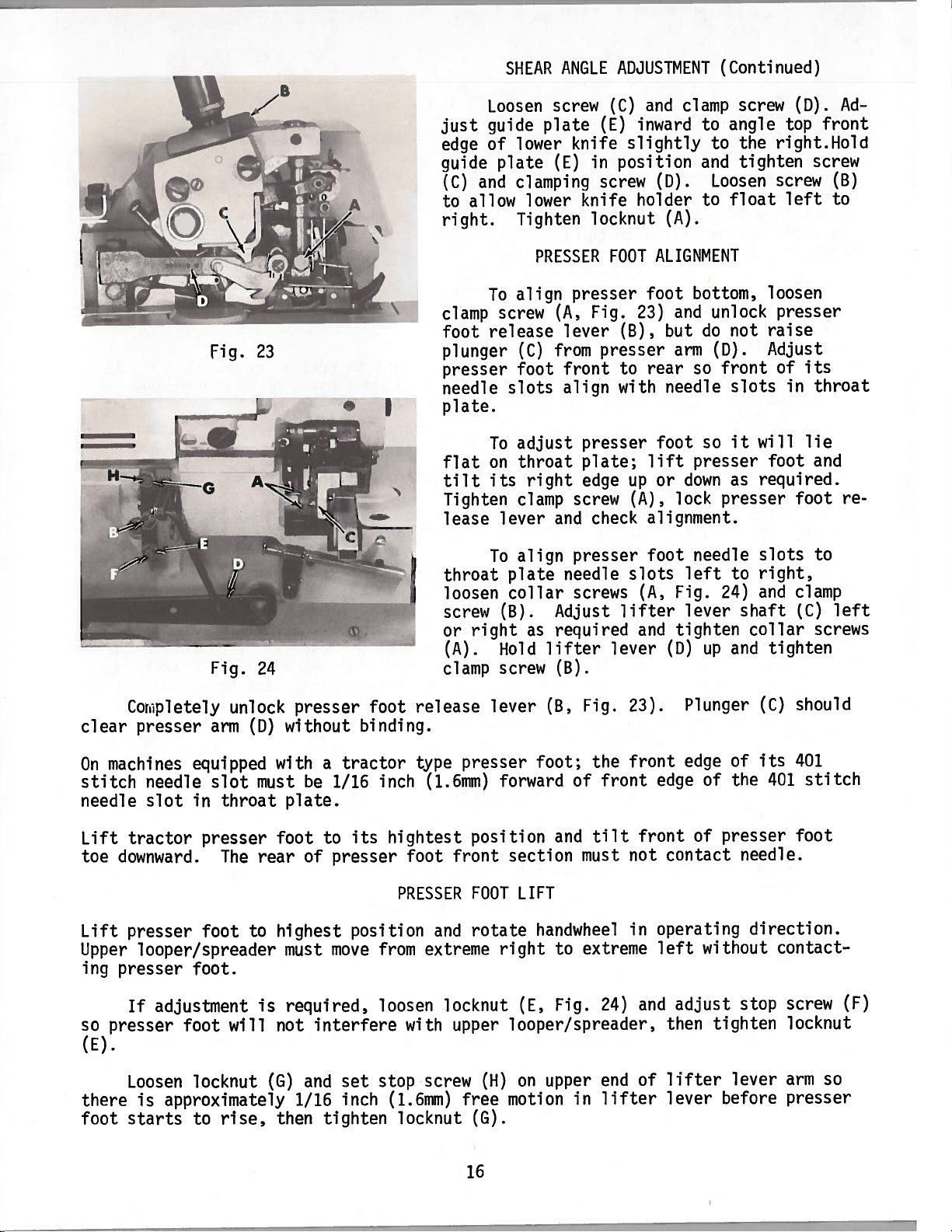

LOWER

KNIFE

INSERT

ASSEMBLE

Upper

with

of

to

the

plate.

(B)

edge

en

tilted,

screw

needle

NOTE:

REMOVE

ING

edge

top

the

obtain

width

If

and

is

screw

(C).

ARM.

SPRING

lower

adjustment

move

even

guard

See

NEEDLES

HOLDER

of

surface

knife

proper

of

the

knife

with

(B).

loosen

Holder

centered

shear

ALSO

BACK

knife

INTO

TO

THROAT

(A,

of

throat

cutting

seam

stitch

is

up

top

If

cutting

screw

AND

REPLACE

(C)

should

angle

RE-ASSEMBLE

LOWER

PLATE

Fig.

plate.

edge

width

required,

or

of

in

adjustment.

UPPER

is

tongue

down

throat

edge

and

move

slot

KNIFE

SUPPORT.

21)

is

left

determined

of

loosen

so

its

plate.

of

rotate

freely

of

knife

UPPER

KNIFE

HOLDER

set

even

Positioning

to

right

the

throat

screw

cutting

Tight-

knife

IN

is

holder

left

holder

UPPER

KNIFE

ITS

AND

by

(D)

front

right

to

shaft.

KNIFE

HOLDER

HOLDER

INTO

AND

to

and

ITS

HOLD

rear

not

bind

SLOT

FIRMLY

as

Fig.

22

required.

with

UPPER

ON

IN

POSITION.

Tighten

overedge

KNIFE

rear

DRIV

At

lowest

inch

its

holder

ing

position.

Set

ting

right.

against

NOTE:

NOTE:

The

shown

scissors.

adjusting.

(.8mm)

With

cutting

this

chip

edge.

Loosen

proper

(F)

adjustment.

guard

If

knife

Locking

also

ment.

Be

sure

angle.

in

Fig.

position

below

upper

edge

left

Assemble

(J)

Tighten

screw

desired,

holder

nut

serves

lower

shear

22.

Best

results

cutting

knife

1/32

to

CL)

angle

This

the

CE,

inch

right.

Tighten

knife

against

nut

to

lower

shaft.

(M)

must

as

a

and

between

front

edge

Fig.

clamp

(K).

enable

knife

latch

upper

results

are

tip

of

21)

(.8mm)

Upper

upper

top

surface

can

be

tightened

pin

SHEAR

knives

cutting

in

obtained

of

lower

at

below

knife

(H)

spring

for

a

cutting

knife.

lowest

cutting

must

knife

and

chip

of

pressed

be

locked

cloth

ANGLE

are

edge

cutting

if

both

edge

of

point

edge

be

held

holder

upper

to

hold

plate.

ADJUSTMENT

adjusted

of

guard

knife

lower

in

upper

action

knives

screw

position

screw

upper

travel;

of

of

firmly

(G)

(J)

in

and

knife

CL)

Proceed

properly

and

similar

are

sharpened

knife

lower

against

to

position

slightly

to

by

in

lower

should

position

knife

lock

move

tightening

position;

shear

to

before

knives

that

to

extend

front

by

moving

lower

upper

using

back

of

freely

screw

screw

angle

setting

is

of

a

correctly prior

knife

knife

nut

left

adjust

shear

degree

1

pair

tip

(K).

its

of

1/32

of

knife

dur

in

cut

to

CL)

(L)

as

to

If

holder

adjustment

out

of

position

is

required,

away

from

loosen

upper

locknut

knife

15

with

(A,

Fig.

screw

22)

(B).

and

lock

lower

knife

Page 16

just

edge

guide

(C)

to

right.

Loosen

guide

of

and

allow

SHEAR

lower

plate

clamping

lower

Tighten

ANGLE

screw

plate

knife

in

(E)

knife

locknut

PRESSER

ADJUSTMENT

clamp

and

(C)

inward

(E)

slightly

position

screw

FOOT

(D).

holder

(A).

ALIGNMENT

(Continued)

screw

to

angle

to

the

tighten

and

Loosen

float

to

(D).

top

front

right.Hold

screw

screw

left

(B)

to

Ad

clear

Corpletely

presser

Fig.

Fig.

arm

23

24

unlock

(D)

presser

without

foot

binding.

clamp

foot

plunger

presser

needle

plate.

flat

tilt

Tighten

lease

throat

loosen

screw

or

(A).

clamp

release

To

release

To

on

its

To

right

lever

align

screw

(C)

foot

slots

adjust

throat

right

clamp

lever

align

plate

collar

(B).

as

Hold

screw

presser

(A,

lever

from

front

align

presser

screw

and

presser

needle

screws

Adjust

required

lifter

(B).

(B,

Fig.

presser

plate;

edge

check

Fig.

23)

(B),

to

with

up

(A),

slots

lifter

and

lever

23).

but

foot

lift

or

foot

bottom,

and

arm

so

needle

presser

down

lock

needle

left

Fig.

lever

tighten

CD)

Plunger

foot

rear

alignment.

(A,

unlock

do

(D).

front

so

presser

24)

up

not

slots

it

as

to

shaft

collar

and

loosen

presser

raise

Adjust

its

of

in

will

lie

foot

required.

foot

slots

right,

clamp

and

(C)

tighten

should

(C)

throat

and

re

to

left

screws

machines

On

stitch

needle

Lift

toe

Lift

Upper

ing

so

presser

(E).

there

foot

equipped

needle

slot

in

tractor

downward.

presser

looper/spreader

presser

If

Loosen

is

starts

foot.

adjustment

foot

locknut

approximately

to

slot

throat

presser

The

foot

will

rise,

must

rear

to

is

with

plate.

foot

highest

must

required,

not

(G)

1/16

then

a

tractor

be

1/16

to

of

presser

move

interfere

and

set

inch

tighten

inch

hightest

its

position

from

loosen

stop

(1.6mm)

type

(1.6mm)

foot

PRESSER

with

locknut

front

and

extreme

locknut

upper

screw

presser

position

FOOT

rotate

(H)

free

(G).

16

and

to

Fig.

the

of

tilt

must

extreme

in

foot;

forward

section

LIFT

handwheel

right

(E,

looper/spreader,

upper

on

motion

front

24)

end

lifter

front

front

not

in

and

of

edge

of

edge

of

contact

operating

without

left

adjust

then

lifter

lever

of

the

presser

needle.

direction.

stop

tighten

lever

before

its

401

contact

401

stitch

foot

screw

locknut

arm

so

presser

(F)

Page 17

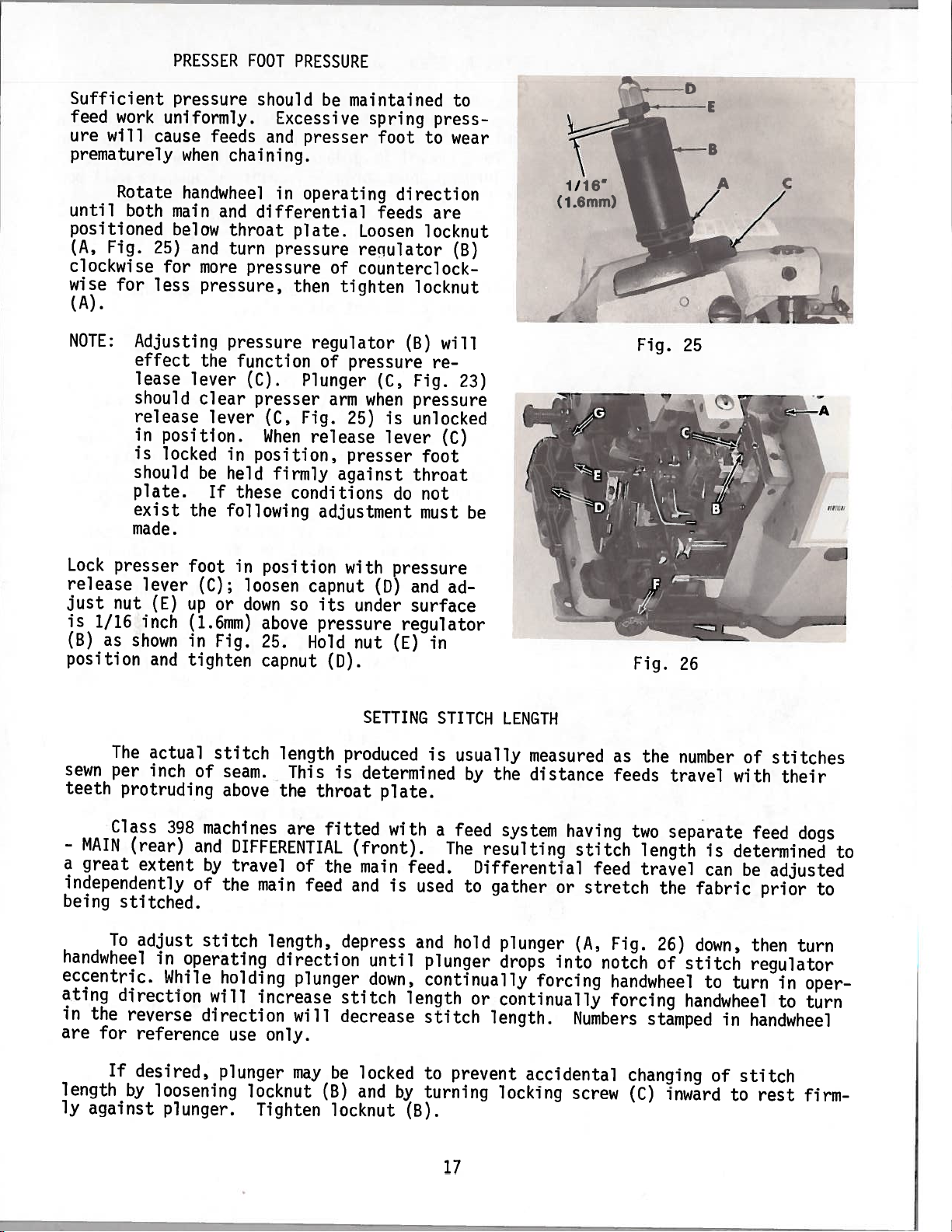

PRESSER

FOOT

PRESSURE

Sufficient

feed

work

ure

will

prematurely

Rotate

until

positioned

(A,

clockwise

wise

(A).

NOTE:

both

Fig.

for

Adjusting

effect

lease

should

release

in

is

should

plate.

exist

made.

pressure

uniformly.

cause

when

handwheel

main

below

25)

and

for

more

less

pressure,

the

lever

clear

position.

locked

be

the

feeds

chaining.

and

throat

turn

pressure

pressure

function

(C).

lever

in

held

If

these

following

should

Excessive

and

presser

in

operating

differential

plate.

pressure

then

regulator

Plunger

presser

Fig.

(C,

When

position,

release

firmly

conditions

adjustment

maintained

be

Loosen

reciulator

of

counterclock

tighten

of

pressure

arm

25)

presser

against

spring

foot

feeds

(C,

when

is

lever

do

press

to

direction

are

locknut

locknut

(B)

will

re

Fig.

pressure

unlocked

(C)

foot

throat

not

must

to

wear

(B)

23)

be

(1m)

D

E

\

Fig.

25

Lock

presser

release

just

is

1/16

(B)

position

sewn

teeth

-

MAIN

a

great

independently

being

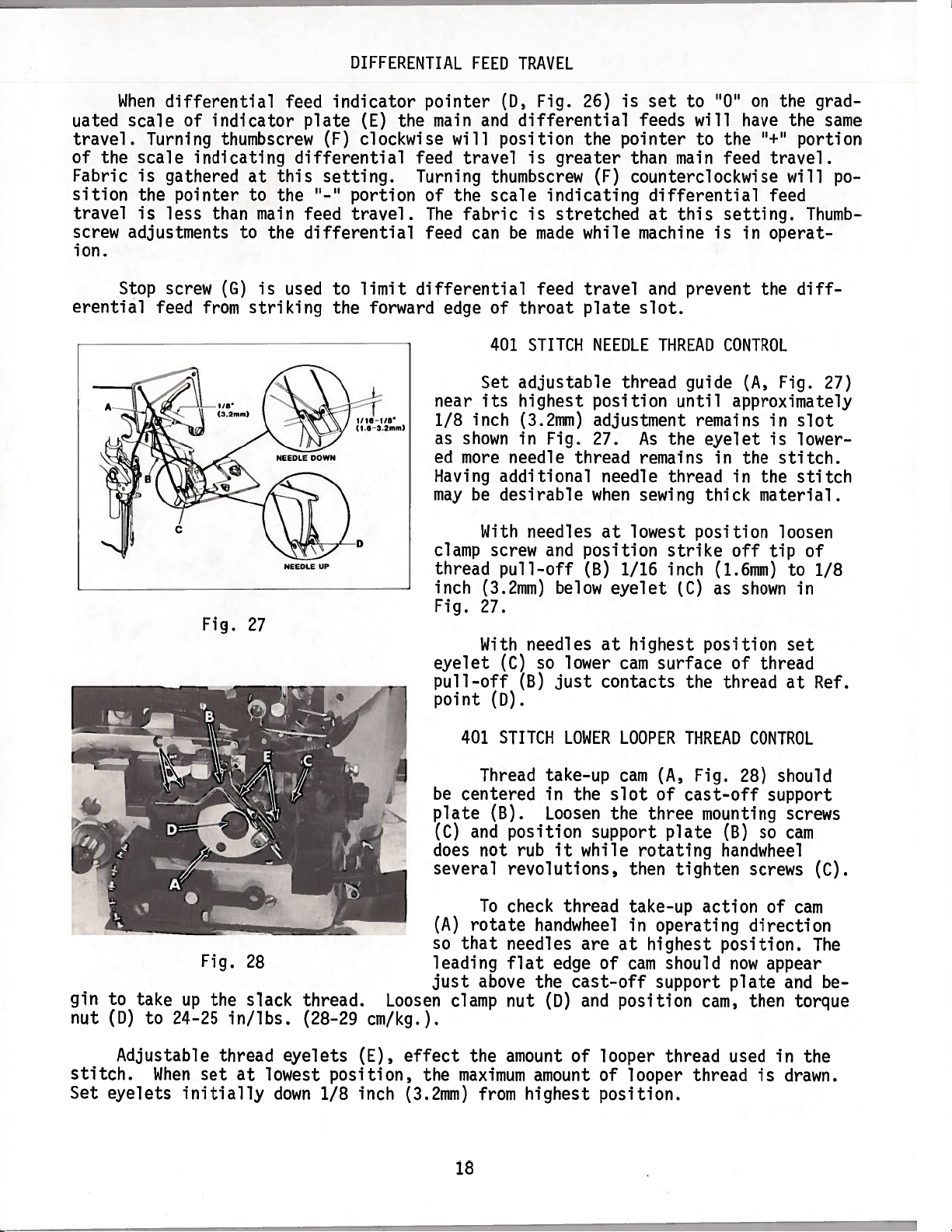

handwheel

eccentric.

ating

in

the

are

nut

as

shown

The

per

protruding

Class

(rear)

extent

stitched.

adjust

To

direction

reverse

for

reference

lever

inch

(E)

and

actual

inch

398

in

While

foot

up

(1.6mm)

in

tighten

operating

in

(C);

or

Fig.

stitch

of

seam.

above

machines

and

DIFFERENTIAL

by

travel

of

the

stitch

holding

will

direction

use

position

loosen

down

above

25.

capnut

main

length,

direction

increase

only.

capnut

so

Hold

length

This

the

are

of

feed

plunger

will

with

its

under

pressure

nut

CD).

produced

is

determined

throat

fitted

(front).

the

main

and

depress

stitch

decrease

pressure

CD)

and

surface

regulator

(E)

SETTING

plate.

with

feed.

is

used

and

until

down,

plunger

continually

length

stitch

ad

in

STITCH

is

usually

by

a

feed

The

to

hold

LENGTH

measured

the

distance

system

resulting

Differential

gather

plunger

drops

forcing

or

continually

length.

having

stitch

stretch

or

(A,

into

Numbers

Fig.

the

as

feeds

two

length

feed

travel

Fig.

notch

handwheel

forcing

26

number

travel

separate

the

26)

of

stitch

handwheel

stamped

is

can

fabric

down,

to

in

of

stitches

with

determined

turn

their

feed

dogs

be

adjusted

prior

then

turn

regulator

in

to

handwheel

to

to

oper

turn

If

length

ly

against

desired,

by

loosening

plunger.

plunger

locknut

Tighten

may

be

(B)

locknut

locked

and

by

to

turning

(B).

prevent

17

accidental

locking

screw

changing

(C)

inward

of

stitch

to

rest

firm

Page 18

_

uated

travel.

of the

Fabric

sition

travel

screw

ion.

erential

When

differential

scale

Turning

scale

is

gathered

the

pointer

is

less

adjustments

Stop

screw

feed

of

indicator

thumbscrew

indicatinq

than

(G)

from

at

to

main

to

the

is

striking

feed

plate

(F)

differential

this

setting.

“-“

the

feed

differential

used

DIFFERENTIAL

indicator

(E)

pointer

the

clockwise

feed

Turning

portion

travel.

of

The

feed

limit

to

the

differential

forward

FEED

main

will

travel

the

fabric

can

edge

near

inch

1/8

as

shown

ed

more

Having

may

be

TRAVEL

Fig.

CD,

and

differential

position

is

thumbscrew

scale

is

be

made

feed

of

throat

401

STITCH

Set

adjustable

its

highest

(3.2mm)

in

needle

additional

desirable

26)

the

greater

(F)

indicating

stretched

while

travel

plate

NEEDLE

position

adjustment

Fig.

27.

thread

needle

when

is

set

to

“0”

feeds

pointer

than

will

to

main

the

feed

counterclockwise

differential

this

at

machine

and

setting.

is

prevent

slot.

THREAD

thread

CONTROL

guide

until

remains

As

the

eyelet

remains

in

thread

sewing

thick

the

on

have

“+“

grad

the

portion

travel.

will

feed

Thumb

in

operat

the

diff

(A,

Fig.

approximately

in

slot

is

lower

the

stitch.

in

the

stitch

material.

same

po

27)

gin

nut

to

CD)

take

to

Fig.

up

24-25

Fig.

the

27

28

slack

in/lbs.

NEEDLL

thread.

(28-29

With

needles

(3.2mm)

27.

With

401

Thread

centered

and

not

To

rotate

that

above

clamp

screw

and

pull-off

needles

(C)

so

(B)

(D).

STITCH

take-up

in

(B).

Loosen

position

rub

revolutions,

check

handwheel

needles

flat

the

nut

(0)

it

edge

UP

thread

inch

Fig.

eyelet

pull-off

point

be

plate

(C)

does

several

(A)

so

leading

just

Loosen

clamp

position

(B)

below

lower

just

LOWER

the

support

while

thread

are

cast-off

and

at

lowest

1/16

eyelet

at

highest

cam

contacts

LOOPER

cam

slot

the

rotating

then

take-up

in

at

of

cam

position

strike

inch

(C)

surface

the

THREAD

(A,

of

cast-off

three

plate

tighten

operating

highest

should

support

position

off

(1.6mm)

shown

as

position

of

thread

Fig.

28)

mounting

(B)

handwheel

action

position.

now

plate

cam,

loosen

tip

of

to

1/8

in

set

thread

at

Ref.

CONTROL

should

support

screws

so

cam

screws

of

(C).

cam

direction

The

appear

and

then

torque

be

cm/kg.).

stitch.

Set

Adjustable

When

eyelets

thread

set

initially

at

eyelets

lowest

down

CE),

position,

inch

1/8

effect

the

(3.2mm)

the

amount

maximum

from

amount

highest

18

of

looper

of

looper

position.

thread

thread

used

is

in

drawn.

the

Page 19

OVEREDGE

NEEDLE

THREAD

CONTROL

With

screw

(A,

Fig.

face

of

below

thread

ines

or

FOUR

thread

With

eyelet

off

(A)

(D).

OVEREDGE

With

screw

the

to

(A,

looper

thread

Threading

through

of

looper

needles

securing

29)

its

the

centerline

eyelet

1/8

needles

(B)

so

barely

needles

Fig.

thread

tube

wire

thread

thread

needle

and

set

strike-off

holes

to

3/16

machines

at

the

lower

contacts

LOWER

at

30)

take-up

(C),

No.

tube

take-up

at

lowest

thread

the

tip

of

(B)

inch

-

Ref.

highest

thread

LOOPER

highest

and

center

then

39899

(C)

and

position,

cam

lower

1/32

overedge

on

FIVE

(3.2

point

position,

cam

surface

THREAD

position,

lower

(B)

front

tighten

A

should

the

-

Ref.

pull-off

extended

inch

needle

thread

to

4.8mm)

(C).

at

Ref.

CONTROL

screw

pass

lower

point

(.8mm)

of

slots

to

slots

(D).

loosen

sur

mach

on

set

pull-

point

loosen

of

back

(A).

freely

NEEDLES

L

Fig.

IN

HIGHEST

29

NEEOLES

UP

POSITION

9

-D

To

(E),

loosen

or

down

(G)

contacts

as

the

blade

reach

front

their

thread.barely

Ref.

point

tighten

With

take-up

back);

this

barely

(B).

thread

also

time,

contact

Reposition

in

set

until

needles

(H)

screw

needles

eyelet

set

the

the

the

screw

its

the

start

to

back,

lowest

contacts

on

(F).

(K)

auxiliary

upper

the

slot

lower

(F)

curved

lower

position

the

in

in

rear

eyelet

of

looper

and

position

section

looper

descending.

so

when

the

vertical

cast-off

OVEREDGE

highest

a

horizontal

thread

looper

thread

portion

(K)

if

take-up

cast-off

thread

the

the

lower

blade,

UPPER

position,

guide

of

necessary,

(B),

blade

-

Ref.

as

Position

needles

surface

position

should

the

then

blade

up

point

soon

looper

then

LOOPER

loosen

with

(L)

slightly

be

slot

in

(slightly

tighten

-

THREAD

screw

its

taut

left

screw

CONTROL

(J,

mounting

above

through

side

upward

(J).

Fig.

a

the

of

or

Fig.

30

30)

and

slot

horizontal

eyelet

looper

downward)

set

centered

position.

holes

thread

to

upper

(front

and

take-up

center

looper

to

At

should

19

Page 20

Fig.

31

BOTTOM

VIEW

If

properly,

set

result

as

adjustments

correct

Lower

-

Needle

-

Lower

-

rear.

the

Needle

-

If

of

edge

looper

erage

in

the

threads

of

Fig.

edge,

adjustments:

POSITIONING

needle

the

excessive

shown

which

condition

this

looper

thread

thread

looper

cast-off

thread

purl

the

fabric,

the

seamed

the

If

32.

check

thread

Fig.

in

should

strike-off

tension

is

NOT

an

indicated

is

edge

purl

the

the

THE

loop

seam

31.

be

include:

tension

blade

too

being

imbalance

would

is

following

PURL

grinning

Thread

checked

too

tip

too

loose.

formed

and

being

thread

NOT

is

tight.

low.

too

far

between

improper

occur

pulled

being

would

control

to

towards

on

as

control

the

the

cov

shown

under

Fig.

32

BOTTOM

*

TOP

VIEW

VIEW

Lower

-

Lower

-

the

Upper

-

the

Upper

-

edge

thread

Upper

-

Upper

-

rear.

Lower

-

Lower

-

rear.

front.

If

as

control

looper

looper

looper

looper

the

shown

looper

looper

looper

looper

thread

cast-off

thread

thread

in

is

Fig.

purl

adjustments:

thread

thread

cast-off

thread

too

eyelet

tension

being

33,

tension

eyelet

tension

tight.

blade

PULLED

check

blade

too

too

too

too

too

too

too

far

far

loose.

over

the

tight.

far

far

loose.

towards

towards

the

following

to

the

forward.

on

postal

The

type

Thread

threads

the

scale,

following

and

size

Fig.

tension

should

the

tensions

of

33

is

adjusted

only

be

measurements

are

thread

or

enough

are

starting

material

THREAD

and

taken

regulated

points

being

to

secure

TENSIONS

at

proper

with

the

only

sewn.

the

needles

and

may

20

tension

stitch

have

assemblies.

formation.

the

at

to

top

be

of

their

changed

Tension

Using

due

a

stroke.

to

Page 21

-

401

out

-

Overedge

straight

-

Overedge

straight

-

Overedge

straight

-

401

straight

needle

of

lower

lower

thread

needle

out

lower

out

upper

out

looper

out

eyelet

of

looper

of

looper

the

of

tension

thread

lower

thread

bottom

thread

eye

located

tension

eyelet

thread

tube

thread

at

point

THREAD

is

located

of

thread

tension

2

to

on

left

is

located

tension

tension

of

TENSION

2

1

tube

is

1

looper.

1/2

side

1/2

on

is

to

is

to

(Continued)

oz

of

to

2

right

to

1

rear

1

to

located

1

1/2

(57

needle

oz

side

1

of

1

oz

to

(43

1/2

throat

1/2

to

(28

71

head.

to

of

oz

oz

right

gr),

57

needle

(28

plate.

(28

to

of

43

to

gr),

to

to

upper

qr),

be

to

head.

43

43

measured

be

measured

gr),

gr),

to

to

knife

to

be

straight

be

measured

be

measured

driving

measured

arm.

The

is

derived

to

the

feed

segment

rocking

a

result,

erential

The

and

E)

feed

travel

travel

the

highest

position

feed

and

differential

The

regulator

to

produce

7

S.P.I.

the

differential

basic

from

individual

motion

any

feeds.

location

within

individually.

is

obtained

position

of

the

adjusted

adjustable

assembly

a

maximum

for

(C).

stitch

each

feed.

the

drive

stitch

by

link

by

main

feed.

motion

feed

Both

an

adjustable

length

of

the

segment

with

within

is

a

eccentric

(A)

stitch

feed

for

regulator

bars

by

segments

change

feed

drive

will

The

the

link

the

fixed

for

thumbscrew

within

is

set

at

length

and

INTERNAL

horizontal

assembly

means

are

of

affixed

eccentric

will

links

effect

longest

located

segment.This

the

main

for

the

stitch

the

factory

of

5

S.P.I.

FEED

the

within

effect

the

feed

at

for

ADJUSTMENTS

travel

(A,

main

to

Fig.

of

34).

feed

a

common

the

the

travel

(D

B

T

u

L

K

the

main

This

segment

shaft

stitch

c

D

regulator

of

both

S

and

motion

(B)

which

the

E

N

V

differential

is

transmitted

and

differential

is

driven

assembly.

main

H

A

and

feeds

in

diff—

G

/

a

As

obtained

and

Tighten

throat

the

slots.

duced,

located

for

this

plate

(B

and

Longer

turning

plate

If

then

Both

by

C).

feed

by

loosening

limit

screw

(F).

slots

necessary,

torque

at

the

adjustment.

main

following

travel

screw

left

and

for

inner

(G)

Rotate

making

repeat

limit

front

sure

procedure

screw

of

differential

instructions

both

feeds

lock

screw

counterclockwise.

handwheel

the

in

feeds

until

(G)

to

20

casting

feeds

below

can

listed

can

be

(F)

operating

do

desired

in.

the

be

in

sequence

not

contact

lbs.

upper

centered

direction

or

maximum

(23

cm/kg).

looper

front

for

adjusting

21

the

Fig.

and

front

stitch

An

thread

to

back

34

check

or

access

tube

feed

feed

rear

length

in

the

drive

ends

screw,

is

travel

of

is

pro

provided

throat

segments

in

Page 22

DIFFERENTIAL

button

push

Set

-

and

holding

ing

handwheel

FEED

in

operating

DRIVE

stitch

plunger

SEGMENT

regulator

down

(H)

direction.

(A,

in

Fig.

notch

34)

of

to

stitch

maximum

regulator

stitch

length

eccentric

by

and

depress

turning