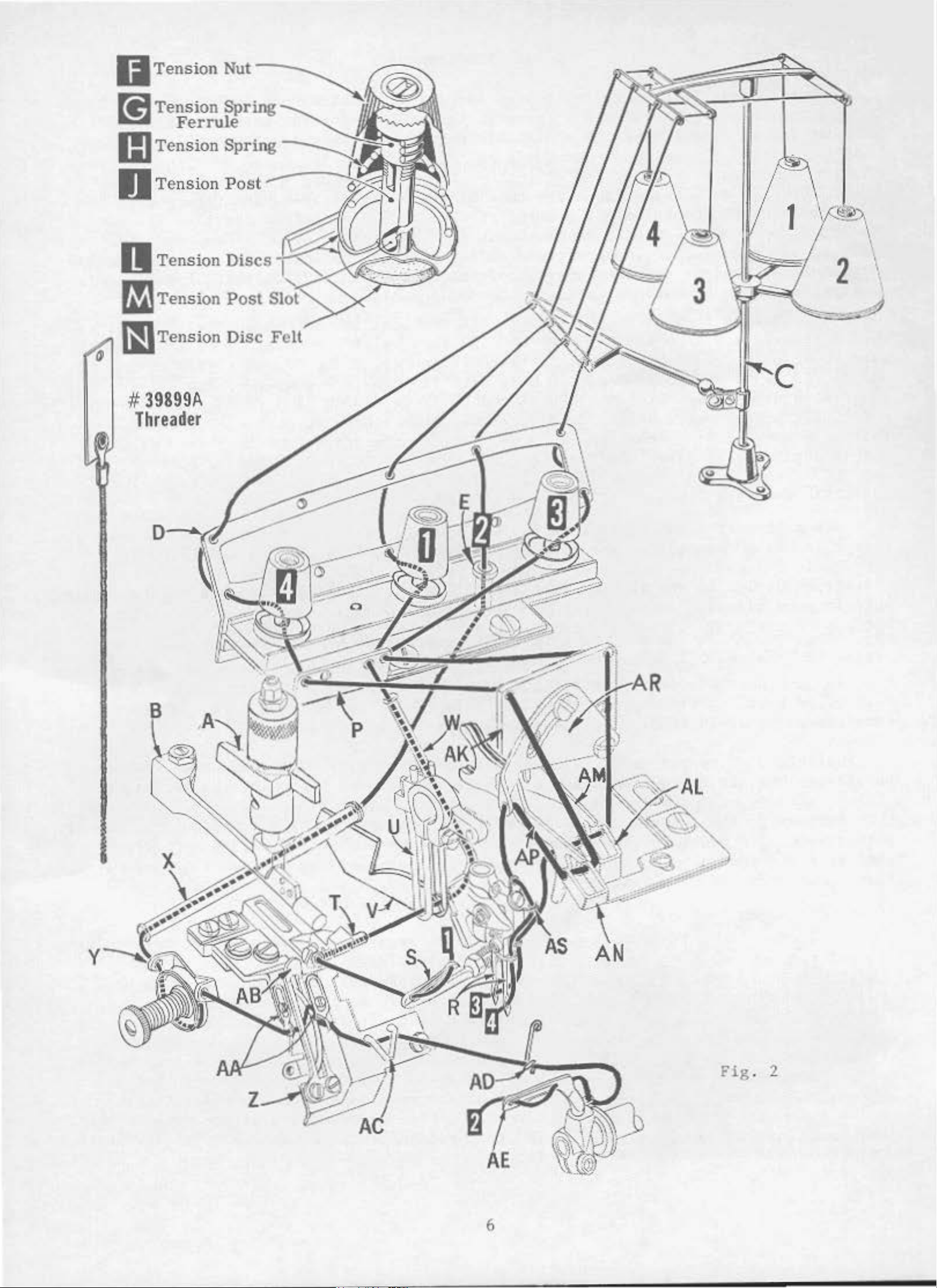

Page 1

#

39S99A

Threader

6

Fig

. 2

Page 2

SETTING

THE

FEED

DOGS

Assemble main

dogs

(A,

8,

Feed

throat

tilting

raises

bar.

time

plate.

plate

adjusting

or

Feed dogs

teeth

Screw

adjusting

at

highest

differential

3/64

inch

Fig.

dogs

should

surface

lowers

shoul

first

(D)

pin

in

point

feed

(1.19

and

15).

pin

the

d

appear

l ocks t

plac

of

tra

dog t

mm)

above

differential

be

level

by

rotating

(C).

back

be

This

end

level

above

he

feed

e.

No

1~

set

vel.

eeth

Hain

should

the

with

feed

pin

of

feed

at

the

the

throat

tilting

feed

and

throat

feed

the

dogs

be

plate.

set

C

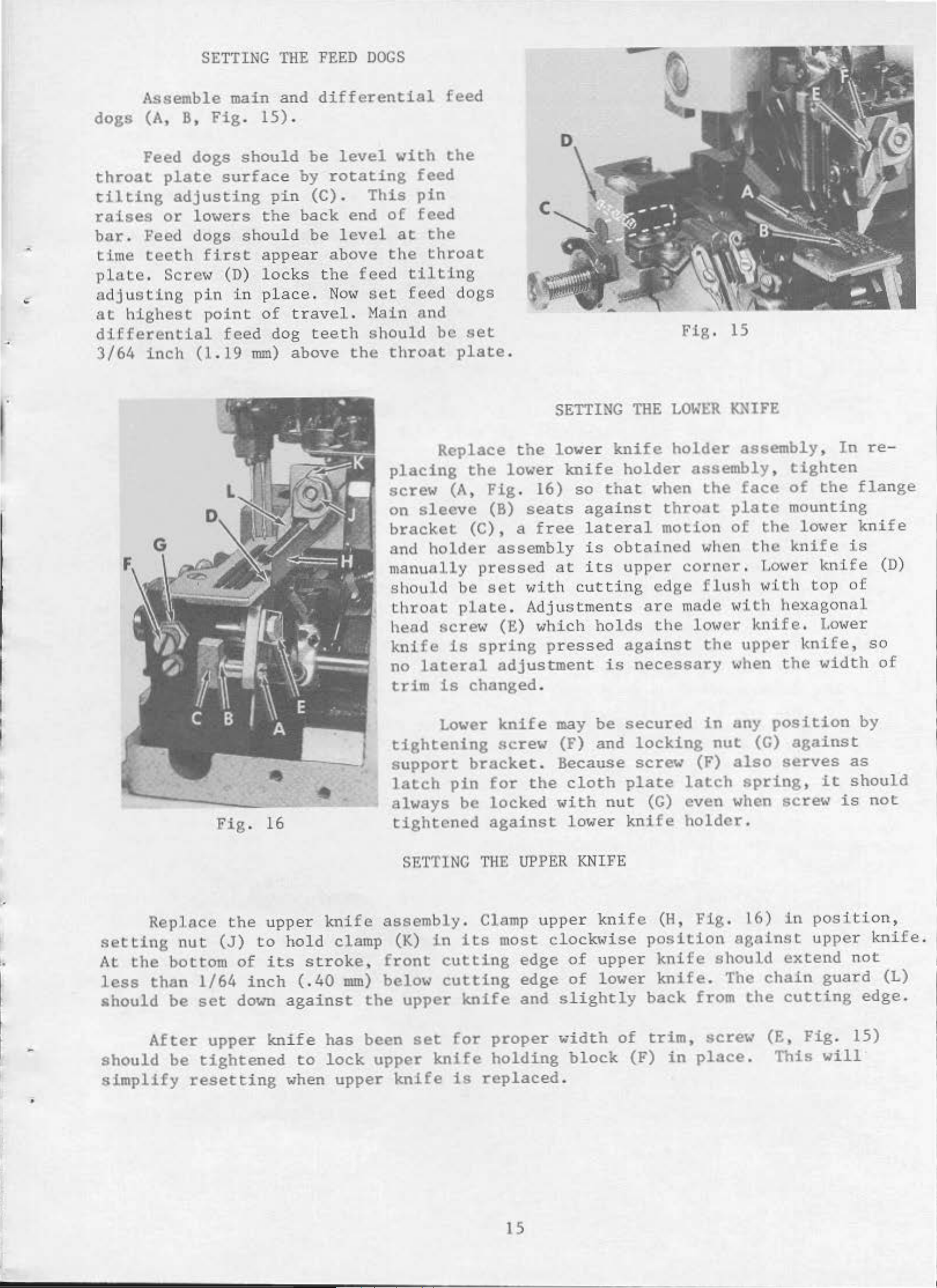

SETTING

THE

Fig

.

15

LOWER

KNIFE

Fig.

16

Replace

placing

screw

on

(A,

sleeve

bracket

and

holder

manually

should

throat

head

knife

no

lateral

trim

be

plate.

screw

is

is

Lower

tightening

support

latch

always

pin

be

tightened

the

the

(C),

lower

Fig

(B)

. 16)

seats

a

free

assembly

pressed

set vlit

Adjustments

(E)

which

spring

adjustment

changed.

knife

screw

bracket.

for

the

locked

against

lower

knife

so

that

against

lateral

is

at its

h cutt

holds

pressed

may

(F)

be

and

Because

cloth

1•ith

lower

knife

holder

when

throat

motion

obtained

upper

ing

edge

arc

the

against

is

necessary

secured

locking

screw

plate

nut

(G)

knife

holder

assembly,

the

plate

of

when

corner

flush

made

with

lower

the

in

nut

(F)

latch

even

holder.

assembly,

tighten

face

of

mounting

the

the

.

Lo1•er

lower

knife

with

hexagonal

knife.

upper

when

any

(G)

also

knife,

the

position

against

serves

spring,

when

sere<>'

In

the

knife

top

Lower

width

it

is

re-

flange

knife

is

(D)

of

so

of

by

as

should

not

SETTING

Replace

setting

At

the

less

should

nut

bottom

than

be

After

should

simplify

•

be

resetting

the

(J)

1/64

set

upper

upper

to

of

its

inch

down

knife

tightened

knife

hold

clamp

stroke,

( .

40

against

has

to

lock

when

upper

mm)

the

been

assembly.

(K)

front

below

in

cutting

cutting

upper

set

upper

knife

knife

THE

Clamp

its

knife

for

is

replaced

UPPER

upper

most

proper

holding

clock,.ise

edge

edge

and

KN

IFE

knife

of

upper

of

lower

slightly

width

of

block

.

(H,

position

knife

knife.

back

trim,

(F)

in

Fig.

analnst

should

The

from

screw

place.

16)

chain

the

(E,

in

position,

upper

extend

cutting

Fig.

This

not

guard

edge.

15)

will

knife.

(L)

15

Page 3

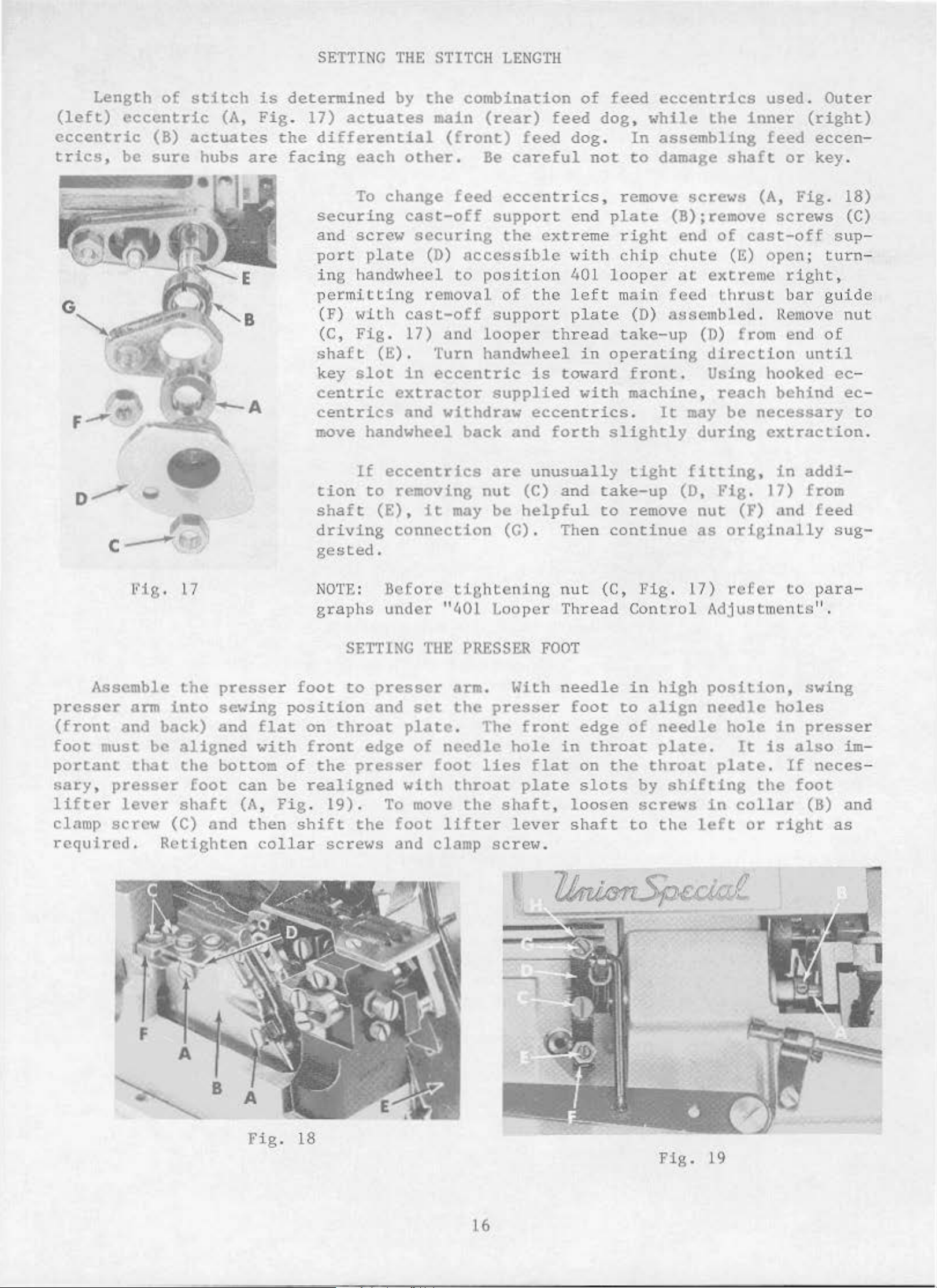

SETTING

THE

STITCH

LENGTH

Length

(left)

eccentric

eccentric

trics,

be

of

(B)

sure

stitch

(A,

actuates

hubs

are

is

determined

Fig. 17)

the

differential

facing

securing

and

port

ing

permitting

(F)

(C,

shaft

key

centric

centrics

move handwheel

by

actuates

each

To

other.

change

cast-off

screw

securing

plate

handwheel

IJith

Fig.

slot

cast-off

17)

(E).

in

extractor

and

the

(D)

removal

combination

main

(rear)

(front)

Be

feed

eccentrics

support

the

accessible

to

positio

of

supp

and

looper

feed

feed

careful

extre

n 401 l oop

the

ort

t h

dog.

end

w

left

plate

read

Turn handwheel i n

eccentric

is

tot<ard

supplied

withdraw

back

eccentrics

and

forth

of

feed

dog,

not

eccentrics

while

In

assembling

to

damage

the

shaft

, remove screwH (A,

plate

me

right

ith

chip

m

take-up

operating

with

slightly

ain

(D)

front.

machine,

.

(B); remove

end

chute

er

at

feed

a~semb!ed.

of

(E)

extreme

thrust

(D)

direction

Using hooked

reach

It

may

be

during

used.

inner

(right)

feed

or

Fig.

screws

cast-off

open;

right

bar

Remove

from end

until

behind

necessary

extraction.

Outer

eccen

key.

18)

(C)

sup

turn

,

guide

nut

of

ec

-

ec

-

-

-

-

to

D__.........

c-

Assemble

presser

(front

foot

portant

sary,

lifter

clamp

required.

and

must

presser

lever

screw

w

Fig

. 17

arm

into

back)

be

that

(C)

Retighten

the

presser

sewing

and

aligned

the

botton

foot

shaft

and

flat

with

can

(A,

then

collar

tion

shaft

driving

gested

NOTE:

graphs

SETTING

foot

to

position

on

throat

front

of

the

be

realigned

presser

Fig. 19).

shift

screws

If

eccentrics

to

removing

(E),

connection

.

Before

under

presser

and

plate.

edge

with

To

the

foot

and

it

"401

THE

set

of

needle

foot

move

lifter

clamp

may

are

nut

be

unusually

(C)

helpful

(G)

. Then

tightening

Lo

oper Thread

PRESSER

FOOT

arm. With

the

presser

The

front

hole

lies

throat

the

flat

plate

shaft

lever

screw

.

and

nut

needle

foot

edge

in

throat

on

slots

,

loosen

shaft

tight

take-up

to

remove

continue

(C,

l'ig.

Contro

in

high

to

align

of

needle

plate.

the

throat

by

screws

to

fitting,

(D,

nut

as

17)

Fig.

(F)

originally

rc

l Adjustments

position,

needle

hole

It

plate.

shifting

ln

collar

the

left

in

17) from

and

Eer co

holes

in

is

also

If

the

or

foot

right

addi-

feed

sug-

para".

swing

presser

im

-

neces

-

(6) and

as

F

A

~

B

Fig

. 18

16

Pig.

19

Page 4

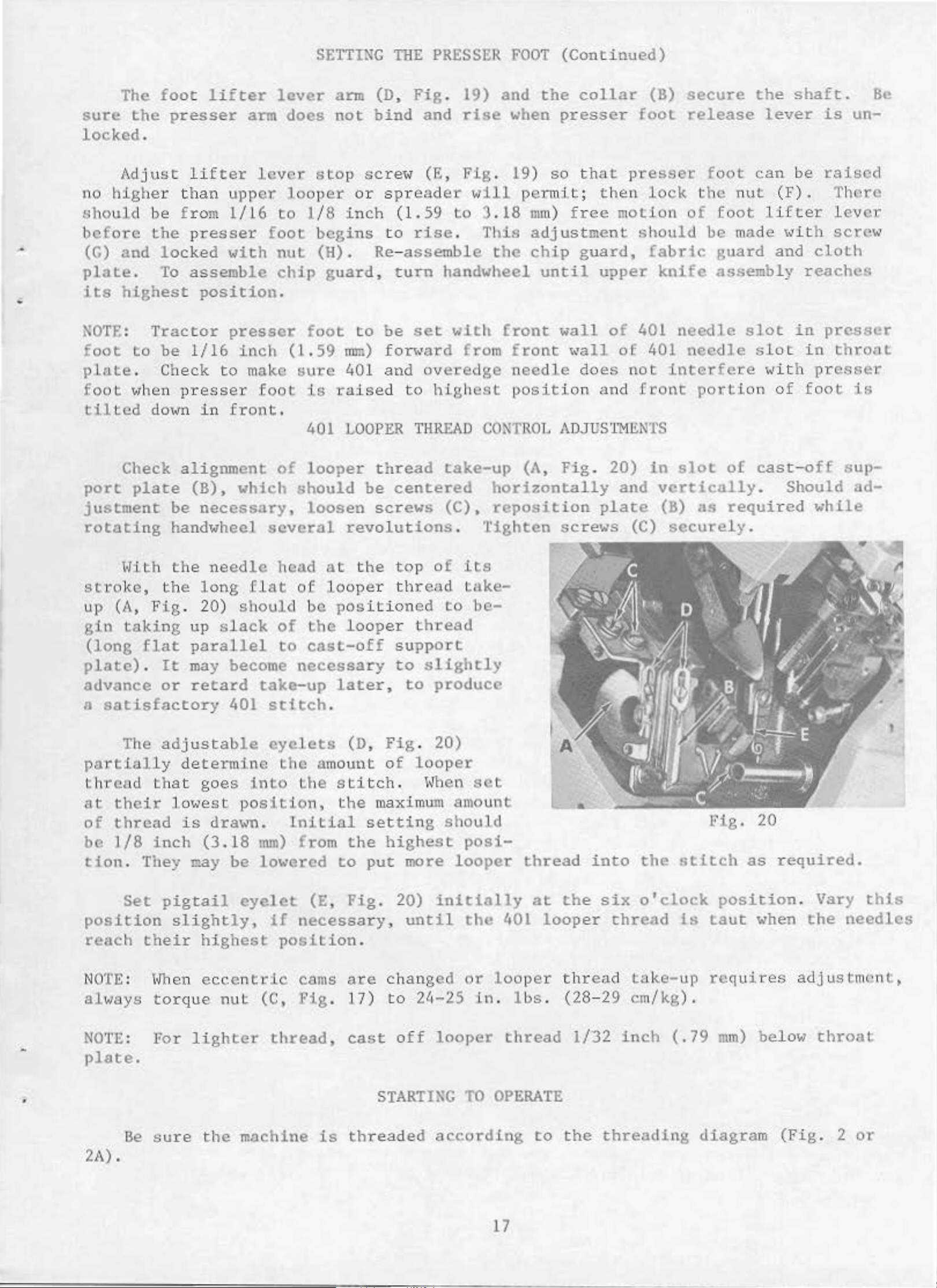

SETTING

THE PRESSER

FOOT

(Continue

d)

The

su-.:e

the

locked.

Adjust

no

higher

l'hould

before

(G)

and

plate.

its

NOTE:

foot

plate

fo

highest

to

. C

ot

when

tilted

foot lifter

presser

lifter

than

be from

the

presser

locked

To

assemble

position.

Tractor

be

1/16

heck

to

presser

down

in

lever

arm

lever

upper

1/16

to

foot

with

nuL (H).

chip

presser

inch

make

foot

front.

arm

does

not

stop

looper

l/8

begins

guard, turn

foot

(l.59

sure

i.s

1~aised

401

(D,

Fig

bind

sere'~

or

spre

inch

(1.59

to

rise.

Re-assemble

to

be

set

mm)

401

fon,ard

and

to

LOOPER

THREAD

. 19) and

and

(E,

ader

rise

Fi

g .

will

to

:3.18 m

Tl1is

handwheel

with

from

the

front

the

when

19)

presser

so

permit;

m)

adjustment

chip

until

wall

fron

t

overedge needle

highest

position

CONTROL

ADJUSTMEN

collar

that

then

free

guard,

upper

wall

does

and

(B)

foot

pre

lock

motion

should

fabric

of

401

of

401

not

front

TS

secure

release

sser

foot

the

of

be

knife

needle

needle

interfere

por.t'lon

the

lever

can

nut (F).

foot

guard

lifter

made

'~ith

and

assembly

slot

slot

with

of

shaft.

is

be

raised

There

lever

screw

cloth

reaches

in

presser

in

throat

presser

foot

Be

un-

is

Check

port

plate

justment

rotating

l·li.th

strol<e,

up

(A,

gin

(long

plate)

Fig

taking

flat

.

advance

a

satisfactory

The

partially

thread

at

their

of

thread

that

alignment

(B),

be

necessary,

which

handwheel

the

the

.

up

long

20)

needle

should

slack

parallel

It

or

may

retard

become

401

adjustable

determine

goes

lowest

is

position,

dra-.>n.

of

several

head

flat

of

to

take-up

stitch

eyelets

the

into

Initial

looper

should

be

loosen

revolutions

at

the

of

looper

be

pos

itione

the

looper

cast-off

necessary

later,

.

(D,

amount

Lhe

stitch

the

setting

thread

centered

screws

top

thr

of

ead

d

thread

support

to

slightly

to

produce

Fig

.

20)

of

looper

.

\~hen

maximum

take-up

horizontally

(C),

.

reposition

Tighten

its

take-

to

be-

set

amou11t

should

(A,

Fig.

20)

in

and

plate

scre\.'S (C)

slot

of

vertically.

(8)

as

required

securely

fig.

cast-off

Should

.

20

sup-

ad-

while

be

1/8

tion.

position

reach

NOTE: Hhen

al

ways

NOI"E:

They

Set

their

inch

may

pigtail

slightly,

tor

que

For

lighter

(3.18

be

eyelet

highest

ecce

nt ·

nut

mm)

£-.:om the

lowe-.:ed

(E,

if

necessary,

position.

dc

(C,

cams

Fig.

thread,

to

Fig

are

17)

cast

highest

put

.

20)

chang

to

off

more

initially

until

ed

2lo-25

looper

posi-

looper

the

or

401

looper

in. lbs

thread

at

looper

.

thread

into

the

six

thread

(28-29

1/32

the

o'clock

thread

take-up

em/kg).

inch

stitch

is

(.

79

as

position

taut

when

requires

mm)

below

required.

. Vary

the

needles

adjustm<'nt,

throat

this

plate.

•

2A).

Be

sure

the

machine

is

STARTING

threaded

TO OPERATE

according

to

the

threading

diagram

(Fig.

2

or

17

Page 5

OVEREDGE

LOlmR

LOOPER

THREAD

CONTROL

·

thread

lhth

(U)

should

made

ret

ighten

or

2A)

Set

needles

by

thread

tube

(T

at

be

loosening

screw.

is

to

position

head commences

its verti

head

completes its

raised

in

the syst

NOTE

the

: l,lhen

fabric

or

cal

lm

<ered

surface

em.

adjusting

guard

tube

),

though

high

centered

screw

A

preliminary

its

downward

downward

to

rests

(14,

Fig.

late

position,

between

(A,

its

Fig.

curved section

stroke

located

stroke.

increase

cast-off

on

top

OVEREDGE NEEDLE

2

or

r

it

the

the

setting

at trhe

or

blade

of

2A)

may

so

be

openiQg

thread

21),

resposition

of

and

barely

heel

T

he

decrease

and

thread

the

opening

repositioned

of

the

tubes,

lower

front

take-up

the

to

lm~er

contact

touches

of

the

cast-off

amount

blade

blade

of

tightening

tube

(T).

THREAD

CONTROL

at

slightly

l

ooper

thread

the

as

thread

its

mounting

its

looper

to

back.

wire

cast-off

as

thread

the

can

later

required

left

to

end

suit

thread

Adjustment

lever

soon

on

as

·-

needle

be

screw,

aligns

conditions.

take-up

as

required

blade.

the

needle

Fig.

be

sure

with

can

(V,

21

wires

be

and

Fig.

that

2

l<hile

needle

2A)

it

should

can

position,

(.79

mm)

requires

4.76

est

mm)

position,

needle

tions.

Hith

mately

barely

needles

strike

needle

se~~ing

thread

be adj

the

below

more

is

be

set

usted

finger

the

strike-off

depending

the

thread.

Adjust

needles

horizontal

contacts

ar

e

at

down

the

dmm

inside

stroke.

on

material

drawn on

approxi

up

or

of

thread

on t

curved

eyelet

at

high

and

so

inside

position,

of

eyelet

,

needle

mately

down

the

take

holes

and

hread,

should

material

section

bracket

UPPER

postion,

positioned,

front

wire

(AH). Us

check need'i).e

to

down

in

suit

-up

in

stroke.

the

centet

conditions.

(AH)

eyelet

be

set

and

of

thread

(AL)

LOOPER

set

loo

with

of

th

e

the

rear

wire

ually

thread

' '

/Needle

to

upper

l'ith

should

(AL)

be

for

set

approximately

stitch

length.

take-up

fon1ard

THREAD

per

thread

thread

left

take-up

of

all

looper

or

CONTROL

taut

the

control

thread

portion

the

approximately

the

(AH)

504

should

rearward

eyelet

through

wire

left

tak

thread

as

follol<s:

take-up

of

needle

stitch

1/8

to

With

needle

barely

to

(AH,

eyelet

(U). Hake

e- up

should

(Al'l,

its

slot,

head

1/32

. The 503

3/16

inch

head

touch

meet

these

Fig. 2A)

holes,

sure

wire

(U)

be

drawn on

Usually

Fig.

all

2

though

at lowest

inch

stitch

(3.18

a t

high-

the

condi

approxi-

thread

'<hen

does

not

or

to

-

Set needle

needle

head

should

t•ith

thread

The "

in

the

inch

thread

tensions

AIR

throat

(.762

be

take

-KLIPP"

mm)

thread

is

drawn

positioned

-up

s and

to

obtain

"A IR-

chain

plate

as

clearance

401

adjustable

on

the

with

eyelets

do•10

the

set,

desired

KLIPP~'

cutter

possible

.

NE

EDLE tHREAD

eyelet

stroke.

bottom

THREAD

as

401 and

VACUUM

tube

"ithout

(AR,

Fig

Eyelet

eye

in

TENSIONS

described

overedge stitch

CHAIN CU

should

touch

be

ing;

CONTROL

. 2

line

under

TTER

or

(AS)

2A)

located

with

thread

ADJUSTIIENTS

assembled

. 005

inch

so

the

.

as

( .127 m

that

at

left

most

top

needle.

controls,

close

to

m)

of

of

needle

balance

the

to

. 030

the

the

cut-out

18

Page 6

"AIR-KLIPP&'

VACUUH

CHAIN

CUTTER

ADJUSTHENTS

(Continued)

knife

single

the

station

stroke

of

"A

etld

of

lent

Check

to

The

that

trim

"AIR-KLIPP"

strand

The

cutting

ary

.

Care

must be

IR-KLIPP"

stro

ke.

Lubricate

to

Union

knife

.

of

thread

edge

knife

taken

chain

felt

Special

pressure

chain

cutter

when

of

the

a minimum

to

provide clea

,

cutt

oil

er

wick and movable

Specification

is

turning

movable

of

tube

"hen

only

enough

should

machine

knife

l/64

inch

rance

t he movable

No

. 175 .

to

be

capable

ove

should

(.40

bet

..

knife wit

ensure

of

proper

cutting,

r by hand.

extend

rom)

een

"hen

movable

knife

h a

beyond

is

straight

at

at

cutting.

NOT

Lhe

extre

knlfe

Lhe

mineral

TEARING,

cutting

me

right

and i

extre

me

Set

end

nner

right

oil

movable

a

ed

ge

of

of

wal

l

equiva-

SKIPPING

(A)

Overedge

l.

2. R

3.

4. Recheck

(B) 401

:

If

stitch

Reche

echeck

Recheck

Skitch

skipping

ck

lo"

er

overedge

upper

upper

occurs,

lo

oper.

need

looper

looper

SPECIAL

check

to

le

guard

or

spreader

or

spreader

and/or

needle

sett

ADJUSTMENTS

set

to

to

adjust

ting

ing

.

lower

needle

the

.

looper

setting.

following:

setting

.

1.

2.

Recheck 401

Rechec

3 Check

Thread

4.

Should 401

k 4

01

401 l

Contro

loop

needl

ooper

er

e gu

ca

l Adjustm

chain

skipping

to

401

ard

st-off

ents

needle

settings

ea

rn

take-up

".

occur,

setting

.

timing

recheck

.

"Sett

-

ing

see

note under

The

Presser

"401 Looper

Foot"

.

19

Page 7

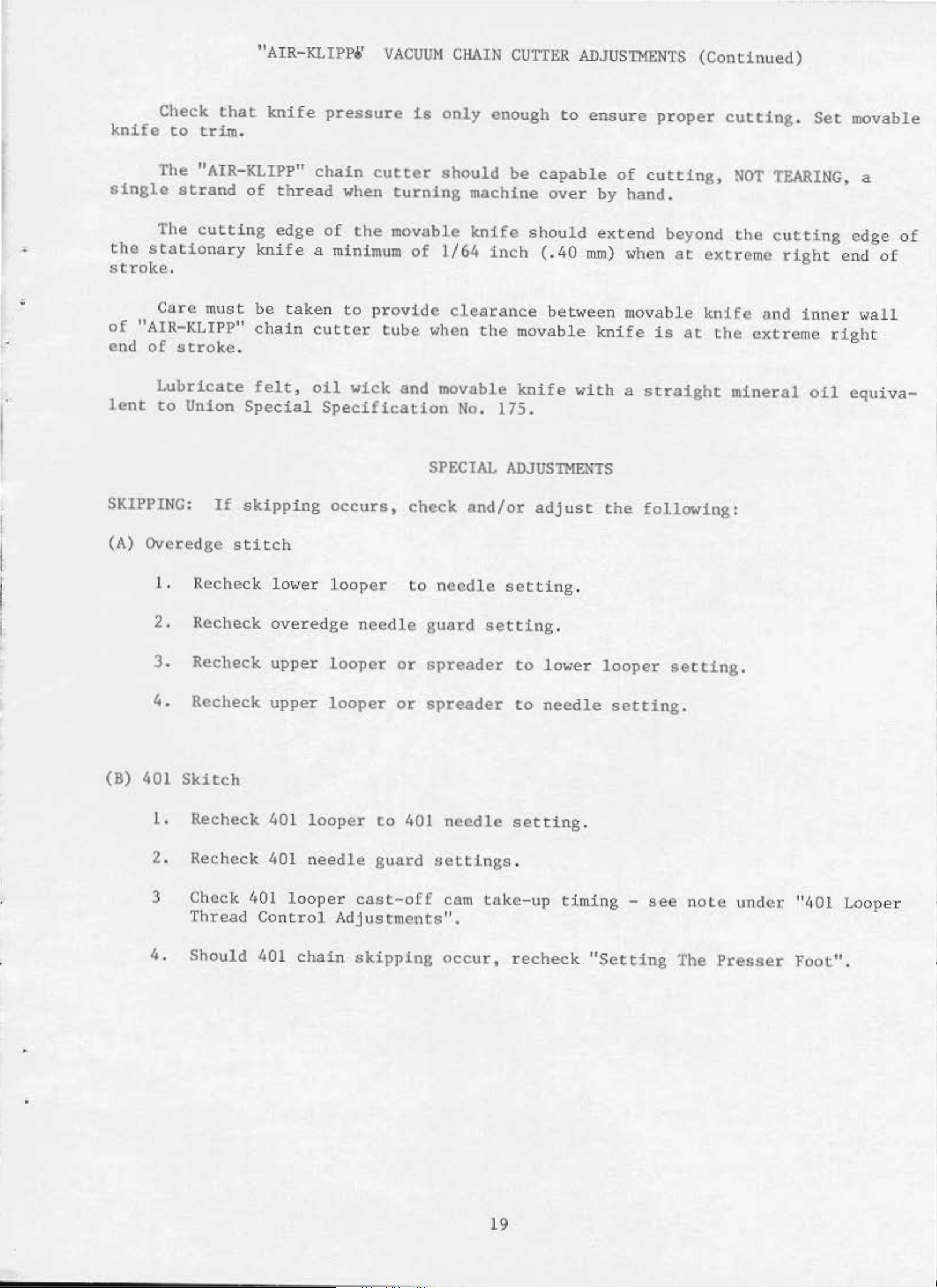

TO

REMOVE

CRA...~KSHAFT

Crankshaft

I.

2. Re

3. Remove

Drain

base

.

move top and

can

oil

nut

be

withdrawn

by

removing

(A,

bottom

Fig

.

22)

easier

plug

covers

401

if

screw

of

loo

per

these

located

machine.

thread

steps

on

take-up

are

back

follow:

of

machine

(B)

T

and

near

eccentrics

s

bot

R

tom

(C).

edge

p

of

<

'

/

'

/

'

'

'

/

Fig

/

E

. 22

4.

S. Remove two

Remove

be

re-assembled

key

(D).

counterweights

in

the

(E). Identify

prop

er

places.

20

these

counterweights

so

that

they will

Page 8

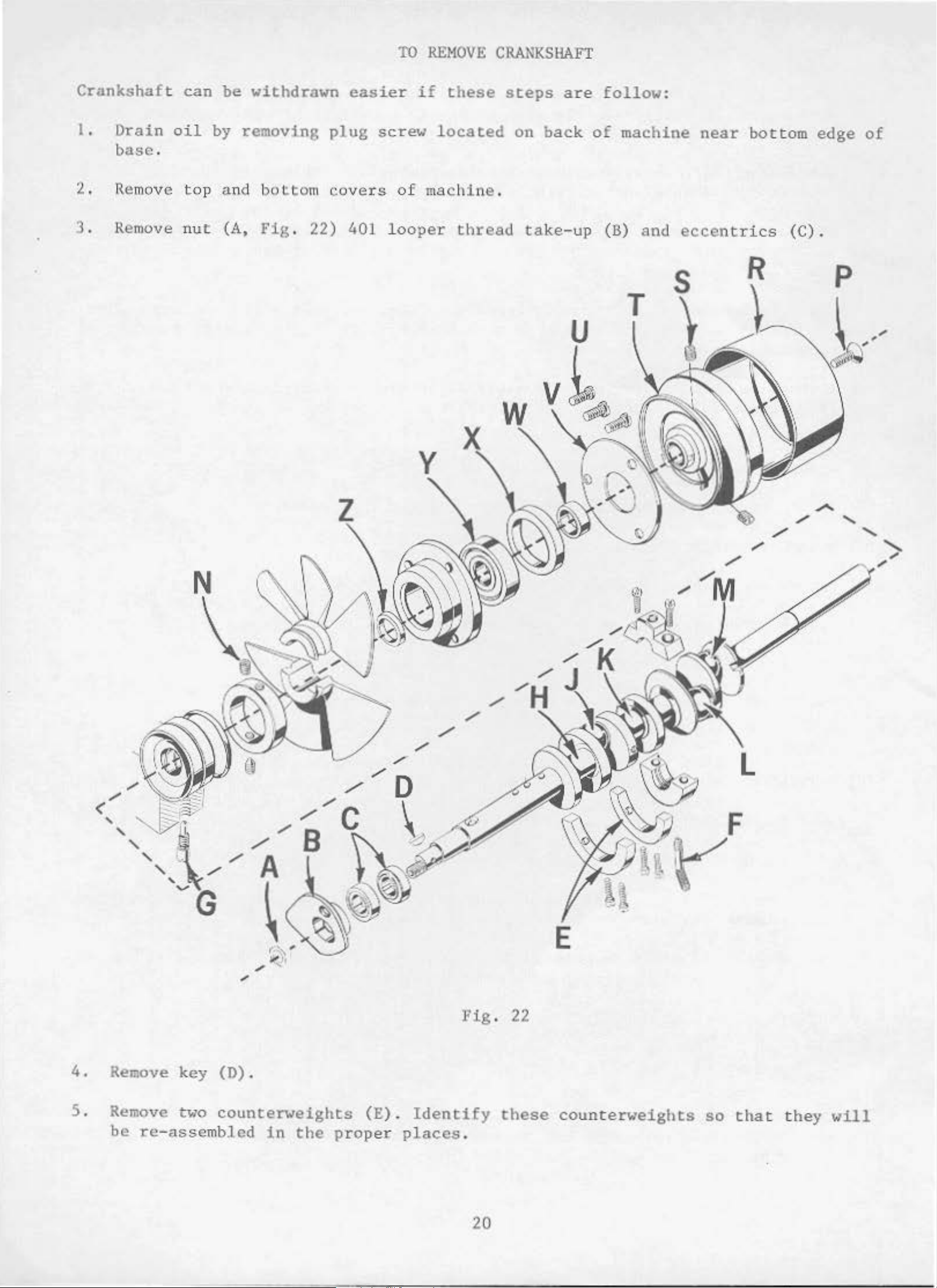

T.O

REMOV'Jl. CRANl<.Sl\Al?'.t ( Con

l:.

i.nued)

6.

7.

8.

9.

Remove

scre\·1

thro

ugh

Remove

bearing

stamped

side

of

"hich

Remove

shaft.

Remove

drive

of

machine

drive

oil

(G)

caps

they

401

tube

which

bottom

of

caps

on

the

make s

both

bearings

'1ere

looper

of

bearings

upper looper

lever

lever

sha£ t fr

and

lift

and

(F)

holds

~1hich

the

bed

casting.

on

ure they

halves

.

of

Also

removed .

drive

or

om

out

lever

spreade

the

the

connecting

holds

inner

cra

are

the

crankshaft

right

nksh

in

caps

, screx<s

·r

rear

rod

.

aft

their

and

should

split

crankshaft

at

points

original

both

trademarks

bt'

reassembled

bearing

bearing.

H,

J,

p

osition.

and

Land

should

in

oil

They a·

~1.

pump,

re

~lhen

Trademarks

be

on

the

same holes

and

the

accessible

reasse

mbling

are

the

same

fro

m

E

1

0.

11.

12.

13.

1

4.

Remove

drive

upper

shaft

guide.

Remove

shaft

l01~er

from

disconnect

li

ft

out

lever

Remove

Remove

Loosen

Access

upper

and

lower

throat

clamp

to

knife

bearing

sa

me

precautions

looper

bushing

looper

the

connecting

lower

connecting

looper

plate

nut

clamp

drivi

cap

(E).

or

and

drive

rear

of

looper

thread

and

(A,

nut

ng

is

lever

This

"hen

sp

reader

cam

lever

machine,

link

drive

and

~

rod.

take-up

l01•er

Fig.

23)

"h

through

is

(C)

at

and

bearing

reassembling

knife

ich

top

~~ire

and

support

holds

cover.

the

Dra"

connecting

point

cap

(K,

as

described

take

-up eyelet

bracket.

upper

driving

rod

(D)

Fig.

Fig

knife

drop,

2

2)

in

.

23

mounting

driving

arm

to

the

allo,,•ing

on

crankshaft

paragraph

bracket.

arm

left

removal

7 .

(B).

until

.

Observe

of

.1.5.

16.

17.

Loose

n

Remove

Loosen

18. Remove

19.

20.

coll

Cr

side.

If

arbor

it

ars

ankshaft

necessary

seats

t"o

sere«

tHo

three

(~

I)

press.

against

screHs

(

P);

scre1•s

scre'ls

and

(X) may

may no"'

to

replace

In

replaci

ground

(N)

take

(S):

(U);

be

in

fan

off

collar;

pulley

remove pulley

be

re

moved

ball

ng

thrust

take

off bearing

removed

1~hile

bearing

the

bearing

~~asher

remove

cap

(T).

at

holding

(Y),

(R).

this

it

(Z).

both

retaining

tim

e .

needle

it

can

must

be

halves

plate

lever

be

pressed

press

of

cooling

(V):

connecting

off

sed on

fan

also,

r od

shaft

carefully

.

spacer

to

on

an

until

the

21

Page 9

21

22

.

Carefully

bly

and

.

Before

kets.

prevent

observing

of

cranksha

con

stant

reassembling,

Coat

oil

the

leakage

ft.

testing

oil

TO

REMOVE

reverse

Ch

ecking

for bin

thoroughly

drain

.

No

plug

. 1 Crane Lead

CRANKSHAFT

of

the

exploded

ds

durin

with

foregoing

g

clean

a

(Con

operations

view draw

reassembly

and

sealing

Seal

dry

is

tinu

ings

the

compound

recommended.

wi

ed)

for

ll

top

loca

also

and

before

should

tion

prove

bo

ttom

reassembling

simplify

of

various

help

covers

ful

reassem-

parts

.

and

gas

to

-

tL

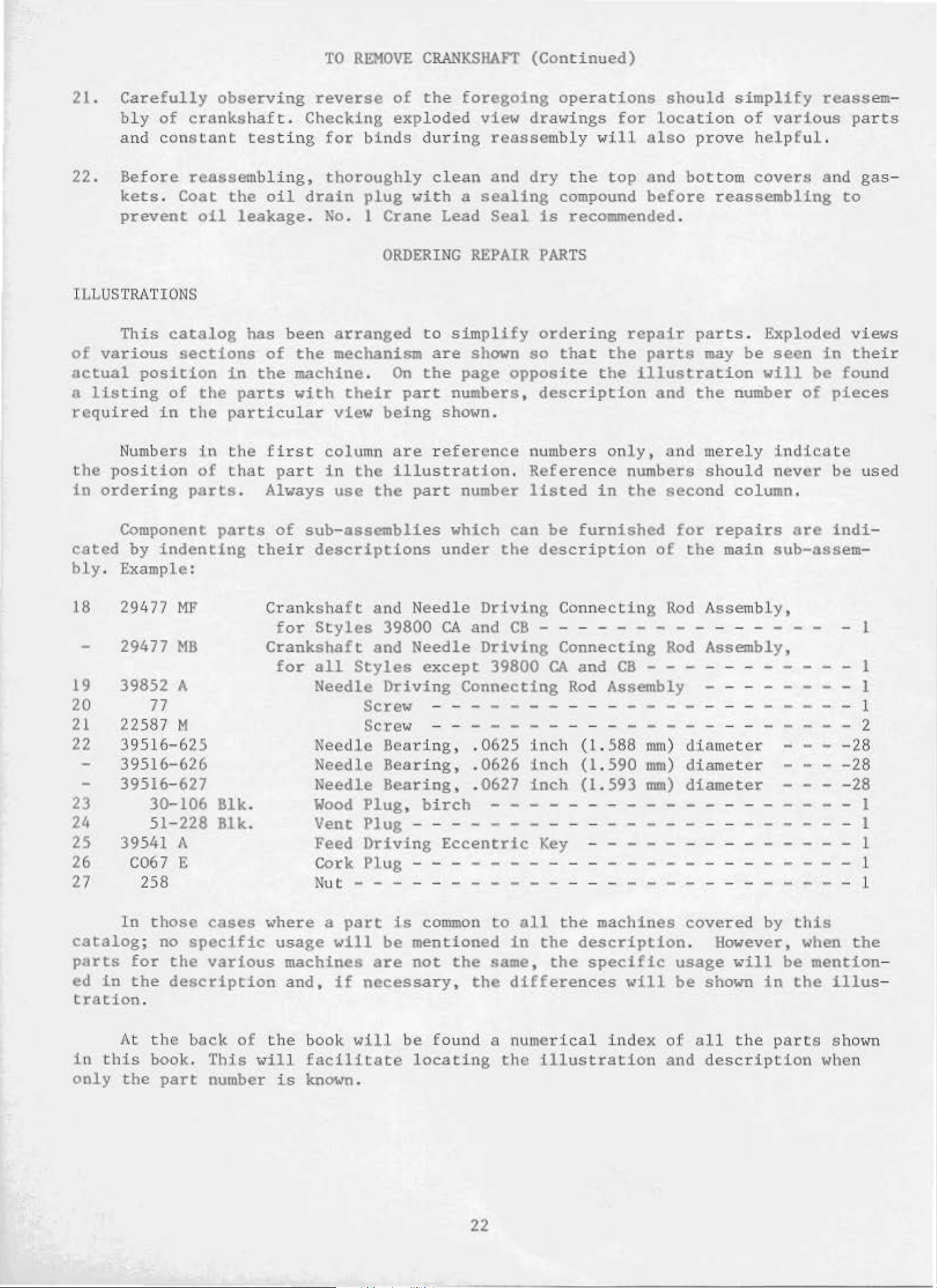

LUSTRATIONS

This catalog

of

various

actual

listing

a

req

uired

the

in

ordering

cated

bly

. E

position

in

Numbe

position

Component

by

indenting

xample:

sections

of

the

the

rs

in

of

parts

parts

has

in

parts

par

the

tha

. Always

been

of

the

ticu

first

t p

art

of

their

the

machine

with

lar

ORDER

arranged

mechanism

.

their

view

column

in

use

sub-assemblies

description

being

the

the

to

On

the

part

are reference

illustration.

pa

s

ING

are

rt

REPAIR

sim

plify

shown

page

numbers ,

shown.

number

which

under

PAR

or

dering

so

that

opposite

descr

numbers onl

Ref

erenc

lis

ted in

can

the

be

description

TS

repair

the

the

ipti

furnished

on

e numbers

the

parts.

parts

illustration

and

y,

and

second

of

the

for

the

may

merely

should

repairs

Exploded views

be

seen

will

number

indica

never

column.

main

sub-assem-

be

of

are

in

found

piec

te

be

indi-

thei

es

used

r

18

19

20

21

22

23

24

25

26

27

catalog

parts

ed

tration

29477

29477

39852 A

22587 M

39516-62 5

39516-626

39516-627

39541

In

in

77

30-106

51

C067

258

th

; no

for

the

.

MF

MB

Blk

.

- 228

Blk

.

A

E

ose

the

description

cases "'he

specific

various

Cranksha

for

Crankshaft

for all

re a

usage

machines

and,

ft

Styles

Needle

Needle Bea

Needle

Needle

Yood

Vent

Feed

Cork

Nut - - - - - - - - - - - - - - - - - - - - 1

part

will

if

and

and

Styles

Scre

Scre

Plug, birch

Plug

Drivi

Plug

are

necessa

Needle

39800

Driving

w - - - - - - - - - - - - - - - - - - - - 1

w - - - - - - - - - - - - - - - - - - - - 2

Bear

Beari

is

be

CA

Needle

ex

cept

ring,

ing,

ng,

- - - - - - - - - - - - - - - - - - - - - - - 1

ng E

common

mentioned

not

ry,

Driving

and

CB

Driving

39800

Connecting

. 0625 i

.06

26 i

. 0627

- - - - - - - - - - - - - 1

ccentric

- - - - - - - - - - - - - - - - - - - 1

to

all

in

the

same,

the

differences

Connecting Rod

- - - - - - - - - - - - - - - - 1

Connecting

CA

and

Rod

nch

nch

inch

Key

the

(1.588

(1.590

(1.593

- - - - - - - - 1

the

description

the

specific

CB

Assembly - - - - - - 1

machines

will

Rod

- - - - - - - - - 1

mm)

mm)

mm)

Assembly,

Assembly,

dia

meter

diameter

dia

met

er

covere

. However, when

usage

be

shown

d by

will

---

in

-

--

- - -

this

be

the

-28

-28

-28

mention

illus

the

-

-

At

the back

in

this

only

the

book.

part

of

the

This will

number

is

book

facilitate

known.

will

be

locating

found a

22

num

the

eri

ill

cal

ustrati

ind

ex

on

of

and

all

the

descript

part

ion

s

sho

when

'm

Page 10

IDENTIFYIN

G PARTS

•

When

too

small

tinguish

Part

IMPORTANT! ON

PART

IS

Success

SPECIAL

sub

sidiaries

approved

ciency

and

Genuine

parts

your

are

guarantee

the

for

one

numbers

ORDERE

construction

a

complete

part

from

represent

D.

in

the

Needles and

and

scien

durabil

authorized

tific

ity

needles

stamped

with

of

the highest

catalog

another

ALL

ORDERS, PLEASE

USE

operaton

Repair

principles,

are

are

assured

packaged

the

permits,

stamping

that

the

same

GENUI

of

these

Par

ts

as

di

stributors

and

.

Union

Special

quality

each

is

part

NE N

furnishe

arc

with

part

are

similar

is

stamped

identified

in

appearance.

regardless

INCLUDE PART

EED

LES

machi

AND

nes

can

d by

. They

are

NAME

REPAIR

be

the

desig11 ed

made with utmos t

labels

trademark

in

materials

marked

, U S Emblem. Each

and

of

AND

with

by

catalog

its

letter

STYLE

PARTS

secured

Union

only

Special

according

precision.

~

workmanship.

part

symbols

in

which

OF

with

Corpo

.

number.

Pa

which

they

~lACHINE

appear

FOR

genuine

ration, its

to

the

~~ximum

Genuine

most

effi

repair

trademark

rts

dis-

.

lmiCH

UNION

-

is

Prices

are

~~ise

forwar

directed.

Torque

distance

a

driver,

of

torque

All

unless

hand

as

The

are

ded

f.

A

(measured

by a

etc

.

~~ny

will

straps

otherwise

tightly

scre

ws

strictly

o.

b.

shipping point

charge

lever

of

these

tighten

and

eccentrics

noted.

as

possible,

requiring

net

cash

is made

in

inch-pounds)

(in

inches

devices

the

part

All

unless

a

specific

and

to

TORQUE

or

to

should

other

TE~lS

subject

. Parcel

cover pos

REQUIR~fENTS

is

a

rotating

feet)

are

the

nuts

.

available

correct

be

tightened

,

bolts,

otherwise

torque, will

to

change

Post

tage

shipments are

and

insurance.

forc

This

is

,

which

acco

amount and no

to

screws,

noted

.

be

indicated

with

e

(in

mplished

when

19-21

etc

out

notice.

insured

pounds)

by a

set

at

tighter

wrench, screw

the

.

inch-pounds

.,

should

on

the

All

unless

applied

proper

(22-

be

tightened

picture

ship

throug

24

men

ts

other-

h

amount

em/kg)

by

•

plat

es

.

23

Page 11

6

'

1

2

24

I

I

lb

Page 12

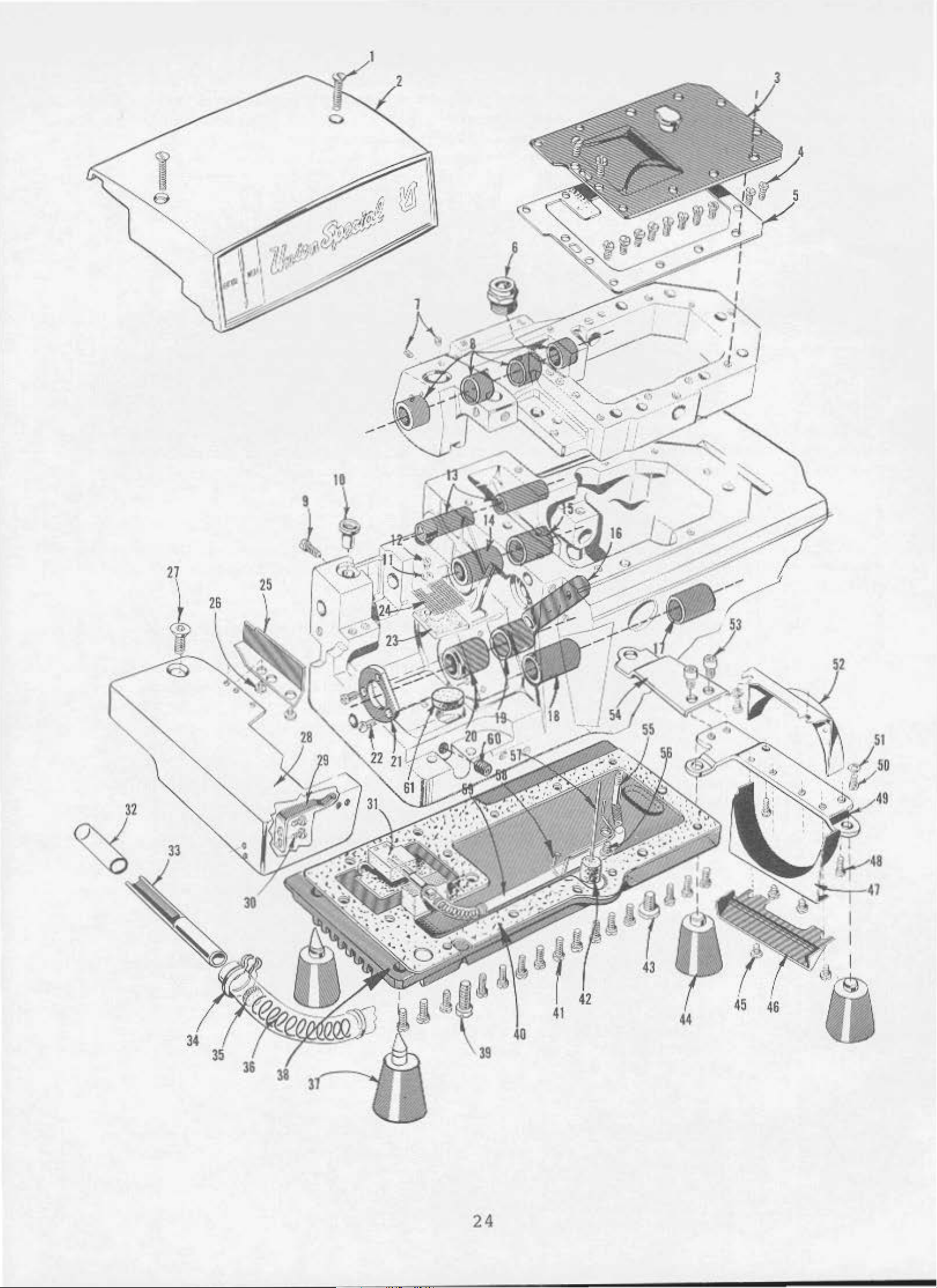

THREADING

Thread

of

tension

back to

the

sion

dies

hole

upper

post

(L),

in

It

quence

No.

1,

thread

Thus,

is

as

follm<s;

2,

401

color

code;

from

thread

front:

hole

thread

through

front

\dll

as

designated

then

have

No.

been

the

looper

thread

thread

guide

NOTE: Thread

of

tension

bar

eyelet

tension

thread

simplify

guide

the

by

2,

etc.

color

threading

Thr ead

thread

No.

-

No.

stand

(D)

from

No. 2 (401

thread

(E).

post

(P

threading

the

The

numbers

various

coded

sequence

1,

blue

4,

color

401

(C,

Fig.

front

guide

All

slot

(M)

).

of

assigned

eyelets

to

further

for

lo\<er

looper

code;

needle thr

2

to

lo

(D)

other

in

these

aid

Styles

thread

ead

or

2A)

back

oper

fro

and

-

m

threads

tension

machines

to

and

the threadi

39800

thread

No.

-

red

is

threaded

then

blue

color

back

continue

post

each

guides

CA,

-

golden

3,

color

through

code)

to

front

(J)

to

follo"

thread,

on

the

ng

process.

CP,

CX,

beige

overedge

code.

through

the

is

and

dmm

bet"een

and

on

the

starting

machine

VCP,

colo:r

needle

the

lo"er

upper

holes

threaded

through

the

throug

tension

h

its

recommended

"ith

for

VCX,

code;

thread

each

(503

thread

thread

holes

from

through

ten-

proper

se-

stitch

No.

-

green

)

The

follo"s

401

color

401

; T

looper

code;

needle

Before

direction

pressure

er

arm (B)

Tu

rn

Use

and

or

threading

push

in

front

protrudes

thread

the

(No.

left

treme left

the

rear

threading

hread

No.

thread

thread

thread

beginning

until

on

out

pre

the

sser

of

handwheel

wire

through

of

cast-off bla

out

end

1)

of

of

in

tube

positon;

and

through

sequence

1,

504 lo\<er

-

blue

No. 4,

-

red

color

to

color

ov

thread,

needles

foot

by

position.

THREADING

until

/139899

same;

same

to

the

in

A

through

front

threading

(T) . Turn

then

the

thread

right

for

eredge

code.

(R,

turning

LOWER

the

point

(Fig.

de

(V)

Styles

looper

code;

thread

needle

S\<ing

Fig

. 2

presser foot

LOOPER

of

2

or

the

of

inside

and

the

through

front

1<ire

hand,.heel

lower

eye,

looper

entering

39800

thread-

thread

cloth

or

2A)

(Golden

lower

2A)

by

of

and

pull

until

CB,

CQ,

golden

No. 3,

plate

are

release

Beige

loop

er

inserting

take

- up

long

thread

back

the

through

from

CY,

504 up

-

green

open,

at

their

(S)

wires

tube

guide

until

lower

its

the

VCQ,

beige

per

turn

lever

Color

is

into

(W)

(P).

left

front

VCY,

color

looper

color

hand>~heel

highest

Cod

all

the

(U)

until

the

looper

eye, entering

.

(504

code;

thread

code;

position,

(A),

and

e)

the

way

left

passing

the

Hook

lo,.er

thread

(S)

stitch)

thread

-

thread

in

operating

swing

to

the

end

of

over

threading

looper

comes

is

at

its

is

black

No.

release

press-

right

tube

and/

wire

out

of

ex

from

as

No.

5,

(T)

-

2,

.

THREADING

Double end

threa

tension

the

(Z)

d

tube

bottom

.

Thread

(X)

thread

of

through

off 1<ire (AB)

eye

let

doubled

•

through

doubled

(

4.

76

NEEDLE

(AD)

end

f rom

of

approximately

end

mm)

LOOP

of

projection

AROUND

of

401

or

use

eyelet

tension

and

over

left

thread

thread

LOOPER.

looper

threading

(Y)

post,

from

then

adjustable

the

to

into

an

into

of

take

right

right

inch

left

thread

REHOVE

401

thread

"ire

back

continuing

eyelets

-up,

and

up

eye

or

so

ey

e, from

fro

m

LOOP,

LOOPER

(No.

1139899

to

front

(AA)

under

through

of

looper

of

thread.

point

OTHERWISE

(Blue

2)

and

A

passing

fon>ard

from

thread

eyelet

front

of

tt<eezers.

7

Color

feed

in

reverse

between

to

left

guide

on

(AE)

fro

Holding

to

back,

~lACHI

Code)

same

fro

m

manner;

tension

the

to

cast-off

right

passin

1<ires (AC),

shank

m

right

of

to

tweezers

using

DO

NE

NOT

WILL

about

THREAD

right

thread

through

looper

left,

in

left

NOT

to

left

through

discs

around

support

g

under

pigtail

(AE).

pushing

hand,

3/16

inch

LOOPER

SEI~.

through

plate

cast

Insert

insert

IHTH

-

Page 13

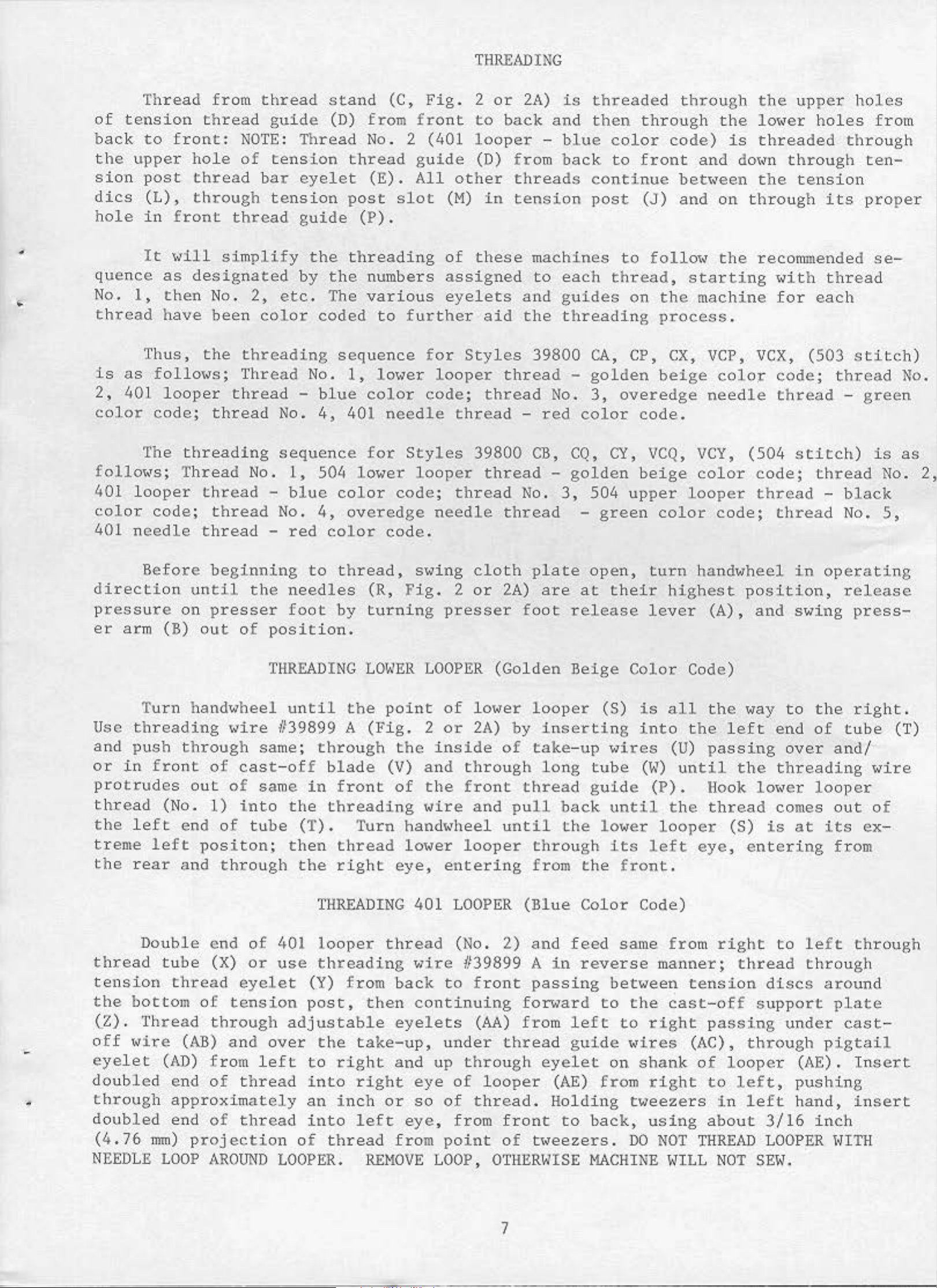

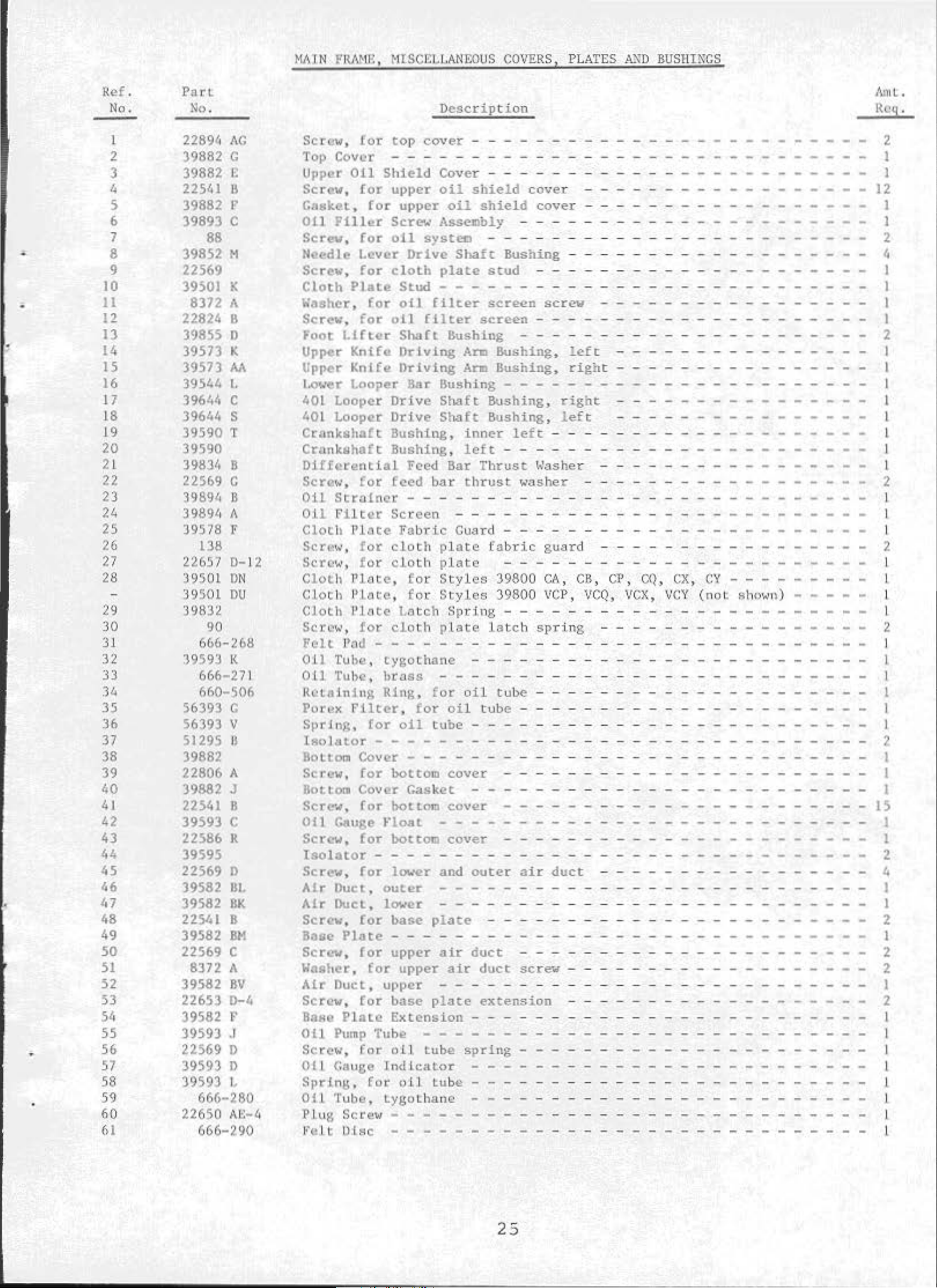

f1A1

N FIWIIJ,

~1lSCELt.ANEO

U S

COVER

S,

PLATES

A~D

BUSlllNCS

Ref .

No.

l

2

3

4

s

6

7

8

9

10

II

12

13

14

IS

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

~2

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

110

61

Part

No

.

22894

AG

39882 c

39882 c

22541

Jl

39882 r

39893 c

88

39852 H

22569

39501

K

8372 A

22824 8

39855 0

39573 K

39573 A.\

395'4

1,

39644 c

39644 s

39590 T

39590

3983'•

B

22569 c

39891,

39891, A

B

39578 F

138

22657

D-

12

39501 ON

39501

ou

39832

90

666-268

39593 K

666-271

660-506

56393 G

56393 v

51295 ll

39882

22806 A

39882

22541

39593

J

8

c

22586 R

39595

22569

39582

39582

225lo

39582

0

BL

BK

I B

811

22569 c

8372 A

39582

BV

22653 D-4

39582

F

39593 J

22569 D

39593 D

39593

I,

666-280

22650

""-4

666-290

Description

Screw,

Top

Upper

Screw,

Casket,

011

Screw,

Needle Lever

Scre:w,

Cloth

Washer,

Screw,

Foot

Upper

Upper

Lower

401

401

Crankshaft

Crankshaft

Differential

Scre~~o•,

011

Oil

Cloth

Sere

Scrc:::w, for

Cloth

Cloth

Cloth

Sere

Felt

OJ.l

011

Rctalnillg

Porex

SprJn~,

lBolutor

BoLtom

Screw,

BoLtoo Cover Gasket - -

Screw,

0!1

Screw,

Isolator

Screw,

Air

Alr

Screw,

Bose

Scr~~,

Washer,

Air

Screw,

BaHc

011

Scr:cw,

OLI

Sprlng,

OU

Plug

Jo'

c I t 0

for

top

cover

- - - - - - - - - - - - - - - - - - - - - - - 2

Cover - - - - - - - - - - - - - - - - I

Oil

Shield

!or

upper

for

upper

Filler

Plate

Llfter

Kntfe

KnHe

l.ooper

Looper

for

for

for

for

Sere.•

oil

cloth

Stud

oll

oil

Shaft

Driving

Driving

Drive

Looper Drive

Bushing,

Bushing,

for:

feed

Strainer

filter

l'lote

....

•,

Plate,

l

'lote,

Plate

....

•,

Pod - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Tube,

Tube:,

filter,

Screen

Fabric

for

cloth plate

clot

La

for

cloth plate

cygothanc

brass

Ring,

for

oil

- - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Cover - - - - - -

for

bottom

for

botLom

Cover - - - - - - - - - - - - - - - - I

oil

shield

oil

shield

Assembly

system

Drive

plate

- - - - - - - - - - - - - - - - - - - - - I

filter

filter

- - - - - - - - - - - - - - - - - - - - 2

Shaft

stud

screen

scr~cn

cover

cover

- - - - - - - - - - - - - - - - - - - - - - I

- - - - - - - - - - - -

- - - - - - - - - - J

---

Bushing - - - - - - - - - - - - - - - 4

- - - - - - - - - - - - - - - - - - - I

screw

- - - - - - - - - - - - - - - - -

- - - - - - - - - - - - -

Bushing - - - - - - - - - - - - - - - - - - - -

Arm

Bar

Feed

b.ar

Am

Bushing

Shaft

Shaft

B.ar

Bushing,

Bushing,

inner

left

Thrust

thrust

Bushing,

Bushing,

- - - - - - - - - - - - - - - - - - - - - - -

left

- - - - - - - - - - - - - - - - -

-...•asher

left

right

right

left

- - - - - - - - - - - - - -

t,'asher - - - - - - - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - - - - - - - - -

- - - - - - - - - - - -

- - - - - - - - -

- - - - - - - -

Guard

h

plate

fo

r

Styles

fo

r

Styles

tch

Spr

- - - - - - - - - - - - - - - - - - - - - - - - - - -

for

oil

for

oi

l tube - - - - - - - - - - - - - - - - - -

tube

cover

cover

- - - - -

fabric

- - - - - - - - - - - - - - -

39800 CA,

39800 VCP,

ing

- - - - - - - - - - - - - - - - - - - - -

latch

- - - - - - - - - - - - - - - - - - - - -

tube

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - -

gu.ard - - - - - - - - - -

CJ\

, Cl' ,

VCQ,

spring

- - - - - - - - - - - - - - - - - - - - -

CQ, CX,

\fCX, V

- - - - - - - - - - - - - - -

CY

CY

(not

-------

shown} - - - - -

- - - -

Gauge FloaL - - - - - - - - - - - - - -

for

bottom

- - - - - - - - - - - - - - - - - - -

for

lower and

l)uct,

DueL, lower - -

Plote

Duct,

Plate

Pump

C8uge

Tube,

Screw-

outer

for

base

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

for

upper

for

upper

upper

(or

base

Extension

Tube - - - - - - - - - - - - - - - - - - - - - - - - - - - -

for

oll

Indicator

Cor oil. tube - - - - - - - - - - -

Lygolhili

- - - - - - - - - - - - - - - - - - - -

1sc

- - - - - - - - - - - - - - - - - - - - - - - - - -

cover

---

plate

air

air

-----

plate

tube

)C

- - - - - - - - - -

outer

--

duct

duct

extension

air

duct

----------------

-

--

- - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - -

screw

- - - - - - - - - - - - - - - - - - -

------------

- - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - -

------

-

- - - - - - - - - - - - - - - - - - - - - - -

spring

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - -

--

- - - - - - - - - -

--

- - - - - - -

--

---

Amt.

Roq.

- 12

I

I

2

I

I

I

I

1

l

I

l

2

I

l

I

2

I

L

l

I

2

I

I

I

I

I

I

2

I

I

I

1$

I

I

2

4

I

I

2

I

2

2

I

2

I

I

l

I

I

l

l

I

25

Page 14

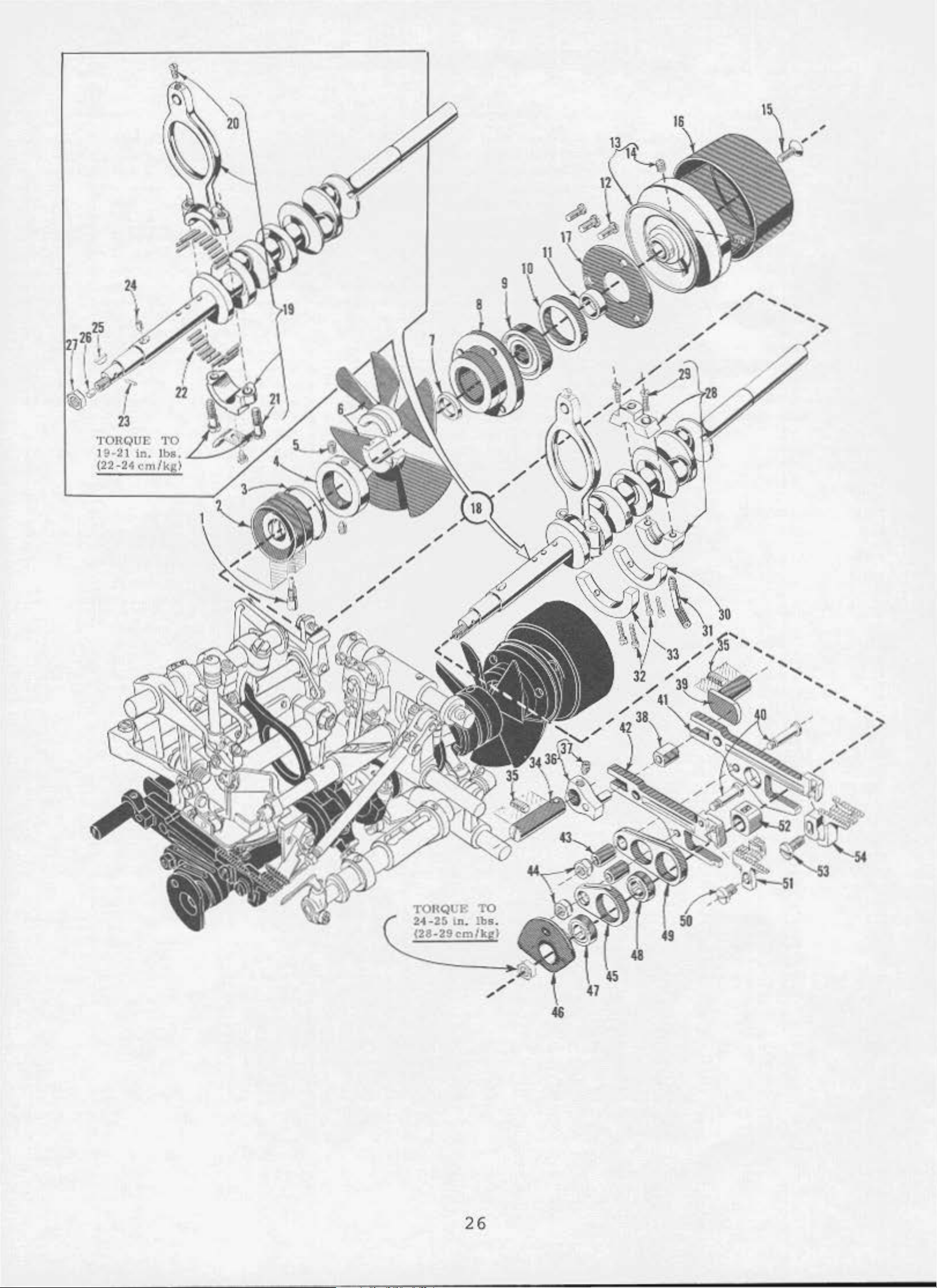

TORQUE

19

· 21

(22-2<cm/kg)

in.

'1'0

1

bs.

L--"

"'

/

/

"'

/

/

"'

/

/

'I'OJIQJ.;P.

2•-2s l

(28-29c:mlkg)

n.

'1'0

lbs

26

.

Page 15

Ref.

No

CRANKSHAFT

Par

t

No

.

.

AND

FEED HECHAN!

Description

SN

Aro

t .

Rcq.

1

2

3

4

5

6

7

8

9

1.

0

11

12

13

14

15

16

17

18

39690 A

39890 c

660-443

39

591

11

2289/o

D

39591 L

39590 .J

39590 G

660-268

39590

R

39590 s

22569 B

395

21

c

95

22769

ll

39821

39590 H

29477

~IF

29477 HB

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

39852

22587

A

77

}{

39516-625

39

516-626

39516-

39541

C067

627

30-106

51-

228

A

E

258

39890 E

97

A

39691

39593

227io7 8

39591

J

K

39835 B

22

894 J

39835 c

22894 u

39535

3

983

J

5 A

39536 B

3953/o C

39534

39536

c

39536 e

39536

AF

39868 R

39540

B-10

Blk.

Blk.

39540 ll- 8

48

49

•

50

39540 8-

39540

39536

93

ll-8

AE

A

10

51

52

53

5(•

39838

93

Stu

d, f

or

crankshaft

Crankshaf t

11

"0

Ring, for

Crank Chamber

Spot Sere"'

Crank.

Thrust

C

ranksha

Crankshaf

Ball

S

pace

Screw,

Pulley

Ser

Pulley Cap - - - - - - - - - - - - - - - - - - - - - - - - - - - - l

Crankshaf

Cranksh

Chamber

Bearing

r

Sere~,

e•

...

•,

39800

Crankshaft

Styles

Need

Needle

Need

Needle Be

Hood

Ven

Feed Dri

Cork

~ut

Split

Bearing

ScL"'et..'

Bearing,

cran k

Cooling Fan

',

for

crank

Cooling

H

ash~r

f t

t Jla

Collar

for

- - - - - - - - - - - - - - - - - - - - - - 1

for

t

aft

CA and

except

le

Screw - - - - - - - - Scre

le

Plug

t Plug - - - - - - - - - - - - - - - - - - - - - -

Pl ug - - - - - - - - - - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - -

,

- - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

llall Bearing

ll Bearing

Stop

- - - - - - - - - - - - - - - - - - - - - - - - - - 1

bal.l bea

f

or pulley

pulley

Ba

ll

Bea

and

Needle

CB

and Needl e

39800

Or'lvi

w - - - - - - - - - - - - - - - - - - - 2

Bearing

l\ e

aring,

aring

,

birch

vit

)g

and

for spl i t

Cr.ankshaft Counter

Oil

Pump

Screw, f

Crankshaft

ed Adj

Fe

Screw,

Feed

Feed

Feed

Feed Bar

Differenti

Hain

Feed

Nu

t ,

~lain J.o~eed

401

Looper

Naio

Hain

all

Differential

all

if

ferential Peed

D

a

ll

Differential Fee

Scret..•,

Ha

i n

Pee

d Lift B

Sere•

...

Differential

Tub

e - - - - - - - - - - - - - - - - - - - - - - - -

or cran

usti

for

Leveling

Screv

llor

Bar Gui

Fee

llar

for

Feed D

Fee

Styles - - - - - - - - - - - - - - - - - - -

Style

Styles

Peed Dog (Sec

•,

,,

Guide Block

Driv

~l

d Bar - - - - - - - - - - - - - - - - - - - - - -

[)ri vi ng St ud B

fee

Bar

d Driving

s - - - - - - - - - - - - - - - - - - - - - - -

for

for dif fer

kshaft

Counterweight

ng Pi n - - - - - - - - - - - - - - - - - - - - - -

fee

d adjust

Le

ver

for

fee

de,

ri ght - - - - - - - - - - - - - - - - - - - -

ing Stud - - - - - - - - - - - - - - - - - - - - - -

Feed Bar - - - - - - - - - - - - - - - - - -

d bar d

Drivi

Thr

ead Take-up - - - - - - - - - - - - - - - - - -

riving

feed

- - - - - - - - - - - - - - - - - - - - - - -

d Sa

main

loc

feed

k - - - - - - - - - - - - - - - - - - - - -

Feed

bea

ring

inner

shaft bear

chamber

Fan

Housing

Collar

ring

cap

ring Rctai

r~tainin

nriving

- - - - - - - - - - - - - - - - - - - 1

ri gh t - - - - - - - - - - - - - - - - - - - 1

ing,

Collar

inner

- - - - - - - - - - - - - - - - - 1

cooling

right

fan

- - - - - - - - - - - - 1

collar

- - - - - - - 2

- - - - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - - - I

g

pl ate and

- - - - - - - - - - - - - - - - - - - - 2

- - - - - - - - - - - - - - - - - - - - 1

ni•>t Plat

COt)l)eCting

e - - - - - - - 1

housing

Rod

Assembly) f

- - - - - - - - - 3

or Styl

es

- - - - - - - - - - - - - - - - l

Driving

CA

and

ng

Connect

, . 0625

. 06

26

,

.0

627

Eccentric

Oil

Pump - - - - - - - - - - - - - - - - - - - -

bearing

weight,

counterw

,

ing

- - - - - - - - - - - - - - - - - - - - -

d l

eveling

- - - - - - - - - - - - - - - - - - - - -

ushing

riving

ng

Connection

Ecc

entr

ic, for

Ecc

entr

i c , f

Dr

i vi ng Eccent

Driving

r.

l)ri

ving

dog - - - - - - - - - - - - - - - - - - - - -

Pages

ctltial feed

l)

og (See

43

CB

ing

inch

inch

inch

Connect

Rod

(I.

(

(1. 593

i ng

- - -

As~ero

588

I.

590 mm)

Rod

bly

mm)

mm)

Ass

d

iameter

di

ameter

di

ameter

emb

l y, for a

ll

- - - - - - - - -

- - - - -

- - - - - - -

- - - - - - - - - - - - - - - - - - - - 1

Key - - - - - - - - - - - - - - -

and

oil

pump - - - - - - - - - - - -

right

left

pin &l)d fee

stud - - - - - - - - - -

Eccentric,

and

Pages

- - - - - - - - - - - - -

eight

- - - - - - - - - - - - - -

lever

- - - - - - - - - - - - - - - -

or

ric, for

CO

I)n

- - - - - - - - - - - - -

d bar

- - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - -

No

. 5 1/8

No

. 8

for No

ection.

gui

de,

ri

ght - - - - - - -

gauge,

3/16

or

No

. 5 1

. 8 3/16

- - - - - - - - - - - - - - -

al.l

Styles

12 3/1 6

/8 gauge,

or

gauge,

12 3/16

gauge,

45) - - - - - - - - - - -

dog

43

and

45)

- - -

28

28

28

l

1

1

I

1

I

l

1

2

1

l

4

1

1

2

I

I

1

1

2

I

I

2

2

1

I

I

l

I

1

I

1

I

I

1

1

27

Page 16

10

30

3

36

1

28

Page 17

NEEDLE

DR

IVE

HECHANISM

AND

TAKE-UP

S

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Part

No

.

39852 J

22733

CL21

2289l, c

228%

39852

1~0-3

L

c

660- 220

660- 416

39852

22852

lo0

c

- 139

39863 c

39852 E

39573

A

660-442

39852

D

22852 c

40

- 139

51236 A

H0

- 3

39843 D

22652 B-

10

22588 A

39863 D

39863 J

39863

22752 B

22564 D

39852 F- 5

39852

39852

F-8

F-

12

22784 L

39852 N

28

c

39852 K- 5

39852

K-8

39852 K-12

22738 B

605

120

GS

D

escription

N

eedle

Pipe

Se t Sere•,, - - - - - - - - - - - - - - - - - Spot

Needle

"0"

Retaining

Needle

LO\•.'er

Need

Thrust

Ret

aining

dl

Nee

Link

dle

Nee

Sere",

503

4

01

Lo,;er

Sere"''

Needle

Styles

Nee

dle

Styles

Nee

dle

Styles

Needle,

gauge

Guide

Sere",

Clean

Sere"

Lever

Wool

Ring, for

Lever

Sere''',

\~asher,

Looper

le

Lever

W

asher

e

Driv

Sere,<,

Hasher,

Pin,

Wool

Lever D

Scre\·7, for

for

Needle

Needle Thread

Looper

Screw, for

£or

Head,

Head,

Head,

ScreH, for

Needle Head Eyelet,

ScreH, for

Needle

Needle

Nee

dle

Ser

e,,•

Scre~J,

for

on

Bar

for

er

(oi

- - - - - - - - - - - - - - - - - - - Roller

Yarn

Ring

- - - - - - - - - - - - - - - 1

for needle

for

Thread

Drive

Ri

ng,

e

Lever

for

f.

for

Yarn

needl

Thread

Threa

take-up

ma

marke

marke

Head

Head

Head

for

fo

all

Sty

les

- - - - - -

needle

l

"ick)

Pi

- - - - - - - - - - - - -

needle

, f

or

needle

needle

Take

Sha

- - - - - - - - - - - - - - - - - - 2

for

needle

or

needle

- - - - - - - - - - - - - - - -

rive

t h

e

take-up

r ked

top

needles

needle

- - - - - - - - - - - - - - - - 1

needle

Sha

rust

thread

Cam

Cam

d

Take

lever

"AV

d "BN" ,

d

"AH

needle

Eyelet,

Eyelet,

Eyelet,

39852

r No.

5

39852

1/8

39800

gui

de

bar

- - - - - - - - - - - - -

n - - - - - - - - - - - - - - -

guide bar

lever

lever

lever

- up

ft

- - - - - - - - - - - - - 1

drive

drive

drive

ft

Thrust

cla

cam pul

Pull-off

Pull-off

- up

lever

·

h~ire

" ,

" , f

top

fo

for No

for No.

F-5

or

- - - - - - - - - 1

Wire

lever

lever

l ev

mp

col

Lever

for No

for

or

head

r No. 39852 F- 5

39852

F-12

, 8

CA

3/16

and

- - - - - - -

as

- - - - - - - - - - 1

roller

- - - - - - - - - - 1

- - - - - - - 2

drive

- - - - - - - - 1

lever

er

- - - - - - - - - 1

Clamp

la

r - - - - - - - - - 1

l -

off

- - - - - - - - 1

- - - - - - - - - - 1

- - - - 4

. 5

No

. 8

No.

eyelet

. 39852

1/S

3/

12

- - -

- - - - - - -

39852

F-

8 - - - - - - - -

pi n - - - - - 2

shaft

Collar

- - - - - - 1

- - - - - - - - - 1

- - - - - - - 1

gauge,

16

gauge,

3/16

- - - - - - - -

F-8

F-12

- - - - - 1

- - - 1

as

- 1

all

all

gauge,

- - - -

all

- - -

- - - - - - - - - -

gauge

CB

machi

- - - - - - · - - - - -

nes;

12

3/16

required

r e

Amt

Req.

1

1

1

1

1

1

quire

1

1

1

1

1

2

1

1

1

1

1

2

.

d

120

37

•

38

39594 N

87

GAS

u

Need

le

39800

Oil

Sere"',

Spl

,

for

CA

asher

for

all

and

oil

12

CB

- - - - - splasher

29

3/16

- - - - - - - - - - - - - - - - -

gauge

machines

except

Styles

2

1

l

Page 18

'J

01\QUJ.;

1

9-2

1

{22-24

ln.

<"

m

'J'O

Jb

s.

/)tg)

16

30

Page 19

LOWER LOOPER

DRIVING

HECHANISM

Ref.

No

.

1

2

3

4

5

•

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

Part

No.

39808 D

39151

52344

77

660-206

22

894

AE

482 c

22894 c

39894 c

12982

22894

J

538

39644 X

39644 R-2

39644 R- 5

666-

255

39644 F

22729 0

22729 E

77

39844

39

844 B

39544 D

39544 B

Description

Lower

Nut,

Looper,

for

lower

marked

looper

"ACZ"

bar

- - - - - - - - - - 1

- - - - - - - - - - 1

Lower Looper Bar - - - - - - - - - - - - - - - - - - - 1

Screw,

"

O"

S

cre

Lower Looper

Oil

N

ut,

Screw,

Screw,

Ball

Shim,

thick

Shim,

thick

Felt

Lower Looper

Screw,

Low

er

Lo

~<

er

Low

er

Lower

for

Ring,

w,

for

Sere•~,

Pu

mp

for

for

for

Joint

for

connecting

for

lowe-r

lowe-r

Shaft

f.

or

col

Oiler

oil

oil

- - - - - - - - - - - - - - - - - - - - - - 1

)>Ump

pump

ball

Guide

ball

joint

link

looper

looper

Collar

pin

bar

bar dr

drivin

iving

- - - - - - - - 1

g

lever

lever

shaft

- - - - - - - - - - - - - - 1

l ar - - - - - - - - - - - - - - 2

oiler

oiler

joint

Fork

screw - - - - - - - - - - 1

- - - - - - - - - - - - 1

gui

de

fo

rk

- - - - - - - - - 2

- - - - - - - - - - - - 1

guide

fork

, . 002

inch

- - - - - - - - - - - - - - - - - - - - - -

for

ball

joint

guide

fork,

. 005

inch

- - - - - - - - - - - - - - - - - - - - - -

Plug,

Screw,

Screw,

for

Loo

Looper

Looper

T

,ooper

for

lower

Drive

fo-r

for

co

co

connecting

per

Bar

Bar.

Ba-r

Bar Connecting Link - - - - - - - - - - - - - 1

looper drive

Lever

nnectin

nnecting

Drivit~

D-riving

Connec

g

rod

rod

link

pin

Lever - - - - - - - - - - 1

Lever

Connecting

lever

ting

Rod

connecting

- - - - - - - 1

- - - - - - - - - - - - - - 2

- - - - - - - - - - 2

- - - - - - - - - - 1

Shaf t - - - - - - - - - 1

Link

Pin

- - - - - - - - - 2

shaft

( .

051

( .

127

- - - - 1

- - - 2

mm)

as

required

mm)

as

required

rod 1

Amt.

Req

.

•

31

Page 20

8

<

/

.....

17

18

4\

'I

-®·

/

/

--

'

'

'

'

'

T

ORQ

19·Z

(22

(4)

UE

1 i

n. lb$.

-2~

em/kg)

SCI'f!WS

TO

32

Page 21

UP

PER KNIFE

liND

<\01

LOOPER DRIV

ING

~!ECHANIS M

Ref.

~o.

I

2

3

4

Part

No

.

9937

39871

39870

22738

5 39572

6 39571 c

7

8

9

10

I 1

I 2

13

14

15

16

I 7

39873 B

39873

39573 A

39573 E

55235

6042 A

55235

39673

22587

22565

39644

39644 v

18

19

20

21

22

23

2l

25

26

27

28

29

30

o

22729

39644

98

482 c

22894 c

39644

395lo3 P

3951 o3 M

22562 A

396<\1

22729 £

22729 D

3961.4

39641, R-5

31

32

33

34

35

36

37

39644 X

538

66o-206

2289/o

3961.4

39644 A

3984/o A

38 22652

39

40

41

42

43

44

2289to

39808

22503

39543 E

39644

39644 L

45 39571

46

47

48

49

39536

22781

41336

39844

50 39844 D

*51 22775

*52 39644

A

0

E

E

c

K

tl

p

, u

R- 2

AF.

N

A-

AF

f

l'

B

E

c

c

M

6

Am

Nut,

Upper

Upper

Screw,

Upper

Upper

Upp

Up

Up

Upper

for

upper

Knife

Knife

for

Knife

Knife

er

Kn

ife

per

Kn

He

per Knife

Kn

ife

L

ocking

Clamp - - - - - - - - - - - - - - - - - - - - - - I

- - - - - - - - - - - - - - - - - - - - - - - - - I

upper

Holder

Clamp

Driving

Drlvl.ng Arm - - - - - - - - - - - - - - - - - - - 1

DrJ.vlng

Dr l

Washer,

Nut,

Upper

Knife

Screw,

Set

Screw,

Bushing

Bushing

Screw,

Thrust

Sere'-',

Looper

Screw,

Lo

oper

Lo

oper Bar

Cla

mp Col

Scrc

Loop

er Drive

Sere"'',

Scre

Shlm,

thick

Shim,

thick

Ball

for

for

Joint

Screw,

"0"

Ring,

Screw,

Looper

Looper

Looper H

Screw,

Scre

Looper , marked

Scr

ew. f

Cam Follower

Looper n

for

Driving

for

for

and

C!lll

and

Cam

for

Collar

for

Drive

Drive

Lever

for

Lever - - - - - - - - - - - - - - - - - l

Th

lar

to.

•,

for

Lever A

for

to.•

,

ror

ball