Page 1

CHAKGlNG

NEEDLES

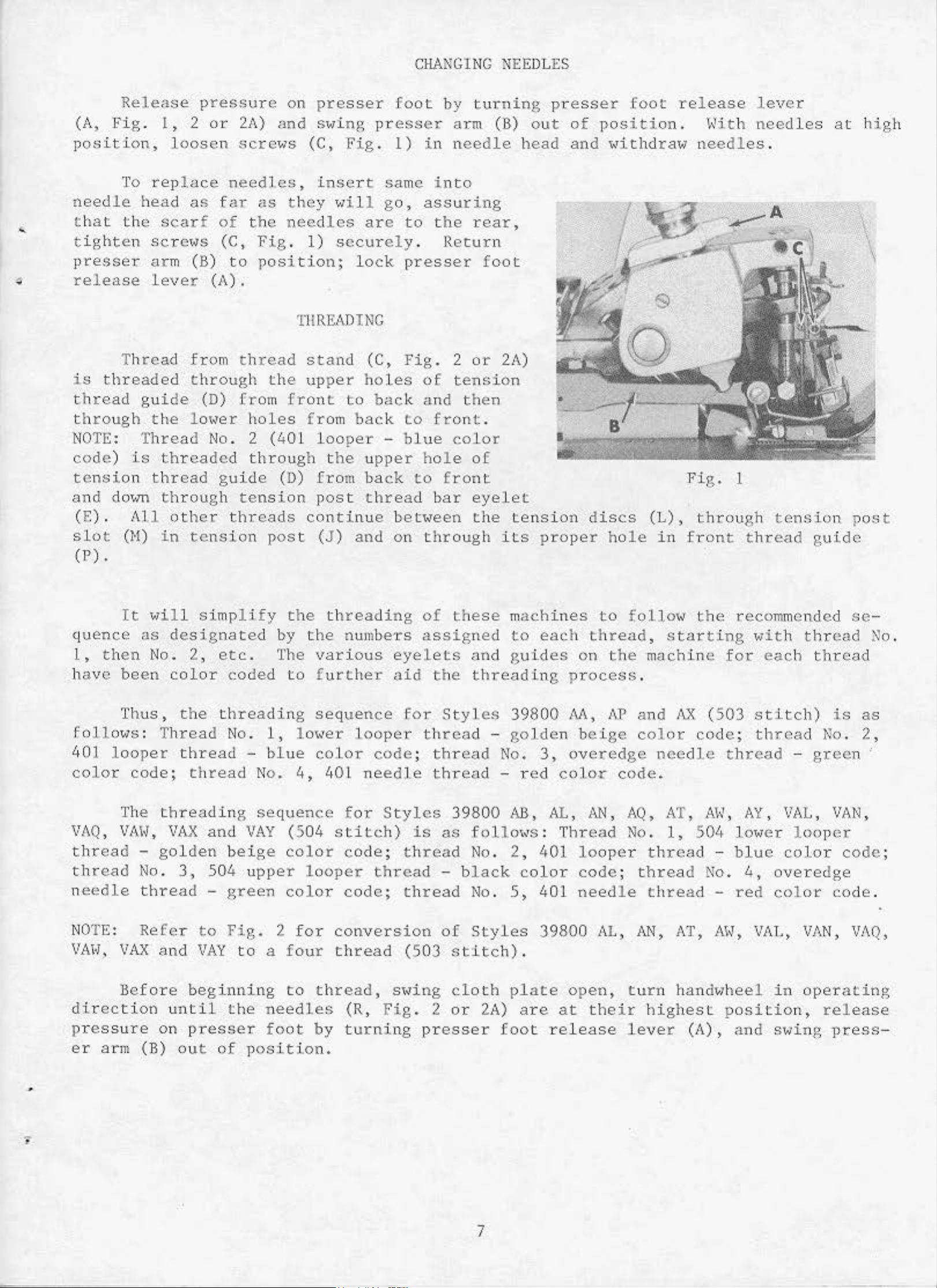

Rele<•se p

(A,

Fig

position,

To

needle

t

hat

t

ight

head

the

en

presser

relea

is

thread

se

T

hread

threaded

guide

through

NOTE: T

code)

is

.

l,

2 o·r 2A)

loosen

rep

la

as

scar

sc

r ews

arm (B)

lever

from

through

the

lo,.er

hread

threaded

ress

ce nee

ure

scre•

dles,

on

and

,;s

presser

S>~ing

(C,

insert

far as they <Ji l l

f

of

the

(C,

to

(A).

needles

Fig

. 1)

position;

THREADING

t h

(D)

No. 2

read

the

from

holes

(40! looper

stand

upper

front

fr

om

through the upper

Fig.

are

secur

lock

(C, Fig.

holes

to

back

foot

press

l)

by

er

in

same into

go,

el

assuring

to

the

y .

Return

presser

of

bac

k and

to

front

-

blue

hole

turnin

arm (B)

needle

head

rear,

foot

2

or 2A)

ten~;ion

then

.

color

of

g

presser

out

•

I

of

and

foot

pos

iti

'~ithdraw

release

on.

\~j

needles

th

lever

needles

.

at

high

t

ensi

and

(E)

slo

(P) .

do

.

t (H)

quence

l,

then

have

Thus,

fo

llows

40

1

looper

color

The

VAQ,

VAH,

thread

thread

ne

edl

e

on

thread

<m

All

It

<Jill

as

No.

been

: T

code;

-

No

thread

guide (D)

through

other

in

tension

s i

tension

threads

mp

lify

designated

2,

etc.

color

the

hread

thread

thread

threading

VAX

coded

threading

No

. 1,

No. 4,

sequence

and

VAY

golden beige

. 3, 5

04

-

green

u

pper

from

post

conti

post

(J )

the

by

the

The

various

to further

sequence

1

0\~er

blue

color

40

(504

color

l oope~;

colo

r

back

thread

nue bet,.een

and

on

threading

numbe-rs

eyelets

aid

looper

code

l n

eedle

for

St

stitch)

code; t h

thr

code;

to front

bar

through

of

these mac

assigned

the

fo r

Styles

thread

;

thread

thread

yles

is

3

as

read

ea

d -

thread

eyelet

the

tension

its

to

and guides

threading

39800

-

golde

No. 3,

-

re

d coJ.o

9800

follo

No

black

No. 5,

AB,

«s: Thread

. 2,

401

color

401

discs

proper

hines

each

hole

to foll

thread, star

on

the

process

M,

n

AP

beige col

overedge

<:

cod

AL, AN, AQ,

No.

looper thread

code

need

;

le

Fig.

.

(L),

in

front

o"

through

the

t i

ng wit

machine for

.

and

AX

(503

or

code; thread

needle thr

e.

AT,

1,

A\~

50

'•

-

threa

thread

d No.

-

l

tension

thre

recommend

eac

ad

h

thread

h

guide

ed

thread

stitch)

No

ead

,

AY, VAL, VAN,

low

blue

4,

red

-

green'

er

looper

colo

overedge

color

r

post

se

is

. 2 ,

code

code

No.

as

;

.

NOTE:

VAH. VAX

direction

pr

essure

er a·rm

•

Refer

and

Before

until

on

(B)

to

Fig

VAY

to a

beginning

the

presser

<>u

t of p

. 2 fo r

four

to

needles

foot

osition

conversion

t h

read

thread,

(R, Fi

by

turning

.

of

Styles

(503

s'~ing

g.

2

pr

stitch)

cloth

or

esser

39800 AL,

.

2A)

plate

ar e

open,

at their

foot release

AN,

turn

highes

lever

AT,

hand~1hee

AI~,

t

(A),

VAT.,

l

in

position,

and

s"1ing

VAN, VAQ,

opera

ti

rele

pJ;ess

ng

ase

-

7

Page 2

SETTING

401 STITCH

REAR NEEDLE GUARD

(Continued)

lfuen

(E,

.102

to

pinch

but

not

needle

direction,

check

pinched.

be

and

Thread

feed

er

action

401

Fig.

mm)

5 . 56

thread

With

not

pinch

guard.

"hether

For

threaded

as

described

401

dog,

and

reset

toith

looper

9)

so

clearance.

mm)

deflect

convenience,

belo"

needle

thread

making

Lock

as

Looper".

throat

thread.

point

it

in

needle

at

needle,

in

Turn

needle

'''ith

sho\m

under

plate,

upper

is

at

the

touches

This

throat

SETTING

bottom

needle

handv7heel

complete

is

sere"

the

in (Fig.

Replace differential

knife.

but

guard

plate

eye.

position,

. 000

eye.

revolutions

disturbed

(H).

looper

parapraph

lower

Check

center

does

setting

seat.

Then

401 STITCH

to

. 004

Check

in

operating

may

2 or

"To

knife

cutting

not

lock

set

or

noto

2A

hold-

of

the

deflect

••i

ll

Hith

the

FRONT NEEDLE GUARD

front

inch

for

)

(.

clearance

to

needle

needle,

be

approximately

needle

guard

40

000

in

in

1

needle

to

place

. 102

bet"een

scarf,

.000

down

guard

mm)

set

position,

toith

40

to

.0

3/16

set

(G,

clearance.

401

looper

1

rear

04

to

screto

Fig.

needle guar

inch

7/32

guard

9)

Guard

and

(.000

inch

should

(F).

to

front

d

to

(4

. 76

not

touch

should

40

1

Asse

dogs

adjusting

should

locks

travel.

the

(A,

Feed

the

throat

SETTING

mble main

B,

Fig.

dogs

be

Main

pin

level

feed

should

(C).

and

plate.

THE

and

15).

be

This

at

the

tilting

differential

FEED

differential

time tee

ad

DOGS

level

pin

just

t<ith

raises

i ng

feed

p

(A,

sleeve

(C),

holder

feed

the

th

first

pin

dog

Replace

lacillg

Fig.

a

throat

or

lov1ers

appear

in

place.

teeth

the

16)

(B)

free

assembly

seats

plate

the

should

SETTING

the

lotoer

lateral

so

lo"er

that

is

surface

back

above the

Noto

against

set

klli

fe

"h

m

otion

obtained

end

feed

be

set

TilE

knife

holder

en

throat

of

throat

3/64

LO\mR

holder

the

of

vlhen

Fig.

by

rotating

feed

plate.

dogs

assembly,

face

the

at

in

ch

KNIFE

assembly

of

plate

loV~er

the

15

feed

bar.

highest

(

the

mounting

kllife

Feed

Sere•<

1.19

tightell

flallge

knife

is

tilting

point

mm)

.

In

brack

and

manually

dogs

(D)

above

re

-

screto

on

of

et

pressed

set

Adjustments

"hich

pressed

m

tightening

port

pin

be

ed

·

Fig.

16

~·--·

with

ent

Low

for

locked

against

is

brac

at

its

cutting

holds

against

necessary

e~:

knife

scr.e«

ket.

the

Vlith

lo,.er

are

the

cloth

16

upper

edge

made

lo"er

t

he

may

(F)

Because

nut

knife

corner

'•ith

upper

t<hen

be

and

plate

(G)

flush

hexagollal

knife.

knife,

the

secured

locking

scre"'

latch

even

holder.

. Lo<•er

Vlith

Lotoer

"'idth

in

(F)

spring

when

knife

top

so

of

any

nut

also

scre

of

head

knife

no

lateral

trim

position

(G)

serves

,

it

w

is

(D)

throat

scr.e

is

is

changed

against

should

not

should

p

late

t<

(E)

spr

ing

adjust-

.

by

sup-

as latch

altoays

tighten

be

.

-

Page 3

SETTING

THE

UPPER

KNIFE

Replace

setting

most

knife

cutting

not

cutting

guard

upper

cutting

;

proper

should

holding

1

simplify

replaced.

less

nut

clockwise

.

At

edge

edge

(L)

knife

edge.

After

<'Jidth

be

bl

the

(J)

the

than

should

and

upper knife

tightened

ock

resetting

upper

to

position

bottom

of

upper

1/64

of

lo~1er

slightly

of

trim,

(F)

knife

hold

of

knife

inch

knife

be

set

sc;rev7 (

to

in place

~>hen

clamp

against

its

( .

40

do<m

back

has

lock

been

.

upper

assembly

(K)

upper

stroke,

should

nun)

. The

against

from

set

E,

Fig

upper

This

knife

SE

.

in

its

front

extend

bel.Oiif

chain

the

the

for

. 1

5)

kni

fe

•<ill

is

TTING

Clamp

THE

STI

upper

TCH

knife

LENGTH

(H,

Fig.

16)

Fig.

in

position,

17

'·

feed

The

eccentrics

stitch

length

used

is

deter.mined

and the

other

The

main

adjusting

d

.ic

stitch

the

fore,

control

lengthens

feed

set,

feed

The

T

he

ator

shortest

moving

After

,

and

turn

by

two

the

length),

setting

dif

ferential

.

hand

the

uppermost

plate

do•m

the

selecting

the

the

factors

of

operated

differential

letter

indicates

,,,bile

feed

the

shortens

stitch.

main

differential

travel

indicator

and

in

combination;

the

feed

the

the

the

differential

control

knurled

stitch

"L"

the

lo(o]e

(shortest

pointer

stitch

pro

differential

knob

knob

marked

longest

rmost

lengt

per ecc

until

is

independent

marked

length.

on

feed

letter

stitch

of

the

h a

entrics

feed

the

one

feed contro

the

is

the

"D

IFF" is

stitch

trave

length).There-

differential

nd

dogs

desired

l

"S"

for

indicates

upward

the

have

main

l.

of

in

(long

main

been

seam

the

for

-

est

leng

Sty

l e

trol;

limit

bling

the

Turn

th

des

39800

a

stop

the

The out

feed

sh

aft

Fig

.

18

the

ire

travel

or

stitch

d

and

AT

is

screw

er

(left

eccentrics,

key.

SETTING

regu

tighten

al

so

is

of

differentia

)

is

length

t

hat

and

THE

lating

lockscrew

equipped

provid

eccentrics

be

ed

sure

obtained.

check

there

the main

the

is

aod

DIFFERENTIAL

sere•~

«ith

in

the

l

feed

REHOVINC

(A ,

hubs

(B)

a

Fig

are

(A,

to

knee

stitch

dog

THE

.

facing

As a

clearance

Fig

to

precaution,

travel

differential

FEED

.

17)

lock

press

indicator

avoid

CONTROL

as

differential

intermittent

striking

ECCENTRICS

18

)

actuate

each

after

of

both

bet1~een

required

plat

main

other.

feed

the

feed

e

'"hich

ends

(rear)

Be

feed

setting

dogs

throat

dogs.

to

obtain

cont

dif

ferential

can

of

feed

careful

to

plate

rol

be

throat

dog. In

not

the

make

stitch

in

feed

ad

just

plate

to

stitch

sure

slots

place.

con

ed

slots

assem-

damage

-

to

.

17

Page 4

To

end

plate

support

401

looper

guide

looper

tion

tor

be

until

supplied

necessary

I€

take-up

(G)

and

change

(D);

plate

at

(H)

~olith

thread

key

eccentrics

(D,

Fig.

feed

feed

remove

(F)

accessible

extreme

cast-off

take

-up

slot

<dth

to

machine,

move

18)

driving

REMOVING

eccentrics,

screws

right,

support

(D)

in

ecc<mtric

hand wheel

are

unusually

from

connection

THE ECCENTRICS

(E)

with

permitting

fr

om

end

reach

bac.k

shaft

remove scre<,•s

and

scre1o1

chip

securing

chute

removal of

plate

is

behind

(F)

of

shaft

to.,ard

assembled.

the

eccentrics

and forth

tight

(E),

(H). T

it

fitting

may

hen

be

continue

(Continued)

(C,

Fig.

the

(G)

open;

the

Remove

(E).

Turn

front.

Using

and

slil~htly

,

in

addition

helpful

as

17)

extre

securing

me

turning

left

main

nut

hand"heel

hooked

withdra"

during

e

to

to

remove

originally

cast

right

end

handwheel

feed

(C,

in

thrust

Fig

operating

eccentric

eccentrics

xtrac

ti

on.

removing

nut

(F),

suggested.

-o

ff

of

to

.

18)

.

nut

ferrule

support

cas(

-o

ff

position

bar

and

direcextracIt

may

(C)

and

NOTE:

Thread

(B)

and

right

Control

clamp

as

required.

Before

Adjustments"

Fig.

screw

tightening

19

(C)

and

Retighten

nut (C,

.

then

collar

B

shift

scre«s

Fig.

the

18)

refer

SETTING

Assemble

arm.

presser

the

(front

The

foot

needle

portant

foot

necessary,

with throat

foot

move

foot

and

~l

ith

presser

and

front

must

hole

lies

lifter

the

lifter

clamp

to

paragraph

THE

the

needle

arm

that the

in

foot

bac

edge

be

aligned

in

fl

at

presser

pl

lever

shaft,

le

ver

scre1o1.

to

k)

of

on

ate

under

PRESSER

presser

in

high

se~oling

to

align

and

throat

loo

flat

needle

"ith

pl

bottom

the

foot

slots

shaft

sen

shaft

throat

F

OOT

foot

position,

pos

iti

needl

on

hole

front

at

e .

of

the

can

by

(A,

be

shifting

Fig

screws

to

the

"401

to

on

e

Looper

presser

and

holes

throat

in·presser

ed

It

is

presser

pl

ate.

realigned

.

19).

in

collar

left

s

wing

set

plate.

ge

of

im-

If

the

or

To

The

and

the

presser

the

collar

presser

foot

Adjust

19)

higher

so

that

than

permit;then

from

motion

presser

should

«i

fabric

chip

th

1/16

of

foot

be

nut

guard

guard,

assembly

foot

lifter

arm

release

lifter

presser

upper

lock

to

1/8

foot

begins

made

(H)

.

and

turn

reaches

lever

(B)

secure

does

not bind and

lever

lever

foot

looper

the

inch

lifter

Hith

nut

(1.59

lever

to

r.ise.

sere"

Re-assemble

cloth

plate

hand"1heel

i.

ts

highest

arm

the

is

stop

can

or

(D,

shaft.

unlocked.

scre\J

be

spreader

(F).Tbere

to

3.18

before

This

(G)

the

and

chip

. To

until

position.

Fig.

Be

rise

(E,

raised

will

should

m

m)

the

adjustment

locked

guard,

assemble

upper

19)

sure

lohen

Pig.

no

be

free

knife

Fig.

20

18

Page 5

SETTING

THE

PRESSER

FOOT

(Continued)

NOTE:

presser

throat

plate

presser

fo

ot

is

•

Checl<

port

pl

ate

justment

rotating

l~ith

take

th

to

-up

rea

d

slightly

(long

Tractor

fo

ot

to

.

foot

lvhen

tilted

alignment

(B),

be

necessary,

handYlh

the

(A,

needle

Fig.

flat

advance

presser

be

1/16

Check

presser

do1m

Ylhich

eel

several

20)

parallel

to

in

front

t,01

of

looper

should

loosen

head

should

or

retard

foot

inch

ma

ke

f

oot

.

LOOPER

revolutions

at

the

be posit

to

to

(1.

59

sure

is

THREAD

thread

be

centered

screws

top

cast-off

take-up

be

set

nun)

401

and

raised

with

forward

overedge

to

CONTROL

take

- up

horizontally

(C), ·reposition

.

Tighten

of

its

ioned

stroke

to

support

later,

front

fro

m

front

needle does not

highest

position

ADJUSTNENTS

(A,

Fig.

screws

,

the

begin

taking

plate)

to

produce

t<all

20)

and

pl

ate

long

.

It

a

of

t,01

Y1all

of

and

in

slot

vertica

(B)

(C)

as

securely

flat

up

slack

may become

satisfactory

needle

401

s l

needle

interfere

front

o£

ll

y .

portion

cast

Should

- o

required

.

of looper

of

the loop

necessary

401

ot

in

slot

with

f£

Ylhil

thread

stitch.

of

sup

ad-

e

er

in

-

The

thread

amount

that

of

highest

required.

Set

this

position

needles

NOTE:

justments,

NOTE:

throat

Be

sure

plate.

adjustable

goes

thread

into

is

position.

pigtail

eyelet

slightly,

reach

their

When

ecce

al.,ays

For

lighter

the machine

eyelets

the

dra,m

They

highest

ntric

torque

is

(D,

stitch.

.

Initial

may be

(E,

Fig.

if

necessary,

position

cams

nu t

(C,

thread,

STARTING

threaded

Fig.

20)

Hhen

setting

lowered

20)

initially

'until

.

are

cast

changed

Fig

. 18)

of£

TO

according

partially

se.t

at

should

to

put

the

or looper

to

24-25

looper

OPERATE

to

the

determine

their

more

at

the

401

thread

threading

l

o••est

be

1/8

loope

r

six

looper

thread

in. lbs

1/32

the

position,

inch

thread

o'clock

thread

take-up

.

(28

inch

diagram

amo

unt

(3.18

into

position.

is

- 29

em/kg).

(.

79

(Fig.

of

looper

the

mm)

the

taut

maximum

from

stitch

•1hen

requires

mm)

belo.,

2

the

Vary

ad-

or

2A).

as

the

Set

thread

l~ith

needles

Fig

cast-off

thread

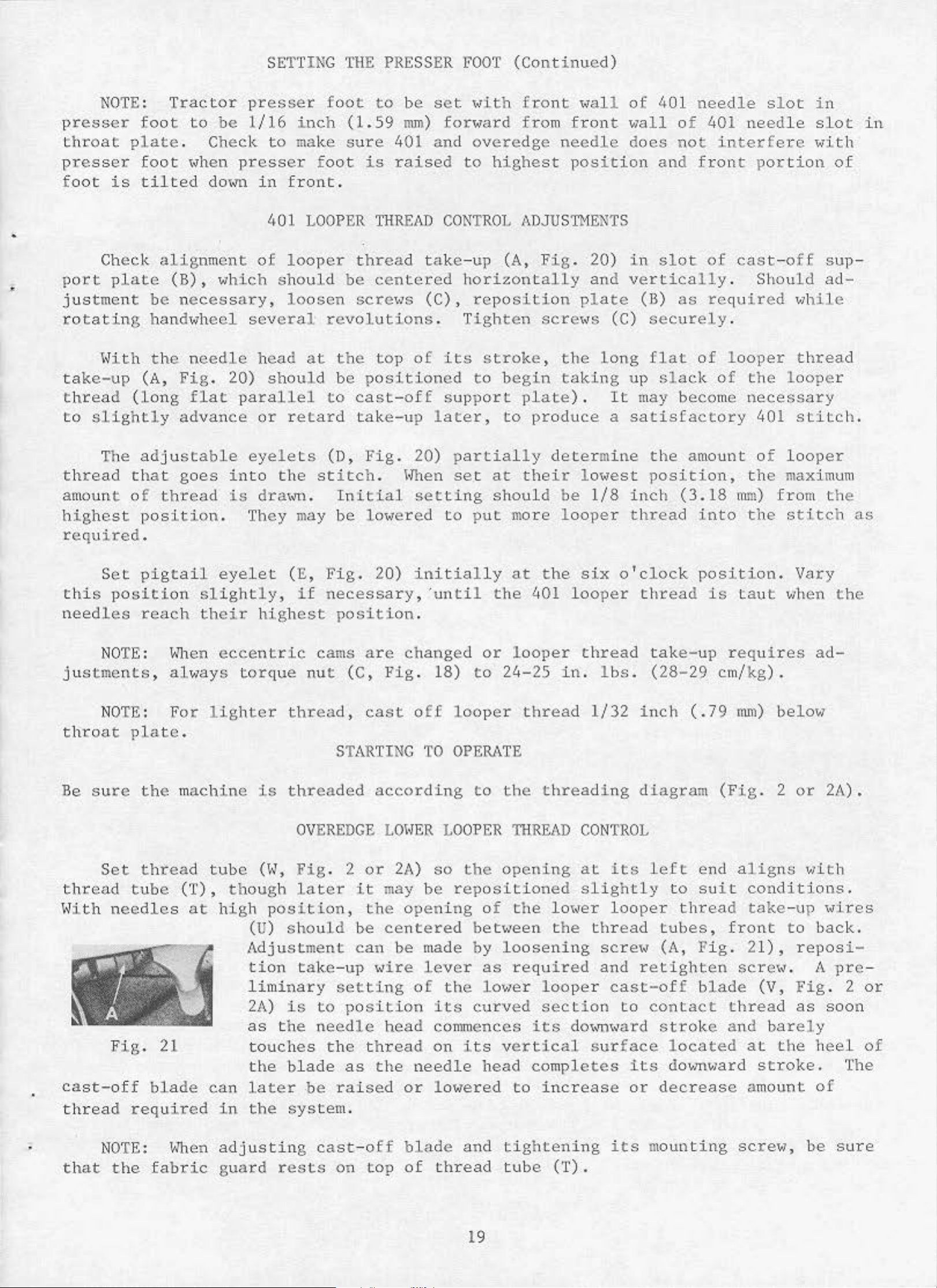

NOTE:

threa

tube

d

(T),

at

. 21

blade

required

Hhen

OVEREDGE

tube

high

(H,

thoug

(U)

Fig

h

later

po

sitio

should

Adjustment

tion

take-up

liminary

2A)

as the

is

to

need

touches

the

blade

can later. be

in

the

adjusting

system

cast-off

LOHER LOOPER

. 2

n,

or

it

may be

the

be

centered

can

2A)

opening

be

Hire

setting

of

position

le

head

the thread

as

the

raised

ne

or

.

blade

so

the

rep

osition

of

bet<·teen t

made

lever

its

the

by

as

lo"er

curved

commences

on

its

edle

head

loY7ered

and

THREAD

opening

ed

the

lo

1~er

he

loosening

required

looper

section

its

dot

vertical

completes

to

increase

tightening

CONTROL

at

its

left

slightly

looper

thread

sere<•

and

retighten

cast-off

to

contact

,•

m~ard

surface

its

or

its

mounting

end

to

suit

thread

tube

(A,

s ,

Fig.

blade

stroke

located

dov1m1ard

decrease

aligns ,,,ith

conditions.

take-up

front

2

scret~

thread

and

at

1),

(V,

bare

to

reposi

.

Fig

as

l y

the

stroke.

a

mount

sere.,,

be

"'ires

back.

A

pre

. 2

soon

heel

The

of

sure

-

-

or

of

that

the

fabric

guard

rests

on

top

of

thread

19

tub

e

('I').

Page 6

OVEREDGE

NEEDLE

TKREAD

CONTROL

~~ile

needle

thread

2A) should

ca

n be

sition,

below

more

adjus

the

the

strike-off

depending

sition

thread.

,

the

Adjust eyelet

With

mately

barely

les

the

horizontal

contacts

are

at

inside

stroke.

sewing on

is

dra

be

set

ted

up

finger

thread

holes

and

on

thread,

curved

needles

inside

down

of

positi

eyelet

materia

wn

on

l,

needle down

approximately

or

down

of

the

in

should

to

take-up

eyelet

be

material

section

of

bracket

UPPER

at

and

high

so

on,

(AH) •

position,

positioned,

front

wire

the

Usuall

check

needle

stroke.

in

the ce.nt

suit

set

and

conditions.

(AM)

(AL)

should

for

approximately

st

itch

length.

thread take-u

(AL)

f

on•ard

LOOPER

set

looper

with

of

rear

wire

y

all

the

left

of

loop

thread

Needle

er

to

\Hth the

be

the

504

1/8

p

(AM)

or

rean<ard

THREAD

thread

thread

take

the

er

left

thread

control

thread

upper

se

t approxima

stitch

With

to

port

. The 503

3/16

needle

should

to

CONT

ROL

eyelet

taut

- up

through

wire

take-up

should

as

follow

take-up

ion

needle

tely

inch

head

barely

meet

(AH,

eyele

(U).

wire

be

s:

(AN,

of

its

head at

l/32

stitch

(3

. 18

at

touch

these

conditions.

Fig .

t

holes,

Make

(U)

sure

does not

drawn on

Usually

Fig

slot,

low

though

est

inch(.79

requires

to

4. 76

highest

the

2A)

needle

approxi

when

needle

all

. 2

po

or

-

mm)

mm)

po

-

thread

need-

strike

d01m

it

-

Set

needle

should

\

-lith

thread

Style

operate

needle

thread

be

positioned

take-ups

tensions

39800

s

in

conjunction

thread

is

drawn on

to

AT

adjustable

with

and

eyelets

obtain

i s

equipped

'~ith

401

the

the

downstroke. Eyelet

bottom

set

desired

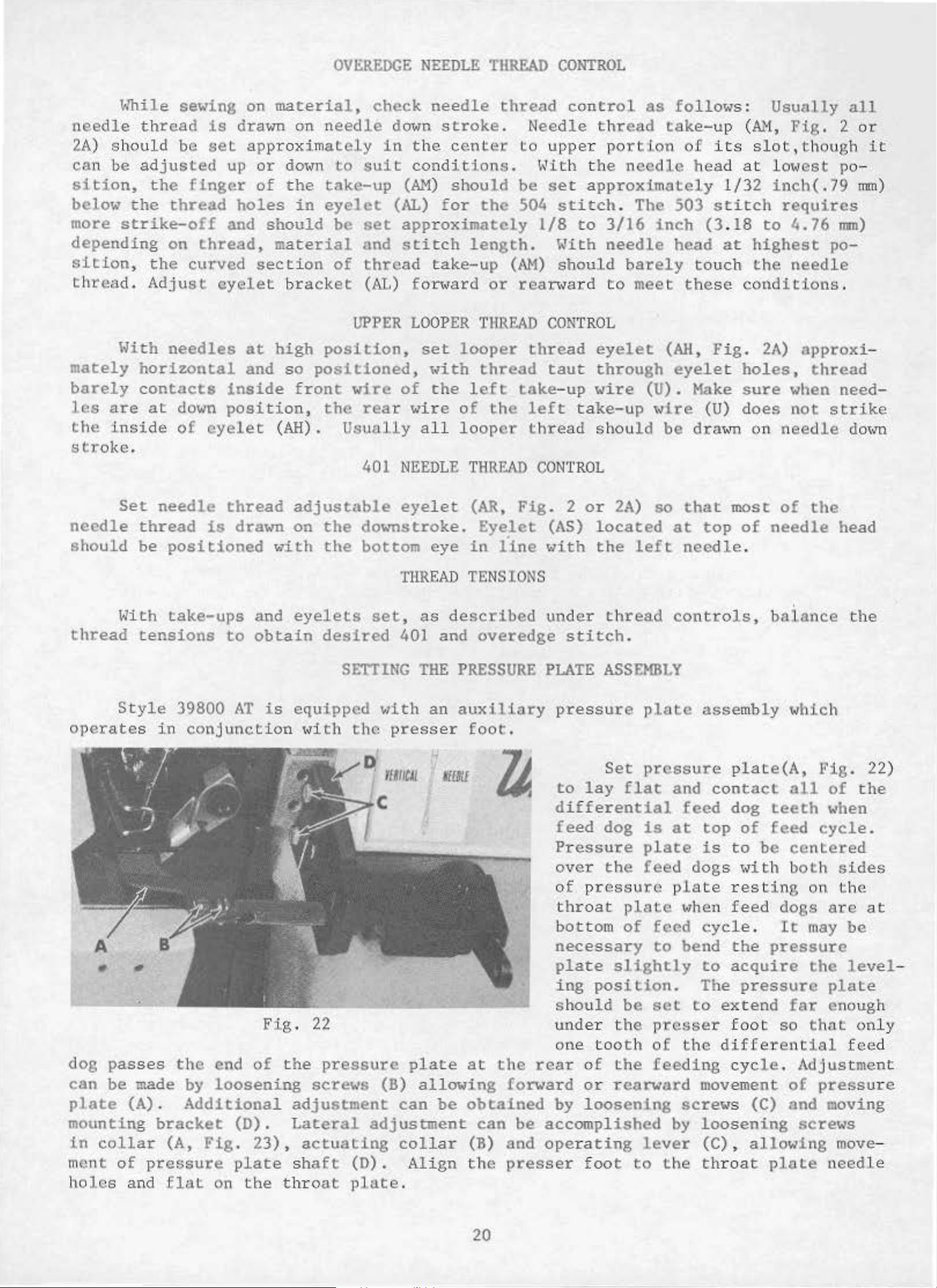

SETTING

the

NEEDLE

eyelet

eye

THREAD

,

as

401 and

THE

with

press

rWICil

an

THREAD

(AR,

in

line

TENSIONS

de

scribed

overedge

PRESSURE

auxiliary

er

foot.

11{111

CON

Fig

TRO

L

. 2

(AS)

with

under

or

2A)

located

the

thread

stitch.

PLATE

ASSEMBLY

pressure

Set

to

lay

flat

differential

feed

dog

Pressure

so

that

at

left

needle

controls

plate

pressure

and

feed

is

at

plate

most

top

of

needle

.

,

balance

assembly

plate(A,

contact

top

is

dog

to

of

teeth

feed

be

of

the

which

Fig.

all

of

when

cycle

centered

head

the

22)

the

.

A

dog

can

plate

pa

sses

be

made by

(A).

mounting

in

collar

ment

holes

of

and

the

Additional

bracket

(A,

Fig.

pressure

flat

Fig.

end

of

the

loosening

(D).

23) ,

plate

on

the

throat

22

pressure

screws

adjustment

Lateral

adjustment

actuating

sha

ft

(D).

pJate.

plate

(B)

can

collar

Align

at

allowing

be

obtained

can

(B)

the

the

rear

forward

be

accomplished

and

operating

presser

over

of

throat

bottom

the

pressur

plate

of

necessary

plate

ing

should

under

one

by

slightly

position.

be

the

too

th

of

the

or

rearward

loosening

foot

feed

e

plate

feed

to

set

presser

of

feeding

by

lever

to

the

dogs

restin

when

feed

cycle

bend

to

the

acquire

The

to

extend

foot

the

different

cycle.

movement

screw

s (C) and moving

loosening

(C),

th

roat plate

<Jith

both

g

dogs

.

It

pressure

pressure

far

so

Adjustment

of

screws

allowing

sid

on

the

are

may

the

plate

enough

that

ial

pressu

move

needle

es

at

be

level

only

feed

re

-

-

20

Page 7

SETTING

THE

PRESSURE

PLATE

ASSE~lliLY

(Continued)

Adjust

clearance

foot

contact

Thrust

in

the

the

loosening

spanner

in

the

( .

762

enough

movable

presser

bottom.

collars

pressure

shaft

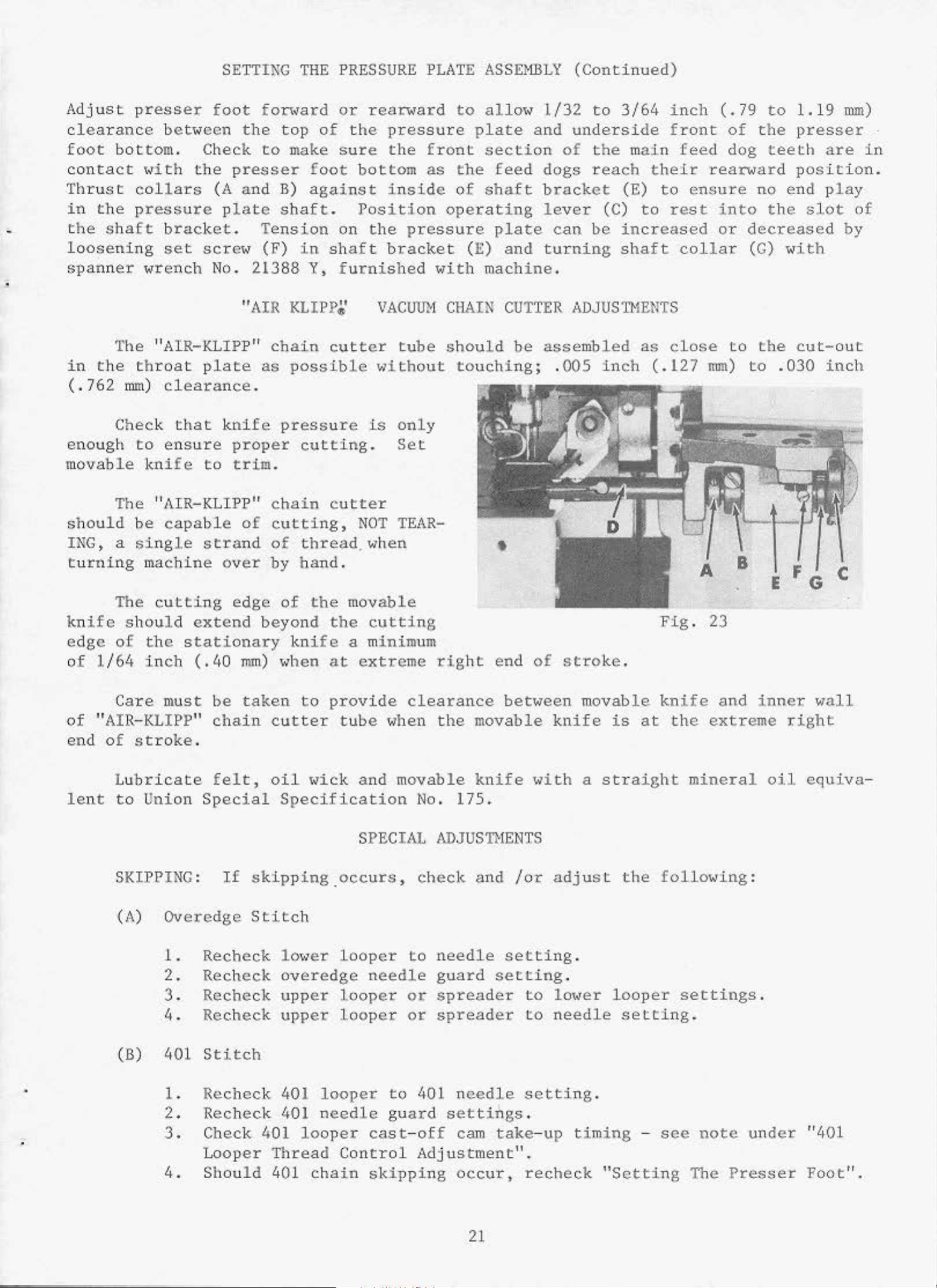

The "AIR-KLIPP"

throat

mm)

Check

to

between

Check

1~ith

wrench

knife

the

bracket.

set

clearance.

ensure

screw

plate

that

to

foot

(A

plat

No.

knife

for"ard

the

presser foot

and

"AIR

proper

trim.

top

to

make

B)

e

shaft.

Tension

(F)

21388 Y,

as

in

KLIPP,&

chain

possible

pressure

cutting.

or

of

the

sure

bottom

against

Position

on

shaft

furnished

cutter

rear"ard

pressure

the

inside

the

bracket

VACUU"H

"lithout

is

front

as the

pressure

with

tube

only

Set

to

allow

plate

section

feed

of

shaft

operating

plate

(

E)

and

machine.

CH

AIN

should

touching;

CUTTER

be

1/32

and

dogs

bracket

le

can

turning

assembled

.005

to

underside

of

the

reach

ver

(C)

be

ADJUSn 1

inch

3/64

main

(E)

increased

shaft

inch

front

their

to

to

rest

collar

ENTS

as

close

(.127

feed

ensure

(.

79

to

of

the

dog

rearward

into

or

teeth

no end

the

decreased

(G)

to

the

mm)

to

1.19

presser

are

position.

play

slot

with

cut-out

.030

inch

rom)

·

in

of

by

The "AIR-KLIPP"

should

ING,

turning

knife

edge

of

1/64

of

"AIR-KLIPP"

end

le

nt

be

a

single

The

should

of

Care

of

stroke

Lubricate

to

capable

strand

machine

cutting

extend

the

inch

Union

stationary

(.

must

.

Special

of

over

edge

40

mm)

be

taken

chain

felt,

chain

cutting,

of

by

of

beyond

knife

when

cutter

oil

Specification

cutter

thread

hand.

the

to

~<ick

mov

the

at

provide

tube

NOT

. when

a m

extreme

and movable

SPECIAL

TEAR-

able

cutting

inim

um

clearance

when

No.

right

the

ADJUSnlENTS

mov

knife

175.

•

end

of

between

able

"ith

stroke

movable

knife

a

Fig.

.

knife

is

at

straight

A

23

the

extreme

mineral

B

and

E F G C

inner

oil

wall

right

equiva

-

S

KIPPING

(A)

Overedge

1.

2.

3.

4.

(B)

401

1.

2.

3.

4.

:

If

skip

Stitch

Recheck lm<er

Recheck

Recheck

Re

c.heck

Stitch

Rec

heck

Recheck 401

Check 4

Looper

Should

ping.

overedge

upp

upper

401

01

looper

Thread

401

occurs,

looper

er

looper

looper

looper

needle

Control

cha

in

check

to

needle

to

guard

cast-off

skipping

guard

or

or

401 n

Adjustment".

and

needle

setting

spreader

spreader

eedle

settiilgs.

cam

occur,

take

/or

setting.

adjust

to

lower

to

needle

setting.

-up

recheck

.

timing

"Setting

the

looper

setting.

-

see

following:

settings.

note

The

Presser

under

"401

Foot".

21

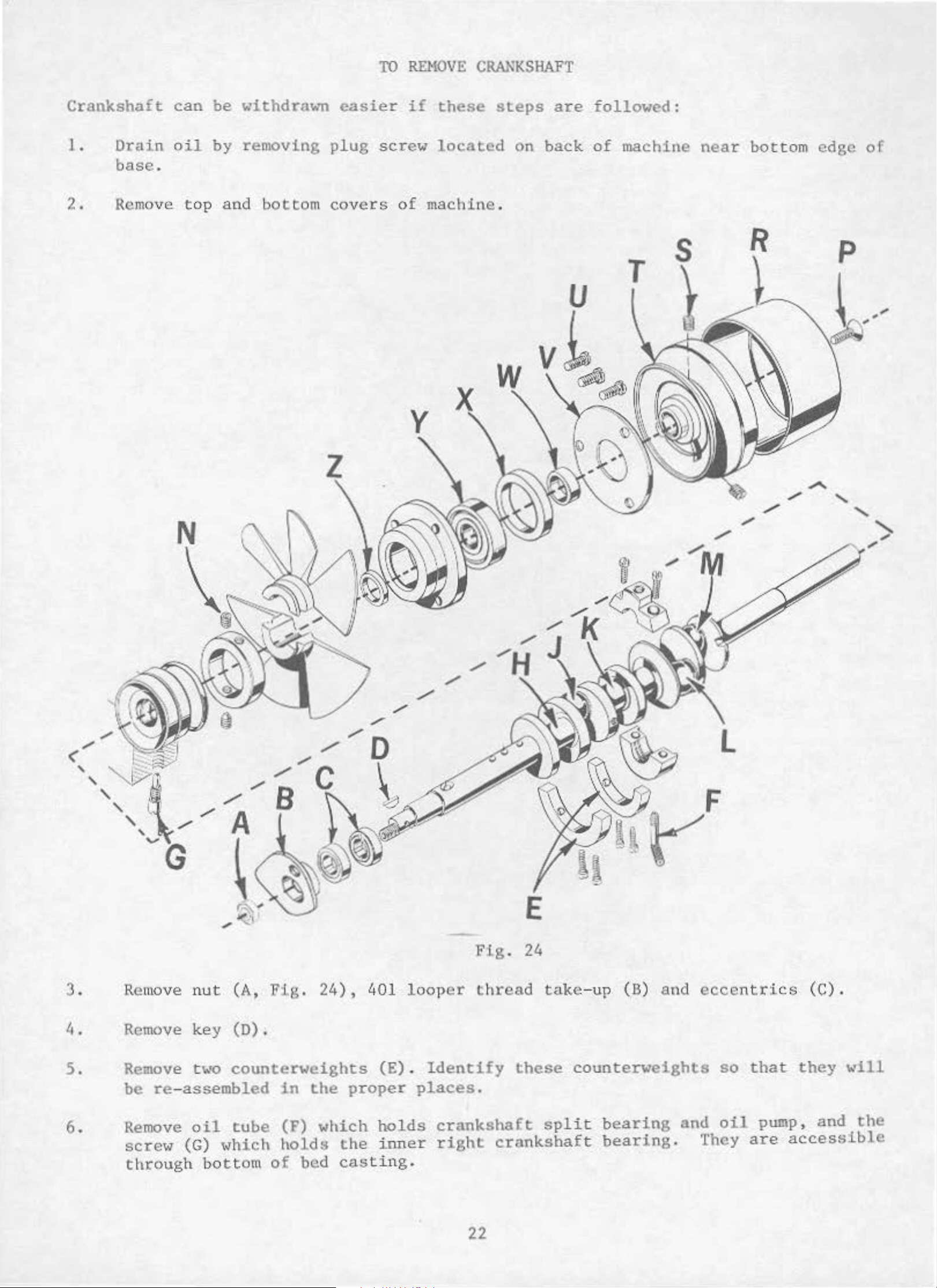

Page 8

TO

REHOVE

CRANKSHAFT

Crankshaft

1.

2.

Drain

base

Remove t

.

can

oil

op and

be

withdrawn

by

removing

easier

plug screw

bot torn cov

ers

if

of

these

located

machine

steps

on

.

are

back

followed:

of

machine

T

near

bottom

R

edge

p

of

'

'

'

'

'

3 . Re

4.

5.

Remove k

Remove two

be

move nut

re-assembled

(A,

ey

(D).

counterweights

Fig

in

. 24) ,

the

proper

401

l oop

(E). Identify

er

places.

Flg.

t h

read

E

24

take-up

these

( B)

counterweights

and

ecce

so

nt

that

ri

cs

(C).

they

••ill

6.

Remove

screw

through

oil

(G) which

bo

tube

tto

m

(F)

holds

of

which

bed

the

cas

holds

inner

t i ng .

crankshaft

right

crankshaft

22

spli

t

bearing

bearing.

and

oil

They a r e

pump,

accessible

and

the

Page 9

TO

REHOVE

CRANKSHAFT

(Continued)

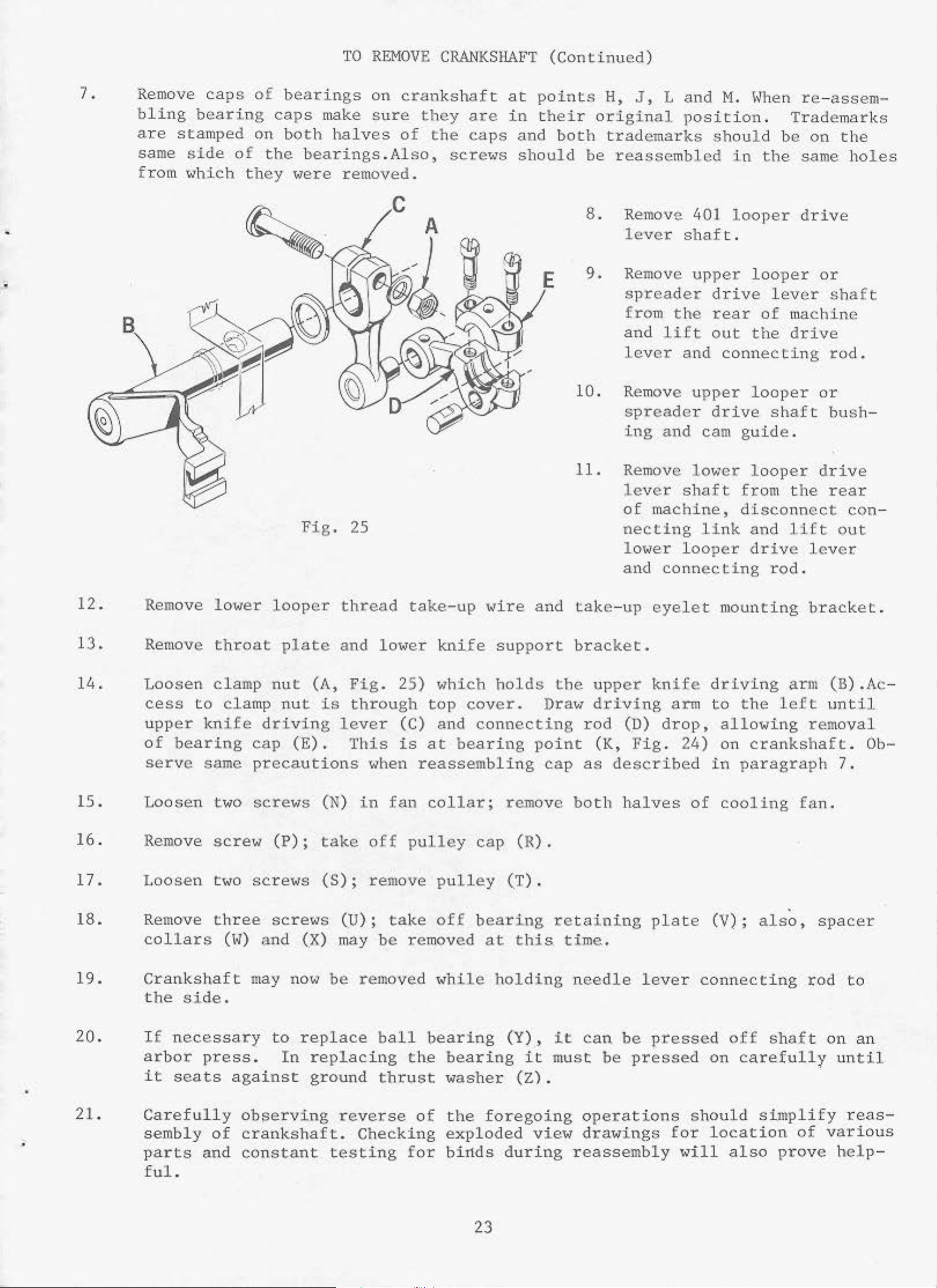

7.

•

Remove

bling

are

same

fr

stamped

side

om

which

caps

bearing

of

they

of

bearings

caps

on

bo

the

on

th

make

halves

sure

bearings.Also,

were

removed.

crankshaft

of

they

the

are

caps

screws

at

points

in their

and both

should

H,

J,

original

trademarks

be

reassembled

8.

Remove 401

lever

9. Remove

spreader

from

and

lever

10.

Re

move

spreade

ing

L

and

position

shaft

upper

the

lift

and

upper

r

and

M.

l~hen

should

in

the

looper

.

loo

drive

rear

out

of

the

connecting

looper

drive

cam

guide

re-assem-

.

Trademar

be

same

d

per

lever

ma

drive

shaft

.

on

the

rive

or

shaft

chine

rod.

or

bush

ks

holes

-

12.

1

3.

14.

15 .

Remove

Remove

Loosen

cess

u

pper

of

to

bearing

serve

Loosen

lo•1er

throat

clamp

clamp

knife

same

two

Fig.

looper

plate

nut

nut

(A,

is

driving

cap

(E).

precautions

scre•1s

(N)

25

thread

and

lower

Fig. 25)

through

lever

This

(C)

is

"hen

in

fan

take-up

kn

ife

which

top

and

at

bearing

re

assembli

collar;

~~ire

and

support

holds

cover

. Draw

connecting

point

ng

remove

the

cap

11.

Remove

l

of

necting

lower

and

tal<e- up

bracket.

upper

driving

rod

(D)

(K, Fig.

as

described

both

halve

ever

shaft

machi

lo

connecting

eyelet

knife

a:rm

drop,

24

s

lower

ne,

link

oper

mounting

driving

to

allowing

)

on

in

of

cooling

looper

drive

from the rea

disconnect

and

drive

rod

Uft

lever

.

out

bracket.

t he

arm

left

(B) .Ac-

until

removal

crankshaft.

paragraph

fa

7.

n.

r

con

Ob-

-

16. Remove

17.

18.

L

oosen

Re

move

collars

19.

20.

Crankshaft

the

I£

side.

necessary

arbor

it

seats

2

1.

Carefully

sembly

p

arts

ful.

screw

t\<O

three

(

H)

press.

agai

observing

of

crankshaft.

and

constant

(P);

screws

screws

an

d

may

no.,

to

In

nst

take

(S);

(U);

(X)

may

be

removed

replace

replacing

ground

reverse

Checking

testing

off

rem

ove pull

ta

be

b

all

thrust

pulley

ke

off

removed

\<hile

bearing

th

.e

be

aring

washer

of

the

exploded

f

or

bii1ds

c

ap

(R) .

ey

(T).

bearing

at

this. time

holding

(Y),

it

(Z).

foregoing

view

du

ring

retaining

.

needle

it

mu

can

st

o

be pressed

be

pressed

pera

tio

drawings for

reassembly

plate

l

eve

(

V);

r c

onnecting

off

on

also

shaft

care.fully

ns should simplify

location

"ill

also

pro

.

,

spacer

rod

of various

ve

on

un

help

to

an

til

reas

-

-

23

Page 10

TO

RE~lOVE

CRANKSHAFT

(Continued

)

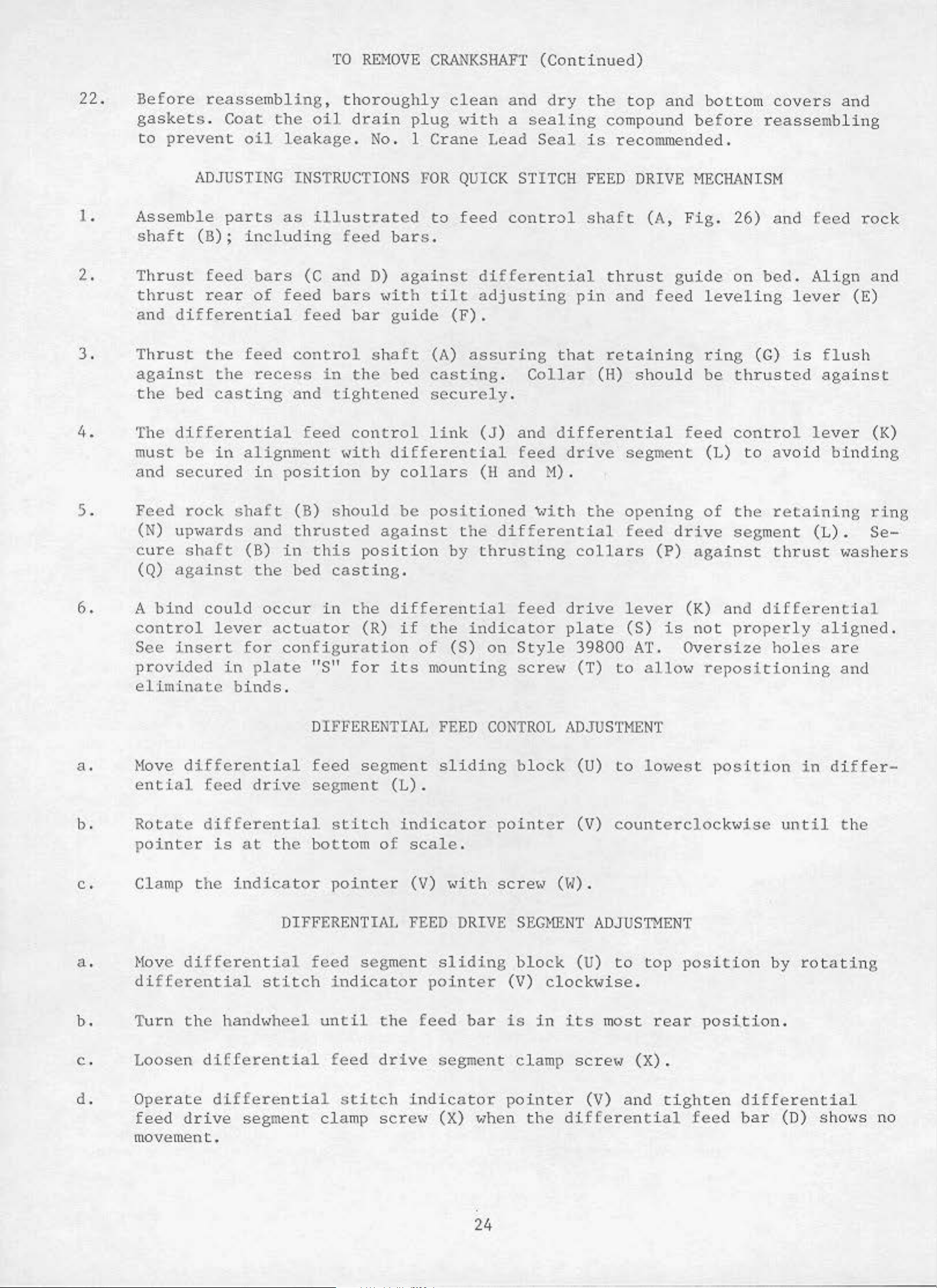

22.

l.

2.

3.

4.

Before

gaskets.

to

prevent

ADJUSTING

Assemble

shaft

(B);

Thrust

thrust

and

differential

Thrust

against

the

The

bed casting

differential

reassembling,

Coat the

oil

leakage.

INST

parts

as

including

feed

rear

bars

of

(C

feed

feed

the

the

feed

recess

control

and

feed

thoroughly

oil

dra

in

No. 1

RUCTIONS FOR

illustrated

feed

and

bars

bar

bar

D)

against

'~ith

guide

shaft

in

the

bed

tightened

control

plug

Crane

to

s.

tilt

(A)

casting

securely

link

clean

"ith

Lead

QUICK

feed

differential

adj

(F).

assuring

.

(J)

and

a

dry

sealing

Seal

STITCH

control

ust

ing

that

Collar

.

and

differential

the

compound

is

recommended.

FEED

shaft

thrust

pin

and

retaining

(H)

top

DRIVE

(A,

feed

should

and

bo

before

HECHANISH

Fig

.

guide

leveling

ring

be

feed

ttom

covers

reassembling

26)

on

and

bed.

(G)

thrusted

control

and

feed

Align

lever

is

flush

against

leve.r (K)

rock

and

(E)

5.

6.

a.

must

and

Feed

be

in

secured

rock

(N) up<Oards

cure

(Q)

A

control

See

provided

against

bind

inser

shaft

could

lever

t

in

eliminate

Hove

ential

dif

ferent

feed

alignment

in

po

shaft

and

(B)

the

thrusted

in

bed

occur

actuator

for

configuration

plate

binds

.

ial

drive

sition

(B)

this

in

"S"

DI

feed

se

'~ith

differential

by

should

against

position

casting.

the

differentia

(R)

for

FFER

its

ENTIAL

segment

gme

nt

(L).

collars

be

positioned

if

the

of

mounting

FEED

sliding

(H

t

he

by

thrusting

indicator

(S)

on

CONTROL

feed

and

driv

N) .

'<lith

dif

fe

rential

l

feed

drive

plate

Style

sere'~

ADJUST}ffiNT

b

lock

e

the

collars

39800

(T)

(U)

to

to lo.,

segment

opening

feed

drive

(P) against

lever

(S)

is

AT.

allo••

est

(L) to

of

the

segment

(K)

not

and

properly

Oversize

repositioning

position

avoid

binding

retaining

(L

) .

thrust

"ashers

differential

aligned.

holes

are

and

in

differ

ring

Se-

-

b.

c.

a.

b.

c .

d.

R

otat

p

ointer

Clamp

Hove

e

differential

is

the

differen

differential

Turn

Loosen

O

per

feed

movement.

the

differential

ate

differential

drive

stitch

at

th

e bo t

indicator

tom

pointer

DIFFERENTIAL

tia

l

feed

stitch

hand,~heel

in

dicator

until

feed drive

stitc

segment

clamp

indicator

of

scale.

(V)

FEED

segment

pointer

the

sere'~

feed

h

indicator

with

DRIVE

sliding

bar

segment

(X)

>~hen

pointer

screw

SEGHENT

block

(V)

(H).

ADJUSTNENT

(U)

(V) clockwise.

is

in

its

clamp

pointer

the

scre1~

(V)

differentia

counterclockwise

to

m

top

ost

rear

po

sit

position.

(X).

and

tighten

l

feed

until

ion

by

rotating

differential

bar

(D)

t

he

shm~s

no

24

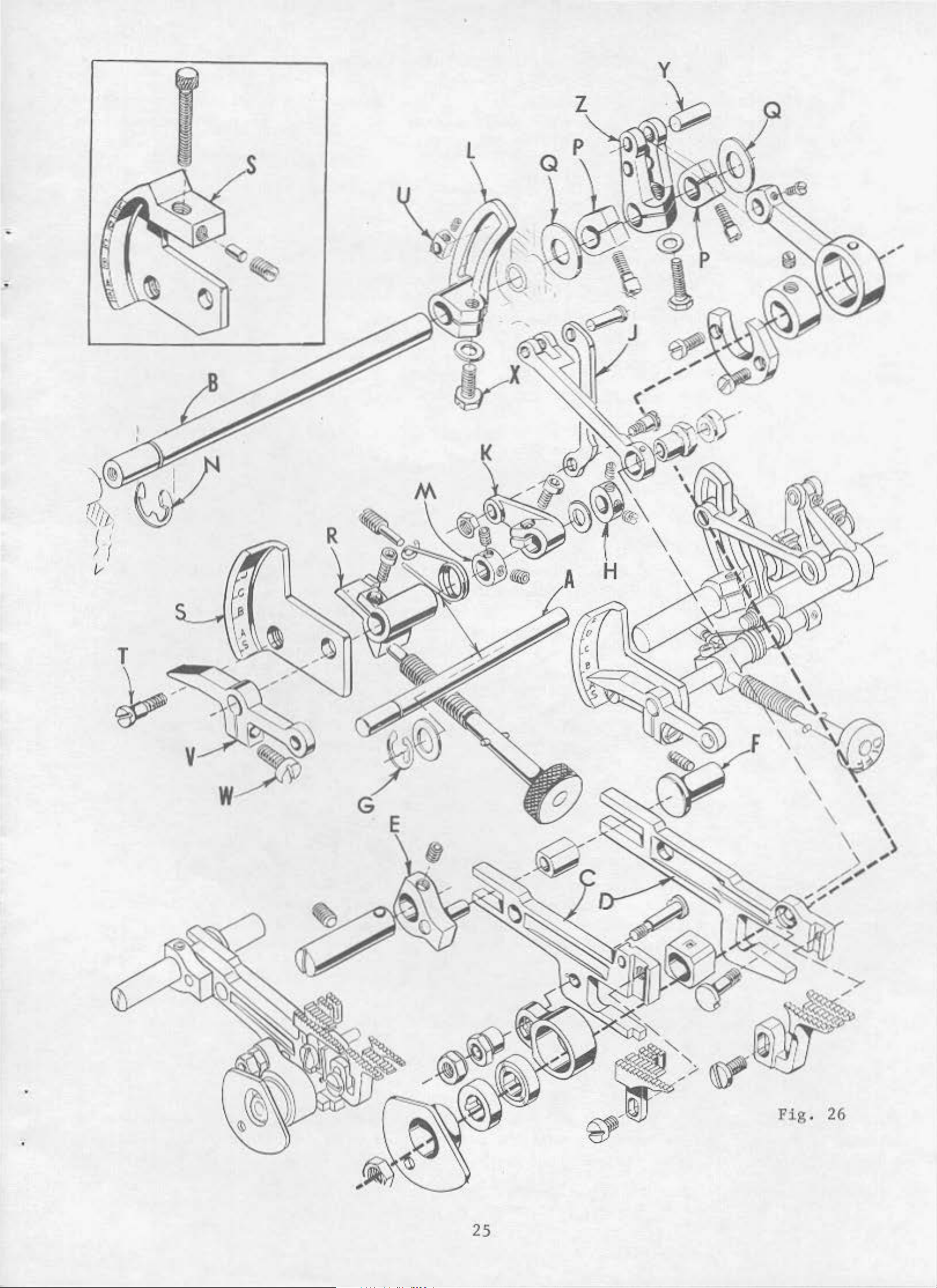

Page 11

y

v

'

'

·r

E

25

Fig.

26

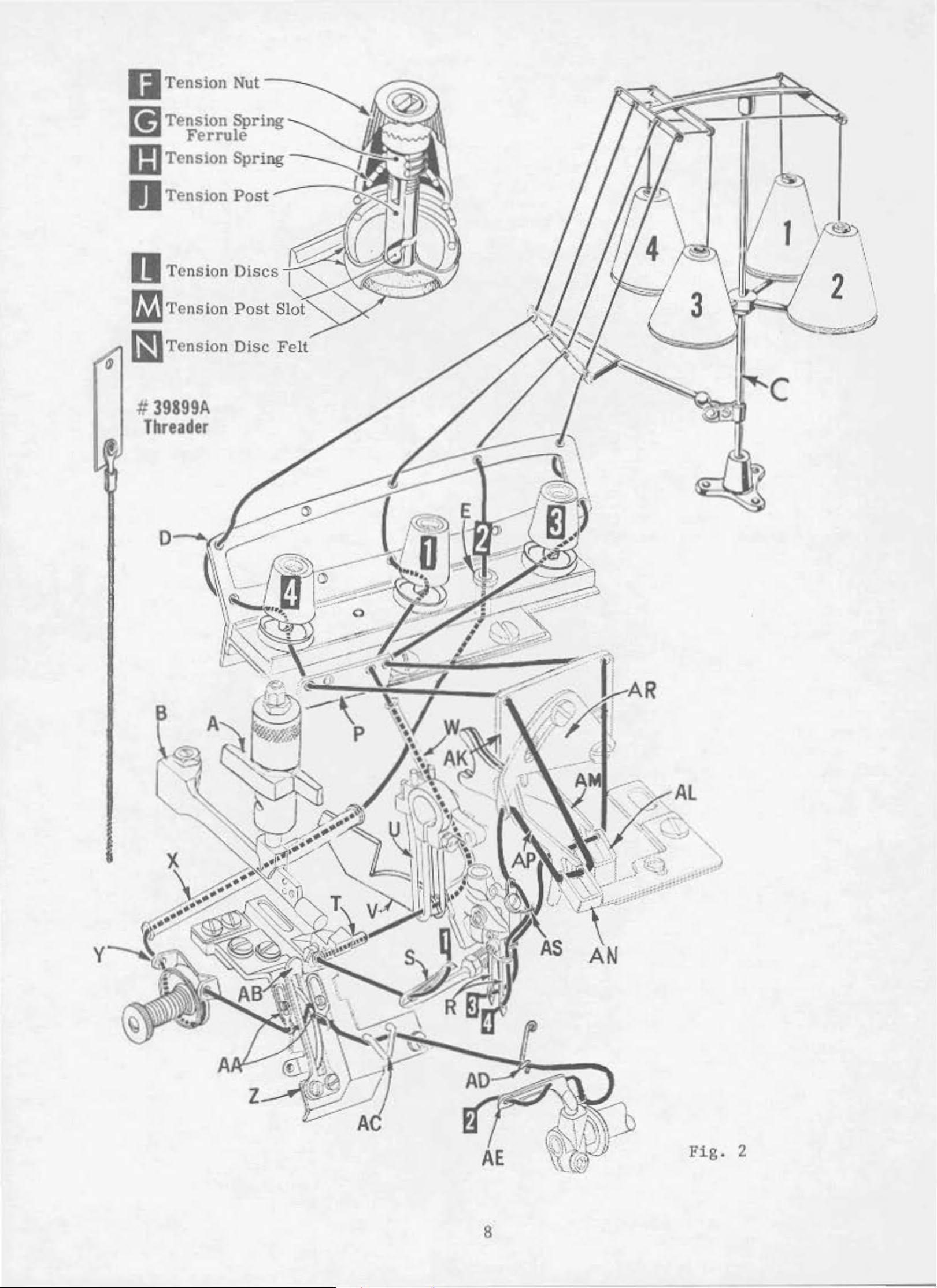

Page 12

IJI

Tension

Nut

[!J

Tension Spring

Ferrule

m Tension Spring

~

Tension

Tension

fi]

Tension

IIJ

Tcns

#

39899A

Threader

Post

Discs

Post

ion Disc

1

2

Slot

Fig. 2

8

Page 13

D

IFFERENTIAL

FEED DRIV

E L

EVER

a.

Standard

feed

ing,

drive

move

ILLUSTRATIONS

This

of v

th

eir

ario

actual

found a

ieces

p

Numbers

position

ordering

catalog has

us

secti

position

listi

ng of

require

in

of

t h

parts

Component

cated

by

indenting

location

leve

pin

r (Z) .

(Y)

been a

ons

of

in

the

d

in

t he

the fi

at

part

rs

in

. Always

parts

the

of

ir

of

to

link

For

lower

pin

longer

hole

ORDERING

the

mechani

the mach

part

part

t

colu

s with

ic

rran

ged to

sms are

ine .

th

ular vie

mn

are

the illustration

use

the

part

sub-assemblies

descriptions

(Y)

is

to

differen

of

leve

r (Z) .

REPAIR

simpl

sho

i fy

wn

On the page

ei r

pa

r t numb

1< being sho

reference

.

Reference

number

which

under

lis

can

the

be

in

ti

al

PARTS

orderin

so

ers

••n.

numbe

ted i n

be

des

t he upper

fee

d

tr

avel

g repai r

that

opp

, d

rs

the part

osite

escription and

onl

y,

number s shou

th

e second column.

furnished

criptio

n

hole

,

of

such

parts

s m

ay

differe

as

for

. Exp

be

loded

see

n

gather

n

the illustration wil

th

e number

and m

for

of

erely

ld

never

repairs

the main

indica

be

used

are

sub

-assembl y .

tial

-

view

s

in

l be

of

te the

in

indi

Example:

Ref.

No

.

18

19

20

21

22

23

24

25

26

27

Part

No

.

294

77

m·

29

4 77

~

Ill

39852 A

77

22587

M

39516-625

39516-626

39516-

30-

51

627

106

-228

39541 A

C067

258

E

Blk

Blk

.

.

Cranksha

for

Sty

ft

les

Crankshaft

for

al l St

Needle Dri

Screw - - - - - - - - - - - Screw - - -

Needle

Needle

Needle

Wood

Vent

Feed

Cork P

Nut - - - - - - - - - - - - -

D

escription

and Needle

39800

a1

1d Needle

yles

AA

except

vi ng Connecti ng

Bearing

Bearing

Bearing

, .0625

, .0626

, .0627 i

Plug, birch

Plug

Driving

lug

- - - - - - - - - - - - - - - - Ecce

- - - - - - - - - - - - - - - - - - -

Driving Co

an

d AB - - - - - - - - - - - - - - 1

Driving

39800

nnecti ng Rod Assembl

Connectin

AA

and

Rod Asse

g Rod Assem

AB-

mb

- ly

- - -

y,

bly

- - - 1

- - - 1

- - 2

r-

-

-

-

-

inch

in

nch

(1. 588

ch (1.590

(1 .593

mm)

mm)

mm)

diameterdiameter

diamete

- - - - - - - - - - - - -

ntric

Key

- - - - - - - -

- - -

Am

Req

,

-2

-28

-2

t.

.

1

8

8

1

1

1

1

1

I

11

t h

cat

alog

arts

p

ed

in

ration.

t

in

this

only

, no spe

!or

lhe

Al

the

book.

the

\./hen

too small

distinguis

ose

the va

desc

back

part

the con

for

h one

cas

es

cific

rious

ription

of the

This

number

s t

ructi

a compl

part

•<here a

usa

ge

par

1~ill

machines

and,if necessa

will

is

ete

from

book

facilitate

known

on pe

ca

will

.

rmits,

talog

anoth

t

is

common

to

be menti on ed

a rc not the

sa

r y, t he

be

found a

locating

IDENTIFYING PART

each

stampi.ng a

er

th

at

is

pa

rt i s

re

simil

al

l

the

in the

me, t

he

descr

speci

differences

nume

the

rical

illust

S

sta

mp

ident i fi

ar

in

appea

machin

iption.

fic

will

index

rati

ed

ed

on and

with

by

ranc

es covcr

usa

ge

e.d

How

•~

ill

eve

by

r,

be me

be s hown i n t he

of

all

the

parts

description

it

s

part number . Parts

l etter

sym

bol s

e .

this

when

nti

illu

sho

wh

which

th

on-

s-

'm

en

e

26

Page 14

IDENTIFYING

PARTS

(ConLinued)

Part

IMPORTANT!

WHICH

PART

Success

UNION

aries

Sl?ECTAL

and

:;clentifi.c

durability

Prices

are

wise

forwarded

directed.

numbers

IS

ORDERED

in

represent

0~

the

Repair

authorize

principles,

ore

assured.

are

strictly

f.o.b

A

charge

ALL

ORDERS,

.

operation

Parts

d

distributo

and

net

.

shipping

is

the

same

PLEASE

USE

as

GENUlNE

of

these

furnish

rs.

are made

cash

and

point.

made

to

part,re~ardless

HCLt:DE

ed

They

~'i

Lh

REPAIR

machines

by

ore

utmost

Lhe

desig

PART

NAME

PARTS

can

be

Union

ned

precision.

TERMS

subject

Parcel

cover

postage

to

Post

change

shipments

and

of

catalog

AND

STYLE

secured

Specia

l

according

~laximum

without

are

insurance.

in

which

OF

MACHINE

only

l~ith

Corporation,

to

the

mofiL

ef

Ciciency

noLic:e.All

insured

unless

they

appear

FOR

genuine

iL

subsidi

approved

nnd

shipments

other-

.

-

Torque (measured

a

distance

driver,

of

torque

All

unless

hand

as

The

by a

ecc.Many

'~ill

sL

r.:tps and

otherwise

tightly

screws

lever

of

these

tighten

eccentric"'

noted.

as

possible,

requiring

TORQUE

in

inch-pounds)is

(in

inches

devices

the

part

should

All

other

unl

a

specific

or

are

to

ess

REQUIRP.l-!E:XTS

a

rotating

feeL)

.

This

availnbJe,

the

nuts,

correct

be

ci.ghtened to

bolts,

otherwise

torque,

amou

noted

will

force

is

nccomplished

"hich

nt

'<ben

and

(in

no

19-21

screws, etc.,

.

be

indicated

pounds)

by a

set

at

applied

wrench,

Lhe

tighter.

inch-pounds

should

on

i>e

th~

through

s"rew

proper

nmount

(22-zt,cm/kg)

LighLened by

picture

plate

.

27

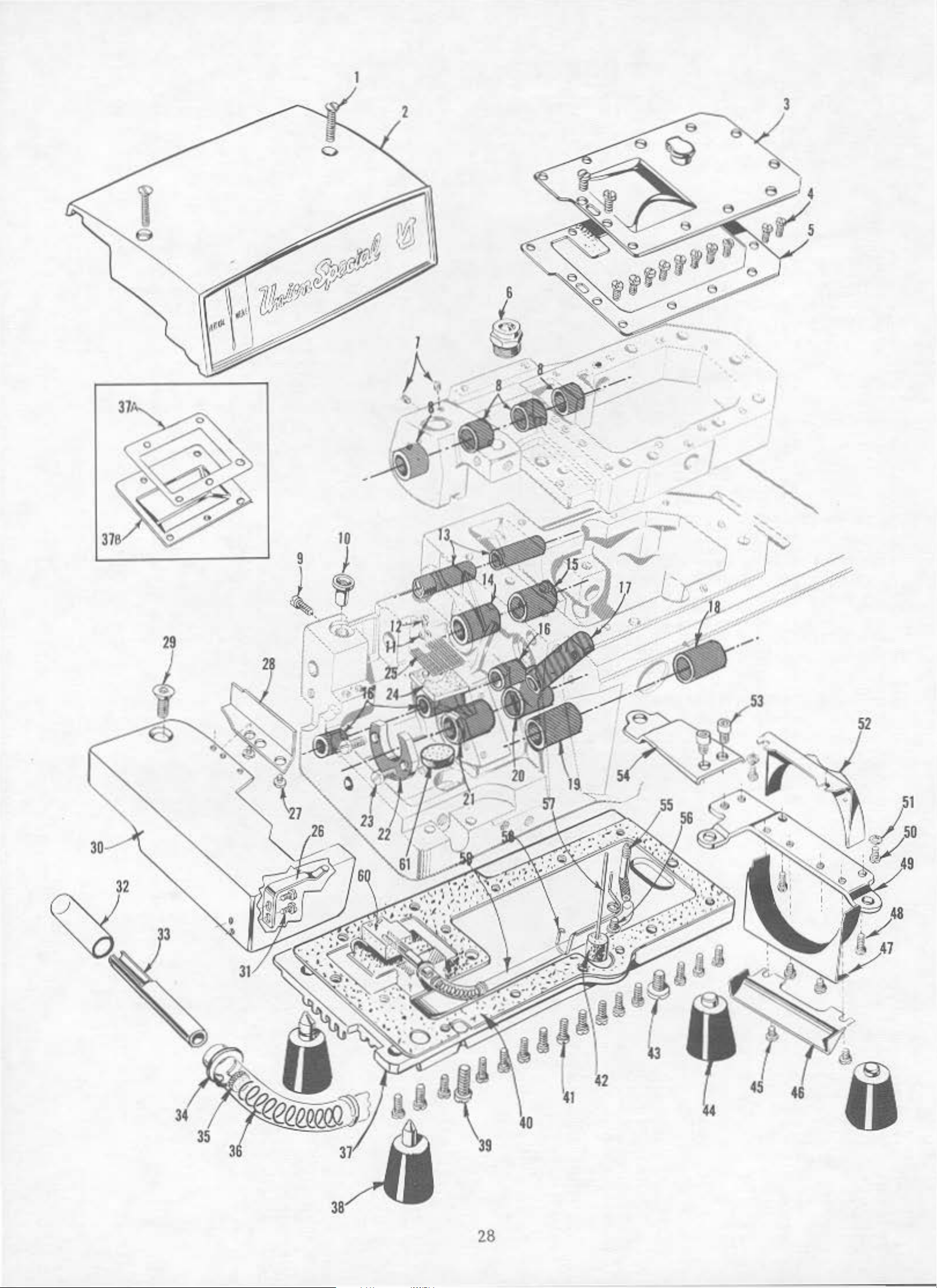

Page 15

i

9

1

39

28

Page 16

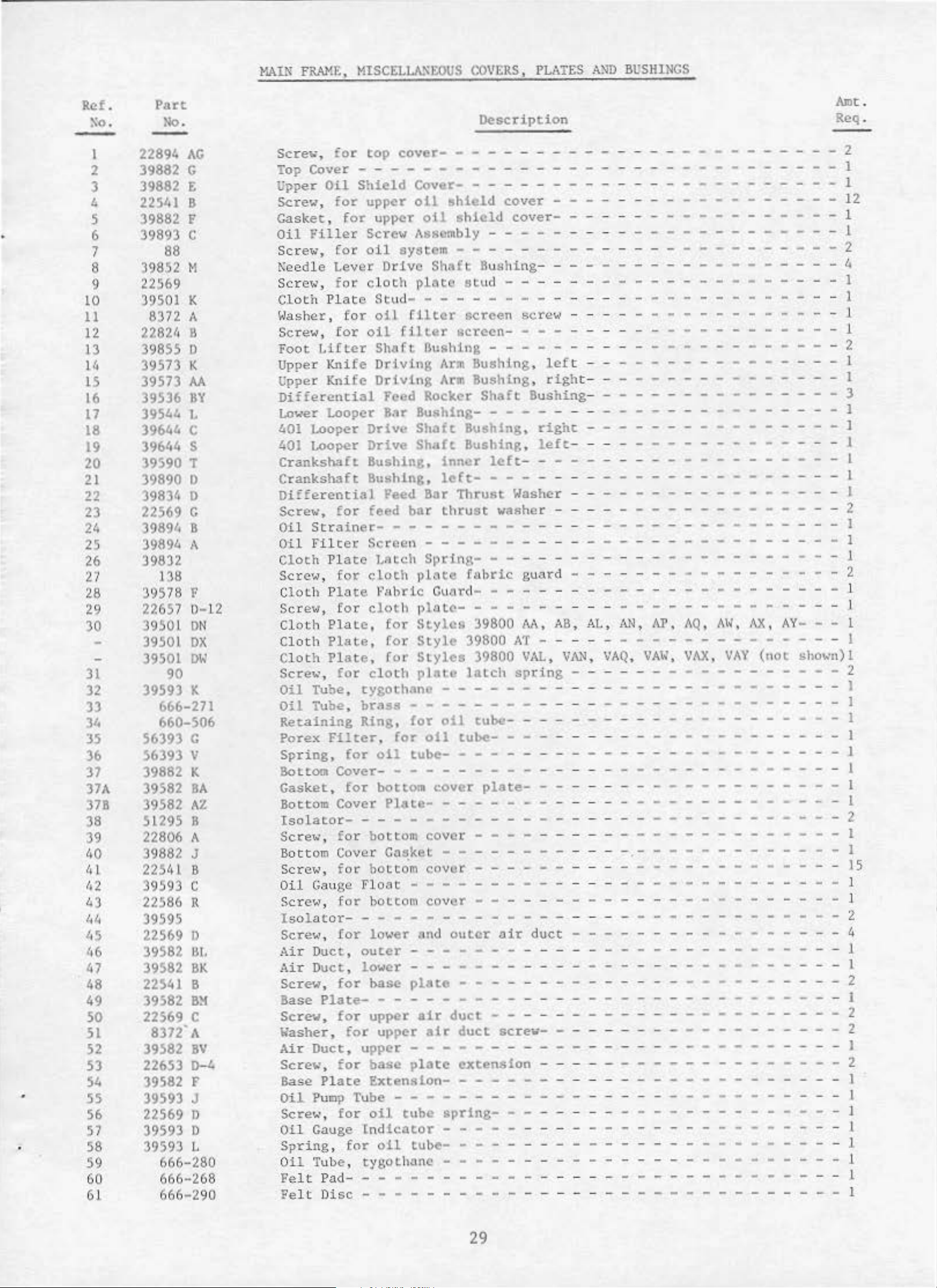

MAIN

FUM",

MISCELLA~t;OUS

COVERS,

PLATES

A~D

llUSHlNGS

Ref.

xo.

Part

llo.

Description

Amt.

Req .

-

I

2

3

~

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

37A

37B

38

39

40

ld

1

12

~3

41•

ll5

46

47

48

49

50

51

52

53

54

•

55

56

57

58

59

60

61

22894

AG

39882 c

39882 t

22541 B

39882 F

39893 c

88

39852 M

22569

39501 K

8372 A

22824 B

39855 D

39573 K

39573

39536

39544

AA

BY

I.

39644 c

39644 s

39590 T

39890 0

39834 0

22569 c

39894 B

39894 A

39832

138

39578 F

22657 L

39501

39501

39501

>-12

ON

ox

OW

90

39593 K

666-271

660-506

56393 G

56393 \'

39882 K

39582

39582

BA

AZ

51295 B

22806 A

39882 J

22541 B

39593 c

22586 R

39595

22569 0

39582

39582

JlL

BK

22541 B

39582

Ill!

22569 c

8372' A

39582

BV

22653 D-4

39582 F

39593

J

22569 D

39593 0

39593 L

666-280

666-268

666-290

Sere~,

Top

Upper

Scret..•,

Gasket,

Oil

Scr

~eedle

Screw, for:

Cloth Plate

Washer,

Screw,

FootLiflcrShaftl)ushing------

Upper

Upper

Differential

Lower Looper Bar

401

401

Crankshaft

Crankshaft

Differential

Screw·,

011

Oil

C

loth

Serer..;~,

Cloth Plate

Screw,

Cloth

Cloth

Cloth

Scre1.o.•,

Oil

Oil

Recaining

Porex

Spring,

Bottom

Casket,

Bottom Cover

Isolator-

Screw, for

Bottom

Screw,

Oil

Screw,

x~ol

Screw,

Air

A.ir Duct,

Screw,

Base

Screw,

Washer,

Air

Screw,

Sase

Oil

Sere

Oil

Spring, for

O

il

Felt

Fe

lt

for

top

cover-

- - - - - - - - - - - - - - - - - - - - - - 2

Cover - - - - - - - - - - - - - - - - - - - - - - - - - - - - l

Oil

Shield

for

for

Filler

ew,

for

Le

ver

for

for

Knife

Knife

Looper

Loo~r

for

StrainetFilter

Plate

for

upper

upper

Screw Assembly - - - - - - - - - - - - - - 1

oil

cloth

Stud-

oi.l r11car

oil

DrjvinQ

Driv1nj:;

Drive

Drive

Bushing,

Bushing,

feed

Sctccn

J.•tch

cloth

system

Drive

Cover-

oil

oil

Shaft Bu"loing-

p.Latc

- - - - - - - - - - - - - - -

shield

shield

- - - - - - - - - - - - - - - - - - - - 2

stu

cover

cover-

- - - - - - - - - - - - - 1

- - - - - - - - - - - - - - 4

- - - - - - - - - - 12

d - - - - - - - - - - - - - 1

...

- - - - - - - - - - - - - - - - - - - - - - - - 1

fjl~er

Arm

Arm

Feed

Rocker

BushingShnft

Shaft

inner

left-

Feed Bnr

bor

thrust

screen

screen-

Bushing,

Bushing,

Shaft

Bushing,

Bushing,

Thrust

!:>crev.•

- - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - 1

left

right

Bushing

-

- - - - - - - - - - - - - - 1

- - - - - - - - - - - - 3

-- --

- - - - - - - - - - - - 1

---

--2

- - - - - - - - - - - - - - - - - - 1

right

left

left

- - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - I

- - - - - - - - - - - - 1

- - - - - - - - - - - 1

Washer - - - - - - - - - - - - - 1

washer - - - - - - - - - - - - - - - - 2

- - - - - - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - 1

Spring-

pl.:'lte

- - - - - - - - - - - - - - I

fabric

guard

- - - - - - - - - - - - - - - 2

- 1

F'nhric CuCird- - - - - - - - - - - - - - - - - - - 1

for

Plate,

Plate

Plate,

for

Tube,

Tube,

Filter.

for

Cover-

for

cloth

, Cor

cloth

tygothane

brass

Ring,

oil

bottom

plllt~-

for

Styles

Style

for

Styles

plate

- - - - - - - - - - - - - - - - - - - - - 1

39800

39800

39800

latch

M,

118,

AL,

,\N,

liP,

AQ,

Al<,

AX,

AY-

AT

- - - - - - - - - - - - - - - - - I

VAL,

spring

Vlll<,

VAQ,

- - - - - - - - - - - - - - - - - 2

VAl~,

V/IY.,

VAY

(not

sho•·n)l

- - - - - - - - - - - - - - - - - - - - - I

- - - - - - - - - - - - - - - - - - - - - - - J

for

oil

for

oil

tube-

cube-

tube-

- - - - - - - - - - - - - - 1

- - - - - - - - - - 1

- -

--

- -

--

- - - - - - - 1

- - - - - - - - - - - - - - - - - - - - - - - - 1

Plate-

cover

- - - - - - - - - - - - - - - - - - - l

plate-

- - - - - - - l

- - - - - - - - - - - - - - - - - - - - - - - - 2

bottom

Cov~r

fot

bottom

Gauge

ator-

Duc

Plate-

Floot

for

bottom

- - - - - - - - - - - - - - - - - - - - - - - - - - 2

for

lower

t,

outer

lower

for

base

for

upper

for

Duct,

Plate

Pump

....

•,

Gauge

Tube,

Pad-

D

upper

for

base

Extennlon-

Tube

for

oil

Cndlcacor

tygothanc

isc

- - - - - - - - - - - - - - - - - - - - - - - - 1

Ca~keL

- - - - - - - - - - - - - - - - - - - - - - - - - - - 1

upper

oil

cover

cover

- - - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - lS

- - - - - - - - - - - - - - - - - - - - - - - - .. 1

cover

and

- - - - - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - 1

ploto

air

atr

- - - - - - - - - - - - - - - - - - - - - 1

outer

air

duct

- - - - - - - - - - - - - 4

- - - - - - - - - - - - - - - - - - - - - - - - 2

duct

- - - - - - - - - - - - - - - - - - 2

duct

screw-

- - - - - - - - - - - - 2

- - - - - - - - - - - - - - - - - 1

place

extension

- - - - - - - - - - - - - 2

- - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - - - - - - - - I

tube

spring-

- - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - - - 1

tube-

- - - - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - - - - - J

1

29

Page 17

19

lbs

.

TORQUE

in.

TO

lb

8.

I

30

Page 18

CRA.

l'l

KSHAFT

HECHANISN

.,

'

I

'

•

' ;

I

•

'i

•

R

ef.

No.

1 39690

2 39890 c

3

4 39591 H Crank

5

6

7 39590

8 39590 G

9

10 39590 R B

ll

12 39590 H

13

14

15 95

16

17

18

19

20

21

22

23

24

25

26

27

28 39890 E

29

30

31

32

33

Part

No

.

A

660-443

22894

39591

660-268

39590 s

22569

39521

39821

22769 B

29477 MF

29477

39852 A

22587

39516- 625

39516- 626 N

39516-627

39541 A

C067 E

39691

39593 J

22747 B

39591 K

D

L

J

B

G

HB

i7

~1

30- 106

51- 228

258

97

A Sere''',

Blk.

Blk.

Stud,

Crankshaft

"0"

Spot

Crank

Thru

Crankshaft

Crankshaft

all

Spacer

Crankshaft Ball

Scr

Pu

lley

Pulley

Screw ,

Cranksha

Styles

Cranksha

all

S

plit

Cranksha

Oil

Screr.-1

Cranksha

for

Ring,

Chamb

S

cre't-7

Chamber

\olasher- - - - - - -

st

Bearing

Collar

e~

..r,

for

-

ScretJ,

Cap

fo

St y

Needle

Needle

eedle

Ne

edle

Hood Pl

Vent

Fee

d

Cork

Nut-

Bearing

Pump

,

for

crankshaft

Bearing,

for

,

crankshaft

er

Cooling

for

Ball

Ball

ball bea

crank

Cooling

Bearing

Bearing

Stop

- - - -

Bearing

- - - -

for

pulley

- - - - - -

lle

pu

r

and Nee

ft

39800

ft

and

les

Sere,<-

Se

except

Drivin

re,,,_

B

earin

Bearing,

B

earin

ug,

Plug

iv

Dr

Plug-

y

AA

Needle

-

-

birch

-

- -

ing

- -

- - - -

and

f

or

split

ft

Coun

Tube

cra

Counter,~

ft

ten

- - -

nksha

Description

bearing

inner

bearing,

Fan

chambe r cool

Fan-

Collar

Housing

- -

Collar

ring

-

-

- -

Retainin

re

- -

-

-

cap

dle

and

g

- -

- -

g,

g,

AB

39800

Connecting

- -

- - - - - - -

.0625

.0626

.0627

-

-

-

Eccentric

- - - -

- -

-

Oil

b

1eight,

- - - - -

ft

eig

-

-

Drivin

- - -

D

riving

AA

- - - - - -

- - - - - - -

- - - - -

-

-

Pump

earing

counter'Neight-

ht,

- - - - -

right

- -

inner

- - -

ing

-

-

-

-

- -

-

- -

-

- - -

- - -

- -

-

g

Plate

taining

- - - - -

- -

- - - - - -

g

Connecting

Connecting

and

Rod

in

ch

inch

inch

K

ey

-

-

- -

and

right

left

plate

- - -

- -

- - - - - - -

AB

Assembly

(1.

588

(1.

590

(1.

593

- - - -

-

-

- -

- -

-

oil

- -

- - -

- - - -

- - - - -

- -

-

fan

- - - - - -

- - - - - -

- - -

-

r i

ght

- -

collar

- - -

- -

- -

-

-

-

-

and

housing

-

-

-

-

- - -

Ro

d

Rod

- - - -

- -

- - - - - -

·- - - - 1

- -

-

- - - - -

rrnn)

rrnn

nun)

diameter

)

diameter

diameter

- - -

- - - - - -

-

- - - - -

- -

pump

- - - -

- - - - -

-

-

-

-

-

- - - - - 1

- - - - - - 1

- - 1

-

- - - 2

-

-

-

-

- - 1

-

- - 1

-

- -

-- -

--

- -

-

-

- -

Assembl

-

Assembl

-

- 1

- - - - - 1

-

- - - - - - 2

-

- - - - - 1

-

-

- 1

- -

- -

-

- - - - 1

y, for

- - - 1

-

y,

for

- -

- - - -

- - - -

- -

- - -

- - - -28

- - - - -

- - - - -

-

-

-

-

-

-

- -

-

-

-

- - - 1

- - -

-

-

-

- -

- - - - 1

-

- - 2

- - -

-

-

- -

- - - - -

- -

Amt.

Re

1

1

1

1

3

-

1

1

-

2

-

-2

8

-28

1

-

1

-

1

1

1

1

4

1

q.

31

Page 19

'-""

•·

1

35A

•

32

Page 20

FEED

ORH'E

}~ECH;\NlS

f.l

•

Ref

tl"o

I

2

3

'

s

6

8

9

10

II

12

13

14

IS

16

17

18

19

20

21

22

23

2

'·

2~

26

2i

28

29

30

31

32

33

34

35

35 ,\

35

35

35

36

37

38

39

:.o

41

42

43

.:

,t,

45

46

47

48

49

50

51

52

53

$4

55

56

57

58

S9

60

61

6Z

63

64

65

66

67

.

.

39836

39

J9S:)6 A

39536 A)'

?..27:))

39536

39836 r

8055

2:>.8!>1

622

35751 c

22512 8

51236 A

39536 AU

395J6

22852

39

39S~O

2289

J9SJ::. D

2256

39536 E

395JO

22760 E

395

39536

395%

61248

39536

226$?. A-6

ld 071 c

39536

39.536

39036

2

39836 p

39836

3

22i89

c

0

22565

22)Ji

39836 R

39836

92ZOI

39536

J98J6

22894

J9835

39SJS c

2

39

39

J98J:. c

39S3t.

J9

2289G

39

39836

39536 m;

39536 "

39868

39540