Page 1

®

INDUSTRIAL

SEWING

FINEST QUALIT

Y

STYLES

39600A

39600P

LEWIS

•

COLUMBIA

MACHINES

CLASS

39600

STREAMLINED

CATALOG

No.

HIGH

FOUR

127M

SECOND

SAFETY

EDITION

STITCH

CHICAGO

SPEED

THREAD

MACHINES

MACHINE

COMPANY

Page 2

Catalog

INSTRUCTIONS

ADJUSTING

No.

FOR

AND

127

OPERATING

M

Four

Rights

Thread

39600

Union

LIST

CLASS

Safety-Stitch

A

Second

Copyright

Special

Reserved

OF

39600

STYLES

Edition

by

Machine

in

PARTS

39600

1964

All

Machines

p

Co.

Countries

MACHINE

INDUSTRIAL

CHICAGO

Printed

COMPANY

SEWING

in

MACHINES

U .

S.A.

January,

1971

Page 3

IDENTIFICATION

OF

MACHINES

Each Union

into the

Special.

contain

the

is

suffixed

which

by a gauge

width

the

5-1/8

and

right

herein.

this

from

handwheel

name plate on

the

letter

Styles

differs

The

distance

of

overedge

width

gauge

the

right

of

the

This

It

class.

the

Standard

letter

"Z".

to

the

of

machines

from

number

of

overedge

represents

needle

right

catalog

can

also

Reference

operator's

is

away

Spe

cial

StjYle

"Z'.

When

Standard

between

is

hand

applies

only

the

style

measured

represented

represent

(503

needle.

be

applied

to

position

from

machine

the

machine.

numbers

Example:

minor

Style

similar

the

a

distance

stitch)

APPLICATION

specifically

direction,

operator.

number.

in

number

rows

in

1/

by a fraction.

and

with

while

the

is

identified

Style

have

"Style

changes

of

64ths

discretion

such

seated

one

39600

Example:

construction

in

that

stitches

of

machine

of

5/64

the

1/8

OF

to

the

as

by a Style

numbers are

or

more

A".

are

made

"Style

are

it

contains

or

between

an

inch,

Collectively,

gauge.

inch

between

represents

CATALOG

Standard

to

some

right,

at

the

left,

machine.

number

classifi

letters

Special

in a standard

grouped

no

letters.

the

going

Example:

the

the

Styles

Special

front,

suffixed,

Style

39600

under a class

needles

from

the

left

width

of

Styles

back,

Operating

which

ed

as Sta

numbers

machine,

AZ".

Example:

is

represented

left

to

gauge

needle

of

machines

"5-1/

overed

of

etc.,

number

machines

direction

is

stamped

ndard

but

contain

number

"39600".

right.

8".

(401

ge

as

are

and

never

a

"Z"

Th

and

Thus,

stitch)

to

the

listed

in

given

of

e

Two

Thread,

edge

ming

39600

39600

filled

straight

should

sight

gauge

Curved

Stitch

Mechanism

on

cases

fication,

stitch

slacks,

pads

CAUTION!

Machine

Dual

A

Light

sport

P

Same

and

before

mineral

be

used.

gauge

lines

Needles,

Stitch,

on

Right

with

to

medium

shirts,

and

similar

401-503-SSa-2;

range,

jackets,

similar

is

on

when

8

as

Style

Oil

was

beginning

oil

of a Saybolt

This

filled

front

machine

STYLES

Left

401

Rear

Spring

ladies'

operations

to

sport

garments.

is

with

of

Needle

Double

Needle,

Pressed

duty

blouses,

standard

16

per

39600 A except

shirts,

drained

to

operate.

equivalent

oil

at

the

machine.

is

stationary.

OF

in

Locked

Differential

Lower

machine

street

on

light

gauge

inch;

cam

street

OILING

from

viscosity

spring cap

Oil

to

machine

Union

Red

MACHINES

Front,

Stitch

for

to

medium

and

capacity

Two

on

Knife,

simultaneously

and hou

medium

and

adjusted

house

when shipped,

of

90

Special

in

top

tip

of

Loopers,

Left

Feed,

Needle,

Low

Automatic

se

dresses,

weight

seam

to

oil

widths

main

to

heavy

dresses,

of

Class

125

seconds at

Specification

cover.

indicator

One

503

and

seaming

materials.

are

and

differential

duty, for

coat

so

39600

Oil

level

should

Spreader,

Two

Thread

High

Lubricating

coat

Throw,

and

linings,

5-1/8

linings,

reservo

is

six

100°

No.

174.

is

checked

Se

and

feeds.

operations

Fahrenheit

show

Four

Over-

Trim-

System.

overedging

pillow

am

speci-

12-3/16;

on

shoulder

ir

must

ounces.

between

be

A

at the

Machine

main

It

may

reservoir

The

is a magnetic

have

drain

entered

is

automatically

filled.

plug

screw

screw

the

Check

is

locat

designed

crank

lubric

oil

daily

ed

ca

se.

at e

d.

before

at

the

to

accumulate

It

should

No

back

3

oiling is

the

morning

of

machine

possible

be

removed

necessary,

start;

near

foreign

and

other

add

oil

bottom

materials

cleaned

than

keepin

as

required.

edge

periodically.

of

which

base.

g

Page 4

NEEDLES

Each

denotes

number,

in

thousandths

size

number

packaged

Two

needle

shank,

for the

round

spotted,

036,

040,

The

a

round

double

and

groove,

is

available in

To

sample

on

needle,

label.

Selection

should

pass

Success

of

needles

reputation

more

than

Union

the

stamp

kind

ed

Spe

of

of

r e

present

and

sold

needl

es

overedge

point,

chromium

044,

longer

shank,

049,

needle

round

milled

have

needle

or

A

complete

of

proper

freely

in

the

packaged

for

producing

three-quarters

cial

shank,

on

the

an

inch,

the

by

Union

having

curved

plated

054.

for

point,

groove,

sizes

orders

the

type

order

through

operation

under

needle

has

point,

needle

shank,

midway

complete

Special.

different

stitch,

located

blade,

needle

the

401

curved

long

029,

032, 036, 040, 044.

promptly

and

size

would

needle

size

needle

of

Union

our

brand

highest

of a century.

both a type

length,

denotes

between

symbol

lengths

at

standard

and

is

available

stitch,

blade,

spot,

and

number

read:

is

determined

eye

in

Special

name,

quality

and

groove,

finish

largest

shank

which

are

the

is

used

right,

length,

in

located

flat

at

tapered

government

accurately

should

"1000

order

needles,

to

machines

~

needles

in

size

number.

and

other

and

given

in

is

single

sizes

the

diameter

eye.

on

this

Type

022,

left,

of

Collectively,

the

label

machine.

154

GAS.

groove,

025,

is

Type

blade,

point,

be

by

size

chromium

filled,

an

forwarded.

Type

of

thread

154

produce a good

can

be

secured

..

which

materials

and

The

type

details.

blade,

The

measured

type

of

all

The

It

is a round

struck

027,

Class

158

"B"

029,

GJ.

plated

empty

GAS,

Use

description

package,

Siz

used.

stitch

formation.

only

is

backed

workmanship

number

size

and

needles

shorter

groove,

032,

It

is

length,

needle

e 032

11

Thread

by

use

by

for

a

•

a

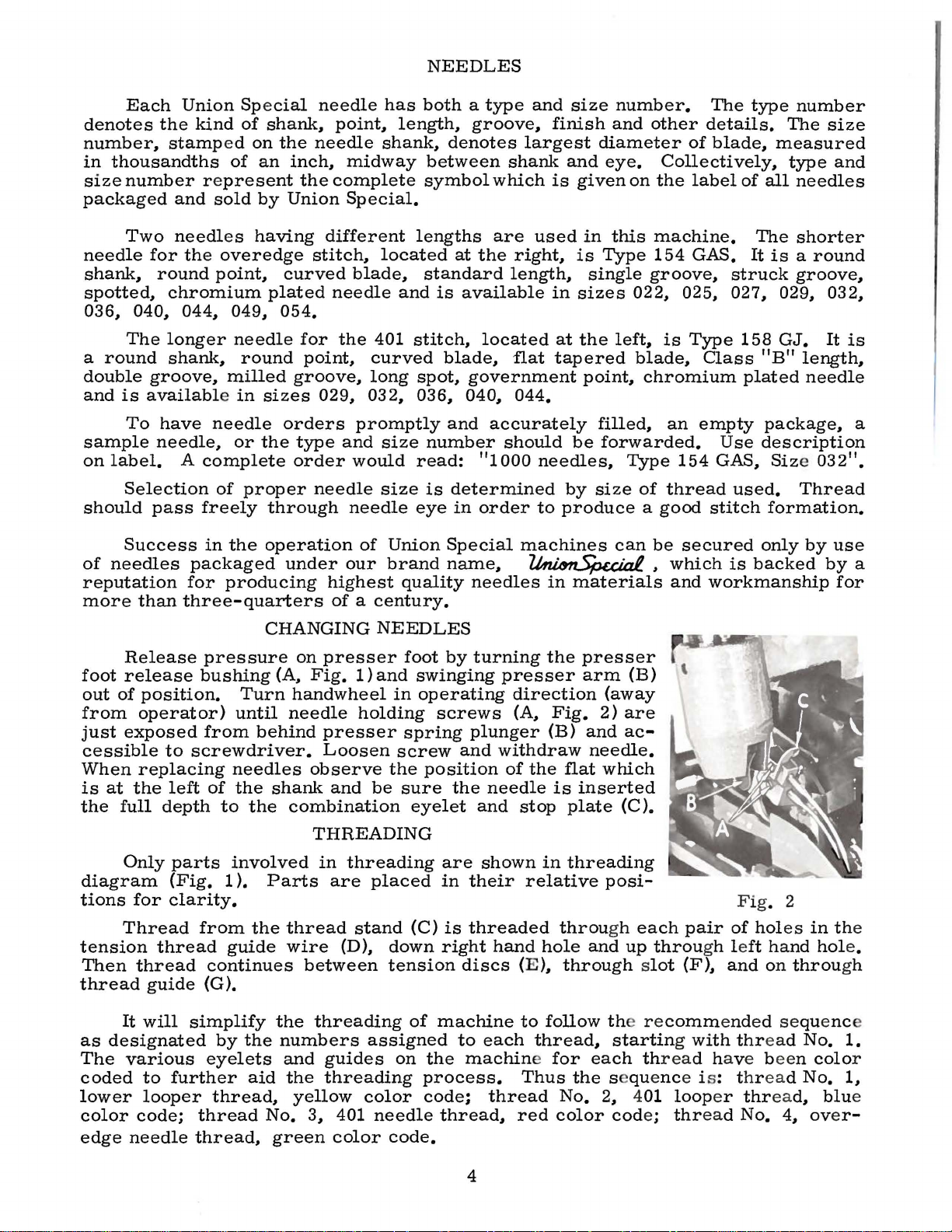

Release

foot

release

out

of

from

just

operator)

exposed

cessible

When

is

the

replacing

at

the

full

Only

diagram

tions

for

Thread

tension

Then

thread

thread

It

as

designated

The

various

coded

lower

color

edge

code;

needle

pressure

bushing

position.

from

to

screwdriver.

left

depth

parts

(Fig.

clarity.

from

thread

guide

will

to

(G).

simplify

further

looper

thread

thread,

CHANGING

(A,

Turn

until

behind

needles

of

the

shank

to

the

involved

1 ).

Parts

the

guide

continues

the

by

the

eyelets

aid

thread,

No.

green

on

presser

Fig.

1)and

handwheel

needle

holding

presser

Loosen

observe

and

combination

THREADING

in

threading

are

thread

wire

stand

(D),

between

threading

numbers

and

guides

the

threading

yellow

color

3, 401

color

NEEDLES

foot

swinging

in

operating

screws

spring

screw

the

position

be

sure

eyelet

placed

(C)

down

tension

of

machine

assigned

on

the

process.

code;

needle

code.

by

turning

presser

direction

(A,

plunger

and

withdraw

of

the

needle

and

stop

are

shown

in

their

is

threaded

right

hand

discs (E),

to

to

each

machine for

Thus

thread

thread,

red

the

presser

arm

(away

Fig.

(B)

2)

and

needle.

the

flat

which

is

inserted

plate

in

threading

relative

hole

throu

and

posi-

gh

through slot

follow the r e

thread,

starting with

each threa

the sequenc

No.

2, 401

color

cod

(B)

are

ac-

(C).

each

up

e;

throu

Fig

pair

of

gh le

ft

(F),

and

commend

ed sequenc

thr

d have been

e is: thread

loop

er

thr

thread

No.

. 2

hol

es

hand

on

throu

ead No.

No.

ead,

4, ove

in the

hol

e.

gh

e

1.

colo

r

1,

blu

e

r-

4

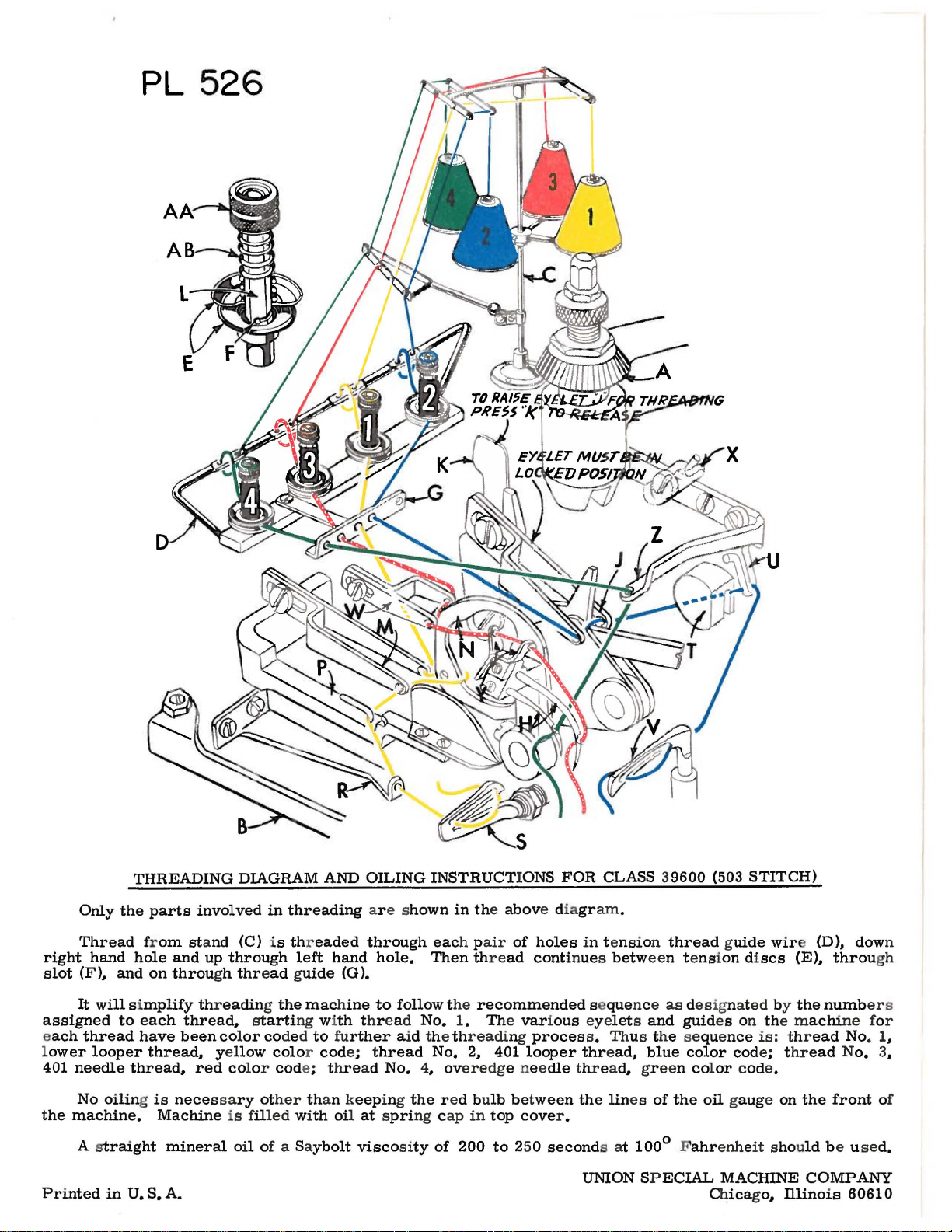

Page 5

PL

526

THREADING

Only

the

parts

Thread from stand (C) is thr

right

slot

assigned

e

l

401

the

Printed

(F),

It

ach

ower

needle

No oi

machine.

A s

hand

hole

on

each

have

thread,

thread,

Machine

U.S.

A.

and

throu

been col

necessary other than k

mineral

and

will simplify thr

to

thread

looper

ling is

traight

in

thread, starti

DIAGRAM AND

involved

up

through

gh

thread

eading the

or coded

ye

llow

red color

is f

ill

oil

of a Sa

in

threading

eaded

left

guide

machine

ng with

to further

color cod

cod

e; thread

ed with

ybolt

OILING

through

hand

(G).

thr ead

e; t

eeping

oil

at spri

viscosity

INSTRUCT

ar e s

hown

eac

hole.

to

hread

Then thre

follow the

No.

aid th e threadi

No. 2, 401

No.

4, overedg

the

ng cap

of

IONS

in the

1.

r ed bu

200

abov

e diagram.

h p

air

of

holes

ad

continues between t ensi

recommended seque

The various

ng

proces

looper

e nee

lb bet

ween

in

top

cove

to

250

FOR

dle

r .

second

CLASS 3

in te

nsion thread guide

ey e

lets and

s. Thus the seque

thread, blue

thr ead, green col

the

lin

s at

UNION SP

9600

nce

as designat

guid

color

es

of

the

100° Fahr

ECIAL

(503

STITCH)

wir

on discs

ed

by

es on the m

nce

is:

thr

cod

e; thread No.

or cod

oil gauge on

enheit should

Ch

e.

MACHINE

icago,

illinois

e (D), down

(E),

throu

gh

the

numbers

achi

ne

for

ead No. 1,

the

front

be used.

COMPANY

60610

3,

of

Page 6

THREADING

(Continued)

Before

direction

presser

(B)

out

RAISE

LATCH

Be

tension

Double

looper

inside

guard

wheel

then

in

thread

entering

are

held

Double

thread

Return

latch

will

upper

stroke.

an

inch

into

left

DO

NOT

LOOP,

beginning

until

foot

of

position.

by

401

the

LOOPER

(K) AND

sure

discs

TO

thread

of

bracket

the

(E)

THREAD

end

of

eyelet

needle

(P)

operating

through

from

with

take-up

eyelet

knife

Insert

or

ey e, u

the

left

TO

end

to

snap

support

so

of

THREAD

of

eyelet

lower

into

double

thread.

sing about

THREAD

OTHERWISE

to

thread,

needles

turning

RAISING

threads,

and

in

diagonal

LOWER

lower

(M)

thread

and

through

direction

left

front.

hand.

401

401

looper

(J)

position

place.

block

end

LOOPER

MACHINE

swing

(H)

are

presser

THREAD

at

foot

TAKE-

cloth

their

release

UP

EYELET.

as

they

looper

from rig

cover

until

eye,

Left

LOOPER

from

Pass

(T),

of

Holding

come

slots

(F)

LOOPER

thread

ht

to

pull-off

eye

of

frame

heel

entering

eye

of

lower

(Thread

thread

left

by

pressing down.

(#2)

to rig

thread

and

over

thread

in rig

tweezers

from

(Thread

(#

left.

(N).

of

from

3/16 inch projection

WITH

NEEDL

WILL

NOT SEW!

plate

highest

EYELET

the

in

tension

1)

and

Lead

looper

lower

the

looper

and

ht,

when

under

hook

ht

eye

·n

left

E L

open, turn handwhe

position,

bu

shing

tension

No.

lead

NOTE:

loop

rear,

can

No.

lead

(A),

and swing presser arm

(J)

BY

thread

posts

1 -

Yellow

it

throu

(L

Thread

thread

back

thread

guid

r (S) i s

and then

be

threaded

2-Blue Color Cod

it

throu

the eyelet

When

knife

(U).

of

hand

of

OOP

eyelet

arm,

Bring needl

401

loop

er (V)

insert

thread

from

AROUND

into the g

el

in

oper a

release pressure

RELEASI

guide,

NG EYEL ET

are betw

).

Color Cod

gh

both

mu

st

e )

eyes of

pass

under hook

e (R). Turn hand-

all

the

way

to the lef

throu

eas

gh r ight ye,

ily

if twee

e )

gh

both

is

is

ey es

in rais

in

correct

ed

of

positio

roove

e a

rm

to

bottom

and

push

doubl

ed e

point

LOOPER.

nd

of threa

of twe

REMOVE

tin

g

on

een

low

er

throu

gh

of fabric

t;

zer s

loop

er

n.

positio

n

of the

of

throu

gh

d

ezer

s.

Lower

Thr adi

through

the

needle

back

eye

needl

to

of

e (H)

Tu

Pass

throu

gh

Th

nurl

k

se

ed t ens

cur

e pr ope r

TO

THREAD

ne

edle

ng

from

both

left

eyes

thread

the left

needle.

from

to

Raisin

front.

TO THREAD

r n h

andwheel in

ov

er edge nee

hole

in

top

e a

mount

ion

of

nuts

stit

401

NEEDLE

arm

to

bottom

to rig

ht,

of needle

cam

pull-off

the

top eye

g ne

edle

OVEREDGE

operatin

dle

thread

of stroke, turning

pass the doubled e

thread

(N), then

of needle arm eyelet (Y)

by

NEEDLE (Th

g d

(#

4)

cover needle threa

TH

tension

(AA,

ch

formation.

on the need

Fig. 1 ). T

Usin

(Thread No.

pull-o

rotatin

ire

ction until

und

d eyelet

READ

ension

g a post

ff

eye

throu

g ha

ndwhe

read No. 4-

er ove

TENSION

le and

on

6

3-

Red

handwheel

nd

of

let

(W),

gh n

eedle thread

passing over the

into

el i n

operatin

the needle

rhanging arm

(Z).

loop

Thread needle (H)

er thr

the threads

al

scal

e,

the

Color Code)

in ope

ratin

g dir e

ction.

the 401 needle thread (#

outside

frame eyelet

lower

Green

is

at its

of

eads

should

eye

g di

rection,

Color Cod

hig

top

cov

is reg

be

measurement

and

hest pos

er a nd down

ulat

only

(X)

finally

thread

e)

ition.

from

ed

front.

by

enough to

s a r e t

and

the

aken

3)

of

to

Page 7

THREAD

TENSION

(Continued)

with

the

As a start

401

Overedge

401

Lower

Further

adjusting

needles

the

needle

at

tensions

thread;

needle

looper

thread;

looper

refinement

instructions.

the

top

of

may

be

3

112

thread;

1

112

thread; 4 to

in

tension

their stroke

as

follows:

oz.

straight

1

to

1 1 I 2

to 2 oz.

4 1 I 2

oz.

adjustment

Sufficient

be

maintained.

decrease

lock

nut

Adjusting

increases

When

set,

on

under

from

cap

pressure

tighten

the

the

(D) ag

throat

surface

and

out

oz.

straight

straight

PRESSER

pressure

amount

(A,

Fig.

screw

the

pressure,

lock

plate,

is

top

surface

ainst

pulled

of

lower

straight

out

out

is

out

of

looper

of

frame

discussed

FOOT

to

Should

of

3)

it

pressure

and

has a right

loosening

adjusting

nut

(A).

position

approximately

of

the

locking

in

the

direction

eye

of

of

thread

thread

looper

at

PRESSURE

feed

work

be

necessary

on

turn

the

hand

screw

With

locking

adjusting

nut

(C).

needle

guide

the

conclusion

presser

adjusting

thread

decreases

(B)

has

presser

nut

1132

screw

as indicated.

arm

eyelet

(G).

eyelet

thread

(U).

guide

uniformly

to

increase

foot,

screw

so

tightening

pressure.

been

foot

(C)

so

inch

to

1116

(B).

(Y).

(R).

of

the

should

loosen

(B).

properly

resting

that

its

inch

Set

the

or

Fig.

It

will

be

noted

eccentric

mately

wise

is

the

number

specified,

No.

Generally

number

relation

of

operation.

4. 5, 6,

36,

may

The

40.

be

of

stitches

to

the deg

following

1.

a. 9,

Only

two

ordered

numb r suffixed

It

is

suggested

sewing

and

parts.

lower

knife

3

that

the

part

39540

of

stitches

B-12.

machine

speaking,

produced;

ree

and

stitch

10.

11.

eccentrics

separately.

to

indicate

ASSEMBLING

that

the

remove

hold

cloth

er

assembly.

selected

number

Minor

obtainable

will

be

differential

the

direction

number

12. 13,

are

To

number

AND

follow

plate,

Feed

to

of

numbers

shipped

main

of

feed

14,

supplied

order

an

of sti

ADJUSTING

ing sequ

fabric

FEED

eccentrics

produce

both

the

when

with

(right

above

hand)

(left

stretch

eccentrics

15, 16.

with

each

eccentric,

tches

ence

guar

d,

ECCENTRICS

used

in

approximately

main

of

using

the

feed

part

that

eccentrics.

feed

hand)

of

1a.

feed eccentr

material

are

available

20.

22. 24.

machine.

use No.

desired.

SEWING

be

follow

ed.

chip guard,

this

m a

chi

ne

12

stitches

and

the

differential

symbol

eccentric.

eccentric

bein

indicate

ic

g

sewn,

Unless

determin

is

selected

or the

und r No.

26,

28,

30,

Additional

eccentrics

39540 B with a minor

Example: 1139540

PARTS

Before

upper

assem

knife assem

have been

per inch.

feed

approxi-

other-

es

the

in

type

39540

B:

32, 34.

B-12".

bling the

bly

7

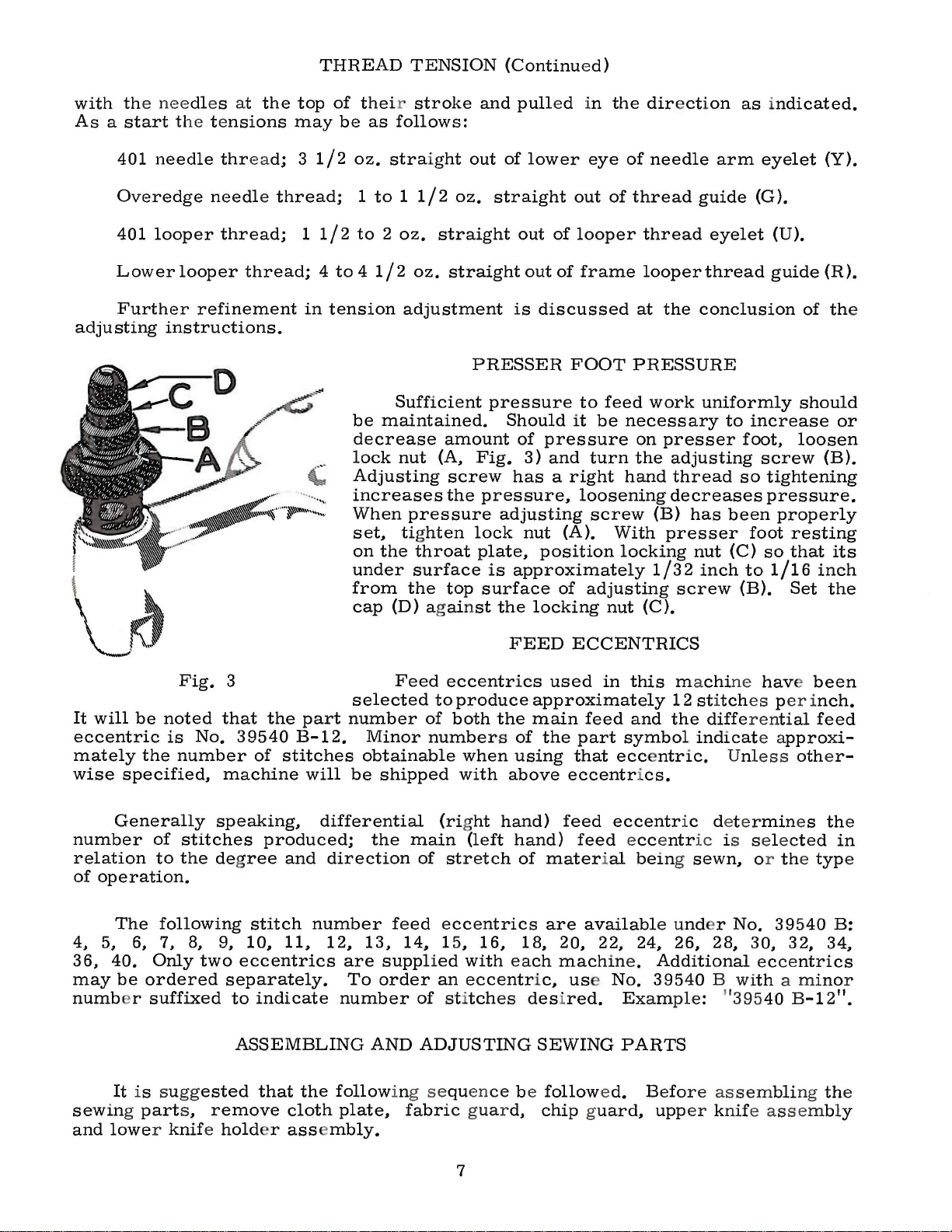

Page 8

SETTING

THE

NEEDLES

Release

position.

Type

154

holes,

that

the

position

With

center

loosen

the

left

used

this

gauge

until

to

gauge

in

needle

contact

been

obtained

Remove

If

gauge

by

measuring

throat

the

pressure

Insert

GAS

both

for

respectively,

butt

ends

with

clamp

throat

in

the

clamp

or

set

the

plate

throat

screw

right

needle

remove

its

place.

driving

the

throat

and

throat

plate.

No.

21227

17/32

plate,

when

needles

the

of

contact

screws

assembled

plate

(B,

as

required.

driving

the

Be

arm

plate.

needles

inch

needle

on

presser

(Type

overedge

the

needle

the

(A,

needle

Fig.

left

needle

sure

is

gauge

at

Tighten

have

CR

is

not

from

driving

stop

Fig.

in

4)

and

Gauge

arm

its

lowest

available

the

arm

158

GJ

stitch)

driving

plate.

2 ).

position,

holes.

move

No.

at

the

(401

seats

clamp

been

401

arm

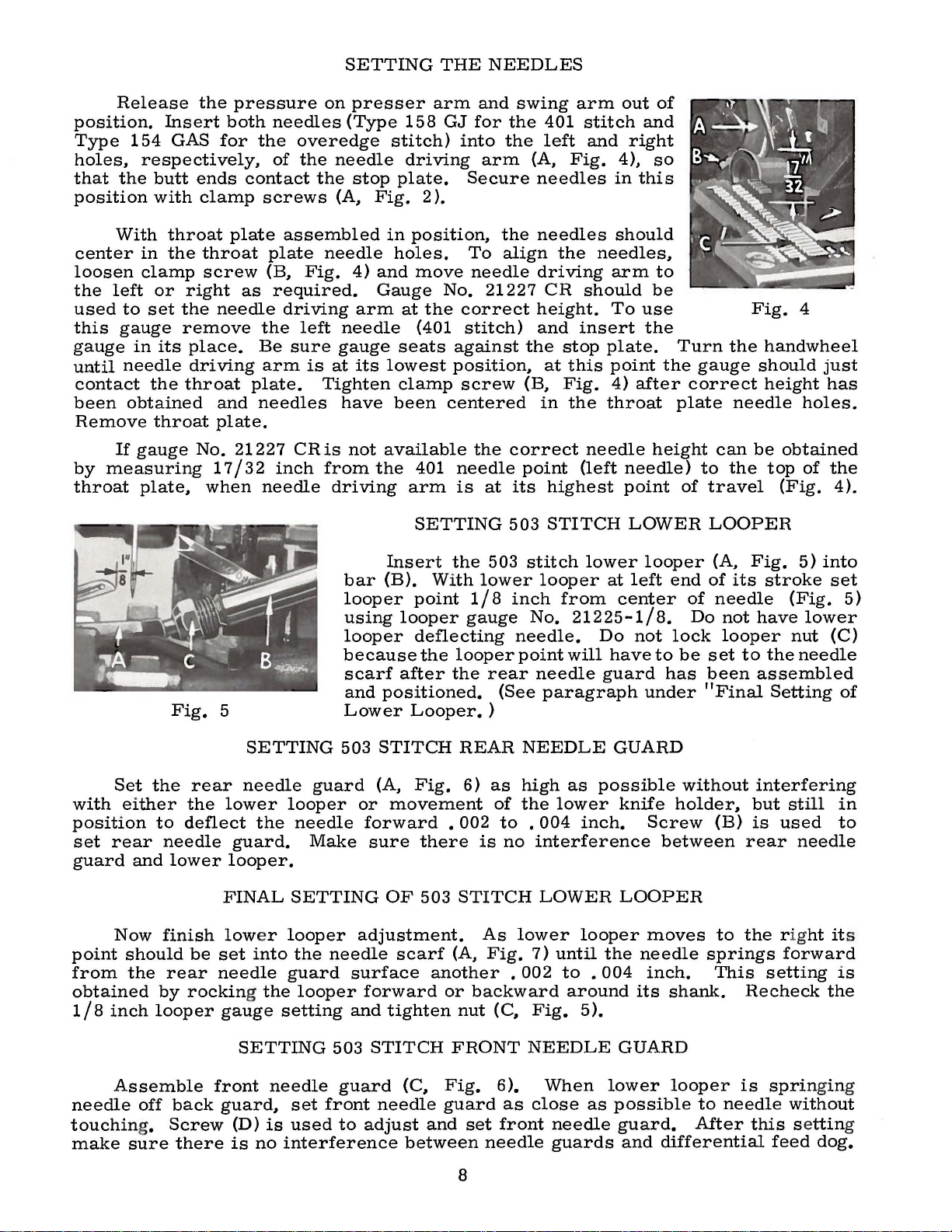

SETTING

and

for

the

into

the

arm

Secure

the

To

align

needle

21227

correct

stitch)

against

position,

screw

centered

the

needle

is

at

503

swing

401

left

(A,

needles

needles

the

driving

CR

height.

and

the

at

(B,

in

correct

point

its

highest

STITCH

arm

stitch

and

Fig.

should

insert

stop

this

Fig.

the

needle

(left

out

and

right

4),

so

in

this

should

needles,

arm

to

be

To

use

the

plate.

point

4)

after

throat

height

needle)

point

LOWER

of

the

plate

Turn

gauge

correct

to

of

travel

LOOPER

the

needle

can

the

Fig.

4

handwheel

should

height

holes.

be

obtained

top

of

(Fig.

just

has

the

4).

Set

with

either

position

set

rear

guard

and

Now

point

from

should

the

obtained

1/8

inch

Fig.

the

rear

the

to

deflect

needle

lower

finish

be

rear

by

rocking the

looper

5

SETTING

needle

lower

the

guard.

looper.

FINAL

low

er

set

into

needle

gauge

bar

looper

using

looper

because

scarf

and

Lower

503

guard

looper

needle

Make

SETTING

looper

the

needle

guard

looper

setting

Insert

(B).

point

looper

deflecting

the

after

positioned.

Looper.

STITCH

(A,

Fig.

or

movement

forward

sure

OF

there

503

adjustment.

scarf

surface

forward

and

tighten

the

503

stitch

With

lower

1/8

gauge

looper

inch

No.

needle.

looper

the

rear

(See

point

needle

paragraph

)

REAR

6)

• 002

STITCH

(A,

NEEDLE

as

high

of

the

to . 004

is

no

As

lower

Fig.

interference

LOWER

7)

another • 002

or

backward

nut

(C,

Fig.

lower

at

from

center

21225-1/8.

Do

will

have

guard

GUARD

as

possible

lower

knife

inch.

LOOPER

looper

until

the

to • 004

around

5).

looper

left

not

to

has

under

Screw

between

moves

needle

inch.

its

(A,

end

of

of

Do

lock

be

set

been

"Final

without

holder,

springs

shank.

Fig.

its

needle

not

have

looper

to

assembled

interfering

but

(B)

is

rear

to

the

This

Recheck

5)

stroke

(Fig.

lower

nut

the

needle

Setting

still

used

needle

rig

ht its

forward

setting

into

set

5)

(C)

of

in

to

is

the

Assemble

needle

touchin

make

off

g.

sure

back

Screw

there

SETTING

front

guard,

(D)

is

no

needle

is

interference

set

used

503

guard

front

to

STITCH

(C,

needle

adjust

between

FRONT

Fig.

guard

and

8

set

needle

NEEDLE

6).

as

close

front

When

needle

guards

GUARD

lower

as

possible

guard.

and

looper

to

is

needle

After

differential

springin

without

this settin

feed

dog.

g

g

Page 9

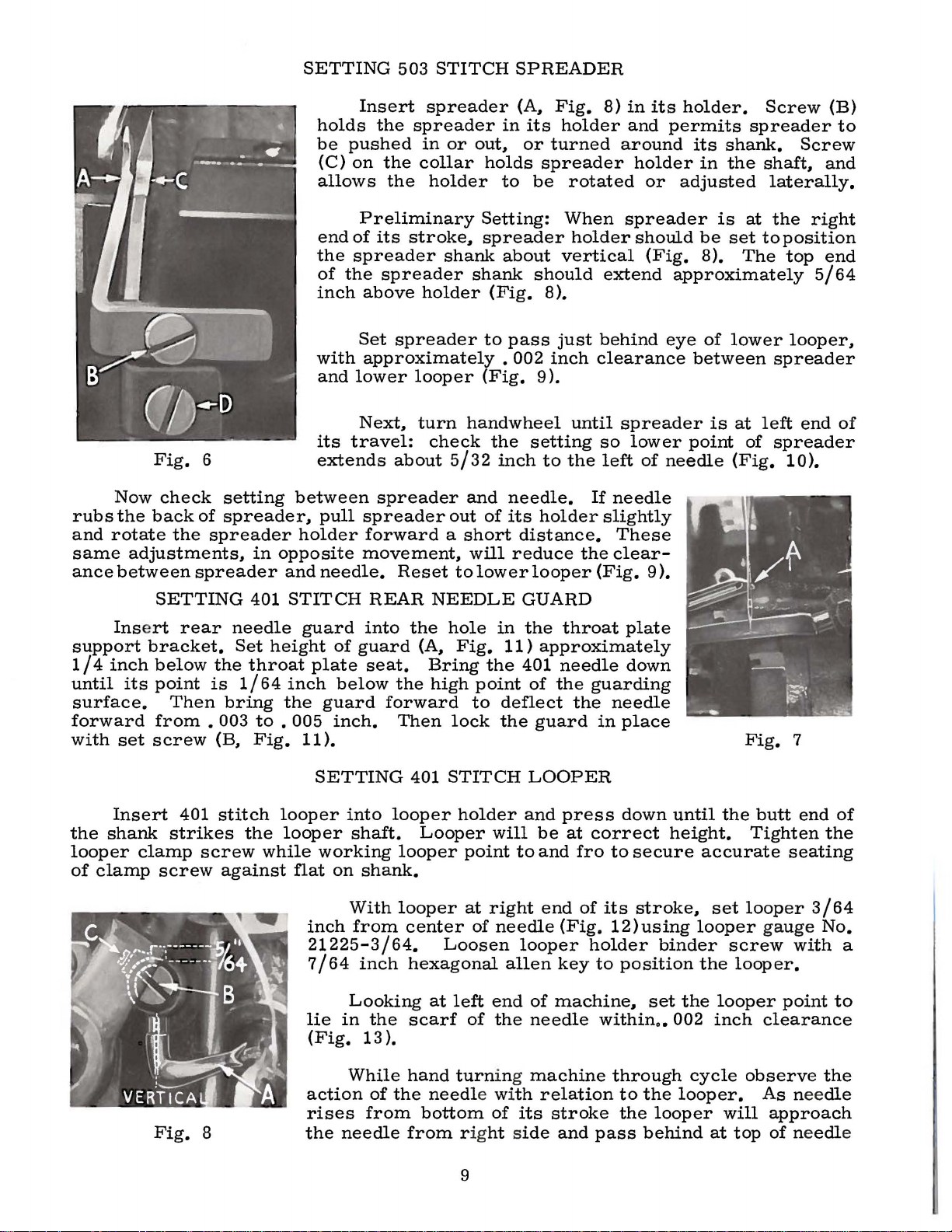

SETTING

503

STITCH

SPREADER

rubs

and

same

ance

Fig.

Now

check

the

back

rotate

the

adjustments,

between

6

setting

of

spreader,

spreader

in

spreader

holds

be

(C)

allows

end

the

of

inch

with

and

its

extends

between

pull

holder

opposite

and

needle.

Insert

the

pushed

on

Preliminary

of

its

spreader

the

above

Set

spreader

spreader

in

the

collar

the

holder

stroke,

shank

spreader

holder

spreader

or

out,

shank

holds

Setting:

spreader

(Fig.

to

approximately • 002

lower

Next,

travel:

spreader

looper

turn

check

about

spreader

(Fig.

handwheel

the

5/32

inch

and

out

of

forward a short

movement,

Reset

will

to

lower

(A,

in

its

or

spreader

to

be

about

should

8).

pass

9 ).

setting

to

needle.

its

holder

distance.

reduce

looper

Fig.

holder

turned

rotated

When

holder

vertical

just

inch

until

the

If

the

8)

in

its

and

around

holder

or

spreader

should

(Fig.

extend

behind

eye

clearance

spreader

so

lower

left

of

needle

needle

slightly

These

clear-

(Fig.

9 ).

holder.

permits

its

in

adjusted

is

be

8).

Screw

spreader

shank.

the

shaft,

laterally.

at

set

to

The

the

approximately

of

lower

between

is

point

at

of

spreader

left

spreader

(Fig.

(B)

to

Screw

and

right

position

top

end

5/64

looper,

end

of

10).

Insert

support

1/4

inch

until

its

surface.

forward

with

set

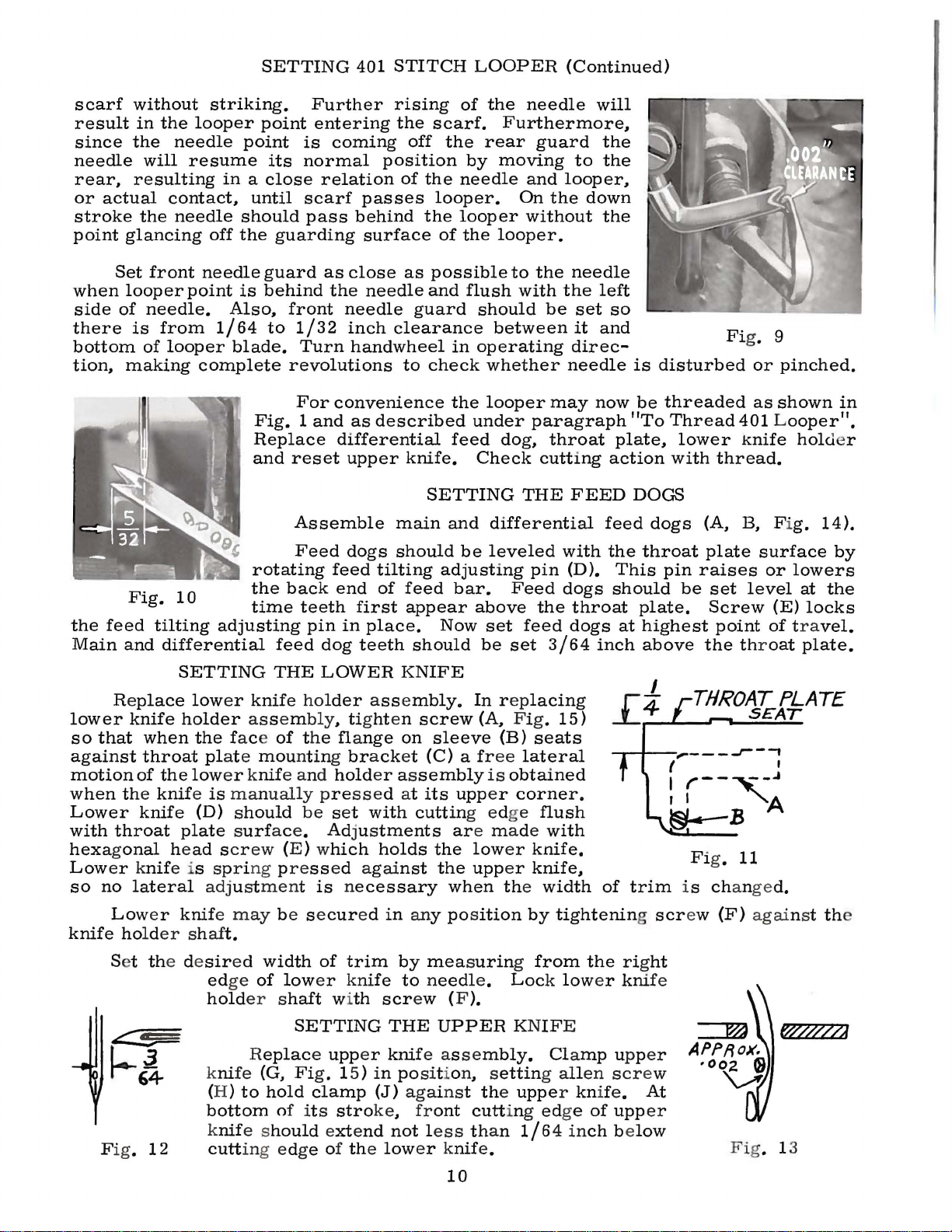

Insert

the

shank

looper

of

clamp

SETTING

rear

bracket.

below

point

Then

from

screw

401

strikes

clamp

screw

needle

Set

the

is

1/64

bring

• 003

(B.

stitch

screw

against

401

STITCH

height

throat

inch

the

to • 005

Fig.

looper

the

looper

while

flat

REAR

guard

plate

of

into

guard

seat.

below

guard

forward

inch.

11).

SETTING

into

shaft.

working

on

shank.

With

inch

from

21225-3/64.

7/64

inch

Looking

lie

in

the

(Fig.

13

).

NEEDLE

the

hole

(A,

Bring

the

high

Then

401

STITCH

looper

Looper

looper

looper

center

Loosen

hexagonal

at

scarf

Fig.

the

point

to

lock

holder

point

at

of

left

of

GUARD

in

the

11 )

401

of

deflect

the

LOOPER

and

will

to

right

needle

looper

allen

end

the

throat

plate

approximately

needle

the

the

guard

press

be

at

and

end

(Fig.

fro

of

down

guarding

needle

in

place

down

correct

to

its

12)using

holder

key

to

position

of

machine,

needle

within

until

height.

secure

stroke,

binder

set

••

002

the

accurate

set

looper

the

the

looper

inch

Fig.

butt

Tighten

looper

gauge

screw

looper.

clearance

7

end

the

seating

3/64

No.

with

point

of

a

to

Fig.

8

action

rises

the

needle

While

of

the

from

hand

turn

needl

bottom

from rig

9

ing

e wi

th

of

ht side

machine

relation

its

stroke

and

through

to

the

pass

cycle

the

looper.

looper

behind

will

at

observe

As nee

approach

top

of needl

the

dle

e

Page 10

SETTING

401

STITCH

LOOPER

(Continued)

scarf

result

since

needle

rear,

or

actual

stroke

point

Set

when

side

of

there

bottom

tion,

the

feed

Main

without

in

the

the

needle

will

resulting

contact,

the

needle

glancing

front

looper

needle.

is

from

of

looper

making

Fig.

10

tilting

and

differential

striking.

looper

point

resume

in a close

should

off

the

needle

point

is

Also,

1/64

blade.

complete

adjusting

Further

point

entering

is

its

normal

relation

until

scarf

pass

guarding

guard

as

behind

front

to

1/32

Turn

revolutions

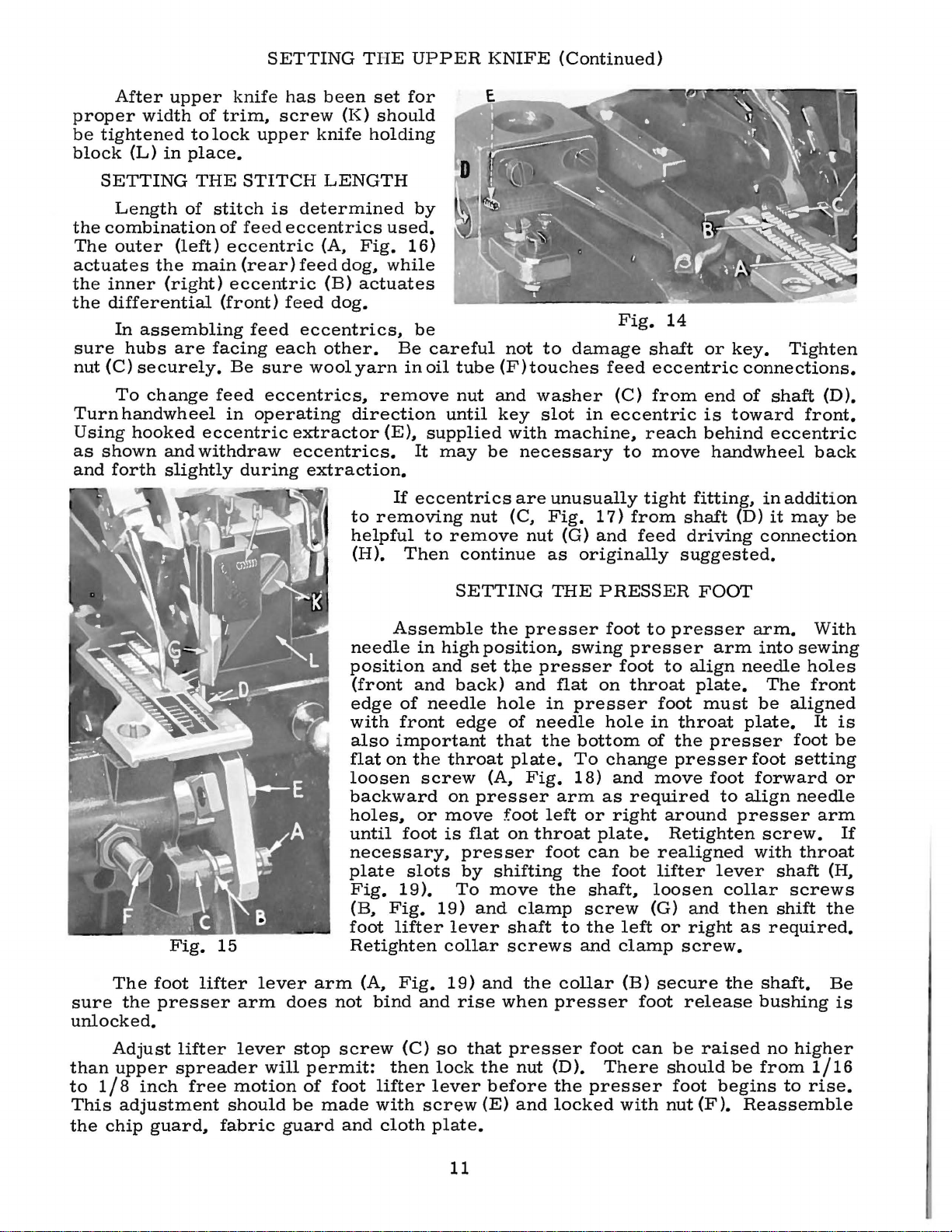

For

Fig. 1 and

Replace

and

reset

Assemble

Feed

rotating

the

back

time

teeth

pin

feed

dog

rising

the

coming

off

position

of

passes

behind

surface

close

the

needle

inch

as

needle

guard

clearance

handwheel

to

convenience

as

described

differential

upper

knife.

main

dogs

feed

end

in

tilting

of

first

place.

teeth

should

feed

appear

should

of

the

needle

scarf.

the

the

looper.

the

of

possible

and

Furthermore,

rear

by

moving

needle

looper

the

looper.

to

flush

and

On

without

with

should

between

in

operating

check

the

whether

looper

under

feed

dog,

Check

SETTING

THE

and differential

be

leveled

adjusting

bar.

Feed

above

Now

set

feed

be

set

will

guard

to

looper,

the

down

the

needle

the

left

be

set

it

and

direc-

needle

may

now

paragraph

throat

cutting

FEED

with

pin

(D).

dogs

the

throat

dogs

3/64

inch

the

the

the

so

is

be

"To

plate,

action

DOGS

feed

the

This

should

plate.

at

disturbed

threaded

Thread

lower

with

dogs

throat

pin

be

highest

above

Fi

thread.

(A,

plate

raises

set

Screw

point

the thr

g. 9

or

as

401 L

knife

B,

surface

or

level

(E)

of tra

oat

pinched.

shown

ooper".

hold

Fi

g.

14).

lowers

at

the

locks

vel.

plate.

in

er

by

SETTING

Re

place

lower

so

knife

that

against

motion

of

when the

Lower

with

knif

throat

when

throat plat e

low

holder asse m

the

the

low

knife is man

e (D) s

plate surf

hexagonal head

Low

er k

nif

e i s spr i

so

no

lateral

Low

er

knife may

knife hold

er shaf

Set the de

Fig.

12

er

knife hol

THE

LOWER

der assembly.

bly, tight

face

of

the fla

mounting brack

er k

nif

scr

e and

ually pre

hould

ace.

ew

(E ) w

be

hold

set

Ad

hich

sse

jus

ng pressed against

adj

ust

ment is necessary

be s e

cur

ed

t.

sir

ed

width

ed

ge

of

hold

er shaft with

low

of

er

trim

kni

SETTING

R

ni

fe

k

to

(H)

bottom

nif

e s

k

eplace upp

(G,

Fi

hold

clamp

of its

hould extend

er

g. 15) in posi

stroke, front

cutting edge of the

KNIFE

In rep

en

nge

screw

on

sleeve

(A, Fig.

(B)

et (C) a free

er as

d at

with

tments

holds

sembly

its

cuttin

the

the

is

upp

er

g edge

ar

e made

low

upp

when the

in any pos

by

measuring from

fe

to needle.

scr

ew (F ).

THE

knif

e assembly.

(J)

against the upper kn

ition

UPPER

tion, s

ettin

cutt

not less than

low

er k

nif

e.

lacing

15)

seats

lateral

obtained

corner.

flush

with

er

knife.

er

knife,

width

by

tightening scr

Lock low

KNIFE

Clamp

g allen

ing edge

1/64 in

-r--t-

___

of

trim

the rig

er

kni

ht

fe

upper

scre

w

ife .

of

upp

At

er

ch below

,_--

( I

1

I I

~-.,

r--,--.J

.""A

~B

Fi

g. 11

i s changed.

ew

(F)

agai

Fig

. 13

nst the

10

Page 11

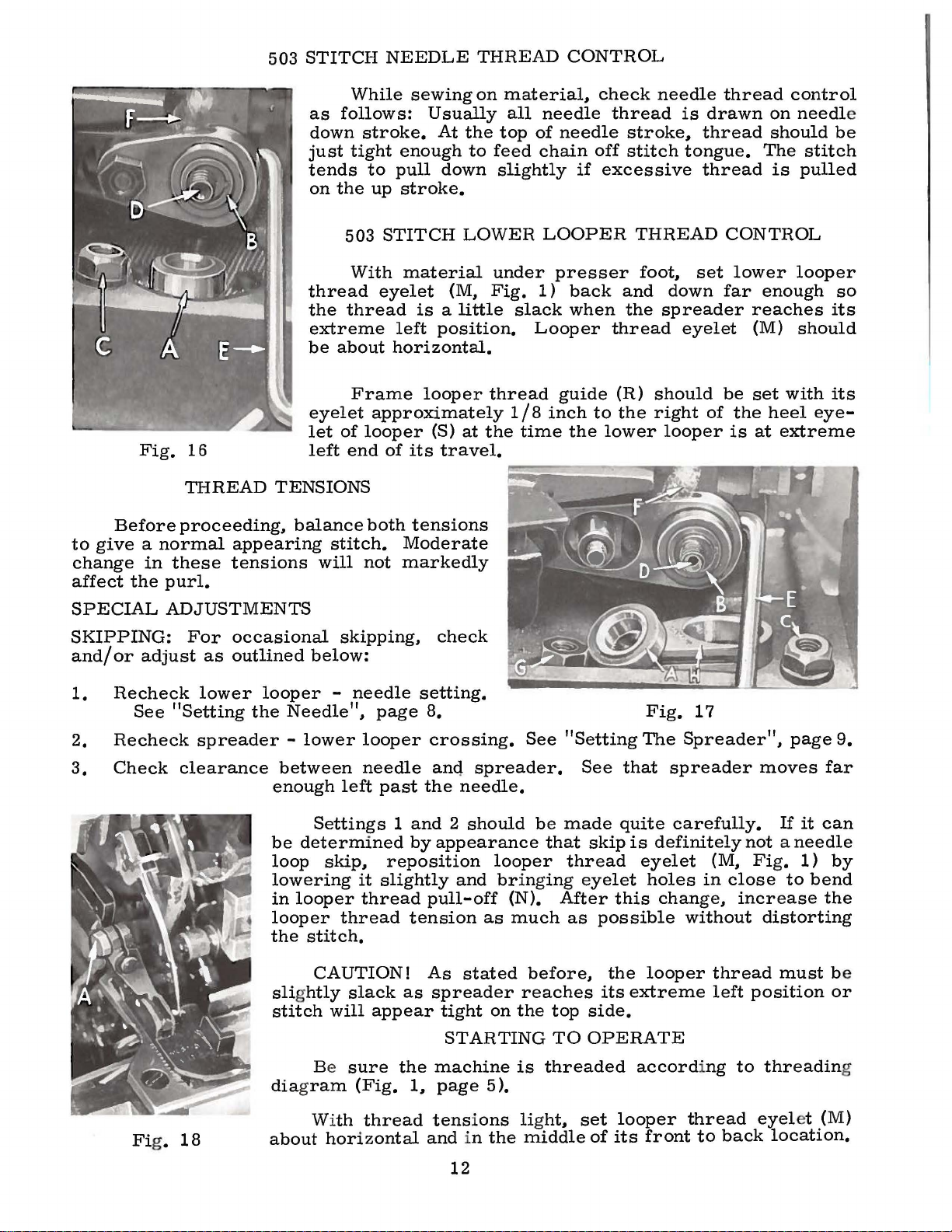

SETTING

THE

UPPER

KNIFE

(Continued)

After

proper

be

tightened

block

the

The

actuates

the

the

sure

nut

Turn

Using

as

and

(L)

SETTING

Length

combination

outer

inner

differential

In

hubs

(C)

To

handwheel

hooked

shown

forth

upper

width

assembling

securely.

change

of

to

in

place.

THE

of

(left)

the

main

(right)

are

and

withdraw

slightly

lock

stitch

facing

feed

eccentric

knife

trim,

upper

STITCH

is

of

feed

eccentric

(rear)

eccentric

(front)

feed

each

Be

sure

eccentrics,

in

operating

during

has

been

screw

eccentrics

feed

extractor

eccentrics.

(K)

knife

LENGTH

determined

(A,

feed

dog,

(B)

dog.

eccentrics,

other.

wool

extraction.

set

for

should

holding

by

used.

Fig.

actuates

yarn

direction

to

helpful

(H).

16)

while

be

Be

in

remove

(E),

It

If

eccentrics

removing

Then

careful

oil

tube

nut

until

supplied

may

nut

to

remove

continue

not

to

(F)touches

and

washer

key

slot

with

machine,

be

necessary

are

unusually

(C,

Fig.

nut

as

Fig.

damage

feed

(C)

in

eccentric

17)

(G)

and

originally

shaft

eccentric

from

reach

to

move

tight

from

feed

14

or

key.

end

is

toward

behind

handwheel

fitting,

shaft

driving

suggested.

Tighten

connections.

of

shaft

eccentric

in

(D)

it

connection

(D).

front.

back

addition

may

be

The

sure

unlocked.

the

Fig.

foot

lifter

presser

15

lever

arm

arm

does

Assemble

needle

position

(front

edge

with

also

important

flat

on

loosen

backward

holes,

until

necessary,

plate

Fig.

(B,

Fig.

foot

lifter

Retighten

(A,

not

bind

in

and

of

needle

front

the

screw

or

foot

slots

19).

Fig.

and

SETTING

high

position,

and

set

back)

edge

throat

on

presser

move

is

flat

presser

by

To

19)

and

lever

collar

19)

and

rise

the

presser

tbe

and

hole

of

needle

that

plate.

(A,

Fig.

foot

on

throat

shifting

move

clamp

shaft

screws

the

when

THE

swing

presser

flat

in

presser

the

bottom

To

18)

arm

left

or

foot

can

the

the

shaft,

screw

to

the

and

collar

presser

PRESSER

foot

to

presser

presser

foot

to

on

throat

foot

hole

in

of

change

and

move

as

required

right

plate.

foot

be

realigned

lifter

loosen

(G)

left

clamp

(B)

secure

foot

around

Retighten

or

FOOT

arm

align

plate.

must

throat

the

presser

presser

foot

to

lever

collar

and

right

screw.

the

release

arm.

into

needle

The

be

plate.

foot

forward

align

presser

screw.

with

then

as

required.

shaft.

bushing

With

sewing

holes

front

aligned

It

foot

setting

needle

throat

shaft

screws

shift

is

be

or

arm

If

(H,

the

Be

is

than

to

This

the

Adjust

upper

1/8

adjustment

chip

inch

guard,

lifter

spreader

free

lever

motion

should

fabric

will

guard

stop

permit:

of

be

made

screw

foot

and

(C)

then

lifter

with

cloth

so

lock

lever

screw

plate.

11

that

the

before

(E)

presser

nut

(D).

the

and

locked

foot

can

There

presser

with

be

raised

should

foot

nut

(F).

no

be

from

begins

Reassemble

higher

1/16

to

rise.

Page 12

503

STITCH

NEEDLE

THREAD

CONTROL

Fig.

Before

to

give a normal

change

affect

in

the

16

THREAD

proceeding,

appearing

these

tensions

purl.

While

as

follows:

down

just

stroke.

tight

tends

on

the

503

With

thread

the

thread

extreme

be

about

Frame

eyelet

let

of

left

end

TENSIONS

balance

stitch.

will

sewing

Usually

At

the

enough

to

pull

down

up

stroke.

STITCH

LOWER

material

eyelet

(M,

is a little

left

position.

horizontal.

looper

approximately

looper

both

of

its

tensions

(S)

at

travel.

Moderate

not

markedly

on

to

thread

the

feed

under

Fig.

slightly

material,

all

needle

top

of

chain

LOOPER

presser

1)

slack

Looper

guide

1/8

inch

time

check

needle

off

if

excessive

back

when

to

the

lower

needle

thread

stroke,

stitch

THREAD

foot,

and

the

thread

(R)

should

the

right

thread

is

drawn

thread

tongue.

thread

set

down

far

spreader

eyelet

be

of

looper

control

on

needl

should

The

stitch

is

pulled

CONTROL

lower

looper

enough

reaches

(M)

should

set

with

the

heel

is

at

extreme

e

be

so

its

its

eye-

SPECIAL

SKIPPING:

and/

or

adjust

1.

Recheck

See

2.

Recheck

3.

Check

ADJUSTMENTS

For

occasional

as

outlined

lower

"Setting

spreader

clearance

looper

the

between

Needle",

-

enough

be

loop

lowering

in

looper

looper

the

slightly

stitch

skipping,

check

below:

-

lower

left

needle

looper

needle

page

past

setting.

8.

crossing.

anq

the

needle.

spreader.

Settings 1 and 2 should

determined

skip,

it

thread

thread

by

appearance

reposition

slightly

pull-off

tension

and

as

stitch.

CAUTION!

slack

will

appear

As

as

spreader

stated

tight

STARTING

See

be

that

looper

bringing

(N).

much

before,

reaches

on

the

"Setting

See

made

skip

thread

eyelet

After

as

possible

top

side.

TO

OPERATE

that

quite

is

this

the

its

extreme

Fig.

The

17

Spreader",

spreader

carefully.

definitely

eyelet

holes

change,

without

looper

not a needle

(M,

in

close

increase

thread

left

position

page

moves

If

it

Fig.

to

1)

bend

distorting

must

9.

far

can

by

the

be

or

Be

Fi

g.

18

diagram

Wi

about

horizontal

sure

th

(Fig.

thread

the

machine

1,

page 5 ).

tensions lig

and

in

12

the

is

threaded

ht,

middle

set

of

according

looper

its

front

thread

to

back

to

threadin

eyel

g

et (M)

location.

Page 13

STARTING

TO

OPERATE

(Continued)

inch.

and

Set

then

needle

bring

is a starting

described

corner

of

the

SETTING

If

looper

refer

to

the

Cast-off".

20)

7/32

several

while

direction

thread

thread

Fig.

inch

feet

checking

until

straight

eyelet,

1)

to 1 1/2

Fig.

position

under

19

thread

it

forward

"Sewing

bed

casting.

401

thread

eyelet

1/8

for

this

Off 401

LOOPER

casting-off

paragraph 11Timing

Set

the

of

looper

below

thread

the

tension.

the

needle

toward

adjust

thread

crotch

through

is

the

tension

to 2 ounces.

(X.

inch,

eyelet.

Thread

THREAD

point

401

of

cast-off

the

Turn

totally

operator,

with

Operate

in

place.

the

tongue

SETTING

Bring

eyelets

paragraph

the

needle.

Position

so

that

needle

ward

to

needle

thread

Fig.

tilt

1)

slightly

Later

Stitch".

needle

EYELETS

has

Stitch

cast-off

blade

looper

to

handwheel

raised.

over

the

knurled

Make

freely.

needle

as

shown

"To

Lower

needle

the

thread

bow

arm

is

will

clear

to

the

it

The

from

not

been

Looper

eyelet

(B).

provide

in

Pulling

the

machine

sure

401

NEEDLE

thread

in

Thread

needle

thread

thread

pull-off

the

needle

at

the

the

rear,

upward

may

tail

front

have

of

to

timed

Thread

(A,

Fig.

Pull

slack

operating

the

looper

nut

(AA,

slowly,

chain

Fig.

401

pull-off

is

at

cam

thread

top

pull-off

against

and

to

the

back.

forms

THREAD

through

1

and

Needle".

to

bottom

the

middle

(N)and

of

its

cam

the

tighten

be

adjusted

eyelet

with

presser

and

EYELETS

its

as

described

Do

of

eyelet

mark

far

slightly.

stroke,

by

mounting

the

screw.

may

Fig.

moves

respective

not

thread

its

stroke.

(W,

Fig.

of

enough

When

the

needle

about

1/32

screw,

This

slightly

rest

on

20

foot

off

in

1)

the

for-

the

as

the

Final

observing

foot

and

the

needle

formation

overedge

Fig.

adjustments

the

stitch

observe

thread

is

as

shown

needle,

less.

arm

and,

A

desired

at

the

needle

More

The

enters

21

tight

to

formation.

formation

take-up

in

yet

be

round

To

to

top

using

slight

result.

Needle

two

separate

cam

as

thread

needle

needle

the

when

SEWING

the

401

stitch

Insert

of

the

eyelet

Fig.

(W,

21.

and

lower

the

position

needle

movement,

Then

thread

times.

shown

is

drawn

thread

thread

material.

the

needle

OFF

are

two

needle

Fig.

The

loop

full.

eyelet

and

insert

arm

as

of

1/64

retighten

is

drawn

between

as

will

becomes

The

reaches

13

401

made

narrow

loop

upon

1)

by

should

At

full

tap

left

support,

inch

from

Thread

the

the

be

drawn

slack

needle

STITCH

while

plies

the

raising

not

speed

side;

wide

blade

or

the

eyelet

the

is

first

marks

needle

the

just

thread

the

bottom

hand

of

rising

or

touch

the

to

raise

screwdriver

twist

less,

holding

cone

drawn

(A,

Fig.

reaches

first

before

should

of

turning

the

material

of

the

lowering

the

front

loop

will

eyelet

screwdriver

will

usually

screw.

on

the

upstroke

at

the

22).

The

the

top

time,

the

or

eye

become

its

stroke,

machine

under

needle.

it

until

guard

tend

to

bring

under

to

produce

high

second

of

its

at

point 11A".

of

the

snug

and

and

presser

Adjust

the

loop

of

become

needle

eyelet

the

left.

only

and

point

time,

stroke.

needle

but

should

the

the

of

not

Page 14

SEWING

OFF

401

STITCH

(Continued)

become

is

again

condition

thread

back.

Observe

take-up

The

looper

lobes,

As

the

needle

thread

until

again

nature

amount

slightly

at

occur

The

slack

drawn

it

frame

at

the

slack

will

the

tension

of

the

of

looper

down.

as

from

may

eyelet

the

bottom

thread

from

arm

begin

end

and

material

Use

the

needle

be

necessary

action

is

the

rises

to

of

the

the

of

the

thread

reverse

the

cone.

(X,

of

of

lying

previous

to

tighten

rise,

looper

looper

being

pull-off

raises

to

Fig.

1)

the

the

needle

across

the

top,

across

casting-off

thread

sewn

procedure

until

To

obtain

move

forward

looper

stroke.

the

casting-off.

the

the

will

thread

and

move

is a notch

movement

required,

when

this

developed

tight

up

thread

this

needle

or

thread

cain

looper

cam

will

lie

at

this

the

the

looper

to

obtain

If

the

time

looper

needle

in

the

crotch

position

operation

thread

less

in

the

with a screwdriver.

a

relaxed

the

needle

the

at

pull-off,

thread

loop.

will

performed.

looper

cast-off

looper

looper

is

at

tension

Fig.

of

be

cast-off

thread

blade

thread

thread

the

top

in

the

is

setting

will

interfere

22

the

cast-off

determined

To

increase

blade

(B, Fig.

pull-off.

to

facilitate

in

the

should

of

its

need

the

with

travel.

1 e

blade.

by

There

stitch

be

slack

thread,

stitch.

pulling

the

the

23)

this

is

At

A

When

shaft

vertically

needle

This

checked

the

needle

maintained.

ing-off

the

be

the

(Fig.

needle

the

the

(B,

holding

the

arm

adjustment

and

cam

arm

may

needle

cast-off

looper

24).

will

top

of

time

of

Fig.

screw.

Fig.

TIMING

the

401

cast-off

below

is

in

moved,

functions

shaft

If

this

be

timed.

(A,

Fig.

when

thread

At

this

be

approximately 1 /6 4 inch

front

casting-off,

23)

up

needle

or

23

looper

corner

top

surface

its

highest

is

made

it

as a thrust

and

correct

setting

24),

the

eye

against

position

move

down,

401

STITCH

thread

will

at

must

is

On

the

looper

of

the

the

guard

rotating

-

cam

be

of

the

bed

position

the

factory,

be

observed

collar

thrust

correct

down

thread

looper

left

side of

the

point

(C).

the

cast-off

Only

the

looper

and

eyelet

off

only

from

LOOPER

is

25/32

when

(Fig.

but

for

must

the

cast-

stroke

should

(B)

brings

needle

of

below

To

chan

blade

it

about

enough

thread

system.

during the

left

to

THREAD

correctly

inch

the

20).

if

that

the

be

of

the

ge

its

tension

to

return

right

and

CAST-OFF

positioned

should

resist

Thread

travel

cease

Fig.

friction

should

on

the

24

be

carried

of

be

of

the

at

casting-off.

needle

in

looper

pulled

looper

arm

14

Page 15

List

this

of

additional

catalog

parts

to a 504

required

stitch

39600

to

convert

machine.

the

503

stitch

39600

machine

covered

in

Part

No.

52 A

107

108

109

376

21101

22565

22768

22849

29477

35792

39508

39568

39568

39663

43139

51292

A

H-6

c

HU

H

A

E

L

H

A

F-5

Description

Frame

Tension

Tension

Eyelet~

Post

Post

for

Ferrule------------------------------------

Nut----------------------------------------

504

needle

thread

----------------------

TensionDisc--------------------------------------------

Screw~

Thread

Screw~

Screw~

Screw~

Upper

Looper

for

upper

Stand~

for

tension

for

504

for

504

Knife

Driving

Thread

looper

thread

eyelet

(39568

complete----------------------------------

post

needle

frame

thread

eyelet

Arm

(35792

pull-off

(52

Thrust

H)

------------------------eyelet

A)------------------------

Block

and

Tube-----------------------------------TensionPost-------------------------------------------Upper

Auxiliary

Upper

Neejle

Nut~

Tension

Looper-------------------------------------------

Eyelet~

Looper

Thread

for

upper

Spring~

for

Thread

Pull-off

looper

for

504

upper

looper---------------------

Eyelet------------------------------

Eyelet~

thread

504

needle

for

eyelet

thread

504

needle

screw

---------------------

L)

------------

(39663

504

Upper

thread--------

(376

A)-----------

H)-------

Amt.

Req.

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

ASSEMBLING

The

setting

guards

as

adjustments

used

needle

503

5/32

stitch

in

the

stitch

inch

spreader

to

spreader

and

described

for

the

504

stitch

formation.

dimension

(Fig.

the

point

or

the

adjustment

earlier

504

formation

from

10).

of

the

upper

AND

stitch.

The

the

upper

looper

ADJUSTING

of

the

needles~

for

the

503

Also~

is

similar

exception

center

The

504

looper

to

be

or

line

stitch

(Fig.

taken

Fig.

SEWING

stitch

the

adjusting and

to

the

difference

of

the

measurement

1 OA).

when

lOA

PARTS

lower

are

applicable

setting

needle

The

they

FOR

looper~

setting of

of

the

being

to

is

the

the

taken

measurement

are

at

504

STITCH

front

when

and

making similar

the

spreader

measurement

lower

point

from

the

left

end

rear

upper

used

the

for

needle

looper

in

of

of

the

center

either

of

travel.

the

the

503

of

the

15

Page 16

PL529

THREADI

Only the parts involv

Thread fro

r

ig

ht

hand hole an

sl

ot (F

),

and

on throu

It

wi

ll simplify threa

assigned

ea

ch thre

504

N

o.

N

o.

the machin

Pr inted

to each

ad have been

low

er

3, 504 upper

5, ove

No o

A s

loop

red

ili

ng

e.

traight

in

U.S.

ge nee

is

NG

m st a

d up throu

thr

ead, start

er thr e

loop

dle

necessary

Ma

chi

ne

mine

ral

A.

DIAGRAM AND OILING INSTRUCTIONS

ed in thr e

nd

(C)

is

gh thread

colo

ad, yellow

er thr e

gh l

ding the

r c

ad,

threa

other than

is filled with oil

oil

of a Saybolt vis

ading are s

threaded

eft

hand

guid

e

machine

ing

oded

d, green

with

to

color

black

throu

hol

lG

further

keeping

e.

).

to

thread

aid

code; thread

color

code; thread

color

code.

at

spring cap

cosity

hown

gh e

ach

Then thr

follow

No.

the

the

red

of

in the a

pair

ead

recommended

1.

The

thr

eading

No. 2, 401

No.

bulb

in

top

200

to

FOR

bove diagram.

of

holes

continues

various eyelets an

proce

loop

4, 401 nee

between

cover.

250 s

econds

CLASS 3

in

tension

between tension dis

sequence

ss.

Thus the sequence

er

the

lines

at

UNION SPE

9600

thread

as des

d g

thread, blue

dle

thre

ad, red color code;

of the

100° Fahrenheit

CIAL

Chicago,

(504

STITCH)

guide

wir e (D

cs (E

),

igna

ted

by

the

uides

on

the

machine for

is:

thread

color

oil gauge

MACHINE COMPANY

illinois

code;

on

the

should

60610

),

down

throu

number

No. 1,

thread

thread

front

be

used.

gh

s

of

Page 17

TO

REMOVE

CRANKSHAFT

Crankshaft

1.

Drain

of

base.

2.

Remove

3.

Remove

eccentric

4.

Remove

5.

Remove

be

6.

Remove

through

7.

Remove

assembling

marks

on

the

same

can

be

oil

by

removing

top

and

the

feed

extractor,

key

(H).

two

counterweights

reassembled

screw

bottom

caps

bearing

are

stamped

same

holes

side

from

withdrawn

plug

bottom

eccentric

slip

in

the

(K)

which

of

bed

casting.

of

bearings

caps

on

of

the

which

more

screw

covers

nut

off

the

(J).

proper

holds

on

make

both

halves

bearings.

they

were

Fig.

easily

if

located

of

machine.

and

washer

eccentrics

Identify

place.

crankshaft

crankshaft

sure

they

of

the

Also,

removed.

17

25

these

on

these

split

at

are

screws

back

(F#

(G).

points

in

caps

steps