Page 1

LEWI

S •

SEWING

MA

CHI

NES

NEST

QUALITY

STYLES

39500S

39500T

39500U

.

CLASS 39 500

No.

STREAMLINED

103U

Second

Edition

HIGH

SPEED

OVERSEAMERS

Page 2

Page 3

Catalog

INSTRUCTIONS

FOR

No.

103

U

39500

furnished

ADJUSTING

LIST

s

The

parts

at

list

CLASS

39500

listed

prices

Second

AND

OF

Styles

Edition

OPERATING

PARTS

39500

T

in

this

for

39500

catalog

repairs

u

are

only.

Union

Rights

MACHI

INDUSTRIAL

Copyright

Special

Reserved

NE

CHIC A

Printed

by

COMPANY

SEWING

in

1958

Machine

in

All

MACHINES

GO

U.S.A.

Countries

Co.

November,

1967

Page 4

Page 5

FOREWORD

The

streamlined

performance

precision

It

enable

Specials.

and

Union

anxious

Class

is

our

the

illustrate

to

39500

styling,

are

methods

constant

customer

The

following

and

Special

cooperate

machine

automatic

characteristics

insuring

aim

to

describe

representatives

with

complete

to

secure

pages

the

you

furnish

is

lubrication,

of

all

possible

contain

parts

will

to

plan

Union

these

interchangeability.

carefully

for

and

Special's

machines.

advantages

valuable

Styles

be

found

estimate

and

prepared

operating

in

in

~

latest

light

All

Class

all

manufacturing

requirements.

overedger.

running

parts

information

from

and

39500.

New

high

are

the

use

adjusting

MACHINECOMPANY

speed

made

that

will

of

Union

data,

centers,

by

3

Engineering

Department

Page 6

IDENTIFICATION

OF

MACHINES

Each

plate

Standard

the

letter

letter

is

suffixed

Styles

ber,

This

herein.

Class

back,

Operating

Single

chine.

Pressed

Union

on

the

Style

"Z".

"Z".

of

which

catalog

It

39500.

etc. , are

direction

Curved

Intermittent

Lower

39500 S For

materials.

Knee

foot

on

press

to

separate

stitch

Special

machine.

numbers

Example:

When

to

the

machines

contains

applies

can

also

All

taken

Blade

Knife,

seaming

Seam

controlled

length.

carries

Style

only

minor

standard

similar

no

letters.

APPLICATION

specifically

be

applied

references

from

of

handwheel

Needle,

Differential

Automatic

and

specification

top

and

a

Style

numbers

have

one

"Style

or

39500

changes

Style

numbe:r.

in

construction

Example:

to

with

to

directions,

the

operator' s position

is

STYLES

Two

OF

Looper,

Feed

Lubricating

intermittently

504-SSa-1.

tandem

bottom

intermittent

plies.

number

are

classified

more

letters

S".

aremade

Example: "Style

"Class

OF

the

standard

discretion

away

from

MACHINES

,

Trimming

gathering

Gathering

which

suffixed,

Special

Style

in a standardmachine,

are

grouped

39500

CATALOG

Styles

to

some

such

as

while

operator.

Three

Thread,

System.

on

knit

Standard

differential

ratio

is

stamped

as

standard

but

numbers

39500

under a Class

11

•

of

machines

special

right

and

seated

Overseamin

Mechanism

or

light

width

of

feed.

up

to 3 to 1 depending

in

the

and

special.

never

contain

contain the

SZ".

as

listed

machines

left, front

at

the

machine

g

with

weight

seam

Spring

woven

1/8

Slotted pres

nam

a

"Z"

num-

and

Ma-

inch

ser

e

in

.

.

39500

T

For

rial.

Knee

press

bottom

plate

39500

attachment.

U

For

rial.

Knee

press

bottom

plate

attachment.

CAUTION!

must

ounces.

1

00°

Fahrenheit

be

filled

A

Machine

at sig

ht

ga uge

between gau

seaming

Seam

specification

controll

grooved

seaming and

Seam

specification

controll

groov

ed

Oil was

before beg

straight

should

is

filled

on front

ge lines.

and

ed

tandem

for

1/8

inch

Gathe

ed ta

for

1 I 8 inch

Gathering

dr ained

inning

m i ner al o

be

with

oil

of

machine.

intermittently

504-SSa-1.

intermittent

cord. Independent

ring

ratio

intermittently

504-SSa-1.

ndem

intermittent

cord.

Independent

ratio

OILING

from

to

operate.

il

of a Saybolt

used.

at spring cap

Red

gathering

Standard

primarily

width

differential fee

swing-out

up

to 3 to

gathering

Standard

1 depe

primarily

width

differenti

ndi

al

swing-out aux

up

to 5 to 1 depending on

machine

in

bulb

wh

Oil

capacity

viscosity

top

cover.

on

oil

level

en s

of

hipped,

of

200

indicator

on

of

seam

d.

auxiliary

ng

on

on

of seam

feed.

iliary pres

Clas

s 395

to

250 s e

Oil

level

woven

Pr

sti

wov

mate-

3/16

inch.

esser foot

pr

es s

ure

tch

leng

th.

en m at e -

3/16

inch.

Presser foot

sure

stitch

s o r e s e

should

00

conds

is

checked

length.

rvoir

is

six

at

show

4

Page 7

THREAD

STAND

Afterthread

through

is

threaded

right

hand

tension

Only

Parts

It

are

will

threading

Before

ating

foot

of

direction

by

position.

Be

sure

tension

Double

eyelet

thread

of

heel

from

are

(E,

pull-off

frame

of

left

in

left

back

through

hole

discs

parts

placed

simplify

lower

beginning

turning

threads.

discs

end

Fig.

looper

lower

to

right.

hand.

comes

thread

and

(AD).

involved

in

looper

until

presser

(AD)

of

thread

1)

from

(T).

thread

looper

from

eyelet.

each

up

pair

through

through

in

their

relative

threading

first.

to

thread.

needle

foot

as

they

and

in

diagonal

TO

and

right

Lead

thread

guide

(K)

is

Left

eye

cone

then

down

of

holes

left

slot

THREADING

threading

this

machine

upper

swing

(N)

is

at

release

come

THREAD

lead

to

left.

behind

(G).

all

the

way

of

lower

on

thread

through

in

hand

hole.

(AE).

are

shown

positions

looper

cloth

high

position.

bushing

from

slots

the

(AE)

LOWER

it

through

Note:thread

fabric

Turn

handwheel

to

the

looper

stand

front

tension

Then

and

on

for

to

follow

second.

plate

( U);

tension

in

LOOPER

both

guard

left;

can

(V.

thread

thread

thread

through

in

threading

clarity.

recommended

and

open.

turn

release

and

swing

thread

tension

eyes

must

(F)

in

operating

then

thread

be

threaded

Fig.

guide

needle

pressure

posts

of

pass

and

presser

lower

1).

it

is

brought

eyelet

(W).

wire

continues

thread

guide

diagram

sequence

third.

handwheel

on

arm

guide,

are

(AC).

looper

in

front

through

direction

through

easily

if

Next

(A).

down

between

(Fig.

in

oper-

presser

(H)

between

thread

of

looper

both

holes

until

both

eyes

tweezers

up

it

(B).

1).

of

out

Turn

thread

through

through

both

threadmust

looper

and

push

thread

down

tube

CAUTION!

passing

from

Turn

highest

needle

hole

knurled

to

secure

in

The

position.

thread

top

amount

tension

handwheel

auxiliary

eyes

pass

in

tube

through

down,

then

Be

tube

handwheel

Insert

eyelet

cover

needle

of

nuts

proper

stitch

TO

until

of

upper

front

assembly

thread

insert

sure

upper

assembly

TO

in

operating

needle

(R),

thread

tension

(AA.

formation.

THREAD

point

looper

looper

of

looper

(M).

tube

assembly

thread

looper

to

upper

THREAD

thread

under

eyelet

THREAD

on

needle

Fig.

1).

UPPER

of

upper

thread

thread

thread

lead

through

thread

looper

direction

neck

of

and

Tension

LOOPER

looper

eyelet

eyelet

pull-off

thread

(M).

upper

is

eye.

THE

NEEDLE

until

from

(P).

top

right

cover

Thread

TENSION

looper

on

7

(L)

(D)

(C)

under

Pull

looper

under

needle

to

casting;

threads

threads

is

from

from

(T).

neck

thread

eye

lower

left.

needle

all

the

back

left

After

of

out

from

looper

(N.

through

then

from

is

should

way

left.

to

front,

to

right.

pulling

top

cover

bottom

front

thread

Fig.

1)

both

down

front.

regulated

be

only

Lead

then

Note:

up

upper

casting

of

tube;

to

back.

when

is

at

eyes

through

by

three

enough

its

of

Page 8

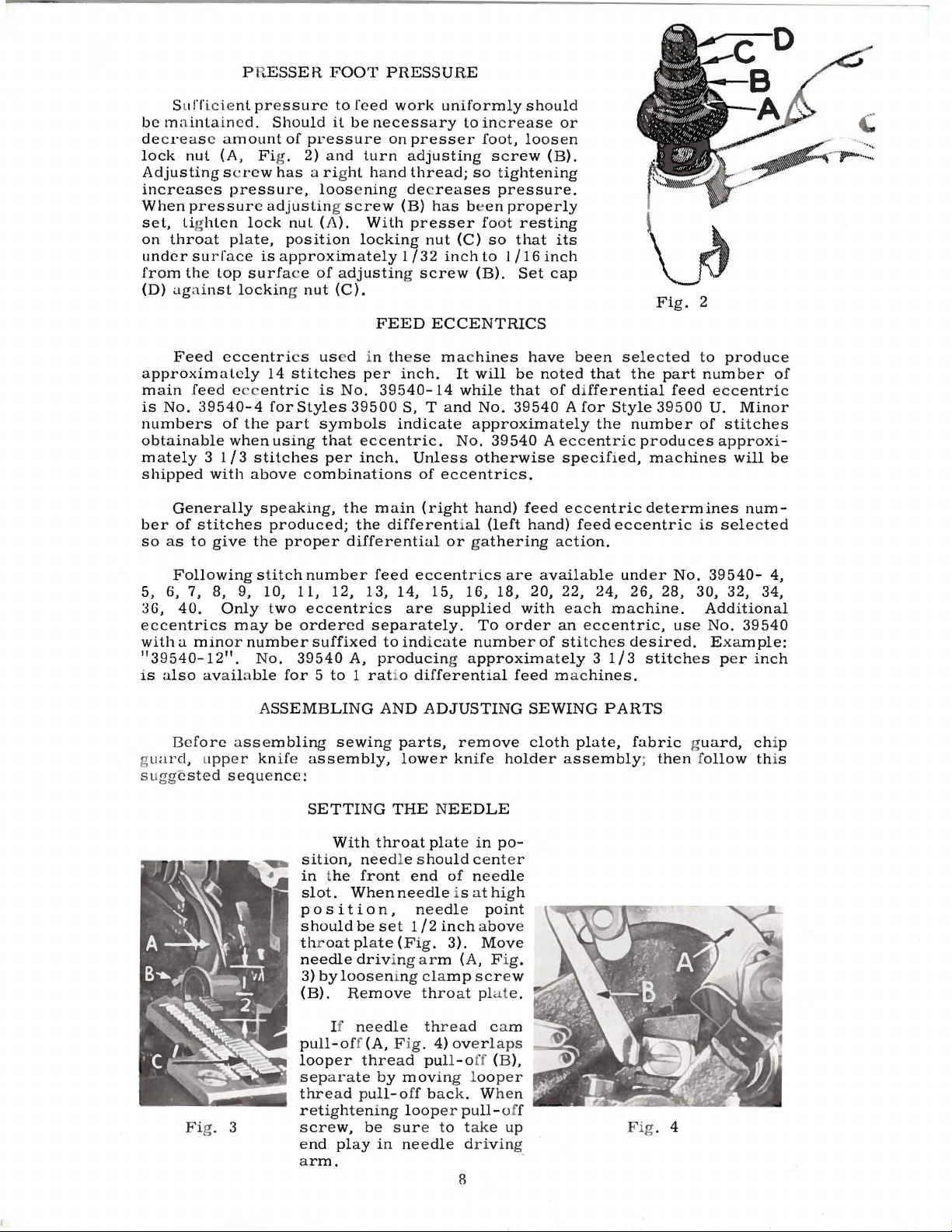

Suffi

be

maintained.

de

crea

s e

lock

nul

Adjusting

increases

When

pressure

set, lig

on

throat

under

from

(D) ug·

surface

the

1insl

P

,ESSER

ci e

nt

pressure

Should

amount

(A, Fig . 2)

s c

rew

has a right

pressure,

adjusting screw

hten

lock

plate,

is

approximately

lop

surfa

locking nut

FOOT

to

il

be

of

pressure

and

loosening dec

nul

(i\).

position

ce

of

adjusting screw

(C).

PRESSURE

feed

necessary

on

turn

hand

Wilh

locking

FEED

work

uniformly

presser

adjusting

thread;

reases

(B)

has been

presser

nut

1 I

32

inch

ECCENTRICS

lo

so

(C)

(B).

should

increase

foot,

loosen

screw

tightening

pressure.

properly

fo

ot

resting

so

that

to

1 I

16

Set

or

(B).

its

inch

cap

Fig.

2

Feed

approximately

main

is

No.

numbers

obtainable

mately

shipped

Generally

ber

of

so

as

Following

5,

6,

36,

eccentrics

with a minor number

"39540-12".

is

also

Defore

uard, upper

g

sugge

feed

39540-4

3 1 I 3

stitches

to

7,

40.

available

sted

eccentri

e c

of

the

when

with

give

8,

9,

Only

may

asse

sequence:

14

stitches

entric

for

part

using

stitches

above

speaking,

produced;

the

proper

stitch

10,

two

be

No.

for 5 to 1 ratio

ASSEMBLING

mbling

knife

s

us

d i n

per

is

No.

Styles

combinations

11, 12, 13,

ordered

39540

39500

symbols

that

eccentric.

per

inch.

the

the

differential

number

eccentrics

suffixed

A,

sewing

assembly,

main

feed

separately.

producing approximately

these

39540-14

different'al

to

AND

machines

inch.

S, T and

indicate

Unless

of

eccentrics

(right

or gathering

eccentrics

14,

15,

are

supplied

indicate

differential

ADJUSTING

parts,

lower

It

knife

have

will

be

noted

while

No.

remove

that

No.

39540 A for

approximately

39540 A eccentric

otherwise

.

hand)

16,

number

(left

18,

To

feed

hand)

are

available

20,

with

order

of

feed mac

SEWING

cloth

holder

been

of differential

specified,

eccentric

action.

22,

each

an

stitch

assembly; then follow this

selected

that

the

Style

the

number

feed

eccentric

under

24, 26, 28,

machine.

eccentric,

es

desired.

3 1 I 3

hines.

PARTS

plate,

fabric guard, chip

to

part

feed

39500

of

produces

machines

determines

is

No.

30, 32, 34,

use

stitches

produce

number

eccentric

U.

Minor

stitches

approxi-

will

num-

selected

39540-

Additional

No.

39540

Example:

per

of

be

4,

inch

Fi

g . 3

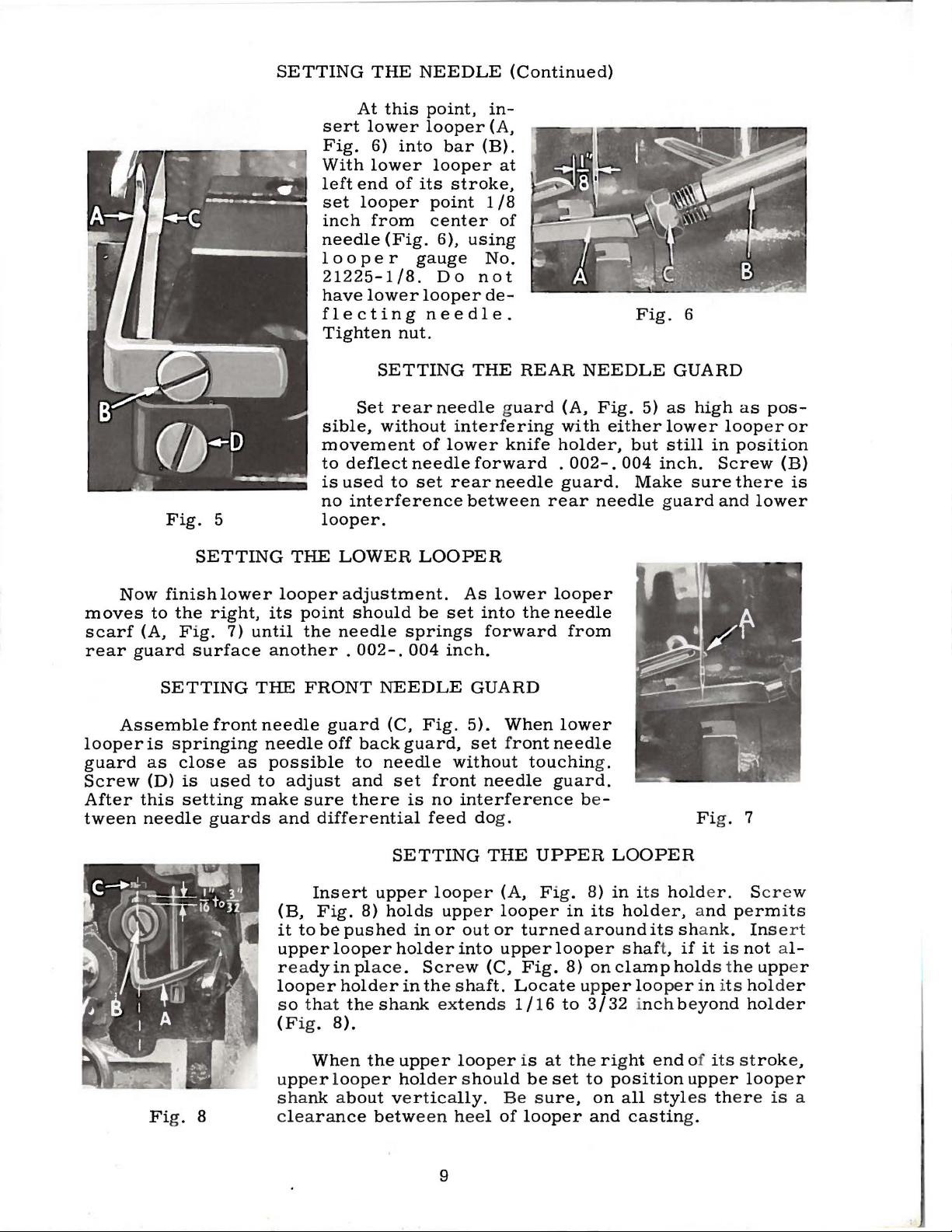

SETTING

With

sition,

in the

slot.

position,

should

throat

needle

3)

by

loosening

(B).

If

pull-off(A,

looper

separate

thread

retighten

screw,

end play

arm.

THE

throat

need

front

When

be

set

plate

driving

Remove

needle

F i

thread

by

pull-off

ing

be

sure

in

NEEDLE

plate

in

po-

le

should

end

needle

needle

112

(Fig.

arm

clamp

throat plat

thread

g.

pull-o

mov

loop

needle driving

of

is

inch

3).

(A, F i

4)

overlaps

ing loo

bac

k. W

er

pull-o

to

8

center

needle

at

high

point

above

Move

screw

cam

ff (B),

take

per

hen

g.

e.

ff

up

Fig. 4

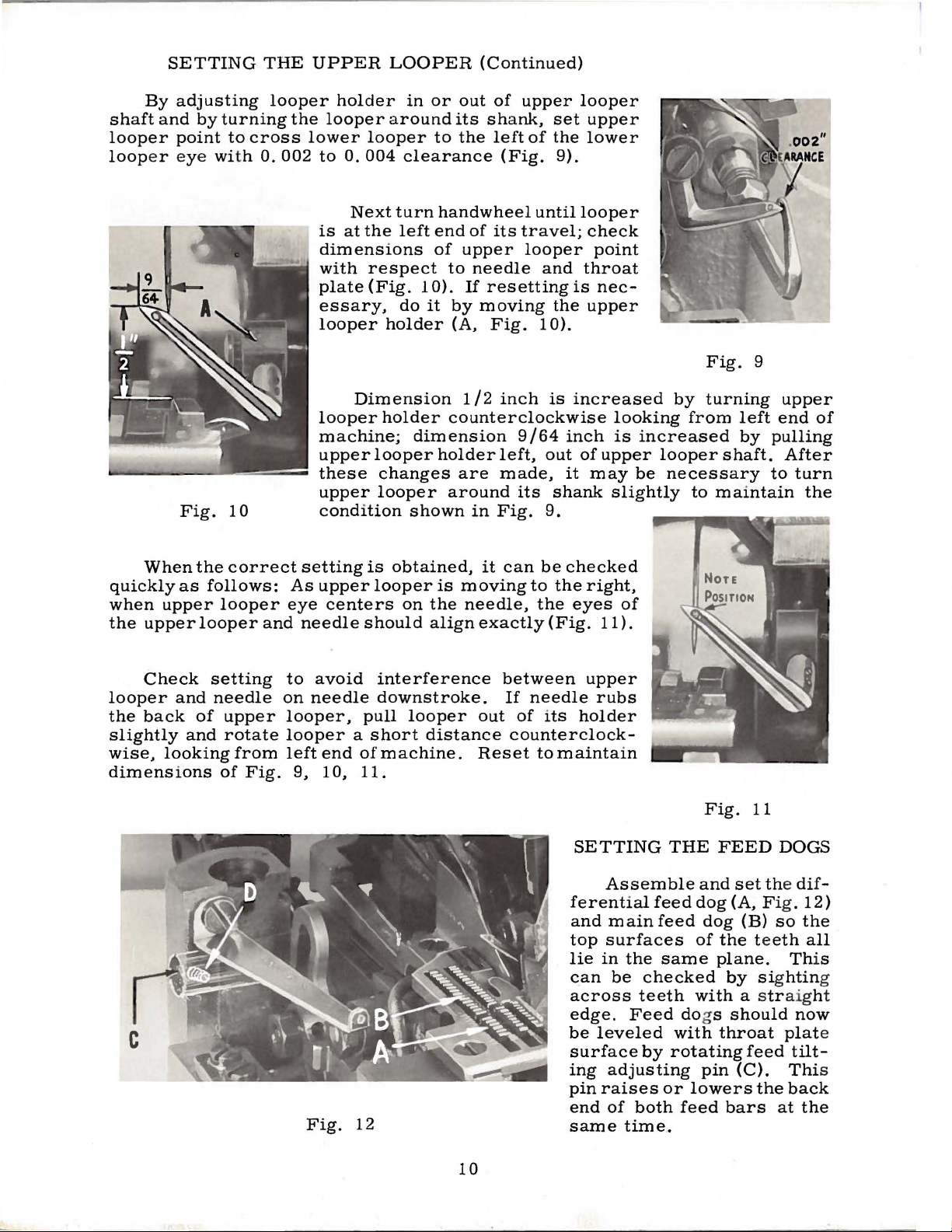

Page 9

SETTING

sert

Fig.

With

left

set

inch

needle

looper

21225-118.

have

flecting

Tighten

THE

At

this

NEEDLE

point,

lowerlooper(A,

6)

into

bar

lower

end

looper

from

(Fig.

of

looper

its

stroke,

point

center

6),

gauge

Do

lower

looper

needle.

nut.

(Continued)

in-

(B).

at

1

18

of

using

No.

not

de-

Fig.

6

Now

moves

scarf

rear

Assemble

looper

guard

Screw

After

tween

Fig.

finish

to

the

(A,

Fig.

guard

SETTING

is

springing

as

close

(D)

this

needle

5

SETTING

lower

right,

7)

surface

front

as

is

used

setting

guards

THE

looper

its

until

another

THE

needle

needle

possible

to

adjust

make

and

Set

sible,

movement

to

deflect

is

used

no

interference

looper.

LOWER

adjustment.

point

the

should

needle

.

002-.

FRONT

guard

off

back

to

and

sure

there

differential

SETTING

rearneedle

without

of

lower

needle

to

set

LOOPER

be

set

springs

004

inch.

NEEDLE

(C,

Fig.

guard,

needle

set

front

is

no

feed dog.

THE

REAR

g

uard

interfering

knife

forward

rear

needle

between

As

lower

into

the

forward

GUARD

5).

When

set front

without

touchin

needle

interference

NEEDLE

(A,

with

holder,

.

002-.

guard.

rear

looper

needle

from

lower

needle

guard.

be -

Fig.

either

but

004

Make

needle

g.

5)

inch.

as

lower

still

guard

GUARD

high

looper

in

Screw

sure

and

Fi

g. 7

as

pos-

or

position

(B)

there

is

lower

Fi

g. 8

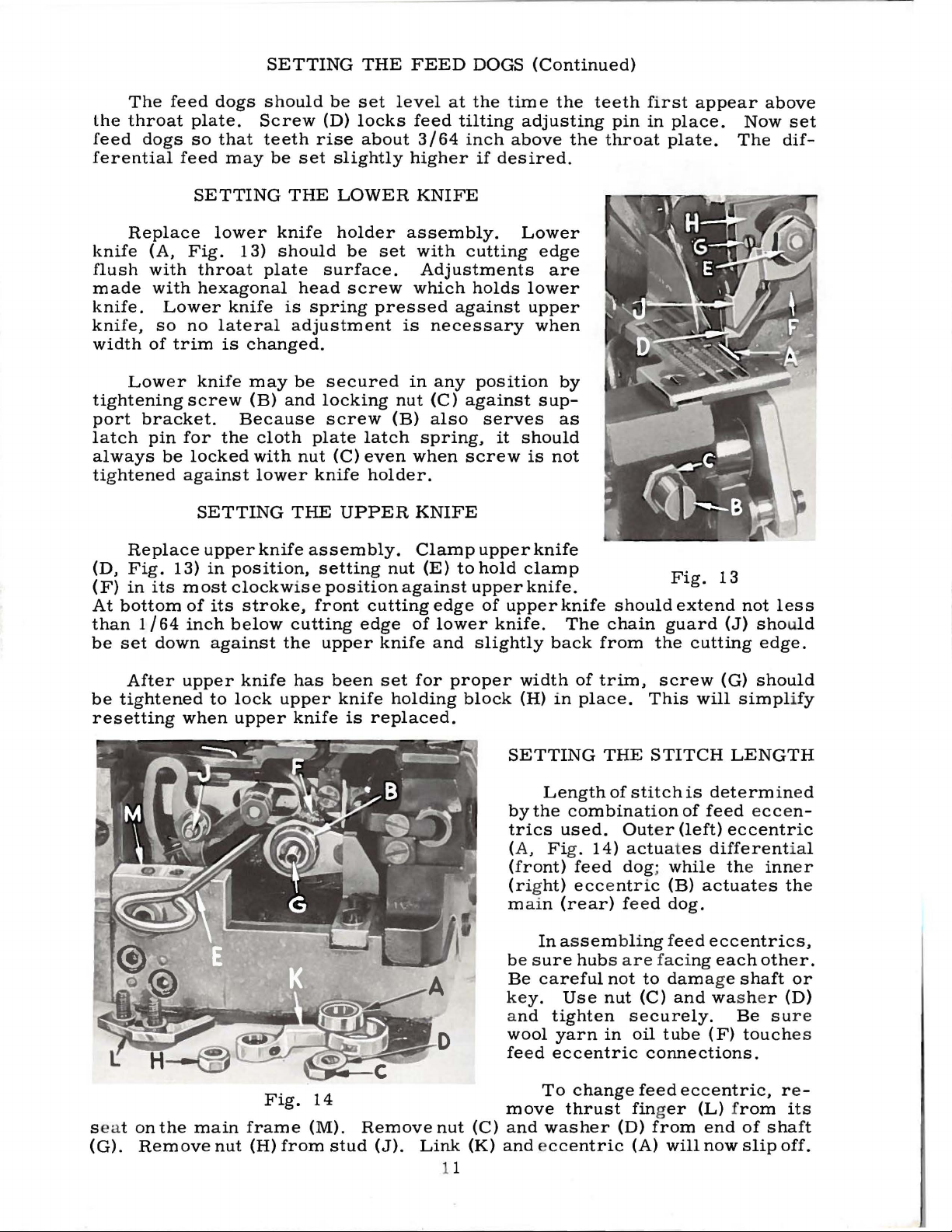

SETTING

Insert

(B,

it

to

upper

Fig.

be

upper

8)

pushed

looper

holds

in

holder

readyin place .

loop

er

hold

er

in the s ha

at the sha

s o th

(Fig.

u

sha

8).

Wh

en

pp

er l

oop

nk about vertically.

clearance

the

er

betw

nk exte

upper

hold

loop

or

Scr

er s

een heel of

9

upp

into

ew

loop

THE

er

er

out

(C,

ft.

nd

hould

UPPER

(A,

Fi

g. 8)

looper

or

turned around

upp

er

looper shaft,

Fig.

Locate upper

s 1 I 16

er is

to

at the rig

be

set

Be sure,

looper

in

8)

LOOPER

in its holde

its

holder, and perm

its shank. Inse

if

on

clamp

hold

looper in it s holde

3 I 32 i

to

on

and

nc

h beyond holde r

ht

end

position

all styl

castin

of

upp

es ther e

g.

r. Scre

it

is

not al-

s the

its strok

er

loop

upp

is

w

it s

r t

er

r

e,

er

a

Page 10

By

shaft

and

looper

loop

er eye with

SETTING

adjusting

by

turning

point

to

THE

looper

cross

0.

002

UPPER

holder

the

looper

lower

to

0.

is

at

dimensions

with

plate

essary,

looper

LOOPER

in

around

looper

004

clearance

Next

turn

the

left

respect

(Fig. 1 0).

do

holder

(Continued)

or

out

its

shank,

to

the

handwheel

end

of

of

upper

to

needle

If

resetting

it

by

moving

(A,

Fig.

of

left

(Fig.

its

upper

set

of

the

9).

until

travel;

looper

and

the

10).

looper

upper

lower

looper

check

point

throat

is

nec-

upper

Fig.

When

quickly

when

the

as

upper

upperlooperand

Check

looper

the

slightly

wise,

and

back

and

looking

dimensions

10

the

correct

follows:

looper

setting

needle

of

upper

rotate

from

of

looper

machine;

upper

these

upper

condition

setting

As

upper

eye

needleshould

to

avoid

on

needle

looper,

looper a short

left

end

Fig.

9,

Dimension

is

centers

pull

ofmachine.

10,

11.

holder

looper

counterclockwise

dim

ens

holder

changes

looper

around

shown

obtained,

looper

on

is

the

alignexactly(Fig.

interference

downstroke.

looper

distance

1/2

inch

ion

left,

are

made,

in

Fig.

it

can

moving

needle,

between

If

out

Reset

is

increased

9 I

64

inch

out

of

upper

it

may

its

shank

9.

be

checked

to

the

right,

the

eyes

11).

upper

needle

of

its

rubs

holder

counterclock-

to

maintain

looking

is

increased

looper

be

slightly

of

Fig.

by

turning

from

shaft.

necessary

to

maintain

Fig.

9

left

by

11

upper

end

of

pulling

After

to

turn

the

Fig.

12

10

SETTING

Assemble

ferential

and

main

top

surfaces

lie

in

the

can

be

across

edge.

be

Feed dogs

leveled

surface

ing

adjusting

pin

raises

end

of

both

same

time.

THE

feed

feed

same

checked

teeth

with

by

rotating

or

feed

FEED

and

set the dif-

dog

(A,

dog

of

the teeth

plane.

by sig

with

should

throat

pin

lowers

bars

DOGS

Fig.

12)

(B)

so

the

all

Th

is

htin

a straight

now

plat

feed

tilt-

(C).

the

Thi

back

at

the

g

e

s

Page 11

The

the

throat

feed

dogs

ferential

feed

plate.

so

feed

dogs

that

may

SETTING

should

Screw

teeth

be

(D)

rise

set

THE

be

set

locks

about

slightly

FEED

level

feed

3/64

higher

DOGS

at

the

tilting

inch

if

(Continued)

time

adjusting

above

desired.

the

the

teeth

pin

throat

first

in

place.

plate.

appear

The

above

Now

set

dif-

Replace

knife

flush

made

knife.

knife,

width

(A,

with

with

Lower

so

of

Lower

tightening

port

latch

always

bracket.

pin

be

tightened

Replace

(D,

Fig.

(F)

in

its

At

bottom

than

1/64

be

set

down

SETTING

lower

Fig.

throat

hexagonal

no

lateral

trim

is

knife

screw

for

the

locked

against

SETTING

upper

13)

in

most

of

its

inch

against

THE

knife

13)

should

plate

knife

is

adjustment

changed.

may

be

(B)

and

Because

cloth

with

lower

THE

knife

position,

clockwise

stroke,

below

cutting

the

LOWER

holder

be

surface.

head

screw

spring

secured

locking

screw

plate

nut

(C)

knife

UPPER

assembly.

setting

position

front

upper

set

pressed

nut

(B)

latch

even

holder.

nut

cutting

edge

knife

KNIFE

assembly.

with

cutting

Adjustments

which

holds

against

is

necessary

in

any

(C)

against

also

spring,

when

screw

KNIFE

Clamp

(E)

to

against

upper

edge

of

lower

and

slightly

Lower

lower

upper

position

serves

it

should

is

upper

hold

clamp

knife.

of

upper

knife.

edge

are

when

by

sup-

as

not

knife

knife

The

back

should

chain

from

Fig.

extend

guard

the

13

(J)

cutting

not

less

should

edge.

After

be

tightened

resetting

seat

on

(G).

Remove

the

upper

to

when

main

nut

knife

lock

upper

Fig.

frame

(H)

has

upper

knife

14

(M).

from

been

knife

is

stud

set

for

holding

replaced.

Remove

(J).

nut

Link

11

proper

block

(C)

(K)

width

(H)

SETTING

in

of

trim,

place.

THE

Length

by

the

combination

trics

(A, Fig .

(front)

(right)

main

be

Be

key.

and

wool

feed

move

and

used.

feed

eccentric

(rear)

In

assembling

sure

hubs

careful

Use

tighten

yarn

eccentric

To

change

thrust

washer

14)

and eccentric

screw

This

STITCH

of

stitch

Outer

actuates

dog; while

(B)

feed

dog.

feed

are

faci

not

to

dama

nut

(C)

securely.

in

oil

tube

connections.

feed

finger

(D)

from

(A)

will

(G)

should

will

simplify

LENGTH

is

determined

of

feed

eccen-

(left)

eccentric

differential

the

inner

actuates

the

eccentrics,

ng

each

other.

ge

shaft

or

and washe r (D)

Be

sure

(F)

touches

eccentric,

(L) from

end

now

of

slip

re-

its

shaft

off.

Page 12

SETTING

THE

STITCH

LENGTH

(Continued)

Using

eccentric

handwheel

shirring

so

for

The

For

the

upper

hooked

intermittent

adjusting

eccentric

(B)

as

shown

back

micrometer

operations

position.

Fig.

and

15

screw

extractor

and

forth

where

slightly

adjusting

various

operations,

stop

withdraw

during

ential

the

lever

top

Amount

and

near

(moving

action.

reverse.

screw

sizes

it

may

(B)

is

for

(E),

supplied

eccentric.

extraction.

SETTING

Differential,

feed

micrometer

The

(A)

stop

(C)

determines

Rotation

tension

top

A

for

the

are

be

advantageous

lower

with

It

THE

action

position

is

governed

(B)

and

of

movement

ofadjustingthumbscrew

stop

counterclockwise

top

stop

encountered.

stop,

and

machine,

may

be

DIFFERENTIAL

plain,

is

obtainable

adjusting

of

the

by

the

lower

by

feed

action.

post

down)

assembly)

increases

is

ideal

to

the

stationary

reach

necessary

or

reverse

thru

screw

differential

two

settings--the

stop

lever

reverse

screw

between

differential

turn

for

the

behind

to

move

RATIO

differ-

use

of

(Fig.

clockwise

continuous

stop

15).

control

(C).

(located

acts

stops--

(C)

(B)

the

is

The 3 to 1 ratio

differential

maximum

Assemble

presser

can

be

Foot

collar

arm

does

release

foot

and

plate

screw.

Adjust

presser

looper

this

maximum

so

point

foot

tongue.

the

presserfoottreadle

toe

of

the

upper

lever

locked

before

differential,

arm

realigned

lifter

(B)

secure

not

bushing

stitch

needle

lifter

foot

will

of

upper

foot.

looper.

with

feed

presser

into

lever

bind

is

tongue

hole,

can

be

permit,

safe

looper

Raise

Height

presser

nut

(F).

machines

dogs

unlocked.

lever

There

from

and

foot

sewing

with

arm

the

shaft.

and

rise

with

loosen

stop

raised

then,

position,

is

presser

and

adjustment

foot

are

striking

screw

SETTING

to

position

throat

(A,

when

To

respect

presser

screw

no

higher

lock

turn

directly

foot

manuallylowerthe

should

begins

should

THE

presser

and

plate

Fig.

Be

sure

presser

center

nut

(D).

the

over

by

is

correct

be

from

to

rise.

(C)

depressing

equipped

the

throat

not

PRESSER

arm.

lock

in

slots

16)

and

presser

foot

presser

to

throat

foot

hinge

so

that

than

upper

To

find

handwheel

presser

if

1/16

This

with a stop

plate

be

removed.

FOOT

With

by

presser

to

adjustment

place.

shifting

1/8

needle

inch

screw

when a machine

in

high

If

necessary,

foot

lifter

Fig.

foot

tongue

free

is

made

does

motion

with

(D)

to

position,

presser

lever

16

not

of

foot

screw

prevent

is

set

swing

foot

shaft.

contact

lifter

(E),

at

Finally,

re-assemble

chip

guard,

fabric

guard,

12

cloth

plate.

Page 13

SETTING

THE

AUXILIARY

PRESSURE

PLATE

Styles

(Fig.

17)

To

this

assembly,

follows:

1.

Swing

position

hinges

Adjustment

screw

2.

Set

(C)

parallel

main

in

(B,

39500

which

check

it

freely

the

so

shaft

either

Fig.

T,

operates

the

operation

proceed

out

of

and

on

is

(A)

and

adjusting

that

to

the

of

shaft

the

direction

18).

U

are

operating

see

that

its

made

nut

screw

(D)

axis

machine.

equipped

in

of

as

it

pivot.

by

(B).

is

of

the

Fig.

about

with

conjunction

18

180°

from

an

auxiliary

with

the

operating

pressure

presser

Fig.

3.

position

foot.

17

Adjust

erally

sure

plate

centrally

ferential

Loosen

B,

Fig.

Making

will

release

tension

plate.

tension,

sure

the

plate

shaft

and

plate

the

so

that

screws

18)

this

on

To

swing

tighten

assembly

shaft

(D)

the

(E)

locates

over

the

feed

to

do

adjustment

the

the

pressure

re-gain

the

out

and

(D,

Fig.

lat-

pres-

dif-

dog

(A

and

this.

spring

the

pres-

turn

17)

screw

.

4.

With

the

the

pressure

the

spring

operating

loosen

5.

With

the

mountingbracket

with

feed

6.

Adjust

parallel

end

of

the

top

7.

There

used

fo·r

8.

A

chain

with

the

to

the

pressed.

normally

differential

plate

will

lever

screw

(A,

differential

dog

teeth.

the

pressure

with

the

plate

ply

are

and

being

two

increasing

is

provided

presser

presser

the

presser

attached

resting

allow,

(F,

Fig.

Fig.

(C,

feed

presser

sewn.

spring

or

foot.

foot

to

feed

dog

there

17)

18)

feed

dog

Fig.

plate

dog,

foot

Use

anchoring

decreasing

for

raising

Couple

lifter

chain

foot

the

operating

down

on

should

and

and

at

18)

in

so

to

the

this

raises

the

the

move

its

below

throat

be

hinge

highest

the

plate

about

block

lever

surface

1/32

to

point

with

the

inch

(G).

To

desired

of

travel,

of

the

maximum

clearance

make

position.

sothattheauxiliarypressureplateisparallel

or

out

that

permit

two

the

towards

there

screws

holes

spring

auxiliary

chain

so

that

before

lever

is

free

in

tension

from

when

presser

sufficient

passage

(D,

Fig.

collar

pressure

the

the

the

pressure

at

the

clearance

of

18)

(E.

Fig.

on

auxiliary

operating

foot

lifter

plate.

inside

hole.

foot,

the

for

plate

13

throat

between

this

raise

or

maintaining

between

thickest

this

adjustment.

18)

which

pressure

in

conjunction

lever

(F,

treadle

The

plate,

and

pressure

the

adjustment

lower

the

the

part

may

be

plate.

Fig.

17)

is

de-

chain

is

it

of

Page 14

Be

With

the

middle

foot

in

presser

sure

thread

place,

foot

machine

tensions

of

their

to

into

is

light,

front

make

position,

threaded

to

back

sure

STARTING

according

set

looper

locations.

that

chain

insert

material,

TO

thread

forms

OPERATE

to

threading

eyelets

Operate

and

moves

and

sew

(C &

machine

off

slowly.

diagram

E)

about

slowly,

the

tongue

(Fig.

1,

horizontal

without

freely.

page

and

presser

Swing

6).

in

While

needle

be

just

if

excessive

position

contacts

It

(toward

With

far

enough

rearward

needle

left

hand

time

lower

While

of

lower

comes

lower

looper

keeping

thread

tight

needle

needle

is

also

the

material

position.

thread

eyelet

sewing

looper

off

upper

the

sewing

is

enough

thread

desireable

operator)

so

thread

cam

looper

thread

thread

same

on

material

drawn

thread

to

is

on

needle

feed

pulled

eyelet

thread.

to

to

delay,

LOWER

under

presser

is a little

Looper

pull-off

approximately

is

at

extreme

on

material,

should

looper.

amount

is

To

on

of

NEEDLE

,

check

down

chain

on

(R,

adjust

slightly,

LOOPER

slack

thread

(S).

Frame

1

check

be

drawn

increase

upper

pull-off

THREAD

off

stitch

the

Fig.

the

foot,

when

pull-off

/8

inch

left

end

drawing

amount

looper,

action.

needle

stroke.

up

stroke.

1)

so

needle

the

THREAD

set

lower

looper

looper

right

of

through

move

CONTROL

thread

At

tongue.

that

thread

tightening

looper

thread

(T)

is

threadguide

of

its

travel.

off

oflooper

the

of

thread

lower

control

top

of

needle

Stitch

With

needle

needle

pull-off

of

CONTROL

thread

pull-off

set

about

lower

looper

tension

drawn

looper

as

tends

thread

the

1/8

(G)

thread

before

through

thread

follows:

stroke,

to

at

cam

eyelet

needle

eyelet

(T)

inch

should

(K)

as

lower

thread

pull

down

bottom

pull-off

well-forward

thread.

(E,

Fig.

reaches

distance

beset

heel

eyelet

follows: A portion

looper

the

tension

eyelet

Usually

should

slightly

of

stroke,

(S)

1)

its

behind

with

at

thread

while

(E)

down,

all

just

back

most

its

the

Before

three

will

tensions

not

During

upper

drawn,

pull-off

Tom

should

slightly

If

it

end play

markedly

needle

looper

upper

reaches

ove

be

raised

more

becom

in needle

proceeding

is highe r over

near

top edge

Th

e needl

ing

be

without

be

pulled

sewn.

causing needle

increas

too

ed

far over

to

give a normal

effect

down

thread

through

looper

its

most

the

purl

more

keep

pull-

off

es

necessary

drive

throat

.

e t h

If

plate

upper

read

In general,

as long as

the

UPPER

to

the

LOOPER

adjust

purl.

stroke,

the

thread

will

rearward

POSITIONING

under

ing

the

same

on

upp

er

to

move

shaft

before

than

loop

er is

tension

lower

thread

required

looper

to

the elasticity

top.

THREAD

upper

appearing

forward

tension.

have

looper

stitch.

stroke

When

almost

position.

the

edge,

both

amount

thread

than

looper

tightenin

recommended

too

low, the

THREAD

TENSIO

is a f

thread tens

be pu

lled

down.

of the

14

CONTROL

thread

eyelet

Moderate

of

looper

thread

normal

all

slack

THE

PURL

looper

of

pull-off.

on

lower

thread

g.

If

thread

thread.

pull-o

upp

er

in (F ig . 1 0), the

purl wil

l f

NS

unction

of needle

ion should

Upp

er

loop

cha

in incr

(C,

change

pull-off

amount

taken

up

eyelets

Usually

ff

(T)

be s

looper

purl will tend

orm nearer

thread a nd m at

be set

er

thread t e ns i

eases, or

Fig.

1)

balance

in

these

(T)

of

looper

as

looper

(C & E,

it

is

better

ure

to

is loca

ted so t ha t

bottom

as high

as possible

until the purl

all

tensions

will

draw

thread

is

thread

Fig

.

1)

to

hav

e

take up all

it

to form

ed

ge .

eria

on should

is

l

Page 15

~~

E F

TO

REMOVE

Fig.

19

CRANKSHAFT

U V T

M

Crankshaft

1.

Drain

cated

edge

2.

Remove

chine.

3.

Remove

and,

tractor,

4.

Remove

5.

Remove

Identify

they

per

6.

Remove

shaft

reached

7.

Remove

at

points

assembling

they

Trade

halves

should

ings.

assembled

which

8.

Loosen

holds

Access

cover.

until

connecting

moval

bearing point

shaft.

re-assembling

above.

9.

Remove

inner

screw

casting.

10.

Loosen

remove

11.

Remove

(N).

12.

Loosen

(R).

13.

Remove

bearing

14.

Crankshaft

can

oil

on

back

of

base.

top

feed

with

key

these

will

places.

screw

split

through

caps

are

marks

of

the

be

Also,

they

clamp

upper

to

Draw

upper

of

Observe

screw(K,

right

is

reached

two

both

screw

two

retaining

be

withdrawn

by

removing

of

and

bottom

eccentric

the

aid

slip

off

(G).

three

counterweights

be

re-assembled

(J)

bearing.

bottom

of

bearings

A,

B,

bearing

in

their

are

caps

on

the

same

screws

in

the

were

nut

knife

clamp

driving

knife

rod

(D)

bearing

(C,

same

cap

crankshaft

screws

halves

(M);

screws

three

screws

may

easier

plug

machine

of

the

counterweights

which

and

original

stamped

and

same

removed.

(A,

nut

driving

drop,

cap

Fig.

as

Fig.

through

(L)

take

(P);

plate

near

covers

nut

(E,

the

eccentric

eccentrics

in

holds

This

of

bed

on

crankshaft

D.

When

caps

both

side

driving

precautions

now

make

trade

of

should

holes

Fig.

is

through

arm

lever

allowing

(E).

This

19)

on

described

19)

which

bearing.

bottom

in

fan

of

cooling

off

remove

(S);

(T).

be

if

screw

bottom

of

ma-

Fig.

(F).

(H).

so

that

the

pro-

crank-

screw

casting.

re-

sure

position.

on

both

marks

the

bear-

be

re-

from

20)

which

arm

(B).

to

the

left

(C)

and

re-

is

crank-

when

in

holds

This

of

bed

collar;

fan.

pulley

removed.

cap

pulley

take

these

lo-

19)

ex-

is

top

at

7

off

steps

15.

If

(V),

an

it

it

(U).

16.

Carefully

foregoing

re-assembly

ing

tion

testing

will

17.

Before

clean

and

bottom

pressed

crankshaft

in

The

spring

drain

fore

leakage.

recommended.

15

are

followed:

necessary

it

should

arbor

must

seats

be

against

exploded

of

various

for

also

re-assembling,

and

gaskets.

cover

oil

casting

wick

against

plug

re-assembling

to

replace

be

pressed

press.

pressed

observing

operations

binds

prove

dry

bearing

and

stands

with a sealing

No. 1 Crane

of

view

top

Before

make

wick

that

bottom

In

replacing

on

ground

crankshaft.

drawings

parts

during

helpful.

and

which

is

it

v e r t i c a

to

Fi

g.

ball

off

shaft

carefully

thrust

reverse

should

thorough

bottom

re-assembling

sure

lubricates

inserted

contacts

cover.

20

simplify

for

and

constant

re-assembly

that

11 y on

Coat

compound

prevent

Lead

bearing

on

bearing

until

washer

of

the

Check-

loca-

1 y

covers

sprin

lef

in

hole

shaft.

its

oil

be-

oil

Seal

is

g

t

Page 16

ILLUSTRATIONS

ORDERING

REP

AIR

PARTS

This

of

various

actual

listing

required

Numbers

position

ordering

Component

indicated

assembly.

40

41

42 97

43

44

45

It

not

listed.

mended,

catalog

sections

position

of

the

in

the

of

that

parts.

by

Example:

29126

22729

39544

39544

22729

will

be

so

has

in

the

parts

particular

in

the

part

Always

parts

indenting

DF

D

s

u

E

noted

The

reason

complete

been

of

with

first

in

in

arranged

the

mechanism

machine.

their

view

column

the

illustration.

use

of

sub-assemblies

their

Lower

Rod

Assembly----------------------------------------Screw,

Screw,

Ball

Lower

Screw,

the

above

is

that

sub-assembly

to

On

the

part

being

are

the

part

descriptions

Looper

for

for

Joint

Looper

for

example

replacement

should

simplify

are

shown

page

number,

shown.

reference

Reference

number

which

Bar

Driving

No.

39544 N -----------------------------

No.

39544 S -----------------------------

Guide

Fork-------------------------------

Bar

No.

39544 N -----------------------------

that

be

ordering

so

opposite

description,

numbers

listed

can

under

Lever

Driving

the

eccentric,

of

these

ordered.

that

the

numbers

in

the

be

the

description

Lever

parts

repair

the

only,

second

and

parts.

parts

illustration

and

the

and

should

furnished

Connecting

--------------------

ball

individually

may

be

number

merely

never

column.

for

of

stud,

and

Exploded

seen

will

be

of

indicate

be

repairs

the

main

bearing

is

not

views

in

their

found

pieces

the

used

are

sub-

are

recom-

a

in

1

2

2

1

1

2

At

the

this

book.

part

number

Where

some

identification

appear.

Union

Company,

to

Maximum

parts

trademark

of

Part

Success

Special

the

most

Genuine

are

the

numbers

efficiency

stamped

back

its

is

of

This

is

known.

the

construction

smaller

letter

in

the

Needles

subsidiaries

approved

needles

your

the

book

will

will

facilitate

parts,

is

stamped

represent

USE

GENUINE

operation

and

scientific

and

durability

are

packaged

with a reproduction

guarantee

locating

IDENTIFYING

permits,

and

on

in

the

of

Repair

and

authorized

of

be

found a numerical

the

illustration

each

part

those

to

distinguish

same

NEEDLES

these

Parts

principles,

are

with

the

where

part,

machines

as

distributors.

assured.

lables

of

the

highest

TERMS

AND

furnished

marked

familiar

quality

PARTS

is

stamped

the

construction

the

part

regardless

REPAIR

can

and

are

Union

in

index

and

from

of

PARTS

be

secured

by

the

They

made

~

materials

of

all

the

description

with

its

part

does

similar

the

catalog

only

Union

are

designed

with

Special

utmost

•

trademark.

and

parts

when

not

ones.

in

Special

Genuine

workmanship.

shown

only

number.

permit,

which

with

genuine

Machine

according

precision.

in

the

On

an

they

repair

Each

Prices

forwarded

directed.

are

f. o.

A

charge

net

b.

shipping

cash

is

and

point.

made

are

to

subject

Parcel

cover

to

Post

postage

change

without

shipments

and insurance.

16

notice.

are

insured

All

unless

shipments

otherwise

are

Page 17

ILL

US T RATIONS

AND

PARTS

STYLES

LISTINGS

FOR

39500

S,

T,

U

1 7

Page 18

18

Page 19

MAIN

FRAME.

MISCELLANEOUS

COVERS,

PLATES

Ref.

No.

l

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

19A

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36.

37

38

39

40

41

42

43

44

45

46

47

48

49 -

50

51

52

J

Part

39557

39557

39557

39557

39557

39556

39557

22541

39582

51-103

39582

39582

39582

39563

22569

22571 E

22565

29477

39568

39568

22743

660-234

39594

22565

22569

39501

39501

39501

39501

39501

39501

39578

138

39532

90

22569

39594

39594

39578

22569

39593

39593

660-243

39593

22894

22565

39582

39582

22569

39582

22653

22586

22657

39501

22569

39535

No.

B

E

c

F

A

A

s

Blk.

L

v

AA

F

B

GW

G

J

B

B

A

AH

J

c

B

K

A

A

G

H

H

D

D

c

E

AD

y

X

c

F

D-4

R j

D-l

y

K

c

H

Description

Cap

Nut---------------------------------------------

Locking

Adjusting

Lock

Presser

Presser

Presser

Screw----------------------------------------------Top

Top

Top

Screw-----------------------------------------------

Magnetic

Screw -Upper

Upper

Oil

Feed

Screw -Cloth

Screw -Cloth

Cloth

Cloth

throat

Cloth

Cloth

throat

Cloth

Cloth

Cloth

Screw----------------------------------------------LatchSpring----------------------------------------Screw---------------------------------------------Screw--------------------------------------------Oil

Oil

Chip

Screw----------------------------------------------Oil

Oil

Oil

Oil

Screw -Lower

Screw -Upper

Bottom

Bottom

Screw -Bottom

Bottom

Screw----------------------------------------------Screw -Bottom

Screw -Cloth

Stud -Cloth Pla

Screw-

Feed

Nut

-----------------------------------------

Screw--------------------------------------

Nut--------------------------------------------

Spring--------------------------------------

Foot

Release

Spring

Cover-------------------------------------------

Hinge

Oil

Filler

Spring

Cover

Cover

Oil

Looper

Thread

Spring

Set

Screw -Tube

Tube

Filter

Strainer

Gauge

Gauge

Gauge

Sight

Coupling------------------------------------

Bar

Connecting

Plate -semisubmerged

Plate -semisubmerged

plate

Plate -nonsubmerged

Plate -nonsubmerged

plate

PlatePlate -nonsubmerged

Plate

Screen-------------------------------------

Guard------------------------------------------

Indicator-----------------------------------

Float--------------------------------------

Seal

Gauge

Cover

Cover-----------------------------------

Cover

Feed

Bar

Guide,

Plunger

Pin---------------------------------------

Cover

------------------------------------------

Gasket-----------------------------------Needle

Drain

Looper

Thread

Tube-------------------------------------

------------------------------------------

Plate,

Plate

1/16

1/16

semisubmerged

Fabric

-----------------------------------------

Ring

--------------------------------------

Looper

Looper

Gasket-----------------------------

Cover-----------------------------

and

Cover--------------------------------

Plate

te------------------------------------

Bar

rear

Bushing-------------------------

------------------------------

---------------------------------

Thread

Plug

Stud

inch

inch

Guard

----------------------------------

Base

----------------------------------

Guide, rea

Eyelet-----------------------

Screw

Thread

Tube

Tension

Rod

Oil

with

No.

longer

longer

-----------------------------

Bar

Drive

Plate Extension----------------

--------------------------------

------------------------

Tube

Assembly------------------

Spring-------------------

Tube---------------------

stud

39501 K ------------------

installation--------------installation.

in

installation

installation,

in

installation---------------

installation----------------

Drive

Lever

r-------------------------

Assembly-----------

attached-----------------

front------------------

front------------------

Lever

Shaft

for

use

with

---------------for

use

with

Shaft-----------

---

- -

----------

-

- - -

- 2

- - 3

---

--

-

--

Amt.

Req.

1

1

1

1

1

1

1

8

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

1

1

2

2

1

1

14

1

-2

1

1

1

1

1

19

Page 20

A -

NEEDLE

B -

SPHEADER -UPPEH

DRIVE

C -

UPPER

D -

LOWER

DRIVE

BEAHING

KNIFE

LOOPER

BEAHING

LOOPER

DRIVE BEARING

DRIVE

BEARING

20

Page 21

CRANKSHAFT

MECHANISM

AND

BUSHINGS

Ref.

No.

1

2

3

4

5

6

6A

6B

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

Part

No.

22769

39521

39521

95

39590

22569

39590

39590

660-268

39590

39590

39591

39591

22894

39590

22565

39590

77 Q

39522

39590

97

39591

39591

39591

22747

22747

39590

22747

39541

666-94

39590

39590

39544

39552

39573

39142

39573

39555

43243

A

A

H

s

R

G

J

G

H

D

K

F

p

B

D

A

B

A

B

B

N

B

c

L

B

L

G

K

E

N

Description

Screw

Pulley

-----------------------------------------Cap--------------------------------------

Pulley------------------------------------------

Screw---------------------------------------

Crankshaft

Screw

------------------------------------------

Spacer

Ball

Bearing

Crankshaft

Crankshaft

Thrust

Crank

Crank

Screw

Crankshaft

Screw

Oil

Chamber

Chamber

------------------------------------------

------------------------------------------

Slinger

Ball

Collar

Ball

Ball

Washer

Bearing,

Bearing

-----------------------------------

Stop

Collar-------------------------Bearing-------------------------Bearing

---------------------------------Cooling

Cooling

Fan

Fan

inner

Retaining

Housing

----------------------

Collar----------------

right-------------------

Collar--------------------------------

Plate------------

------------------

Screw--------------------------------------Crankshaft-------------------------------------Crankshaft

Split

Bearing--------------------------

Screw--------------------------------------Crankshaft

Crankshaft

Crankshaft

Counterweight,

Counterweight,

Counterweight,

right-------------------

middle

-----------------

left--------------------

Screw------------------------------------------

Screw

Stud--------------------------------------------

Screw

Feed

Oil

Crankshaft

Crankshaft

Lower

Needle

Upper

Foot

Upper

Foot

Differential

------------------------------------------

------------------------------------------

Driving

Wick

Looper

Driving

Knife

Lifter

Knife

Lifter

Eccentric

and

Spring-----------------------------Bushing,

Bushing,

Bar

Arm

Driving

Shaft

Bushing,

Driving

Shaft

Feed

Bushing,

Rocker

Key-----------------------

left-------------------------inner

Bushing

Crank

Arm

left

-----------------------

Bushing----------------

Bushing,

right-------------------

Arm

Bushing,

left

Shaft

--------------------

right

-----------

left-------------

-------------------Bushing-------------

Amt.

Req.

1

1

1

2

1

3

1

1

1

1

1

1

1

2

1

1

1

2

1

1

2

1

1

1

2

2

1

2

1

1

1

1

1

1

1

1

1

1

2

21

Page 22

22

Page 23

Her.

..!!.£:__

1 22569 B

2 8372 A

39578

3

4

39578

5 87

22565 B

6

39536 M

7

39536 L

8

39536 J

9

10

39536 N

11

12

39536 u

13

22557 E

39536 v

14

39

15

16

17

18

19

20

21

22 8372 A

23

24

25

26

27

28 22569 B

29

30 39534 H

31

32

33

34

35

36

37

38 39534 A

39

40 39534 B

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66 39563 G

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

536 y

39536 w

39536 p

22565 F

39535 E

22728 A

8372 A

39536

43139 A

43139 A

22569 c

39535 D

53634 c

22569 G

39526 s

39526 T

39526

39505 s

39536

39536 X

22726 L

39535 B

39536 R

39536 E

39538

39536 z

39535 G

53634 c

22569

39540 B-14

39536 F

39536 G

39536 K

39536

39540

39540 c

39536 H

53634 c

22569

14077

39551 A

39552

22596 E

50-774 Blk.

39551 F

28

22564

39568 A

39568 N

88

39552 c

39

552

39

552

58

22

395

94

28

3

95

36

39536

39

536 AB

161

22

764

161

88

28

25

18

93

94

20

18

7 J

Part

No.

p

M

cc

AA

u

s

E

B-4

c

B

A

E

N

AD

AC

A

NEEDLE DHIVE

Screw--------------------------------

Washer-----------------Fabric

Guard Mounting

Fabric

Guard-----------------------Screw------------------------------------------------------------------------Screw--------------------------------

Differenti

Differential

Differen

Screw--------------------------------------

Differenti

Differenti

Stud----------------------------------------

Differential

Screw--------------------------------------

Differential

Differential

Screw------------------------------------

Feed Adjusting

Screw, for

Screw-------------------------------------

Washer,

Washer,

Differential

Nut, for

Nut,

Nut

Screw-------------------------

Feed

Screw----------------------------------------------------------------------------Washer·---------------------------------------------------------------------------

Feed

Screw-------------------------

Differential

Di

Differential

Screw-------------------------Main

Screw---------------------------------------------------------------------Differential

Differential

Main

Screw-------------------Differential

Main and Di

Feed

Nut

Feed

M

Main Feed B

Washer---------------------------------------------------------------------------Screw--------------------------------------------------------------

Main

Diff

D

if

Bushing

Nut

Differential F

Diff

Washer---------------------------------------------------------------------------

Nut

Thrum

Washer-----------------------------------------------------------Screw-----------------------------------------------------------------------------

Nut-----------------------------------------------------

Needle Clamp W

Need

Needle

Needle Cl

Needle Thr ead Cam P

S

crew----------------------------------------------------------------------crew---------------------------------------------------

S

Looper Threa

Looper Thread Pull-o

Needle Driving

eed

N

Needle D

O

il

Screw-----------------------------------------Spring

Feed Cont

Feed Co

Stop Collar

Stop

al

Feed

Hocker

Feed

ti

al

al

al

for

for

Styles

for

Style 39500 U

----------------------------------------------Bar

Bar

fferential

Feed

Feed

Bar

---------------Lift Block

ain Feed

Feed

erential

ferential Feed

-------------------------------------------------------

-------------------------------------------------------------------------------

erential

---------------------------------------------------------------------

Finger--------------------------------------------------------------

le-------------------

Drivin

Screw--------------------------Stop Pi

amp Stud------------------------

Screw-------------------------------------------------------------------------

le Driving Arm Crank

ri

Screw--------------------------------------------

Splasher

Washer------------------------------------------

rol

ntrol AdJUSti

crew---------------

S

Collar