Page 1

INDUSTRIAL

SEWING

®

QUA

LITY

STYLES

39500QJ

39500QL

39500QN

39580QV

39500QX

39500RP

39500RU

39500SJ

·

C O L U M B I A®

MACHINES

39500SR

39500SX

39500TG ·

39500TY ·

CATALOG

No.

103QJ

MARK

TWO

SERGING

AND

CLASS

IV

SINGLE

AND

THREE

PLAIN

39500

HIGH

SPEED

NEEDLE

THREAD

FEED

OVERSEAMING

MACHINES

UNION SPECIAL

CHICAGO

CORPORATION

Page 2

Catal

A

DJUSTING

I

NST

o g N

R

FOR

AND

UC

o.

103

TIO

NS

OPERATING

QJ

39500

39500

39500

Righ

QJ

39500

39500

39500

Union

ts

LIST

CLASS

QL

QN

QV

QX

First

Copyright

Special

Reserved

RP

OF

Styles

Edition

by

PARTS

39500

39500

39500

39

500

39500

39500

©

1973

Corporation

in

All

39500

SR

sx

TG

TY

Countries

RU

SJ

UNION SPECIAL CORPORATION

INDUSTRIAL

Prin

SEWING

CHICAGO

te

d

in

2

MACHINES

U.S.A.

March,

1978

Page 3

IDENTIFICATION

OF

MACHINES

Each

on

the

Style

numbers

Example:

minor

Style

changes

number.

Styles

which

39500

differs

11

•

This

herein.

Class

given

of

MARK

39500.

from

handwheel

IV

Spreader,

Feed,

cating

Trimming

System,

UNION

machine.

"Style

o'f

machines

from

catalog

It

can

also

References

the

is

Hi-Styled

Two

SPECIAL

Style

have

one

39500

are

made

Example:

the

applies

be

applied

operator's

away

from

High

Thread

Mechanism

Improved

machine

numbers

or

more

QJ".

Special

in a standard

"Style

39500

similar

Style

number

APPLICATION

specifically

with

to

directions,

position

operator.

STYLES

Speed,

or

Two

with

Air

Cooling

is

identified

are

classified

letters

Style

QJZ".

in

construction

in

that

to

discretion

while

OF

Single

Looper,

Spring

System.

as

suffixed,

numbers

machine,

are

it

contains

OF

CATALOG

the

standard

to

some

such

seated

as

at

MACHINES

Curved

Three

Pressed

by a

standard

but

contain

a

"Z"

grouped

right,

the

Blade

Thread

Lower

Style

never

number

contain

the

is

suffixed

under a Class

no

letters.

Styles

Special

left,

front,

machine.

Needle,

Serging

Knife.

and

special.

letter

Example:

of

machines

Styles

Operating

One

Machines.

Automatic

on a name

Standard

the

letter

"Z".

When

to

the

standard

number

as

of

machines

back,

etc.,

direction

Looper,

plat

"Z"

only

"Class

listed

are

One

Plain

Lubri-

e

•

in

39500

39500

39500

terials.

width

Maximum

39500

edging

and

Seam

mm);

spee

39500

flies

and

SSj-1;

cam

QJ

Light

weight

trousers

503-EFd-1;

inch;

weight

QL

cam

Light

trousers

505-SSa-1;

cam

adjusted

QN

Medium

suits,

garment

Three

3/16

QV

Medium

without

other

specification

stitch

.d

7500

QX

Medium

and

similar

standard

adjusted

to

medium

and

standard

adjusted

to

medium

and

standard

feed.

to

heavy

pockets

thread

inch

(4.

recommended

to

heavy

cord

articles

range

made

7-20

R.P.M.

to

heavy

zipper

tapes

operations.

seam

feed.

duty

similar

seam

feed.

Maximum

duty

similar

seam

width

Maximum

duty

and

similar

stitch.

76

mm);

speed

duty

machine

on

rayon

from

504-EFe-1

per

duty

to

pants

Three

width

Maximum

machine

garments.

width

3/16

recommended

machine

garments.

3/16

inch

recommended

machine

operations

Seam

stitch

7500

specification

range

R.P.M.

for

bedspreads,

fabrics

(inverted);

inch;

cam

machine

fronts;

thread

3/8

inch

recommended

for

serging

Two

thread

inch

for

Three

(4.

serging

thread

(4.

76

speed

for

overseaming

8-20

turned

bed

that

fray

standard

adjusted

for

simultaneously

also

attaching

stitch.

(9.

52

mm);

speed

stitch.

76

mm);

speed

mm);

7500

on

medium

504-SSa-1;

per

edge

seaming

blankets,

readily.

seam

feed.

Seam

specification

stitch

7500

light,

medium

Seam

stitch

7500

light,

medium

stitch.

stitch

R.P.M.

pants,

to

inch;

cam

towels,

Three

width

Maximum

attaching

zippers

range

R.

P.

specification

range

R.P.M.

Seam

range

specification

4-8

jackets,

heavy

standard

adjusted

and

straight

wiping

thread

3/16

recommended

to

right

504-SSa-1

6-16

M.

and

4-8

and

per

weight

cloths

stitch.

inch

right

flies

per

heavy

per

heavy

inch;

snow

ma-

seam

feed.

over-

(4.

76

pants

only

or

inch;

3

Page 4

STYLES

OF

MACIDNES

(Continued)

39500

and

specification

range

R.P.M.

39500

sliders

skirts.

504-SSa-1;

inch;

39500

sers

Seam

stitch

7500

39500

flies

and

specification

stitch

speed

39500

flies

zippers

Three

width

mum

RP

Light

heavy

4-10

RU

Light

and

jackets

cam

SJ

Light

and

specification

range

R.P.M.

SR

Medium

and

similar

range

7500

SX

Medium

and

to

thread

3/8

recommended

to

weight

504-EFd-1;

per

to

medium

staples

standard

adjusted

to

medium

similar

4-8

to

zipper

operation

504-SSa-1

6

R.

P.

to

zipper

right

stitch.

inch

(9.

medium

trousers

inch;

already

and

similar

feed.

garments

503-EFd-1;

per

heavy

tapes

to

16

M.

heavy

tapes

flies

52

mm);

speed

duty

and

standard

cam

seam

inch;

adjusted

duty

width

Maximum

duty

machine

cam

duty

to

pants

of

Durable

or

per

inch;

duty

to

pants

only

and

Seam

stitch

7500 R.P.M.

machine

similar

seam

feed.

machine

in

place

garments.

of

machine

fronts;

SSj-

1;

machine

fronts

similar

specification

(and

3/16

recommended

for

Durable

standard

adjusted

Press

standard

cam

of

range

for

serging

garments.

width

Maximum

for

simultaneously

overedge

Three

inch

for

also

adjusted

for

6-16

(4.

serging

Press

seam

feed.

simultaneously

attaching

material.

seam

simultaneously

Durable

operations

504-SSa-1

per

and

Three

3/16

the

thread

76

mm);

speed

light

material.

width

Maximum

Three

width

feed.

Press

on

inch;

trimming

thread

inch

recommended

facings)

stitch.

and

zippers

Maximum

material;

Durable

or

cam

(4.

76

attaching

Seam

stitch

7500

medium

3/16

attaching

3/16

attaching

SSj-1;

adjusted

range

R.P.M.

Two

inch

recommended

to

right

thread

inch

Press

standard

light,

to

thread

recommended

also

medium

stitch.

mm);

speed

zippers

pants

specification

weight

(4.

right

stitch.

(4.

right

feed.

Seam

stitch

7500

with

flies.

4-10

trou-

stitch.

76

mm);

speed

pants

flies

material.

only

Seam

76

mm);

pants

attaching

se

Maxi-

per

am

39500

39500

maximum

sewing

50-100%

may

maximum

mum

readjustment

TG

Light

are

folded

material.

7

1/2

inches

ation

per

or

of

mm)

stitch

Maximum

39500

be

The

recommended speed

503-EFd-1;

inch;

TY

Medium

synthetic

two

plies

in

range,

MARK

rated

operation

machine

necessary

MARK

performance,

to

medium

and

similar

Smallest

(190.

cam

adjusted

to

heavy

mesh

of

material

diameter.

4-20

recommended

IV

machines

speeds. Varied

m ay

necessitate

running

to

reduce

IV

is a

of

precision

duty

machine

operations

cuff

that

can

50

mm)

standard

bags.

Three

per

precision manu

the

for the

in

circumference.

seam

feed.

duty

Will

and

inch,

SPEED

cycl

the

machine should

mechanism s .

Maximum

machine

turn

finish

thread

cam

speed

RECOMMENDATION

ha

ve

been tes

field

operating at a lower

e a

nd a longer

ma

chin

fir

for

serging

on

light,

be

sewn

width

up

from

into a tight

stitch. Seam specification

adjusted

5500

condition

e 's s

fac

tured and tested s

st 20

is 2 3/8

3/16

recommended

for

hemming 5 to

3/4

feed.

R.P.M.

ted

in

s ,

than

peed

be ope

days of

around

medium

Two

inch

to 1 1/4inch

roll

when

their

severity

recommend

by

10-15%.

rated

field ope

and

inch

thread

(4.

approximately

Maximum

sewing

complete stitch range

speed.

at

1000

ration. This will minimi

76

ewi

pants

heavy

(60.

32

stitch.

mm);

speed

25

pound

(19.05

504-SSp-1

mesh bag

and clea

Wh

ed s

ng

R.P

cuff

before

weight

mm)

7500

speed

en

ma

diameter

Seam

stitch

R.

P.

paper, cotton

to

31.

1/4 inch (6.

6500 R.P.M.

s.

nlin

operating from

tit

ch length,

chin

e. To

. M. below

cuffs

trouser

spe

cific-

ran

ge

4-8

M.

75

mm)

modified;

at

their

ess

of

the

obtain

maxi-

or

35

it

ze

4

Page 5

OILING

CAUTION!

filled

straight

should

before

mineral

be

Machine

sight

gauge

gauge

lines

Machine

main

when

no

It

have

reservoir

To

maintain

operating

case

The

should

drain

is a magnetic

entered

beginning

used.

is

on

when

is

the

Oil

was

drained

to

oil

of a Saybolt

filled

front

with

of

machine.

machine

automatically

filled.

Check

maximum

continuously.

oil

remain

plug

screw

screw

crank

designed

case.

from

operate.

Oil

viscosity

oil

at

spring

Red

is

stationary.

lubricated.

oil

daily

recommended

the

oil

in

machine

is

located

to

accumulate

It

should

machine wh

capacity

of

cap

bulb

on

oil

No

oiling

before

speed

must

for

at

be

be

more

back

removed

NEEDLES

en

of

Class

90

to

125

in

top

level

is

the

morning

and

changed

than

of

machine

possible

and

shipped,

so

39500

seconds

cover.

Oil

indicator

necessary,

start;

serviceability

at

one

foreign

least

year.

near

every

bottom

materials

cleaned

reservoir

is

eight

at

100°

level

should

other

add

of

is

oil

this

six

show

than

as

ounces.

Fahrenheit

checked

equipment

months.

edge

which

periodically.

must

between

keeping

required.

of

base.

may

be

A

at

In

Each

denotes

number,

in

thousandths

size

number

packaged

Class

needle

s

izes

Type

154

GAS

To

sample

on

label. A complete

UNION

the

kind

stamped

and

39500

for

the

available

No.

have needle

needle,

Selection

should

pass

freely

SPECIAL

of

shank,

on

of

an

represent

sold

by

machines

Styles

of

the

Round

s

truck

shank,

055/022,

the

inch,

Union

covered

recommended

groove, spotted.

needle

point,

needle

midway

the

complete

Sp-~cial.

use a curved

round

065/025,

110/044, 125/049,

of

or

the

orders

the

type

order

proper

through

promptly

and

would

needle

needle

has

length,

shank,

between

symbol

here

is

Type

needle.

Description

point.

070/027,

140/054,

and

size

number

read:

size

eye

in

both

type

groove.

denotes

shank

which

blade

154

and

curved

blade,

chromium

075/029,

150/060.

accurately

should

''1000

is

Ne edles

determin

order

and

size

finish

largest

and

is

needle.

number.

and

diameter

eye.

given

The

GAS. Below

Sizes

standard

plated

and

080/032,

filled,

be

forwarded.

, T

ype

ed

by

size

to

produce a good

The

oth·~r

details.

of

blade,

Collectively,

on

the

label

standard

is

the

description

length.

is

available

090/036,

an

empty

Use

154

GAS,

of

thread use

stitch

type

number

The

measured

type

of

all

needles

recommended

single groov

in siz

100/040,

packa

ge, a

description

Size

110/044

d.

Thread

formation.

size

and

and

e.

es

" .

Success

of

us e

a

reputation

for

more

needles

than

in

the

packaged

for

producing

thr

ee -

operation

under

quarter

of

UNION

our

brand

highest qua

lity ne

s of a century

SPECIAL

nam e

,~

edl

.

5

machines can

es

in

m ater i

be secured

® •

which

als

and

onl

y by

is

backed

by

workmanship

Page 6

Re

lease pressure

Fig.

in

1,

operating

socket

1/ 4 turn.

To

left,

insert

position,

nut.

Return

lA,

direction

wrench

Again

replace

needle

turn

presser

lB

or

lC)

No.

21388

turn

needle,

in

handwheel

on

presser

and

swing

until

needle

AU,

handwheel

leave

holder

until

arm

(U)

CHANGING

foot

presser

is

furnished

until

needle

until

holder

it

rests

needle

holder

to

position;

by

at

with

is

NEEDLE

turning

arm

its

lowest

machine,

is

at

against

again

re-lock

(U)

at

high

at

its

presser

presser

out

point

loosen

high

position;

position

stop

low

foot

of

position.

of

travel.

pin.

point

foot

release

needle

withdraw

and,

Keeping

of

travel;

release

Turn

Using

clamp

with

bushing

handwheel

hexagonal

nut

needle.

the

flat

needle

then

bushing

(AG,

about

to

the

in

this

tighten

(AG).

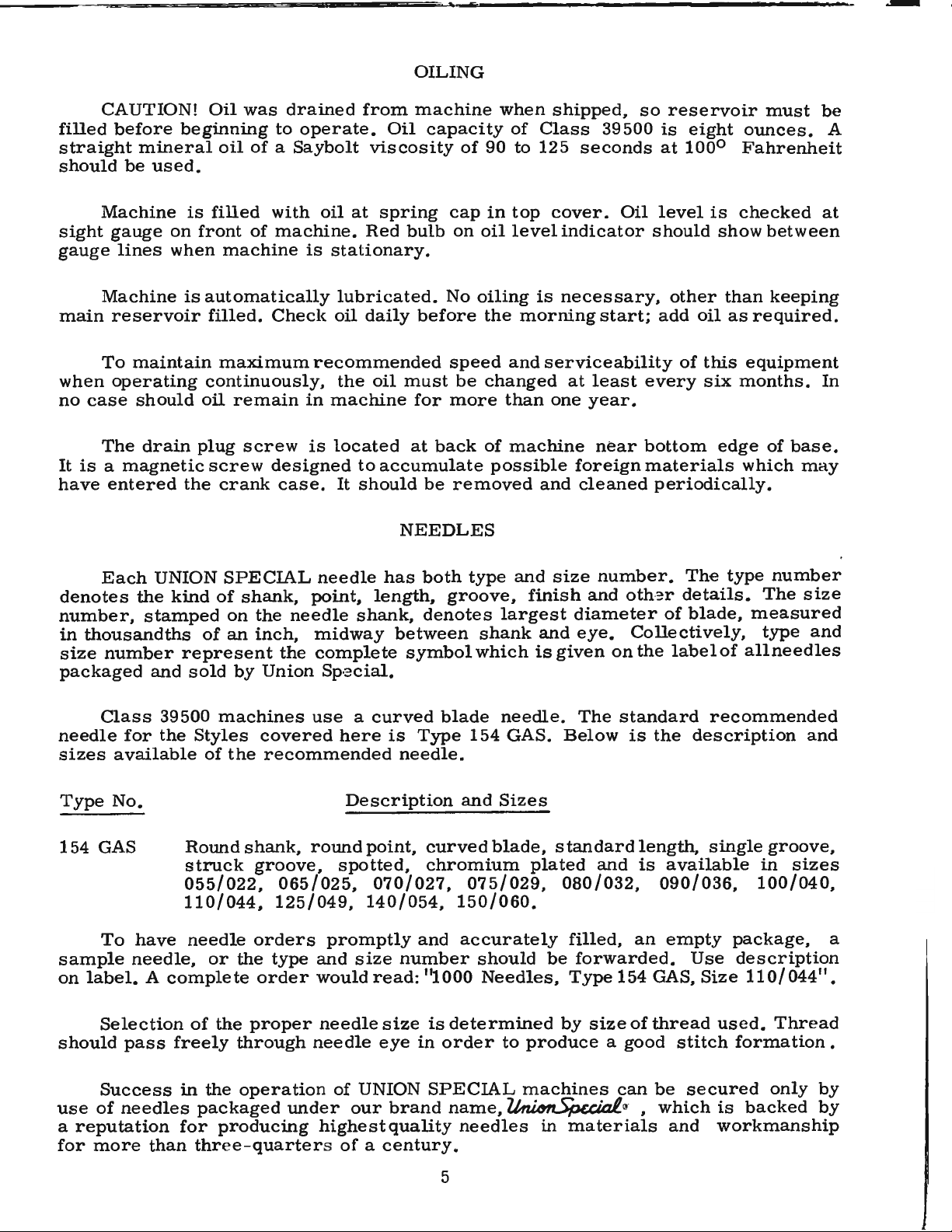

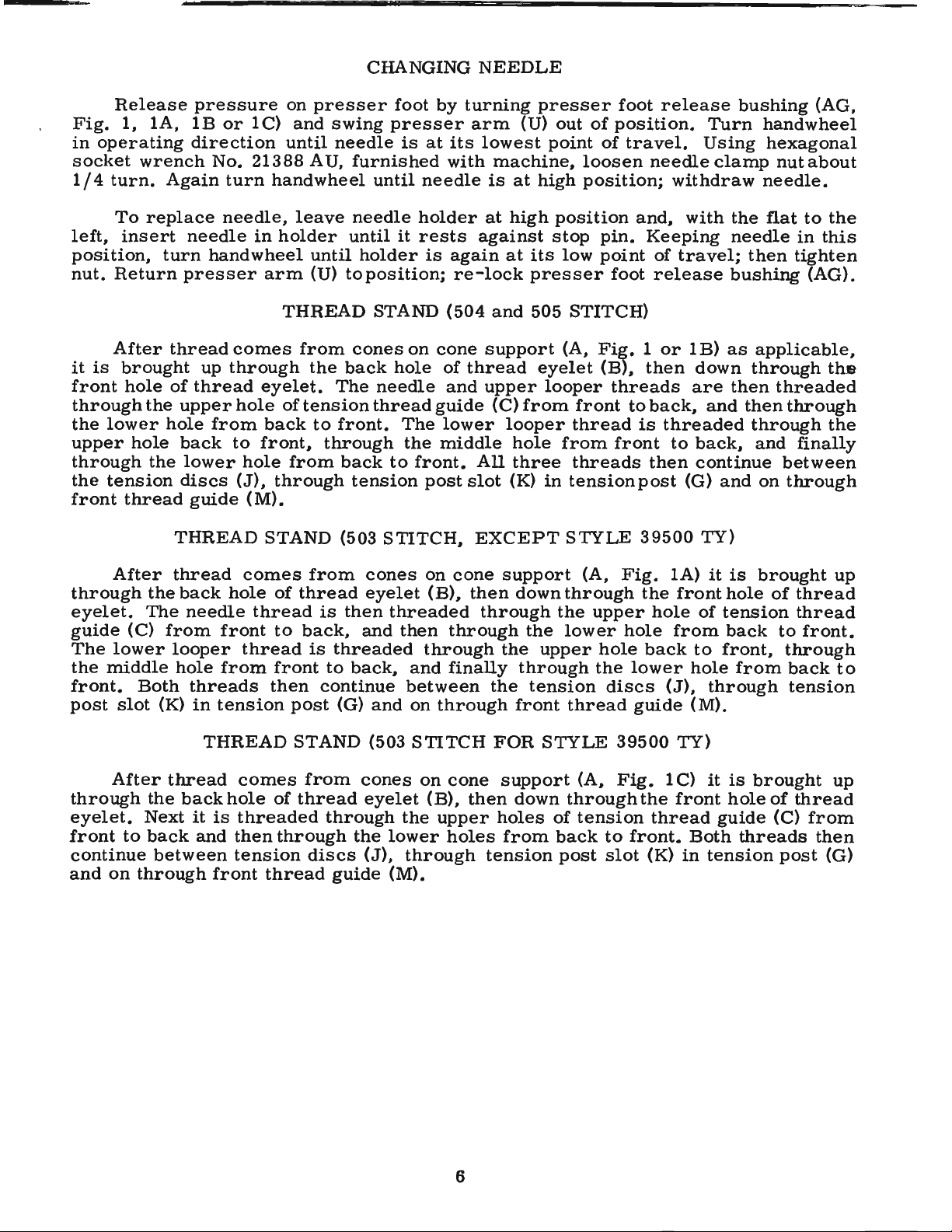

After

it

is

brought

front

hole

through

the

lower

upper

through

the

tension

front

thread

After

through

eyelet.

guide

The

lower

the

middle

front.

post

slot

the

hole

the

the

The

(C)

Both

thread

up

of

thread

upper

hole

from

back

lower

discs

guide

THREAD

thread

back

needle

from

looper

hole

threads

(K)

in

THREAD

comes

through

eyelet.

hole

back

to

front,

hole

(J),

(M).

STAND

comes

hole

thread

front

thread

from

tension

THREAD

from

the

of

tension

to

through

from

through

from

of

thread

is

to

back,

is

front

then

to

continue

post

STAND

STAND

cones

back

The

hole

needle

thread

front.

back

to

tension

(503

STITCH,

cones

eyelet

then

threaded

and

threaded

back,

(G)

and

(503

(504

on

cone

of

and

guide ( C)

The

lower

the

middle

front.

post

on

cone

(B),

then

through

through

and

finally

between

on

through

STITCH

and

support

thread

upper

from

looper

hole

All

three

slot

(K)

EXCEPT

support

then

down

through

the

the

through

the

front

FOR

505

STITCH)

(A,

eyelet

looper

front

thread

from

threads

in

tensionpost

STYLE

through

the

lower

upper

tension

thread

STYLE

Fig. 1 or

(B).

threads

to

is

front

(A,

Fig.

upper

hole

hole

the

lower

discs

guide

39500

then

back,

threaded

to

then

(G)

39500

lA)

the

front

hole

from

back

(J),

TY)

lB)

as

down

are

then

and

then

back,

continue

and

TY)

it

is

hole

of

tension

back

to

front,

hole

from

through

(M).

applicable,

through

the

threaded

through

through

and

the

finally

between

on

through

brought

of

thread

thread

to

front.

through

back

tension

up

to

After

through

eyelet.

front

continue

and

on

the

Next

to

back

between

through

thread

back

it

is

and

front

comes

hole

of

threaded

then

through

tension

thread

from

thread

through

discs

guide

cones

eyelet

the

lower

(J),

on

(B),

the

through

(M).

cone

then

upper

holes

6

support

down

holes

from

tension

of

back

post

(A,

Fig.

through

tension

to

slot

1 C)

the

thread

front.

(K)

it

front

Both

in

tension

is

brought

hole

guide

threads

of

(C)

post

up

thread

from

then

(G)

Page 7

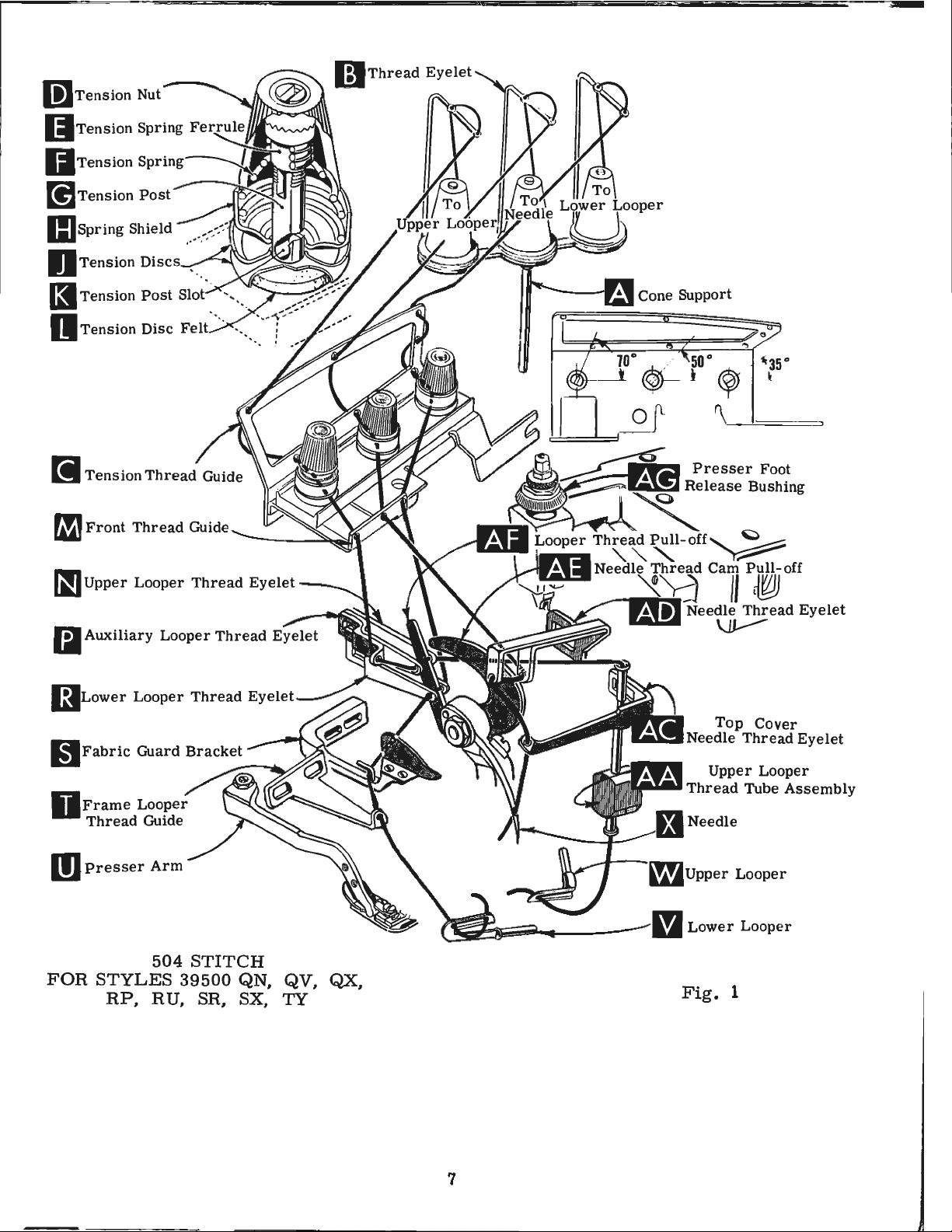

l!]

Tension

II

Tension Spring

II

Tension

Nut

Spring~

Ferrule

--,!.J

!lt'f"

.......

[.illl~

-::::;

~ ~

li)

Thread

Eyelet

[!l Tension

ll)

spring Shield

g Tension

l3

Tension

II Tension

[i

Tension

f,IJ

Front

ll)

upper Looper

liJ

Auxiliary

Post

Discs

Post

Disc

Thread

Thr

ead Guide

Looper

·:.·_

-----

Slo< ',. __

Felt · ..

Guide

Thread

Thread

Eyelet

Eyelet

'---

~'-

-'=

==

'9

Lower

D

Frame

Thread

m

Presser

FOR

L0oper

Looper

Guide

Arm

504

STYLES

RP,

RU,

Thread

STITCH

39500

SR, SX,

Eyelet

QN, QV,

TY

QX,

..

.._

m

,.

Needle

Thread

Lower

Fig.

Top

Thread

Upper

Looper

1

Cover

Looper

Tube

Eyelet

Assembly

7

Page 8

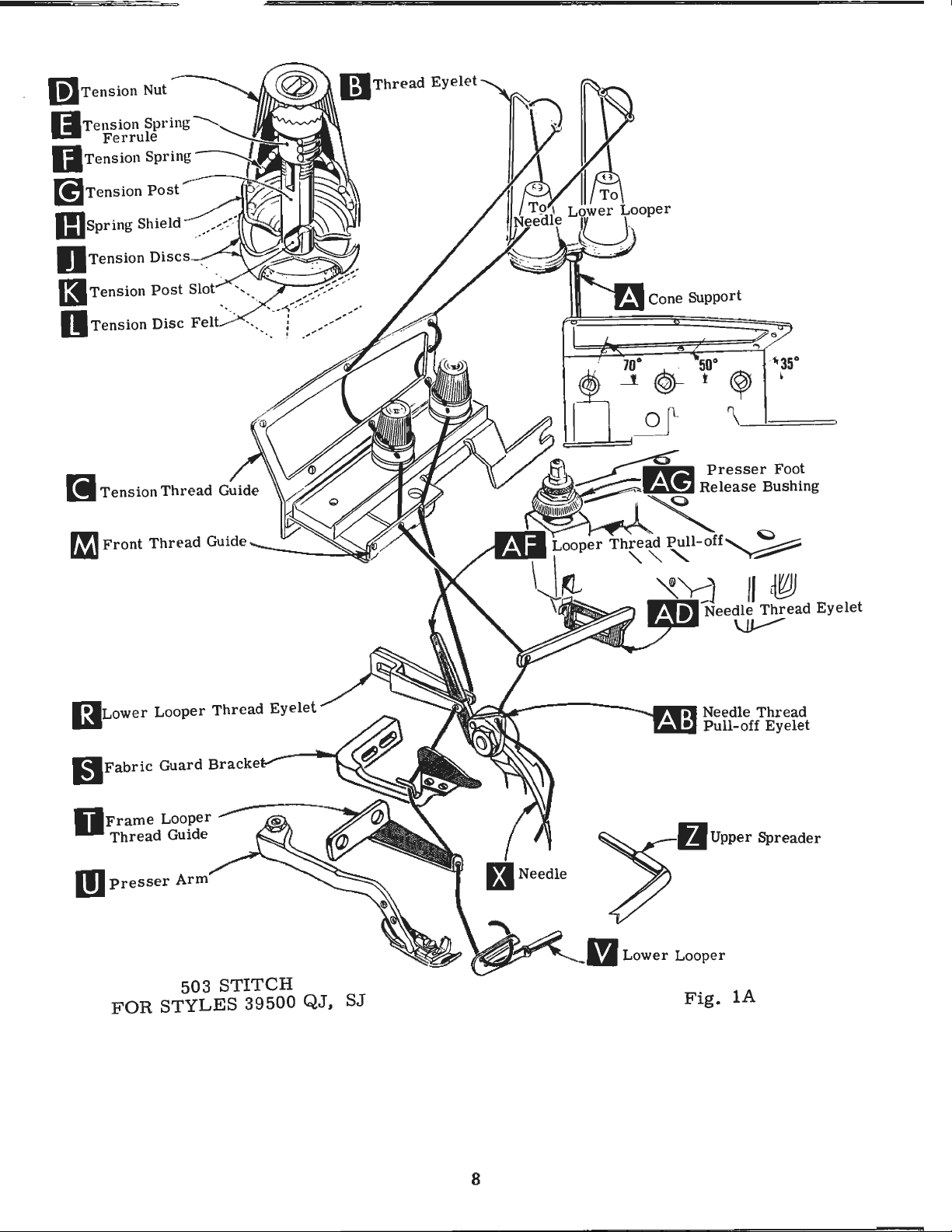

(;]

Tension Nut

Sprin

A Tension

IS

II

[!]

ll)

Fe

rrul

Tension Spring --J.,

Tension

spring Shield

g---._____

e

Post

~

/~

-~~

~\

O Tension

l3

Tension

II

Tension

[I

Tension

fl1

Front

Disc

s ·

-.·

._

Post

Slot :

Disc Felt ··.

Thr

ead Guide

Thr

ead Guide

m Lower

-

Fabric

Frame

D

Thread

DJ

presser

FOR

Looper

Guard

Looper

STYLES

Thread

Bracke

Guide

Arm

503

Eye

STITCH

39500

let

QJ,

SJ

Ne

edle

Upper

lA

Thread

Eyel

et

Spreader

Pull-off

~

fj

Fig.

8

Page 9

li]

Tension Nut

(I

Tension

II

Tension

[!]

Tension

ll)

spring Shield

Sprin~

Ferrule

Spring--f.J.

Post

~

/

Jl&..""'-

~~a.

~

O Tension

(311

Tension

n Tension

~

Front

Im

Upper

II

Auxiliary

Discs

Post

Disc

Thread

Looper

Looper

· .. -

Slo~

· ·

Felt

··

Guide

Thread

..

Eyelet

Thread

Eyelet

B Cone Support

Presser

Foot

l3

Lower

IJI

Fabric

D Frame Loop er

Thread

FOR

Looper

Guard

Guide

505

STITCH

STYLE

Thread

Bracket

39500

Eyelet---~

QL

J3

"'

/

Needl

e ~

~ -

Jj

Thread

Needle

Pull-off

Upper

-

Tube

Upper

Fi

g. l B

Thread

Eyel

Looper

Assembly

Looper

et

9

Page 10

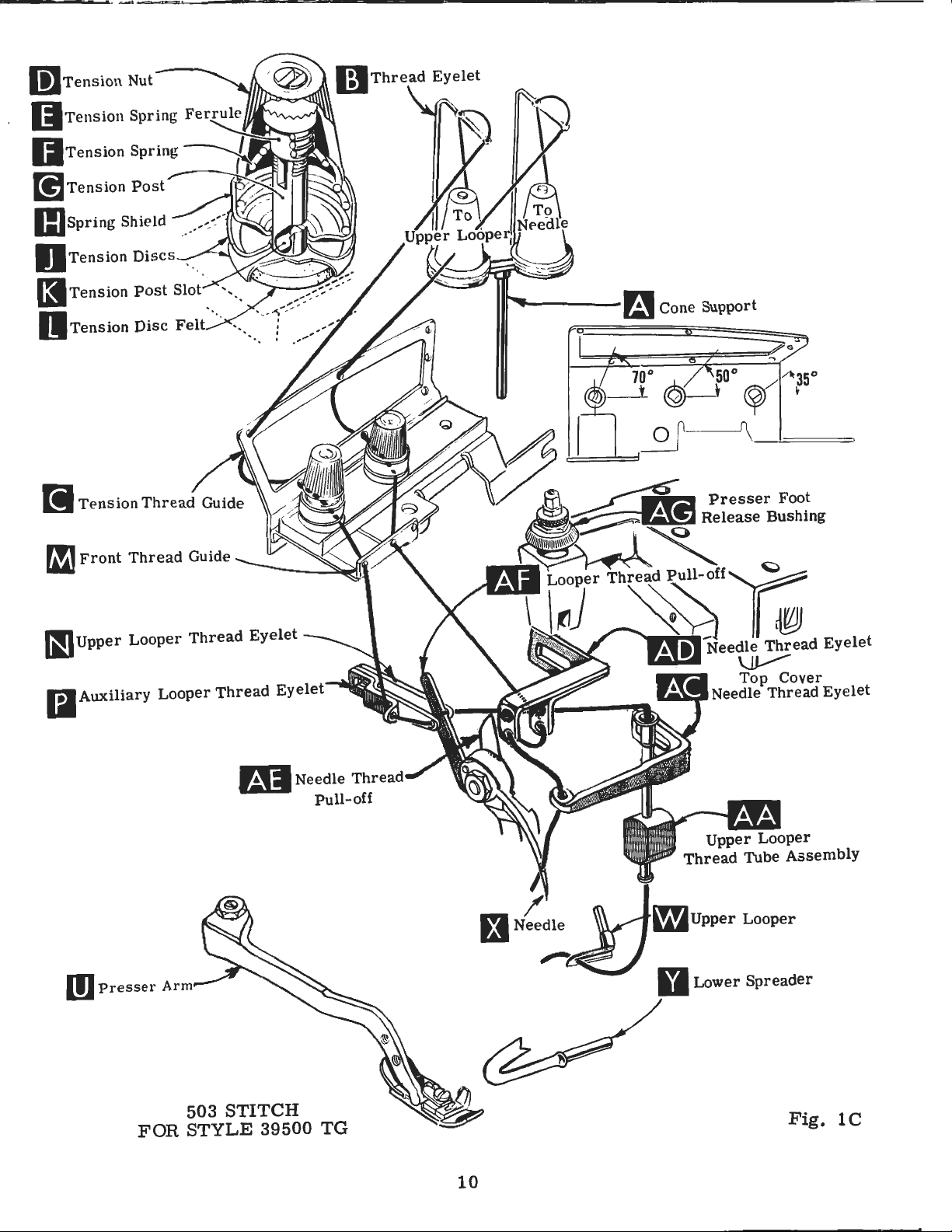

m Tension Nut

(I

Tension

II

Tension

P'-1

~ Tension

ll)

spring

Sprin

Spring

Post

Shi ld _

g Fe

~

--

-~

~

rrul

e

'

~---~~

~

D Tension

l3

Tension

II

Tension

flJ

Front

tm

upper

Iii

Auxiliary

Disc

s .> .

Post

Slo~

Disc

Thread

Looper

Looper

·- --..

Felt

·· ..

Guide

Thread

'"~-,:-z

Thre

~

<:::,,,

J~',...,;;;~"'J

Eyelet

ad

Eyelet

.,._

_____

m Cone Support

- Needle

m

Press

er

Arm

503

STITCH

FOR

STYLE

39500

Thread

Pull-off

TG

10

t3

L.;.Jj

Upper

Thread

rn

upper

1:1

Lower

Looper

Tube

Assembly

Looper

Spreader

Fig.

lC

Page 11

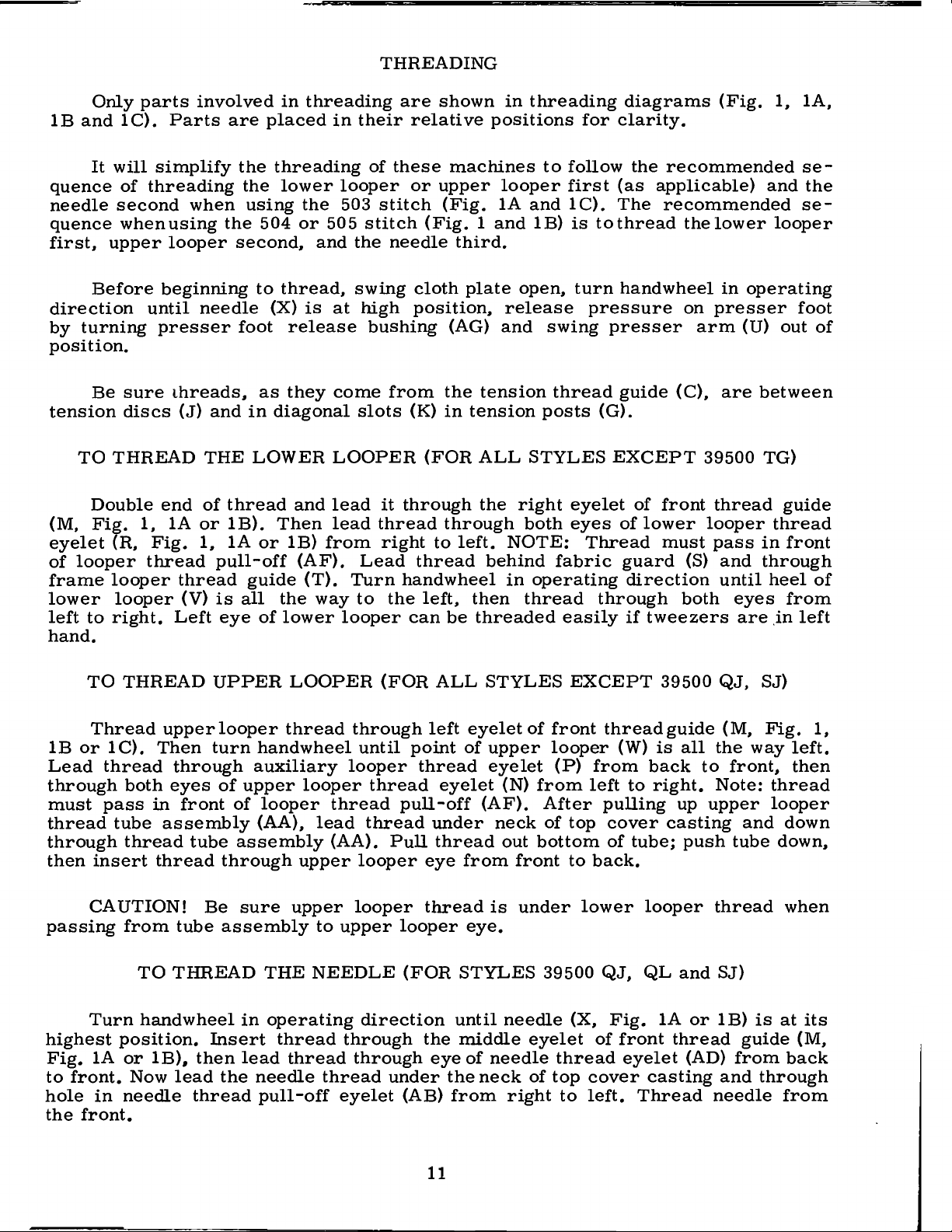

THREADING

Only

1 B

and 1 C).

It

quence

needle

quence

first.

direction

by

position.

tension

(M.

eyelet

of

frame

lower

left

hand.

upper

Before

turning

Be

TO

Double

Fig.

looper

to

parts

Parts

will

simplify

of

threading

second

whenusing

looper

beginning

until

presser

sure

discs

THREAD

(R.

looper

looper

right.

end

1.

lA

Fig.

thread

Left

hreads,

(J)

thread

involved

when

the

needle

and

THE

of

thread

or

1,

pull-off

(V)

is

eye

are

placed

the

threading

the

using

504

second,

to

(X)

foot

as

in

diagonal

LOWER

lB).

lA

or

guide

all

of

in

threading

lower

the

or

and

thread,

is

release

they

and

Then

lB)

(AF).

(T).

the

way

lower

in

their

of

looper

503

stitch

505

stitch

the

swing

at

high

bushing

come

slots

LOOPER

lead

lead

from

it

thread

right

Lead

Turn

to

looper

are

shown

relative

these

needle

from

through

handwheel

the

machines

or

upper

(Fig.

(Fig. 1 and

cloth

position,

(AG)

the

(K)

in

(FOR

through

to

thread

left.

can

be

positions

third.

plate

tension

tension

ALL

the

left.

behind

then

threaded

in

threading

looper

lA

and

lB)

open,

release

and

STYLES

right

both

NOTE:

in

operating

thread

to

follow

first

lC).

is

turn

swing

thread

posts

eyelet

eyes

fabric

easily

diagrams

for

clarity.

the

(as

The

tothread

handwheel

pressure

presser

guide

(G).

EXCEPT

of

Thread

guard

direction

through

if

recommended

applicable)

recommended

the

on

arm

(C).

39500

of

front

lower

tweezers

looper

must

(S)

both

(Fig.

lower

in

operating

presser

(U)

are

between

thread

pass

and

until

eyes

are .in

1.

lA,

se-

and

the

se-

looper

foot

out

of

TG)

guide

thread

in

front

through

heel

of

from

left

TO

Thread

lB

or

Lead

through

must

thread

through

then

insert

CAUTION!

passing

Turn

highest

Fig.

lA

to

front.

hole

the

in

front.

THREAD

lC).

thread

both

pass

in

tube

thread

from

TO

handwheel

position.

or

lB).

Now

needle

UPPER

upper

Then

assembly

thread

turn

through

eyes

front

tube

Be

tube

THREAD

Insert

then

lead

thread

looper

handwheel

auxiliary

of

upper

of

looper

(AA).

assembly

through

sure

assembly

THE

in

operating

thread

lead

the

needle

pull-off

LOOPER

thread

looper

looper

thread

lead

(AA).

upper

upper

to

upper

NEEDLE

through

thread

thread

eyelet

(FOR

through

until

thread

pull

thread

Pull

looper

looper

looper

(FOR

direction

through

under

(AB)

ALL

left

point

thread

eyelet

-off

under

thread

eye

thread

the

eye

STYLES

eyelet

of

upper

eyelet

(AF).

neck

from

is

eye.

STYLES

until

middle

of

needle

the

neck

from

of

(N)

from

After

of

out

bottom

front

under

39500

needle

eyelet

of

right

EXCEPT

front

looper

(P)

from

left

top

to

back.

lower

(X.

of

thread

top

cover

to

left.

thread

(W)

back

to

pulling

cover

of

tube;

looper

QJ,

QL

Fig.

front

eyelet

casting

Thread

39500

guide

is

all

right.

up

casting

push

and

lA

or

thread

(AD)

QJ,

( M,

the

to

front,

Note:

upper

tube

thread

SJ)

lB)

from

and

needle

SJ)

Fig.

way

thread

looper

and

down.

is

guide

through

left.

then

down

when

at

its

(M.

back

from

1,

11

Page 12

TO

THREAD

THE

NEEDLE

(FOR

ALL

STYLES

EXCEPT

39500

QJ,

QL

and

SJ)

Turn

highest

Fig. 1 or

thread

cover

tension

to

eyelet

needle

The

secure

Fig.

handwheel

position.

1 C,

then

(AD),

thread

amount

nuts

(D,

proper

2

Insert

insert

of

tension

Fig.

stitch

in

operating

thread

needle

under

eyelet

1,

lA,

formation.

should

decrease

nut

screw

pressure,

adjusting

(A).

ing

to

justing

through

thread

neck

1 / 16

of

(AC).

THREAD

on

the

lB

Sufficient

be

(A,

has

With

nut

( C)

inch

screw

FEED

direction

the

from

top

cover

Thread

needle

or

lC).

PRESSER

presser

maintained.

amount

Fig.

2)

and

a

right

loosening

screw

presser

so

(B)

that

(.

79

(B).

ECCENTRICS

until

middle

right

casting;

needle

TENSION

and

Tension

of

foot

its

to

Set

from

looper

foot

Should

pressure

turn

hand

decreases

has

been

resting

under

1. 59

cap

needle

eyelet

to

left,

then

the

threads

on

threads

FOOT

pressure

it

adjusting

thread,

properly

on

surface

mm)

(D)

against

(X,

Fig. 1 or

of

front

through

down

front.

is

should

PRESSURE

to

be

necessary

on

presser

screw

so

tightening

pressure.

throat

is

from

the

locking

lC)

thread

both

eyes

through

regulated

feed

foot,

set,

plate,

approximately

top

hole

by

be

only

work

to

increase

loosen

(B).

When

tighten

position

surface

nut

is

at

its

guide

of

uniformly

Adjusting

increases

pressure

(C).

(M,

needle

in

top

knurled

enough

lock

lock

nut

lock-

1/32

of

ad-

or

Feed

approximately

eccentric

mately

specified,

exploded

The

-5. -6,

-28,

Additional

39540 B with a minor

stitches

Before

cloth

lower

NOTE:

chines

eccentrics

is

the

views

following

-7,

-30,

desired.

plate,

knife

Adjusting

covered

5

stitches

No.

39540

number

machine

in

catalog

-8, -9,

-32,

eccentrics

-34, -36,

Example:

ASSEMBLING

assembling

fabric

holder

assembly;

instructions

in

this

of

Style

stitch

guard,

SETTING

used

in

Style

per

inch.

B-5.

stitches

number

-10, -11, -12,

may

number

catalog,

39500

for

-40.

be

"39540

and

chip

then

Minor

obtainable

QJ

eccentrics

feed

Only

ordered

suffixed

AND

adjusting

guard,

follow

will

unless

THE

39500

It

B-5".

NEEDLE

QJ

will

be

numbers

when

will

be

furnished

eccentrics

-13, -14,

one

eccentric

separately.

to

ADJUSTING

sewing

upper

this

pertain

otherwise

machines

noted

using

shipped

indicate

knife

suggested

to

that

of

the

on

are

-15,

is

SEWING

parts,

assembly

all styles

specified.

have

been

the

part

that

with

available

-16, -18,

To

symbol

eccentric.

above

other

supplied

order

approxima

PARTS

remove

sequence.

of

part

Styles

under

-20.

with

an

and

ma

-

selected

number

indicate

Unless

eccentric.

of

machines.

No.

-22, -24,

each

eccentric,

ely

the

to

produce

of

the

approxi-

otherwise

Refer

39540

number

B-4,

machine.

use

feed

to

-26,

No.

of

With

should

high

position,

above

1/2

inch(12.

throat

center

throat

in

ne

plate

70

mm)

plate

the

edle

(Fi

(A, Fig. 3) assembl

front

for

point

g.

3)

Styl

end

of needle

should

for

Styl

es 39500

be set

es

QN

ed

in

slot.

33/64 inch

39500

and

12

QJ,

SR;

position, needle

When needle

(13.

QL,

and

10

RP a

nd

15/ 32 in

is

at

mm)

SJ ;

ch

Fig. 3

Page 13

(11.

91

height

clamp

remove

On

if

needle

looper

thread

off

screw,

ing

arm.

At

lower

39500

lower

1/8

looper

inch

using

39500

lower

and

looper

lower

needle,

spreader

mm)

above

screw

throat

all

thread

thread

pull

be

this

looper

TG

insert

(3.17

looper

QJ,

spreader

using

deflecting

for

the

(C).

plate.

Styles

pull-off

-off

back.

sure

point

(A,

at

left

mm)

QL,

point

looper

Styles

39500

throat

After

except

cam

pull

(B),

When

to

take

on

all

Styles

Fig.

lower

end

from

gauge

QN, QV,

for

Styles

point

gauge

needle.

SETTING

QV,

plate,

needle

39500

-off

(A,

separate

retightening

upend

except

5)

into

spreader

of

its

stroke,

center

No.

21225-1/8

RP,

39500

for

Style

No.

Tighten

THE

QX,

RU,

move

QJ,

has

needle

been

QL,

Fig.

by

movinglooper

play

inneedle

39500

bar

(B).

into

bar

set

of

needle

RU,

SJ

QX,

39500

21225-3/32.

nut

NEEDLE

SX,

TG

driving

properly

SJ

and

4)

overlaps

looper

TG,

insert

On

(B).

looper

(Fig.

for

Styles

and

SR.

SX

and

TG

(C).

(Continued)

and

TY.

arm

set,

TG,

pull

-

driv-

Style

With

point

5).,

Set

TY;

3/32

Do

inch

not

To

(2.

have

align

(B,

Fig.

tighten

38

mm)

lower

needle

3)

clamp

Fig.

from

looper

or

by

loosening

screw

4

center

or

set

lower

the

and

of

Now

to

the

7)

until

•

002-.

SETTING

Now

to

the

7 A)

until

surface

Fig.

SETTING

finish

right,

the

needle

004

inch(.

THE

lower

its

5

THE

point

springs

051-.102

LOWER

complete

right,

the

its

point

needle

another . 002-.

looper

the

should

springs

LOWER

should

forward

mm).

SPREADER

spreader

004

inch(.

Now

Set

possible,

looper

deflect

mm).

Make

needle

LOOPER

adjustment.

be

set

into

from

adjustment.

be

set

into

forward

051-.102

assemble

SETTING

rear

without interfering

or

lower

needle

Screw

sure

there

guard

(ALL

As

lower

the

needle

rear

guard

(STYLE

As

the

needle

from

mm).

THE

needle

spreader,

forward.

(B)

is

is

and

lower

STYLES

looper

scarf

surface

39500

spreader

scarf

rear

the

main

REAR

guard

used

no

interference

looper

EXCEPT

TG

ONLY)

(A,

needle

feed

NEEDLE

(A,

but

002-.

to

set

moves

(A,

Fig.

another

moves

Fig.

guard

dog.

Fig.

with eith

still

004

inch(.

rear

or

spreader.

39500

GUARD

6)

as

er

in

position

051-.102

needle

between

TG)

high

lower

guard.

rear

as

to

Assemble

springing

as

possible

and

set

between

SETTING

needle

to

front

needle

needle

front

needle

THE

off

guards

FRONT

needle

back

guard,

without

guard.

and

guard

touching.

After

feed

dog.

NEEDLE

(C,

Fig.

set

front

Screw

this

setting

GUARD

6).

When

needle

(D)

is

make

guard

used

13

spread

as

to adjust

sure

er

close

ther

is

e is

Fi

g. 6

no

interference

Page 14

SETTING

THE

UPPER

LOOPER

(ALL

STYLES

EXCEPT

39500

QJ,

SJ)

Insert

its

holder

Fig.

of

looper

of

upper

set

upper

lower

looper

clearance

upper

and

7

and

looper

looper

(Fig.

looper

permits

the

casting.

shaft

point

eye

9).

(A,

it

to

upper

in

holder

the

looper

place.

in

shank

holder

SX

and

39500

RP

When

upper

shank

(Fig.

SR

be

and

set

looper

about

8).

to

slightly

Styles,

By

and

by

turning

to

cross

with . 002

Fig.

be

pushed

holder

Screw

the

extends

(Fig.

TY;

and

the

vertical

On

TG

the

position

back

there

adjusting

lower

to . 004

8)

in

its

holder.

in

or

out

into

upper

(C,

Fig.

shaft.

8),

1/32

1/16

for

Locate

Styles

to

1/16

to

TG.

upper

holder

Styles

upper

of

vertical.

the

looper

should

on

Styles

39500

looper

upper

is a clearance

looper

the

looper

around

looper

inch

(.

051

or

8)

on

upper

3/32

39500

inch

is

be

QL,

holder

looper

Be

sure,

between

holder

to

the

to • 102

Screw

turned

looper

clamp

looper

inch

(.

at

set

39500

RP,

in

its

left

(B)

around

shaft,

(1.

QL,

79

to

the

right

to

QN,

RU,

should

shank

on

all

heel

or

out

shank,

of

the

mm)

holds

if

holds

in

its

59

to

2.

QN,

QV,

1.

59

end

position

QV,

upper

its

it

the

38

mm)

QX,

shank.

is

not

upper

holder

mm)

QX,

for

of

its

upper

SX

looper

Insert

already

loop

so

beyond

RU,

Styles

stroke,

looper

and

in

er

that

SR,

TY

As

heel

head

of

with

Next,

travel;

needle

looper

39500

as

follows:

centers

(Fig.

the

bottom

the

the

check

and

holder

QL

Fig.

on

12).

upper

upper

1/32

turn

looper

looper

to

1/16

handwheel

dimensions

throat

and

(A,

RP.

plate

Fig.

8

As the

the needle,

For

Styles

of

the

needle

moves

should

inch(.

of

(Fig.

10).

NOTE:

the

other

example,

ion

is

holder

left

end

dimension

looper

looper

made

looper

tain

the

When

for

Styles

SR,

SX

upper

looper

the

39500

eye

toward

pass

79

to

until

looper

upper

10).

If

Figure

For

Styles

1/2

increased

the

behind

1.

59

is

looper

resetting

10

represents

the

dimensional

refer

inch

by

counterclockwise,

of

machine;

is

increased

holder

to

the

shaft. After

it

may

be

necessary

around its

condition

the

39500

and

TY

shank

shown

correct

QL,

it

can

is moving

eyes

of

RU

and

should

the

TG

be

upper

about

top

of

its

the

lower

mm)

at

the

point

is

clearance.

left

with

necessary,

the

settings

to

Fig.

(12.

70

mm)

turning

upper

looking

5 / 3 2

by

left,

these

inch ( 3.

pulling

out

changes

to

turn

slightly

in

(Fig.

setting

is

QN, QV,

be

checked

to the right and

looper

when

the

level

looper

with

stroke,

the

looper

end

of

its

respect

dimensional

do

to

it

bymoving

setting

of

11.

For

dimens-

looper

from

9 7

mm)

upper

of

upper

are

upper

to

main-

9).

obtained

QX,

RP,

quickly

the

upper

and needle should

eye

centers

the

top

surface

Fig.

7A

theupper

for

Styles

Fig.

loop

9

er

align exactly

on

the

needle,

of

the

looper.

eye

14

Page 15

SETTING

THE

UPPER

LOOPER

{ALL

STYLES

EXCEPT

39500

QJ,

SJ)

{Cont.)

Check

downstroke.

slightly

of

machine.

Machine

39500

39500

and

Styles

QL,

QN,

3 9 500 QV,

39500

39500

39500

RU

SR

TG

setting

If

needle rubs

rotate

Reset

RP

TY

QX,

SX

to

avoid

interference

the

looper a short

to

maintain

dimensions

Looper

Needle

5/32

9/64

9/64

5/32

9/64

5/32

back

distance

Point

Center

inch

inch

inch

inch

inch

inch

of

Fig.

(3.

(3.

(3.

(3.

(3.

(3.

between

upper

upper

looper,

counterclockwise,

of

Figs.

10

to

Left

Of

line

97

mm)

57

mm)

57

mm)

97

mm)

57

mm)

97

mm)

9,

looper

pull

10,

and

looper

looking

11,

12.

Looper

Throat

1/2

1/2

1 5 / 3 2

29/64

31/64

15/32

needle

out

inch

inch

inch

inch

inch

inch

of

from

Point

Plate

(12.

(12.

(11.

(11.

(12.

(11.

on

needle

its

hold

left end

Above

70

mm)

70

mm)

91

51

30

91

er

mm)

mm)

mm)

mm)

to

left,

behind

(.

051

looper

Fig.

the

the

12

Vee

eye

to . 102

(Fig.

of

mm)

9A).

notch

the

lower

clearance

SETTING

Insert

(B)

holds

pushed

holder

{C,

shaft,

in

into

Fig.

and

Preliminary

of

its

stroke,

er

shank

Top

end

of

extend

1.

59

er

of

mm)

(Fig.

As

the

1/32

8A).

spreader

spreader

looper,

between

THE

upper

upper

or

out

spreader

8A)

allows

Setting:

spreader

about

spreader

to

above

with.

Fig.

UPPER

11

SPREADER

spreader

spreader

or

turned

shaft,

on

clamp

collar

holder

When

holder

vertical

(Fig.

shank

1/16

the

moves

should

inch

spreader

002

to . 004

from rig

pass

spreader and

(A,

in

its

around

if

to

be

upper

should

(.

79

hold-

lower

Fig.

holder,

it

is

not

holds

rotated

spreader

should

8A).

to

ht

just

inch

(STYLES

8A)

in

and

its

shank.

already

spreader

or

be

set

39500

its

holder.

permits

Insert

in

place.

holder

adjusted

is

at

the

to

position

QJ

and

Screw

it

to

spreader

Screw

in

laterally.

right

spread-

SJ)

be

the

end

left

Turn

end

of

the

handwheel

its

travel.

At

until

this

upper

position,

spreader

the

is

lower

at

point

15

the

Fig.

8A

Page 16

SETTING

of

the

line

of

THE

spreader

the

needle

UPPER

should

and

SPREADER

extend

should

plate

ing

about

be

the

31 /

64

(Fig.

spreader

(STYLES

5/32

inch

l0A).

inch

(12.

If

holder

39500

(3.

97

30

mm)

resetting

(A,

QJ

mm)

is

Fig.

and

SJ)

to

the

above

necessary,

10A).

(Cont.)

left

the

top

of

do

of

the

the

it

center-

throat

by

mov-

feed

bar.

The

appear

justing

of

travel,

3/64

inch

39500

throat

of

throat

SR

and

be

set

Fig.

feed

above

pin

(1.

TY

which

plate.

plate,

SX.

to

the

in

the

19

On

same

9A

dogs

the

place.

top

mm)

should

Now

for

Style

should

throat

With

of

the

above

set

Styles

39

height

needle.

out

ward

opposite

spreader

feed

spect

pin

be

plate.

the

teeth

the

rise

the

chaining

39500

500

QV,

as

the

Now

of

its

a

check

If

needle

holder

short

movement,

and

Assemble

dog

(B).

to

the

(C).

set

This

level

Screw

feed

throat

on

dogs

the

plate,

depth

feed

the

dog

QJ,

QL,

chaining

main

distance.

needle.

SETTING

chaining

Main

throat

pin

at

(D)

locks

at

main

of a full

teeth

QN,

feed

dog

setting

rubs

the

slightly

will

Reset

feed

plate

raises

the

time

feed

their

feed

on

all

tooth

flush

QX,

feed

dog

teeth.

between

back

and

These

reduce

THE

feed

dog

by

rotating

or

teeth

tilting

highest

dog

should

Styles,

above

with

RP,

teeth

of

rotate

to

lower

FEED

dog

should

lowers

first

point

except

the

RU,

should

upper

spreader,

spreader

same

the

adjustments,

clearance

looper

DOGS

(A,

Fig.

be

levelled

feed

the

ad-

be

the

top

SJ,

spreader

pull

holder

(Fig.

13)

tilting

back

Fig.

spreader

for-

between

9A).

to

main

with

adjusting

end

of

l0A

and

in

re-

the

NOTE:

C

screw

be

locked

Styles

(B)

also

with

39500

serves

nut

(C)

TG

Fig.

as

even

or

TY

DO

SETTING

13

latch

pin

when

scr

NOT

THE

for

ew

have a chaining

LOWER

KNIFE

assembly.

14)

flush

Adjustments

gonal

lower

pressed

no

ary

i n

screw

against

the

is

cloth

not tig

plate

htened

feed

Replace

dog.

lower

Lower

should

with

be

set

throat

are

head

knife.

screw

Lower

against

lateral

when

Lower

any

adjustment

width

knife

position

(B)

and

support

latch spring,

agai

nst

lower

knife

with

plate

made

knife

upper

of

trim

may

locking

bracket.

it

should

knife

knife

(A,

cutting

surface.

with

which

is

knife,

is

necess-

is

changed.

be

secured

by

tightening

nut

Because

holder.

holder

Fig.

edge

hexa-

holds

spring

so

(C)

always

16

Page 17

SETTING

THE

UPPER

KNIFE

Replace

setting

At

than

should

the

nut

bottom

1/64

be

After

trim,

screw

holding

when

upper

Length

Note

that

machine

ploded

views

machines.

In

assembling

sure

of

side,

on

key.

the

feed

so

the

feed

Assemble

upper

(E)

to

of

inch

set

down

upper

(H)

block

(J)

knife

SETTING

of

stitch

the

part

Style

39500

in

hub

and

eccentric

the

undercut

eccentric.

knife

hold

its

stroke,

(.

40

mm)

against

knife

should

in

place.

is

replaced.

is

number

QJ

catalog

the

oil

groove

spacer

washer

assembly.

clamp

(F)

front

below

the

has

been

be

tightened

This

THE

STITCH

determined

of

the

is

No.

for

eccentric

feed

eccentric

is

(B)

should

on

the

spacer

Be

careful

(D)

and

in

its

cutting

cutting

upper

set

will

LENGTH

by

feed

39540

to

the

not

tighten

Clamp

most

edge

knife

for

proper

to

lock

simplify

feed

eccentric

eccentric

B-5.

on

(A,

left.

also

will

be

to

damage

nut

upper

clockwise

edge

of

of

and

upper

Refer

other

Fig.

Beveled

be

to

over

(C)

securely.

knife

upper

lower

slightly

width

knife

resetting

used.

used

to

on

ex-

Styles

15),

be

edge

the

left

the

hub

shaft

or

(D,

position

knife

knife.

back

of

of

Fig.

14)

against

should

The

extend

chain

from the

in

position,

upper

not

guard

cutting

knife.

less

(G)

edge.

To

(D)

and

operating

eccentric

and

withdraw

slightly

foot

can

change

feed

direction

extractor

during

Fig.

be

raised

feed

eccentrics,

eccentric

until

(E),

eccentric.

extraction.

15

no high

spacer

key

supplied

It

may

needle

position

(front

of

needle

edge

that

plate.

throat

(H,

(B,

lifter

tighten

(B)

bind

ed.

er

than

remove

(B).

Turn

slot

in

with

be

necessary

Assemble

in

high

and

and

back)

hole

of

needle

the

bottom

If

necessary,

plate

Fig.

Fig.

16).

16)

lever

collar

The

foot

secure

and

rise

Adjust

upper

nut

(C),

handwheel

eccentric

machine,

SETTING

the

position,

set

the

and

in

presser

hole

of

slots

To

move

and

clamp

shaft

to

screws

lifter

the

shaft.

when pres

lift

er

lever stop

looper

washer

is

reach

to

presser

presser

flat

in

throat

the

presser

presser

by

shifting

the

and

lever

Be

ser

or spread

toward

move

THE

swing

on

foot

the

screw

left

clamp

arm

sure

foot

in

the

behind

handwheel

PRESSER

foot

to

presser

foot

throat

must

plate.

foot

foot

can

the

foot

shaft,

(G)

and

or

right

screw.

(A,

Fig.

the

presser

r e

lease

screw

er

will

front.

eccentric

FOOT

presser

to

align

plate.

be

aligned

It

is

be

flat

be

lifter

loosen

then

as

16)

bushing is

(C)

permit;

Fig.

Using

back

arm

into

needle

The

also

on

realigned

lever

collar

shift

required.

and

arm

so

that

14

hooked

as

shown

and

forth

arm.

With

sewing

holes

front

with

edge

front

important

the

throat

with

shaft

screws

the

the

collar

does

unlock-

presser

then

lock

foot

Re-

not

17

Page 18

the

nut

inch

lifter

rise.

screw

the

chip

To

assemble

upper

tion.

SETTING

(D).

(1.

59

lever

This

(E)

and

guard,

knife

THE

(

Continued)

There

to

before

3.

should

17

the

adjustment

locked

fabric

chip

guard,

assembly

PRESSER

mm)

presser

should

with

guard

reaches

be

free

nut

turn

FOOT

from

motion

foot

be

(F).

Re-assemble

and

cloth

handwheel

its

highest

1/16

begins

made

to

of

foot

with

plate.

until

posi

1/8

to

-

CLOTH

PLATE

CAUTION:

loosen

plate

the

with

assembled.

In

assembly,

stud

are

tightened

turn

in

cloth

machine

towards

ly

which

that

ed

according

only

Be

with

the

collapses

sure

threaded

according

Fig.

REMOVAL

When

cloth

the

plate

cloth

plate.

the

rear.

the

cloth

machine

to

according

to

Fig.

16

removing

stud

plate

the

cloth

to

the

The

cloth

flat

and

Stud

locking

the

body

plate

will

Styles

threading

to

threading

lB

and

AND

the

locking

stud

(C)

plate

point

plate

"V"

slot

screw

of

turn

STARTING

39500

diagram

machine

ASSEMBLY

cloth

screw

and

cloth

screw

of

removing

is

then

of

the

(B)

the

stud

when

QN, QV,

Fig.

diagram

Style

plate

(B)

and

plate

and

the

all

assembled

cloth

is

tightened

to

the

opening

TO

OPERATE

QX,

1.

Fig.

39500

(A,

Fig.

lift

up

screw

\

cloth

play

plate

and

stud

secure-

screw

or

closing.

RP.

RU,

Machine

lA.

Thread

TG

according

cloth

plate

to

(D)

Styles

17)

(D).

yet

the

(C)

so

SR, SX

machine

39500

to

and

Fig.

Fig.

TY

are

QJ

Style

lC.

17

thread-

and

39500

SJ

are

QL

With

or

thread

in

the

presser

Swing

While

needle

be

just

if

excessive

tion

needle

contacts

It

ator)

thread

middle

foot

presser

thread

tight

needle

is

desirable

to

delay

eyelet

of

in

foot

sewing

is

enough

thread

thread

slightly,

tensions

(R,

Fig.

their

place,

into

NEEDLE

on

material,

drawn

to

is

eyelet

thread.

to

adjust

light,

lA)

front

to

make

position,

on

needle

feed

pulled

(AD,

the

set

and

thread

to

back

sure

insert

THREAD

check

down

chain

on

the

off

up

Fig.

the

needle

tightening

looper

eyelet

locations.

chain

material

CONTROL

needle

stroke.

stitch

stroke.

1)

so

that

thread

of

the

18

thread

forms

thread

At

tongue.

With

needle

eyelet

needle

eyelets

(N,

Operate

and

and

(504

top

Stitch

needle

thread.

(N

and

Fig.

lC)

about

machine

moves

sew

off

slowly.

STITCH)

control

of

thread

well

as

follows:

needle

tends

at

bottom

stroke,

to

cam

-forward ( toward

R,

Fig. 1 and

horizontal

slowly,

the

tongue

thread

pull

down

of

stroke,

pull-off

without

freely.

Usually

should

slightly

posi-

(AE)

the

oper-

lB)

and

all

just

Page 19

NEEDLE

THREAD

CONTROL

(Styles

39500

QJ,

SJ,

TG

- 503

STITCH)

While

of

needle

increase

and

1 C)

While

of

needle

To

1 B)

farther

With

back

its

mm)

far

most

distance

should

looper

While

portion

looper

the

tension

eyelet

sewing

thread

thread

farther

NEEDLE

sewing

thread

increase

material

enough

rearward

be

set

(V)

heel

sewing

of

lower

thread

while

(R)

down,

to

the

behind

with

comes

on

material,

required

drawn

to

the

THREAD

on

material,

required

thread

rear.

LOWER

under

so

thread

position.

needle

its

eyelet

eyelet

on

looper

off

lower

keeping

for

on

downstroke,

rear.

for

drawn

LOOPER

presser

is a little

Looper

thread

approximately

at

the

time

material,

thread

upper

looper

the

same

check

the

stitch

CONTROL

check

the

stitch

on

downstroke,

THREAD

foot,

slack

thread

cam

lower

check

should

looper.

thread

is

amount

needle

should

position

(Style

needle

should

CONTROL

set

when

pull-off

pull-off

1/8

looper

drawing

be

drawn

To

increase

on

upper

of

thread

be

needle

39500

thread

be

position

lower

looper

(AE).

inch

is

off

pull

-off

control

drawn

QL -505

control

drawn

needle

(504

looper

thread

(AF)

Frame

(3.

17

at

extreme

of

looper

through

amount

looper,

action.

on

thread

on

needle

thread

STITCH)

thread

is

set

mm)

the

of

move

as

follows:

needle

eyelet

STITCH)

as

follows:

eyelet

pull-off

about

looper

to

left

thread

tension

thread

lower

About

downstroke.

(AD,

About

downstroke.

eyelet

(AD,

(R,

1/32

thread

the

end

(AF)

right

as

inch(.

guide

of

its

follows:

reaches

of

before

drawn

looper

75%

To

Fig.

lA

60%

Fig.

Fig.

1)

79

(T)

lower

travel.

A

lower

through

thread

With

back

and

treme

Frame

inch

(3.

extreme

Set

forward

Frame

inch

(3.

at

the left

Before

three

will

tensions

not

material

down

left

position.

looper

17

mm)

left

lower

in

its

looper

17

mm)

end

proceeding

markedly

LOWER

under

far

enough

Lower

thread

to

the

end

of

its

LOWER

looper

slot.

thread

to

the

of

its

stroke.

UPPER

to