Page 1

®

INDUSTRIAL

SEWING

FINEST

39500RK

QUAliTY

STYLE

LEWIS

•

COLUMBIA

MACHINES

CATALOG

No.

103RK

MARK

SINGLE

NEEDLE

KNIFE

CHICAGO

CLASS

IV

39500

HIGH

WITH

SHIFT

SPEED

OVERSEAMER

MECHANISM

Page 2

Catalog

No.

103

RK

(Supplement

ADJUSTING

to

Catalog

INSTRUCTIONS

FOR

AND

LIST

CLASS

OF

Style

39500

PARTS

39500

RK

No.

OPERATING

103

QA)

Union

Rights

First

Copyright@

Special

Reserved

Edition

by

Corporation

in

All

1973

CORPORATION

INDUSTRIAL

Printed

SEWING

CHICAGO

in

MACHINES

U.S.

Countries

A.

2

August,1973

Page 3

IDENTIFICATION

OF

MACHINE

Each

the

machine.

numbers

Example:

only

minor

standard

Styles

which

39500

differs

11

•

This

junction

are

illustrated.

parts

with

Numbers

position

ordering

This

herein.

Class

given

of

39500.

from

handwheel

Union

Style

have

"Style

changes

Style

number.

of

machines

from

catalog

therewith.

their

in

the

of

that

parts.

catalog

It

can

also

References

the

operator's

is

Special

machine

numbers

one

or

more

39500

RK".

are

made

Example:

similar

the

Style

APPLICATION

is a supplement

Only

On

the

part

first

part

Always

applies

be

page

numbers.

column

in

the

use

applied

parts

illustration.

specifically

to

position

away

from

operator.

is

identified

are

classified

letters

Special

in a standard

"Style

in

construction

number

to

found

opposite

description

are

reference

the

part

with

discretion

directions.

while

suffixed.

Style

39500

in

that

OF

Catalog

on

Style

the

illustration

Reference

number

to

the

such

seated

by a Style

as

standard

but

numbers

machine.

RKZ".

are

it

contains

CATALOG

No.

103

39500

and

the

numbers

listed

Standard

to

some

as

right,

at

number

and

never

contain

grouped

no

QA

and

RK.

will

number

only.

numbers

in

the

Style

Special

left,

the

machine.

on a name

special.

contain

the

letter

a "z"

is

under a Class

letters.

Example:

should

but

not

on

be

found a listing

of

pieces

and

merely

should

second

of

machine

column.

Styles

front,

Operating

Standard

the

suffixed

be

used

Style

never

of

machines

back,

plate

letter

"Z".

to

number

"Class

in

39500

of

required.

indicate

be

used

as

listed

etc.,

direction

on

Style

"Z".

When

the

con-

QB

the

the

in

in

are

MARK

IV

Thread,

Pressed

cating

39500

System.

RK

warp

general

ments

variable

bite

seam

cam

R.

P.M.

39500

maximum

sewing

operation

50-100%

may

be

necessary

Hi

-Styled

Overseaming

Lower

Knife,

Improved

Light

and

to

ribbed

purpose

which

when

widths.

adjusted

MARK

rated

have

width

crossing

3/32

main

IV

speeds.

knife

may

machine

running

to

High

Machine.

and

Air

medium

knit

fabrics

seaming

varying

shift

elastic,

and

and

machines

Varied

necessitate

reduce

STYLE

Speed

Single

Differential

Variable

Cooling

duty

machine

on

plies

mechanism

lace,

1/8

inch

differential

SPEED

have

cycle

the

machine's

OF

MACHINE

Curved

Width

Knife

Blade

Feed,

Shift

Trimming

System.

for

seaming

of

cotton,

"T"

shirts,

of

etc.

(2.

silk,

material

permits

Seam

38

and

feeds.

or

polo

requiring

quick

specification,

3.

17

Maximum

RECOMMENDATION

been

field

operating

and a longer

tested

in

conditions.

at a lower

than

speed

their

by

Needle,

Mechanism.

light

similar

shirts,

and

weight

panties

an

change

mm);

stitch

recommended

complete

severity

and

speed.

recommended

10-15%.

Two

Looper,

Mechanism

Automatic

medium

synthetics.

and

adjustable

from

narrow

504-SSa-1;

range

stitch

8-30

range

cleanliness

When

operating

stitch

with

weight

similar

bite.

standard

per

speed

at

length,

Three

Spring

Lubri-

flat,

For

gar-

The

to

wide

inch;

8000

their

of

the

from

it

The

MARK

maximumperformance,

mum

recommended

readjustment

IV

is a precision

speed

of

precision

the

machine

for

the

mechanisms.

manufactured

first

should

20

be

days

3

and

tested

operated

of

field

sewing

at

1000

operation.

machine.

R.

P.M.

This

below

will

To

obtain

maxi-

minimize

Page 4

OILING

CAUTION!

filled

straight

should

sight

gauge

main

when

no

It

have

denotes

number,

in

size

packaged

before

mineral

be

Machine

gauge

lines

Machine

reservoir

To

maintain

operating

case

is a magnetic

thousandths

should

The

oil

entered

Each

the

stamped

number

used.

on

when

is

drain

the

Union

kind

represent

and

sold

Oil

was

beginning

oil

of a Saybolt

is

filled

front

machine

automatically

filled.

maximum

continuously,

oil

screw

crank

Special

of

of

an

of

remain

plug

shank,

on

the

inch,

by

Union

with

machine.

Check

screw

designed

the

drained

to

operate.

oil

is

stationary.

lubricated.

oil

recommended

the

in

machine

is

case.

needle

needle

It

point,

midway

complete

Special.

from

Oil

viscosity

at

spring

Red

daily

oil

must

located

to

accumulate

should

NEEDLES

has

both a type

length,

shank,

between

symbol

machine

capacity

cap

bulb

on

No

before

speed

for

more

at

back

be

removed

groove,

denotes

of

90

in

oil

oiling

the

be

changed

possible

shank

which

when

and

than

of

and

largest

shipped,

of

Class

to

125

seconds

top

cover.

levelindicator

is

necessary,

morning

serviceability

at

one

year.

machine

foreign

and

cleaned

size

finish

and

is

and

diameter

eye.

given

so

39500

Oil

should

start;

least

number.

every

near

on

bottom

materials

periodically.

other

Collectively,

the

reservoir

is

at

100

level

other

add

oil

of

this

six

The

details.

of

blade,

label

si8-

ounces.

Fahrenheit

is

checked

show

than

as

equipment

months.

edge

which

type

measured

of

all

must

between

keeping

required.

of

base.

may

number

The

size

type

and

needles

be

A

at

In

Class

needle

blade,

is

available

To

sample

on

label.

Selection

should

Success

of

needles

putation

more

Fig.

direction

No.

Again

left,

position,

nut.

than

Release

1)

21388

turn

To

insert

Return

39500

for

Style

standard

in

have

needle,

A

complete

pass

freely

in

packaged

for

producing

three

pressure

and

swing

until

AU,

handwheel

replace

needle

turn

presser

machines

39500

length,

sizes

needle

of

the

needle

needle,

handwheel

022, 025,

orders

or

the

proper

through

operation

under

-quarters

presser

is

furnished

until

in

holder

arm

use a curved

RK

is

Type

single

type

and

order

needle

needle

our

highest

of a century.

on

presser

arm

at

its

with

needle

leave

until

(U)

154

GAS.

groove.

027,

promptly

would

of

brand

CHANGING

lowest

needle

until

holder

to

position;

029,

size

size

Union

quality

machine,

read:

eye

foot

(U)

is

it

number

is

name,

out

point

at

holder

rests

is

blade

struck

032,

and

"1000

determined

in

order

Special

needles

by

turning

of

high

again

re-lockpresser

needle.

It

has a round

groove,

036, 040,

accurately

should

Needles,

machines

~

in

NEEDLES

position.

of

travel.

loosen

position;

at

high

against

at

by

to

produce

materials

presser

Using

needle

position

stop

its

low

The

shank,

spotted,

044,

filled,

be

forwarded.

Type

size

can

,

which

foot

Turn

hexagonal

clamp

withdraw

pin.

point

foot

standard

round

chromium

049,

an

of

thread

a

good

be

and

release

handwheel

and,

Keeping

of

release

054,

empty

Use

154

GAS,

stitch

securetd

is

backed

workmanship

nut

about

needle.

with

travel;

recommended

point,

used.

bushing

in

socket

the

needle

then

bushing

curved

plated

060.

package,

description

Size

027".

Thread

formation.

only

by

by a re-

(AG,

operating

wrench

1/4

turn.

flat

to

in

tighten

(AG).

and

a

use

for

the

this

4

Page 5

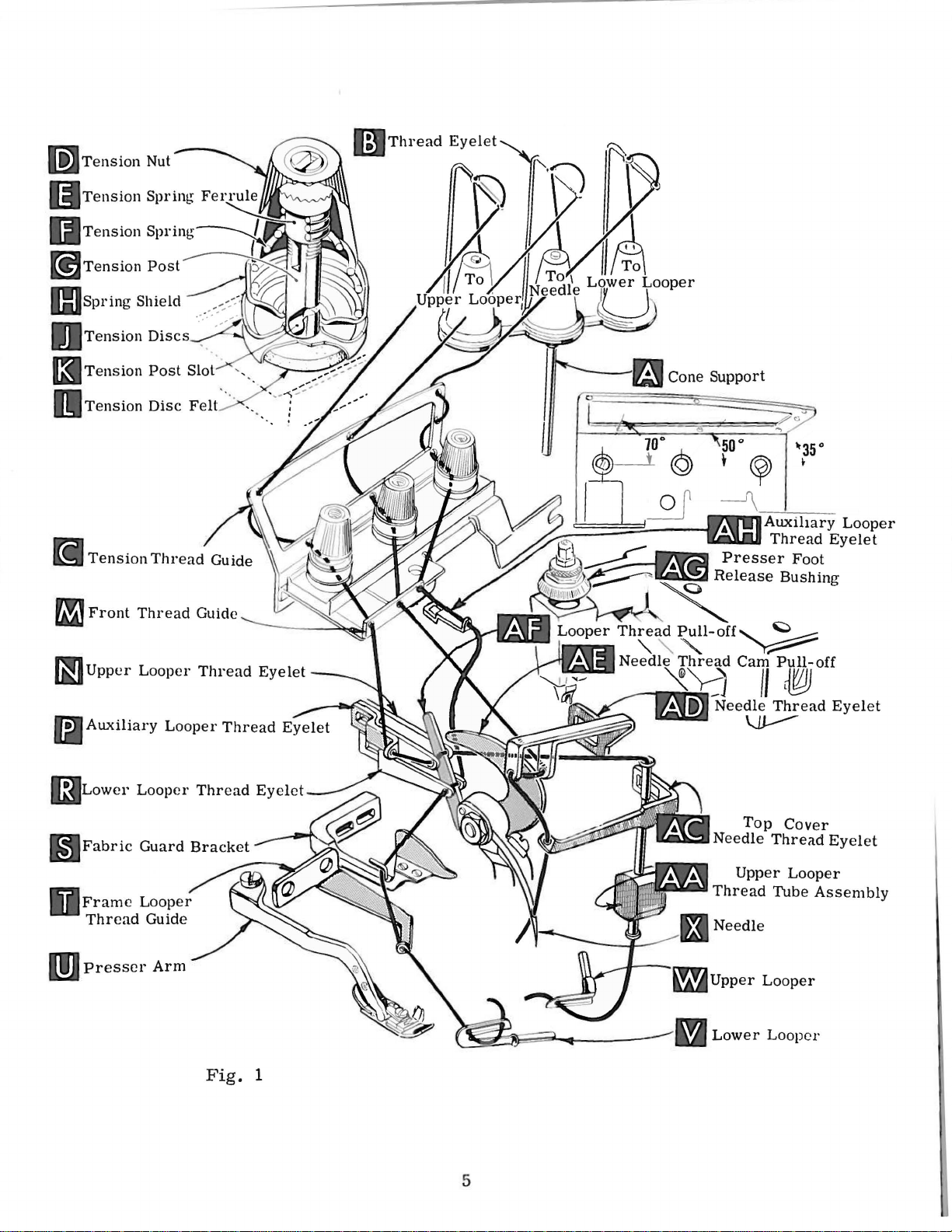

[i

ZJ

Tension

Front

Thread

Thread

Cone Support

Guide

Guide

~Upper

(3Lower

DFramc

Thread

m

Presser

Looper

Looper

Looper

Guide

Arm

Thread

Thread

Fig.

Eyelet

Eyelet

1

..

Needle

Thread

Lower

Top

Upper

Looper

._..._

~Upper

Cover

Thread

Looper

Tube

Looper

Eyelet

Assembly

5

Page 6

THREAD

STAND

After

t

hrough

eyelet.

hole

of

from

to

hole

(J).

(M).

back

front.

from

through

Only

are

placed

It

will

quence

third.

Before

ting

direction

by

turning

position.

Be

tension

thread

the

back

The

needle

tension

to

through

back

tension

parts

in

simplify

of

threading

beginning

presser

sure

threads.

discs

comes

hole

thread

front.

the

to

involved

their

until

(J)

and

of

and

guide

The

middle

front.

post

relative

the

the

to

needle

foot

as

in

from

thread

upper

(C)

lower

hole

All

three

slot

(K)

in

threading

positions

threading

lower

thread.

(X)

is

release

they

come

diagonal

cones

eyelet

looper

from

looper

on

(B),

threads

front

thread

from

threads

in

tension

THREADING

are

for

of

this

looper

swing

at

high

bushing

from

slots

(K)

cone

then

to

is

front

to

then

post

shown

clarity.

machine

first.

cloth

plate

position.

(AG)

the

in

tension

support

down

are

then

back.

threaded

back.

continue

(G)

and

in

threading

to

upper

open.

release

and

tension

(A,

through

threaded

and

then

through

and

on

follow

looper

swing

thread

posts

Fig.

1),

the

through

finally

between

through

diagram

the

second.

turn

hand

pressure

presser

guide

(G).

it

is

brought

front

the

hole

through

the

upper

through

the

tension

front

thread

the

lower

hole

the

(Fig.

recommended

and

the

wheel

on

arm

(C).

in

presser

(U)

are

of

thread

upper

hole

back

lower

discs

guide

1).

Part

se-

needle

opera-

foot

out

between

up

s

of

Double

(M.

Fig.

front.

from

Lead

Then

right

thread

handwheel

left.

be

then

threaded

Thread

turn

handwheel

through

eyes

front

of

of

upper

assembly

tube

thread

assembly

through

CAUTION!

passing

from

end

1).

Lead

lead

to

left.

behind

in

operating

thread

easily

upper

auxiliary

looper

looper

(AA),

upper

tube

of

thread

thread

thread

NOTE:

fabric

through

if

looper

until

looper

thread

lead

(AA).

Be

assembly

TO

and

through

guard

direction

both

tweezers

TO

thread

point

thread

thread

pull-off

thread

Pull

looper

sure

upper

THREAD

lead

through

both

Thread

(S)

eyes

are

THREAD

through

of

upper

eyelet

(AF).

under

thread

eye

from

looper

to

upper

TO

THREAD

THE

it

through

auxiliary

eyes

must

and

until

heel

from

in

left

THE

looper

eyelet

(N)

from

After

neck

out

bottom

front

looper

LOWER

looper

of

lower

pass

through

of

left

hand.

UPPER

left

eyelet

(P)

from

left

pulling

of

top

cover

to

thread

eye.

THE

LOOPER

the

right

thread

looper

in

front

frame

lower

to

right.

LOOPER

of

(W)

is

back

to

right.

casting

of

tube;

back.

is

under

NEEDLE

eyelet

oflooper

looper

looper

Left

front

all

the

to

Note:

up

upper

push

lower

of

eyelet

thread

thread

thread

(V)

eye

thread

way

front.

Thread

and

tube

front

(AH)

eyelet

is

all

of

lower

guide

left.

then

looper

down

down.

looper

thread

from

(R,

pull-off

guide

the

way

looper

(M).

Lead

through

must

thread

through

then

thread

back

Fig.

(T).

pass

guide

to

1)

(AF).

Turn

to

the

can

Then

thread

both

in

tube

thread

insert

when

Thread

handwheel

Insert

(AD).

under

thread

needle

in

needle

eyelet

thread

operating

thread

neck

of

(AC).

direction

from

top

cover

Thread

through

right

casting;

needle

middle

until

to

left,

from

eyelet

needle

throu

then

front.

6

of

(X,

gh

down

front

Fig.

both

through

thread

1)

eyes

is

of

hole

guide

at

its

needle

highest

in

top

(M).

thread

cover

Then

turn

position.

eyelet

needle

Page 7

The

tension

stitch

amount

nuts

(D,

formation.

of

Fig.

tension

1).

Tension

on

the

THREAD

needle

on

threads

TENSION

and

looper

should

threads

be

only

is

regulated

enough

to

by

secure

knurled

proper

Sufficient

ly

should

or

decrease

lock

ing

screw

pressure,

adjusting

(A).

locking

1/32

face

nut

(C).

nut

With

nut

inch

of

Feed

be

(A,

has a right

loosening

screw

presser

to

adjusting

eccentrics

approximately

feed

of

chine

39540

stitches

eccentric

B-10.

obtainable

will

b - c:;hipped

PRESSER

presser

maintained.

amount

Fig.

(B)

2)

has

foot

(C)

so

that

1/16

inch(.

screw

12

stitches

is

No.

Minor

numbers

FOOT

foot

pressure

Should

of

pressure

and

turn

hand

decreases

been

resting

its

under

79

(B).

used

in

per

39540

when

with

above

PRESSURE

it

be

on

adjusting

thread

so

pressure.

properly

on

surface

to

1. 59

Set

FEED

Style

39500

inch.

B-12,

using

of

while

the

that

combination

to

feed

necessary

presser

screw

tightening

When

set,

tighten

throat

plate,

is

mm)

cap

(D)

from

against

ECCENTRICS

RK

It

will

that

part

symbol

eccentric.

work

to

foot,

(B).

uniform-

increase

loosen

Adjust-

increases

pressure

lock

position

approximately

the

top

sur-

locking

machines

be

noted

of

the

have

that

differentialfeed

indicate

Unless

of

eccentrics.

nut

been

selected

the

part

approximately

otherwise

Fig.

to

number

eccentric

the

specified,

2

produce

of

main

is

No.

number

rna-

of

stitches

and

with

Generally

produced;

direction

Fig.

the

cloth

speaking,

of

stretch

3

plate

main

of

under

16,

100.

Additional

an

to

12

cloth

lower

quence:

CAUTION:

the

stud

(C)

differential

(left

hand)

material

Following

No.

18,

20, 22, 24, 26, 28,

Only

eccentric

indicate

".

ASSEMBLING

Before

plate,

knife

CLOTH

cloth

and

plate

cloth

(right

feed

being

stitch

39540

two

B-4,

eccentrics

eccentrics

use

No.

number

assembling

fabric

holder

PLATE

When

removing

stud

plate

hand)

eccentric

sewn,

feed

is

or

type

number

feed

5, 6, 7, 8,

eccentric

selected

of

9,

30, 32, 34, 36,

are

supplied

may

be

ordered

39540 B with a minor

of

stitches

AND

ADJUSTING

and

guard,

assembly,

REMOVAL

locking

screw

desired.

adjusting

chip

guard,

then

the

cloth

screw

(D),

follow

AND

(B)

assembled.

determines

in

relation

operation.

eccentrics

are

10, 11, 12, 13,

40,

with

each

separately.

number

Example:

SEWING

sewing

upper

this

PARTS

parts,

knife

suggested

ASSEMBLY

plate

and

(A,

lift

Fig.

up

number

to

degree

available

14,

50,

60,

machine.

To

order

suffixed

"39540

remove

assembly,

3)

loosen

cloth

plate

15,

70,

B-

se-

7

Page 8

point

bled

rear.

stud

In

assembly,

of

removing

to

the

Stud

to

the

CLOTH

machine

locking

screw

PLATE

the

cloth

allplay

with

screw

(D)

so

REMOVAL

plate

and

the

flat

(B)

is

that

only

screw

yet

turn

and

tightened

the

AND

and

in

"V"

cloth

ASSEMBLY

the

cloth

clothplate.

slot

of

the

securely

plate

will

plate

The

cloth

which

turn

(Continued)

stud

are

cloth

plate

plate

stud

collapses

when

opening

tightened

is

then

(C)

towards

the

body

or

to

the

assem-

the

of

the

closing.

front

With

per

(Fig.

have

Fig.

With

end

Insert

lower

point

6),

lower

Now

13).

throat

of

needle

Fig.

lower

looper

1/8

inch

using

assemble

looper

looper

plate

4

(A.

slot.

looper

at

left

(3.17

gauge

deflecting

differential

Fig.

When

(A,

end

mm)

SETTING

4)

assembled

needle

1/2

align

move

clamp

tighten

laps

looper

pull-off

driving

Fig.

of

its

from

No.

21225-1/8.

needle.

(front)

THE

is

inch

needle

needle

screw

clamp

If

needle

looper

thread

screw.

arm.

6)

into

stroke,

center

Tighten

feed

at

(12.

bar

set

of

high

NEEDLE

in

position,

position,

70

mm)

or

set

driving

(C).

After

screw

thread

thread

pull-off

be

(B).

loo-

needle

Do

not

nut

(C).

dog

(A,

above

the

height

arm

needle

(C)

cam

pull-off

back.

sure

to

needle

needle

throat

(B.

and

remove

pull-off

(B).

When

take

should

point

plate

above

Fig.

has

been

(A,

separate

retightening

up

end

center

should

the

4)

by

set

throat

Fig.

play

(Fig.

throat

loosening

properly,

plate.

5)

by

in

in

the

be

set

4).

To

plate,

over-

moving

looper

needle

SETTING

Set

rear

possible,

looper

in

inch(.

is

to

After

differential

or

position

051-.102

no

interference

needle

this

THE

needle

without

movement

to

deflect

mm).

Fig.

without

setting

feed

dog.

REAR

guard

interfering

of

lower

needle

Screw

between

6

touching.

make

sure

NEEDLE

(A,

Fig.

with

knife

forward . 002-.

(B)

rear

Screw

there

GUARD

7)

holder,

is

used

needle

Now

looper

into

springs

another.

SETTING

Assemble

When

guard,

(D)

is

as

either

to

guard

SETTING

finish

moves

the

needle

forward

002-.004

lower

set

is

used

no

interference

high

lower

but

set

looper

front

as

still

004

rear

and

lower

to

THE

front

to

needle

lower

THE

the

scarf

from

inch(.

FRONT

is

needle

adjust

looper.

LOWER

looper

right,

(A,

rear

051-.102

needle

springing

guard

and

between

Fig.

guard.

LOOPER

adjustment.

its

point

Fig.

NEEDLE

needle

guard

as

set

8)

close

front

needle

5

Make

should

until

guard

mm).

GUARD

(C.

needle

as

needle

guards

sure

As

be

the

needle

surface

Fi

g.

off

possible

guard.

there

lower

set

7).

back

and

8

Page 9

SETTING

THE

UPPER

LOOPER

Insert

holds

in

or

holder

Screw

in

the

shank

holder

As

looper

mm)

upper

upper

out,

into

(C,

looper

or

upper

Fig.

shaft.

extends

(Fig.

Fig.

the

8

upper

should

clearance.

turned

9)

Locate

1/32

9).

pass

looper

in

its

around

looper

on

upper

to

end

should

shank

tween

adjusting

upper

looper

looper

to

.

002

ance

looper

behind

(A,

holder.

shaft,

clamp

1/16

When

of

slightly

Be

the

to . 004

(Fig.

moves

the

Fig.

its

holds

looper

inch(.

the

its

stroke,

be

set

sure

heel

looper

looper

around

point

left

of

lower

9)

in

and

permits

shank.

if

it

is

the

in

79

upper

to

back

there

of

looper

shaft

to

the

(.

051

10).

toward

its

holder.

it

Insert

not

already

upper

its

to

1. 59

looper

holder

mm)

looper

upper

position

of

vertical

is a clearance

and

holder

and

by

its

shank,

cross

lower

looper

to . 102

the

top

looper

head

Screw

to

be

upper

so

above

is

at

looper

upper

casting.

in

or

turning

set

lower

mm)

of

its

with

pushed

looper

in

place.

holder

that

the

holder

looper

(Fig.

out

upper

looper

eye

clear-

stroke,

(B)

the

the

right

9).

be-

By

of

the

with

1/64

to

the

1/32

heel

inch(.

Fig.

of

7

the

40

upper

to . 79

Next,

of

its

travel;

spect

to

essary,

Figure

For

creased

looking

mension

left,

it

out

may

slightly

needle

do

11

represents

example,

by

from

is

of

be

to

Fig.

turn

handwheel

check

and

it

by

moving

turning

left

increased

upper

looper

necessary

maintain

10

until

dimensions

throat

the

plate

the

correct

upper

31/64inch02.30

end

upper

of

by

looper

machine;

pulling

shaft.

to

the

turn

condition

upper

When

quickly

when

needle

looper

as

upper

eye

(Fig.

Check

and

needle

upper

looper

end

11,

looper.

a

of

machine.

12.

upper

of

(Fig.

looper

upper

11).

looper

dimensional

mm)

holder

5/32

upper

After

these

looper

shown

the

correct

follows:

looper

should

12).

setting

on

needle

pull

short

distance

is

at

looper

If

holder

point

resetting

(A,

setting.

dimension

counterclockwise

inch

looper

(3.

holder

changes

around

in

Fig.

10.

setting

As

upper

eye

centers

be

about

to

avoid

interference

downstroke.

looper

out

counterclockwise,

Reset

to

maintain

the

Fig.

97

are

its

level

of

left

with

is

nec-

is

mm)

to

made

shank

is

obtained,

looper

on

with

its

end

re-

11).

indi-

the

is

moving

the

needle,

top

between

If

needle

holder

dimensions

it

can

bottom

surface

upper

rubs

slightly

looking

of

Fig.

be

to

the

and

Figs.

9

checked

the

r i

of

of

upper

looper

back

rotate

from

ght,

the

of

left

10,

9

Page 10

ma

Now

assembl

in

(back) feed dog

e di

(B)

SETTING

fferential

and

chaining

dogs

(A

faces

This

teeth

ble

be

can

with a straight

throat

leveled

rotating

This

pin

of

both

(front)

and

of

teeth

be

feed

raises

feed

THE

feed

B,

checked

plate.

with

tilting

bars

feed

Fig.

lay

Feed

throat

or

lowers

at

FEED

dog

(A,

dog

(C).

13)

so

in

the

by

sighting

edge.

dogs

plate

adjusting

the

same

DOGS

Fig.

Set

the

same

Now

should

surface

the

back

time.

13),

the

top

sur-

plane.

across

assem-

pin

if

not

differential

now

by

(D).

end

already

and mai

in

plac

e,

n feed

nch

i

so

Fig.

(1.

19

its tee

11

mm)

th

are level

above

dogs

teeth

plate.

tilting

set

so

throat

with

The

should

first

main

that

top

main

appear

Screw

adjusting

and

teeth

plate

of

at

throat

and

be

set

level

above

(E,

Fig.

pin

differential

are

approximately

high

point

plate

Fig.

SETTING

differential

at

the

the

13)

locks

in

place.

feed

of

travel.

when

feed

13

THE

feed

time

throat

feed

Now

dogs

3/64

Set

is

at

top

LOWER

chaining

of

its

KNIFE

Fig.

feed

travel.

12

dog

(C)

Fig.

14

Replace

(A.

Fig.

throat

gonal

is

plate

head

spring

adjustment

Lower

tightening

port

bracket.

pin

for

the

be

locked

ed

against.

lower

14)

should

surface.

screw

pressed

is

knife

screw

cloth

with

lower

10

knife

be

Adjustments

which

against

necessary

may

(B)

and

Because

plate

nut

(C)

knife

even

holder assembly.

set

with

cutting

are

holds

when

be

screw

latch

lower

upper

width

secured

locking

(B)

spring.

when

knife,

nut

also

screw

holder.

edge

made

knife.

of

trim

in

any

(C)

serves

it

Lower

flush

with

Lower

so

no

is

position

against

should

is

not

knife

with

hexa-

knife

lateral

changed.

by

sup-

as

latch

always

tighten-

Page 11

SETTING

THE

UPPER

KNIFE

Replace

setting

At

bottom

1/64

be

set

inch

down

After

tightened

when

upper

Loosen

move

knives

obtaining

operator's

upper

position

Standard

upper

nut

(E)

of its

(.

40

against

upper

to

lock

knife

SETTING

set

{E

the

standard

position

seam

to

hold

stroke,

mm)

knife

upper

is

THE

screws

and

and

width

knife

assembly.

clamp

front

below

the

upper

has

been

knife

replaced.

VARIABLE

{A

and

F)

by

pushin~

3/32

while

seated

tighten

or

constant

(F)

cutting

cutting

knife

set

holding

B,

or

1f8

set

screws

in

its

edge

and

for

WIDTH

Fig.

down

inch

at

the

trim

Clamp

most

edge

of

slightly

proper

block

15)

{2.

machine,

(A).

line.

upper

clockwise

of

upper

lower

{J)

KNIFE

on

on

pawl

38

This

knife.

back

width

in

place.

pawl

or

knife

knife

from

of

SHIFT

shaft

lever

3.

17

rotate

will

(D,

Fig.

position

should

The

trim,

This

chain

the

against

extend

cutting

screw

will

MECHANISM

stop

{G)

mm)

collar

collars

to

position

seam

{C)

position

14)

guard

edge.

{H)

simplify

{C

width.

clockwise

the

knives

in

position,

upper

not

less

{G)

should

resetting

and

desired

From

knife.

than

should

D)

and

for

the

to

for

the

be

its

Next,

down

tighten

lever

Screw

for

holding

NOTE:

of

the

on

lever

set

{G)

is

This

cutting

move

{G)

screws

pulled

{H)

holds

the

machine

knives

knives

and

{B).

downwardly,

the

tension

from

to

the

rotate

This

variable

post

is

designed

the

right

to

collar

will

position

when

shift

mounting

to

constant

Fig.

obtain

{D)

crossing

mechanism

bracket.

give a maximum

15

the

variable

counterclockwise

the

knives

elastic,

in

trim

11

line

to

the

for

trim

the

etc.

place,

of

5/64

variable

line

to

its

variable

while

inch

desired

upper

screw

{1.

trim

position

trim

98

mm)

line.

by

pushing

line

(J)

when

is

used

travel

and

Page 12

SETTING

THE

STITCH

LENGTH

withdraw

during

extraction.

If

eccentrics

addition

Fig.

17)

move

Then

nut

continue

Fig.

16

eccentrics.

to

removing

from

(G)

shaft

and

as

SETTING

It

may

are

unusually

nut

(E),

it

feed

driving

originally

THE

PRESSER

Length

of

feed

16)

actuates

eccentr

In

facing

key.

To

washer

operating

the

front.

with

be

necessary

tight

(C)

and

may

be

connection

suggested.

eccentrics

ic (B)

assembling

each

Tighten

change

(D)

direction

Using

machine,

fitting,

washer

helpful

FOOT

of

stitch

main

actuates

other.

nut

feed

from

hooked

reach

to

move

(D,

to

re-

(H).

used.

(rear)

the

Be

(C)

end

until

in

securely.

is

determined

Outer

feed

dog;

the

differential

feed

eccentrics,

careful

eccentrics,

of

shaft

key

slot

eccentric

behind

handwheel

by

(left)

eccentric

while

not

to

remove

(E).

Turn

in

eccentric

extractor

eccentrics

back

the

the

(front)

be

sure

damage

nut

handwheel

(F),

as

and

forth

combination

(A,

Fig.

inner

(right)

feed

hubs

shaft

(C)

dog.

are

or

and

in

is

toward

supplied

shown

and

slightly

With

(U,

Fig.

er

foot

flat

on

in

presser

needle

be

flat

plate

nut

(F).

chip

Assemble

needle

in

1)

intosewingpositionandsetthepress-

to

align

throat

foot

hole

in

on

the

slots

by

Re-assemble

guard,

turn

the

high

needle

plate.

must

throat

throat

shifting

Fig.

handwheel

presser

position,

holes

The

front

be

aligned

plate.

plate.

the

18

the

foot

swing

(front

edge

with

It

is

If

necessary,

foot

lifter

chip

until

to

presser

presser

and

of

needle

front

also

guard,

upper

arm.

arm

back)

hole

edge

important

presser

lever

loosen

screw

shaft

to

collar

The

the

collar

presser

er

foot

Adjust

presser

looper

should

mm)

free

presser

should

fabric

knife

and

of

that

shaft

(H,

collar

(G)

and

the

left

screws

foot

(B)

arm

does

release

lifter

foot

can

will

permit;

be

from

motion

foot

be

made

guard

assembly

the

foot

Fig.

screws

then

or

and

lifter

secure

not

bushing

lever

be

1/16

of

begins

with

and

reaches

bottom

can

shift

right

clamp

lever

bind

raised

then

to

foot

to

screw

cloth

be

realigned

18).

(B,

the

as

screw.

arm

the

and

is

stop

lock

1/8

lifter

rise.

of

1

7

the

move

18)

Fig.

To

Fig.

foot

required.

(A,

shaft.

rise

unlocked.

screw

no

higher

the

nut

inch

(1.

lever

Th

is

(E)

and

plate.

its

To

highest

presser

with

throat

the

shaft,

and

clamp

lifter

lever

Retighten

Fig.

Be

sure

when

(C)

than

(D).

59

18)

press-

so

upper

There

to

before

adjustment

locked

assemble

position.

foot

and

the

that

3.

17

the

with

12

Page 13

Be

thread

tensions

horizontal

ly,

without

tongue

freely.

sure

machine

and

in

presser

Swing

light,

the

is

set

middle

foot

in

presser

STARTING

threaded

looper

of

their

place,

foot

TO

according

thread

front

to

make

into

position,

OPERATE

to

eyelets

to

back

sure

insert

threading

(N

and

locations.

chain

forms

material

diagram

R,

Fig.

Operate

and

and

(Fig.

1)

approximately

1).

machine

moves

sew

off

slowly.

With

slowstitch

While

needle

be

just

if

excessive

position

just

contacts

It

tor)to

With

back

its

mm)

far

most

distance

should

looper

While

portion

looper

the

tension

eyelet

sewing

thread

tight

needle

is

desirable

delay

material

enough

rearward

be

set

(V)

heel

of

lower

thread

(R)

down,

is

enough

thread

thread

needle

slightly,

so

behind

with

eyelet

sewing

comes

while

on

material,

drawn

to

is

thread.

to

adjust

the

under

thread

position.

needle

its

eyelet

on

looper

off

lower

keeping

NEEDLE

on

needle

feed

chain

pulled

eyelet

the

tightening

LOWER

presser

is a little

Looper

thread

approximately

at

the

time

material,

thread

upper

looper

the

same

UPPER

check

down

off

on

the

(AD,

Fig.

needle

of

LOOPER

foot,

slack

thread

cam

lower

check

should

looper.

thread

amount

LOOPER

THREAD

needle

stroke.

stitch

up

tongue.

stroke.

1)

so

thread

the

needle

THREAD

set

lower

when

pull-off

pull-off

1/8

looper

drawing

be

drawn

To

increase

is

on

upper

of

THREAD

CONTROL

thread

At

top

control

of

Stitch

With

that

needle

eyelet

well-forward

thread.

CONTROL

looper

looper

(AF)

(AE).

inch

(3.

is

at

off

of

through

amount

looper,

pull-off

CONTROL

needle

tends

needle

thread

thread

thread

is

Frame

17

mm)

extreme

looper

the

move

action.

as

stroke,

at

pull-off

set

looper

to

left

thread

tension

of

thread

follows:

to

pull

bottom

cam

(toward

eyelet

about

1/3 2 inch

thread

the

right

end

as

drawn

lower

Usually

thread

down

of

pull-off

the

(R,

(AF)

guide

of

its

follows:

before

looper

should

slightly

stroke,

(AE)

opera-

Fig.

reaches

(. 79

(T)

of

lower

travel.

lower

through

thread

all

1)

A

Before

three

will

not

During

draw

is

drawn,

pull-off

To

Fig.

to

1)

have

If

all

end

that

it

to

form

edge.

The

being

ble

without

should

purl

is

tensions

markedly

upper

upper

reaches

move

should

slightly

it

becomes

play

is

higher

near

needle

sewn.

be

increased

pulled

proceeding

to

give a normal

affect

needle

looper

down

thread

looper

its

most

the

purl

be

raised

more

necessary

in

needle

over

top

edge.

thread

In

general,

causing

needle

as

too

far

to

adjust

the

stroke,

through

thread

rearward

more

keeping

pull-off

drive

throat

If

upper

tension

lower

long

over

the

upper

looper

appearing

purl.

forward

the

tension.

will

have

position.

POSITIONING

under

on

to

shaft

plate

the

upper

move

before

than

looper

the

edge,

same

thread

looper

recommended

is

THREAD

required

looper

thread

as

the

thread

to

be

elasticity

top.

thread

stitch.

stroke

Moderate

of

When

almost

THE

all

PURL

both

amount

than

thread

pull-off

tightening.

too

low,

the

TENSIONS

is a function

tension

pulled

down.

of

the

eyelet

looper

normal

slack

looper

of

pull-off.

on

lower

If

in

purl

of

should

Upper

chain

(N,

change

thread

amount

taken

thread

thread.

(AF),

upper

Fig.

will

needle

be

increases,

Fig.

pull-off

up

eyelets

Usually

be

looper

11,

the

form

thread

set

as

looper

in

of

as

sure

nearer

high

thread

1)

balance

these

looper

looper

it

to

is

located

purl

and

or

tensions

(AF)

thread

thread

(Nand

is

better

take

will

tend

bottom

material

as

possi-

tension

until

all

will

R,

up

so

the

13

Page 14

14

Page 15

The

that

parts

are

illustrated

used

on

Style

on

the

39500

preceding

RK,

but

not

page

used

and

on

described

Style

39500

below

QB.

represent

the

parts

Those

Styles

Use

this

Reference

descriptions,

Ref.

No.

1

1A

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

parts

39500

Catalog

catalog.

Part

39592

39592

39592

39592

39592

39592

22891

39568

29477

22743

39568

39568

39573

39573

39573

39578

39573

55235

6042

55235

39573

39573

43544

39573

39573

39573

39573

22891

39592

39573

22572

39573

660-264

421

39550

39550

22559

21660

shown

QB

No.

numbers

indicate

No.

AT

AS

AR-5

AR-8

T-3

AP

88

A

E

HR

G

J

X

y

z

u

w

E

A

D

A

v

A

98

T

R

88

p

88

M

u

88

s

93

A

N

D-8

K

J

H

A

and

103

in

phantom

RK.

QA

that

they

view

(Style

are

inside a bracket

are

Leaf

Needle

Looper

Needle

Tension

Tension

Screw,

Screw,

Auxiliary

Upper

Thread

Knife

Chip

Upper

Driving

Upper

Upper

Upper

Knife

Pawl

Pawl

Screw,

Needle

Pawl

Screw,

Knife

"S"

Treadle

Spring

Lower

Screw,

Knee

Spring

Looper

Set

Thread

Spring,

Knife

Support

Guard

Knife

Nut,

Washer,

Locking

Knife

Knife

Screw------------------------------------------

Knife

Regulating

Set

Shaft

Set

Shaft

Set

Lever-----------------------------------------

Screw,

Regulating

Hook,

press

Press

and

bearing

39500

component

Thread

Thread

Thread

Post

Post

for

for

Screw,

Tube

Arm

Screw--------------------------------------Screw---------------------------------------

for

Thread

Screw---------------------------------------

for

Chain, 8 inches

assembly------------------------------------

Cover

Knife

for

QB)

for

---------------------------------------Tension

Tension

Tension

Mounting

Bar-----------------------------------tension

auxiliary

Lower

Support

-----------------------------------------

for

Stop

Support

pawl

pawl

for

lower

Assembly

Looper

Thread

for

Tube------------------------------------

for

thread

Block------------------------------

Guide

Block

Driving

driving

for

driving

Stud,

Washer---------------------------------

Driving

Driving

Driving

Pawl--------------------------------

Collar

shaft

Tension

for

pawl

shaft

Pawl

treadle

---------------------------------------

Pressure

knife

no

reference

all

parts

on

the

parts

post

----------------------------------

for

Bracket---------------------------

of a complete

Description

Plunger-----------------------

Spring------------------------

Spring------------------------

Bracket

bracket-----------------------

lower

thread

Spring

Lever

lever

Arm

Arm

Arm

support

lever

support

chain---------------------------

looper

Thread

Tube

driving

Shaft---------------------------

(not

Assembly------------------

tube------------------------

tube---------------------------

---------------------------

---------------------------

---------------------------

lever------------------------

Spring

Collar

----------------------------

-------------------------------

Release

---------------------------

(203.

Equalizing

holder

shown

numbers,

not

illustrated

picture

-----------------------

Eyelet

lever

----------------------

bracket

Arm

bracket

200

locking

plate

part

thread

-------------------

----------------------

mm)

Spring---------------

on

picture

eyelet---------

----------------

-----------------

------------------

-----------------

long

stud

-------------

are

or

and

have

or

assembly.

for

knee

plate)

common

described

indented

Amt.

------

to

in

Req.

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

2

2

1

1

1

2

1

1

1

1

2

1

1

1

1

1

15

Page 16

,..o

"'

..

'

()

WORLD'S

,..

' l f

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

facilities throughout

aid

you

in

the selection of

equipment

for your particular

Special representatives

tory

trained

promptly

tion,

there

serve you.

ATLANTA,

BOSTON,

CHICAGO,

DALLAS, TEXAS

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

GA.

MASS.

YORK,

and

and

is

a Union Special Representative to

Check with him

ILL.

N.

Y.

PA.

maintains sales

the

world. These offices

and

are

able

efficiently.

and

service

will

the

right sewing

operation.

service men

to serve

Whatever

Union

are

fac-

your

needs

your loca-

today.

MONTREAL, CANADA

TORONTO,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS,

STUTTGART, GERMANY

CANADA

ENGLAND

ENGLAND

FRANCE

Representatives

industrial

and

cities

distributors

throughout

in

the

all

important

world.

CORPORATION

400

N.

FRANKLIN

ST.,

CHICAGO,

ILL.

60610

Loading...

Loading...