Page 1

® /

INDUSTRIAL

SEWING

·-

FINEST QUALITY

ST

YL

E

395

00R

•

COLUMBIA

MACHINES

I

CATALOG

CLASS

39500

No.

STREAMLINED

103T

HIGH

SPEED

CHICAGO

OVERSEAMERS

Page 2

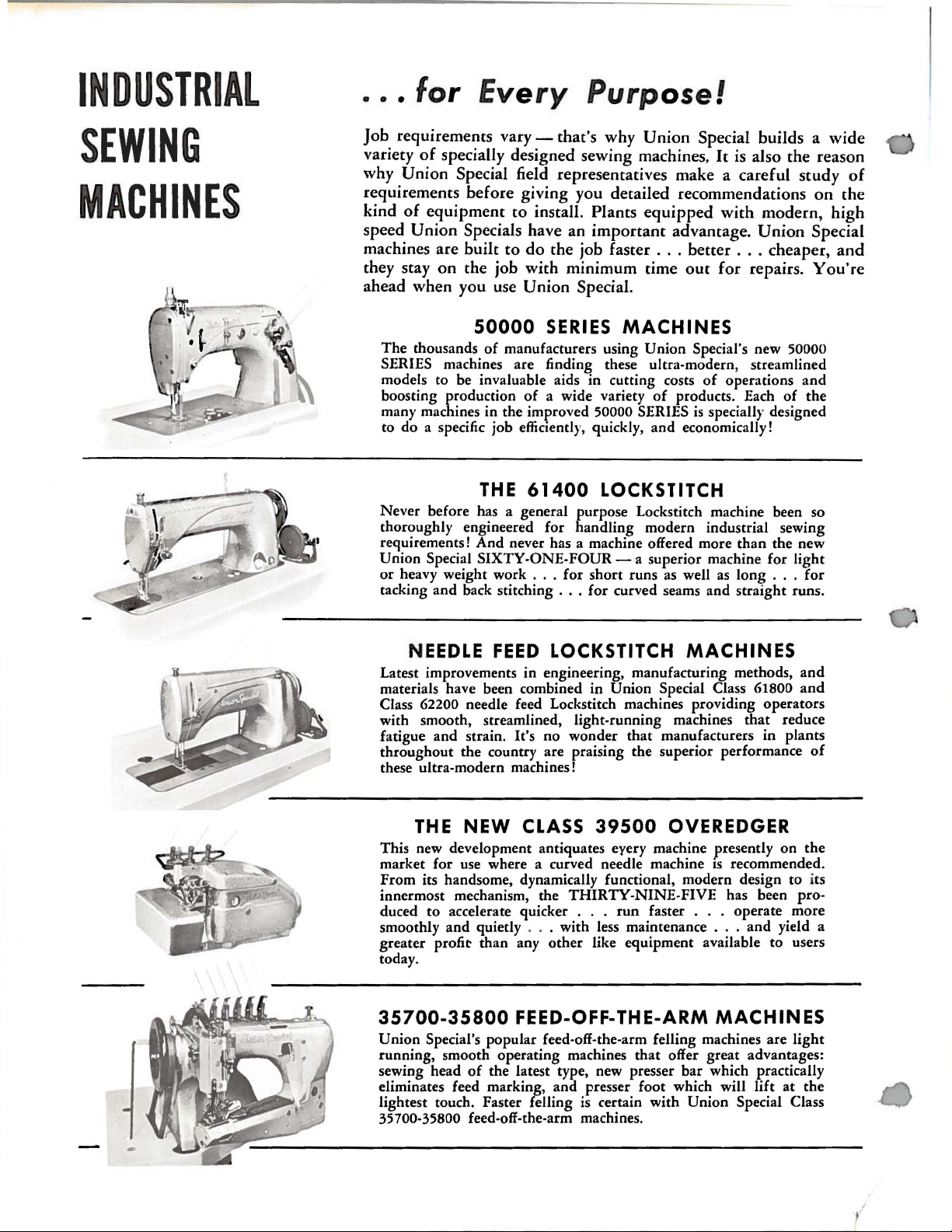

INDUSTRIAL

• •

. f

or Eve

ry

Purp

ose!

SEWING

MACHINES

Job requirements

variety

of

specially designed sewing machines,

vary-

that's why Union Special builds a

It

is also the reason

wide

why Union Special field representatives make a careful study

requirements before giving you detailed recommendations

kind

of

equipment

speed Union Specials have an

machines are built

they stay

on

the job with minimum time

to

install. Plants

to

do

the job faster

equipped

important

...

with modern, high

advantage. Union Special

better

out

...

for repairs.

on

cheaper,

You're

ahead when you use Union Special.

50000

The

thousands

SERIES

models to be invaluable aids in cutting costs

boosting production

many machines in the improved

to do a specific job efficiently, quickly,

of

machines are finding these ultra-modern, streamlined

THE

Never before has a general purpose Lockstitch machine been so

thoroughly engineered for handling modern industrial sewing

requirements! And never has a machine offered more than the new

Union Special

or

heavy weight work . . .

tacking

SIXTY-ONE-FOUR-

and

back stitching

SERIES

manufacturers using Union Special's new 50000

of

a wide variety

61400

for

...

MACHINES

of

operations

of

products. Each

50000 SERIES

is

and

economically!

specially designed

LOCKSTITCH

a superior machine for light

short

runs

as

well

as

long

for

curved seams and straight runs.

of

. . .

and

the

for

of

the

and

NEEDLE

Latest improvements

materials have been combined

Class 62200 needle feed Lockstitch machines providing operators

with smooth , streamlined, light-running machines

fatigue

throughout the country are praising the superior performance

these ultra-modern machines!

and

THE

This new development antiquates eyery machine presently

market for use where a curved needle machine

From its handsome, dynamically functional, modern design to its

innermost mechanism, the

duced

smoothly

greater

today.

to

and

profit than any

35700-35800

Union

running, smooth operating machines that offer great advantages:

sewing head

eliminates feed marking,

lightest touch. Faster felling is certain with

35700-35800 feed-off-the-arm machines.

Special's popular feed-off-the-arm felling machines are

FEED

strain. It's no wonder

NEW

accelerate quicker . . .

quietly ... with less maintenance

LOCKSTITCH

in

engineering, manufacturing methods,

in

Union Special Class 61800

that

CLASS

other

39500

THIRTY-NINE-FIVE

run

like equipment available to users

FEED-OFF-THE-ARM

of

the latest type, new presser

and

presser foot which will

MACHINES

and

and

that

reduce

manufacturers

in

plants

of

OVEREDGER

on

the

ts

recommended.

has been

faster . . . operate more

...

and

MACH

bar

which practically

Union

Special Class

lift

pro·

yield a

IN

ES

light

at

the

Page 3

(Supplement

C

atalog

to

Catalog

INSTRUCTIONS

FOR

N

o.

103

T

No.

103

S)

The

furnished

ADJUSTING

LIST

parts

at

listed

list

CLASS

39500

prices

First

AND

OF

Style

in

Edition

OPERATING

PARTS

39500

R

this

catalog

for

repairs

are

only.

Rights

Union

Copyright

by

Special

Reserved

1957

Machine

in

All

Countries

MACHINE COMPANY

INDUSTRIAL

Printed

May,

1965

SEWING

CHICAGO

i n

3

MACHINES

U.S.

A.

Co.

Page 4

Page 5

FOREWORD

The

streamlined

performance

precision

It

enable

Specials.

and

Union

anxious

Class

is

our

the

illustrate

to

39500

styling.

are

methods

constant

customer

The

following

and

Special

cooperate

machine

automatic

characteristics

insuring

aim

to

describe

representatives

with

complete

to

secure

pages

the

you

furnish

is

lubrication.

of

all

possible

contain

parts

will

to

plan

Union

these

interchangeability.

carefully

for

and

Special's

and

machines.

prepared

advantages

valuable

Styles

be

found

estimate requirements.

operating

in

Class

in

~

latest

light

All

all manufacturing

overedger.

running

parts

information

from

the

and

adjusting

39500.

MACHINECOMPANY

high

are

use

New

speed

made

that

of

centers.

by

will

Union

data,

5

Engineering

Department

Page 6

IDENTIFICATION

OF

MACHINE

Each

plate

on

Standard

the

letter

letter

is

"Z".

suffixed

Styles

ber,

which

This

be

used

NOTE:

cover

instructions

for

Exception

above

This

can

also

All

references

taken

from

direction

Union

the

Style

"Z".

of

Special

machine.

numbers

Example:

When

to

the

machines

only

standard

contains

edition

in

conjunction.

two

Style

throat

catalog

be

of

is

supplementary

The

threading

thread

for

three

39500

to

P.

the

plate.

applies

applied

to

direction

the

operator's

39500 R handwheel

carries

Style

have

"Style

minor

similar

no

letters.

APPLICATION

and

seaming,

thread

above

is

instruction

described

specifically

with

discretion

such

position

a

Style

numbers

one

or

39500

changes

Style

in

construction

Example:

to

adjusting

stitch

seaming

on

to

as

is

away

number

are

more

R".

are

made

number.

OF

catalog

instructions

Type

503.

are

for

page

to

8.

the

some

right

and

while

from

which

classified

letters

Special

suffixed,

Style

in a standard

Example:

are

grouped

"Class

39500

CATALOG

No.

103 S and

The

threading

detailed

adjustment

standard

special

left,

seated

front

at

operator.

is

stamped

as

standard

numbers

"Style

under a Class

11

•

is

as

described

in

Catalog

of

height

style

as

machines

and

the

machine.

in

and

but

never

machine,

intended

and

adjusting

No.

of

listed

in

Class

back,

the

name

special.

contain

contain

a

39500

RZ".

num-

it

shall

herein

103

S,

needle

herein.

39500.

etc.,

Operating

the

"Z"

It

are

Single

Curved

Differential

Medium

39

500 R Four

to

hemming

fabrics

medium

503

and

inch,

CAUTION!

must

oun8es.

100

be

filled

A

Fahrenheit

Machine

at

sight

between

gauge

gauge

Machine

keeping

oil

as

required.

main

Blade

Feed,

Heavy

way

or

used

to

heavyweight

504

EFc-1,

standard

Oil

before

straight

is

filled

on

lines.

is

automatically

reservoir

Needle,

Trimming

Duty,

Automatic

combination

seaming

on

undergarments,

standard

setting

was

beginning

mineral

should

be

with

front

of

filled.

STYLE

Two

Mechanism

machine,

of

all

types

materials.

12

per

drained

oil

used.

oil

at

machine.

lubricated.

OF

MACHINE

and

Three

Lubricating

for

and

weights

outerwear,

Seam

seam

width

inch.

OILING

from

to

operate.

machine

of a Saybolt

spring

Check

Red

cap

bulb

oil

Thread

with

Spring

System.

general

of

and

specifications

1/8

inch;

when

Oil

capacity

viscosity

in

top

cover.

on

oil

level

No

oiling

daily

before

Overseaming

Pressed

utility,

flat,

two

warp,

similar

503

stitch

shipped,

of

Class

of

200

to

Oil

indicator

is

necessary,

the

morning

Lower

or

three

and

ribbed

operations

and

504

range

so

39500

250

seconds

level

is

should

other

Machine,

Knife,

thread

knit

SSa-1,

8-20

per

reservoir

is

six

checked

show

than

start;

add

on

at

6

Page 7

OILING

(Continued)

Drain

of

base.

materials

cleaned

Each

type

number

details.

of

blade,

plug

It

which

periodically.

Union

The

measured

Collectively,

Style

Style

To

a

sample

order

39500 R machines

39500 R is

have

needle,

would

Selection

used.

good

Thread

stitch

Success

by

use

of

needles

backed

by a reputation

workmanship

screw

is

is a magnetic

may

have

Special

denotes

size

the

number,

in

type

needle

read:

of

number

Type

orders

or

"1000

proper

should

154

the

pass

formation.

in

the

operation

packaged

for

more

located

at

screw,

entered

needle

kind

has

of

shank,

stamped

thousandths

and

size

use a curved

GAS.

promptly

type

and

Needles,

needle

size

freely

of

Union

under

for

producing

than

three

the

back

designed

the

crank

NEEDLES

both a type

point,

on

needle

of

an

inch

number

blade

and

accurately

size

number

Type

should

154

be

through

Special

our

brand

highest

quarters

of

the

machine,

to

accumulate

case.

number

length,

shank,

midway

It

and a size num

groove,

denotes

between

represent

needle.

filled,

should

GAS,

Size

determined

needle

eye

machines

name,

quality

~

needles

of a century.

should

the

complete

Standard

the

be

given.

11

027

by

the

in

order

can

near

bottom

possible

be

removed

finish

largest

shank

empty

•

size

to

be

secured

in

materials

foreign

ber.

and

diameter

and

symbol.

needle

package,

A

complete

of

thread

produce

,

which

edge

and

The

other

eye.

for

a

only

is

and

Release

Fig.

1)

operating

onal

socket

clamp

position:

To

to

the

left,

needle

travel,

presser

Mter

through

it

is

threaded

right

hand

tension

Only

diagram

found

in

locations

pressure

and

direction

wrench

nut

about

withdraw

replace

insert

in

this

then

foot

thread

back

hole

discs

parts

(Fig.

Fig.

for

swing

1/4

needle,

needle

position,

tighten

release

comes

thread

through

and

(AD)

used

1,

page

1,

page

clarity.

CHANGING

on

presser

presser

until

arm

needle

is

No. 213 88 AU,

turn.

Again

needle.

leave

turn

nut.

bushing

needle

in

holder

handwheel

Return

(U).

THREAD

from

eyelet,

each

up

through

through

cone

then

pair

slot

of

left

THREADING

for

threading

9).

Parts

7,

Catalog

foot

(H)

out

at

its

furnished

turn

holder

until

presser

on

thread

down

holes

hand

(AE),

two

thread

used

103 S.

NEEDLES

by

turning

of

position.

lowest

the

handwheel

at

it

rests

until

holder

arm

STAND

stand

through

in

tension

hole.

and

on

machines

in

threading

Parts

point

with

high

against

(H)

front

Then

through

are

the

foot

Turn

of

machine,

until

position

is

again

to

position

(V,

Fig. 1 ),

thread

thread

thread

are

three

illustrated

release

travel.

loosen

and,

stop

at

eyelet

guide

continues

the

thread

shown

thread

bushing

the

handwheel

Using hexag-

the

needle

is

with

pin.

its

and

it

is

Keeping

low

relock

brought

(W).

wire

guide

in

threadin

machin

in

their exac

needle

at high

the

point

Next

(A),

down

between

es

(U,

in

flat

the

of

the

up

(B).

g

ar e

t

7

Page 8

It

will

threading

simplify

lower

threading

looper

THREADING

this

first,

needle

(Continued)

machine

second.

to

follow

recommended

sequence

of

Before

ating

foot

by

of

position.

Be

tween

Double

eyelet

thread

looper

lower

left

to

in

left

Turn

highest

needle

hole

in

beginning

direction

turning

sure

the

tension

end

(E,

Fig.

pull-off

thread

looper

right.

hand.

handwheel

position.

thread

top

cover

until

presser

threads,

discs

of

1)

(T).

guide

(K)

is

Left

eyelet

to

needle

(AD)

thread

from

Lead

(G).

all

eye

in

Insert

(R),

needle

thread,

(N)

is

foot

release

as

they

and

in

TO

THREAD

and

lead

right

to

thread

Turn

the

way

of

lower

TO

THREAD

operating

needle

under

t h r e

swing

at

cloth

high

bushing

come

diagonal

LOWER

it

through

left.

Note:

behind

handwheel

to

the

left,

looper

THE

direction

thread

neck

ad

from

of

eyelet ( P).

plate

position,

(U)

from

the

slots

Thread

fabric

in

then

can

be

NEEDLE

until

right

top

cover

open,

release

and

swing

tension

(AE)

LOOPER

both

eyes

must

guard

operating

thread

threaded

needle

to

casting,

T h r e

turn

thread

in

tension

of

pass

(F)

direction

through

easily

left,

ad

handwheel

pressure

presser

lower

in

and

if

(N,

Fig.

through

then

needle

on

arm

guide,

posts

looper

front

through

until

both

eyes

tweezers

1}

both

down

from

in

oper-

presser

(H)

are

(AC).

thread

of

looper

frame

heel

from

is

at

eyes

through

front.

out

be-

of

are

its

of

The

amount

knurled

to

secure

tension

PRESSER

Sufficient

should

to

presser

turn

a

be

increase

adjusting

right

hand

foot,

pressure,

pressure

set, tig

adjusting screw

hten lock

resting on

so

that

its

inch

to

1 I 16

justin

nut

g screw

(C).

of

tension

nuts

(AA,

proper

stitch

FOOT

pressure

maintained.

or

decrease

loosen

screw

(B).

thread,

looseni

ng

decreases

nut

throat plate,

under surface

inch from

(B)

. Set

on

Fig.

formation.

PRESSURE

to

feed

Should

amount

lock

nut

Adjusting

so

tightening

(B)

(A).

With

position

is

approximat

the

top

ca

p (D) ag

THREAD

needle

1).

work

it

be

of

(A,

TENSION

and

looper

Tension

uniformly

necessary

pressure

Fig.

scr

2)

ew has

on

on

and

increases

pressure.

When

has been properly

pre

s s er

locking nut

surf

ace

ain

st lock

el

y 1 I 32

of ad-

foot

(C)

ing

threads

threads

is

regulated

should

Fi

be

g. 2

only

by

enou

two

gh

8

Page 9

~Tension

Nut

---------.

---

---

-

--

-----

T.-nston lhn·

1!1

Thread Guide

D

Lower

D

Fabri

B

f'r

am

CJPrc

..,~t·r

nd

Loope

r ThrP

c Guard Brack

~

L

oop

e r

Arm

Fig.

ad Fyelt

et

1

l'u ll-u

f r

..,..

_

Thr

e a d r no

·l

Pull-of

.....

_-

__

N rdl • l h

f

.....

read

E•e

l e t

~yc.]

et

I y

9

Page 10

FEED

ECCENTRICS

Feed

imately

eccentric

39540-12.

ber

of

stitches

machine

Generally

number

relation

operation.

Following

5, 6,

36,

trics

a

7,

40.

may

minor

Example:

Before

guard,

upper

assembly;

eccentrics

12

stitches

is

No.

Minor

obtainable

will

be

speaking,

of

stitches

to

degree

stitch

8,

9, 10,

Only

two

be

ordered

number

"39540-1

assembling

knife

then

used

in

per

inch.

39540-14

numbers

of

when

shipped

with

differential

produced;

and

direction

number

11,

12, 13, 14, 15, 16, 18, 20, 22, 24, 26, 28, 30,

eccentrics

separately.

suffixed

O".

to

ASSEMBLING

sewing

assembly,

follow

this

suggested

this

machine

It

will

while

the

part

using

above

main

of

feed

eccentrics

are

supplied

indicate

AND

parts,

lower

have

been

be

noted

that

that

of

differential

symbol

that

eccentric.

combination

(right

(left

stretch

hand)

hand)

of

are

with

each

To

order

an

approximate

ADJUSTING

remove

knife

holder

sequence.

selected

the

indicate

Unless

of

eccentrics.

feed

feed

material

available

machine.

eccentric,

number

SEWING

cloth

assembly,

to

produce

part

number

feed

eccentric

approximately

otherwise

eccentric

eccentric

being

sewn,

under

Additional

use

No.

of

stitches

PARTS

plate,

fabric

hemming

approx-

of

main

the

specified,

determines

is

selected

or

No.

39540-

39540

desired.

guard,

feed

is

No.

num-

in

type

of

4,

32, 34,

eccen-

with

chip

guide

Fig.

3

With

center

is

inch

driving

(B).

at

high

in

above

arm

Remove

CAUTION!

to

the 1 /2"

stitch

sert

Fig.

With

left

set

inch

needle

Type

At

this

lower

4)

lower

end

of

looper

from

(Fig.

into

looper

21225-1/8.

have

lower

flecting

Tighten

SETTING

throat

the

front

position,

throat

(A,

throat

Needle

setting

504,

point,

looper

bar

looper

its

stroke,

point 1 /8

center

4),

using

gauge

Do

looper

needle.

nut

plate

end

needle

plate

Fig.

when

as

in(A,

(B).

at

of

No.

not

de-

(C).

THE

in

position,

of

needle

point

(Fig.

3)

by

loosening

plate.

height

adjusting

indicated

NEEDLE

slot.

should

3).

must

NOT

for

in

Catalog

Fig.

needle

When

be

set

Move

clamp

be

three

4

should

needle

15 I 32

needle

screw

changed

thread

103

S.

10

Page 11

SETTING

Set

rear

sible,

movement

to

(B)

without

deflect

is

used

needle

interfering

of

lower

needle

to

set

THE

REAR

guard

knife

forward . 002

rear

(A.

with

holder;

needle

NEEDLE

Fig.

5)

either

but

- .

004

guard.

GUARD

as

high

lower

still

in

inch.

as

looper

position

Screw

pos-

or

Assemble

needle

without

this

setting

feed

dog.

Insert

(B.

Fig.

spreader

shank.

holder

or

adjusted

Fig.

off

back

touching.

make

SETTING

spreader

7)

holds

to

be

Screw

in

the

laterally.

5

front

guard.

Screw

sure

spreader

pushed

(C.

shaft.

SETTING

justment.

to

set

6)

ward

another . 002

SETTING

needle

set

(D)

there

THE

(A.

Fig.

in

or

Fig.

and

7)

allows

THE

Now

the

into

until

THE

guard

front

is

is

SPREADER

7)

in

out

on

finish

right,

the

the

from

FRONT

(C.

needle

used

no

interference

in

its

its

holder.

or

collar

holder

As

turned

lower

its

needle

needle

rear

- .

Fig.

to

adjust

holder.

holds

to

LOWER

lower

looper

point

scarf

springs

guard

004

inch.

NEEDLE

5).

When

guard

and

be

as

and

between

Screw

permits

around

spreader

rotated

LOOPER

looper

moves

should

(A.

surface

GUARD

lower

close

set

front

its

ad-

be

Fig.

for-

as

needle

looper

possible

needle

guard

Fig.

is

springing

to

guard.

and

6

needle

After

main

Preliminary

end

of

to

position

Top

end

5/64

inch

Fig.

Setting:

its

stroke.

of

above

spreader

spreader

holder

8

When

spreader

spreader

holder

shank

about

shank

(Fig.

Set

just

behind

looper.

. 002

inch

spreader

(Fig.

Next

until

spreader

of

its

so

lower

extends

1 e f t o f n e e d 1 e

vertical

should

7).

spreader

with

clearance

and

8).

turn

travel;

point

about

is

at

the

right

should

extend

eye

approximately

lower

handwheel

is

check

of

5/32

11

be

(Fig.

about

to

pass

of 1 owe

between

looper

at

left

setting

spreader

inch

(Fig.

set

7).

r

end

to

9)

Fig.

Fig.

7

9

Page 12

Now

spreader,

forward

will

reduce

(Fig.

8).

check

pull

a

short

the

SETTING

setting

spreader

distance.

clearance

between

out

These

between

THE

spreader

of

its

spreader

SPREADER

and

needle.

holder

same

slightly

adjustments,

and

(Continued)

If

needle

and

rotate

in

needle.

Reset

rubs

spreader

opposite

to

the

back

holder

movement,

lower

looper

of

Now

set

feed

teeth

flush

set

with

SETTING

Replace

rep 1 acing

tighten

of

the

plate

of

when

corner.

edge

ments

holds

against

n e c e s

flange

mounting

the

lower

the

flush

are

lower

screw

Lower

upper

sa

3/64

surface

lower

on

knife

knife

with

made

knife.

r y

dogs

inch

the

(A,

sleeve

bracket

and

is

manually

knife

throat

with

knife,

when

Fig.

at

of

THE

knife

lower

Fig.

highest

above

throat

LOWER

knife

11)

(B)

10

throat

plate.

holder

so

seats

(C) a free

holder

assembly

pressed

(D)

should

plate

hexagonal head

Lower

so

wid

knife

no

t h

lateral

point

KNIFE

holder

that

against

be

set

surface.

is

spring pr

of

trim

of

travel.

plate,

assembl

and

y.

chaining

assembly,

when the face

the

thro

lateral

screw

is

at

its

with

motion

obtain

upp

cuttin

Adju

which

ess

ed

er

st-

ed

adjustment

is

changed.

SETTING

ential

(A,

veled

face

adjusting

raises

of

be

first

plate.

tilting

Main

In

at

g

is

Assemble

and

B,

C,

Feed

with

by

or

feed

bar.

set

level

appear

Screw

adjusting

and

differential

feed

THE

main,

chaining

Fig.

Dogs

throat

rotating

pin

(D).

lowers

Feed

at

(E)

dog

teeth

FEED

feed

10).

should

plate

feed

the

dogs

the

time

above

locks

pin

set

DOGS

differ-

be

tilting

This

back

should

throat

in

place.

feed

dogs

le-

sur-

pin

end

teeth

feed

dog

about

Lower

by

tightening

Set

from

ne

sc

edl

r e w

the rig

e,

Repla

setting screw

knife.

not

less

knife

the

desired

lock the

(E).

SET

ce

upp

At

bottom

than

may

screw

ht

edge

TING

er

(G)

1/64

be

(E)

against

width

of

lower

THE

knife ass

to

hold

of

its

inch

s e

cured

knife holder

of trim

the

lower

knife

holder

UPPER

embly. Clamp

clamp

stroke,

below

(H) in

front

cutting

in a

ny posi

by

knife

KNIFE

cutting edge

tion

shaft.

m easuring

to

the

shaft

its

edge

upp

mo

with

er

st

clockwise

of

lower

knife

12

F ig . 11

(F, Fig . 11) in positi

position agains t

of

upper knif

e s

knife.

hould

on,

upper

exte

nd

Page 13

SETTING

THE

UPPER

KNIFE

(Continued)

After

be

tightened

resetting

Length

of

feed

Fig.

12)actuatesmain(rear)feeddog,

(right)

feed

dog.

In

assembling

facing

key.

in

oil

each

Tighten

tube

To

end

of

shaft

tion

until

hooked

reach

behind

trics.

and

forth

upper

to

when

SETTING

of

stitch

eccentrics

eccentric

other.

(F)

change

(D).

key

slot

eccentric

eccentrics

It

may

slightly

knife

lock

upper

has

upper

knife

THE

is

determined

used.

(B)

actuates

feed

eccentrics,

Be

careful

nut

(C)

securely.

touches

feed

eccentrics,

feed

Turnhandwheel

in

eccentric

extractor

as

be

necessary

during

been

knife

is

replaced.

set

holding

STITCH

Outer

(left)

the

differential

not

Be

eccentric

remove

in

is

toward

(E),

supplied

shown

to

and

move

extraction.

for

proper

block

LENGTH

by

the

combination

eccentric

whilethe

be

sure

to

damage

sure

connections.

nut

operating

front.

with

withdraw

handwheel

width

(K)

inner

(front)

hubs

shaft

wool

(C)

yarn

from

direc-

Using

machine,

eccen-

back

in

(A,

are

or

of

trim,

place.

screw

This

Fig.

will

12

(J)

should

simplify

Foot

and

collar

presser

presser

To

with

loosen

arm does

foot

center

respect

presser

Adjust

that

presser

than

upper

nut

(D).

1/8

inch

before

presser

adjustment

(E).

and

Fig.

lifter

(B) secure

release

presser

to

lifter

lev

er

not

foot

thro

at

foot hi

lever s

13

arm

the

bind

bushing is unlocked.

plate needle

nge screw.

foot can be raised

looper

Ther

free

will

e s

hould

motion

of

foot begi

should

locked with

be

nut

(A.

Fi

g.

shaft.

and

and stitch

Be sure

rise

tongue

wh

holder.

top scr ew (C) s o

no high

perm

it; then lock

be

from 1/16

foot

lift

ns

to

r ise . This

er lever

made with scr

(F ).

If

eccentrics

•

ting,

13)

remove

tion

in

from

(H).

addition

shaft

nut

Then

suggested.

SETTI

Assemble

arm.

With nee

presser a r m

in

place.

be

realigned

shift

ing f

14)

If

oot

en

er

to

ew

are

to

(D).

(G)

and

c o n t i n u e

NG

THE

press

dle

into

sewingpositionandlock

necessary.

with

lift

er

unusually

removing

it

may

feed

PRESSER

er

foot

in high

press

throat

lever

Fi

g. 14

tight

nut

be

helpful

driving

as

originally

FOOT

to

position.

er

plate slots

shaft.

fit-

(C.

Fig.

connec-

presser

swin

foot

can

to

g

by

Reassemble chip guard,

fabric guard. clo

th plat e .

13

Page 14

NEEDLE

THREAD

CONTROL

While

all

needle

thread

to

at

thread

1)

its

imately

at

Moderate

SKIPPING:

should

pull

down

bottom

cam

With

back

extreme

and

extreme

Frame

1/8

Before

material

sewing

thread

slightly

of

pull-off

down

looper

left

proceeding,

change

be

stroke,

left

position.

inch

end

For

occasional

on

just

far

thread

right

in

material,

is

drawn

tight

if

excessive

position

(S)

just

LOWER

under

enough

of

of

its

balance

these

on

enough

needle

contacts

LOOPER

presser

so

Looper

guide

(G)

heel

travel.

THREAD

tensions

SPECIAL

skipping,

check

needle

to

thread

foot,

thread

thread

should

eyelet

both

needle

down

feed

thread

needle

THREAD

of

tensions

will

ADJUSTMENTS

thread

stroke.

chain

is

pulled

eyelet

thread.

CONTROL

set

lower

is a little

eyelet

be

looper

TENSIONS

not

check

(E)

set

with

(K)

to

give a normal

markedly

and/

off

control

At

stitch

on

the

(R,

looper

slack

should

its

at

effect

or

adjust

up

Fig.

thread

when

left

the

as

follows:

top

of

tongue.

stroke.

1)

spreader

be

hand

time

the

as

needle

Stitch

With

so

that

eyelet

about

appearing

horizontal.

eyelet

lower

purl.

outlined

looper

Usually

stroke,

tends

needle

needl

(E,

Fig.

reaches

approx-

stitch.

below:

e

is

1.

Recheck

page

2.

Recheck

er",

3.

Check

moves

Settings 1 and 2 should

by

appearance

thread

close

thread

spreader

side.

page

and

eyelet

to

bend

tension

CAUTION!

reaches

Be

sure

7)

With

in

the

thread

middle

lower

8.

spreader

page

clearance

far

that

(E,

in

looper

as

As

machine

tensions

9.

enough

skip

Fig.

thread

much

stated

its

extreme

is

of

its

looper -needle

-lower

between

left

be

is

definitely

1)

by

as

possible

before,

STARTING

threaded

light,

front

looper

needle

past

needle.

made

lowering

pull-off

without

looper

left

position

according

set

looper

to

back

setting.

crossing.

and

spreader.

quite

not a needle

(T).

TO

location.

carefully.

it

slightly

After

distorting

thread

or

OPERATE

thread

stitch

to

See

"Setting

See

"Setting

loop

skip,

and

bringing

this

change,

stitch.

must

will

threading

eyelet

See

If

it

be

appear tig

(E)

the

Needle",

the

Spread-

that

spreader

can

be

reposition

eyelet

increase

slightly

diagram

about

determined

looper

holes

looper

slack

ht

(Fi

horizontal

on

g.

as

top

in

1,

and

Operate

moves

machine

off

tongue

slowly,

freely.

with

presser

14

foot

in

place;

make

sure

chain

forms

Page 15

SETTING

THE

HEMMING

GUIDE

SUPPORT

BRACKET

Assemble

support

knife

of

screw

knurled

the

edge

side

parallel

right

this

edge

of

be

screw

towards

block

bracket

edge

sate

seams.

tip

the

bracket

the

of

feed

When

position,

should

parallel.

made

Under

is

for

is

controlled

spring

edge

bracket

support

(A,

adjusting

guide

its

tip

to

the

slot

the

be

by

(Ref.

the

and

edge

(D).

normal

spring

the

The

(Ref.

(D).

guide

the

hemming

onto

bracket

Fig.

edge

the

This

positioning

47,

front

pressed

differences

amount

Removing

15).

screw

(C)

so

that

is

even

right

in

the

throat

guide

front

slightly

adjustment

page

of

guide s up

conditions,

by

adjusting

46,

page

prevents

the

by

means

With

(B),

the

with

side

tip

or

leading

to

the

the

15)

located

the

to

compen-

in

material

of

movement

15)

this

movement

guide

lower

the

set

left

and

of

the

plate.

is

in

right

can

stop

hinge

p o r t

the

the

screw

located

spring

thickness.

and

the

(Ref.

in

and

turning

of

the

pressure

the

edge

For

45,

page

hinge

the

guide.

Fig.

example,

applied

15)

block

screw

15

which

and

all

as

to

edge

the

in

going

the

edge

presses

guide

way

out

over

guide

against

support

against

Adjust

(B)

so

that

face

of

the

its

guiding

terial

that

vertically.

tightening

port

to

the

bracket

be

tip

the

fabric.

edge

of

the

FINAL

edge

the

stitches

and

hemmed.

the

overhanging

If

desired,

locking

(D).

ADJUSTMENT

guide

Adjust

the

(C,

are

the

edge

Adjust

the

screw

Fig.

located

overhanging

guide

the

overhanging

(G)

15)

in

corresponds

stop

guide

located

is

OF

HEMMING

by

turning

the

folded

guide

screw

located

guide

in

the

edge,

(E)

with

(F)

for

at

can

hinge

the

the

be

block

GUIDE

knurled

yet

so

that

the

the

overhangi

center

locked

adjusting

do

not

the

space

thickness

of

the

into

and

edge

screw

show

ng

position

between

of

the

guide

edge

guide

on

the

ma-

so

guide

by

sup-

15

Page 16

---

il'

--24

~

~f---

~~

·

;~~

.,

~

~~~

~~

23

~

~r

27A

278

25

26

21

16

Page 17

The

parts

illustrated

on

the

preceding pag

e,

described

below,

represent

parts

used

on

Style

39500

R.

Parts

39500

Use

He

f.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

27A

27B

28

29

30

31

32

33

34

35

36

37

38

39

40

40A

40B

41

42

42A

43

44

45

46

47

48

49

50

50

A

51

52

53

shown

P.

39500

Catalog

39580

39525

22585

39525

39524

39550

39550

39550

39550

22559

39550

39582

39582

39582

22513

39532

39501

39568

39560

39563

39520

22738

39530

22768

39530

22738

3

3 597 F

39556

39556

39540-12

39540-14

39505

39526

3950

51292

51292

51292 F-8

39589 H-1/2

39589 H-1

39589 H-3/4

29481

39

22760

39503

39589

79077

39

129

39568

7907

22799

227

39

227

228

39589

22 593

in

phantom

AF

No. 103 S,

Part

No.

BA

D

G

E

G

H

IJ

L

J

T-T

88

B

K

G

J

H

D

G

B

A

J

G

E

B

530

B

605

c

B

F

II

5 G

F - 5

F-4

98

A

F

589 u

A

G

F

77Q

589 G

35 A

J

7

.

43

58

9 E

38

73

J

and

view,

39500

Style

bearing

R.

39500

Throat

Needle

Screw,

Needle

Thro~

Lower

Lower

Lower

Knife

Adjusting

Screw

Spring

Side

Screw

Latch

Cloth

Looper

Spreader,

Needle

Presser

Screw

Chain

Chain

Differential

Main

~lain

Differential

Chaining Feed Dog

ooper

L

ooper

e

edle Thr

Overhanging Gui

erhangin

Ov

Overhangin

S

crew

emm

H

Screw, for

P,

Plate

Guard,

side

Guard,

Pl~e

Knife

Knife

Knife

Pressure

Screw

----------------------------------------------------------

Cover

Cover

Hivet

Spring

Screw

Chain

Screw

Hinge

Screw

Chip

Stitch

Hemming Guide

Screw

Ed

Overhan

Scr

Hinge Blo

Screw

Ed

Screw --- Hinge Scr

Sc

Overha

Screw

Adjusti

Sp

-------------------------------------------------------

-----------------------------------------------------

Spring

Plate

Thread

for

Thread

Foot

Shield

Spring

Guard

Tongue

------------------------------------------------

Cutting

Cutting Knife,

Feed

Driving Eccentric

Feed Dog

and

Thread

ead

g Gu i

g Gu i

-------------------

ing

Guide Ass

---------

ge

Guide

Scr

ew

-----------------------------

-----------

ge Gui

rew --------

ngi

----------

ng S

ring

--------

hemming

no

reference

for

all

Support

front

cover

------------------------------------------------------

-------------------------------------------

-----------------------------------------

------------------------------------------------------

------------------------------------------------------

---------------------------------------

Feed

Feed Dog

Needle

ging Guide Hinge -------------

ew

latch

rear

----------------------------------------------------

Holder

Clamp

Clamp

Equalizing

-------------------

----------------------------------------------------

---------------------------------Eyelet,

two

thread

Cam

----------------------------------------------------

------------------------

-------------------------------------------

-----------------------------------------

------------------------------------------------

Knife,

Driving Eccentric----------------

------------------------------------

------------------------------

Thread

Tension

Tension

de, for

de,

de, for 3

---------

----------------------

ck and Edge

de Tensi

---------

ew

------

ng Gu

cre

w -------

numbers,

parts

not

illustrated

Description

Bracket

---------------

------------------------------------------

------------

-----------------

Spring

----------------------------------------------

Pull-off---------------------------------------

upper

lower

for 1 inch

em bly

Spri

-

ide

- - -----gui

----------------------------------------

Spring

used

in

seaming

--------------------------

------------------------

------------------------

-----------Tension

Sprin

g,

Sprin

g,

1/2

inch hem------------

/4

inch

-

--------------------

----------------------

ng

------------------------

-

------------

-

------------------------

Guide Su

-

----------

on Spring

- - - ----

-------

----

- - - ------------------

Base

- - ----

---------

de

assemb

-----------

- -

are

common

or

described

----

- -

----------

--

------------

----

------------------------------

-

----------------------------

----------------------------------

-

-----------------------------

top

position for

---------------------------------

-

--------------

Sprin

g, fort

for

three thr

for

three

thread

hem

-------------

hem ---

pport ---

- -

------ - - ---- ---- -

---------------

- -

---------------

- ---- -----------

---------------ly

-----------

-

---------------

-

-----------

-

-------------

--------

- -

----------

- - -

two

-

------------------------

woth

ead seaming

s e

- - -

---------

-

----------

---------

-

-------- ------

------

---

to

Styles

------------------

-

thread

- ---- - ----

-

read seaming

aming

------ - ----

-

-- --

--

-----------

-----

---

----

- - - - - - - - - - -

----- - - -

- ---- - - -

-------

--

- - -

---

39500

here.

-

--------------

-----------------

-

-----------seaming----

-

--------------

- -------------

---

--------

-

-----------

- -

--------

-- -----------

------

-----

------

---------

- -

----

- -

---

------ - - - - - 1

- -

-----------

--

------------

---

----

- - - -

--

- - -

-----------

---- -

--

- - -

------

- -

---------

---

- - ----

----------

-----------

- -------

----------

- ---- ------

A,

-

----------

-

--------

-

---------

---

- -

--------

- - -

- - - ---- 1

--------

----

- - - - - - 1

-

------

-- --

---

--------

-------

----

---

------- 1

------

------

---------

----- 1

39500

Amt.

Req.

- - 1

-

----

---- - 1

---- - 1

- -

--

-

---

- 1

- -

--

---

--

---

- 2

-

---

- 1

- - 1

--

--

- - 1

- - - 1

- - - 1

- - 1

- - 1

----

- - - - 1

B,

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

17

Page 18

®

FINEST

QUALITY

SALES

tHandle Union Sped

l:

Handle

lew

All

others

c

erta

in eaceptlons.

AlABAMA,

Baldwin, Tot.

ALABAMA,

H. Hamlot,

ARKANSAS, li

CALIFORNIA,

Baylen,

*CALIFORNIA, LOS

Paul M. Mason, Mar., Tel. Mad ison 5-

CALIFORNIA, SAN FRANCISCO

J. Vall, Tot. Undorhlll 1-1580.

tCA

li

FORNIA, SAN FRANCISCO

Mach

ine Co.,

COl

ORADO,

5719

Rood

COlORADO,

Carter, Tel.

CONNECTICUT,

Ga

ines, Tot.

FlORIDA,

Gus M. Buckley, Tel.

FlORIDA, PlANT,

Morgan, Tel.

*GEORGIA,

Merrilt M. Amb roJe, Mar., Tel. 875-9237.

GEORGIA,

T ol .

335

GEORGIA,

377·5559.

Tol.

GEORGIA, DUBLIN, 1615 Knox

272-~663.

*ILLINOIS, CHICAGO 10,

Ullrlck, Mgr., Tol.

KANSAS,

HE

Tol.

KENTUCKY,

Hinton.

LOUISIANA,

s

ham, Tel.

"ARYLAND,

Foslor, Tel.

%MARYLAND,

B

altimore

MASSACHUSETTS, AUBURN, ~ Mount Vlow Avonuo, Larry

en, Tol.

Kols

t *MASSACHUSEnS,

E. Palrn, Mar

al

and

is

and

handle

UNITED

BIRM

INGHAM,

MONTGOMERY

Tol

TTLE

LA PUE

Tel.

330·300.

11.55

ARVADA,

St., Tel.

DENVER

777-7060.

746·3652

NORTH

752-1829.

ATLANTA,

COMMERC

...

061.

DECATUR,

PRAIRIE VILLAGE, 7351 Rooowoad, Cloo C. Smllt!,

2-1705.

lOUI

Tol.

587-00~2.

METAIRIE,

729-4115

BALTIMORE

727-8499

BALTIMORE

St., Tol. lExington 9-

832·3672.

..

Columbia only.

Columbia

only,

Union

Special,

lew

is

and

STATES

732·Uih

Street,

833-

990~

.

7,

.

265·09~2

ROCK,

DANBURY

MIAMI BEACH

CITY,

SVILLE

Tol. Llborty

1959

.

P.O.

Box 1783,

NTE,

1527

ANGELES 21,

7,

Mission St

., Tel, MArket 1·66t.G .

Casey' s SewJng Machl

~U-6630

(Toxlllo Machines).

10,

1801 South Marton St., Louis E.

(Bag Closing Machlnol)

, 22 Barnum Road, Robert W.

.

9~9-1215

.

506 N.

2120

Plarlors Bri

E, lakovlow Drlvo,

1713 Coventry Road, Joo V. Parkor,

~00

N. Frank lin 51., OfYIIIo A.

64~·6920.

7,

P.O. Sax

707

Trudean Drive, Charles Wlckor·

15, P.O.

.

1,

J. Daohow, Inc.,

BOUON

11 ,

2-0U7

South,

Amolla Drlvo, Garnol

James

Chan

nelwoad

1100

E.

.58

28.

1275

Minion

3,

Apparel

, 985 N.E. 1761h St.,

Go

rdon St., James

dge

J.

St.,

John

W.

7261,

Box

250,, Ralph

1838.

179

Lincoln

.

Columbia

Lloyd

T. Taylo r.

Drlvo, Bill

Plea

St.,

City Sowing

ne

Service,

Road, N.E.,

Tom

Hanlov,

Janoo, Tot.

laymand

~17

-..,

Wlllla•

with

llvd.

Robert

LEWIS

INDUSTRIAL

OFFICES

tMASSACHUSETT

& Supply Co. , 205 l inco

tMASSACHUSETT

1

cn, Tel. 8 28 1

:MASSACHUSETT

D.

& Su

•MASSACHU

Wolte r P. Godek, Tel. VanDyke 2-6149.

M

ICHI

lux, Tel. 5B4·4210.

MINN

Po

rk

,

MISSISS

Boy

MISSISSIPPI.

VI 2· 5848 .

SS

t MI

Broadwa y, Tel, Vitlot 2-

MISSO

Mclaughlin, Tel. Chestnut 1-2368.

j N EW

Hober man Jr

! NEW JE RSEY, NOR

Jose ph Loglisci, Tel . 9

m

EW

W ih on, Tel.

C.

NEW

Te l.

NEW

Whe

*NEW

Bldg. ) Clarence

~-8 800.

t NEW

Rd. ,

NEW

Te l. Ivan h

NORTH

D. Ha rrod,

e. M1lt

E.

OHIO,

Equipment Corporat

OHIO,

iste r 1-

B.

OK

LAHOMA,

S

t.,

PENNSYLVAN

W.

Caue

PENNSYLVAN I

Kondig, Tel.

PENNS

Joh,

S, BOSTO N 1

S, CANTON, Yo

.C

S,

pp

ly Co ., 10 59 S. Mo rn St., Tel. OSborne 5 -7BA7.

SETT

S,

GAN,

DEARBORN

ESOTA,

MINN EAPOLIS, 2800 Texas Avo.,

2

6,

Mi

nn., leonard W.

IPP

I,

JACK

ette,

Tel.

Fleetw

TUPL

OUR

I, KA

NSAS CI

URI. ST

. l O U

HAMPSH

IRE, NASHUA, P. O. Box 2

.,

Tel. Turedo 2-9 69

JERSEY,

RUTHERFORD

Gen

JERSEY, WEST

767-4350.

YORK, LATHAM

ele r, Tel. S

YOR

tate

YORK, NEW

YORK, ROCHEST

Te

l. BUller 8-725

K, UNIONDALE, 873 Henry 51

oe

3-7477.

CAROLI

NA,

Te

l.

er, Tel. 296-0734.

CLEVELAND

COLUM

BUS, P.O.

12

22.

OKLAHOMA

G B. Wiley, Tot.

IA.

ll, Tet, 797-21

A,

784

YLVANIA,

CLAR

J. Lafler, Tel. JUniper 7 -2820.

and COLUMBIA

SEWING

AND

11.

FAll

TAUNT

SON 3, 327 Easrviow

ood 5-197

O, 606 Racove Driv

IS

TH

eva 8 -2178.

BERLIN, P.O .

, 57 Sylva , Ave

5-6371 .

YORK

l. Ro\

ER 9, A. J. Adam•

GREENSBORO

299-9367. 4216 Pen nyd

3, 6020 Euclld Ave., Hi

ion, Tal.

All

ENTOWN, P.O.

11

BLOOM

·78

64.

KS SUMM

REPRESENTATIVES

f,

Zolkind Sewi

ln

St. , Tel. HAncock 6-5588.

rk

St.,

RIVER

,

Z alk~nd

ON, P.O. B

6, 574

7 Evororeeo Rood, John F.

Koe

hler

6.

TY

S,

Tox

lllo Machine

9558.

34, 98

60

Gut

8.

ARL

INGTON, 8 Rulherl..-d Place,

91-821

1.

, 246 Sylvan 51., Richard W.

Box

1,

370

7rh Ave., (Penn Te•mlnal

enquht, Mgr., Te

0.

, P.O.

Expran

Box

8

7~.

Jo

..,

CITY

19,

685-2836

.

.

SBURG, P.O . Box 3

IT,

428

MACHINES

ng Machine

RFD, Roy

T. Podor·

Sewing Machine

ox

1 2 Ray

, Tel. 644-6236.

e, Bill Hayw

1-8811.

y Smirh, Tel .

2226 Soulhwosl

Box

St.

St., Jam

ood, Tel.

ry

Co.,

hrie Ave

.,

Carl E.

57,

Horman E.

26, Fronk A.

.,

Clarence

l.

Chickering

Co

..

I 051 Culver

., Anrhony Candell ,

Box

226,

Willia

ale

Dr •• Harold

nch

Garment

AXm

5~2.

lulher

61,

Irvin

Wo•t

Grove

nham,

lou

ie

915

Nd,

53rd

Avo

PENNSYLVAN IA, EGYPT

wich,

Te

l. 262-212

PENNSYlVAN IA,

McFadden, Te l.

*PENNSYLVANIA,

Ave ,,

Be

n W. Meu , Mgr. ,

'

PENNSYLVAN

W. Date Speer, Te

PENNSYLVANIA, REAMSTOWN, P.

is

A.

A.

m

ln·

D.

H.

.,

Bonder, Tel.

PENNSYLVANIA,

8040

.

854

SOUTH

CAROUNA

Virl

yn

R. Cr h ler, Tel. Sunset 7-0663.

SOUTH

CAROLINA,

W. Greg ory, Tel. Cedor 9-

TENNESSEE, KNOXVIllE

E.

Ch

nard, Te

TENNESSEE, MEM

ho

n t, Tel Mutual 5·67 50.

TENNE

SSE

E,

William J. Brauch, Tel. Cypr

Dr

ive, F. M. Blunkoll, Tel. 883-3352.

*TEXA

S,

DAllAS

Zo

ck X. Bennett, M

TEXAS

, DENTON, 24 15 We't

To

l. 387-

5007

H

XA

S, El PASO, P.O. Box 9573,

598 -2928.

TEXAS

, SAN

To

t. Dl 2-5924.

UTAH

, S

ALT lAKE

Rosvo ll, Tel. IN 7- 6931.

VIR

GINIA, LURAY, P.O . Box 4

Rl

3 5271.

A,

VIRGIN I

BRIT

MANITOBA,

*ONTARIO

*OUEBEC,

lYNCHB

5904.

239 -

Union

ISH

COLUMB

E. 15rh Ave. , Tel. 874-1910.

Bl

dg.,

70

Arlhur Sr., Tol. WHileha

. TORONTO 28, l o• Yol.,, Mgr.·Rop

St. West, Tel. Emp,re 6-2939.

MONTREAL 10, Jo

Moliere

St • Tel. 276-2575.

WORLD'S

, 6 28 Ma in Str

.5.

LANSDAL

Ul

~-8 850.

PHILADELPH

IA, PI

TTSBUR

l.

(Pittsburgh) 563 -3589.

267-6109.

YORK

, P. O. Box

, COLUMBIA, 2

GREENVIlLE,

l. 5 88·186

PHIS 17

NASHVILL

E

12

19,

~2

gr.,

.

ANTONI

O, Jeu y

CITY

. 12

URG

, P.O.

CANADA

Special

Mach

IA, VANCOUV E

WINNIPEG, Fro

FINEST

QUALITY

*

eet

, Bernard

Sogon

E,

330

Gr

eenwood Road, Donald

IA

24,

Te

l.

GH (Irw

S.S39.

19,

3905

5.

, 4695 Dunn Rd., Richard J . lind.

, 1602 South

en

00

Hines Blvd.,

Tel. l

15

Box

ine Co.

nk

hn

4234 Ma<a lo•lor

Gl

adstone

5-9800.

in I, 100 Arona Road,

O.

Box

176,

884, Ha

rding T. Powoll,

03

9 Wins

or

Hil

2S

S.r Abbol

St.,

Groonloof Ave., Horace

Observatory Drlve,

2-5123.

2517

Woodberry

P.O.

akeside

Oak

St., Jo

Edward

Gre

gory, P.O.

E.

13rh

01

, Gordon Rickard, Tel .

107

of

R,

lawr

Thiermot~ ,

ll

Caschollo, Mo

Bar

6-83

69,

hn

D. Troeger,

E.

Smith, Tel.

Box

Soul

~

Sr

.,

5,

Tom

Traylor, Tel .

Canada,

Ltd.

ence F. Kay, 792

Rm. 201,

3 -~933.

.,

r.·Rep.

David M.

ls

Drive,

Orv ille

6727,

13126

larry

Whitla

3H King

,

o-

,

F.

~0

FINEST

QUALITY

WORK

•

•

HIGHEST

PRODUCTION

RATES

•

•

1&-'-4

LOWEST

MAINTENANCE

COSTS

Page 19

Also

Sales

Agent

for

Agents

Ill

LEWIS

For IJNION

and

(C)

SPECIAL

COLUMBIA

Machines;

where

marked.

(TE

XTILE & BAG

PUBLIC Of

RE

Pd

tcha

7'1/

7~

Shoot. SOUTHERN

DESIA

BURY

IBAG CLOSING MACHINES)

ltd

. RE

32 Von B.andls

CAPETOWN-

St. EAST LONDON35

_,

PIETERMARITZBURG,

WORCESTER . SOUTHERN RHODESIA, fEDERATION

RHODESIA & NYASALAND BULAWAY0- 2

Rhode•

RHOD

ETHIOPIA,

Asfoha

IVORY

ll

& Cl

KENYA

, NAIROBI-

lor

St. (P.

yl

lta

MALAGASY

Do

l ' Emyrne, Bolte

ll & C)

MAURITIUS.

Machines) Hall,

Newto

'-'OROCCO, CASABLANCA- R.

ldriu l Et

NIGERIA, APAPA, LAGOS- Sunftoo Kni

ltd. 9 Warehouse

SUDAN, kHARTOUM- Franco

305

.

TUNISIA TUNIS-

,.u

1R

MAKING MACHINES) Borza ck

SOUTH AFRICA- JOHANNE

rd St , CAPETOWN- 78 Darling St .

Cornmorcial Road.

& NYASALAND- 8ULAWAY0- 16·

- 102

Slnloa

PUBLIC

Wales

Murchison

Sho•t

. SALISBURY- 95 VIctoria Street NORTHERN

ESIA- KITWE .81ontyro Rood ,

ASMARA

Woosen

COAST. ABIDJAN- Ett.

O.

Box

and

Z

onxibor

REPUBLIC

.

PORT

n St.

Sakall

1L

& Cl

Janvi

er

1957

PORT

RHODESIA, FEDERATION

St.

OF SOUTH AFRICA - JOHANNESBURG-

St.

and

38

PORT

- S.A.

ll

& C)

lronacondlo,

5933)

l

- TANANARIVE- Soc.

Postole

LOUIS- (Boo Cloolng & Bog Moklng

Geneve,

(l)

Road .

Comptolr

(ll

ELIZABETH- 125 Queen

Ill

South

African

BLOMFONTEIN- 53

8reo Sh .

Argyle St

EliZABETH-

PRETORIA,

(l

OURBAN-22

.,

LADYSMITH,

Box

VERHNGING

Caldoront Ahica ,

Joan

Abile·Gol,

ltd

.•

College

& C)

(Also Uganda,

1078,

17 Rue

lanalolt,

ltd

Gelnmonn & flh,

tting

Pinto (Sudan)

ln~ustrla

l

&

.,

SBURG I 35/7

14th

Scale

611.

leander

Ind.

.C2

Millo (N i

ltd

Menoa•r

ASIA

AFRICA

CAMBODIA,

tHor~~·

So

JAPAN.

Cho

at

KOR

B

LAOS VIETIANE-Denh

PAKISTAN, (WES

29

and

Baltic

REPUBLIC Of

(Hong kong )

ton St.

IHongkong) Ltd.,

THAilAND. BANGKOK- Yip In hoi &

Bo•

VIETNAM,

-

PHOM~PENH-Denls

~~cJTTA

varam Bysack 57.

IC

Ashi

EA, S

ldg

Zeenol

147

~

OSAICA-ICondo

ila · ku.

(l)

koga,

Fukal,

EOUl

- Uobeneo.Hondel A.G. ,

180 1 -ka

Ulchho

T)

Mansl

bog

mak

ing

Street,

Dundee,

CHINA,

Ltd.,

(l & C)

23

ll & Cl

SAIGON

Trinh Mlnn · Tho II.

heros, 219

Po~~~

&

s!~ino

Mochi

(l

& C)

Sowin9

Branch- Tokyo 6 ·3

Nagoya,

; Chuno · Ku, Int. P.

froror

KARACHI-2- Univorrol Trodlng

on, Mcleod

machines)

Scotland.

HONGKONG-G. R.

Rm.

305

Wing

TAIWAN,

16

Non

Yono St.

- S.A. Pour

P.

no

MaGhine

Co. 163.

Glnza,

Nilgata,

and

Rm.

. P.O .

TAIPEI-G.

O.

Bo•

Road.

lEAST) (Bag closing

Thomas C. Keay,

Tlng

Bldg.,

R.

(l & C)

Co.,

le

Rlr

ot

AAA) IC &

l ' lnduotrl

l)

(P.)

Choo·Ku

Okayamt.

Box

1JJ.

Coleman

7·13

Col

AUSTRALIA

SOLE

DISTRIBUTORS, Copron,

poo

l S

heet,

8runswlck St. , Valley,

St. AGENTS,

Hindl

MAN IA, LAUNCESTON

St.

ll & C)

SYDNEY. Branches

ADELAIDE-Topp & former, ltd

ey

St.

PERTH

Corter

N.l. MELBOURNE-l

- Thomsons,

·S

ew Knit Ply,

Ply.,

Ltd.,

al:

BRIS&ANE-<i5

Ltd

., 7 89 Hay St .

ltd., 72·

SA A'Bocko

Broo

.,

Lid.

DURBAN

-

Of

RHO·

Avo. SALIS·

Co. Pty

Zodron

St.

Allwal

Notol

-

Also

and

Of

Houoo,

Avenue

Boa

1798.

House, Sod·

Tongan

Et Com.

Clemenceou

Sir

William

Ruo

gorlo)

., P.

O.

Bo•

.

Rue

P.

B.

Slto·

Ltd.

9/1

Umegoo

. Also

60.t,

lando

126

8.

(L)

(C &

Corp.,

ltd.,

Co.

Welling·

omon Co.

ltd.,

P.O.

(Sar

86

liver·

.,

177

TAS

74

George

AUSTRIA,

VIENNA-Firma

Il

l

BEL

G IUM,

BRUSSELS-Un

of Amot l

ca,

90

D

ENMARK,

Sy-

lndustr

BORG, HERNING, KOLDING, ODEHSE, RISSKOV·AARHUS

.,

AND

FINLAND,

Vottunl

u olo

FRANCE

at

P.

El

15

Franc

Diroctour. Branch

LYON, VILLEURBANN E (RHONE)

ERMANY, STUTTGART

G

G .m.b H , Sc

Direct

AT

KOLN

GREAT

Tf R, Uni

B•

ounstono

BRISTOl, J.

and. LEEDS

l

1,

H.

W. F.

(Gla

sgow) Derrick

AGENTSt

Mochinory)

19,

lovenshulme.

GLENGORMLEY, COUNTY ANTRIM,

Ferb ro Bldgo.,

S. E. Allotdico & Co ., 9

ing

Thomo

R•ithh hie'S .

GR

EECE. ATHENS- G

traki

ICELAND,

lo

(l

IRELAND, OUBLIN - {Textilo Machines)

Parnell

Thorna1 C Keay,

ITALY,

lB

. fl & C)

MALTA,

•

Bokery Stroot.

THE NETH

C & H. Ver

ARNHEM, ENS

TARO,

l)

NORWAY, MANGLERU

I

17,

RTUGAL, OPORTO-Ro

PO

de Forrester

SPAIN,

SWEDEN,

nerigaten

MALMO, S. Forstand s.gatan

~/B

SWITZERLAND,

I

Postfachl. ll·Button

i)

Rue

COPENHAGEN- Rothonborg

ion A/ S, Ni

SllKEBOR

G.

HELSINKI·LAUTTASAARI-Suomon

emonkotu

TURKU, Tl

, PARIS-Cie.

e.

91

Avo. do

hwabstr. 33- A.

or.

Th

M. 8

BIElEFElD, EBINGEN, FRANKFURT, HAMBURG,

, MUNCHEN . IC & l Button

BRITA

IN- ITo•tllo Mochinoo)- ENGLAND, LEICES·

on

Spacia l Mochir,e Co..

Golo,

R. Rockin

. C

0. Holt,

Maxwe

ll, 50

lONDON

ltd

.,

S. A.

Smilh

NORTHERN IRELAND, NEWTOWNABBEY,

335

ond

Bog Moklng Mochlneo) SCOTLAND,

t.

C. Koay,

St.

(l

&

()

REYKJAUIK

&C)

.

Stroot

ll)

MILANO-

VALLEnA-A.

(l & C)

ERLANDS,

beek,

CHED

TllBURG.

BERGEN- Biornsongot 24. (C)

91l.

BARCELONA-Ropldo

BORAS

- Rud. Nystrom &