.FIN

EST

STYLES

36200 H

36200 J

INDUSTRIAL

MACHINES

36200

36200 AJ

CATALOG

T118

AH

No.

H

0

CYLI

., --

re

CLASS

IGH

DER

36200

SPEED

FlA

TSEAMER

_

-··-

o_

_

0

o_

MAC

UNION SPECIAL

CHICAGO

I

ES

CO

PORATION

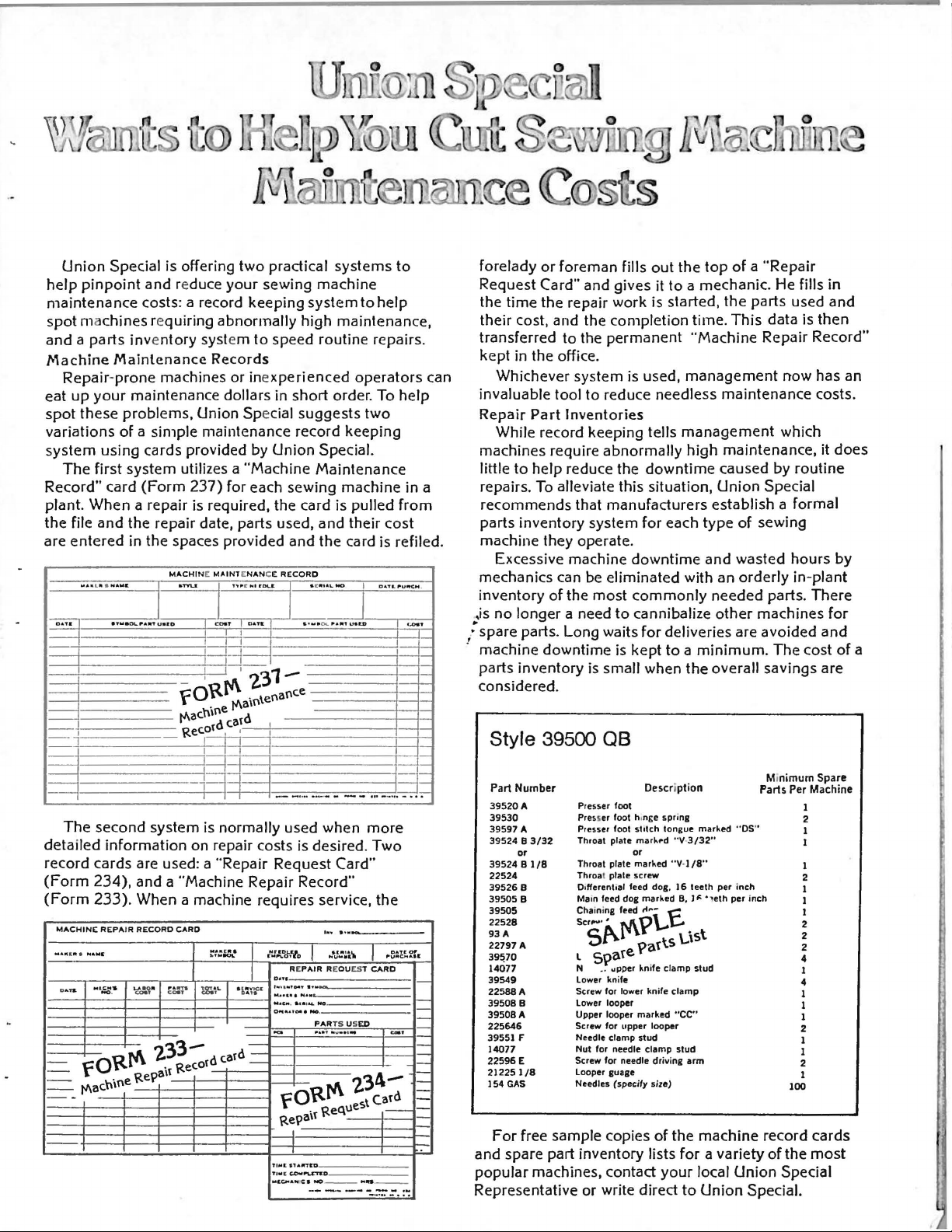

Union Special is offering two practical

help

pinpoint

maintenance

spot m chines

and a parts

/-'a

chine

Repair-

eat

up

your

spot

these

variations of a

system

The

first

Record"

plant.

When

the

file

and

are

entered

.....

L . S

~

and

reduce your sewing

costs: a record

requiring abnormally high

inventory system

Maintenance

prone

machines or ine

maintenance

problems,

simple

using

cards

provided by Union Special.

system

card

utilizes a "Machine

(Form

237)

a repair is required,

the

repair date,

in

the

spaces

NAioll[

ST

...

MACHINE MAINTENAN

•TTU

I I I I

O!..P'AIIt't

US.IO

keeping

to

speed

Records

xperienced

dollars

in

Union Special

maintenance record

for

each

the

parts

used,

provided

CE

T'l~tNI

COOT

RECORD

fOLil

.,.,,

I

,::==j

I

~

J

I

;_J""1

fO'Rf'J\

. ef"\aln e

f"\achll'\

dear

231-

. \ nance

d

systems

to

machine

system

to

help

maintenance,

routine repairs.

operators

short

order. To

suggests

two

keeping

Maintenance

sewing

machine

card is pulled from

and

their

cost

and

the

card is refiled.

• C

.......

"IAL.NO

01..

D4TLPUifC.H

I

"'""'

u•r..o

help

in

,

...,.,

can

a

forelady

Request

the time

their cost,

transferred to the

kept

invaluable tool to reduce

Repair

or

foreman fills

Card"

the

and

in

the office.

Whichever

Part

out

and

gives

it

to

repair work is started,

the

completion time. This

permanent

system

is used,

needless

Inventories

While record keeping tells

machines

little

repairs.

recommends

parts

require abnormally high

to

help reduce the

To

alleviate this situation, Union Special

that

inventory

system

downtime

manufacturers

for

each

machine they operate.

Excessive machine downtime

mechanics can be eliminated with

inventory of the

,is

no

longer a

.:

spare

!

parts. Long waits for deliveries

machine

parts

downtime

inventory is small when

considered

.

most

need

commonly

to

cannibalize

is

kept

to a minimum.

Style 39500 QB

the

top

of a "Repair

a mechanic. He fills in

the

parts

used

and

data

is

then

"Machine Repair Record"

management

maintenance

management

maintenance,

caused

establish

type

and

an

needed

other

the

overall

now

has

costs.

which

it

does

by routine

a formal

of sewing

wasted

hours

orderly in-plant

parts.

There

machines

are

avoided

savings

The

for

and

cost

are

by

of

an

a

R<

~

The

second

detailed

record

(Form

(Form

MACHINE:

MAK

.,

-

-

--

--

- -

information on repair

cards

234),

233).

REPA

IR

t • s

N•WE

MlCOOIS

...

....

.

~

fO'Rf'J\

n-ne Repal

1

f"\aC

lll

system

are used: a "Repair

and

When a machine requires service,

RECORD

-

'l:~~;rd

is normally

a "Machine Repair Record"

CARD

M••E••

.

...

IIOL.

..

...

~

~

...

COO>

·t~~

card

__

used

costs

is desired. Two

Request

r.!~,S,w:.lo

I

I

~

I

RE

PAIR REQUEST

D•TI

,

..

. ,

..

,_,

....

.._

...........

M10~oo

,

•••

1ar.. NO .

o-..•a.•-•

NO

.

PAR

.........

-

fO'Rf'J\

R ques

a\r

ReP

Tl

..

lS1AifTI:D

TIMC C,.0..."'-r'n[0

w,IC,...A

... I

CS NO--

---------

-

·--

when

... -·····-

more

Card"

...

...

.lJ.:'~~

..

I

CARD

TS USED

......

234-

\card

e

.... __

13=

. !-:-

the

o.-·u:

or

"u"c

....

sr

1-

1-

-

1-

~·

1-

-

1-

-

-

-

~-

...

Part

Number

39520A

39530

39597

A

39524 B 3/32

or

39524 B l/8

22524

39526

B

39505

B

39505

22528

93A

22797

A

39~70

14077

39549

22588

A

39508

B

39508

A

225646

39551 F

14077

22596

E

21225

l/8

154

GAS

For

free

sample

and

spare

part inventory lists for a variety of

popular

machines, contact

Representative or write direct

Presser foot

Presser

foot

Presser

Throat

Throat

Throat

Dofferenloal feed

Ma•n feed

Chaining

Scrr•"'

51\1

l

N •.

lower

Screw

lower

Upper

Screw

Needle

Nut

Screw

looper

Needles

h.n

foot

st•tch

plate

or

plate

marked "V·I

plate

screw

dog

feed

N\\'~~

~

~

spate

upper

knife

for lower

looper

looper

for

upper

clamp

for

needle

for

needle

guage

(specify

copies of

Description

&e

spr

tongue

mark~d

.. V·

dog,

marked

r<~-

G

ts

pat

knife

clamp

knife

clamp

marked

ucc••

looper

stud

clamp

driving

size)

the

your

Mmimum

Parts

ing

marked

"OS

3/32

I 6

8,

/&'•

Ieeth

l ~ •1eth

"'

..

per

inch

per

inch

\..\st

stud

stud

arm

machine

record

local Union Special

to

Union Special.

Per

100

the

Spare

Machine

I

2

I

I

I

2

I

I

I

2

2

2

4

1

4

1

1

1

2

1

I

2

1

cards

most

C a t a 1 o g N

o.

T 1 1 8 H

( S u p p 1 e m e n t T o C a t a 1 o g N

I N S T R U C T I 0 N S

F 0 R

A D J U S T I N G A N D 0 P E R A T I N G

L I S T 0 F P A R T S

S

T Y L E S

o.

1 1 8 L )

R

i g

U n

h t

3 6 2 0 0 H

3 6 2 0 0 J

F i

i

o n s p

s

R e s e r v e d

r s t

©

e c i a

E d

1! 9

b y

3 6 2 0 0 A H

3 6 2 0 0 A J

i

t i o n

..

"

...

7

7

1 c

i n

o r p o

A 1 1

r a

C o u n

UNION SPECIAL CORPORATION

INDUSTRIAL

SEWING

CHICAGO

MACHINES

t i

o n

t r

i e s

April,

P r i n t e d i n

1980

U.

S.

3

A.

Each

the

name

Standard

letter

\,'hen

only

standard

UNION

plate

Style

"z".

minor

Style

SPECIAL

on

the

nt@bers

Example:

changes

number.

IDENTIFICATION

machine

machine.

have

"Style

are

Example:

is

identified

Style

one

or

more

36200 H".

made

in a standard

"Style

OF

numbers

letters

Special

36200 HZ".

MACHINES

by a

are

Style

classified

suffixed,

Style'

machine, a "Z"

numbers

number

as

but

contain

which

standard

never

is

suffixed

is

~tamped

and

contain

the

letter

special.

the

to

the

into

"Z".

Styles

which

36200".

This

junction

not

on

of

this

numbers and on

part

num~ers

is

complete

reference

Feed-Off-The-Arm,

Manually

Filter

Front

number,

component

indicated

of

of

machines

differs

Styles

catalog.

in a box

part.

Operated

Type

Needle 8 Inches.

from

catalog

therewith.

36200 A, B,

descriptions

of

another

by

number

Oil

similar

the

Style

is a supplement

Only

At

the

opposite

or

inside a bracket.

indenting

Always

in

the

High

Differential

Return

the

part

use

Speed,

Pump,

the

X,

back

and

is

its

first

in

construction

number

APPLICATION

parts

AA,

are

pages

the

indicated

description

the

part

column when

STYLES

:Hedium Throw,

Feed,

Visual

in

to

Catalog

found

AB,

illustrations

will

number

number

Sight

that

it

OF

CATALOG

No. 118 L and

on

Styles

AK

or

AX

be

found a listing

of

pieces

on

the

On

the

under

in

ordering 'repair

:

OF

MAchiNES

Four

Automatic

Oil

are

grouped

contains

36200 H,

are

illustrated

identifying

required.

picture

copy

page, a component

the

the

second

Needles,

Enclosed

Action

under a Class

no

letters.

should

J,

the

of

plate

description

and

by

column,

parts.

One

Type

Supply

be

AH

and

parts

the

parts,

Any

having

of

never

Looper,

Oiling

Gauges,

Example:

used

and

AJ

listed

by

part

the

of

the

Six

System

number,

"Class

in

conbut

at

the

reference

with

that

another

assembly

use

Space

their

is

reference

the

Thread,

and

back

a

part

or

in

36200 H

men's

36200

undergarments,

Fitted

Maximum

36200

36200 AJ

LAP-SEAMER.

briefs.

added

.050

off

4200 R.P.M.

J

to

inch

AH

strength

inch

the

leg

FLATSEAMER.

medium

weight

with

(.813

recommended

Same

Same

for

of a reinforced

(_1.27

as

as

binding.

infants'

sewing

mm)

wider

Style

Style

mm)

garments

Six

threads

closing

which

Seam

Six

components

than

speed

36200 H,

36200

helps

Specification

threads

clothing,

where

on

4200 R.P.M.

J,

the

except

except

for

crotch

seam

prevent

for

seaming

that

other

simultaneously

seam on

is

required.

simultaneously

corsets,

produce

36200

prepared

prepared

4

men's

uneven

607-LSa-1.

girdles,

and

closing

a seam

styles.

for

for

or

Pedestal

Pedestal

trimming

knitted

The

right

"peaks"

Maximum

trimming

and

elastic

.236

inch

Seam

Specification

and

lap

briefs,

section.is

when

and

similar

Installation.

Installation.

sewing

recommended

flatseaming

knitted

is

necessary.

(6

mm)

seaming

when

raised

on and

wide,

607

on

the

speed

knit

light

.032

FSa-1.

E

ach

denotes

number,

ured

the

in

type

label

UNION SPE

the

ki nd

stamped

thousandths

number and

of

all

CIAL

of

on

needles

needle

shank,

the

needle

of

an

size

packaged

point,

inch

number

has

both a type

length,

shank,

midway

represent

and

sold

NEEDLES

groove,

denotes

between

the

by

Union

number

finish

the

largest

the

shank

complete

Special.

and

and

symbol,

size

and

number.

other

diameter

the

which

details.

of

eye.

The

type

The

the

blade,

Collectively,

is

given

on

number

size

meas-

the

Selection

used.

stitch

these

backed

quarters

Thread

formation.

For

best

machines.

by a reputation

of a century.

Standard

has a round

.060

inch

075/029,

To

needle,

A

complete

080/032.

have

or

of

proper

should

~esults,

They

needle

shank,

(1.52

mm)diameter

needle

the

type

order

orders

would

pass

use

are

for

round

and

read:

USE

needle

freely

only

packaged

for

producing

Styles

point,

shank,

promptly

size

GENUINE

size

through

genuine

36200

extra

number

"1000

NEEDLES

should

the

UNION

under

our

highest

H,

J,

short,

chromium

and

accurately

should

Needles,.?

;

AND

be

determined

needle

SPECIAL

brand

quality

AH

and

double

plated,

eye

needles

name, ,

needles

AJ

is

groove,

and

filled,

be

fo~'arded.

Type 118

REPAIR

GAS,

PARTS

by

the

in

order

in

for

Type 118

struck

is

available

an

empty

Use

description

Size

075/029".

size

the

of

to

produce

operation

the

which

more

than

GKS-075/029.

groove,

in

sizes

package,

on

thread

a good

of

is

three-

It

spotted,

070/027,

a

sample

label.

.

Success

SPECIAL

subsidiaries

proved

and

scientific

durability

Genuine

parts

your

are

guarantee

Prices

ments

are

are

insured

insurance.

in

Needles

and

needles

stamped

are

forwarded

unless

the

operation

and

Repair

authorized

principles,

are

assured.

are

with

of

the

strictly

at

otherwise

Parts

packaged

the

Union

highest

net

the

buyer's

of

these

as

furnished

distributors.

and

are

with

Special

quality

TERMS

cash

and

are

risk

directed.

machines

They

made

with

labels

trademark,

in

materials

subject

f.o.b.

A

charge

5

can

by

the

are

utmost

marked

to

shipping

is

be

secured

Union

designed

Special

according

precision.

~IJ

U S Emblem.

and

workmanship.

change

without

point.

made

to

cover

only

Maximum

•

Each

notice.

Parcel

the

with

genuine

Corporation;

to

the

efficiency

Genuine

trademark

All

Post

shipments

postage

UNION

its

most

repair

is

ship-

and

ap-

V

ll:.l~S

AA

;;nd

BB:

THREADING

Al\TO

OlLING Ih'"FOR>l.ATJON

TPread

sing

ing

VU:W

to

spring

CC:

Clcse

upper;

Pass

.:::nd

"E".

VIEW

DD:

Close

VIE\~

EE:

Close-up

Re

"J".

1000

Fahrenheit.

on

the

the

cylinder,

3,

E,

ferring

Use a

right

AS

indicated

2,

1,

at needle

- up

of t nsion

Disc,

thre;;

- up

lo~er;

cs

of

of

to

straight

side

r e

spectively.

5 and 6

thread

F,

thru

slots

looper

needle

thread

thread

illustration

mineral

The

level

of

the

in

illustration

in

order

frame

post

Post

"F"

oil,

is

main

Maintain

and

eyelet

assembly.

Slot.

in

tension

and

cover

sequence.

on

opposite

v.•ith a Sa);

checked

frAme

under

o~

passing

"G".

A,

thread

OILING

at

the

the

oil

level

opposite

needle

Tension

post

page,

bolt

tv.•o.-sight

foot

between

page,

threads

Nut;

"C",

and

take-ups.

rr.achine

viscosity

lifter

starting

B,

between

is

filled

of

gauges

lever

red

lines

UNDER

Spring;

tension

90

to

"K"

and

of

with

the

at

125

and

at

stitch

C,

Post;

the

seconds

"L",

the

these

04~

progres-

unlock-

D,

discs

caps

located

front

gauges.

"D"

"H"

at

of

Disc,

and

Automatic

of

oil

can

be

observed

cover.

time,

\,~en

priming

installing

may

v.•ith recommended

machine

back

"Q"

hole

Oil

of

be

in

is

is

drive

sure

the

running,

drained

pulley.

the

bottom

Occasionally,

holder

of

the

shank

presser

No. 36273 A,

lubrication

be

necessary.

oil

and

pump

from

hole

foot

in

of

it

is

lifting

the

is

thru

\•.'indO\•'S

a new

replace

is

inoperative.

machine

Belt

the

cover

filter

cylinder.

necessary

guide

mechanism

featured

machine

To

screv.•s

at

must

box,

to

collar

with a continuously

"N"

and

"N"

in

or

starting

do

so, rem

two

first

oil

No.

and

BEFORE

places,

that

ove

operating.

"Q"

be

removed.

the

screw

the

linkage

36273 K and

thread

tension

crank

one

the

and

that

t\-'O

"R".

goes

of

the

driven

chamber

has

plug

If

oil

"R"

''~en

into,

the

presser

various

release.

rotary

cover

been

idle

scre\.'S

does

is

located

replacing

lines

foot,

links

and

"P",

not

up

pump.

front

for

fill

flow

the

with

the

and

Flow

top

some

holes

while

below

screw

the

knife

bearings

and

at

6

cc

THREADING

(FOR

STYLES

7

AND

36200

OILING

H,

J,

DIAGRAM

AH

and

AJ)

In

L,

118

in

this

The

must

foot

lished

which

ing

of

its

elongated

(C)

must

fotTier

der

the

snug

tire

can

be

ing

screws

as

required

the

screws.

addition

the

following

supplement

lap

former

be

centered

slot.

will

(not

length

This

by

loosening

allow

the

lap

be

slide

lap

tight)

set

block

former)

of

accomplished

(D),

and

to

the

instructions

catalog.

(A,

in

the

can

be

screws

the

position-

former

holes.

so

The

the

(located

will

fit,

the

gibs.

by

reposition

retightening

INSTRUCTIONS

"INSTRUCTIONS

Fig.

S)

presser

accomp-

(B)

within

gibs

lap

un-

have

the

a

en-

This

loosen-

gibs

FOR

will

SEWING

FOR

apply

ADJUSTI'IENTS

SE\.JING

to

ADJUSTMENTS"

the

Styles

36200 H and

Fig.

covered

S

in

AH

Catalog

covered

No.

The

Catalog

In

highest

from

the

by

using

used

for

only

difference

No. 118 L

the

"Needles

point

36200

top

of

needle

of

throat

gauge

Hand

and

and

travel,

AH

in

the

"INSTRUCTIONS

the

adjustment

Needle

the

plate

fourth

on 36200 J and

Bar"

for

instructions,

or

lowest

21227 DS), compared

(using

needle

gauge

~

FOR

SE\.JING

36200 J and

with

needle

AJ

(this

to

the

17/32

21227 BU).

ADJUSTHENTS"

AJ

is:

the

Needle

should

be

adjustment

inch

(13.49

Bar.motion

1/2

inch

may

mm)

covered

(12.7

be

obtained

measurement

in

at

mm)

its

8

E X P L 0 D E D V I E W S

A N D

D E S C R I P T I 0 N 0 F P A R T S

E C U L I A R T 0

P

S T Y L E S 3 6 2 0 0 H,

J,

A H

and

A J

H I G H S P E E D C Y L I N D E R F L A T S E A M E R M A C H I N E S

9

e e

10

e

/

32

e,

I

I

I

PRESSER

FO\.)T,

THROAT

(FOR

LAP

FORMER,

PLATE

STYLES

CYLINDER

AND

FEED

36200 H

DOGS

AND

COVER,

AH)

GIBS

Ref.

No.

1

2

3

4

5

~

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20 150

21

22

23

*24

*

25

26

27

28

29

30

31

32

33

34

35

36

37

38

40

41

42

Part

No.

36220 H

36230 E

22565 A

36230

36230

c

s

94

36251 F

22562 A

36251 H

22738 B

36251 u

36251 K

36251

L

36251 G

36251

E

22565 A

22731

36279

36279

D

c

36230 R

22716 A

36250

36250 G

36250 B

22738 G

36232 H

36231 G

36230

23420

D

DB

22738 F

73

A

36283

23423

36283

23424

J

X

H

z

22716 A

36283 G

36224

H

36240

36205 H

36226

H

Description

Presser

Foot

Yielding

Assembly---------------------------------

Section,

marked

11AH11

--------------------

Screw-------------------------------------------Yielding

Presser

Section

Foot,

Spring--------------------------

marked 11BP

11

(late

parts

number)-----------------------------------------

Screw---------------------------------------

Cross

Cover Thread

Hook--------------------------

Screw--------------------------------------Cover

Screw,

Link,

Thread

for

link

for

cover

Hook

Driving

Lever

and

pin-----------------------------thread

carrier

and hook

lever------------------------------------------Link

Cover

Cover

Cover

Pin-----------------------------------------

Thread

Thread

Thread

Carrier

Carrier

Carrier,

and

Hook

Driving

Driving

Lever

marked 11A"-----------------

Screw--------------------------------------------

Screw-------------------------------------------Spring,

for

chip

guard---------------------------

Chip·Guard---------------------------------------

Screw-------------------------------------------Cloth

Screw-----

Stationary

Stationary

Bright

Stationary

Black

Guide

Plate

;:

~-------------------------------------

1

marked

,

"T"--------------------

Knife--------------------------------Knife

Clamp, .326

inch

(8.28

Finish-----------------------------------

Knife

Clamp,

.318

inch

(8.08

Finish-----------------------------------Screw-------------------------------------------Presser

Presser

Shoe

Lap

Former-------------------------------------------Screw,

Screw,

Gib,

for

for

right--------------------------------------------

Lap F0rmer

Gib,

]eft---------------------------------------------

Lap Fvrmer

Foot

Foot

Holding

lap

former---------------------------------

lap

former---------------------------------

Slide

Slide

Shoe,

Shoe,

right------------------------left--------------------------

Wire--------------------------------

Block-------------------------------Block

Spring-------------------------

Screw-------------------------------------------------

Cylin~er

Throa~

Main Peed Dog, marked "PR", 14

(1.8~

Diffe:::-~ntial

(1.8;

Cover----------------------------------------

Plate,

Stitch

.050

inch

(1.27

Tongue, marked

mm)

"D"------------------------

t.p.i.

mm

per

tooth)

----------------------------------

Feed Dog, marked "PQ", 14

mm

per

tooth)-----------------------------------

step

on

t.p.i.

have

Shaft--------

driving

Segment----

and

Shaft-----

mm)

mm)

right

side-~

Amt.

~

1

1

1

1

part

1

1

1

1

1

4

2

4

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

*

When

as

replacing

the

one

being

the

stationary

replaced.

~nife

clamp,

order

the

11

clamp

that

has

the

same

finish

5

r--------

E

FURNISH

REHOVE

BE

FOR

SHIPPING G ON

D

FORE

ASSEMBLIN

PURPOSES

ONLY.

MACHINE.

11-

-~

~

l:=il

12

BALL

PRESSER

JOINT,

(FOR

LEVER,

FOOT

STYLES

NEEDLE

AND

THROAT

36200 J

BAR

PLATE

AND

HEAD,

AJ)

Ref.

No.

I•

1 36251

2

3

4

5

6

7

8 36220 K

9

10 36230 J

11

12

13

14

15 94

16 36251 H

17

18 36251

19 36251

20 36251

21

22

23

24

25

26

*27

* -

28

29

30

31

32

33

34

35

II

-

Part

No.

y

97

A

36251

v

22585

36218

J

22738 H

96651

22565 A

36230 c

36251

FA

22562 A

36230 u

22738 B

u

K

L

36251

22731

36279

36279 c

36251 w

36250 G

36250 B

22738 G

36232 N

36231 N

36250

36230 D

36224 J

22716 A

36240

21227

G

D

150

J

DS

Cover

Ball

Sleeve

Needle

Presser

Yielding

Presser

Cover

Link,

Link

Cover

Cover

Screw---------------------------------------------Spring--------------------------------------------Chip

Cover

Screw---------------------------------------------Stationary

Stationary

Screw----------------------------------------------

Presser

Presser

Stationary

Shoe

Throat

Screw---------------------------------------------Stitch

Needle

Description

Thread

Carrier

and

Hook

Driving

Connecting

Rod

Joint---------------------------------------------

Screw----------------------------------------------

Driving

Screw-------------------------

Bar

Lever------------------------------------

~

--------------------

Head----------------------------------------Screw---------------------------------------------Roll

Pin-------------------------------------------

Foot

Assembly,

for

Styles

36200

J,

AJ----------- 1

Screw----------------------------------------------

Section,

marked

"AP"---------------------Spring--------------------------------------------Cover

Thread

Hook----------------------------------

Screw-----------------------------------------

Foot,

marked

"BT"--------------------------

Screw-----------------------------------------

Thread

Hook

Driving

Lever

and

Shaft----------

Screw----------------------------------------------

for

cover

thread

carrier

and hook

driving

lever---------------------------------------------

Pin-------------------------------------------

Thread

Thread

Carrier

Carrier

and

Hook

Carrier

Driving

Driving

Segment------

Lever

and

Shaft-------:-------------------------------------

Guard-----------------------------------------

Bright

Black

Thread

Finish-------------------------------------

Finish--------------------------------------

Foot

Foot

Carrier,

Knife

Knife

Shoe,

Shoe,

Clamp,

Clamp,

marked

.318

"B"-------------------

.326

inch

inch

(8.28

(8.08

right--------------------------left----------------------------

mm)

mm)

Knife-----------------------------------

Holding

Wire----------------------------------

Plate--------------------------------------------

Height

Tongue, marked

Gauge

(not

"AC"-------------------------

shown)-------------------------

Amt.

~-

1

2

1

1

1

5

5

2

1

1

1

1

1

1

1

4

2

4

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

*

When

as

#

Available

replacing

the

one

being

as

extra

the

stationary

replaced.

send

and

knife

charge

clamp,

item.

13

order

the

clamp

that

has

the

same

finish

e e

re

il

.(or

pacifications

nion

ewing

For

(0

or

quality

(Min.)

(Max.)

A.S.T.M.

& D

No.

with

Specification

oil,

viscosity

for

all

Specification

oil,

viscosity

with a maximum

use

where freedom

Specification

oil,

.viscosi

Specification

grease

It

is

similar

No. 3 grease

SPECIAL

S.S.U. at

(Max.)

No.

Index

Min.)

Corrosion

Buna N

roleum

mended

machines.

roleum

white

1.

mount.

roleum

high

mitters.

3. Where

used.

UNION

SPECIFICATION

Viscosity

Flash

Pour

Color

Neutralization

Viscosity

Compcunding

Copper

*Anline

*Used

M

174

specifies a high

100

oiling

ty

(Max.)

(Max.)

Rubber

seconds at

applications

175 specifies a high

100

seconds at

A.S.T.M. color

from

87 specifies a high

300

seconds at

100

specifies a general purpose

for

use

to

in ball bearings and trans-

commercial N.L.G.I.,

is

not

obtainable, No. 2

NO. 174

I00°F

90-125

350

20

3 1 3

0.10

85

None

1A 1A

1

75-225

"0"

Retainers

pecial

chines

quality

l00°F.

on high speed

quality

l00°F

oil

staining is para-

quality

l00°F.

175 87

90-125

350 350

20

0.10

85

None

1 75-225

Recom-

., water

number

grease

may

300-350

0.10

None

175-225

pet-

pet-

of

pet-

No.

be

20

85

1A

. -

..

•

#

•

NOTE

meeting

essential. These

These additives

and

separate.

NOTE

shall

1:

"fhe

above classification is desirable

1.

Oxidation

2.

Rust

3.

4.

5.

not

not

1.

2. Tackiness

3. Lead soap additives

4. Detergents

fiNlST

QUAlifY

inhibitors

Lubricity

Anti-oxidants

Film

strength additives

removable

2:

Oils

be

used

Extreme

use

of

non-corrosive additives

may

include:

inhibitors

additives

must

be

by

containing

at

any

time:

pressure

or

adhesive additives

completely

wick

the

following

additives-corrosive

soluble

feeding

UNION SPECIAL

CORPORATION

nor

type

in

but

in

the

shall

they

additives

oils

not

oil

Helpful,

cient

machine

Sales

esting,

obligation

•

authoritative

types

of

sewed article

Promotion

illustrated

are

equipment

is

Department.

bulletins

the

following:

information

for

available from Union Special

that

on

making

Among

the

are available

the most effi-

virtually any

many inter-

without

H

REAR

HEL

FU

L

No.

240,

No.

249,

No .

250,

No.

251,

No.

252,

No.

253,

No.

254,

No.

256,

No.

259,

No.

260,

No.

262,

No.

263,

No.

264,

No.

265, "Women's

No.

266,

No.

26

7,

268,

No.

No.

269,

No.

271,

No.

273,

No. 61 0,

No.

710,

No.

730,

No.

740,

750,

No.

1100,

No.

No.

1105,

"Columbia

ing

Machines"

No.

1500,

"Men's,

"Rainwear"

"Men's

"Service

"Men's

"Overalls, Coveralls,

"Men's

"Knit

"Men's

"Work

"Cotton,

Bags"

"Men's

"Men's

"Women's

"Corsets,

"Children's

"Mattresses, Slip Covers,

Upholstery"

"Awnings,

"Curtains & Drapes"

"Kiipp-it"

"MCS

"MCS

Hemmer"

"MCS

"Fusing

"Lewis

stitch,

"Button

"Alteration

Women's,

Dress

Shirts

Shorts

Knit

Outerwear"

Sports

Gloves"

Burlap,

Clothing"

Women's,

Wear"

Wear

Girdles, Brassieres"

Canopies, T-;nts,

ForMation

Automatic

Automatic

Presses"

Blindstitch,

Machines"

Sewers-Ticket

Blindstitch,

Children's

Shirts"

and

Pants"

and

Pajamas"

Underwear"

Shirts"

Jute,

Children's

And

Wear"

Unit"

Dual

Rib-Knit

Saddle

Department

and

High

Chainstitch,

Stitch,

Footwear"

Dungarees"

and

Multiwall Paper

Jackets"

Fashion"

Furniture

Tarps"

Underfront

Cuff Machine"

Tackers"

and Tie Clos-

Machines"

Shirt

Lock·

BU E

0

SE

!NG

U\1S

and

P YOU

PROB

CATALOGS

SOLVE

IE

S

UNION SPECIAL

f

iNUt

OUALITt

CORPORATION

I

..

•

WORLD'S

..

Q

"

'

,..

.,..o

' l f

FINEST

QUALITY

INDUSTRIAL

SEWING

MACHINES

*

UNION

facilities

aid

equipment

Special

tory

promptly

tion,

serve you. Check with

ATLANTA,

BOSTON,

SPECIAL

throughout

you

in

the

for

representatives

trained

and

and

there

is

a Union Special Representative

GA.

MASS.

maintains sales

the

world. These offices will

selection of

your

particular

and

are

able

efficiently.

him

~

f

the

operation.

service men

to

serve

Whatever

today.

MONTREAL,

TORONTO,

and

service

right sewing

Union

are

fac-

your

needs

your

loca-

to

CANADA

CANADA

CHICAGO,

DALLAS, TEXAS

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

ILL.

YORK,

Representatives

industrial

N.

Y.

PA.

and

cities

UNION SPECIAL

400

N.

FRANKLIN

distributors

throughout

ST.,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS,

STUTTGART, GERMANY

in

all

the

CORPORA

CHICAGO,

ENGLAND

ENGLAND

FRANCE

important

world.

TION

ILL.

60610

Loading...

Loading...