Union Special 36200A, 36200B, 36200X, 36200AA, 36200AB User Manual

...

INDUSTRIAL

SEWING

TYLES

6200A

62008

. 6200X

.,6200AA

C 0 L U M B I

A®

MACHINES

6200AB

6200AK

6200AX

ATALOG

No.

118L

THIRD

EDITION

CLASS

HIGH

CYLINDER

MACHI

36200

SPEED

FLATSEAMER

ES

UNION SPECIAL CORPORATION

CHICAGO

Catalog

No.

INSTRUCTIONS

FOR

118

L

ADJUSTING

36200

36200

36200

Copyright

Union

Rights

LIST

STYLES

A

B

X

Third

Special

Reserved

AND

OF

36200

Edition

1960,

By

Corporation

in

OPERATING

PARTS

36200

36200

36200

·AX

1962

All

Countries

AA

AB

AK

UNION

SPECIAL CORPORATION

INDUSTRIAL

Printed

SEWING

CHICAGO

in

U.S.

2

MACHINES

A.

March,

1981

TABLE

CATALOG

OF

CONTENTS

NO.

118 L

GENERAL

GENERAL

INSTRUCTIONS

EXPLODED

SALES

INFORMATION

Introduction--------------------------------------------------------------------------------------------

Table

of

Identification

Application

Description

Needles------------------------------------------------------------------------------------------------

Ordering

ThreadingandOiling-----------------------------------------------------------------------------------Diagram

Machine

Installation

Mounting

MachineSpeed------------------------------------------------------------------------------------------

Setting

Threading

Needle

Needle

Alignment

Timing

LooperAdjustment-------------------------------------------------------------------------------------FeedAdjustments---------------------------------------------------------------------------------------

Adjustment

Needle

Looper

Cover

Adjustment

Sewing

Contents---------------------------------------------------------------------------------------

of

Machines--------------------------------------------------------------------------------

of

Catalog-----------------------------------------------------------------------------------

of

Machine----------------------------------------------------------------------------------

Repair

Parts

Illustrations

Identifying

Use

Terms---------------------------------------------------------------------------------------------

SEWING

Up

Preferred

Sequence

Unlocking

Replacing

to

and

of

Instructions

Feed

Rear

StuchLength--------------------------------------------------------------------------------------Differential

Presser

Thread

Thread

Thread

Plastic

VIEWS

Parts------------------------------------------------------------------------------------

Genuine

INFORMATION

for

Thread

Adjuster's

of

Machine

the

Machine

Thread

the

Machine

Threads----------------------------------------------------------------------------------

of

the

the

FOR

Looper

Needle

of

Needles

Needles

Height---------------------------------------------------------------------------------------Needle

Foot

of

Trimming

Adjustments------------------------------------------------------------------------------

Adjustment-------------------------------------------------------------------------------

Adjustment--------------------------------------------------------------------------------

of

Tension

With

AND

----------------------------------------------------------------------------------

(explanation)---------------------------------------------------------------------------Needles

Stand

Threading-------------------------------------------------------------------------------

Stitch--------------------------------------------------------------------------------Needle--------------------------------------------------------------------------------

SEWING

Setting---------------------------------------------------------------------------------

for

Guard

Control---------------------------------------------------------------------------------

Adjustment----------------------------------------------------------------------------

and

Repair

Parts----------------------------------------------------------------

ing

and

Oiling

Information--------------------------------------------------------------------------

----------------------------------------------------------------------------------

-----------------------------------------------------------------------------------

---------------------------------------------------------------------------------

----------------------------------------------------------------------------------

ADJUSTMENTS

Bar----------------------------------------------------------------------------------

to

Throat

in

Relation

Using

Synchronizing

Adjustment-----------------------------------------------------------------------

Knives--------------------------------------------------------------------------

Release---------------------------------------------------------------------------

Nylon

Thread

DESCRIPTION

------------------------------------------------------------------------

Plate

to

---------------------------------------------------------------------

Looper-------------------------------------------------------------------

and

OF

Gauge

Without

PARTS

the

No.

21227

CG

-----------------------------------------------

36211

Retainer--------------------------------------------

Page

~

10

10

11

11

11

12

12

13

13

14

14

14

14

14

15

16

16

16

16

17

2

3

4

4

4

4

5

5

5

6

6

6

7

8

9

9

9

9

9

9

9

Drive

Unit,

Belt

Guard

and

Reference

Main

Frame,

Reference

Needle

Reference

Foot

L~erand

Reference

Detachable

Reference

Differential

Reference

Feed

Drive

Reference

Looper

Reference

Differential

Reference

Presser

Reference

Presser

Reference

Thread

Reference

NUMERlCAL

UNION

SPECIAL

Domestic

Lever,

Head,

Feed

Assembly,

Rocker

Feed

Bar

Foot

Stand

INDEX

and

Number,

Miscellaneous

Number,

Main

Number,

Tension

Number,

Covers,

Number,

Bar,

Number,

Number,

Shaft,

Number,

Control,

Number,

and

Presser

Number,

Shoes

Number,

and

Accessories----------------------------------------------------------------------------

Number,

OF

SALES

OFFICES

Foreign

Mounting

Part

Covers,

Part

Shaft,

Crankshaft

Part

Parts----------------------------------------------------------------------------

Part

Needle

Part

Main

Feed

Part

Feed

Rocker,

Part

Looper

Part

Cylinder

Part

Feet---------------------------------------------------------------------------

Part

for

36200

Part

Part

PARTS

---------------------------------------------------------------------------

Sales

Offices----------------------------------------------------------------

Stud

Number

Number

Number

Number

Bar

Number

Bar

Number

Number

Drive

Number

Number

Number

Machines-------------------------------------------------------------------

Number

Number

-----------------------------------------------------------------

and

Description------------------------------------------------------

Bushings

and

and

and

and

and

and

and

and

Looper

and

and

and

Covers

and

and

and

and

and

Description------------------------------------------------------

Miscellaneous

Description-----------------------------------------------------Description------------------------------------------------------

Needle

Description------------------------------------------------------

Feed

Description------------------------------------------------------

Description------------------------------------------------------

Knife

Description------------------------------------------------------

and

Description------------------------------------------------------

Description------------------------------------------------------

Description------------------------------------------------------

Description------------------------------------------------------

Take-up-------------------------------------------------

Oiling

---------------------------------------------

Bar

Head-------------------------------------------------

Lift

Avoid

Drive

Bushings

Eccentric

Link

Parts

Assembly-------------------------------------

Ball

Joints------------------------------------------

--------------------------------------------------

---------------------------------------------------

3

Back

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42-43

Cover

Each

UNION

chine. Style

letters

contain

the

suffixed,

the

standard

SPECIAL

numbers

letter

Style

machine

are

classified

but

never

"Z".

When

number. Example:

carries a Style

contain

only

as

the

minor

"Style

IDENTIFICATION

number which

standard

letter

changes

and

"Z". Example:

are

36200 AZ".

OF

special.

made

in a standard

MACHINES

is

stamped

Standard

"Style

in

the

Style

36200 A".

machine,

name

plate

numbers have one

Special

a "Z"

Style

is

suffixed

on

the

ma-

or

more

numbers

to

This

catalog

also

be

applied

such

as

right,

machine.

Feed-Off-The

Dial

turn

Inches.

36200 A

36200 B

36200 X

36200

36200

Operating

Adjusted

Pump,

men's

where seaming and

knit

ial,

Seam

Visual

FLATSEAMER. Six

briefs,

FLATSEAMER.

sleepers

where seaming and

TAPE-SEAMER. Five

Specification

AA

Same

AB

Same

applies

with

left,

direction

Arm,

High

Differential

Sight

shorts

or

as

Style

as

Style

specifically

discretion

front,

back,

of

Speed,

Oil

closing

Six

similar

36200

36200

Medium

Feed

Action

threads

and

all

elastic

threads

garments

closing

threads

607-LS-4 (Mod.)

A,

B,

to

to

some

etc.,

handwheel

Throw Machine,

Control,

and

Supply

for

simultaneously

similar

is

for

simultaneously

and

elastic

for

except

except

APPLICATION

the

Standard

special

are

given

is

clockwise.

DESCRIPTION

Enclosed

Gauges,

knitted

necessary.

all

knitted

is

not

joining

prepared

prepared

machines

from

Four

Automatic

Maximum

trimming

garments

Seam

trimming

necessary.

and

taping

for

Pedestal

for

Pedestal

OF

CATALOG

styles

in

this

the

operator's

OF

MACHINES

Needles

Lubricating

made

Specification

fabrics

fronts

of

machines

Class.

position

and

Retainer

Work

Space

and

flatseaming

of

light

and

flatseaming

made

of

Seam

Installation.

Installation.

light

Specification

of

knit

as

listed

References

while

Abreast,

System,

in

Front

infant's

to

medium

607-FSa-1.

underwear,

to

briefs

herein.

to

seated

Filter

of

Needles

weight

medium

607-FSa-1.

in

gne

It

direction,

at

One

Looper,

Type

Oil

8

panties,

material,

children's

weight

mater-

operation.

can

the

Re-

36200

AK

21114

wheel,

36200

AX

Each

point,

notes

ly,

should

size

double

available

the

read:

length,

the

the

type

Selection

pass

The recommended

080/032

groove,

To

have

type

"1000

Same

AG-6

(1)

Same

needle

largest

number and

freely

for

in

sizes

needle

and

size

Needles,

as

Style

Lead

1421 A

as

Style

has

groove,

diameter

of

proper

Styles

struck

number

36200

Eyelet,

Stud.

32600

both a type

finish

size

needle

through

needles

36200 X and

groove,

070/027, 075/029,

orders

should

Type 118

AA,

(1)

21233 AJ Lead

X,

except

number and

and

of

the

number

size

the

needle

are

Type 118

spotted,

promptly

be

GKS,

except

other

blade

forwarded.

Size

for

prepared

details.

measured

represent

should

eye

AX.

Type 118

.060

and

080/032.

and

accurately

075/029".

size

be

in

GKS,

inch

changes

order

in

Eyelet

for

Pedestal

NEEDLES

number. The

The

size

midway

the

complete

determined

to

size

075/029

GKS

diameter

filled,

Use

description

Packing

Bracket

number, stamped on

between

by

produce

is a round

shank,

List

Connection.

Installation.

type

the

symbol.

the

a good

for

Styles

an

empty

on

size

shank,

chromium

label,

No.

1-P-626;

Remove

number

shank

package, a sample

of

stitch

36200

round

denotes

and

the

formation.

plated

A

complete

the

needle

the

thread

A,

B,

point,

needle

Added

the

eye.

(1)

kind

used.

AA,

extra

needle,

order

(1)

1421 Hand-

of

shank,

shank,

Collective-

Thread

AB

and

AK;

short,

and

is

or

would

de-

4

ILLUSTRATIONS

This

catalog

views

seen

will

the

of

various

in

their

be

number

actual

found a listing

of

pieces

has

been

sections

position

required

ORDERING

arranged

ofthe

in

the

of

the

parts

REPAIR

to

simplify

mechanism

machine.

with

in

the

particular

On

their

PARTS

ordering

are

shown

the

parts

view

repair

sothatthe

page

opposite

numbers,

being

parts.

parts

the

description

shown.

Exploded

maybe

illustration

and

Numbers

dicate

never

second

indicated

sub-assembly.

the

position

be

used

column.

Component

by

27

28

29

30

31

29478

29103 T

22587 E

22894 w

22764

32

33

36244

34

It

will

be

listed.

recommended,

this

when

will

shown

The

In

those

catalog,

the

be

mentioned

in

parts

the

in

the

first

of

in

ordering

parts

indenting

of

Example:

cs

269

18

noted

reason

cases

no

illustration.

in

so

the

where a part

specific

for

the

in

the

column

that

part

in

parts.

sub-assemblies

their

the

is

that

complete

usage

various

descriptions

Feed

above

description

Lift

Feed

Nut~

Connecting

Nut,

example

replacement

will

machines

are

reference

the

illustration.

Always

which

Eccentric

Lift

Ecc.

Screw-------------------------------

numbers

Reference

use

the

can

be

under

the

Assembly----------------

Assembly

only,

part

number

furnished

description

Ball

and

merely

number

listed

for

repairs

of

the

Joint--------

should

in

are

main

Screw------------------------------- 1

Screw------------------------------- 1

left

thread--------------------------

Rod--------------------------

right

sub-assembly

is

common

be

thread

that

of

to

mentioned

are

and1 if

------------------------

the

eccentric

these

should

all

not

necessary,

of

in

the

parts

be

ordered.

the

machines

the

description.

same,

the

and

bearing

individually

covered

the

specific

difference

are

not

is

not

However,

usage

will

inthe

1

1

2

1

1

1

by

be

At

the

shown

when

On

an

appear.

STYLE

in

only

Where

some

identification

Part

IMPORTANT!

OF

back

this

the

the

of

the

numbers

of

the

book.

part

construction

smaller

MACHINE

This

number

letter

represent

ON

book

parts,

is

FOR

will

will

facilitate

is

known.

IDENTIFYING

permits 1 each

and

stamped

the

ALL

ORDERS~

WHICH

be

found a numerical

locating

PARTS

part

on

in

same

PART

those

to

where

distinguish

part1 regardless

PLEASE

IS

5

the

illustration

is

stamped

construction

the

INCLUDE

ORDERED.

index

with

part

of

of

and

its

does

from

catalog

PART

all

the

description

part

number.

not

permit,

similar

in

which

NAME

parts

ones.

they

AND

USE

GENUINE

REPAIR

PARTS

Success

UNION

iaries

scientific

durability

are

insured

ance.

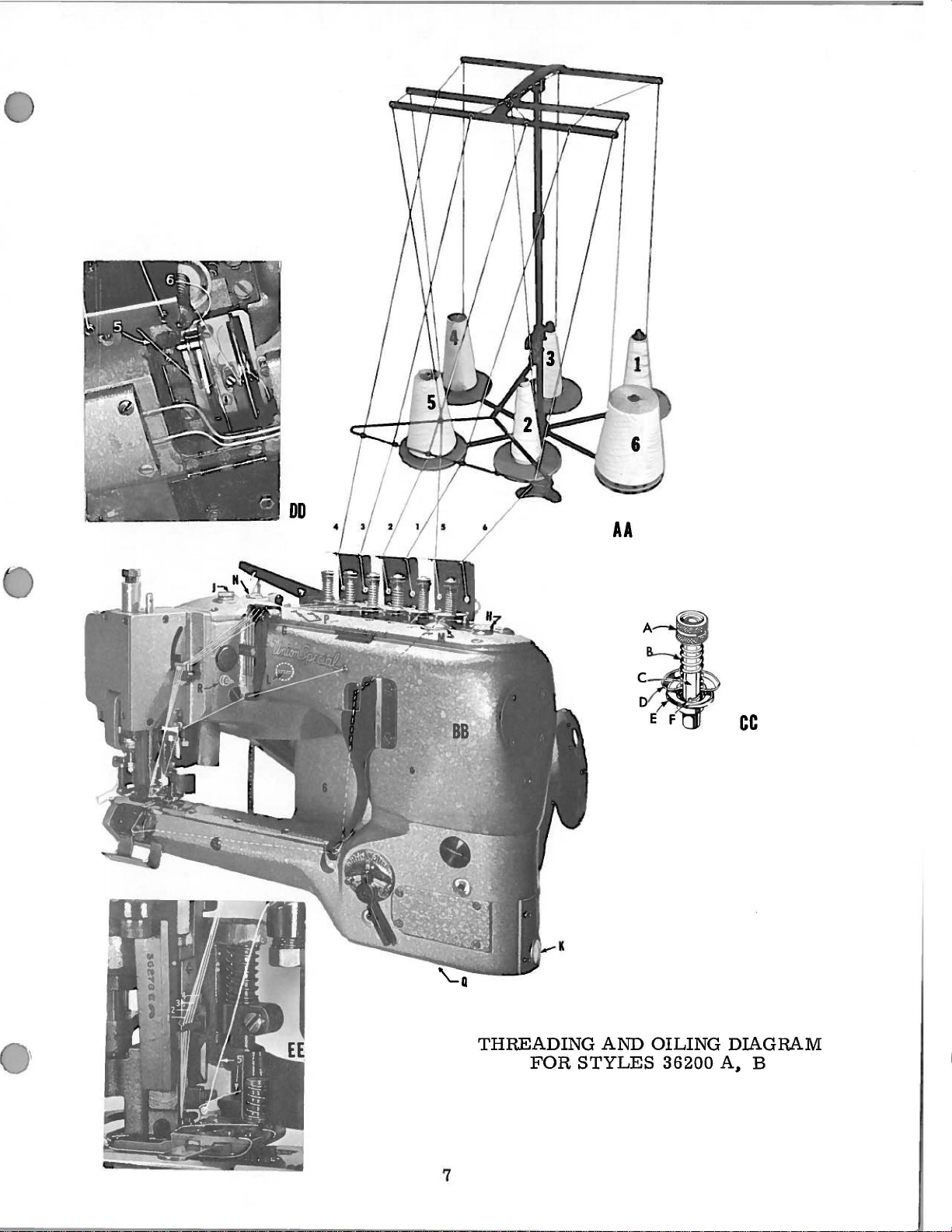

VIEWS

sing

ing

VIEW

upper;

and

SPECIAL

and

Prices

forwarded

AA

Thread

to

spring

CC:

Close-up

E,

Pass

"E".

in

authorized

principles,

are

are

unless

AND

BB:

as

3,

2,

at

Disc,

threads

the

operation

Repair

assured.

strictly

at

the

otherwise

indicated

1,

5 and 6

needle

of

tension

lower;

thru

Parts

buyer's

thread

as

distributors.

and

are

net

cash

risk

directed.

THREADING

in

illustration

in

order

frame

post

F,

Post

slots

"F"

of

these

furnished

They

made

assembly.

and

f.o.b.

AND

and

eyelet

Slot.

in

with

TERMS

A

tension

machines

by

the

are

utmost

subject

shipping

charge

OILING

on

opposite

passing

"G".

A,

Tension

post

can

be

secured

Union

designed

precision.

to

is

made

INFORMATION

needle

Special

according

change

point.

to

page,

threads

Nut;

"C",

and

without

cover

only

Corporation,

Maximum

Parcel

the

starting

UNDER

B,

Spring;

between

with

to

the

efficiency

notice.

Post

postage

with

the

C,

tension

genuine

its

most

shipments

Post;

All

and

#4,

stitch

discs

approved

shipments

progres-

D,

subsid-

and

are

insur-

unlock-

Disc,

"D"

VIEW

DD:

Close-up

VIEW

EE:

Close-up

Referring

and

"J".

ounces

125

seconds

"L",

located

the

front

these

of

cover.

time,

with

machine

and

at

the

gauges.

Automatic

oil

priming

recommended

Oil

back

"Q"

hole

in

can

When

is

is

of

be

in

of

of

Oil

capacity

the

top

at

100o

on

of

the

lubrication

be

observed

installing

may

running,

drained

drive

sure

the

the

looper

needle

to

illustration

reservoir.

Fahrenheit.

the

right

cylinder,

be

oil

pump

from

pulley.

hole

bottom

thread

thread

of

Class

side

respectively.

is

thru

windows

a new

necessary.

and

replace

is

inoperative.

machine

Belt

in

the

of

the

and

cover

sequence.

OILING

on

opposite

36200

Use a

featured

of

straight

The

the

''M"

machine

To

do

screws

at

two

cover

filter

cylinder.

thread

page,

is 2 ounces

level

main

or

must

box,

is

frame

Maintain

with a continuously

and

starting

so,

remove

BEFORE

places,

first

that

take-ups.

machine

in

mineral

checked

under

oil

"N"

in

crank

one

the

operating.

"O" and "R". "R"

be

removed.

the

screw

is

bottom

oil,

at

the

the

level

chamber

that

two

plug

goes

filled

oil

Saybolt

two

foot

between

driven

has

been

screws

If

oil

When

into,

at

the

reservoir

viscosity

sight

lifter

red

rotary

cover

idle

"P",

does

not

is

located

replacing

lines

caps

and

gauges

lever

lines

pump. Flow

and

for

of

and

front

some

fill

flow

below

the

up

with

"H"

2.5

90

"K"

of

to

and

at

top

holes

while

screw

Occasionally,

holder

of

the

shank

presser

No. 36273

foot

it

is

lifting

necessary

A,

guide

mechanism

to

collar

oil

No.

and

the

linkage

36273 K and

thread

6

tension

of

the

the

presser

various

release.

foot,

links

the

and

knife

bearings

AA

cc

THREADING

FOR

7

AND

STYLES

OILING

36200

DIAGRAM

A,

B

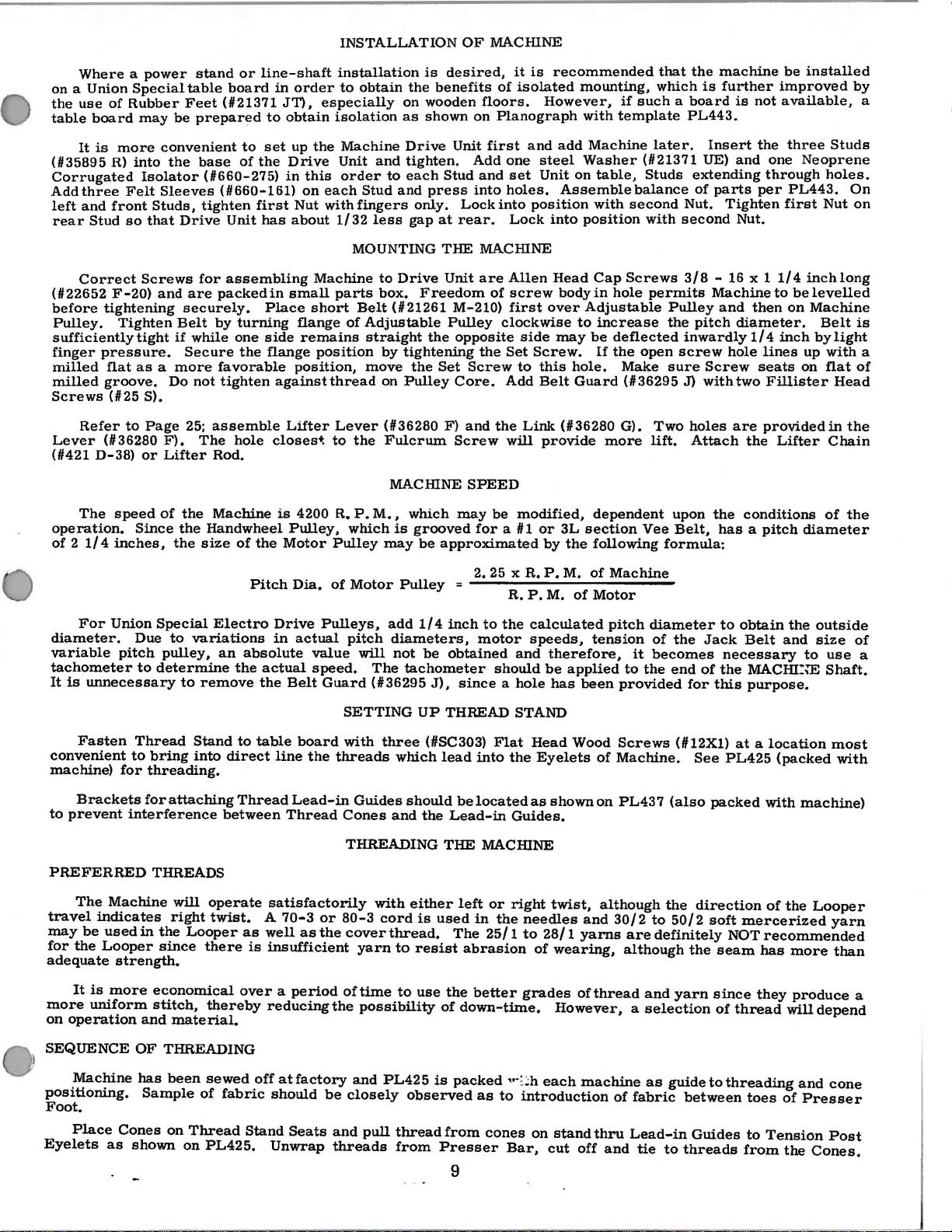

INSTALLATION

OF

MACHINE

Where a power

on a Union

the

use

board

It

is

of

more

table

(1#35895 R)

Corrugated

Add

three

left

and

rear

front

Stud

Correct

(1#22652

before

Pulley.

F-20)

tightening

Tighten

sufficiently

finger

milled

milled

Screws

pressure.

flat

groove.

(1#25

Refer

Lever

(1#421

The

(I#

36280

D-38)

speed

operation.

of 2 1/4

inches,

Special

Rubber

may

be

convenient

into

the

Isolator

Felt

Sleeves

Studs,

so

that

Screws

and

Belt

tight

if

as a more

Do

S).

to

Page

F).

or

Lifter

of

Since

the

the

stand

table

board

Feet

(1#21371

prepared

base

(1#660-275)

(1#660-161)

tighten

Drive

Unit

for

assembling

are

packed

securely.

by

while

Secure

favorable

not

tighten

25;

assemble

The

Rod.

the

Machine

Handwheel

size

or

line-shaft

to

to

set

of

the

first

has

in

Place

turning

one

side

the

flange

hole

of

the

close

in

order

especially

the

this

on

Nut

to

isolation

Machine

Unit

order

each

with

1/32

JT),

obtain

up

Drive

in

about

MOUNTING

Machine

installation

small

parts

short

flange

of

remains

position

position,

againstthread

Lifter

is

Motor

sf;

4200

Pulley,

Lever

to

R.

which

Pulley

obtain

on

as

and

to

Stud

and

fingers

less

to

Drive

box.

Belt

(1#21261

Adjustable

straight

by

tightening

move

on

Pulley

(1#36280

the

Fulcrum

MAClllNE

P.

M. , which

is

may

is

desired,

the

benefits

wooden

shown

Drive

tighten.

each

Stud

press

only.

gap

at

THE

Unit

Freedom

Pulley

the

the

Set

F)

grooved

be

approximated

floors.

on

Planograph

Unit

first

Add

and

into

Lock

rear.

MAClllNE

are

of

M-210)

opposite

the

Screw

Core.

and

the

Screw

SPEED

may

be

for a 1#1

it

is

of

isolated

However,

and add

one

steel

set

Unit

holes.

into

position

Lock

into

Allen

screw

first

over

clockwise

side

Set

Screw.

to

this

Add

Belt

Link

will

provide

modified,

or

by

recommended

moWlt_

ing,

1f

with

template

Machine

Washer

on

table,

Assemble

with

balance

second

position

Head

Cap

in

Screws

hole

body

Adjustable

to

increase

may

be

deflected

If

the

hole.

Guard

(1#36280

Make

(1#36295

G).

more

dependent

3L

section

the

following

that

the

which

is

such a board

PL443.

later.

Insert

(1#21371 UE)

Studs

extending

of

parts

Nut.

with

second

3/8

permits

- 16 x 1

Machine

Pulley

the

pitch

inwardly

open

screw

sure

Screw

J)

with

Two

holes

lift.

Attach

upon

Vee

the

Belt,

formula:

machine

fu~her

lS

be

imp~oved

not

available,

the

and

one

through

per

Tighten

first

Nut.

1/4

to

and

then

diameter.

1/4

hole

inch

lines

seats

two

Fillister

are

provided

the

Lifter

conditions

has a pitch

installed

three

Neoprene

PL443.

Nut

inch

be

levelled

on

Machine

Belt

by

up

on

of

diameter

by

Studs

holes.

On

on

long

light

with

flat

Head

in

the

Chain

the

a

is

a

of

For

Union

diameter.

variable

pitch

tachometer

It

is

unnecessary

Fasten

convenient

machine)

for

Brackets

to

prevent

PREFERRED

The

travel

may

for

adequate

more

on

Machine

indica~es

be

usedm

the

Looper

strength.

It

is

more

unif.orm

operation

Special

Due

to

variations

pulley,

to

determine

to

Thread

to

bring

Stand

into

threading.

for

attaching

interference

THREADS

will

right

the

Looper

since

economical

stitch,

and

material.

Electro

an

absolute

the

remove

to

direct

Thread

between

operate

twist.

as

there

over a period

thereby

Pitch

Dia.

Drive

in

actual

actual

the

Belt

table

board

line

Lead-in

Thread

satisfactorily

A

70-3

well

is

asthe

insufficient

reducing

of

Motor

Pulleys,

pitch

value

speed.

Guard

SETTING

with

the

threads

Cones

THREADING

or

80-3

coverthread.

oftime

the

Pulley

add

diameters,

will

not

The

tachometer

(1#36295

three

which

Guides

should

and

with

cord

yarn

to

to

possibility

1/4

be

J),

UP

THREAD

(i#SC303)

lead

the

THE

either

is

used

resist

use

the

of

2. 25 x

=

inch

to

R.

the

motor

obtained

and

should

since a hole

STAND

Flat

into

the

be

located

Lead-in

Guides.

MACiflNE

left

or

right

in

the

The

25/1

abrasion

better

down-time.

R.

P.

M.

of

Machine

P.

M.

of

Motor

calculated

speeds,

pitch

tension

therefore,

be

has

Head

Eyelets

as

shown

twist,

needles

to

28/1

of

wearing,

grades

applied

Wood

been

provided

Screws

of

Machine.

on

PL437

although

and

30/2

yarns

ofthread

to

are

although

However, a selection

diameter

of

it

becomes

the

to

definitely

and

the

end

for

(1#12Xl)

See

(also

the

direction

50/2

the

yarn

to

obtain

Jack

necessary

of

the

this

at a location

PL425

packed

soft

mercerized

NOT

seam

since

of

thread

the

Belt

and

to

MACm:~

purpose.

(packed

with

machine)

of

the

recommended

has

more

they

produce

will

outside

size

use

Shaft.

most

with

Looper

yarn

than

depend

of

a

a

SEQUENCE

_Mac?J.ne

pos1tiorung.

Foot.

Place

Eyelets

Cones

as

OF

THREADING

has

been

Sample

on

shown

on

sewed

of

fabnc

Thread

PL425.

_off

should

Stand

Unwrap

at

factory

Seats

and

be

closely

and

threads

pull

PL425

observed

thread

from

is

packed

from

Presser

as

to

cones

Bar,

,.-£~

h

each

introduction

on

stand

cut

9

machine

of

thru

off

and

as

guide

fabric

Lead-in

tie

to

to

threading

between

Guides

threads

toes

to

Tension

from

and

of

the

cone

Presser

Post

Cones.

Turn

Pull

thread

With

and

the

Handwheel

threads

above

stitch

knots

Needle

formation.

from

Bar

clockwise.

above

and

cut

raised,

needle

off

lift

Stop

with

eyes

close

Presser

Needle

thru

to

Needle

Foot

Bar

system

and

at

Eyes.

remove

top

until

the

of

its

knots

DO

factory

stroke.

pass

NOT

thru

RE-THREAD

sample.

Needle

Observe

Bar

Head

NEEDLES

method

Eyelet.

AT

of

entering

THIS

Cut

off

TIME.

Foot

Looper

to

re-thread

THREAD

observe

tension;

section

UNLOCKING

then,

downward

mark

threads

the

free

formed.

REPLACING

formation

Check

when

on

Turn

turn

on

the

to

With

threads

needles.

If

the

ends

Tension

"Adjustment

the

the

approximately

be

stitch

of

This

and

Cover

Looper

of

Release

is rai

STITCH

Cover.

from

unlocked,

is

unlocked

the

threads

termed

NEEDLE

Thread

stitch.

the

NEEDLES

Foot

THE

Handwheel

Handwheel

Head

pulled

Without a chain,

all

is

THE

and

Cover

and

when

sed,

of

Tension

in

the

in

the

1/8

Lift

under

it

firmly

"starting

can

place

all

operating

reverse

inch

the

the

must

material

and

now

be

Thread

one

Foot

is

threads

Release".

to

where

Presser

Foot

be

it

is

desired

behind

the

chain".

tied

and

Carrier.

ply

of

material

raised

must

or

clockwise

direction

the

top

Foot

freely.

understood

must

be

to

the

Foot

Machine

pulled

before

be

completely

until

of

the

as

high

that

under

start

before

thru,

under

sewing

direction

the

Needle

Needle

as

it

is

the

Foot

the

machine

starting

will

with

Needle

Foot.

with

free.

Bar

Lever

possible,

only

when

then

chain

Manually

power.

If

until

has

Thread

thus

to

introduce

starting

without

the

machine,

indefinitely.

Bar

these

the

Needle

reached

opening

material,

at

highest

turn

When

conditions

Eyelet

work

to

sew.

until a small

point.

clockwise

Foot

is

Bar

is

its

highest

is

in line

the

Tensions

under

it

is imperative

down,

are

in

its

position

the

It

is

several

all

not

met,

lowest

with

the

which

Foot

amount

unnecessary

times

and

threads

from

refer

position,

and

moved

top

allow

behind

to

hold

of

chain

have

of

the

to

the

the

is

Union

matically

to

Looper.

To

remove

seated

adjustments

Familiarity

but

NEEDLE

Presser

Knife

Cover,

partially

of

remove

on

If

the

care

If

the

To

remove

(#36270)

Needle

Needle,

should

Foot,

left

withdraw

Special

assists

The

Needle,

flat

(Page

machine

be

made

with

be

TO

LOOPER

machine

Throat

Presser

and

(#36289 A,

to

Looper

Needles

operator

Retainer,

To

replace

27).

has

been

in

the

machine

taken

SETTING

is

assembled

Plate

release

Page

Presser

setting,

for

the

FLA

in

to

bring

correctly

the

Needle

Needle,

right

TSEAMER

locating

of

Bar

make

INSTRUCTIONS

disassembled,

the

to

Foot

observe

following

will

and

(#36220),

knife

27)

Bar

sequence,

permit

that

and

it

is

Main

Feed

raise

pressure

and

Presser

(#36278),

individual

the

desired

the

the

fourth

to

maximum

certain

FOR

re-adjusting

which,

proper

Dog

Needle

by

Removal

adjustments

relationship

to

should

unclamping

Foot

Brace

are

made

relative

Needle,

height,

that

Shank

SEWING

for

through

proceed

be

removed,

Bar

to

maximum

Knife

(#36278

of

Throat

with

two

is

flats

of

Needles

no

thread

inserted

orienting

position

requires

break

ADJUSTMENTS

sewing-off

experience,

of

of

with

Plate

is

an

assembled

adjustment

the

Needle

height

Guide

E),

(#36273

Release

and

required,

Main

on

at

to

has

is

to

and

Presser

front

eye,

full

Looper

remove

Feed

of

Shank.

in

Needle

and

consequently

loosen

depth

and

and

setting,

Retainer

Remove

Bar

Dog

it

generally

to

will

proven

machine

maintained,

B),

Bar

Screw

that

is

suggested

correct

Guide

permit

This

design

Head

with

has

(#22738

Screw

satisfactory,

malfunction,

the

Upper

(#36211),

Detachable

(#36278

observation

auto-

respect

no

flat.

H)

and

is firmly

that

the

Knife,

Upper

Head

B)

and

10

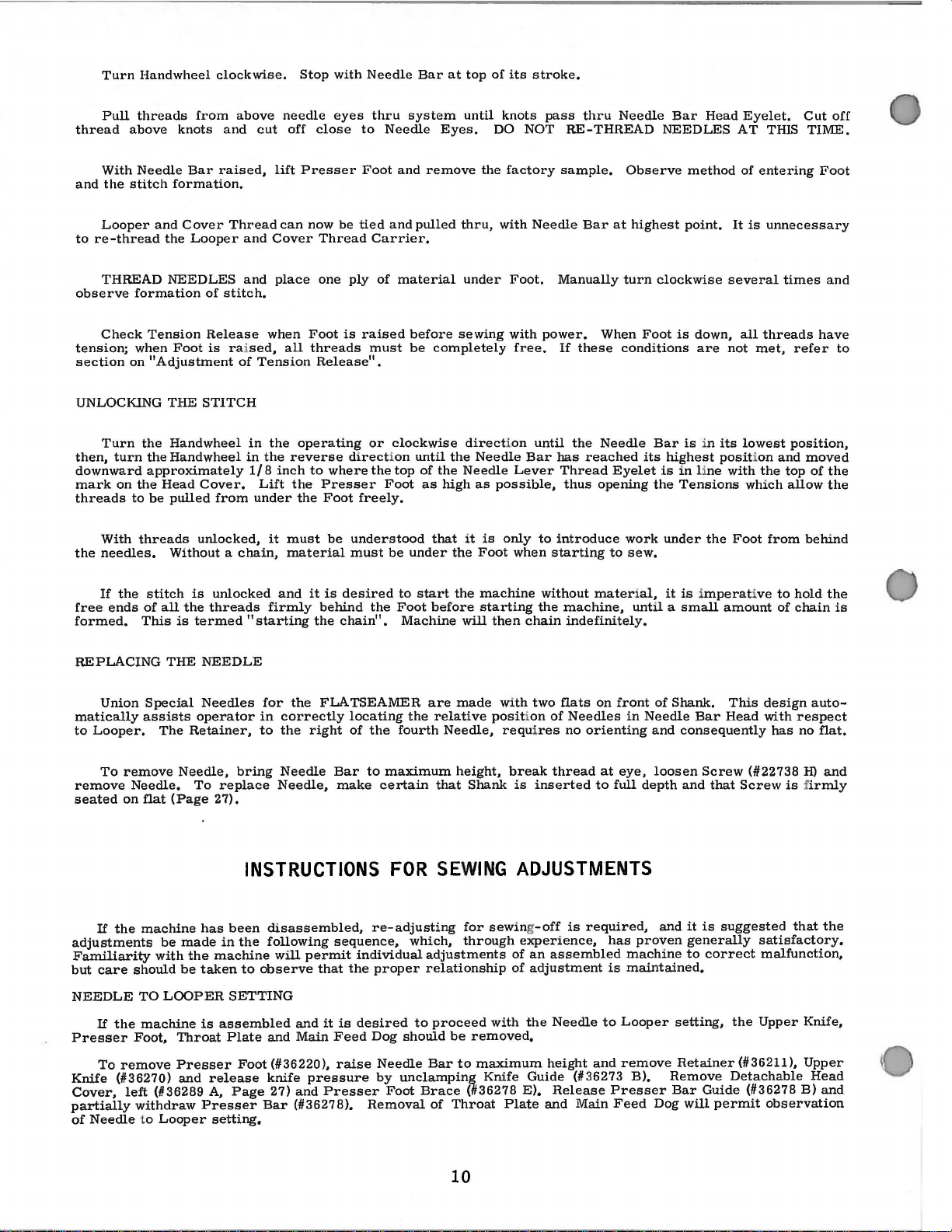

NEEDLES

With

needle

may

the

Bar

Detachable

Needles

as a straight

cross

by

Needle

should

be

obtained

clamping

Connection

To

position

into

grooves

Throat

AND

of

Head

first

edge

Plate

NEEDLE

Bar

be

17/32

by

Needle

( #51254

Cover,

Needle

and

against

of

the

Screws

motion

using

Bar,

fourth

Throat

BAH

inch

needle

J),

left

Head

the

(Fig.

at

its

from

height

loosen

access

(#36289

square

positions

blades

Plate

B).

highest

Throat

Gauge

Screw

to

which

A,

with

only.

of

the

which

travel,

Plate

(#22562

Fig.

the

Needles

has

is

A).

the

fourth

top.

(#21227 BU).

obtained

Throat

The

been

This

A,

Page23)in

Plate,

Upper

and

aligned

previously

or

adjustment

To

by

removal

insert

Knife

lowest

release

Needle

the

is

used

with

the

secured

of

Should

(#36218)

Needle

To

torque

cross

CAUTION!

Head.

Bar

bind

Normal

A

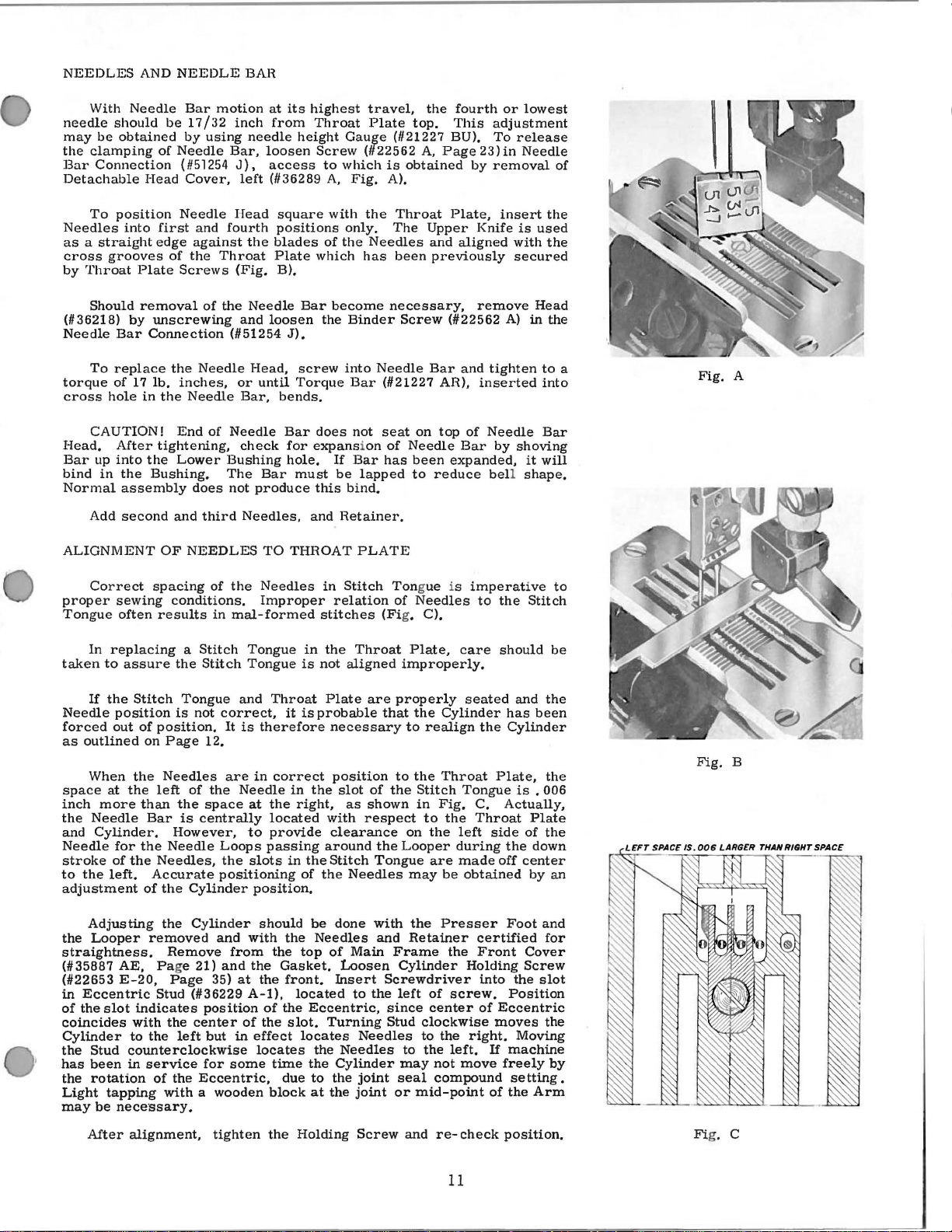

ALIGNMENT

Correct

proper

Tongue

In

taken

If

Needle

forced

as

outlined

When

space

inch

the

Needle

and

Needle

stroke

to

the

adjustment

removal

by

Bar

replace

of

17

hole

After

up

into

in

the

assembly

dd

second

sewing

often

replacing a Stitch

to

assure

the

Stitch

position

out

of

the

at

the

more

Cylinder.

for

the

of

the

left.

unscrewing

Connection

the

Needle

lb.

inches,

in

the

Needle

End

tightening,

the

Lower

Bushing.

does

and

OF

NEEDLES

spacing

conditions.

results

the

Tongue

is

not

position.

on

Page

Needles

left

than

of

the

Bar

is

centrally

However,

Needle

Needles, the

Accurate

of

the

Cylinder

of

the

and

(#51254

or

Bar,

of

Needle

check

Bushing

The

not

third

Needles,

of

the

in

mal-formed

Stitch

and

correct,

It

is

12.

are

the

Needle

space

Loops

positioning

Needle

loosen

J).

Head,

until

bends.

Bar

for

hole.

Bar

produce

TO

Needles

Improper

Tongue

Tongue

Throat

it

therefore

in

correct

at

the

located

to

provide

passing

slots

position.

Bar

become

the

screw

Torque

does

expansion

If

must

be

this

and

THROAT

in

relation

stitches

in

the

is

not

Plate

is

probable

necessary

position

in

the

right,

with

clearance

around

in

the

Stitch

of

the

Binder

into

Needle

Bar

not

Bar

lapped

bind.

Retainer

PLATE

Stitch

Throat

aligned

are

slot

of

as

shown

respect

the

Tongue

Needles

necessary,

Screw

(#21227 AR),

seat

of

has

.

Tongue

of

(Fi

g. C).

improperly.

properly

that

to

the

Looper

(#22562

Bar

on

top

Needle

been

expanded,

to

reduce bell

is

Needles

Plate,

the

Cylinder

to

realign

the

Throat

Stitch

in

Fig.

to

the

on

the

are

may

be

left

during

made

remove

A)

and

tighten

inserted

of

Needle

Bar

by

imperative

to

the

care

should

seated

the

Plate,

Tongue

C.

Actually,

Throat

side

the

off

obtained

Head

in

the

to

into

Bar

shoving

it

will

shape.

to

Stitch

be

and

the

has

been

Cylinder

the

is

• 006

Plate

of

the

down

center

by

an

a

Fig.

Fig.

A

B

Adjusting

the

Looper

straightness.

(#35887 AE, Page 21)

(#22653

in

Eccentric

of

the

slot

coincides

Cylinder

the

Stud

has

been

the

rotation

Light

tapping

may

be

After

the

Cylinder

removed

Remove

E-20,

nece·ssary.

Page

Stud

indicates

with

to

counterclockwise

in

alignment,

(#36229

position

the

center

the

left

but

service

of

for

the

Eccentric,

with a wooden

and

with

from

and

35)

at

A-1),

of

in

some

tighten

should

the

the

Gasket.

the

of

the

effect

locates

time

block

the

the

top

front.

located

the

slot.

locates

due

Holding

be

done

Needles

of

Main

l..oosen

Insert

to

Eccentric,

Turning

Needles

the

Needles

the

Cylinder

to

the

the

joint

joint

Screw

at

with

the

and

Retainer

Frame

Cylinder

Screwdriver

the

left

since

Stud

clockwise

to

to

the

may

seal

or

mid-point

and

Presser

certified

the

Front

Holding

of

center

into

screw.

of

the

right.

left.

not

move

compound

re-check

Foot

Cover

Screw

the

Position

Eccentric

moves

Moving

If

machine

freely

setting.

of

the

position.

and

for

slot

the

by

Arm

11

Fi

g. c

Remove

Gauge

Screw

attach

Turn

Gauge

looper

either

it

is

necessary

To

Loosen

Plate

(1122894

Looper

Handwheel

Plate

travel.

side,

the

adjust

Locknut

Cylinder

(#21227 CS)

and

counterclockwise

NOTE:

to

After

The

movements

disassemble

Adjustment

Page

23),

oriented

pass

orienting

timing

When

same

Only

If

the

two

as

described

When

therefore,

to

through

for

mark

the

same

timing

for

timing

one,

Shafts,

the

This

its

slots

is

as

or

below.

Needle

this

Synchronization

appear

at

the

Synchronization

W),

Travel

then

If

the

looper

to

alter

the

looper

(# 269,

to

setting

the

for

is

Shaft

timing

cut

Shafts

before,

are

both,

and

position

occurs

same

Hinged

so

Remove

Gauge

to

set

lock

in

Pointer

travel

the

travel,

Page

increase

looper

of

the

Main

timing

Needles

Shaft,

the

constructed

by

Spot

which

of

into

will

the

the

and

However,

the

Clamping

Shafts

have

therefore,

Bar

is

does

only

relative

is

easily

Spring

that

the

left

hand

Pointer

Looper

place

stops

is

correct.

looper

travel.

remove

33)

and

looper

travel,

TIMING

and

the

motion

in

Screw

(/122

allow a small

Main

Shaft

Coupling

Coupling

Screws

been

the

at

lowest

not

represent

when

Needle

position

and

accurately

USE

OF

Support

bottom

Screw

(/121227 CM)

(#36208 A)

with

Screw

on

graduation

If

Pointer

Front

turn

adjusting

travel.

machine

OF

NEEDLES

Looper

timing

of

two

means

the

parts

Needles

894 K)

to

the

normal

are

used

it

is

never

released,

renewed,

timing

mark

position,

Bar

to

the

Needles

LOOPER

Stud

(#36283

of

gauge

using

the

is

used

the

far

(#604)

at

(/122894 W).

mark

goes

Top

Cover

Screw

must

be

checked

IN

are

timed

must

be

to

are

in

of

Looper

turning

which

locating

amount

Crankshaft,

to

the

clamped

together,

necessary

the

timing

will

not

the

Looper

synchronization

has

risen.

whether

obtained

by

use

TRAVEL

C,

Page

GAUGE

35)

approximately

to

hold

same

right

Turn

which

beyond

(#35887

(1122795

Looper

screw.

position.

handwheelJn

indicates

either

AE,

B)

for

synchronization,

RELATION

with

each

other

checked,

is

clamped

Vee

obtained

together

grooves

between

After

correct

faces

an

accurate

in

disassembling

will

be

altered

represent

has

already

and

(5/32)

Looper

inch,

156

rotation

of

Gauge

from

horizontal.

Needle

Set

pointer

55

of

the

graduation

Page

clockwise

TO

LOOPER

at

the

in

the

by

milled

the

in

parts,

position

and

on

the

realignment

within

correct

timing

started

timing

At

is

this

effected

(#21227 CG,

Cylinder

Guard

clockwise

401 or

21)

and

to

decrease

factory,

Main

Screws

the

Shafts.

This

is

surface

of

to

release

the

and

its

advance

cannot

height,

clockwise

Page

and

attach

Lock

lightly

(1136210,

at

zero

degrees

direction

within

marks

the

End

If

Shaft

(1122519

graduation

mentioned

Cover

the

looper

it

has

Coupling

F),

The

Clamping

provides

obtained

the

next

mark

the

by

to

the

will

Clamping

manufacturing

retiming

toward

be

accomplished

the

Looper

or

counterclockwise.

43),

Looper

in

place

Page

by

to

check

(1135887

travel

been

necessary

(1135895 X,

Each

the

necessary

the

factory,

Spot

produce

tolerances

should

the

point

Travel

with

33)

and

rotating

marks

above,

and

end

Screws

Screws.

Screws.

be

done

Needles,

there.

should

the

on

Z).

is

a

the

of

INSTRUCTIONS

(1)

Turn

the

(2)

(3)

(4)

(5)

(6)

(7)

Loosen

Bar

the

Setting

Using

laid

between

Clamp

Insert

Height

gauge

Turn

Stop

in

is

Turn

Screw,

on

Follow

above

remove

Coupling

the

the

Setting

Stop

Block

the

on

its

the

Stop

the

Gauge

(#21227

the

Screw.

the

center

accomplished

the

The

the

gauge,

this

condition

Crank

Clamping

right

while

direction,

nizing

Gauge

wise

direction

should

be

procedure

FOR

USING

Handwheel

until

Presser

Block

(#

Screw

long

side

top

Screw

21227 CH,

(1114087,

in

this

portion

as a gauge

of

the

in

position.

position

Synchronizing

(#21227

CJ)

Handwheel

Then

of

Handwheel

end

to

the

by

of

The

CJ)

the

slowly

set

graduations

loosening

in

the

difference

procedure

fails

to

Chamber

Screws

machine

the

Looper

Rod

moves

than a clockwise

advanced,

is

repeated

SYNCHRONIZING

Bar

Needle

Regulating

Bar

Fig.

Fig.

D, B)

of

the

Looper

to

set

Needle

Gauge

securing

heel

the

Bar

at

using

Nut

Rod (#21227 CK,

it

of

the

Looper

in a clockwise

the

Synchronizing

on

Screw

the

opposite

Synchronizing

must

two

or

three

be

met,Coupling

Cover

(#22519

is

rotated

is

too

fast

more

times

(#35888

F),

in a clockwise

and

to

the

direction,

The

Coupling

to

check

the

new

GAUGE

(#35817

Screw

D, A)

under

above

Clamp

Stop

its

lowest

(/11347 A,

with

Screw

(#36208

Gauge

the

Needle

(/122738),

direction

Gauge

not

exceed

to

(#35895 X)

N)

and

If

the

the

Main

right

while

may

be

relationship

NO, 21227

E,

Page

(#36278 G,

the

the

Needle

and

Height

Screw

(1114087)

position

Fig,

Fig.

(#22738,

A)

direction

Rod

Bar

until

Rod

should

two

marks

make

certain

must

Gasket

Synchronizing

direction

Shaft

should

machine

the

Looper

secured

27)

Page

head

Bar.

Gauge

and

D, D).

D,

with

Screw

until

so

that

Setting

the

be

(#35888

is

by

of

the

CG

is

at

bottom

27)

of

and

the

Regularing

Clamp

(1121227

leave,

the

head

E)

into

Fig.

the

D,

(#22703 A,

the

Needle

the

flattened

Block

Needle

come

to

of

the

graduation,

the

timing

repositioned,

P,

Page

Gauge

than

be

is

too

one

in a counterclockwise

retarded,

rotated

slow

Screw

two

Shafts,

of

its

insert

the

Screw

the

Needle

CJ,

(5/32)

the

Stop

then

Fig.

inch

Clamp

clamp

156

F)

of

Looper

and

Fig.

Bar

strikes

end

(#21227 CH),

Bar

strikes

the

same

graduation

is

perfect,

For

21).

Rod

Loosen

moves

If

the

Synchro-

in a counterclock-

and

the

while

Main

the

stroke.

Needle

with

Bar

D, C)

gap

Screw.

and

D,

G),

the

is

about

This

the

Stop

If

the

access,

the

more

Shaft

gauging

the

to

Fig,

D

NOTE:

remove

If

Stationary

Knife

and

Knife

proceed

(#36250)

as

described

interferes

above.

with

12

Synchronizing

Gauge

Rod

(#21227 CK),

read.

Measurement

first

bring

the

Looper

against

position

position

.

Page

Joint.

preceeding

to

(#

Looper

Needle.

point

across

between

accomplished

Needles

FEED

which

end

and

084

to

inch

35)

Raising

Normal

touch

edge

22652 A-6,

point

Adjust

NOT

Looper

all

top

removed

HEIGHT

Before

extends

(Fig.

and

Fi

Fig.

the

Looper

Shaft

hole

of

Looper

check

flush

method.

to

Needles

end

represents . 094

E).

loosening

Ball

Looper

ofgauge

Page

to

back

Looper

exceed.

Needle

of

the

by

means

to

assembling

thru

Fig.

g. E

R

is

made

Shaft

in

end

Shaft.

of

gauge

If

conditions

Looper

Joint

shortens

gauge

is

(/121225-3/16)

33)

to

move

of

Needle

Holder

002

inch

Guard

may

and

observe

Looper

the

of a Screw

check

the

Feed

G

and

the

of

the

to

its

of

Cylinder

Tighten

for

Avoid

3/16

Looper

must

with

(Fig.

bottom

complete

Main

Bars

H)

looper

middle

screw

against

If

and

(B)

is

of

extreme

extreme

Plunger

inch

are

not

Link

avoid

inch.

while

be

Screw

G).

now

be

if

free

set

Feed

at

approximately

In

(//21227 CG)

synchronization

as

follows:

Bar heig

Insert

position.

on

the

Bar,

limit

of

the

5/32

inch

Observe

of

the

to

the

obtain

counterclockwise

II

and w he e 1.

synchronized,

the

Looper

same

Needles.

LOOPER

With

the

and

tighten

shaft.

feed

driver

the

the

looper

turn

looper

securely.

SetLooper

not

available, a depth

the

Cylinder

axial

motion

until

Clamping

travel.

Holder

of

parallel

Dog

the

being

If

less

met,

adjustment

Ball

motion

With

done.

Recheck

installed.

from

cycle.

and

the

left

Needle

right

Turn

on

end

pinching.

the

Stitch

to

FEED

and

on

the

left

T

hi s mid-

raising

feeds

simultaneously

the

Eccentric.

of

ad

j u s t

approximately

measured

Feed

Dog.

prevent

(#531,

Differential

be

installed.

Main

Feed

Guard

to

push

the

movement

Tighten

the

event

is

Certify

ht

and

fl

2

and

/13

Usin

g a

upper

portion

the

Needle

Looper

Needles

with

bar

right

reciprocal

Screw

flush

Joint

Looper

of

Looper

Differential

Page

Screw.

downward

Bar

of

bottom

carefully

point

at

a b 1 e

by

both

will

regard

AD.TUSTMENT

throat

plate

screw

Place

the

slot

(E)

blade

toward

Plunger

Bring

the

or 1 ow e ring

rotation

the

Guard

of

in

the

slide

does

(A)

until

Avoid

in

line

the

(1189,

with

looper

Stud,

lowering

motion

rests

or

left.

Handwheel

Looper

Gauge

this

Looper

Tongue

Shank

ADJUSTMENTS

the

mid-

end

is

set

setting

The

men t obtainable

at

the

rear

The

Stud

35).

Before

Dog,

Main

to

toward

not

available,

may

be

checked

the

Looper

Needles

Collar

clamped

of

the

to

stop

of

the

position

with

both

positions

clockwise

rot

at

If

machine

positions

be

exactly

and

(B).

It

is

narrow

the

cylinder

half

circle

of

the

not

align

blade

to.094

micrometer

with

the

ion

of

the

rear

is

fully

Page

gauge

avoid

is

Feed

add

is

obtained

right

(in

lengthens

at

in

Vee

Before

until

Shaft

to

to

be

Guard

normally

should

hole

in

Feed

area

of

horizontally.

a 11

ow s for

by

total

7/64

of

the

is

locked

by

Set

(Fig.

may

assembling

the

Feed

Dog

the

end

the

Gauge

Needle

gauge.

into

Needle

stroke

within

stroke.

respect

and

ion

of

is

of

the

to

the

feed

dogs

oflooper

casting

cutout

bar

slot

with

the

and

usinggauge

may

Shaft,

Shaft.

from

from

Bring

The

motion

by

removing

avoid

extreme

F).

Release

Holder

first

seats

to . 025

Looper

the

Eccentric

Cylinder,

is

to

its

removed,

to

of

and

end

be

operator).

Looper

use

motion.

left

the

point

has

on

Holder.

important

end

feed

of

looper

inch,

Looper

Looper

(away

extended

35).

body.

required,

1129478 Di\1,

the

(Fig.

clamping

Looper

obtain a clearance

sure

against

be . 018

the

Dog,

the

the

two

turning

amount

inch,

Main

Screw

I, B)

now

Needle

and

of

rear.

Fig.

insert

align

the

gauge

(C), No.

(D).

Insert a 1/8

looper

gauge

also

against

of

the

gauge

Page

Screw

gauge,

are

(1121227 BV,

used

through

or a depth

In

using

insert

the

gauge

Shaft

of

the

step

on

Cylinder

31)

Reposition

of

its

travel,

Looper

tight,

is

flush

between

not

slipped

Needle

top

of

inch. Vertical

Use a Feeler

Stud

should

be

Fig.

F

the

looper

and

the

loosen

aligned.

the

scale

the

gauge

the

while

to

maximum

Plunger

looper

Side

to

raise

gauge

Holder

the

with

right

Needle

on

(Fig.

I-Il.

the

Holder.

(1136234 D,

rotated

H

looper

blade

21227

inch

press

looper

Tighten

Fig.

E).

hole

if

(#21227

gauge

bearing

from

gauge,

Cover

or

lower

set

Looper

Clamp

axial

side

and

Looper

Pass

adjustment

gauge

until

(A,

Fig.

90°

to

CU.

in

diameter

the

gauge

blade.

screw

screw

If

gauge

in

the

end

accurately

BV) ,

through

firmly

forward

extended

which

(/I :l6286 .

Ball

and

repeat

point

Screw

setting

of

left

Looper

Shaft.

Looper

Clearance

with

Page

29),

the

slot

the

the

(B)

is

of

is

13

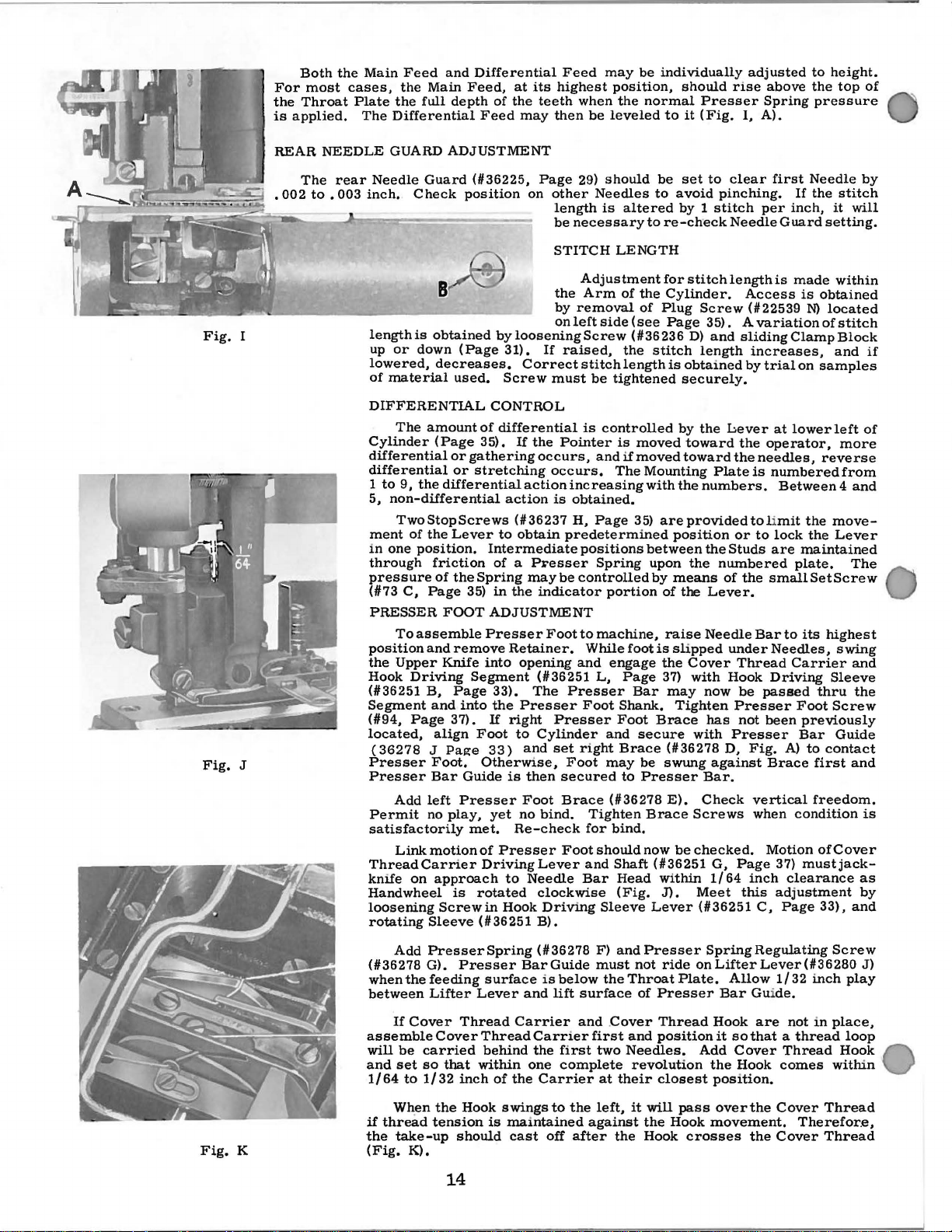

Both

For

the

Throat

is

applied.

REAR

The

•

002

the

most

NEEDLE

rear

to • 003

Main

cases,

Plate

The

Needle

inch.

Feed

and

the

Main

the

full

Differential

GUARD

depth

ADJUSTMENT

Guard

Check

Differential

Feed,

position

at

of

the

Feed

(#36225,

its

may

on

highest

teeth

then

Page

other

length

be

Feed

when

be

29)

Needles

is

necessary

may

be

position,

the

leveled

should

altered

individually

should

normal

to

it

be

set

to

avoid

by 1 stitch

to

re-ch·eck

rise

Presser

(Fig.

to

clear

pinching.

Needle

adjusted

above

Spring

I,

A).

first

per

Guard

to

the

Needle

If

the

inch,

height.

top

pressure

stitch

it

will

setting.

of

by

Fig.

Fig.

STITCH

B

length

is

I

J

up

lowered,

of

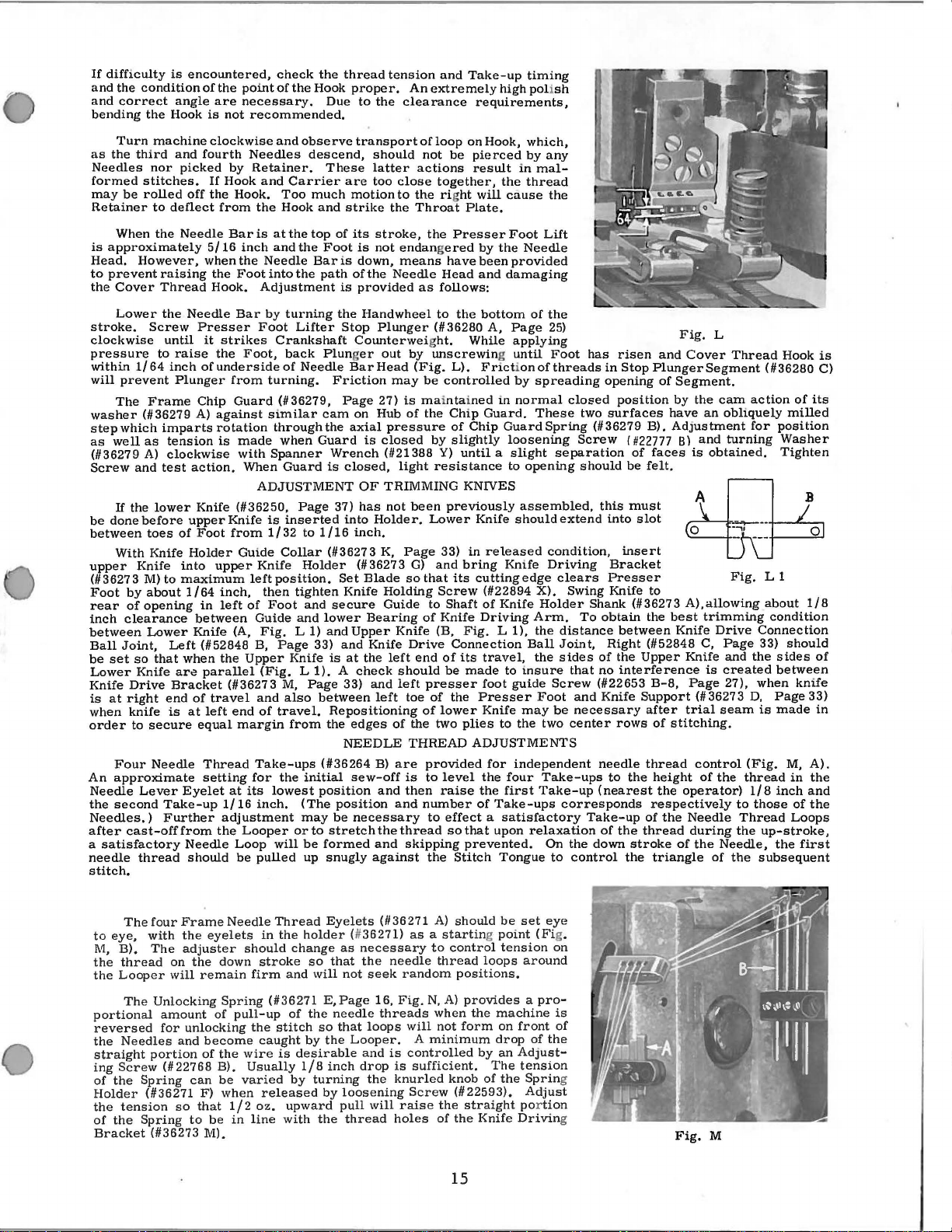

DIFFERENTIAL

Cylinder

differential

differential

1

to

5,

ment

in

through

pressure

(#73

PRESSER

position

the

Hook

(#36251

Segment

(

#94,

located,

(36278 J Page

Presser

Presser

Permit

satisfactorily

Thread

knife

Hand

loosening

rotating

obtained

or

down

material

one

decreases.

The

amount

(Page

9,

the

Two

Stop

of

position.

C,

To

assemble

and

Upper

Driving

B,

Page

Carrier

on

wheel

differential

the

friction

of

Page

FOOT

Knife

and

align

Foot.

Bar

left

no

play,

approach

Screwin

Sleeve

non-differential

Add

Linkmotionof

by

(Page

used.

CONTROL

of

differential

35).

or

gathering

or

stretching

Screws

Lever

37).

is

to

Intermediate

of

the

Spring

35)

in

ADJUSTMENT

Presser

remove

into

Segment

Page

33).

into

the

If

Foot

33)

Otherwise,

Guide

Presser

yet

met.

Presser

Driving

rotated

( # 36 251

31).

Screw

action

is

to

Hook

the

by

on

loosening

If

raised,

Correctstitchlengthis

must

If

the

Pointer

occurs,

occurs.

action

increasing

is

(#36237

obtain

a P:t;"esser