Catalog

INSTRUCTIONS

No.

FOR

118

L

ADJUSTING

36200

36200

Copyright

U

nion

Rights

LIST

STYLES

A

AA

Second

Special

Reserved

AND

OF

PARTS

Edition

1960,

By

Corporation

in

OPERATING

36200

36200

1962

All

Countries

B

AB

CORPORATION

INDUSTRIAL

P

rinted

SEWING

CHICAGO

in

2

MACHINES

U

.S.

A.

Januar

y,

197

5

®

INDUSTRIAL

SEWING

:

INEST QUALIT

STYLES

36200A

362008

36200AA

Y

LEWIS

•

COLUMBIA

MACHINES

36200AB

CATALOG

No.

118L

SECOND

EDITION

CLASS

HIGH

CYLINDER

MACHINES

36200

SPEED

FLATSEAMER

CHICAGO

TABLE

CATALOG

GENERAL

GENERAL

INSTRUCTIONS

EXPLODED

SALES

INFORMATION

Introduction-------------------------------------------------------------------------------------------Table

of

ldentliicationof~achines--------------------------------------------------------------------------------

Application

Description

Needles------------------------------------------------------------------------------------------------

Ordering

ThreadingandOiling-----------------------------------------------------------------------------------Diagram

Machine

Installationof~achine

Mounting

MachineSpeed-·----------------------------------------------------------------------------------------

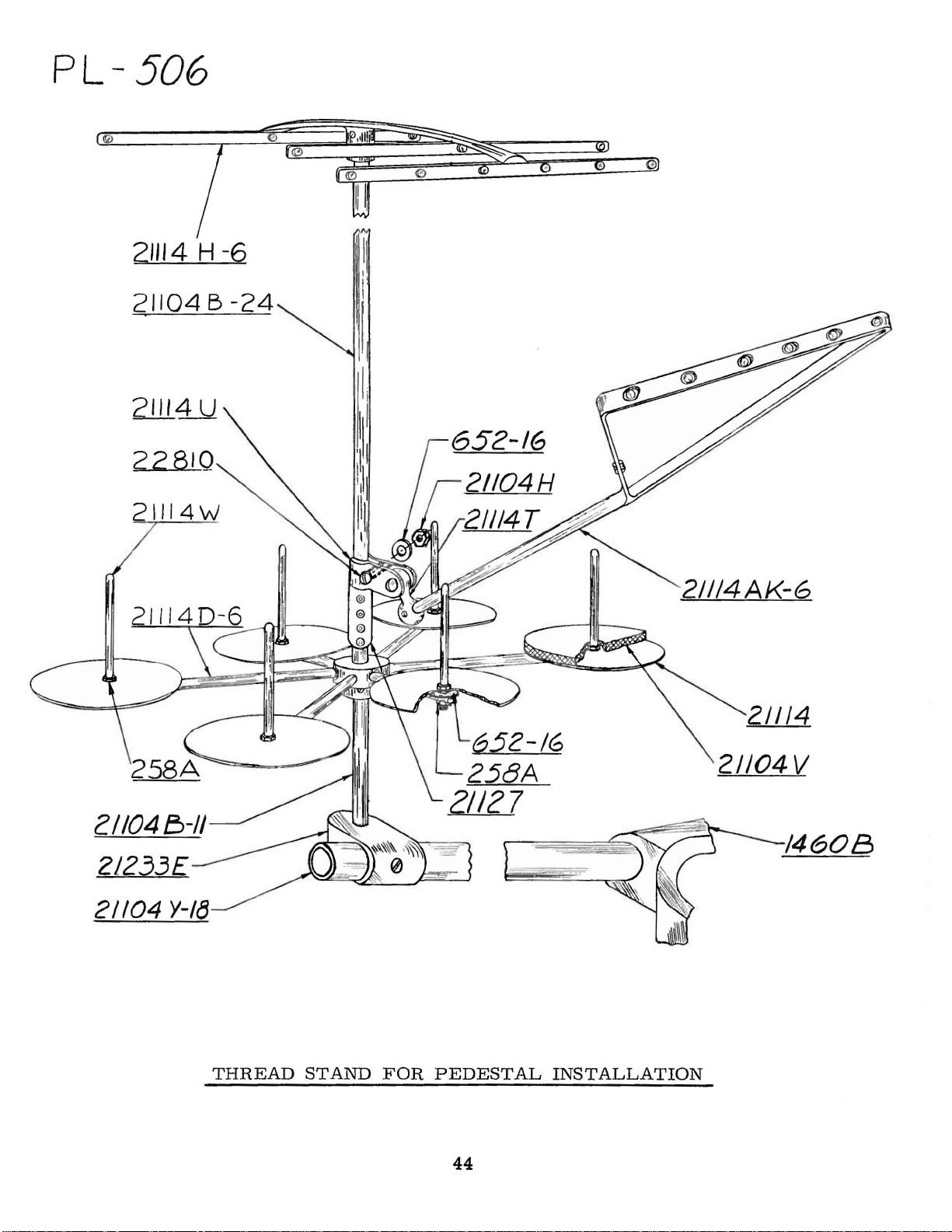

SetiingUpThreadStand

Threading

Needle

Needle

Alignment

Timing

LooperAdjustment-------------------------------------------------------------------------------------FeedAdjustments---------------------------------------------------------------------------------------

Adjustment

Needle

LooperThreadAdjustment------------------------------------------------------------------------------Cover

Adjustment

Sewing

Drive

Main

Needle

Foot

Detachable

Dliferential

Feed

Looper

Dliferential

Presser

Presser

Thread

Contents---------------------------------------------------------------------------------------

of

Catalog-----------------------------------------------------------------------------------

of

~chine----------------------------------------------------------------------------------

Repair

Parts

Illustrations

Identifying

Use

Terms---------------------------------------------------------------------------------------------

SEWING

Preferred

Sequence

Unlocking

Replacing

to

and

of

Instructions

Feed

Rear

StuchLength--------------------------------------------------------------------------------------Differential

Presser

Thread

Thread

Plastic

VIEWS

Unit,

Reference

Frame,

Reference

Lever,

Reference

LUter

Reference

Reference

Reference

Drive

Reference

Rocker

Reference

Reference

Reference

Reference

Stand

Reference

Parts------------------------------------------------------------------------------------

Genuine

INFORMATION

for

Threading

Adjuster's

the

~achine

the

~achine

Threads----------------------------------------------------------------------------------

of

the

the

FOR

Looper

Needle

of

Needles

Needles

Height---------------------------------------------------------------------------------------Needle

Foot

of

Trimming

Adjustments------------------------------------------------------------------------------

Adjustment--------------------------------------------------------------------------------

of

Tension

With

AND

Belt

Number,

Wscellaneous

Number,

~ain

Number,

and

Tension

Number,

Head,

Number,

Feed

Number,

Assembly,

Number,

Shaft,

Number,

Feed

Number,

Bar

and

Number,

Foot

Shoes

Number,

and

Number,

----------------------------------------------------------------------------------

(explanation)---------------------------------------------------------------------------Needles

Threading-------------------------------------------------------------------------------

SEWING

Setting---------------------------------------------------------------------------------

for

Guard

Control---------------------------------------------------------------------------------

Adjustment----------------------------------------------------------------------------

Guard

Covers,

Bar,

Control,

Presser

Accessories----------------------------------------------------------------------------

and

Repair

Parts----------------------------------------------------------------

and

Oiling

Information

----------------------------------------------------------------------------------

-----------------------------------------------------------------------------------

---------------------------------------------------------------------------------

----------------------------------------------------------------------------------

Stitch--------------------------------------------------------------------------------Needle--------------------------------------------------------------------------------

ADJUSTMENTS

Bar----------------------------------------------------------------------------------

to

Throat

in

Relation

Using

Synchronizing

Adjustment-----------------------------------------------------------------------

Knives--------------------------------------------------------------------------

Release---------------------------------------------------------------------------

Nylon

Thread

DESCRIPTION

and

Part

Part

Shaft,

Part

Parts----------------------------------------------------------------------------

Part

Needle

Part

~ain

Part

Feed

Part

Looper

Part

Cylinder

Part

Feet---------------------------------------------------------------------------

Part

for

36200

Part

Part

------------------------------------------------------------------------

--------------------------------------------------------------------------

Plate

to

~ounting

Number

Covers,

Number

Crankshaft

Number

Number

Number

Feed

Number

Rocker,

Number

Drive

Number

Number

Number

~achines

Number

Number

---------------------------------------------------------------------

Looper-------------------------------------------------------------------

Gau

ge

and

Wuhout

OF

Stud-----------------------------------------------------------------

and

Bushings

and

and

and

and

Bar

and

and

Bar

and

and

Looper

and

and

and

Covers

and

and

and

and

the

PARTS

Description-----------------------------------------------------Description------------------------------------------------------

~iscellaneous

Description-----------------------------------------------------Description------------------------------------------------------

Needle

Description------------------------------------------------------

Feed

Description------------------------------------------------------

Avoid

Description------------------------------------------------------

Knlie

Drive

Description------------------------------------------------------

and

Description-----------------------------------------------------Description------------------------------------------------------

------------------------------------------------------------------Description------------------------------------------------------

Description------------------------------------------------------

OF

CONTENTS

NO.

118 L

No.

21227

CG

-----------------------------------------------

36211

Retainer--------------------------------------------

and

Take-up-------------------------------------------------

Oiling

---------------------------------------------

Bar

Head-------------------------------------------------

Lilt

Eccentric

Link

Parts

Bushings

Assembly-------------------------------------

Ball

Joints------------------------------------------

--------------------------------------------------

------------------------------------------7--------

Page

..1!2:....

2

3

4

4

4

4

5

5

5

6

6

6

7

8

9

9

9

9

9

9

9

10

10

11

11

11

12

12

13

13

14

14

14

14

14

15

16

16

16

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

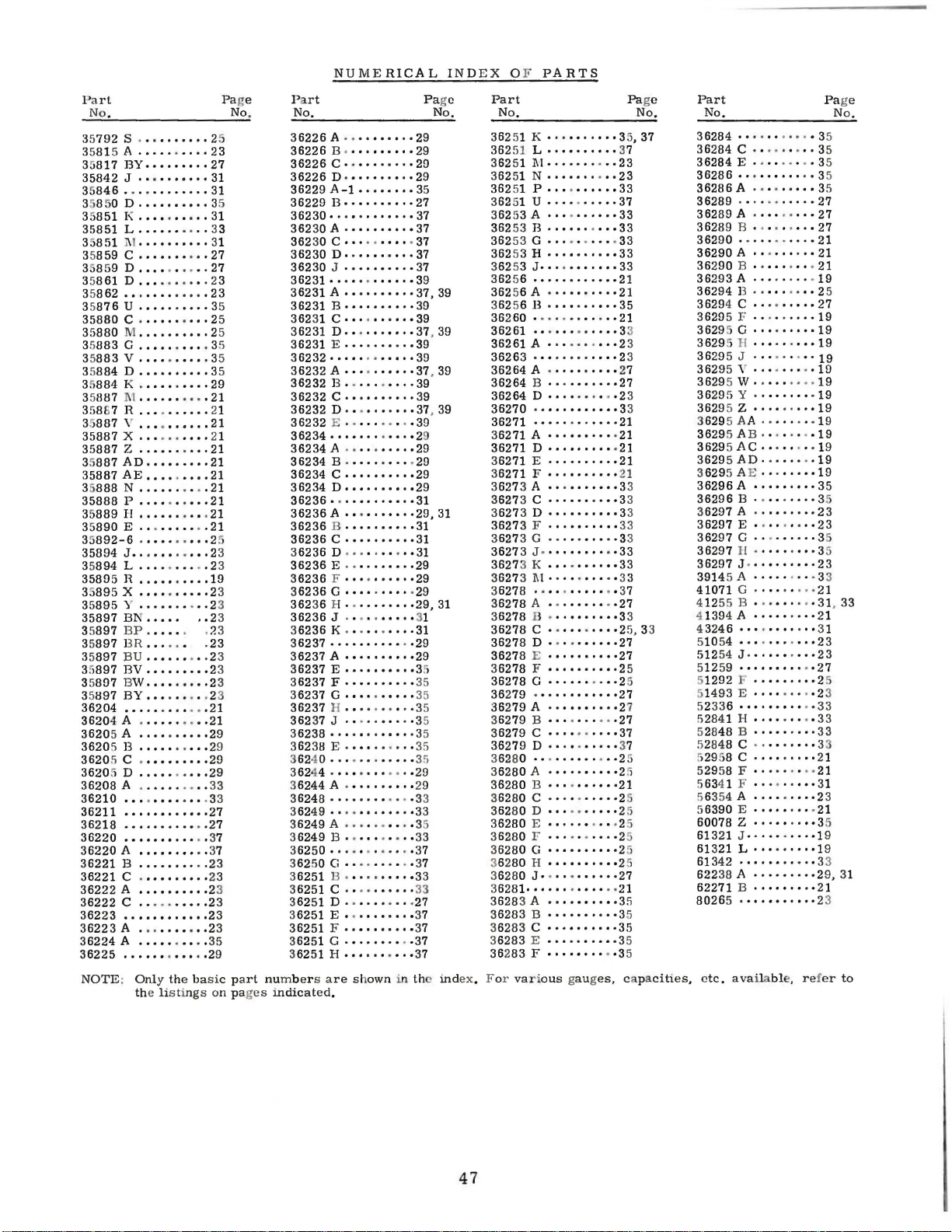

NUMERICAL

UNION

Domestic

INDEX

SPECIAL

and

OF

SALES

Foreign

PARTS------------------------

OFFICES

Sales

Offices----------------------------------------------------------------

.

..

--------------------------------------------------

3

Back

42-43

Cover

IDENTIFICATION

OF

MACHINES

Each

the

machine.

numbers

Example:

only

minor

Style

herein.

References

operator's

is

Cylinder

Threads,

System,

Space

36 200 A

number.

This

It

clockwise.

and

in

and

shorts,

material,

607-FSa-1.

Union

catalog

Flatseamer,

Front

For

Special

Style

have

"Style

can

Manually

one

36200

changes

Example:

applies

also

to

direction,

position

FilterTypeOil

of

Needle 8 Inches.

simultaneously

and

where

carries

numbers

or

more

A".

are

made

be

applied

while

High

Operated

all

similar

seaming

a

Style

are

classified

letters

Special

in a standard

"Style

APPLICATION

specifically

with

such

as

seated

DESCRIPTION

Speed,

Differential

Return

trimming

and

Style

36200

discretion

right,

at

the

Medium

Pump,

knitted

closing

number

suffixed,

AZ".

to

left,

machine.

and

garments

which

as

standard

numbers

machine, a "Z"

OF

CATALOG

the

Standard

to

some

front,

OF

MACHINE

Throw,

Feed,

VisualSight

flat

seaming

elastic

is

stamped

and

but

never

contain

styles

Special

back,

Operating

Four

Automatic

Oil

infants'

made

is

necessary.

in'the

special.

contain

the

is

suffixed

of

machines

machines

etc.,

Needles,

ActionandSupply

of

are

direction

Enclosed

panties,

light

Seam

the

letter

given

One

to

medium

name

Standard

to

in

of

men's

Specification

plate

letter

"Z".

the

this

Looper,

Type

When

standard

as

listed

Class.

from

handwheel

Oiling

Gauges,

briefs

weight

on

Style

"Z".

the

Six

36200 B For

sleepers

weight

Specification

36200

36200

number

The

blade

Collectively,

Thread

formation.

machine.

by a reputation

of a century.

round

diametershank,

AA

AB

Each

Selection

For

StandardneedleforStyles

Union

denotes

size

measured

should

best

shank,

simultaneously

or

material,

Same

Same

Special

the

number,

the

of

proper

pass

results,

They

are

for

round

chromiumplated,

similar

607-FSa-1.

as

as

stamped

in

thousandths

type

packaged

producing

where

Style

Style

needle

kind

number

needle

freely

use

point,

garments

of

seaming

36200

36200

shank,

on

size

through

only

under

36200

extra

trimming

and

A,

B,

NEEDLES

has

both a type

point,

the

needle

of

an

and

size

should

the

genuine

our

highest

A,

short,

and

and

all

and

closing

except

except

length,

shank,

inch

number

be

determined

needle

Union

brand

quality

B,

AA

double

is

available

flatseaming

knitted

number

midway

eye

Special

name,

needles

and

fabrics

elastic

prepared

prepared

groove,

denotes

between

represent

in

needles

~

AB

is

groove,

in

sizes

underwear,

made

is

for

for

and a size

finish,

the

largest

by

the

size

order

for

to

more

Type

struck

025, 027,

in

118

children's

of

light

not

necessary.

Pedestal

Pedestal

number.

and

the

shank

the

complete

of

produce a good

the

operation

•

which

than

GAS-029.

groove, • 060

to

Installation.

Installation.

other

diameter

and

the

thread

is

three-quarters

029, 032,

knit

medium

Seam

The

type

details.

of

the

the

eye.

symbol.

used.

stitch

of

this

backed

It

has

inch

036.

a

To

have

needle,

A

complete

or

needle

the

order

type

orders

and

would

promptly

size

number

read:

and

"1000

accurately

should

Needles,

be

forwarded.

Type

filled,

4

118

an

Use

GAS,

empty

description

Size

package, a sample

on

label.

029".

ILLUSTRATIONS

This

catalog

views

seen

will

the

of

various

in

their

actual

be

found a listing

number

of

pieces

has

been

sections

position

required

ORDERING

arranged

ofthe

in

the

of

the

parts

REPAIR

to

simplify

mechanism

machine.

with

in

the

particular

On

their

PARTS

ordering

are

shown

the

parts

view

repair

sothatthe

page

opposite

numbers,

being

parts.

parts

the

description

shown.

Exploded

maybe

illustration

and

Numbers

dicate

never

second

indicated

sub-assembly.

the

position

be

used

column.

Component

by

27

28

29

30

31

29478

29103 T

22587

22894 w

22764

32

33

36244

34

It

will

be

listed.

recommended,

this

when

will

shown

The

In

those

catalog,

the

parts

be

mentioned

in

the

in

the

first

of

in

ordering

parts

indenting

of

Example:

cs

E

269

18

noted

reason

cases

no

illustration.

in

so

the

where a part

specific

for

the

in

the

column

that

part

in

parts.

sub-assemblies

their

the

is

complete

various

descriptions

Feed

above

that

usage

description

Lift

Feed

Nut,

Connecting

Nut,

example

replacement

sub-assembly

will

machines

are

reference

the

illustration.

Always

Eccentric

Lift

which

Ecc.

numbers

Reference

use

the

can

be

under

the

Assembly----------------

Assembly

only,

part

number

furnished

description

Ball

and

merely

number

listed

for

repairs

of

the

Joint--------

Screw------------------------------Screw------------------------------Screw-------------------------------

left

thread--------------------------

Rod--------------------------

right

is

common

be

thread

that

of

mentioned

are

and,

if

------------------------

the

eccentric

these

should

to

all

not

necessary,

of

in

the

parts

be

ordered.

the

machines

the

description.

same,

the

and

bearing

individually

covered

the

specific

difference

are

However,

will

in-

should

in

the

are

main

not

is

not

by

usage

be

1

1

2

1

1

1

1

1

At

the

shown

when

On

an

appear.

STYLE

in

only

Where

some

identification

Part

IMPORTANT!

OF

back

this

the

the

of

numbers

of

the

book.

part

number

construction

the

smaller

letter

represent

ON

MACHINE

book

This

parts,

is

FOR

will

will

facilitate

is

known.

IDENTIFYING

permits,

and

stamped

the

same

ALL

ORDERS,

WHICH

be

found a numerical

locating

PARTS

each

on

in

PART

part

those

to

where

distinguish

part,

PLEASE

IS

5

is

regardless

ORDERED.

the

stamped

construction

INCLUDE

index

illustration

with

the

part

from

of

catalog

PART

of

and

its

does

similar

all

the

description

part

number.

not

permit,

in

which

NAME

parts

ones.

they

AND

USE

GENUINE

NEEDLES

AND

REPAIR

PARTS

Success

Union

ation.

to

Maximum

repair

your

ments

are

insurance.

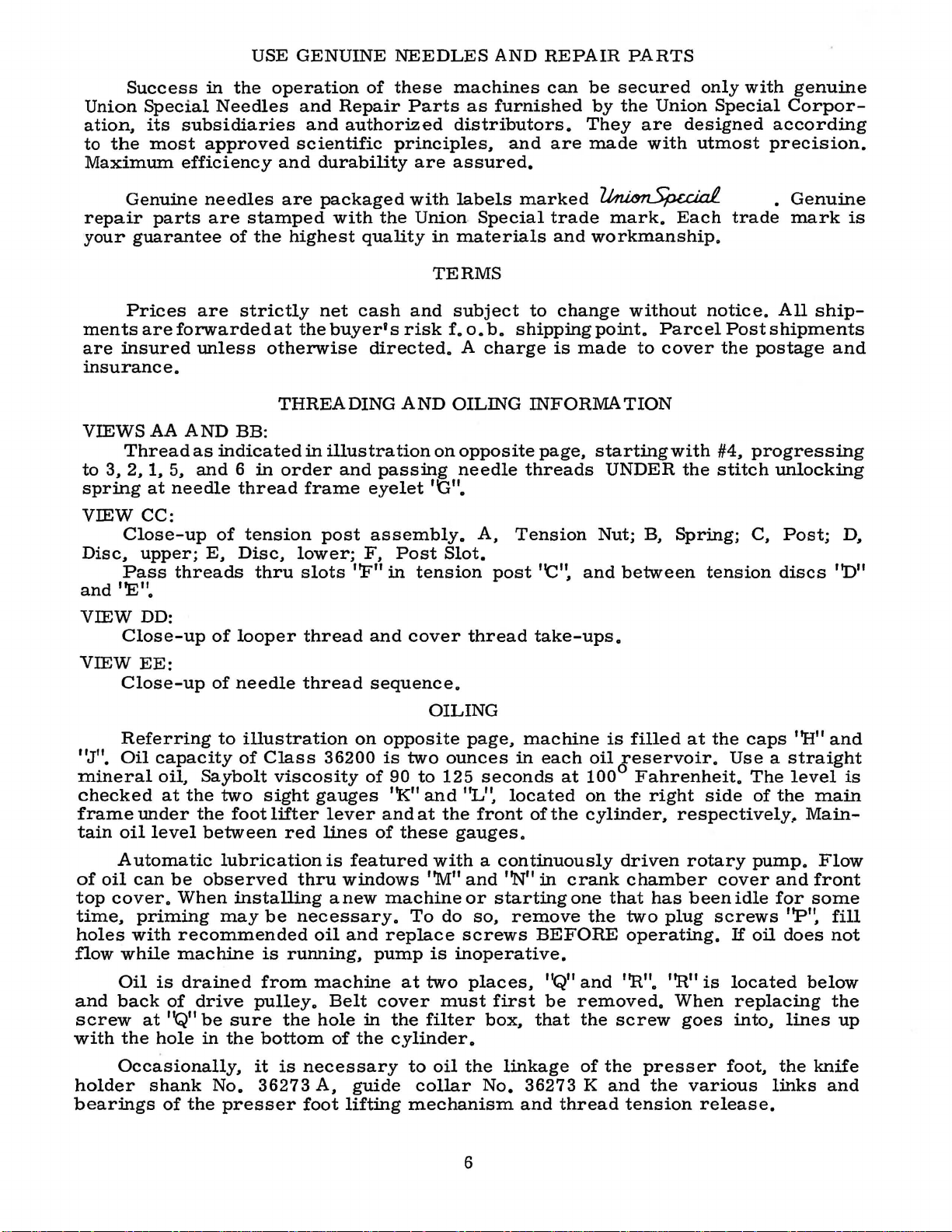

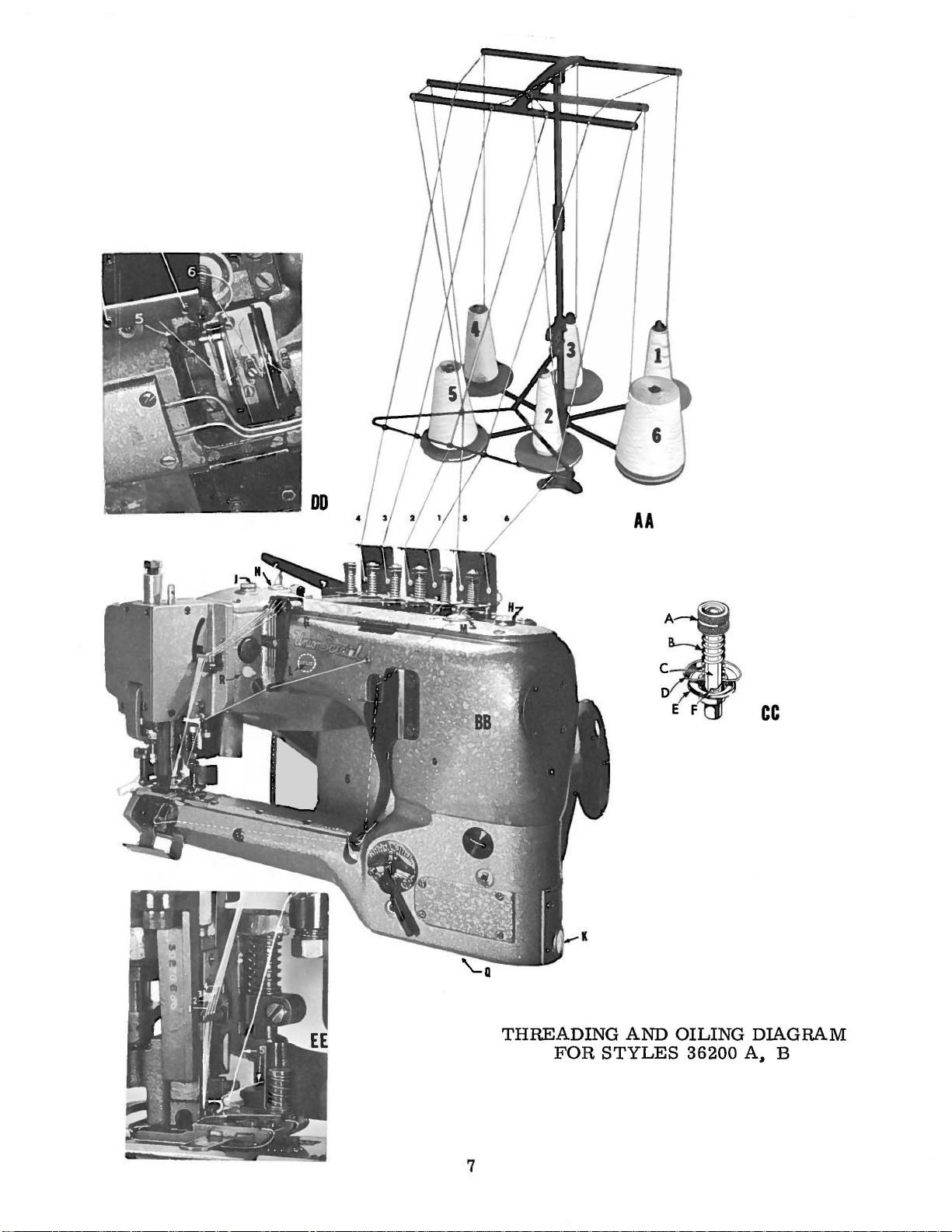

VIEWS AA

to

spring

VIEW

Disc.

and

VIEW

Special

its

the

most

Genuine

parts

guarantee

Prices

are

insured

Thread

3,

2.

1.

at

CC:

Close-up

upper;

Pass

'E".

DD:

Close-up

in

the

Needles

subsidiaries

approved

efficiency

needles

are

of

are

strictly

forwarded

unless

AND

5.

needle

threads

BB:

as

indica

and 6 in

thread

of

tension

E.

Disc.

of

looper

operation

and

and

scientific

and

durability

are

packaged

stamped

the

highest

net

at

the

otherwise

THREADING

ted

in

order

frame

post

lower;

thru

slots

thread

of

these

Repair

authorized

with

cash

buyer's

illustration

and

''F"

Parts

principles.

the

quality

risk

directed.

AND

passing

eyelet

assembly.

F.

Post

in

and

cover

machines

distributors.

are

assured.

with

labels

Union

in

materials

TERMS

and

subject

f.

A

OILING

on

opposite

needle

''G".

Slot.

tension

as

furnished

and

Special

o.

b.

charge

A.

post

thread

can

be

secured

by

the

They

are

made

marked

trade

to

shipping

INFORMATION

page.

threads

Tension

''C'~

take-ups.

~

mark.

and

workmanship.

change

point.

is

made

starting

UNDER

Nut;

and

between

without

Union

are

with

Parcel

to

B.

only

designed

utmost

Each

cover

with

the

Spring;

with

Special

trade

notice.

Post

the

postage

#4.

progressing

stitch

c.

tension

genuine

Corpor-

according

precision.

•

Genuine

mark

All

ship-

shipments

and

unlocking

Post;

discs

D.

''D"

is

VIEW

Close-up

Referring

"J".

Oil

mineral

checked

frame

tain

oil

Automatic

of

oil

can

top

cover.

time.

holes

flow

and

screw

with

holder

bearings

with

while

Oil

back

the

Occasionally.

EE:

capacity

oil.

Saybolt

at

the

under

priming

at

shank

the

level

is

hole

between

be

observed

When

recommended

machine

drained

of

drive

''Q"

be

in

of

the

of

needle

to

illustration

of

two

foot

lubrication

installing a new

may

pulley.

sure

the

it

No.

presser

thread

Class

viscosity

sight

lifter

red

thru

be

necessary.

is

running.

from

the

bottom

is

necessary

36273

foot

gauges

oil

machine

hole

A.

sequence.

on

36200

of

lever

lines

is

featured

windows

and

Belt

in

of

the

guide

lifting

opposite

is

two

90

to

'K"

and

and

at

of

these

''M"

machine

To

replace

pump

at

two

cover

the

filter

cylinder.

to

collar

mechanism

OILING

page.

ounces

125

"L".

the

front

gauges.

with a continuously

and

or

do

so.

screws

is

inoperative.

places.

must

oil

the

machine

in

each

seconds

located

of

''N"

in

starting

remove

BEFORE

first

box.

No.

that

linkage

36273 K and

and

at

the

crank

one

"Q"

and

be

removed.

the

of

thread

100

on

cylinder.

is

filled

oilc5eservoir.

Fahrenheit.

the

driven

chamber

that

the

two

operating.

''R".

screw

the

tension

at

right

respectively,.

rotary

has

been

plug

''R"

When

goes

presser

the

various

the

caps

Use a straight

The

side

is

release.

of

pump.

cover

idle

screws

If

oil

located

replacing

into.

foot.

the

and

for

does

the

links

''H"

level

main

Main-

front

some

''P".

below

lines

knife

and

is

Flow

fill

not

the

up

and

6

AA

cc

THREADING

FOR

7

AND

STYLES

OILING

36200

DIAGRAM

A,

B

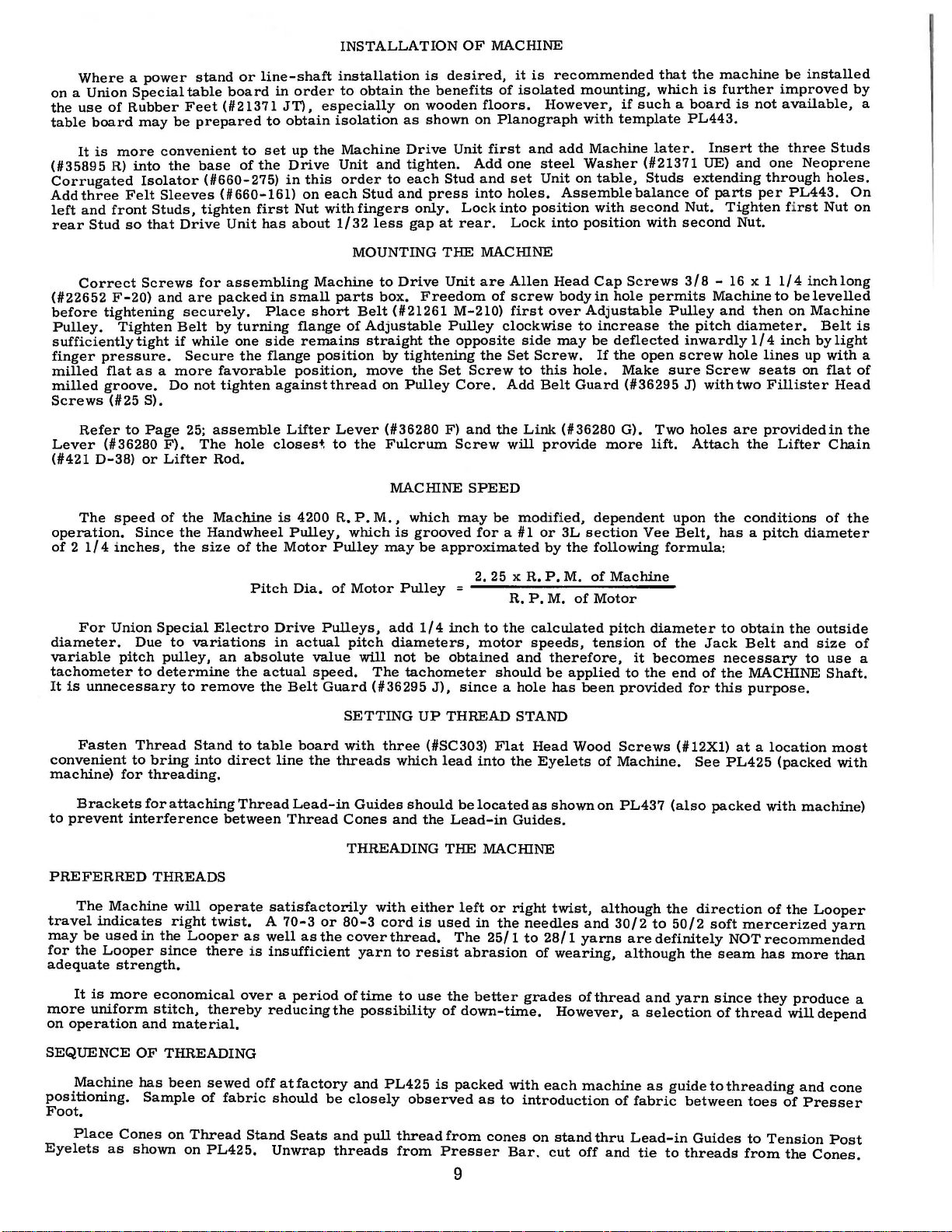

INSTALLATION

OF

MACHINE

Where a power

on a Union

the

use

table

(#35895

Corrugated

Add

left

rear

(#22652

before

Pulley.

sufficiently

finger

milled

milled

Screws

Lever

(#421

operation.

of 2 1/4

of

board

It

is

more

R)

three

and

front

Stud

Correct

F-20)

tightening

Tighten

pressure.

flat

groove.

(#25

Refer

(#36280

D-38)

The

speed

inches,

Special

Rubber

may

be

convenient

into

the

Isolator

Felt

Sleeves

Studs,

so

that

Screws

and

Belt

tight

if

as a more

Do

S).

to

Page

F).

or

Lifter

of

Since

the

stand

table

Feet

(#21371

prepared

base

(#660-275)

(#660-161)

tighten

Drive

for

are

packedin

securely.

by

while

Secure

favorable

not

tighten

25;

assemble

The

Rod.

the

Machine

the

Handwheel

size

or

line-shaft

board

Unit

assembling

to

to

set

of

the

first

has

Place

turning

one

side

the

flange

hole

of

the

closes-t:

in

JT),

obtain

Drive

in

small

againstthread

Lifter

is

Pulley,

Motor

installation

order

especially

isolation

up

the

Unit

this

on

each

Nut

with

about

1/32

Machine

parts

short

flange

remains

position

position,

Lever

to

4200

R.

Pulley

to

obtain

on

as

Machine

and

order

to

Stud

and

fingers

less

MOUNTING

to

Drive

box.

Belt

(#21261

of

Adjustable

straight

by

tightening

move

on

(#36280

the

Fulcrum

MACHINE

P.M.,

which

is

may

is

desired,

the

benefits

wooden

shown

Drive

tighten.

each

Stud

press

only.

gap

at

THE

Unit

Freedom

the

the

Set

Pulley

F)

which

grooved

be

approximated

floors.

on

Unit

Add

and

into

Lock

rear.

MACHINE

are

M-210)

Pulley

opposite

the

Screw

Core.

and

Screw

SPEED

may

for

it

is

of

isolated

Planograph

first

and add

one

steel

set

Unit

holes.

into

position

Lock

Allen

of

screw

first

clockwise

side

Set

Screw.

to

this

Add

Belt

the

Link

will

provide

be

modified,

a #1

or

recommended

moWlting,

However,

with

Machine

Washer

on

table,

Assemble

with

into

position

Head

Cap

bodyin

over

may

(#36280

3L

by

the

hole

Adjustable

to

increase

be

deflected

If

the

hole.

Guard

more

dependent

section

following

that

which

if

such a board

template

later.

(#21371

Studs

balance

second

with

Screws

permits

Pulley

the

open

Make

G).

sure

(#36295

Two

lift.

Vee

formula:

upon

Belt,

the

machine

is

further

PL443.

Insert

UE)

extending

of

parts

Nut.

Tighten first

second

3/8-

Machine

and

pitch

inwardly

screw

Screw

J)

with

holes

Attach

the

has a pitch

is

not

the

and

one

through

per

Nut.

16 x 1

then

diameter.

1/4

hole

lines

seats

two

Fillister

are

provided

the

conditions

be

installed

improved

available,

three

Neoprene

PL443.

1/4

inch

to

belevelled

on

Machine

Belt

inch

by

up

on

Lifter

diameter

Studs

holes.

On

Nut

long

light

with

flat

Head

in

the

Chain

of

the

by

a

on

is

a

of

For

diameter.

variable

tachometer

It

convenient

machine)

to

PREFERRED

travel

may

for

adequate

more

on

Union

pitch

is

unnecessary

Fasten

Brackets

prevent

The

Machine

indica!es

be

used m the

the

Looper

strength.

It

is

more

uniform

operation

for

Special

Due

to

variations

pulley,

to

determine

to

Thread

to

threading.

for

interference

and

Stand

bring

into

attaching

THREADS

will

right

Looper

since

economical

stitch,

material.

Pitch

Electro

an

remove

direct

between

operate

twist. A 70-3

there

thereby

Drive

in

absolute

the

actual

the

to

table

line

Thread

satisfactorily

as

well

is

insufficient

over a period

reducing

Dia.

Pulleys,

actual

value

speed.

Belt

Guard

board

the

Lead-in

Thread

or

as

the

of

Motor

pitch

SETTING

with

threads

Cones

THREADING

80-3

cover

oftime

the

Pulley

add

diameters,

will

not

The

(#36295

three

which

Guides

and

with

cord

thread.

yarn

to

to

possibility

=

1/4

inch

be

obtained

tachometer

J),

since a hole

UP

THREAD

(#SC303)

lead

should

either

the

is

used

resist

use

be

Lead-in

THE

left

The

abrasion

the

of

down-time.

2. 25 x

motor

into

located

in

better

R.

R.

to

the

and

should

STAND

Flat

the

Guides.

MACHINE

or

right

the

needles

25/1

to

grades

P.M.

of

Machine

P.

M.

of

Motor

calculated

speeds,

therefore,

be

has

Head

Eyelets

as

shown

twist,

28/1

of

wearing,

However a selection

tension

applied

been

Wood

of

on

although

and

yarns

ofthread

pitch

it

to

provided

Screws

Machine.

PL437

30/2

are

although

'

diameter

of

the

becomes

the

end

for

(#12X1)

(also

the

to

50/2

definitely

and

yarn

to

Jack

necessary

of

the

this

See

PL425

packed

direction

soft

NOT

the

seam

since

of

obtain

at a location

thread

the

Belt

and

MACHINE

purpose.

mercerized

they

to

(packed

with

machine)

of

the

recommended

has

more

produce

will

outside

size

use

Shaft.

most

with

Looper

yarn

than

depend

of

a

a

SEQUENCE

.Mac~ne

pos1tiorung.

Foot.

Place

Eyelets

Cones

as

OF

THREADING

has

been

Sample

on

shown

on

sewed

of

fabr1c

Thread

PL425.

.off

should

Stand

Unwrap

atfactory

be

Seats

and

closely

and

pull

threads

PL425

observed

thread

from

is

packed

from

Presser

as

cones

to

with

each

introduction

on

Bar.

stand

cut

9

machine

of

thru

off

and

as

guidetothreading

fabric

Lead-in

tie

between

to

threads

Guides

toes

to

Tension

from

and

of

the

cone

Presser

Post

Cones.

Turn

Pull

thread

With

and

the

Handwheel

threads

above

stitch

knots

Needle

formation.

clockwise.

from

Bar

above

and

raised,

cut

needle

off

lift

Stop

with

eyes

close

Presser

Needle

thru

to

Needle

Foot

Bar

system

and

at

Eyes,

remove

top

of

until

knots

DO NOT

the factory

its stroke,

pass thru Needl

RE-THREAD

sample,

e B

ar

Head Eye

NEEDL

Observe method

ES

let.

AT

THIS

of

entering Foot

Cut

TIME.

off

Looper

tore-thread

THREAD

observe

Check

tension;

section

UNLOCKING

Turn

then,

downward app

mark

threads

With

the

needles,

If

free

ends

formed,

REPLACING

formation

Tension

when Foot

on

"Adjustment

the

turn

the

on

the Head

to

be

threads

the

stitch

of

This

and

Cover

the

NEEDLES

THE

Handwheel

Hand

roximately

pulled

Without a chain,

all

is

THE

Thread

Looper

of

stitch.

Rel

ea se when

is ra·

STITCH

wheel

Cover. Lift the Presser Foot

from

unlocked,

is

unlocked

the

threads firmly

termed"

NEEDLE

and

and

sed,

of

Tension

in

in the

1/8

under

start

can

now

Cover

the

it

Thread

place

one

Foot

all

threads

Release".

operating or

reverse

inch

to

where the

the Foot

must

be

material must

and

it

is

behind

ing

the

be

tied

Carrier.

ply

of

is

raised bef

must

direction

freely.

understood

desired

the Foot bef

chain

" .

and

pulled

thru,

with

material

be

clockwise direction

until

top

be

under

to

start

Machine

under Foot.

ore

sewing with

completely free,

the

the

high as

that

the

the

ore

Needle Bar

Needle

possible,

it

is

only

Foot

machine

starting

will

then

of

as

Needle

until

Lever

to

when

the

chain

Bar

Manually

power.

If

the

the Needle

has

reached its hig

Thread

thus

introduce

starting to

without

machine,

indefinitely.

at highest

turn

When

se

conditions

Eyelet

opening

work

sew.

material,

unt

point.

clockwise

Foot

is down,

Bar

is

hest

is

in

the

Tensions

under

it

is

il a small

It

is

several times

all

are

not

in its

lowest

position and

line

with

which

the

Foot

imperative

amount

unnecessary

threads

met, ref

position,

moved

the

top

of

allow

from

behind

to

hold

of

cha

and

have

er

the

the

the

in

to

is

Union

To

remove Nee

Needle.

on

the

machine

should

TO

the

machine

Foot,

remove

(#36270)

left

withdraw

to

Special

assists

flat

matically

to

Looper.

remove

seated

If

adjustments

F

amiliarity with

but

care

NEEDLE

If

Presser

To

Knife

Cover,

partially

of

Needle

The

(Pa

Needles

operator

Retainer,

dle,

To

ge 27).

for

in

correctly

to

the

bring Needle

replace

Needle,

INSTRUCTIONS

has

been

be

made

the

machine

be

taken

LOOPER SETTING

is ass

Throat Plate

Presser Foot

and

(#36289 A, Page 27)

Looper

release knife

Pre

setting,

disassembled,

in

the

following sequenc

will per

to

observe

embled

and

(#36220),

ss er

Bar (#36278),

the

FLA

TSEAMER

locating

right

of

the

Bar

to

make

re-adjusting

mit individual adj

that

the

prop

and

it

is

Main Feed Dog

pressure

and

desired

raise

Presser

Removal

are

the

fourth

maximum

certain

FOR

e,

which,

er

should

Needle Bar

by

unclamping Knife

Foot Brace (#36278

made

relative

Needle,

height,

that

SEWING

for

throu

ustments

relationship

to

proceed

be

to

of

Throat Plate

Shank

sew

removed,

maximum heig

with

two

flats

position

requires

break

is

inserted

of

Needles

no

thread

on

orienting

to

ADJUSTMENTS

ing

-off

is

gh

experience,

of

of

with

E),

an

adjustment

the

Guide

assembl

Needle

ht

(#36273 B ).

Release

and

Main

required,

and

front

of

Shank,

in

Needle

and

consequently has

at

eye,

loosen

full

depth

and

has

ed

is

to

Presser

and

proven generally

machine

maintained,

Looper

remove Retainer

Feed

setti

Remove Detachable

Bar

Dog

Bar

Screw

it

is sugg

to cor

ng,

Gui

will

This

design

Head

with

(#22738

that

Screw

est

ed

sat

rect malf

the

Upper

(#36211), Upper

de (#36278

permit

observation

respect

is

that

isf

actory.

unct

auto-

no

flat

H)

firmly

ion,

Knife,

Hea

B)

and

.

and

the

d

10

NEEDLES

With

needle

may

the

Bar

Detachable

Needles

as a straight

cross

by

Needle

should

be

obtained

clamping

Connection

To

position

into

grooves

Throat

Pl::tte

AND

be

of

Head

first

edge

NEEDLE

Bar

motion

17/3 2 inch

by

using

Needle

(#51254 H),

Cover,

Needle

and

fourth

against

of

the

Throat

Screws

BAR

needle

Bar,

left

Head

the

(Fig.

at

its

highest

from

Throat

height

loosen

access

(#36289 A,

Screw

square

positions

blades

Plate

which

B),

to

with

of

travel,

Plate

Gauge

(#22562

which

Fig,

the

only,

the

Needles

has

the

fourth

top,

(#21227 BU),

is

obtained

A),

Throat

The

been

This

A,

Page

Plate,

Upper

and

aligned

previously

or

adjustment

To

23)in

by

removal

insert

Knife

lowest

release

Needle

the

is

used

with

the

secured

of

Should

(#36218)

Needle

To

torque

cross

CAUTION!

Head,

Bar

up

bind

Normal

Add

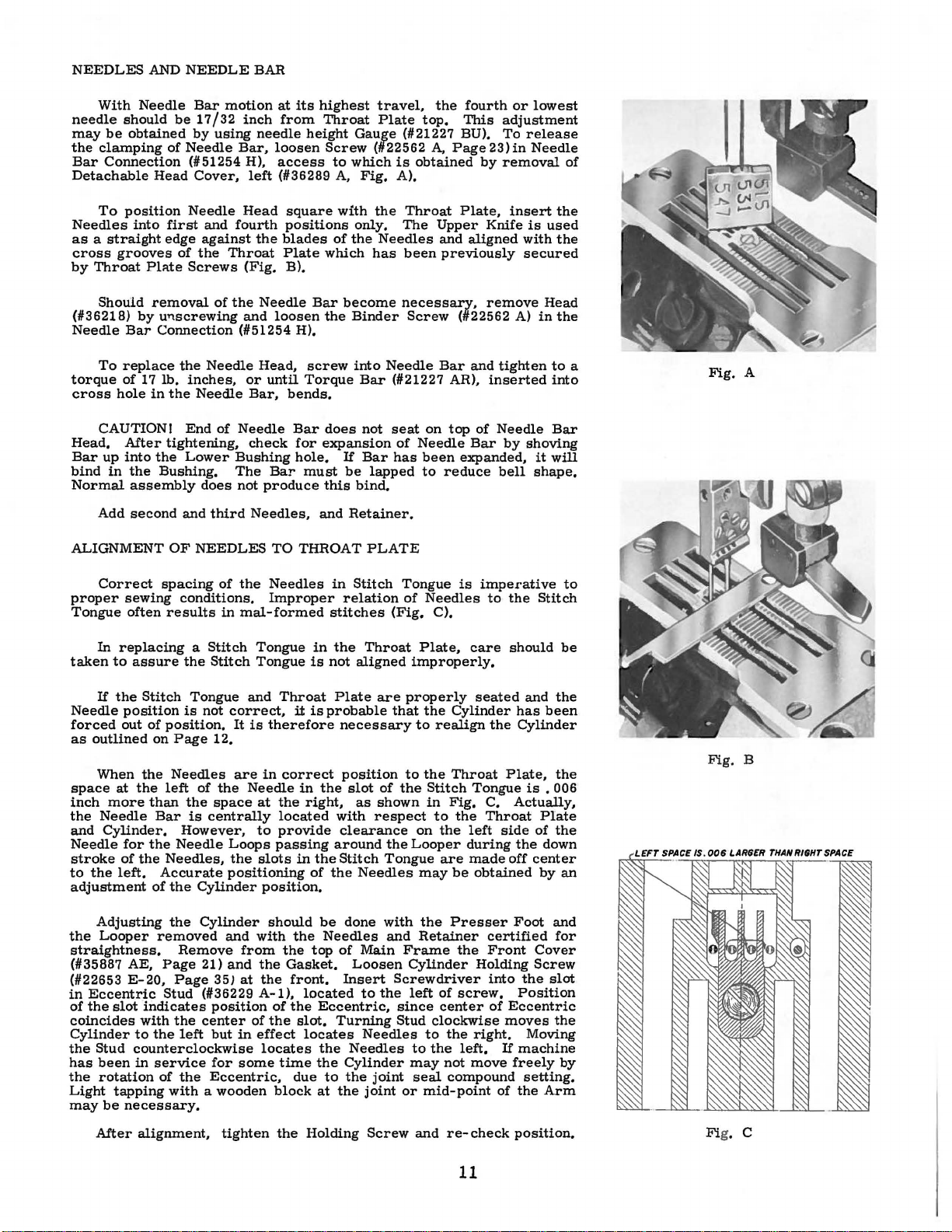

ALIGNMENT

Correct

proper

Tongue

In

taken

If

Needle

forced

as

outlined

When

space

inch

the

Needle

and

Cylinder.

Needle

stroke

to

the

adjustment

removal

by

Bar

replace

of

17

hole

in

After

into

in

the

assembly

second

sewing

often

replacing a Stitch

to

assure

the

Stitch

position

out

of

on

the

at

the

more

than

for

the

of

the

left,

of

U'1Screwing

Connection

lb,

the

tightening,

the

Bushing.

spacing

results

position.

left

Bar

Needles,

Accurate

of

the

Needle

inches,

Needle

End

of

Lower

does

and

third

OF

NEEDLES

of

conditions,

the

Stitch

Tongue

is

not

Page

12,

Needles

of

the

the

space

is

centrally

However,

Needle

the

Cylinder

the

Needle

and

loosen

(#51254 H),

Head,

or

until

Bar,

Needle

check

Bushing

The

Bar

not

produce

Needles,

TO

the

Needles

in

Improper

mal-formed

Tongue

Tongue

and

It

is

are

Needle

Throat

therefore

in

at

the

located

to

provide

passing

slots

position.

correct,

Loops

the

positioning

Bar

screw

Torque

bends,

Bar

for

hole,

must

and

THROAT

in

is

it

is

correct

in

the

right,

in

the

of

become

the

Binder

into

Bar

does

not

expansion

If

Bar

be

lapped

this

bind,

Retainer,

PLATE

in

Stitch

relation

stitches

the

Throat

not

aligned

Plate

probable

are

necessary

position

slot

as

shown

with

respect

clearance

around

Stitch

the

Needles

necessary,

Screw

Needle

of

the

Tongue

Bar

(#21227 AR),

seat

on

of

Needle

has

been

to

reduce

Tongue

of

Needles

(Fig,

C).

Plate,

improperly,

properly

that

the

to

realign

to

the

the

Stitch

in

to

on

the

Looper

are

may

remove

(#22562 A)

and

tighten

inserted

top

of

Needle

Bar

expanded,

bell

is

imperative

to

care

seated

Cylinder

the

Throat

Tongue

Fig,

C,

the

Throat

left

during

made

be

obtained

by

shoving

it

shape,

the

Stitch

should

and

has

Cylinder

Plate,

is

Actually,

side

of

the

off

center

Head

in

the

to

into

Bar

will

to

be

the

been

the

• 006

Plate

the

down

by

an

a

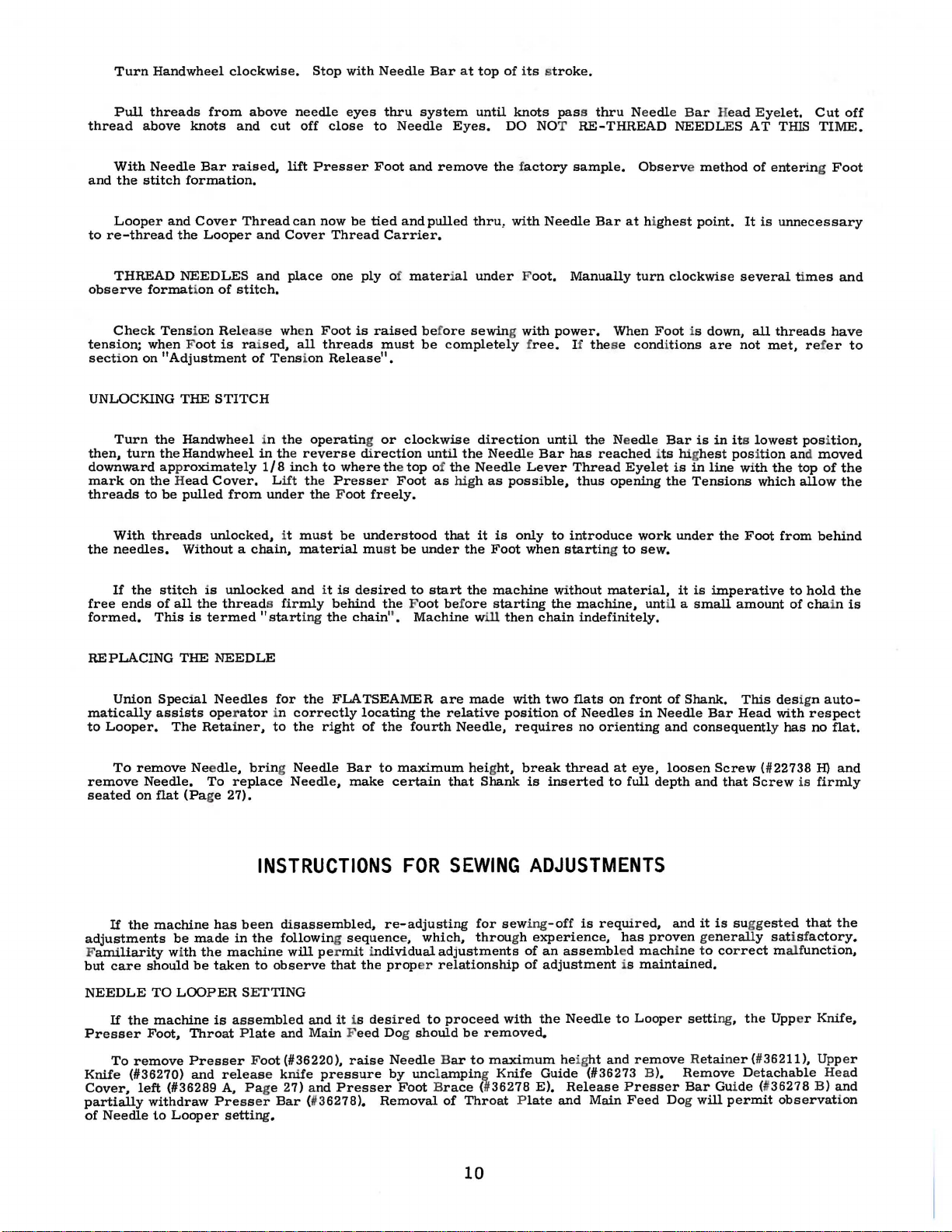

Fig.

Fig.

A

B

Adjusting

the

Looper

straightness,

(#35887 AE,

(#22653

in

Eccentric

of

the

slot

coincides

Cylinder

the

Stud

has

been

the

rotation

Light

tapping

may

be

After

the

Cylinder

removed

Remove

Page

E-20,

indicates

with

to

the

counterclockwise

in

service

necessary.

alignment,

21)

Page

Stud

of

35)

(#36229

position

the

center

left

but

for

the

Eccentric,

with a wooden

and

with

from

and

at

A-1),

of

in

effect

some

tighten

should

the

the

the

Gasket,

the

front.

of

the

the

locates

time

due

block

the

be

Needles

top

located

Eccentric,

slot,

locates

the

the

to

at

Holding

done

of

Main

Loosen

Insert

to

the

Turning

Needles

Needles

Cylinder

the

joint

the

joint

Screw

with

the

and

Retainer

Frame

Cylinder

Screwdriver

left

of

since

center

Stud

clockwise

to

to

the

may

not

seal

or

mid-point

and

Presser

certified

the

Front

Holding

into

screw.

of

the

right.

left,

If

move

compound

re-check

of

Foot

and

Cover

Screw

the

slot

Position

Eccentric

moves

Moving

machine

freely

setting.

the

Arm

position,

for

the

by

11

Fi

g. c

USE

OF

LOOPEH

THAVEL

GAUGE

Hemove

Gauge

Screw

Looper

Turn

Gauge

travel,

side,

necessary

To

Loosen

Plate

{1189

Travel

Handwheel

Plate

If

the

looper

to

adjust

Locknut

Cylinder

{1121227

).

and

the

alte

counterclockwise

NOTE:

to

After

The

movements

disassemble

Adjustment

Page

23).

oriented

pass

orienting

timing

\\'hen

same

Only

If

the

two

as

described

When

therefore,

to

through

for

mark

the

same

timing

for

timing

one,

Shafts,

the

This

its

is

or

below.

this

Synchronization

appear

at

the

Synchronization

He

move

Gauge

then

Pointer

travel

·r

the

looper

(11269,

to

setting

the

for

is

Shaft

slots

timing

cut

Shafts

as

before.

are

both,

and

Needle

position

occurs

same

Hinged

CS)

left

Pointer

to

set

lock

stops

is

the

looper

travel,

Page

increase

looper

of

the

Main

Shaft,

timing

constructed

by

Spot

which

of

the

into

the

and

the

Clamping

Shafts

therefore,

Bar

does

only

relative

is

easily

Spring

so

that

the

hand

Screw

(1121227

Looper

in

(

place with

on graduation

correct,

travel,

remove

3;

i)

and

looper

travel,

TIJ\IING

Needles

and

the timing means

the

motion

in

Scre

will

i\1ain

two parts

w (

11

allow a small

Shaft

Coupling

Coupling

However,

Screws

have

been

the

is

at

lowest

not

represent

when

Needle

position

and

accurately

Support

bottom

{11604)

Cl\l)

using

113

6208

Screw

If

Pointer

Front

turn

adjusting Screw

travel.

machine

OF

NEEDLES

Looper

of

the

22894

K)

to

the

normal

are

used

it

is

never

released.

renewed,

timing

position,

Bar

to

the

Stud

{#

gauge

used

the

at

the

(118f.J

goes

Top

36283

is

to

same scr

far rig

).

Turn hand

which

beyond

Cove

be

checked

IN

approximately

hold

indicates

r (1135887

(#

RELATION

of

)

mark

must

are limed with each

must

be

checked,

Needles

amount

which

locating

to

Looper

are

clamped

in

Vee grooves

of

turning between

Crankshaft,

to

the

clamped

together,

an

necessary

the

mark

timing

will

the

not

Looper

will

represent

synchronization

has

risen.

Needles

obtained

156

whether

by

use

C, Page

Looper

ew,

ht

position,

wheel

either

22795

for

is

After

faces

accurate

in

disassembling

be

has

already

and

(5/32)

rotation

of

Gauge

35)

from

Cylinder

horizontal,

Needle

Guard

Set Poi

f:p

a

clockwise

1

55

40

or

of

the

AE,

B)

clockwise

within graduation

graduation

Page

21)

to

synchronization,

TO

LOOPER

other

at

the

factory.

obtained

together

correct

milled

and

in

by

the

parts,

position

on

the

the

Screws

in

the

realignment

to

altered

correct

within

timing

started

Looper

inch,

is

(#21227

timing

At

this

effected

CG,

Lock

{113

nter

at

direction

marks

and

the

decrease

Main

Shafts.

Th

is

obtained

surface

of

the

release

the

manufacturing

and

its

advance

cannot

height,

clockwise

Page

and

attach

lightly

6210,

Page

zero

degrees

to

check

marks

mentioned

End

Cover

the

looper

If

it

has

Shaft Couplin

(1122519

is

Th e

provides

F).

Clamp

by

next

to

the

mark

will

the

Clamping

retiming

toward

be

accomplished

the

Looper

or

counterclockwise.

41),

Looper

in

33)

place

and

by

rotatin

the

Travel

looper

on

above,

(#

35887

travel

been

necessary

g (

11

35895

Each

end

ing

the

Screws

necessary

the factory,

Spot

Screws.

produce

Screws.

tolerances

should

the

point

be

Needles,

should

with

attach

either

it

Z).

and

W,

the

done

there,

g

is

is

a

of

INSTRUCTIONS

(1)

Turn

the

(2)

(3)

(4)

(5)

(6)

(7)

Loosen

Bar

the

Setting

Using

laid

between

Clamp

Insert

Height

gauge

Turn

Stop

in

is

Turn

Screw.

on

Follow

above

remove

the

Setting

Stop

Block

the

on

its

the

Stop

the

Gauge

(1121227

the

Screw.

the

center

accomplished

the

The

the

gauge.

this

condition

Crank

Coupling

the

right

di

rection,

ni

zing

Gauge

w

ise

direction

s

hould

be

procedure

FOR

USING SYNCI-IHONIZING

Handwheel

Presser

Block

in

this

portion

as a gauge

top

of

Screw

(#21227

(1114087,

the

in

Screw

long

side

Synchronizing

(1121227

CJ)

to

Handwheel

Then

of

the

by

Handwheel

end

of

The

procedure

fails

Chamber

Clamping

while

machine

the

Looper

Rod

moves

than a clockwise

advanced,

is

repeated

until

Needle

Bar

Regulating

Fig,

position,

of

the

Needle

position

Gauge

CJ)

securing

the

heel

slowly

set

the

graduations

loosening

in

the

the

Synchronizing

difference

two

to

be

Cover

Screws

is

is

too

more

The

to

check

GAUGE

Bar

(#35817

Screw

CH,

Fig.

D,

A)

above

Clamp

Stop

its

lowest

with

under

Screw

(111347

Screw

(1136208 A)

direction

D,

B)

Looper

to

set

the

Bar

at

using

Nut

Rod

(#21227

it

of

the

Looper

in a clockwise

Synchronizing Gauge

on

the

Screw

opposite

Need

(112273

direction

8),

Gauge

must

not

exceed

or

three

time

met,

Coupling

(1135888 N) and

(#22519

rotated

fast

and

to

the

directio

Coupling

the

s to

(1135895

F),

If

the

in a clockwi

the Main

rig

ht

while

n,

the

may

be

new rel

ationship

BY,

(#36278

the

the

Needle

and

Height

position

A,

CK,

Fig.

(1122738,

Rod

le

Bar

until

Rod

two

make

W)

Gasket

Synchron

s e

Shaft

machine

Looper

secured

NO.

21227

Page

G,

Page

head

(#14087)

and

Fig.

D,

D,

with

until

so

Setting

the

should

marks

certain

must

(#

izi

directio

should

is

by

of

the

CG

27)

is

25)

of

the

Bar.

Gauge

leave.

the

D).

E)

into

Fig.

D,

Screw

the

that

the

Block

Needle

come

of

the

t he

be

r e

pos

:l5888

ng Ga ug e

n t h

an

be

retarded.

is

rotated

too slow

one

Screw while

two

at

bottom

and

insert

Regulating

Clamp

(1121227

head

156

of

the

Looper

F)

and

(#22703

the

Needle

flattened

(1121227 CH).

Bar

strikes

to

the

same

graduation,

timin

g is

iti

oned,

P, Pag

e

21).

Rod

in a

counterclockwise

in a counterclock-

and

Shafts.

of

its

the

Screw

Needle

CJ/

Fig.

(5

32)

the

inch

Stop

Clamp

then

clamp

A,

Fig.

Bar

strikes

end

the

graduation

perfect,

For

Loosen

moves

If

the Synchro-

the

Main

the

stroke.

Needle

with

Bar

0,

gap

Screw.

and

the

D,

G).

the

is

about

This

Stop

If

the

access,

the

more

Shaft

gauging

C)

to

Fi

g,

D

NOTE:

remove

If

Stationary

Knife

and

Knife

proceed

(1136250)

as

described

interfer

abov

es

e.

with

12

Synchronizing Gauge

Rod

(#

21227

CK),

read.

Measurement

first

bring

the

Looper

against

position

position

.

Page

Joint.

preceeding

to

(#22652

Looper

Needle.

point

across

between

accomplished

Needles

FEED

which

084

touch

end

and

to

inch

35)

and

Raising

Normal

edge

A-6,

point

Adjust

NOT

Looper

all

top

removed

HEIGHT

Before

extends

(Fig.

Fig.

E

Fig.

R

is

the

Looper

Shaft

of

Looper

check

flush

loosening Looper

Ball

method.

Looper

ofgauge (#21225-3/16)

Page

to

Looper

to

exceed.

Needle

Needles

of

the

by

assembling

thru

made

Shaft

hole

in

end

Shaft.

end

of

If

conditions

Joint

gau

ge

33)

to

of

Holder

002

Guard

and

Looper

check

the

Feed

G

gauge

shortens

is

move

Needle

inch

may

observe

of a Screw

the

the

represents . 094

E).

back

means

to

Fig.

of

the

to

its

of

Tighten

3/16

with

(Fig.

and

complete

Main

Bars

R)

looper

middle

screw

against

If

and

(B)

is

of

extreme

extreme

Cylinder

for

Plunger

inch

are

not

Avoid

avoid

inch.

while

Looper

must

be

Screw

G).

now

be

if

free

bottom

set

Feed

at

approximately

In

the

(#

21227

synchronization

as foll

ows:

Bar heig

Insert

position. Usin

on

Bar,

of

5/32

Observe

of

to

obtainable

counterclockwise

Handwheel.

synchronized,

the

same

Needles.

With

and

the

turn

securely.

Set

not

the

until

Clamping

travel.

met,

Link

motion

With

Holder

done.

Recheck

installed.

from

of

parallel

cycle.

Dog

on

T

raising

feeds

the

of

approximately

measured

Feed

prevent

(#531,

be

Main

Guard

push

movement

Tighten

#2

the

upper

limit

the

Needle

inch

the

Looper

the

Needles

Looper

with

LOOPER

the

tighten

shaft.

feed

driver

the rig

looper

looper

Looper

available, a depth micrometer

Cylinder

axial

reciprocation

motion

the

Screw

being

If

less

adJustment

Ball Joi

and

the

Looper

leftNeedle

right

Turn

on

end

of

Looper

pinching.

the

Stitch

to

FEED

and

Differential

the

left

hi s mid-

simultaneously

Eccentric,

ad

j u s t

Dog.

Page

Differential

installed.

Feed

to

the

event

CG) is

ht

carefully

throat

Place

bar

(E)

blade

toward

Plunger

flush

nt

Bring

the

end

or

rotation

the

Guard

Screw.

not

may

Certi

fy

and

Looper

and

#3

g a

Collar

portion

the

downward

Bar

of

bottom

point

at

both

by

rot

both

will

be

regard

ADJUSTMENT

plate

screw

(B).

the

slot

of

in

the

ht

slide

does

(A)

until

Avoid

to.

in

line

the

is

(#89, Page 35).

with

looper

is

Stud, right (in

loweringlengthens

motion

rests

or

left.

Handwheel

Looper

ADJUSTMENTS

the

at

Shaft

Gauge

this

Looper

Tongue

Shank

mid-area

is

set

setting a 11

lowering

The

me

n t

the

rear

The

Stud

35).

Feed

Before

Dog,

add

Main

to

toward

Gauge

available,

be

checked

the

Needle

gauge

Needles

clamped

of

the

Needle

stroke

to

stop

within

of

stroke.

the

position

with

respect

positions

clockwise

at i on

If

machine

positions

exactly

to

and

feed

It

is

narrow

the

cylinder

half circle

of

the

feed

not

align

blade

of

094

inch,

with

the

of

the

rear

(away

fully

extended

gau

ge

body.

avo

id

is

obtained

at

the

in

Vee

(Fig.

Before

until

to

obtain a clearance

to

be

Guard

normally

should

be . 018

hole

in

Feed

Dog,

of

horizontally

ow s for

the

by

turning

total

amount

obtainable

7/64

inch,

of

the

is

locked

by

Set

Screw

(Fig.

I, B)

may

assembling

the

Needle

Feed

Dog

the

end

the

rear.

.

into

and

of

is

of

the

the

dogs

important

end

oflooper

casting

cutout

bar

with

the

looper

using

may

Looper

Looper

from

Bring

The

required,

by

removing

#29478

avoid

extreme

F).

clamping

Looper

sure

Holder

against

seats

the

Looper

the

the

Cylinder,

.

two

is

Main

to

now

and

of

its

removed,

to

align

of

looper

slot

and

end

and

gauge

gauge

be

Shaft,

Shaft.

operator),

from

Looper

motion

use

DM,

motion.

left

Release

the

point

has

first

on

to

. 025

Holder.

Eccentric

insert

the

gauge

(D).

Insert a 1/8

gauge

also

of

the

are

(#21227

used

through

or a depth

In

using

the

gauge

Shaft

of

the

step

on

Cylinder

Page

31)

Reposition

of

its

Looper

Screw

is

flush

between

not

Needle

top

of

inch.

Stud

should

Fig.

F

the

looper

(C),

No. 21227 CU,

and

against

tight,

slipped

the

gauge,

loosen

aligned.

BV,

Fig.

the

scale

the

gauge

insert

the

while

to

maximum

Plunger

looper

Side

to

raise

gauge

travel,

Use a Feeler

Fig.

Holder

the

with

Needle

(Fig.

the

Holder.

Vertical

(#36234

be

rotated

H

set

right

on

H).

looper

blade

90°

inch

press

looper

screw

Tighten

E).

hole

in

if

accurately

(#21227

gauge

bearing

from

gauge,

Cover

or

lower

and

Looper

Clamp

axial

side

and

Looper

Pass

Clearance

adjustment

gauge

D,

Page

until

(A,

Fig

to

in

diameter

the

gauge

blade

screw

If

gauge

the

end

BV) ,

through

firmly

forward

extended

which

(#36286

Ball

repeat

point

Screw

setting

of

left

Looper

Shaft.

Looper

with

29),

the

slot

.

the

the

.

(B)

is

,

of

is

13

For

the

is

applied.

Both

most

Throat

the

cases,

Plate

Main

the

The

Differential

Feed

the

Main

full

and

Differential

Feed,

depth

Feed

of

at

the

may

its

teeth

Feed

highest

when

then

may

be

leveled

be

position,

the

normal

individually

should

Presser

to

it

(Fig.

adjusted

rise

I,

A).

above

Spring

to

height.

the

top

pressure

of

Fig.

Fig.

REAR

•

I

J

002

NEEDLE

The

to • 003

GUARD

rear

Needle

inch.

lengthis

up

or

lowered,

of

material

DIFFERENTIAL

The

Cylinder

differential

differential

1

to

9,

5,

non-differential

TwoStopScrews

ment

in

one

through

pressure

(1#73

C,

PRESSER

To

position

the

Upper

Hook

(1#36251

Segment

(1#94,

located,

(1#36278

Presser

Presser

Add

Permit

satisfactorily

Linkmotionof

Thread

knife

Handwheel

loosening

rotating

ADJUSTMENT

Guard

Check

down

thedifferentialactionincreasingwiththenumbers.

of

the

position.

Page

assemble

and

Driving

B,

Page

B,

left

no

Carrier

on

Sleeve

(#36225,

position

8

~

obtained

(Page

decreases.

used.

amount

friction

of

and

align

Foot.

Bar

approach

(Page

or

or

Lever

the

35)

FOOT

remove

Knife

Page

into

37).

Page

Guide

Presser

play,

met.

is

Screw

of

35).

gathering

stretching

Spring

Segment

Foot

Otherwise,

Driving

rotated

in

(1#36251

Page

on

other

length

be

necessary

STITCH

the

by

removal

on

bylooseningScrew

31).

Correct

Screw

CONTROL

differential

If

action

(1#36237

to

obtain

Intermediate

of a Presser

may

in

the

ADJUSTMENT

Presser

Retainer.

into

opening

33).

the

Presser

If

right

to

33),

and

is

then

Foot

yet

no

Re-check

Presser

to

Needle

Hook

left

If

raised,

must

the

Pointer

occurs,

occurs.

is

obtained.

H,

predetermined

be

controlled

indicator

Foot

to

and

(1#36251

The

Presser

Presser

Cylinder

set

Foot

secured

Brace

bind.

Footshouldnow

Lever

clockwise

Driving

B).

29)

should

Needles

is

altered

LENGTH

Adjustment

Arm

of

the

of