Page 1

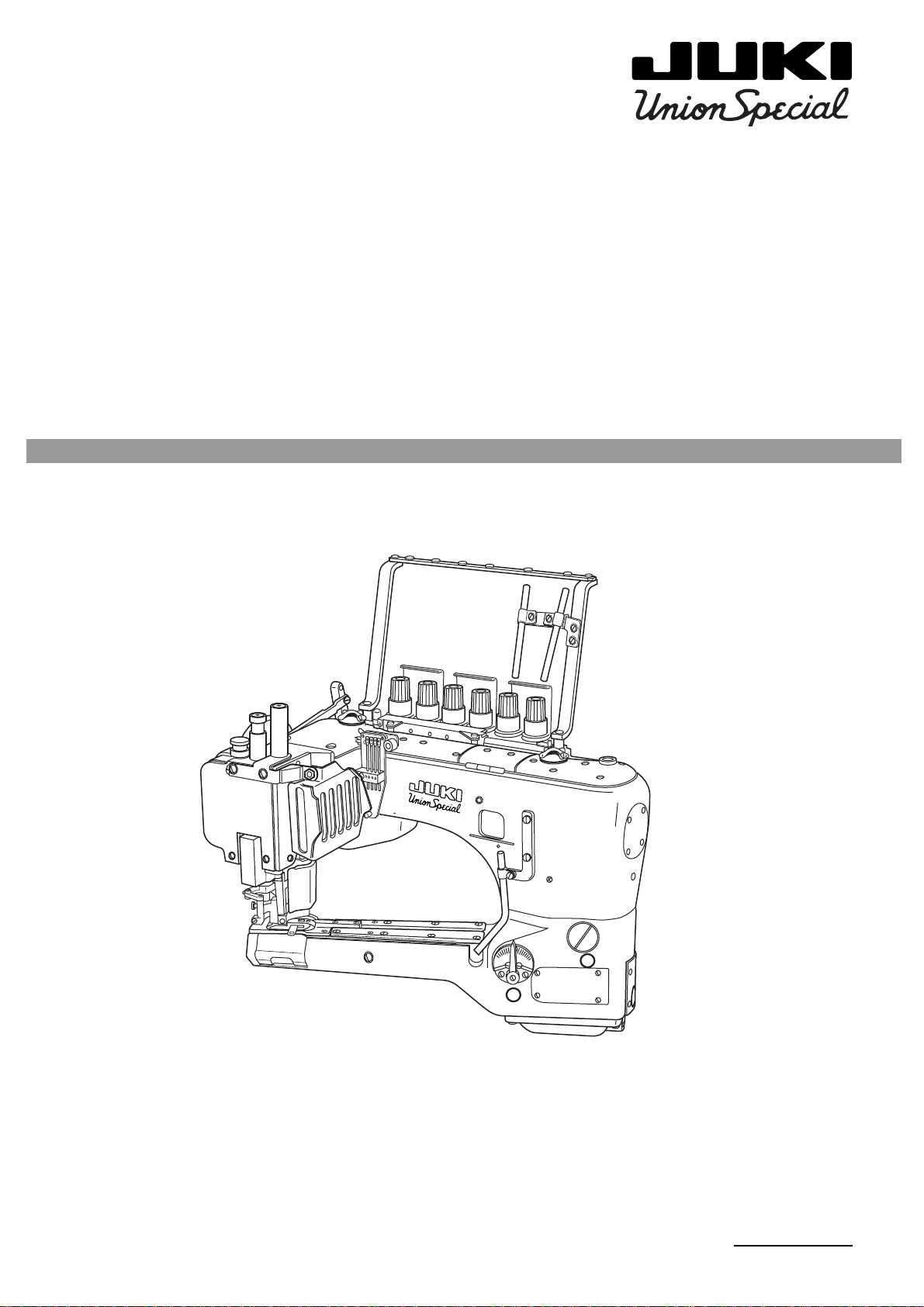

Feed-off-the-arm, 4-needle “Flatseamer” for

Top and Bottom Coverstitch

Minute-quantity

®

36200 Series

lubrication

ENGINEER’S MANUAL

40040898

No.E373-00

Page 2

Introduction

This Engineer’s Manual is written for the technical personnel who are responsible for the service and maintenance of the machine.

The maintenance services to be done on this sewing machine should be based on this manual.

This manual gives the "Standard Adjustment" on the former section under which the most basic adjustment

value is described and on the latter section the "Results of Improper Adjustment" under which stitching errors

and troubles arising from mechanical failures and "How To Adjust" are described.

Page 3

CONTENTS

1. Specifications ........................................................................................................ 1

2. List of models ........................................................................................................ 2

3. Model numbering system............................................................................ 3

4. Configuration.................................................................................................

(1) Head names .............................................................................................................................. 4

(2) Names of presser body ........................................................................................................... 5

5. Needles ......................................................................................................... 6

(1) Needle types ............................................................................................................................. 6

(2) Features of needles ................................................................................................................. 6

(3) Needle applications ................................................................................................................. 6

6. How to conduct threading........................................................................... 7

7. Standard adjustment .............................................................................................. 8

(1) Presser removal work...................................................................................................... 8

Adjusting the height of the needle bar......................................................................... 10

(2)

Adjustment of needle array ........................................................................................... 12

(3)

(4)

Right and left needle entry position adjustments ....................................................... 14

Looper adjustment ......................................................................................................... 16

(5)

1) Returning amount of the looper .........................................................................................................16

2) Adjustment of a clearance between looper and needle .....................................................................16

(6) Adjustment of looper and needle bar timing ..................................................................... 18

(7) Adjustment of looper movement......................................................................................... 20

(8) Adjustment of looper movement locus .............................................................................. 22

(9) Adjustment of the feed dog ................................................................................................. 24

(10)Adjustment of needle holder ............................................................................................... 26

1) Adjustment of rear needle holder.......................................................................................................26

2) Adjustment of forward movement needle holder ...............................................................................26

(11)Adjustment of feed mechanisms ........................................................................................ 28

1) Stitch length adjustment ....................................................................................................................28

2) Adjustment of differential feed amount ..............................................................................................28

(12)Adjustment of presser main body mounting ..................................................................... 30

(13)Adjustment of the presser main body proper .................................................................... 32

1) Adjustment of presser lifter connecting lever .....................................................................................32

2) Adjustment of presser lifting strap plunger ........................................................................................32

3) Adjustment of minute presser lifting...................................................................................................32

(14)Adjustment of top fancy looper and fancy thread carrier................................................. 34

1) Stroke position adjustment of drive sleeve ........................................................................................34

2) Amount of fancy thread carrier injection ............................................................................................34

3) Leftmost point of top fancy looper......................................................................................................36

4) Clearance developed at the time of crossing between the fancy thread carrier and

the tip of the top fancy looper ............................................................................................................36

5) Rightmost point of top fancy looper ...................................................................................................36

6) Height of top fancy looper ..................................................................................................................36

(15)Adjustment of top fancy cam and bobbin thread cam ...................................................... 38

1) Adjustment of top fancy cam .............................................................................................................38

2) Adjustment of bobbin thread cam ......................................................................................................38

4

Page 4

(16) Knife adjustment .................................................................................................................. 40

1) Lower knife adjustment ......................................................................................................................40

2) Upper knife adjustment ......................................................................................................................40

3) Pressure adjustment of upper knife ...................................................................................................40

(17) Adjustment of upper knife drive lever................................................................................ 42

(18) Adjustment of needle thread path ...................................................................................... 44

1) Adjustment of needle thread guide bar ..............................................................................................44

2) Adjustment of needle holder adjusting pin .........................................................................................44

3) Adjustment of needle thread presser spring ......................................................................................44

(19) Adjustment of tension disk rise and protection cover ..................................................... 46

1) Adjustment of tension disk rise ..........................................................................................................46

2) Adjustment of protection cover ..........................................................................................................46

(20) Adjustment of lapformer...................................................................................................... 48

8. Lubrication ........................................................................................................... 50

9. List of rear spring ................................................................................................ 51

(1) One side trim......................................................................................................................... 51

(2) Both side trim........................................................................................................................ 52

(3) Taping .................................................................................................................................... 53

(4) Step gauge ............................................................................................................................ 53

(5) Butted seam .......................................................................................................................... 53

10. Types of feed dogs.............................................................................................. 54

11. Maintenance......................................................................................................... 55

(1) Spare parts ............................................................................................................................. 55

12.Troubles and corrective measures............................................................56

13.

Table drawing ..............................................................................................68

(1) Auxiliary drive table.............................................................................................................. 68

(2) Auxiliary drive sub-table...................................................................................................... 69

Page 5

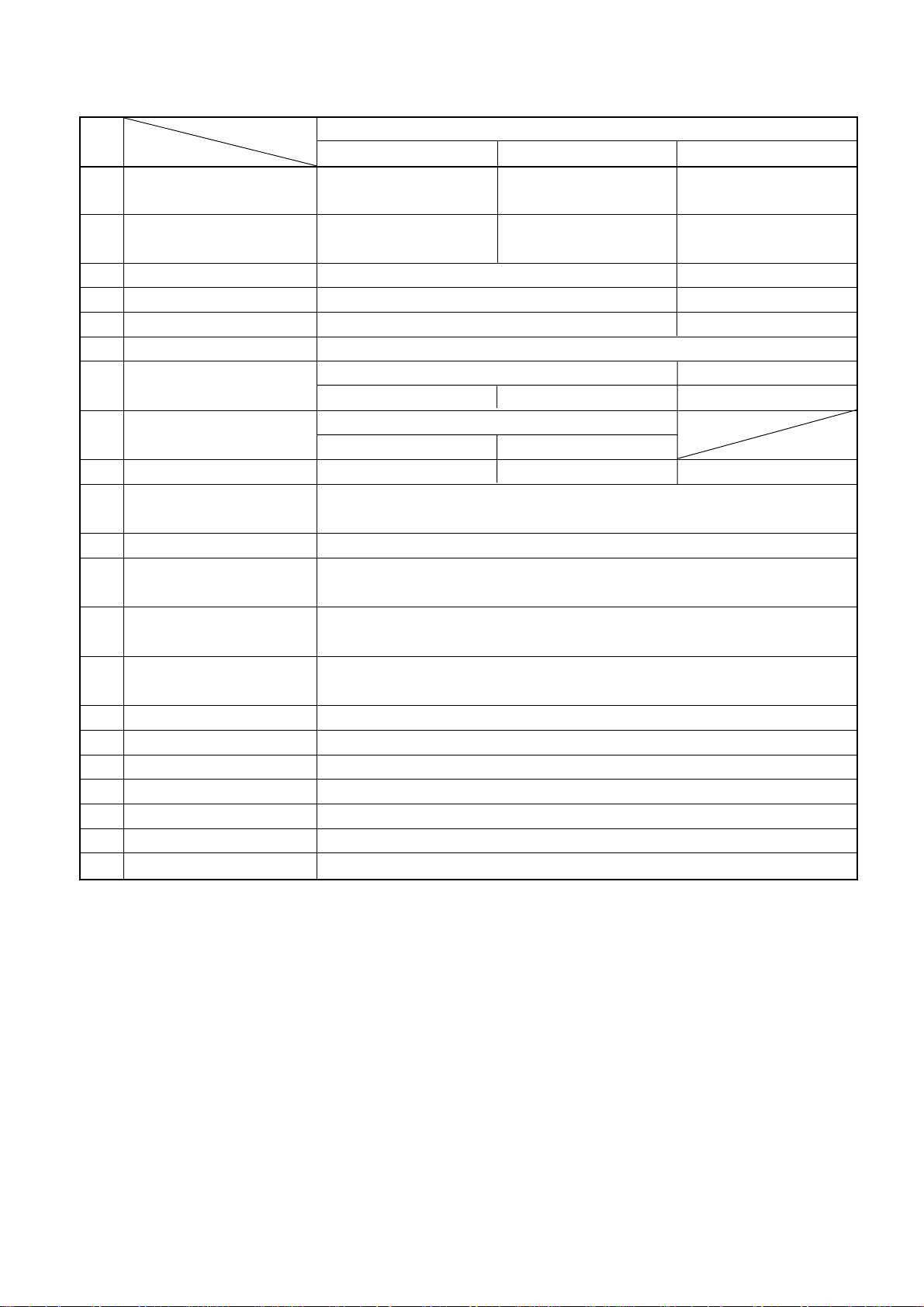

1. Specifications

No. Application

Item

1 Application Intended for taping

2 Sewing type

3 Max. sewing speed (normal) 4,200rpm (normal sewing speed: 3,200rpm) 4,200rpm (normal: 2,500rpm)

4 Stitch length 1.6 to 2.5mm (Standard 2.1mm)

5 Needle gauge 5.2mm, 6.0mm 6.0mm

6 Needle bar stroke 30mm

Needles to be used

7

(Standard needle count)

Retainer needles to be used

8

(Standard needle count)

9 No. of threads used 6 pcs. 5 pcs. 7 pcs.

10 Feed control system

11 Lubrication

12 Quantity of oil storage

13 Lubricating oil

14 Installation system

15 Lifting amount of presser One side trim type 8.0mm, both side trim type 6.0mm

16 Minute presser lifting Provided as standard

17 Needle thread silicone tank Provided as standard

18 External dimensions Height 31.5mm x Width 25.5mm x Depth 42.5mm

19 Weight of head 22kg

20 Working temperature/humidity Temperature : 5°C to 35°C, Humidity : 35% to 85% (no condensation)

21 Supply voltage/frequency Rated voltage ±10% 50 / 60Hz

Model name

36200L/36200U 36200T 36200L220

General light-weight -

medium-weight materials

4-needle both side trim

fancy sewing

UY118GKS065 to 080 (#9 to #12) UY116GKS065

* (Standard 70/ #10) (Standard 80/ #12) (Standard 65/ #9)

36211-060 to 075

* (Standard 65/ #9) (Standard 75/ #11)

Main feed ----- Slide type stitch pitch control system

Differential feed ------------Lever control system

Rotary pump type auto lubrication (minute-quantity lubrication to needle bar and looper sections)

Union Special Specification 175 (equivalent to ISO VG22) or

Table and Aux. Drive mounting system

4-needle one side trim

fancy sewing

Front oil storage: 70ml to 80ml

Rear oil storage: 60ml to 70ml

JUKI Oil SUP2000 – 1L

Pedestal mounting system

For light-weight (swimsuits)

materials

5-needle both side trim

fancy sewing

1.6 to 1.8mm (standard 1.6mm)

* For standard usage in Japan, the needle count is [Standard 65/#9]. The needle count for retainer needles is [Standard 60/

#8].

– 1 –

Page 6

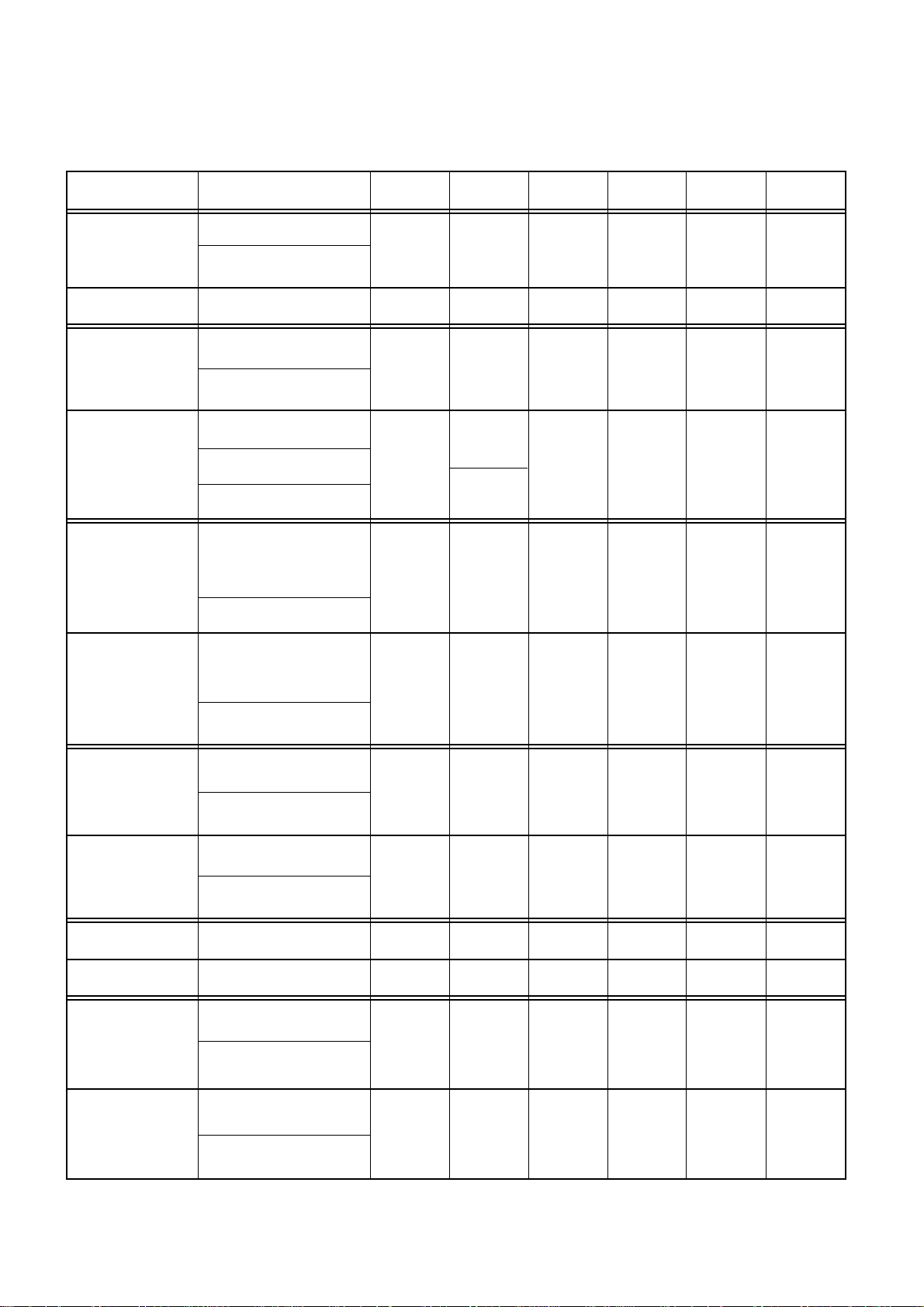

2. List of models

The standard models are the lapseamers with 4 needles and 6 threads for vertical fancy stitch.

According to the model names, they are classified into specifications for the specific gauges, step gauges, taping,

and multi-purpose.

Model name Application Top fancy Knife Lapformer

General knit goods

36200L100-52 4 1 6 With

Light- and medium-weight

materials

Number of

needle

Retainer

needle

Number of

threads

One side trim

Without

36200L100-60 General knit goods 4 1 6 With

General knit goods

36200L200-52 4 1 6 With

36200L200-60 4 6 With

36200L202-52 boxer's briefs, etc.) 4 1 6 With

36200L202-60 boxer's briefs, etc.) 4 1 6 With

Light- and medium-weight

materials

General knit goods

1

Light- and medium-weight

materials

Swimsuits 0

Specific gauges

(Thigh patch-up for

Medium-weight materials

Specific gauges

(Thigh patch-up for

Medium-weight materials

One side trim

Both side trim

Both side trim

Both side trim

Both side trim

Without

With

With

With

With

1.27mm step gauges

36200L210-52 4 1 6 With

36200L210-60 4 1 6 With

36200T300-52 Fly taping 4 1 5 Without

36200T300-60 Fly taping 4 1 5 Without

36200U300-52 4 1 6 With

36200U300-60 4 1 6 With

Medium- and heavy-

weight materials

1.27mm step gauges

Medium- and heavy-

weight materials

Multi-purpose

Light- and medium-weight

materials

Multi-purpose

Light- and medium-weight

materials

Both side trim

Both side trim

One side trim

One side trim

Combined use Combined use

Combined use Combined use

With

With

Without

Without

(Caution) The list shows the models exclusive for 4 needles. It does not include the models for 5 needles.

– 2 –

Page 7

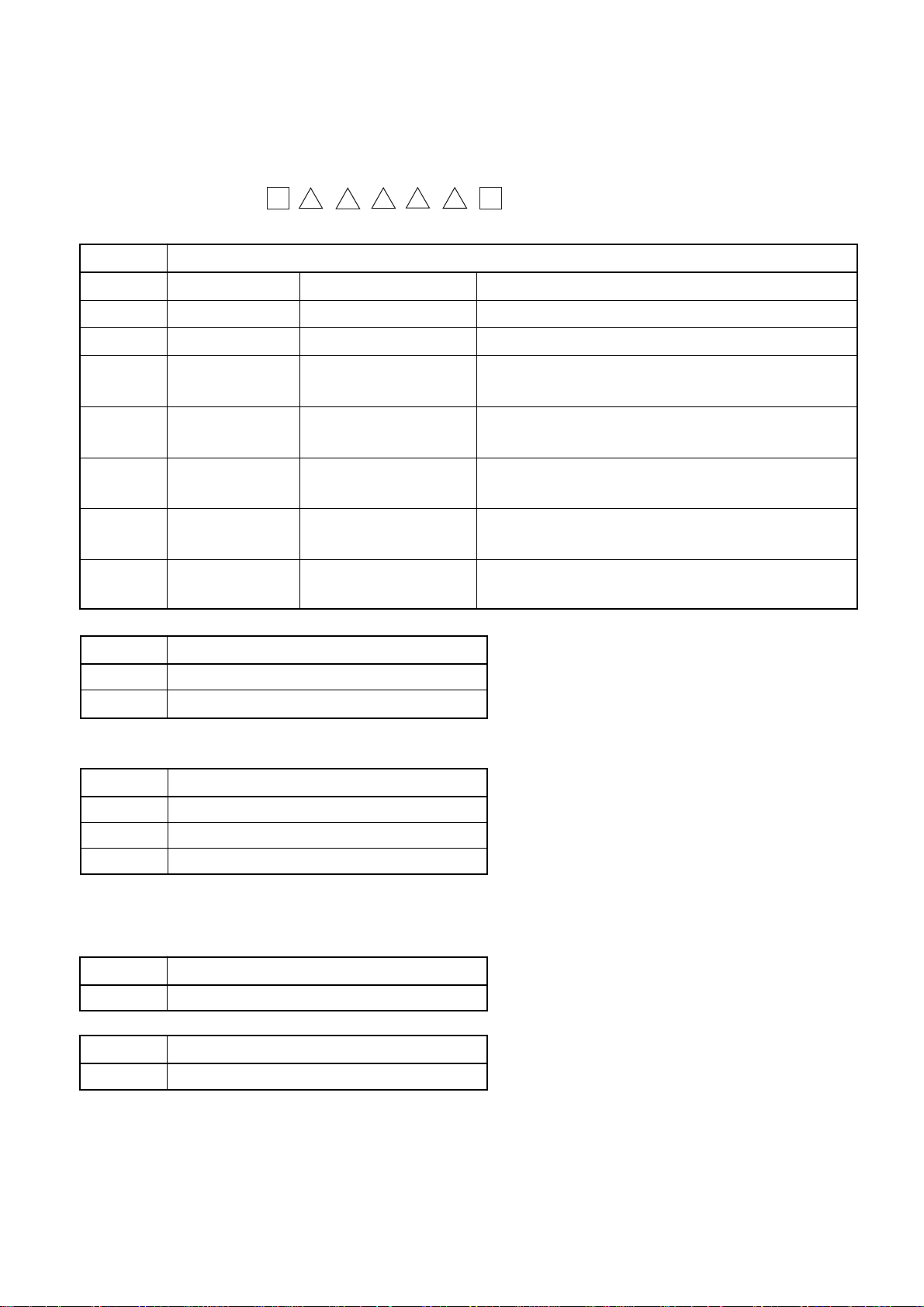

3. Model numbering system

Name: Feed-off-the-arm 4-needle “Flatseamer” for Top and Bottom Coverstitch

123456789101112131415

36200 —AA

6 to 9 Head specifications

Code Specifications Cloth cutting Applications

L100 Lapseam One side trim With edge guide spreader

L200 Lapseam Both side trim With lapformer spreader

L202 Lapseam Both side trim Specific both side trim gauge lapformer

With spreader

L210 Lapseam Both side trim

L220 Lapseam Both side trim Specific 5-needle presser, lapformer

T300 Taping Combined use for one side Without spreader, tape reel

and both side trim With tape folder

U300 Multi-purpose Multi-purpose specifications

10 to 11 Needle gauge

52 5.2mm

60 6.0mm

* Head spec. L220 applicable to 60 (6.0mm) only

12 Region

J Japan

N North America, Europe

S Asia

Combined use for one side

and both side trim

Both side trim 1.27mm, step presser, throat plate, feed dog

With lapformer spreader

With spreader (for swimsuits)

* Head spec. L100 only, Impossible to select J

J (for Japan) of L100 covered by S

14 Place pf destonation

A Standard

15 Accessories type

A Standard

– 3 –

Page 8

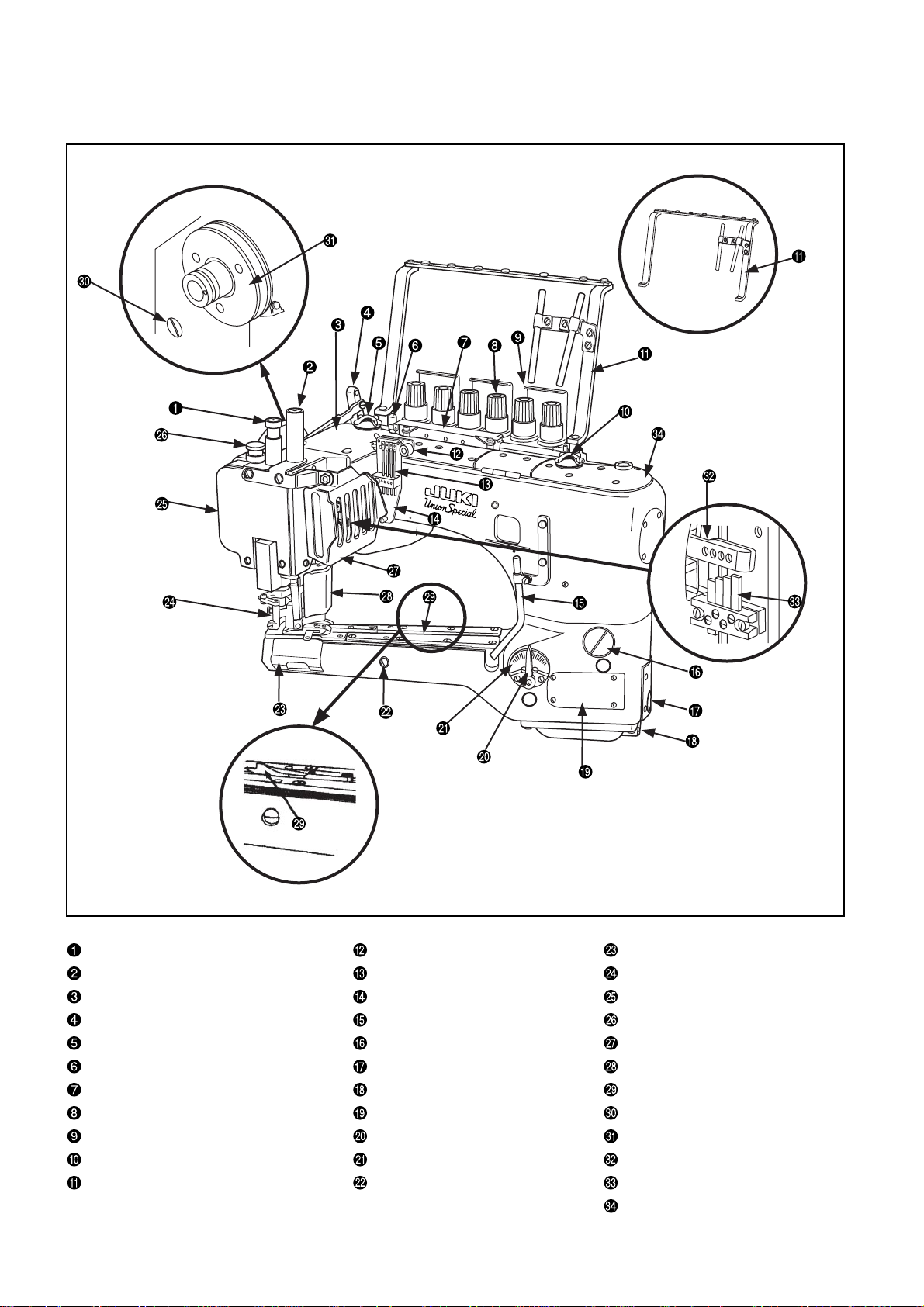

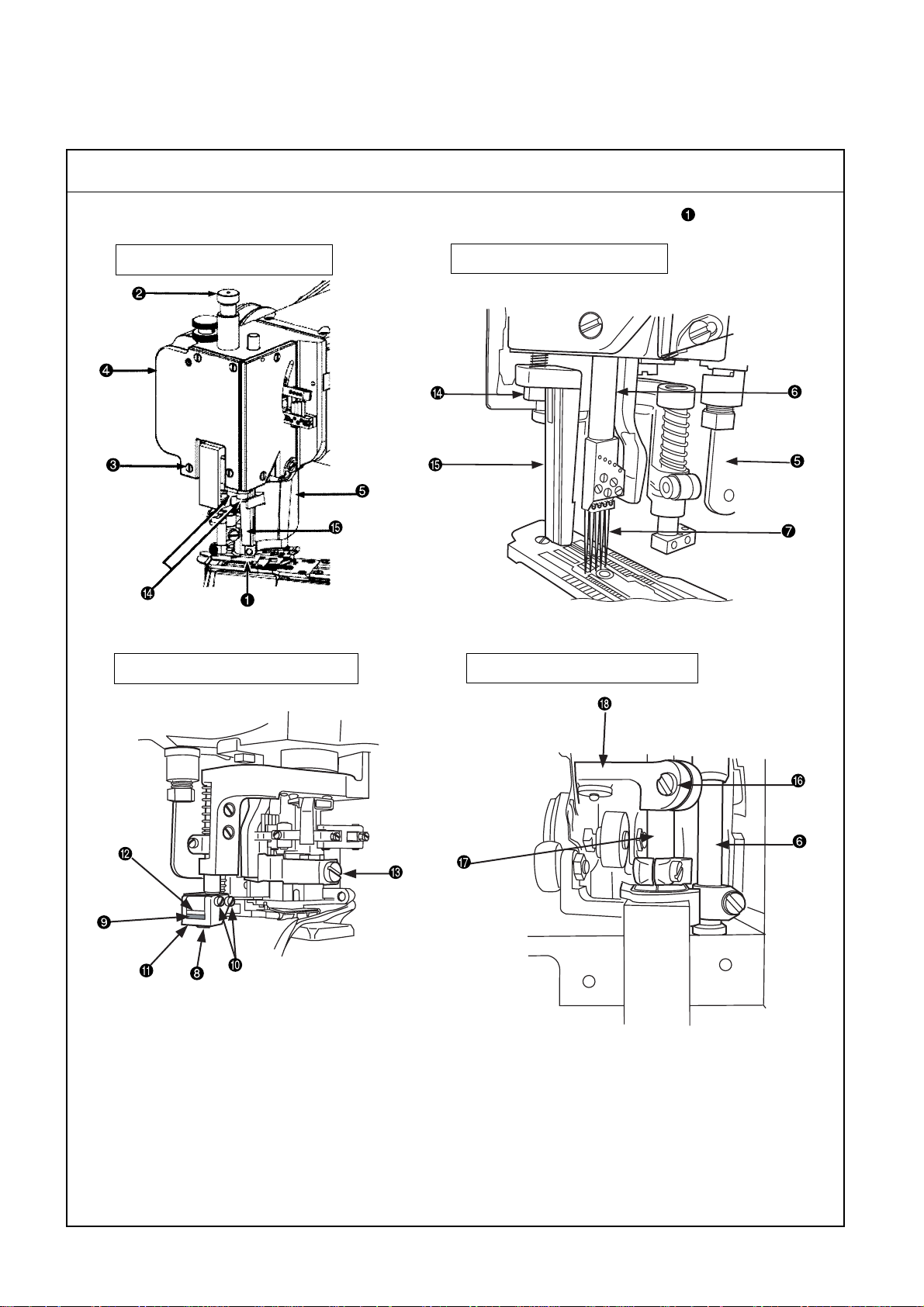

4. Configuration

(1) Head names

Presser pressure stroke adjusting screw Frame needle thread path Looper cover

Needle bar guard Needle thread guide bar Presser

Rear top cover Thread path frame Face cover

Lift lever Looper thread guide Minute presser lifting

Oil circulator check window (rear) Stitch length control window screw Swing guard

Oil gauge (rear) Oil gauge (front) Protection cover

Needle thread silicone unit Oil drain screw (front) Lapformer

Thread tension knob Cylinder side cover Oil drain screw (rear)

Thread guide Differential adjusting lever Pulley

Oil circulator check window (front) Scale plate feed Needle thread rocking guide

Threading guard (Assy) Feed dog eccentric pin Needle thread holder adjusting pin

– 4 –

Front top cover

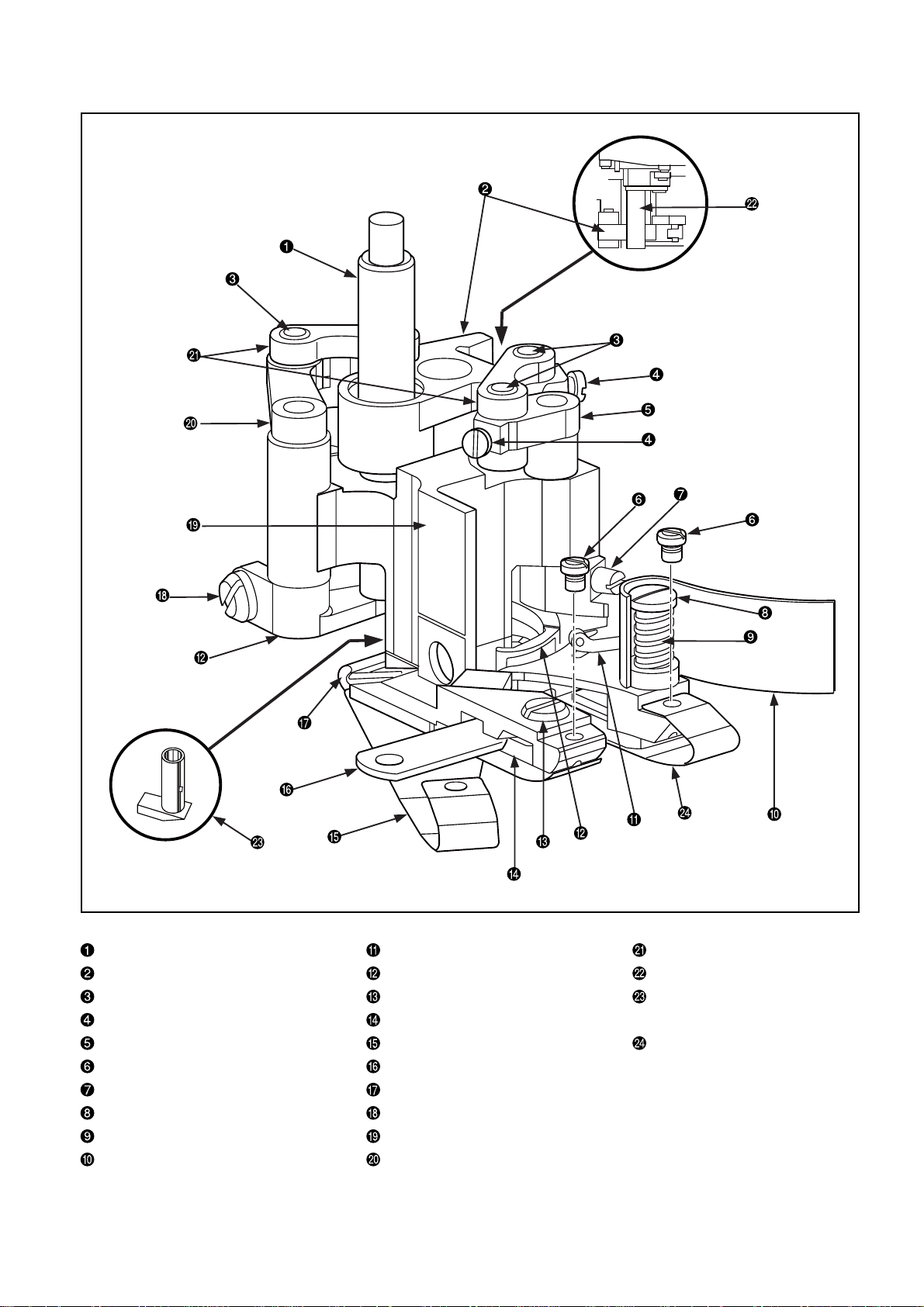

Page 9

(2) Names of presser body

Presser bar Fancy thread carrier Drive lever link

Drive link Top fancy looper Drive sleeve

Link pin Lower knife clamp setscrew Minor presser (Minor presser

Link pin setscrew Lower knife clamp for stepped materials)

Drive lever shaft (carrier) Rear spring, left Rear spring, right

Rear spring setscrew Lower knife

Fancy thread carrier setscrew Rear spring hanger wire

Thread chips guard setscrew Fancy looper setscrew

Spring Presser main body

Thread chips guard Drive lever shaft (looper)

– 5 –

Page 10

5. Needles

(1) Needle types

UNION standard accessory needle GROZ-BECKERT/UY118GKS 070/#10

No. Needle symbol Thread groove Scoop Strength Thread available for sewing

1

2

3

4

UY118GKS With Weak

UY118GAS Without Strong Spun thread

UY118GBS Front only With Weak Wooly thread

36211

Presence of front Spun thread, wooly thread,

and rea Tetoron thread, cotton thread

Presence of front

and rear

(2) Features of needles

No. Features

The front and rear sides of a needle have thread grooves. It is somewhat more difficult to obtain an

adequate tension for the needle thread, compared with the 118GAS.

1

Since there is a scoop behind the needle, the effect of prevention against stitch skipping can be

expected even for a thread that is inefficient in making loops.

There are thread grooves provided to both the front and rear sides of a needle. The needle thread

tension tends to be increased.

Since no scoop is provided to rear side of the needle, needle bend is minimum at the time of

2

needle entry into the materials. This type of needle is suitable for the products of heavy-weight

materials or those that involve thick sections in materials. (General knit goods, etc.)

Since no scoop is provided, it is not suitable for applications to wooly or Tetoron threads.

Since no thread grooves are provided to the rear side of a needle, the needle thread tension tends to

be decreased. Since there is no thread groove and a scoop is provided to the rear side of the needle,

3

the needle thread can produce loops easily and therefore this type of needle is suitable for applications to wooly threads or the like.

4

If a retainer needle (sacrifice needle) is used, softer switches can be obtained.

(3) Needle applications

No. Applications

1

Used for the products of knit goods and swimsuits.

2

Used for general knit products.

3

Used for ladies’ shorts, girdles, etc., made of stretchy textiles.

4

Used for general products of knit products.

(Caution) Standard needles used in Japan are of UY118GKS•GAS, 065 (#9).

– 6 –

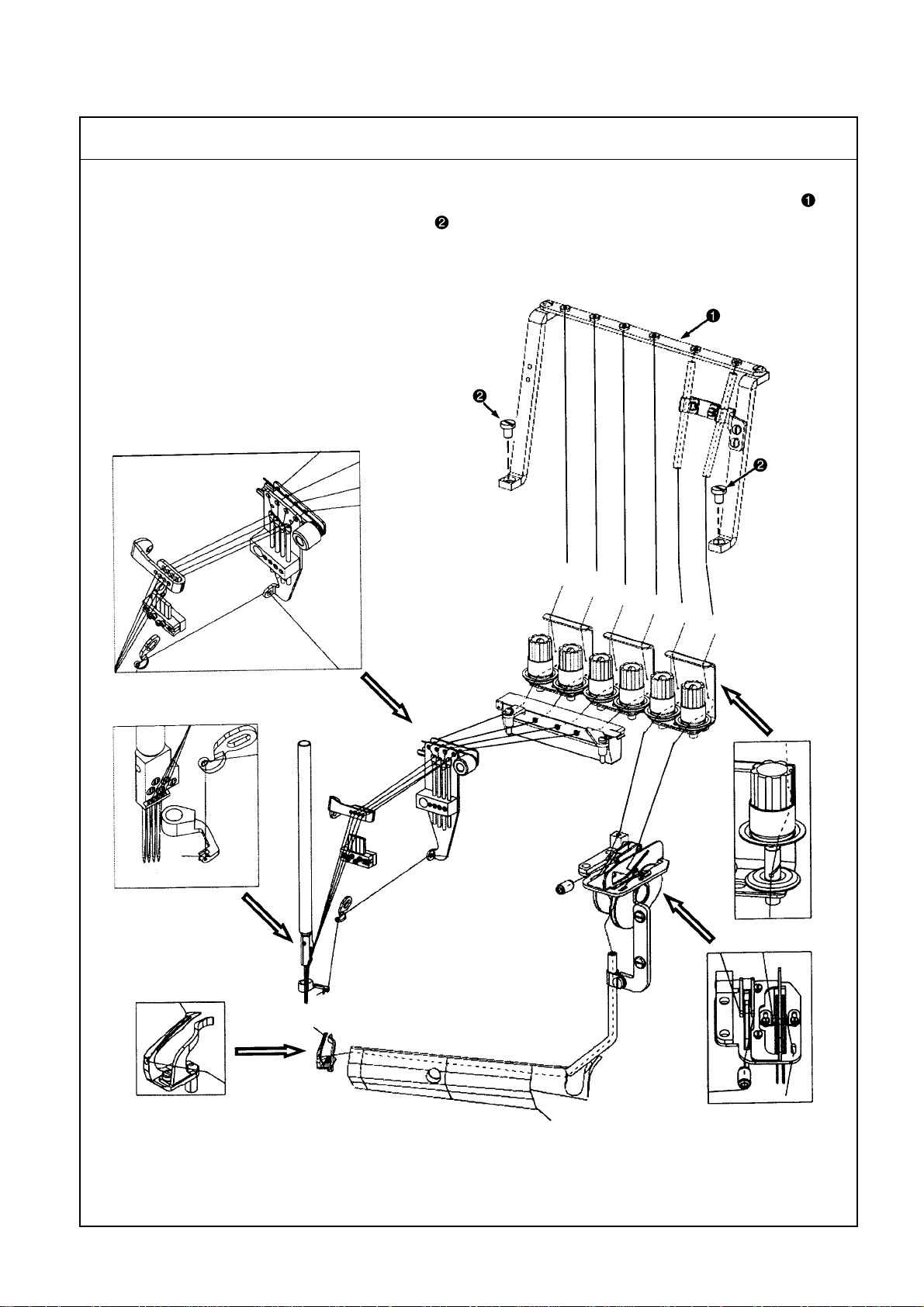

Page 11

6. How to conduct threading

How to make threading for the needle threads and the top and bottom fancy threads

Threading illustration and threading guard setup

1. When you want to use the flatseamer machine head, you have to mount the threading guard (Assy) .

It can be mounted by means of two setscrews (2 pcs.).

2. 1 to 4 correspond to the needle thread, 5 to the top fancy thread, and 6 to the bottom fancy thread.

Make threading according to the threading illustration.

4

3

2

1

4

3

2

1

5

6

5

5

4

1

2 3

56

6

– 7 –

Page 12

7. Standard adjustment

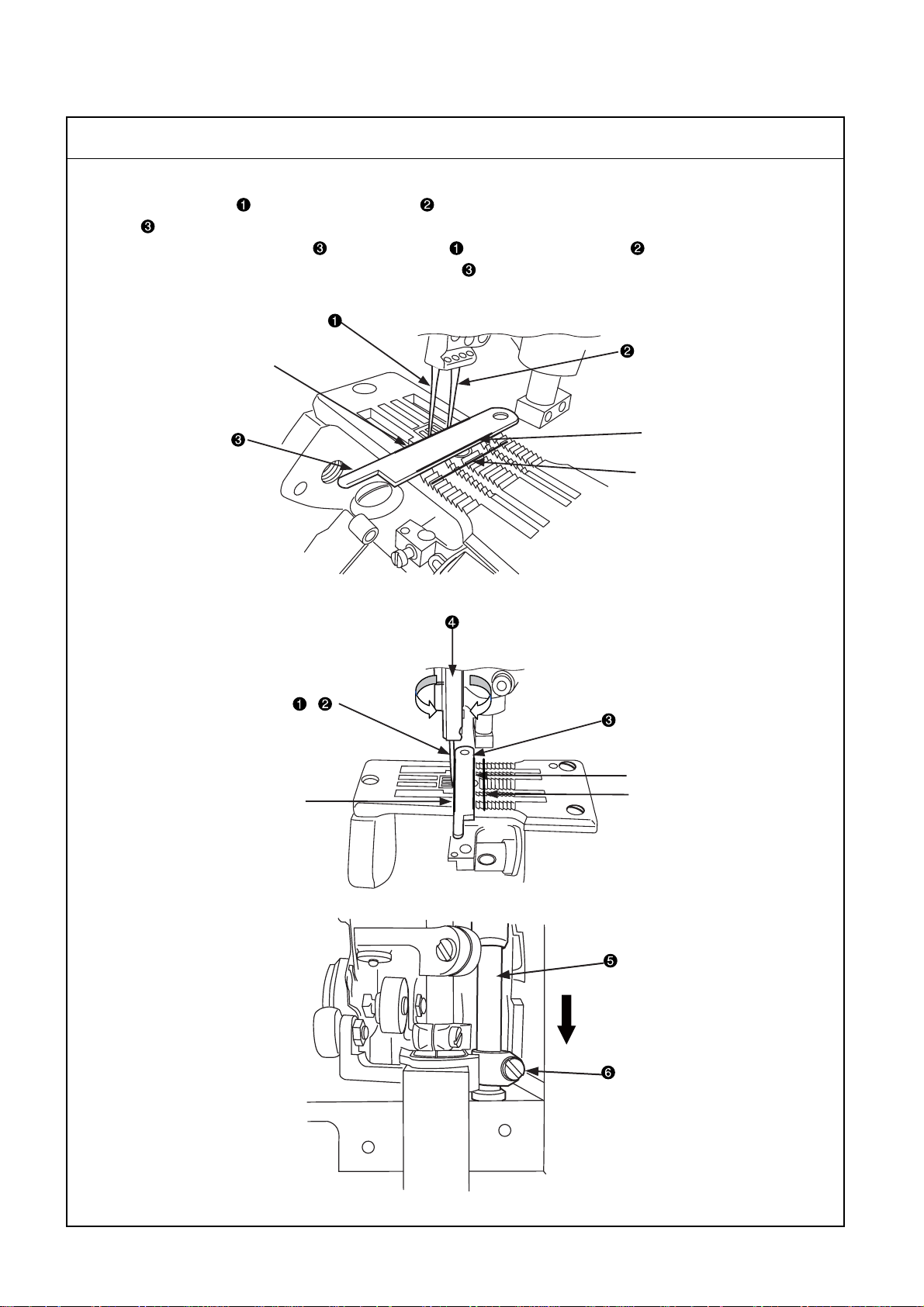

(1) Presser removal work

Procedures of assembling

1. To make the standard adjustments of the flatseamer, remove the presser main body first of all.

Main body assembly diagram

Rear side of the presser main body

State of the presser removed

State of the face cover removed

– 8 –

Page 13

Procedures of assembling

Disassembly procedures for the presser main body

1. Loosen the setscrews (4 pcs.) and take out the face cover .

2. Open the protection cover and take out the needles (5 pcs.) with the needle bars positioned at

the upper dead point.

3. Loosen the upper knife fixing screw (key wrench of 3/8) and remove the upper knife .

4. Loosen the setscrews (2 pcs.) and take out the upper knife fixing block and the upper knife auxiliary

plate .

5. Loosen the presser bar setscrew .

6. Loosen the presser guide left setscrews (key wrench of 5/32) (2 pcs.) and remove the presser guide

left setscrews on the operator side. Make the presser guide left free.

7. Remove the presser pressure adjusting screw and the pressing screw.

8. Loosen the presser bar guide setscrew and remove the presser bar guide and the presser bar

while the presser bar is pulled out upwards.

9. Remove the presser main body .

– 9 –

Page 14

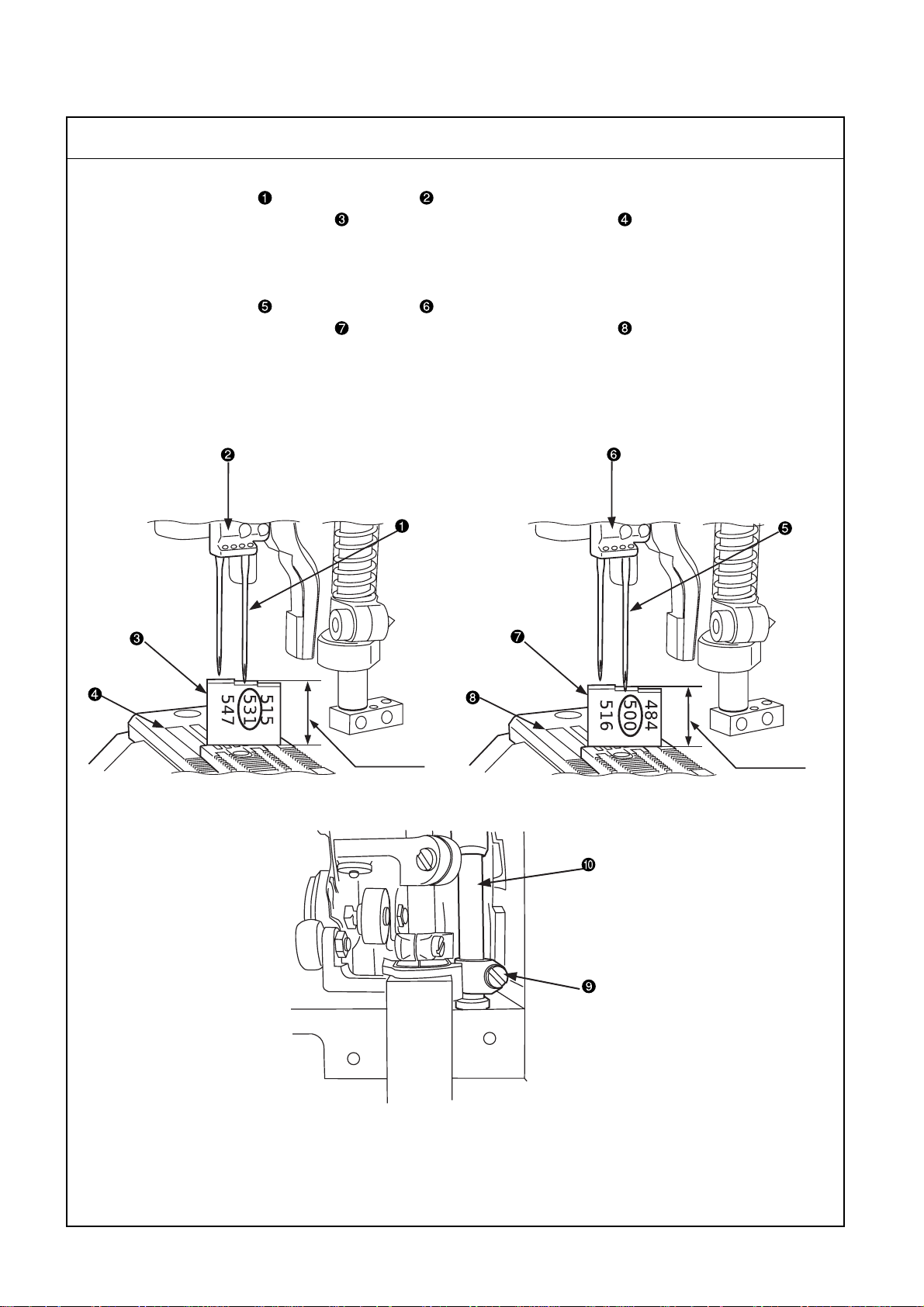

(2) Adjusting the height of the needle bar

Standard Adjustment

o For a needle gauge of 5.2mm

Mount the right needle on the needle clamp with the needle bar positioned at the upper dead point and

put the needle bar height gauge on the upper face of the throat plate . Check this condition in the

position of 531. The standard needle bar height is 13.5mm.

Use the needle bar height gauge (21227BU).

o For a needle gauge of 6.0mm

Mount the right needle on the needle clamp with the needle bar positioned at the upper dead point and

put the needle bar height gauge on the upper face of the throat plate . Check this condition in the

position of 500. The standard needle bar height is 12.7mm.

Use the needle bar height gauge (21227DS).

Needle gauge : 5.2mm

13.5mm

Needle gauge : 6.0mm

12.7mm

– 10 –

Page 15

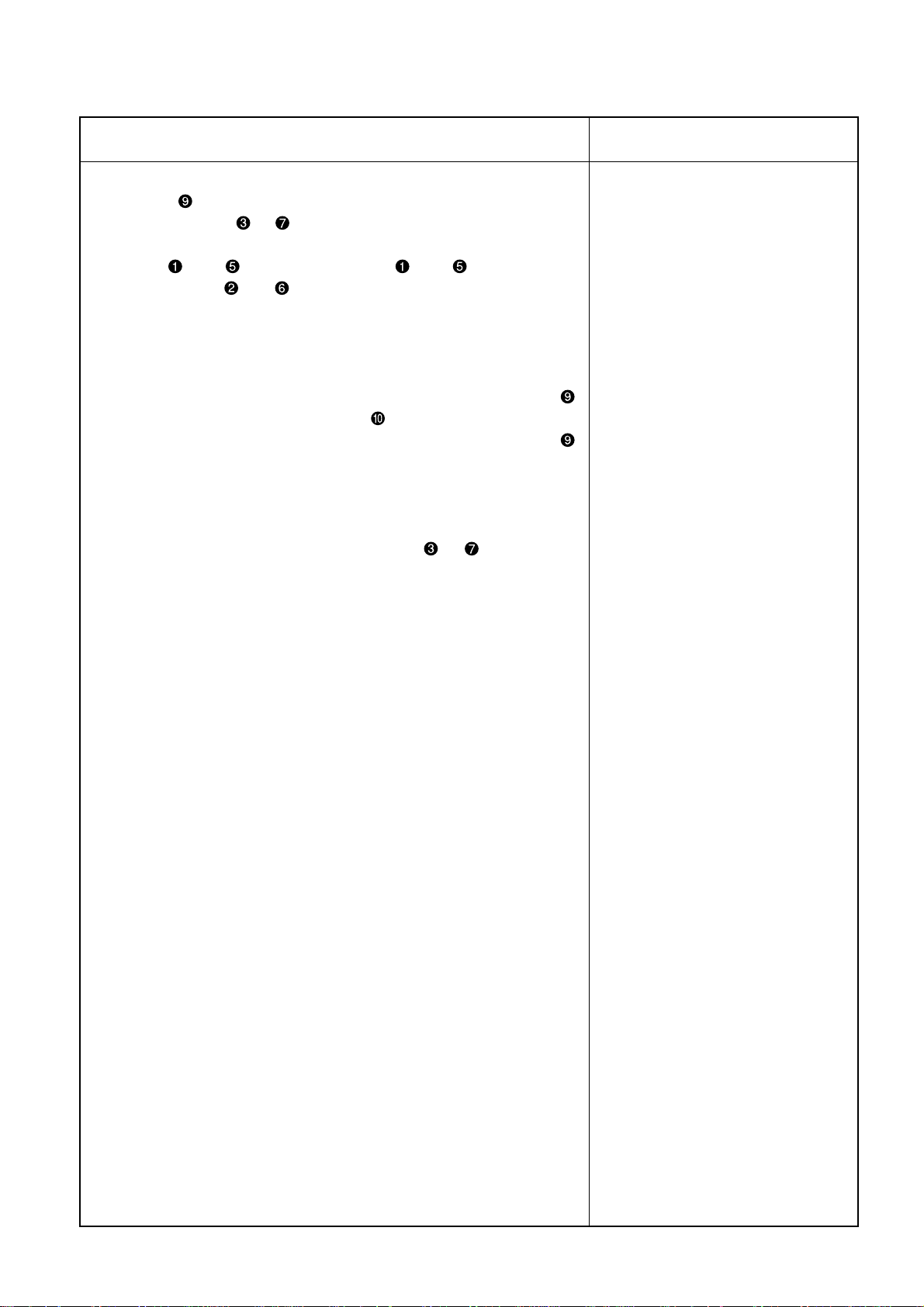

Adjustment Procedures Results of Improper Adjustment

1. Remove the face cover and loosen the needle bar connecting bracket

setscrew to adjust the needle bar height by the means of the needle

bar height gauge or .

(Caution) When checking the needle bar height, change the needles

and , enter the needles and in the needle

clamps and to their uppermost ends, and stop them

in the correct positions. The needle shank has a flat section. Stop the needle with the flat section positioned in

front.

2. After the adjustment of the needle bar height, adjustment of the needle

array is carried out subsequently . Temporarily fasten the setscrew

of the needle bar connecting bracket .

(Caution) 1. When the needle bar connecting bracket setscrew

is fastened temporarily , the needle bar is required not

to come down even when it is rotated.

2. If the needle bar height is changed for a certain reason, readjustment is needed from the beginning, using the needle bar height gauge or .

When the needle bar height is

greatly different

o This will be a cause of stitch skip-

ping, needle breakage, or thread

breakage.

– 11 –

Page 16

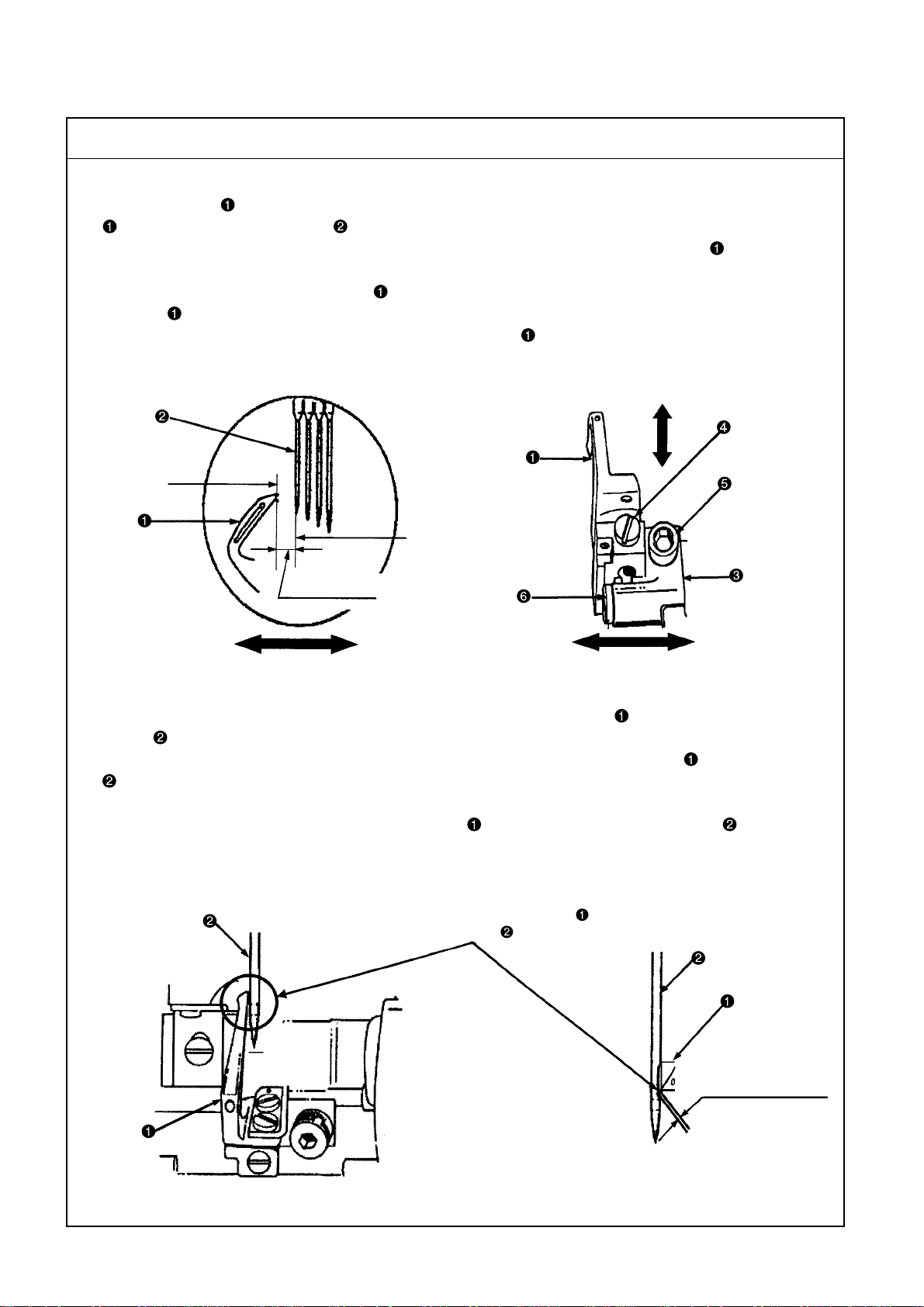

(3) Adjustment of needle array

Standard Adjustment

1. Needle array

Use the left needle and the retainer needle , and check the needle array based on Line A of the upper

knife .

Apply Line A of the upper knife to the left needle and the retainer needle on both sides. In this state,

the standard angle is that Line B of the upper knife is observed in parallel to Line C of the throat plate

groove.

A line

B line

C line

Right and left revolving

,

A line

B line

C line

– 12 –

Page 17

Adjustment Procedures Results of Improper Adjustment

Method of needle array check

1. Checks on the needle array parallelism are carried out after the

completion of needle bar height adjustments.

2. When checking the needle array parallelism, the needle bar is

lowered to the midpoint under the condition that no looper is attached.

3. Make Line A of the upper knife come in contact with the left needle

and the retainer needle on both sides. In this state, check the

parallelism between Line B of the upper knife and Line C of the

throat plate groove.

4. If no parallelism is secured, insert a spanner (7mm/9/32) in the needle

clamp and try to secure the needle array parallelism by turning

the needle bar to the right and left.

(Caution) If checking is intended without the dislodgment of the

looper, do it in the position where the left needle and

the retainer needle do not come in contact with the

rear side of the looper.

5. After the confirmation of parallelism, check the needle bar height

again and fix the needle bar connecting bracket setscrew .

When the needle parallelism is not

secured

o This will be a cause of stitch skip-

ping, needle breakage, thread

breakage, or destruction of throat

plate claws.

– 13 –

Page 18

(4) Right and left needle entry position adjustments

Standard Adjustment

1. Needle entry

Attach the needles (4 pcs.) and the retainer needle , and check the right and left needle entry spaces

in regard to the throat plate claws .

Examine the position where the left space becomes wider by 0.15mm than the right space. In this state, the

standard position is that the needles (4 pcs.) and the retainer needle (1 pc.), five needles in all, do not

touch the right and left throat plate claws .

Left space wider by

0.15mm

Right and left revolving directions

Right space

Left middle needle

regarded as the basis

Throat

plate

Left direction

– 14 –

Right direction

Page 19

Adjustment Procedures Results of Improper Adjustment

Needle entry adjusting positions

1. When adjusting the right and left needle entry, remove the front top

cover and the oil receiver.

2. Loosen the collar setscrew and move the collar toward the

front.

3. Loosen the hexagon coupling bolt and insert a screwdriver in the

eccentric pin . When the screwdriver is turned to the right and left,

the cylinder arm moves to the right and left.

4. Confirm the result of needle entry position adjustments.

5. After adjustments, tighten the hexagon coupling bolt to return the

collar to its initial position. Since then, tighten the collar setscrew

.

Method of confirmation

oTurning the eccentric pin to the right causes the cylinder arm

to move to the left.

oTurning the eccentric pin to the left causes the cylinder arm to

move to the right.

When the needle parallelism is not

secured

o This will be a cause of stitch skip-

ping, needle breakage, thread

breakage, or destruction of throat

plate claws as a result of getting flaws.

– 15 –

Page 20

(5) Looper adjustment

Standard Adjustment

1) Returning amount of the looper When the looper is positioned at the leftmost point, adjust the distance to 4mm from the tip of the looper

to the center of the left needle .

The amount of standard looper return is 4mm. However, the amount of return of the looper may somewhat

change according to the type of thread.

The final amount of return of the looper should be determined by making fine adjustments of the amount

of looper return while making threading and observing the stitches of trial sewing.

4mm shall be regarded as the amount of return of the looper during adjustments.

Right and left directions

Tip

Center

4mm (5/32)

Right and left directions

Forward and backward directions

2) Adjustment of a clearance between looper and needle The standard clearance is 0.0mm (light contact) when the tip of the looper reaches the center of the left needle . After rear needle holder adjustments, check the clearance again between the looper and the left needle

. For the final adjustment, this check should be carried out after making threading.

(Caution) 1. If no rear needle holder is provided, the above-mentioned checks should be carried out

in the state that the tip of the looper slightly touches the left needle .

2. The needles to be used come in two types; with a scoop (118GKS) and without a scoop

(118GAS).

Clearance between the looper

and the left needle

– 16 –

0.0mm

(Light contact)

Page 21

Adjustment Procedures Results of Improper Adjustment

1) Returning amount of the looper

1. Mount the looper on the looper base and fasten it with the

setscrew .

2. Loosen the looper base setscrew and move the looper base to

the right or left for adjustments.

3. After adjustments, tighten the looper base setscrew .

(Caution) When making adjustments by moving the looper base

to the right or left, the forward and backward positioning of the looper base is also changed.

During the right-left adjustment of the looper base ,

make adjustments of "7.-(5)-2), Adjustment of clearance

between looper and needle" simultaneously by means

of the setscrew .

When the amount of looper return,

changing with the type of thread, is

too much

oTightness of stitches becomes

worse for the left needle thread

and the stitches of thread tension

are degraded.

When the amount of return is small

o This can be a cause of stitch skip-

ping when the looper is re-

treated.

o The needle thread, second from

the right needle, is delayed from

the looper and it comes out si-

multaneously with the right needle

thread. Thus, the stitches of thread

tension are degraded.

o This is a cause of second stitch

skipping as seen from the left

needle .

2) Adjustment of a clearance between looper and needle

1. Loosen the looper base setscrew and turn the setscrew to

adjust the looper base by moving it forward and backward.

2. After adjustments, tighten the looper base setscrew .

o When the looper base is moved to the left, the tip of the looper

is separated from the left needle .

o When the looper base is moved to the right, the tip of the looper

comes in contact with the left needle .

(Caution) After the completion of adjustments in accordance with

"7.-(6) Adjustment of looper and needle bar timing" and

"7.-(7), 7.-(8) Adjustment of looper movement and motion locus", make readjustments, without fail, according

to "2) Adjustment of a clearance between looper and

needle".

– 17 –

Page 22

(6) Adjustment of looper and needle bar timing

Standard Adjustment

1. Looper and needle bar timing (synchronization)

Synchronization is adjusted after mounting the respective gauge parts. Turn the pulley in the forward direction and adjust the tip of the synchro-gauge rod to the graduation after the needle bar has been

stopped. The standard position is defined when the pulley is turned in the reverse direction and the tip of the

synchro-gauge rod stops at the same graduation for forward pulley rotation after the needle bar has

been stopped.

(Caution) When the pulley is turned in the forward/reverse direction, the standard value is defined if

the obtained figure is different by less than 1 from the graduation of the tip of the synchrogauge rod .

Tip of the synchrogauge rod

Reverse movement

US gauge Part No. 21227CG

Forward movement

Graduation

Thickness:

4mm

(Caution) Installation of the gauge indicated in

the above drawing falls on the new

36200L type. In regard to the installation of the gauge for the former type

36200, installation of the needle bar

torque tool is not required.

Right and left revolving

directions

Forward and backward

directions

(Caution) The main shaft coupling front and rear, and , are provided

with the fitting mark . Gauge check should be carried out after

making adjustments to the fitting mark .

– 18 –

Page 23

Adjustment Procedures Results of Improper Adjustment

How to mount and use the synchro-adjust gauge

1. Attach the needle bar torque tool to top of the needle bar and

tighten the setscrew . Then, move the needle bar to the lower

dead point.

2. Mount the gauge base on the presser pressure adjusting spring

and fix the needle bar height adjusting screw just above the

needle bar .

3. Insert the 4mm-thick portion of the synchro-gauge base in between the needle bar and the needle bar height adjusting screw

. Turn the needle bar height adjusting screw until it comes in

contact with the synchro-gauge base . In the state that a dimension (thickness) of 4mm is maintained, tighten and fix the needle bar

height adjusting nut .

4. Remove the synchro-gauge base and mount it on the looper .

Tighten the setscrew . When the pulley is turned in forward direction, the needle bar rises by 4mm and stops there. At this time,

adjust the tip of the synchro-gauge rod to the specified graduation position. (Within the scale range)

5. When the pulley is turned in reverse direction, the needle bar

rises, lowers, and stops. Confirm the graduation position of the tip of

the synchro-gauge rod . If there is any deviation by more than 1

from the graduation position in forward revolution, adjust the main

shaft coupling front and rear, and , respectively.

oIncorrect synchro-gauge position-

ing may cause stitch skipping.

Adjusting positions and method of adjustment

To make timing adjustments for the looper and the needle bar ,

remove the rear top cover and loosen three nuts of the main shaft

coupling front and rear, and , respectively. In the state that the

main shaft coupling rear is held, move the main shaft coupling front

to the right and left to adjust it.

(Spanner 1/4 inches for the nut )

oTurning the main shaft coupling front to the right causes the tip of

the synchro-gauge rod to go backward.

oTurning the main shaft coupling front to the left causes the tip of

the synchro-gauge rod to go forward.

(Caution) To move the main shaft coupling front , temporarily

fasten a nut that is located near the fitting mark during adjustment. If the nut is not fastened temporarily,

position of the tip of the synchro-gauge rod cannot

be made stable.

– 19 –

Page 24

(7) Adjustment of looper movement

Standard Adjustment

1. Looper movement

The looper movement is regarded as 0° at the rightmost point. When the pulley is turned in forward direction, the tip of the point gauge moves to the fan-shaped gauge in the direction of the arrow. In this

state, the standard value of 55° 40’ is obtained when the tip of the point gauge reaches the leftmost point.

Tip of the point gauge

0

°

° 40’

55° 40’

54

55° 40’

56

° 40’

Right and left directions

US gauge Part No. 21227CN

2. Looper movement gauge

Since the point gauge and the fan-shaped gauge are used to obtain a correct value of looper movement, the indicated looper movement must be checked each time the head section is adjusted.

0

°

40’

°

54

55° 40’

55° 40’

56

° 40’

Left direction

Right direction

(Caution) Check the point gauge and the

fan-shaped gauge at the time of

looper lot replacement.

– 20 –

Page 25

Adjustment Procedures Results of Improper Adjustment

How to mount and use the gauge

1. Loosen the setscrew and take out the spring stud . Loosen the

cover setscrew and take out the looper cover .

2. With the looper movement at the leftmost point, fix the point gauge

by means of the setscrew in the position where the front needle

holder of the looper is installed. Turn the pulley in forward direction toward the rightmost point.

3. Install the fan-shaped gauge where the spring stud has been

dislodged. At that time, the tip of the point gauge should be adjusted to Position 0∞of the fan-shaped gauge before tightening

the setscrew .

4. Turn the pulley further in forward direction and stop it where the looper

movement falls on the leftmost point. Check the position where the

tip of the point gauge stops at 55° 40’.

5. If the tip of the point gauge seems to stop on the right or left from

the standard position, the following adjustments should be carried

out.

o If the looper movement deviates

from the specified range, this will

cause failure in securing the correct tightness of stitches or stitch

skipping.

Adjusting positions and method of adjustment

To adjust the looper movement, remove the front top cover, loosen the

nut , and turn the changing screw to the right or left.

oTurning the changing screw to the right causes the looper move-

ment to decrease.

oTurning the changing screw to the left causes the looper move-

ment to increase.

(Caution) 1. When loosening the nut , it should be turned to the

right. (Reverse turn nut)

2. At the time of looper movement adjustments, temporarily fasten the nut and confirm the positions of

the fan-shaped gauge and the point gauge .

If the nut is not fastened temporarily for this check,

position of the looper movement may change.

– 21 –

Page 26

(8) Adjustment of looper movement locus

Standard Adjustment

1. Turn the pulley in forward direction and mount the avoid gauge when the looper shaft stays in the

extremely retreated position. At that time, confirm that the face of the plunger has coincided with that of

the avoid gauge . Turn the pulley further in forward direction to move the looper shaft forward. At the

same time, the plunger also moves forward.

When the looper shaft stays in the extremely advanced position, check whether the standard dimension

of 2.4mm has been secured in the position where the plunger is protruded extremely.

2.4mm

Looper shaft extremely advanced

Avoid gauge

Looper shaft extremely retreated

and plunger positioned in the same face

2. When the looper avoid gauge is not used

When the standard looper is installed and it is moved from the right to the left, the standard condition can

be attained when the tip of the right needle touches the point apart by 1/3 - 1/4 from the rear bottom face of

the standard looper .

(Caution) When the avoid gauge is not used, the looper locus cannot be checked unless the

presser, the throat plate, and the feed dog are dislodged.

Right needle

1/3 to 1/4

Left direction

Right direction

Top direction

Down direction

– 22 –

Page 27

Adjustment Procedures Results of Improper Adjustment

How to mount and use the gauge

1. Loosen the setscrew and take out the spring stud . Loosen the

cover setscrew and take out the looper cover .

2. Turn the pulley in forward direction and move the looper shaft to

the extremely retreated position. Fasten the avoid gauge with the

setscrew where the spring stud has been removed. As a cautionary note for mounting, the avoid gauge and the plunger

should be fixed so that their faces coincide with each other.

3. Turn the pulley in forward direction and move the looper shaft to

the extremely advanced position. At that time, measure the size of

the protrusion of the plunger .

For the size other than the standard size of 2.4mm, adjust it to the

standard size in the adjusting position.

When the amount of looper movement is insufficient

o The force of the needle touching

the rear side of the looper becomes strong, thus making the

needle tip blunt.

When the amount of looper movement is excessive

o The clearance between the needle

and the rear side of the looper be-

comes excessive, thus easily

causing stitch skipping behind the

looper.

Adjusting positions and method of adjustment

1. Loosen the setscrews (4 pcs.) and take out the cylinder side cover

.

2. Loosen the fixing screws and move the ball joint up and down

so that the looper movement locus can be adjusted. (Exclusive wrench

(TT85) to be used)

o Moving the ball joint upwards causes the forward/reverse move-

ment to decrease.

o Moving the ball joint downwards causes the forward/reverse move-

ment to increase.

– 23 –

Page 28

(9) Adjustment of the feed dog

Standard Adjustment

1. Height adjustment of differential feed dog

In the first place, attach the differential feed dog . When the differential feed dog is positioned at the

uppermost level, the standard position is obtained in terms of height where the root the tooth in the front

most row of the differential feed dog coincides with the upper face of the throat plate .

Driver groove leveled

Coincidence

2. Height adjustment of main feed dog

When the main feed dog and the differential feed dog are positioned at the uppermost level, adjust the

height of the main feed dog so that the crest of the tooth in the front most row of the main feed dog

attains the same height of the crest of the tooth in the rearmost row of the differential feed dog . This

position is a standard height of the main feed dog .

Standard position

Backward

Forward Backward

Forward

3. Gradient of the front/rear feed dog

The standard gradient of the front/rear differential feed dog is such that it is positioned somewhat lower

than the level of the throat plate .

The standard gradient of the front/rear main feed dog is such that it is positioned level to the throat plate

.

Forward

Horizontal line

Backward

Forward

Backward

– 24 –

Front lowering line

Page 29

Adjustment Procedures Results of Improper Adjustment

Adjusting positions and method of adjustment

1. For the eccentric pin of the feed dog, the standard positioning of

the driver groove is horizontal. If the driver groove seems to be inclined deviating from the standard positioning, loosen the setscrew

and adjust the eccentric pin of the feed dog until it assumes its

horizontal posture. Since then, tighten the setscrew .

2. In the first place, adjust the height of the differential feed dog to

the standard position. Then fix it by tightening the setscrew .

3. Then, adjust the height of the main feed dog to the standard position. After that, fix it by tightening the setscrew .

4. For the differential feed dog and the main feed dog , the front

and rear gradients and the horizontality are kept constant and cannot be adjusted.

(Caution) The top and bottom heights of the differential feed dog

and the main feed dog can be changed simultaneously by turning the eccentric pin of the feed dog.

In principle, however, this adjustment should not be carried out.

When the feed dog height is insufficient

o The amount of feed is decreased

and uneven feeding can occur.

o When the height of the rear

needle holder is lowered and the

margin of the needle contact position is reduced, this will cause

breakage of a needle or stitch

skipping.

When the feed dog height is sufficient

o This can be a cause of the mate-

rials pushed back to the front side,

or of giving rise to feed flaws.

o When the height of the rear

needle holder is raised and the

margin of the needle contact po-

sition is increased, this will cause

failure in producing loops and

stitch skipping.

– 25 –

Page 30

(10) Adjustment of needle holder

Standard Adjustment

1) Adjustment of rear needle holder Make adjustments so that the clearance between the left needle and the rear needle holder can attain

0.0mm (light contact) when the sewing machine pulley is turned in forward direction and the tip of the looper

reaches the position by 1mm toward the left side of the left needle .

The standard posture is that the rear needle holder lightly pushes the left needle .

1.0mm

Tip of looper

Left side

Forward and

backward

directions

0.0mm in position

by 1mm toward the

tip of the looper

(Light contact)

(Caution) After the completion of rear needle holder adjustments, check the clearance again be-

tween the left end of the looper and the center of the left needle . The clearance must

have been adjusted to 0.0mm (light contact).

2) Adjustment of forward movement needle holder Make adjustments so that the clearance between the left needle and the front moving needle holder can attain 0.0mm (light contact) when the sewing machine pulley is turned in forward direction and the tip of the looper reaches the center of the left needle . The standard posture is that the front moving needle holder keeps a light contact with the left needle in “0” position.

When the clearance is “0” between the

looper

clearance is also ì0î between the left needle

and the front moving needle holder .

tip and the left needle , the

– 26 –

Page 31

Adjustment Procedures Results of Improper Adjustment

1) Adjustment of rear needle holder

1. Turn the hand pulley in forward direction and stop it where the tip of

the looper stops in the position by 1mm toward the left side of the

left needle .

2. Loosen the setscrew and move the rear needle holder forward

or backward in order to adjust the clearance toward the left needle

to 0.0mm (light contact). When this clearance is secured, fix it by

tightening the setscrew .

oIf a clearance is actually developed

between the left needle and the

rear needle holder , this can be

a cause of needle breakage or

stitch skipping.

oIf the rear needle holder pushes

the left needle too much, this

can be a cause of needle blunt or

bend.

2) Adjustment of forward movement needle holder

1. Turn the hand pulley in forward direction and stop it when the tip of

the looper reaches the center of the left needle .

2. Loosen the setscrew and move the front moving needle holder

forward or backward in order to adjust the clearance to 0.0mm (light

contact) between the left needle and the front moving needle holder

. When this clearance is secured, fix it by tightening the setscrew

.

– 27 –

Page 32

(11) Adjustment of feed mechanisms

Standard Adjustment

1) Stitch length adjustment (inch/10SPI-16SPI) The stitch length can be adjusted within the range of 1.6mm to 2.5mm. Standard adjustment is 2.1mm. For the adjustment of the stitch length, loosen the lever setscrew wards until the required length is secured.

(Caution) If the stitch length has been changed, check the rear needle holder and make a proper

readjustment.

Vertical direction

and move the lever upwards or down-

2) Adjustment of differential feed amount The amount of differential feed can be adjusted by moving the differential adjusting lever forward or backward. The graduation plate is provided with the engraved numbers of 1 to 9. Numbers 1 to 4 denote differential motion, Number 5 denotes no differential motion, and 6 to 9 denote forward differential.

Forward and backward directions

– 28 –

Page 33

Adjustment Procedures Results of Improper Adjustment

1) Stitch length adjustment

1. When the stitch length adjusting window spring is removed, the

lever setscrew can be seen.

o Loosen the lever setscrew to move the lever upwards and fasten

the lever setscrew there. This action increases the stitch length.

o Loosen the lever setscrew to move the lever downwards and fas-

ten the lever setscrew there. This action decreases the stitch length.

(Caution) No graduation is available for the adjustment of the stitch

length.

When the stitch length is changed

o If the forward or backward move-

ment of the main feed dog is

changed, the amount of contact is

also changed in regard to the left

needle and the rear needle holder.

Since this can be a cause of stitch

skipping, the rear needle holder

should be readjusted.

2) Adjustment of differential feed amount

1. When the differential adjusting lever is advanced in the reverse

differential direction (1 to 4), the differential ratio is decreased and

the sewed materials are extended.

2. When the differential adjusting lever is retreated in the forward

differential direction (6 to 9), the differential ratio is increased and the

sewed materials are shrunk.

*When fixing the differential adjusting lever , pinch it with two set-

screws and .

– 29 –

Page 34

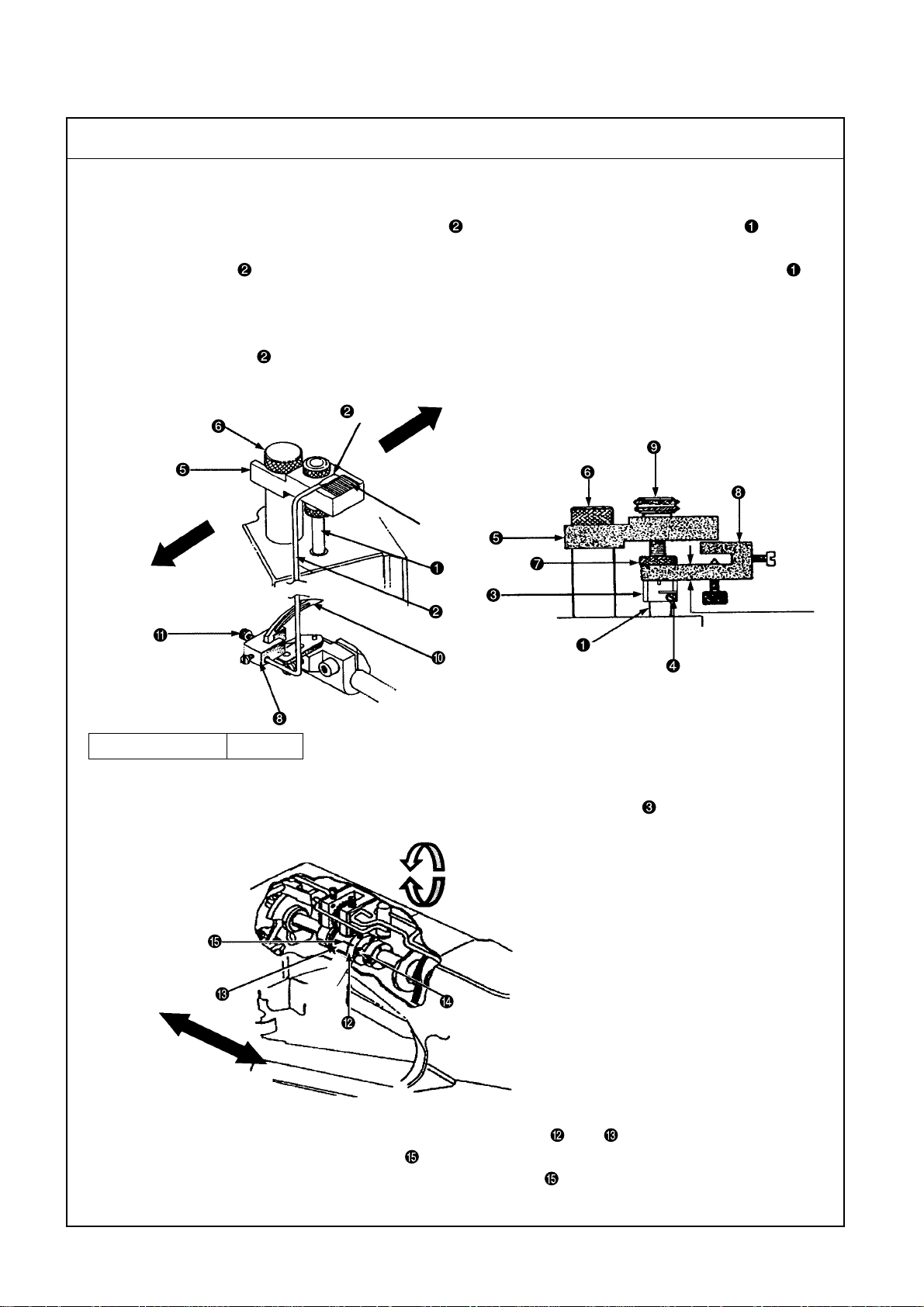

(12) Adjustment of presser main body mounting

Standard Adjustment

1. Adjustment of presser main body mounting

After the completion of "7. Standard adjustments (1) to (1 1)", mount the presser main body . When mounting the presser main body , adjust the fancy thread carrier so that its claws are positioned in the center

of the left needle and the left middle needle. Also make adjustments so that no clearance is secured between

the presser main body and the presser guide right and presser guide left . The condition should be

such that the presser can move lightly in both upward and downward directions.

2. Presser main body assembly procedures

(1) Simultaneous mounting of the presser bar and the presser bar guide

For presser bar guide positioning after the completion of mounting of the presser main body ,

secure a gap of 7mm between the presser bar guide bottom and the ball joint top at the lower dead

point of the needle bar . Since then, tighten the setscrew . The specified clearance is 1mm between

the presser bar guide and the minute-quantity presser adjusting pin . If the clearance is found to be

other than 1mm, make adjustments by moving the minute-quantity presser adjusting pin upward or

downward.

(2) Mount the presser main body with the needle bar set at the upper dead point.

(3) Check the position of claws of the fancy thread carrier .

(4) Using the presser guide right and the presser guide left , fix the right and left sides of the presser

main body .

(5) Mount the presser spring and the presser pressure adjusting screw .

(6) After the completion of the above procedures, return to (1) and readjust the presser bar guide .

Clearance:

1mm

7mm

Left side of

the presser

main body

Center

Presser bar hole

Right side of

the presser

main body

Carrier claws

Left needle

Left middle needle

– 30 –

Page 35

Adjustment Procedures Results of Improper Adjustment

How to mount the presser main body

1. Get the minute-quantity presser adjusting pin inserted in the presser

bar guide and insert the presser bar in the presser bar bush

and the hole of the presser bar guide . Mount them at the same

time and leave the conditions as they are.

2. Insert the driving link of the presser main body in the driving

sleeve . Insert the presser bar in the driving link hole and the

presser bar hole of the presser main body . Since then, tighten the

setscrews .

3. Lightly push the left side of the presser main body until it comes in

contact with the presser guide right . In this state, turn the hand

pulley in forward direction to confirm that claws of the fancy thread

carrier are located in the center of the left needle and the left

middle needle.

(Caution) If claws of the fancy thread carrier seem to stay devi-

ating to the right or left against the needle, loosen the

setscrew and move the presser guide right to the

right or left to check positioning. After confirmation, fix

this setting by tightening the setscrew .

4. Let the right side of the presser main body touch the presser guide

right to hold the left side of the presser main body with the aid

of the presser guide left . Fix them with two setscrews . At that

time, make use not to leave any clearance between the presser main

body and the presser guides right and left so that the presser

main body can move lightly both upward and downward.

5. Upon the completion of adjustments of 1 to 4 above, make adjustments of (5) and (6) described at left.

o When the presser bar guide is

installed, actions of adjustments

should be taken always at the

lower dead point. Otherwise, the

presser may float to cause adverse feeding of materials.

o If claws of the fancy thread carrier

deviate to the right or left from

the center position, this can be a

cause of needle breakage.

o If there is any clearance on the

right or left of the presser main

body , this can be a cause of

stitch skipping or needle breakage.

– 31 –

Page 36

(13) Adjustment of the presser main body proper

Standard Adjustment

1) Adjustment of presser lifter connecting lever The standard clearance is 1.0mm between the lever link and the presser bar guide while the needle bar is located at the lower dead point.

Right and left direction

1.0mm

2) Adjustment of presser lifting strap plunger The standard clearance is 0.4mm between the bottom section of the needle clamp and the top fancy looper when the presser main body is lifted while the needle bar is kept located at the lower dead point.

0.4mm

3) Adjustment of minute presser lifting If feeding flaws or traces seem to remain in the materials, make fine adjustments of the presser main body in the upward direction. Adjust the height of the presser main body to avoid feeding flaws or traces in the materials.

(Caution) Since the presser main body is floated during sewing, this function should be utilized

adequately according to the type of sewing materials.

The standard clearance is 1.0mm.

Tightening the minute-quantity

presser lifter

ance to decrease and presser

floating to increase.

causes the clear-

Upward

direction

– 32 –

1.0mm

Page 37

Adjustment Procedures Results of Improper Adjustment

1) Adjustment of presser lifter connecting lever

Loosen the setscrew and move the lift connecting lever to the

right or left. Confirming the attainment of the standard size of 1.0mm,

tighten the setscrew .

2) Adjustment of presser lifting strap plunger

Loosen the nut while the needle bar stays at the lower dead point

and turn the strap plunger clockwise until it comes in contact with

the balancer. Then, turn it counterclockwise slowly to lift the presser

main body . At that time, make adjustments so that the bottom

section of the needle clamp and the top fancy looper do not

touch each other. Since then, tighten the nut .

o When the clearance is increased

between the lever link and the

presser bar guide , the amount

of rise in the presser main body

is decreased.

oWhen the presser main body

is lifted while the needle bar stays

at the lower dead point, the bottom section of the needle clamp

may come in contact with the

top fancy looper . In such a

case, there may be a problem of

stitch skipping or destruction of

parts.

3) Adjustment of minute presser lifting

When the lock nut is loosened and the minute-quantity presser

lifter is turned, the minute-quantity presser adjusting pin rises

to float the presser main body . Adjust the presser main body to

the required height and tighten the lock nut .

(Caution) Too much lifting of the presser main body will result

in a problem of failure in material feeding.

– 33 –

Page 38

(14) Adjustment of top fancy looper and fancy thread carrier

Standard Adjustment

1) Stroke position adjustment of drive sleeve The standard position of the driving sleeve can be defined when the hand pulley is turned in forward direction and the standard clearance of 2mm is secured between the head of the link setscrew and the closest point on the rear side of the needle clamp .

2.0mm

Right and left directions as seen from behind

2) Amount of fancy thread carrier injection Claws of the fancy thread carrier enter the center of the left needle and the left middle needle. When the tip of the carrier claws is located in the most advanced position, the standard distance is 3.5mm from the needle front to the front face of the fancy thread carrier . Make a final check by passing the fancy thread. The standard position is secured when the fancy thread at the tip of the fancy thread carrier is caught by the tip of the right/left needle.

(Caution) The right and left positions of the fancy thread carrier should be adjusted when the

presser is installed.

Left needle

Forward

movement

Left middle needle

3.5mm

Front face of the fancy

thread carrier

Left needle

Front face of

the needle

3.5mm

Tip of the carrier claws

Left middle needle

Forward and backward directions

– 34 –

Page 39

Adjustment Procedures Results of Improper Adjustment

1) Stroke position adjustment of drive sleeve

When the head of the link setscrew comes closest to the rear face

of the needle clamp , loosen the setscrew of the driving sleeve

lever and move the driving sleeve to the right and left to secure

the standard clearance of 2mm. Since then, tighten the setscrew .

When the driving sleeve is moved to the right and left as seen

from behind, the clearance becomes as follows:

o The clearance is narrowed when the driving sleeve is moved left-

ward.

o The clearance is widened when the driving sleeve is moved right-

ward.

(Caution) When the setscrew is loosened, the driving sleeve

is lowered and a vertical clearance may be developed.

Tighten the setscrew after confirming that there is no

clearance after adjustments.

o If position adjustment is incorrect,

this can be a cause of fancy stitch

skipping, needle breakage, or destruction of parts.

2) Amount of fancy thread carrier injection

Loosen the setscrew and move the fancy thread carrier forward and backward to adjust the injection size to 3.5mm. Since then,

tighten the setscrew .

o This can be the cause of needle

breakage or stitch skipping.

– 35 –

Page 40

(14) Adjustment of top fancy looper and fancy thread carrier

Standard Adjustment

3) Leftmost point of top fancy looper While the top fancy looper is moved leftward, the fancy thread passes through the slider section and the position of being hooked on the thread hanger section is located at the extreme left. When the tip of the top fancy looper reaches the extreme left point, the standard size of 2.0mm from the left middle side face of the presser main body is secured.

Left middle side of face the

presser main body

Thread slider

section

2.0mm

Right and left

directions

Top fancy looper

Tip leftmost point

Thread hanger section

4) Clearance developed at the time of crossing between the fancy thread carrier and the tip of the top fancy looper When the fancy thread carrier is retreated, it is crossed by the tip of the top fancy looper . The standard clearance is 0.4mm when both items make the closest approach.

0.4mm

The crossing clearance is

0.4mm between the fancy

thread carrier

treated and the tip of the

top fancy looper

being re-

.

Retainer needle

5) Rightmost point of top fancy looper The needle lowers when the tip of the top fancy looper reaches the rightmost point and then moves to the left. The standard positioning is that the fancy thread is not caught by the retainer needle at that time.

6) Height of top fancy looper The height of the top fancy looper is kept unchanged.

Upper clearance

– 36 –

Lower clearance

Page 41

Adjustment Procedures Results of Improper Adjustment

3) Leftmost point of top fancy looper

Loosen the setscrew when the tip of the top fancy looper is

located at the extreme left, and move the looper to the right and left

to secure a dimension of 2.0mm. Since then, tighten the setscrew

.

4) Clearance developed at the time of crossing between the fancy thread

carrier and the tip of the top fancy looper

Loosen the setscrew to adjust the amount of injection of the fancy

thread carrier . Then, loosen the top fancy looper setscrew and

secure a dimension of 0.4mm by making right and left fine adjustments for the top fancy looper simultaneously.

o If the fancy thread is not caught

by the thread hanger section of the

top fancy looper , this can be a

cause of top fancy stitch skipping.

o If there is a problem in clearance

adjustments, this can cause breakage of parts.

5) Rightmost point of top fancy looper

If there is no problem in adjustments of the top fancy looper at the

leftmost point and of the fancy thread carrier mechanisms, the

rightmost positioning is automatically secured for the top fancy looper.

6) Height of top fancy looper

If a vertical clearance is developed at the time of adjustment of the

top fancy looper , the top fancy looper is lowered. Tighten the

setscrew to eliminate such a vertical clearance.

– 37 –

o If the rightmost position of the top

fancy looper deviates to the

right too much, the fancy thread

comes out of the right needle.

o If vertical rattling is generated in

the top fancy looper , this can

be a cause of stitch skipping or destruction of parts.

Page 42

(15) Adjustment of top fancy cam and bobbin thread cam

Standard Adjustment

1) Adjustment of top fancy cam

1. While the top decoration cam is moved leftward, the decoration thread passes through the thread

slider section of the top decoration looper and is caught by the thread hanger section.

The standard position is secured when the fancy thread is released from the crest point of the top fancy

looper after the thread has been hooked on the thread hanger section.

2. The standard height (spun thread) of the top fancy thread path is 2.4mm above the top face of the cam

thread path mounting base .

Cam’s crest point

Top fancy thread

2.4mm

Vertical direction

Right and left

directions

Center

(Caution) The amount of thread drawing out may change according to the type of the thread used.

The adjusting height of the top fancy thread path also changes.

2) Adjustment of bobbin thread cam

1. The standard size is 2mm for the position where the bobbin thread (spun thread) is released from the

releasing point of the bobbin thread cam . This size is measured from the side face of the contact screw

in the cam groove position to the upper end of the cam groove.

Upper end of the

cam groove

2mm

Screw side face

Bobbin thread

Thread releasing point

Right and left directions

Center

Coincidence of the thread path mounting

with the right end of the bobbin

base

thread guide thread path

Right and left directions

(Caution) The cam position should be advanced when a wooly thread (high elongation) is used.

Since the wooly thread is stretchy , it is necessary to increase the amount of thread draw-out.

– 38 –

Page 43

Adjustment Procedures Results of Improper Adjustment

1) Adjustment of top fancy cam

1. Check the timing when the upper fancy thread is released from the

crest position of the outer periphery of the cam. Loosen the setscrew

and then tighten it after adjustments.

2. For adjustments of the upper fancy thread path , loosen the setscrew and adjust the upper fancy thread path to the center of

the upper fancy cam in order to secure the height of 2.4mm. Since

then, tighten the setscrew .

2) Adjustment of bobbin thread cam

1. Check the timing when the bobbin thread is released from the thread

releasing point on the outer periphery of the bobbin thread cam .

Loosen the cam setscrew and then tighten it after adjustments.

2. To secure the mounting position for the bobbin thread guide thread

path , adjust it to the center of the bobbin thread cam and tighten

the setscrew . Check the right and left positioning, and let the cam

thread path mounting base coincide with the right end of the bobbin thread guide thread path .

3. If the amount of thread draw is increased for the bobbin thread path

, loosen the setscrew and move the bobbin thread path to the

left. Tighten the setscrew in the adequate position where the required amount of thread is available. To reduce the amount of thread,

move the bobbin thread path rightward.

o If the fancy thread is not caught

by the thread hanger section of the

top fancy looper, this can be a

cause of top fancy stitch skipping.

When the upper fancy thread path

is too low:

o Since the amount of fancy thread

becomes small, this can be a

cause of needle breakage or stitch

skipping of the left middle needle.

In addition, the sewing width of the

upper fancy thread is narrowed.

When the upper fancy thread path

is too low:

o Since the amount of fancy thread

becomes large, this can be a

cause of stitch skipping.

This can be a cause of stitch skip-

ping of idle loops. There is possi-

bility of clogging due to reduced

development of idle loops.

o When the bobbin thread cam

is advanced, the amount of bob-

bin thread is increased. When it is

delayed, the amount of bobbin

thread is decreased.

– 39 –

Page 44

(16) Knife adjustment

Standard Adjustment

1) Lower knife adjustment Insert the lower knife from the left side of the presser main body, left. The standard size is 0.8 to 1.6mm from the right side of the presser main body left to the front corner section of the lower knife right.

Left side face of the

presser main body

left

Right side face of

the presser main

body

left

2) Upper knife adjustment Turn the hand pulley in forward direction and stop the upper knife driving bracket in the leftmost position. Insert the upper knife from the right side of the presser main body right and let it cross the lower knife

. The standard crossing size is 0.4mm between the front corner section of the lower knife right and the

front corner section of the upper knife left.

Front corner section of

the lower knife right

0.8 to 1.6mm

Right direction

Right side of the

presser main body,

right

Front corner section

of the upper knife

left

Right and left directions

Crossing size of 0.4mm

Front corner section

of the lower knife

right

3) Pressure adjustment of upper knife When the upper and lower knives and are crossing, the standard size is 1.6mm between the lower face of the knife base guide and the top face of the mounting section for the knife holder shank

Lower face of the knife base guide

1.6mm

Top face of the mounting section for

the knife holder shank

– 40 –

Page 45

Adjustment Procedures Results of Improper Adjustment

1) Lower knife adjustment

1. Loosen the setscrew and move the lower knife to secure the

standard size of 0.8 to 1.6mm. Since then, tighten the setscrew .

2) Upper knife adjustment

1. Attach the upper knife auxiliary plate to the knife holder shank

and install the upper knife fixing block . Since then, tighten the

setscrew .

2. Turn the hand pulley in forward direction to the leftmost position of

the upper knife driving bracket . Insert the upper knife from the

right side of the upper knife fixing block and tighten the setscrew

after confirming that the standard crossing size of 0.4mm has

been secured in conjunction with the lower knife .

3. If the right to left angle of the upper knife seems to be inadequate

for the lower knife in regard to the meshing condition between the

upper and lower knives and , loosen the screw and change

the angle of the upper knife .

o According to the right and left po-

sitioning mesh between the upper

and lower knives and , the

amount of material stacks is

changed.

o If the knives become blunt,

stitches at the edge of material

cloth become unstable. This can

be a cause of stitch skipping.

o If the spring pressure is too strong

for the upper knife , the sharpness of the knife will soon be lowered.

3) Pressure adjustment of upper knife

1. At the time of crossing of the upper and lower knives and ,

loosen the setscrew and measure the distance of 1.6mm between

the upper face of the knife holder shank of the upper knife driving

bracket and the lower face of the knife base guide . After this

distance has been confirmed, tighten the setscrew .

– 41 –

Page 46

(17) Adjustment of upper knife drive lever

Standard Adjustment

Positiion of upper knife drive lever

1. When the hand pulley is turned in forward direction and Size C is secured for the needle bar height, the

standard position is located at 6:00 for the upper knife driving lever .

Upper face of the machine head section

A

Position of 6:00

Upper face of the needle bar

B

C

72.2mm

Right and left directions

– 42 –

Page 47

Adjustment Procedures Results of Improper Adjustment

How to determine Size

C

1. Set the needle bar at the lower dead point and measure Size A from

the upper face of the needle bar to the upper face of the machine

head.

2. Then, with the needle bar set at the upper dead point, measure Size

B

from the upper face of the needle bar to the upper face of the

machine head.

3. Make a calculation of B – A÷ 2 = D to determine Size D. The

required Size C is obtained from D + A.

Adjustment procedures

1. Loosen the setscrew of the needle bar lever and adjust the

upper knife driving lever to the position of 6:00. Then, tighten the

setscrew .

2. The standard size is 72.2mm from the center of the ball joint to the

center of the ball joint .

3. To adjust the right and left ball joints and , loosen the right and

left nuts and , and turn the joint rod . Confirm the size of

72.2mm and tighten the right and left nuts and .

o If the mounting posture of the up-

per knife driving lever is incorrect, the sharpness of the knife will

soon be lowered.

o If the right and left ball joints

and have wrong sizes, it is impossible to adjust the top fancy

looper and the fancy thread carrier.

– 43 –

Page 48

(18) Adjustment of needle thread path

Standard Adjustment

1) Adjustment of needle thread guide bar The standard height (spun thread) of the needle thread guide bar is defined by T able 1 to 4 below from the upper face of the needle thread guide base to the lower end of the hole. If the needle thread tension is needed according to the type of the thread, lower the needle thread guide bar .

Dimensions of needle thread guide bar

Needle thread guide bar

1 234

Standard height 28mm 30mm 32mm 40mm

2) Adjustment of needle holder adjusting pin The standard height (spun thread) of the needle thread holder adjusting pin is defined by T able 5 and below from the upper face of the needle thread holder base to the crest point of the needle thread holder adjusting pin .

Dimensions of needle holder adjusting pin

Needle holder adjusting pin

Standard height 4.5mm 4.0mm 3.5mm 3.0mm

5 678

4

3

2

1

Standard

height

5

6

7

8

6

Standard height

3) Adjustment of needle thread presser spring In regard to the height of the needle thread presser spring mounted on the needle thread path base , the standard size is 2.5mm between the tip section of the needle thread presser spring and the head top of the screw .

Tip of needle thread presser spring

2.5mm

– 44 –

Page 49

Adjustment Procedures Results of Improper Adjustment

1) Adjustment of needle thread guide bar

Loosen the setscrew of the needle thread guide bar of 1 to

to adjust the height. After adjustments, fix the setscrew .

o Lowering the needle thread guide bar causes the needle thread

to be tightened.

o Raising the needle thread guide bar causes the needle thread to

be loosened.

2) Adjustment of needle holder adjusting pin

Loosen the setscrew of the needle thread holder adjusting pin

of 5, 6 to adjust the height. After adjustments, fix the setscrew .

Size 7, 8 is for reference.

o Raising the needle thread holder adjusting pin causes the needle

thread loop to be enlarged.

o Lowering the needle thread holder adjusting pin causes the needle

thread loop to be diminished.

4

o More precise adjustment to the

standard size is needed for the

needle thread guide bar as it is

positioned closer to the looper.

Otherwise, the thread tension may

become worse.

oSince the left and left middle

needles are located near the

looper, the needle thread holder

adjusting pin has to be adjusted

to the standard size correctly . Otherwise, loop formation will get

worse and stitch skipping may occur.

3) Adjustment of needle thread presser spring

Loosen the setscrew to turn the spring holder and make adjustments to secure the size of 2.5mm between the tip section of the

needle thread presser spring and the head top of the screw .

Then, tighten the setscrew .

* Role of the needle thread presser spring

The needle thread resistance is effective in stabilizing loop formation.

When the hand pulley is turned in reverse direction and then in forward direction for starting, the needle thread once loosened is tensed

again by the function of the needle thread presser spring . For this

reason, stitch formation is improved at the time of starting.

– 45 –

o If the needle thread presser spring

has no needle thread resistance, stitch skipping may be

caused at the time of starting.

Page 50

(19) Adjustment of tension disk rise and protection cover

Standard Adjustment

1) Adjustment of tension disk rise The standard positioning is that the tip of the disk rise pin keeps contact with the top tension disk when the presser main body rises by 0.8mm above the upper face of the throat plate and that the top tension disk keeps rising when the presser main body is located at the crest point. The standard size is 7.5mm between the tip of the disk rise pin and the upper face of the tension thread path .

0.8mm

7.5mm

Driver groove

2) Adjustment of protection cover When the protection cover is shut, this protection cover holds the chips guard . The standard mounting posture is that there is no front and rear play around the chips guard .

– 46 –

Page 51

Adjustment Procedures Results of Improper Adjustment

1) Adjustment of tension disk rise

Insert a screwdriver in the driver groove of the tension disk rise shaft

. Loosen the setscrew of the lift lever and turn the screwdriver to adjust the height of the disk rise pin to 7.5mm. Since

then, tighten the setscrew .

o When pulling out the needle

thread as well as the top and bottom fancy threads, it is necessary

to lift the top tension disk .

2) Adjustment of protection cover

Loosen the hexagon head bolt and make the stepped position of