Page 1

MM

Industrial

Instructions

Sewing

Repairing

List

Pulling

Catalog

of

Parts

Class

Machines

21700

No.

Machines

for

for

3Z

[Second

UNION

SPECIAL

CHICAGO

Edition]

MACHINE

COMPANY

fy

Page 2

Page 3

"Hi.

Instructions

Union

UNION

BRANCHES

Boston,

Mass.

Lynn,

Mass.

Haverhill,

New

Utica,

Rochester,

Newark,

Baltimore,

Detroit,

Union

Union

Union

Union

Union

Union

Compagnto

Corapagnie

York,

N.

Y.

N.

Mich.

Special

Special

Special

Special

Special

Special

Mass.

N.

N.

Y.

SERVICE

J.

Md.

Machine

Machine

Machine

Machine

Machine

des

des

and

Special

SPECIAL

General

AND

Y.

REPRESENTATIVES,

Corporation

Company

Company

Corporation

Corporation

Machine

Corporation

Machines

Machines

Union

Union

Catalog

(Second

No,

Edition)

for

List

of

Pulling

Class

OfTice

and

CHICAGO,

SERVICE

Johnson

Buffalo.

Troy,

Philadelphia,

Reading,

Cincinnati,

Cieveland,

Knoxvllie,

Atlanta,

Milwaukee,

BRANCHES—FOREIGN

of

America.

of

Canada,

of

Canada,

of

America.

of

America.

of

America.

Special

Special

21700

MACHINE

Fnclory:

ILLINOIS

STATIONS,

City,

N.

Y.

N.

Y.

Pa.

Ohio

Ohio

Tenn.

Ga.

Wis.

Ltd.

Ltd.

de

France.

de

France.

400

N.

Pa.

32

Repairing

Parts

for

Machines

North

Y.

Franklin

UNITED

COMPANY

Street

UNITED

Toledo,

Minneapolis,

St.

Kansas

Los

San

STATES

Dallas,

New

Seattle,

Belgium,

Canada,

Canada,

Denmark,

England,

England,

France,

France,

STATES

Ohio

Louis,

Mo.

City,

Angeles,

Francbco,

Texas.

Orleans,

Wash.

Brussels

Toronto

Montreal

Copenhagen

Leicester

London

Paris

Lyons

Minn.

Mo.

Cal.

Cal.

La.

UNION

Berlin

Chemnitz

Argentine

Buenos

Auatritt

Vienna

Australia

Melbourne

Sydney

Brazil

Rio

Santos

Sao

China

Hong

Shanghai

Cuba

Havana

Santiago

Dntch

Soerabaya,

EcuadSr

Guayaquil

SPECIAL

BRANCHES

Foreign

Republic

Aires

de

Janeiro

Paulo

Kong

East

Indies

Java

Copyright,

General

Distributors

-

MASCHINENFABRIK,

Office

and

Factory:

AND

SERVICE

Koln

Ebingcn

and

England

French

Hawaiian

India

Ireland

Italy

Japan

Mauritius

Mexico

1927,

by

Union

STUTTGART,

Service

Leeds

Manchester

Norwich

Indo

Saigon

Islands

Honolulu

Bombay

Calcutta

Belfast

Milan

Osaka

Tokyo

Port

Louis

Mexico

City

Special

Machine

STATIONS,

Stations

China

Co.

GERMANY

are

Printed

G.m.b.H.

GERMANY

Erfurt

Frankfurt

Found

New

Zealand

Auckland

Christchurcli

Wellington

Philippine

Manila

Portugal

Oporto

Scotland

Glasgow

Dundee

Slam

Bangkok

South

Africa

Johannesburg

Durban

Capetown

Port

Spain

Barcelona

Uruguay

Montevideo

in

U.

S.

A.

am

Main

in:

Islands

Elizabeth

$:

Page 4

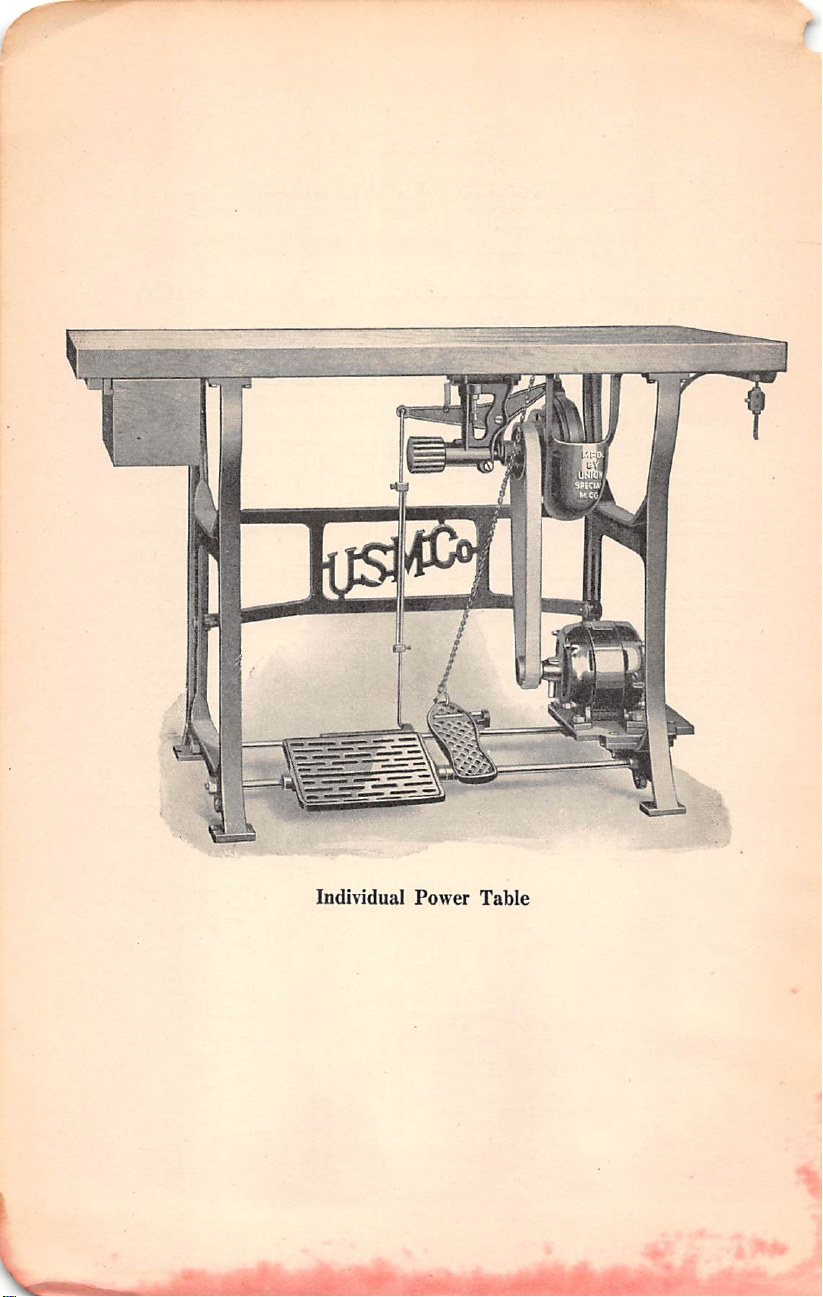

'W

/

ludhidual

Power

Table

■«-

«

Page 5

The

matter

Pulling

Machines,

APPLICATION

contained

in

Class

21700.

this

catalog

OF

CATALOG

applies

only

to

Union

Special

SIMPLICITY

they

require

regular

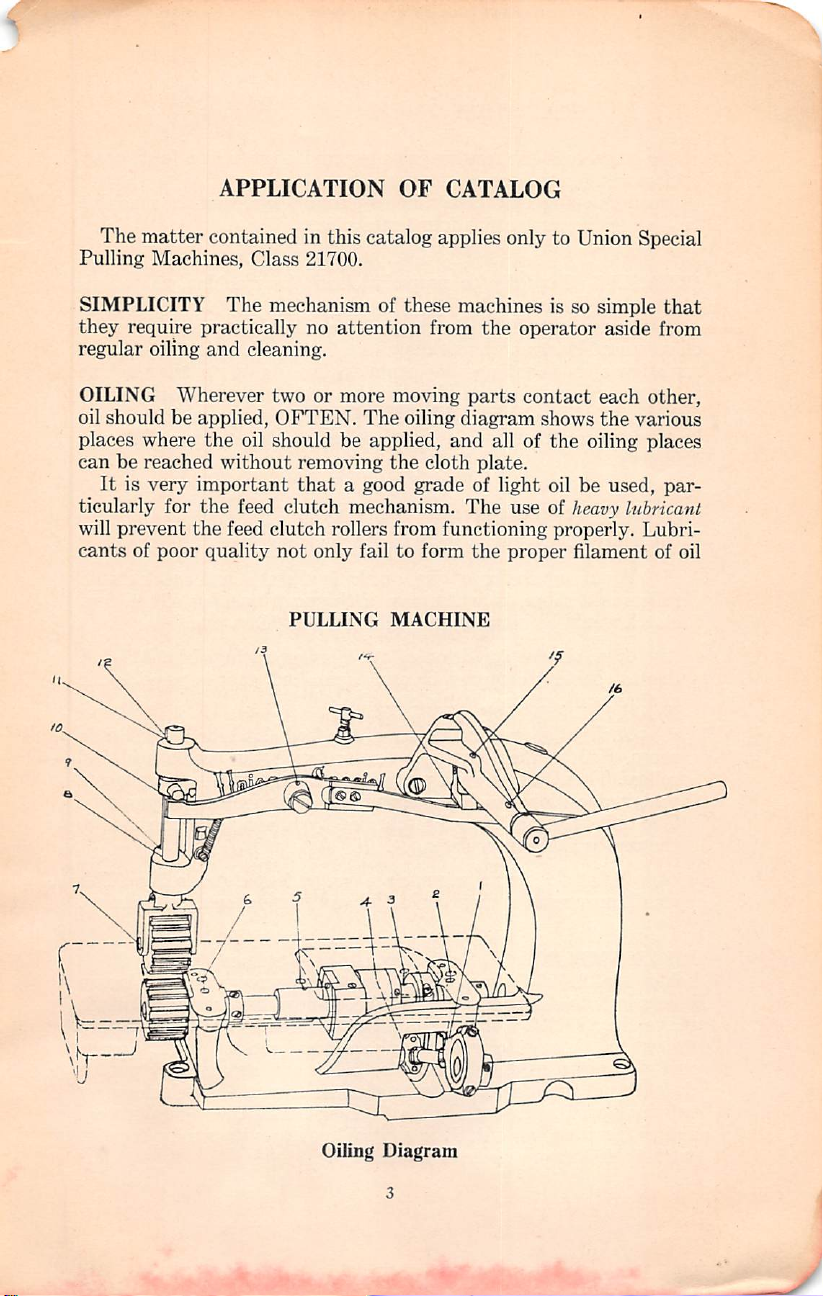

OILING

oil

should

places

can

be

It

is

ticularly

will

prevent

cants

of

practically

oiling

Wherever

be

applied,

where

reached

very

important

for

the

the

poor

The

mechanism

and

cleaning.

two

OFTEN.

the

oil

should

without

feed

feed

clutch

quality

not

of

no

attention

or

more

The

be

applied,

removing

that a good

clutch

mechanism.

rollers

only

fail

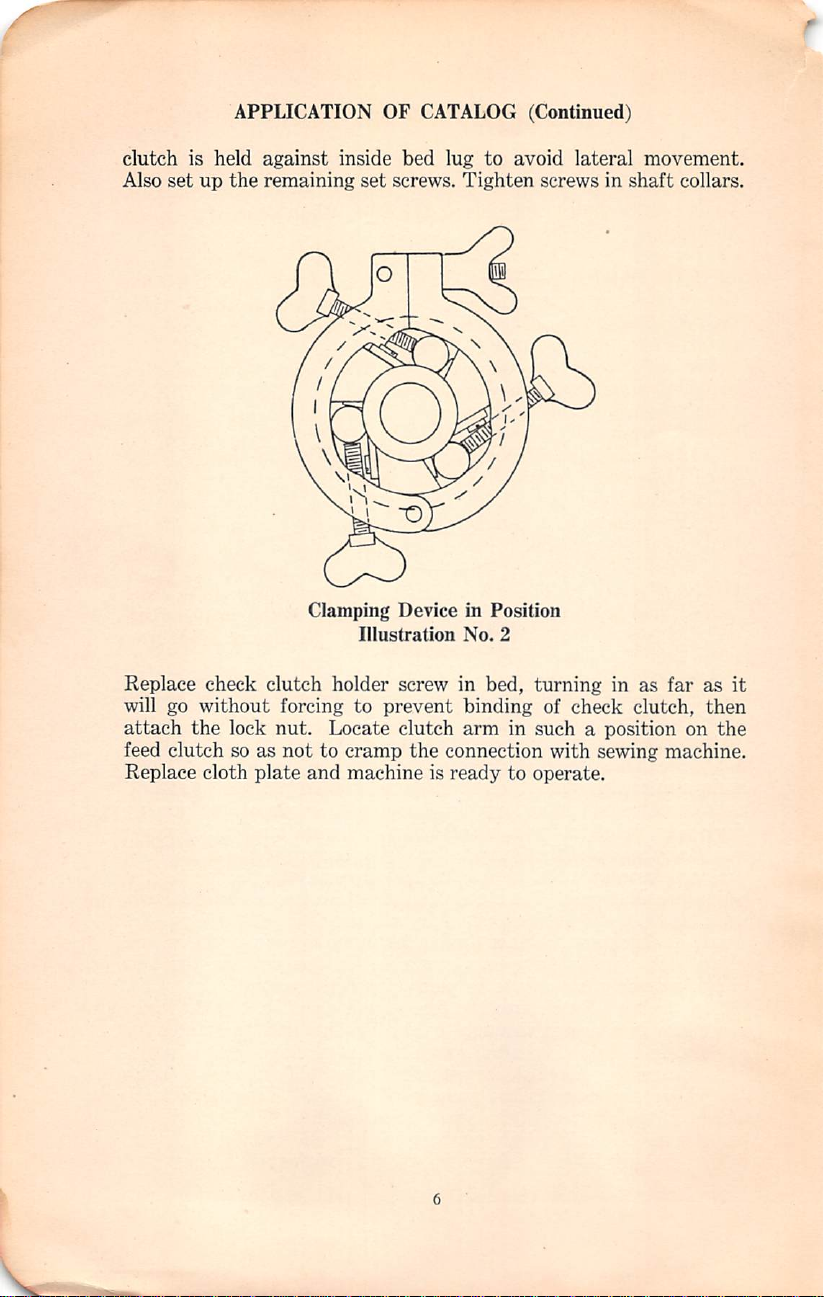

PULLING

these

machines

from

the

moving

oiling

the

parts

diagram

and

cloth

grade

plate.

of

The

from

functioning

to

form

the

MACHINE

is

operator

contact

shows

all

of

the

light

oil

use

of

properly.

proper

so

simple

aside

from

each

other,

the

various

oiling

be

heavy

places

used,

lubricant

Lubri

filament

of

that

par

oil

Oiling

Diagram

y

Page 6

APPLICATION

on

the

surfaces

but

cause

them

Frequent

be

given a thorough

oiling

of

the

moving

to

become

is

necessary,

oiling

OF

CATALOG

parts

gummed.

and

four

times a day.

to

provide

we

recommend

(Continued)

protection

that

from

the

wear,

machine

CLEANING

plate

should

To

clean

oil

recesses

run a few

a

few

seconds

GOOD

be

repeated

tinuously.

GENERAL

it

is

usually

(1)

An

rollers

clutch

(2) A weakened

due

to

of

these

(3) A slight

shoes,

rollers.

wedging

The

difficulty

the

unworn

(4) A fl

condition

In

be

removed.

out

the

Nos. 3 and 5 (see

seconds

until

GRADE

at

least

INFORMATION

due

to

accumulation

and

shoes,

would

be

constant

springs

groove

due

to

These

grooves

position,

side,

at

side

prevents

DISASSEMBLING

holder

screws

sleeve

set

clamping

clutch

twisting

and

catch

No.

21716 C from

in

both

No.

21717 C from

screws.

Grasp

screw

from

clutch

apart,

plungers

them

to

to

shaft

in

using

avoid

order

to

properly

feed

clutch,

diagram).

and

gasoline

the

gasoline

OF

LIGHT

once a month

one

or

more

of

gum

in

which

in

order,

condition

as

compression

may

be

broken.

in

the

their

constant

will

prevent

which

is

so

can

be

easily

or

replacing

or

uneven

their

surface

oscillating

Remove

bed

collars

No.

holes

the

feed

roller

clutch

arm.

fall

arm

Separate

both

hands.

out.

It

their

being

is

clean

the

machine,

gasoline

again

has

OIL.

When

of

the

on

case a thorough flushing

outlined

of

the

and

face

of

contact

essential

remedied

it.

cloth

by

21705,

marked

and

No.

clutches

This

advisable

should

The

machine

applied.

been

This flushing

when

the

following

the

plunger

expansion.

the

the

on

and

plate,

removing

"T"

21709

Again

worked

machine

puller

feed

clutch

under

"Cleaning."

springs

feed

clutch

with

rollers

in

order

by

turning

the

feed

they

release

screw

remove

and

draw

out

and

fails

Or

the

to

time

loosen

from

will

cause

to

provide a receptacle

be

poured

should

run

out.

Re-oil

operation

is

operated

to

feed

causes:

and

it

is

or

oscillating

from

moving

function

over

clutch

should

check

and

screws

the

the

shaft.

separate

the

clutch

the

rollers,

lost.

the

cloth

into

the

then

the

machine

with

should

con

properly,

check

clutch

of

the

feed

No.

21718

possible

check

one

clutch

steel

into

properly.

the

shoe

rollers.

be

This

replaced.

clutch

nut,

loosen

in

clutch

remaining

Loosen

by

pulling

sleeve

springs

be

a

A

a

to

i

by

to

Page 7

APPLICATION

OF

CATALOG

(Continued)

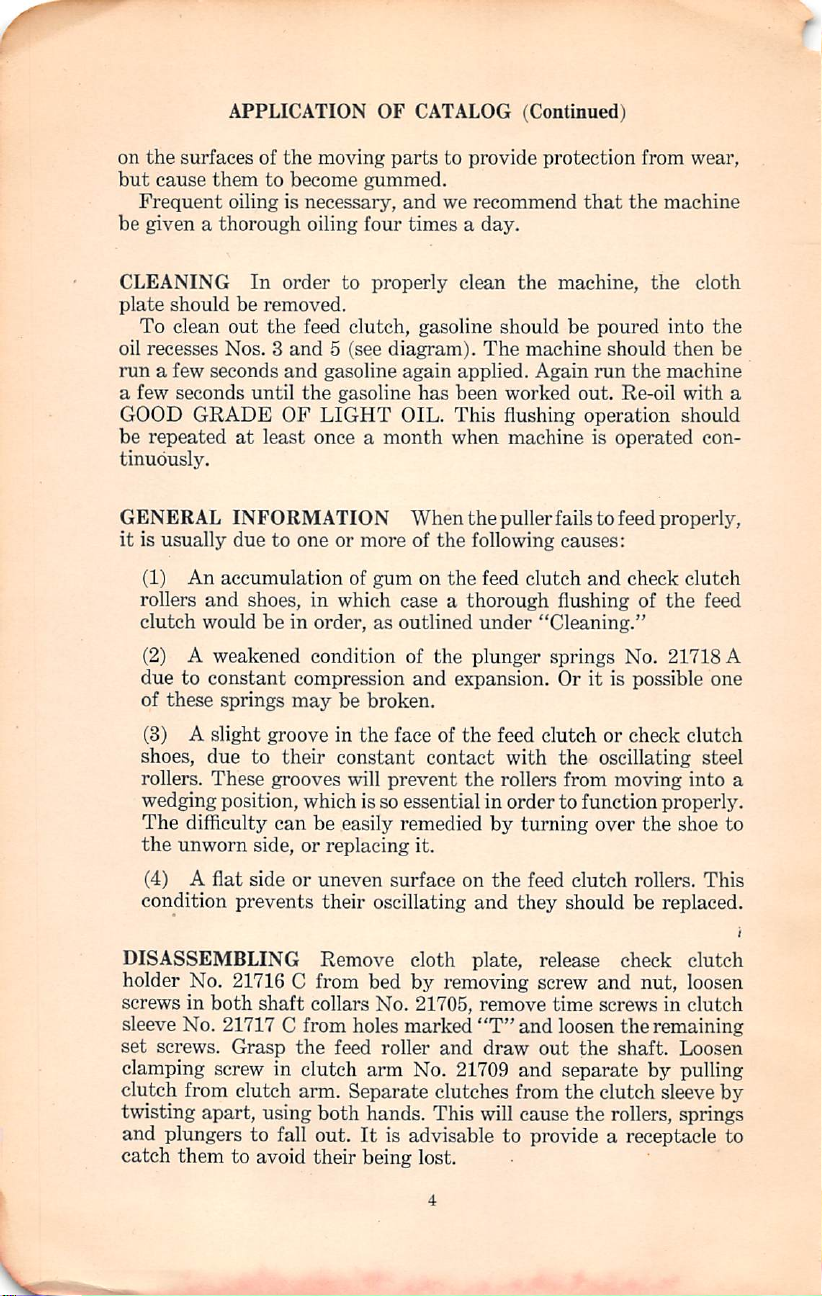

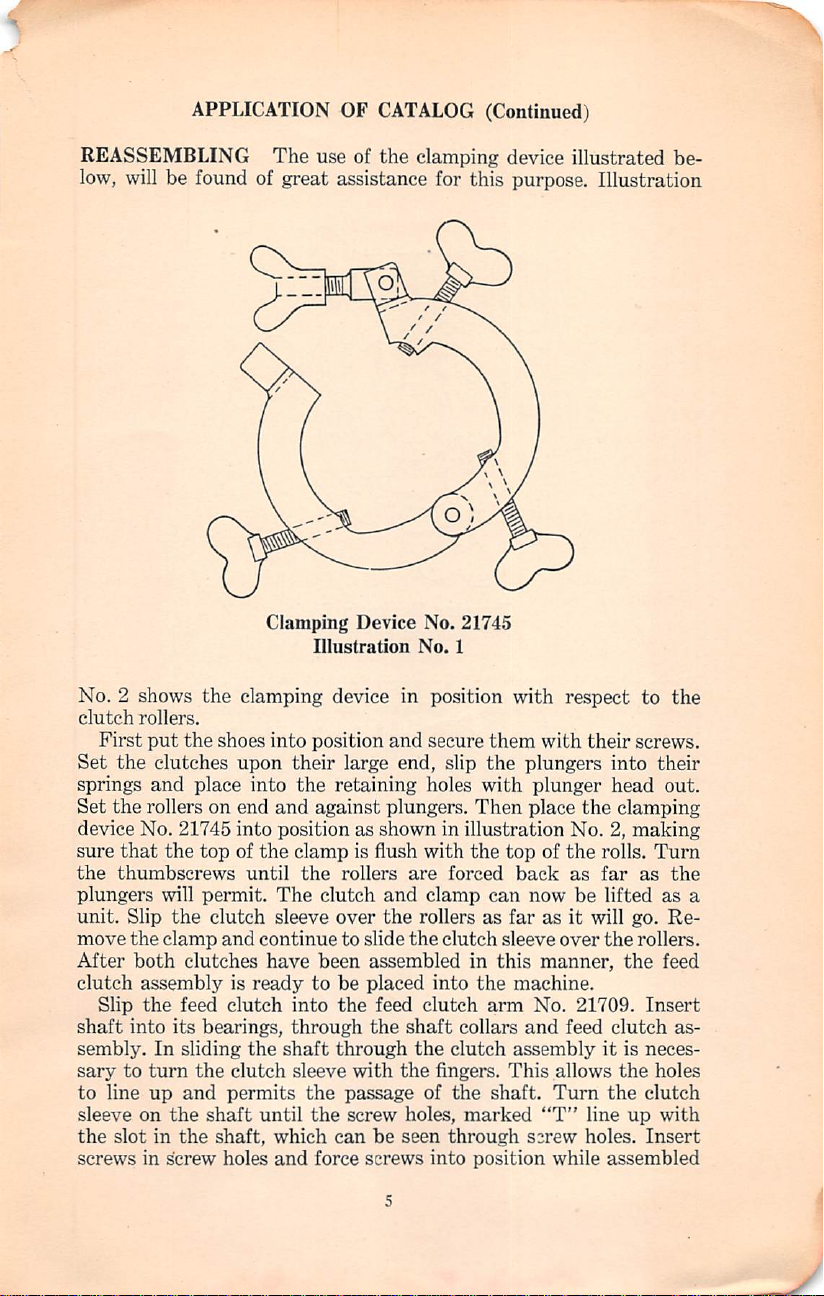

REASSEMBLING

low,

will

be

found

No. 2 shows

clutch

rollers.

First

Set

the

springs

Set

the

device

sure

the

No.

that

thumbscrews

plungers

unit.

Slip

move

the

After

both

clutch

shaft

sembly.

sary

to

sleeve

the

screws

assembly

Slip

into

to

line

on

slot

the

put

the

shoes

clutches

and

place

rollers

on

21745

the

top

will

permit.

the

clutch

clamp

clutches

the

feed

its

bearings,

In

sliding

turn

the

up

and

the

shaft

in

the

shaft,

in

screw

The

of

great

Clamping

clamping

into

upon

their

into

the

end

and

into

position

of

the

clamp

until

The

sleeve

and

continue

have

is

ready

clutch

clutch

the

into

through

shaft

sleeve

permits

until

which

holes

and

use

of

the

assistance

Device

Illustration

device

position

and

large

retaining

against

plungers.

as

shown

is flush

the

rollers

clutch

been

to

the

the

force

and

over

the

to

slide

assembled

be

placed

the

feed

the

through

with

passage

screw

can

be

screws

clamping

for

No.

No.

in

position

secure

end,

slip

holes

device

this

21745

1

them

the

with

Then

in

illustration

with

the

top

are

forced

clamp

rollers

the

clutch

shaft

the

the fingers.

of

holes,

seen

into

can

as

clutch

in

into

the

arm

collars

clutch

the

shaft.

marked

through

position

sleeve

this

illustrated

purpose.

with

Illustration

respect

with

their

plungers

plunger

place

the

No.

of

the

rolls.

back

as

far

now

be

lifted

far

as

it

will

over

the

manner,

machine.

No.

21709.

and

feed

assembly

This

"T"

screw

it

allows

Turn

the

line

holes.

while

assembled

be

to

the

screws.

into

their

head

out.

clamping

2,

making

Turn

as

the

as

go.

Re

rollers.

the

feed

Insert

clutch

is

neces

the

as

holes

clutch

up

with

Insert

a

Page 8

APPLICATION

OF

CATALOG

(Continued)

clutch

Also

is

set

up

Replace

will

go

without

attach

feed

Replace

the

clutch

cloth

held

against

the

remaining

check

lock

so

as

plate

inside

Clamping

clutch

holder

forcing

nut.

Locate

not

to

and

bed

set

screws.

Device

Illustration

screw

to

prevent

clutch

cramp

machine

the

is

lug

to

avoid

Tighten

in

No.

in

binding

arm

connection

ready

screws

Position

2

bed,

turning

of

in

such a position

with

to

operate.

lateral

check

movement.

in

shaft

in

as

clutch,

sewing

collars.

far

as

it

then

on

the

machine.

Page 9

ORDERING

REPAIR

PARTS

PLATES

trations

ponent

anism.

LIST

tion

of

the

symbol

to

furnish

For

and

similar

( ) A dash

dicates

{□) A square

the

part

chinist's

CJ) A double

that

Grouped

of

parts

parts

that

OF

PARTS

each

part

against

the

plate

convenience

articles

in

the

absence

is

commercial

supply

the

component

IDENTIFYING

part

is

stamped

are

stamped

parts

All

in

which

similar

part

with

in

numbers

they

appear.

together

similar

go

in

together

Turning

and

its

principal

its

definition

number.

in

ordering,

are

repeated

the

"plate

of

an

illustration.

in

the

"Sjunbol

and

house.

dagger

in

the

parts

PARTS

with

its

an

identification

appearance.

represent

according

appearance,

in

from

plates

before

minor

after

number"

to

can

"Symbol

cannot

Where

part

number.

the

same

to

and

the

same

to

the

uses

will

ordering.

parts,

each

column

order

by"

be

readily

to

order

be

furnished

the

construction

Some

letter

to

part

scale

will

be

fouiid

to

some

extent,

subdivisions

list

of

be

found.

such

major

of

the

column

purchased

by"

of

parts,

Always

It

is

not

as

screws,

part.

list

of

indicates

in

column

the

the

necessary

parts

any

indicates

separately.

permits,

of

the

smaller

distinguish

regardless

of

them

the

illus

com

mech

defini

check

nuts,

in

that

ma

each

parts

from

catalog

SUPPLIES

hooks,

promptly

TERMS

notice.

risk

f.

o.

otherwise

surance.

All

supplies,

belt

fasteners,

furnished.

Prices

Express

b.

shipping

directed. A charge

are

and

screw

strictly

freight

point.

including

drivers,

net

and

cash

and

shipments

Parcel

is

made

post

taps,

reamers,

powdered

subject

are

forwarded

shipments

to

cover

oil

to

are

the

belting,

stone

change

at

the

insured

postage

belt

will

be

without

buyer's

unless

and

in

Page 10

Plate

1—Full

Size

CCT

ES

wswsm

22597

EB

225I7^^H22754

21725

„

iQ

Eti

(stagECI

El£l

22637D

22811

CBS

gQ

S0

22577^B22d02

22517

A

HUskVMi%

Page 11

2I7I8B

Plate

2—Full

Size

HHFB

21719A

ai7i4

m

15430

2I745B

C

5430

21713

D

E

1745A

Jtfii'l'

2I7I2

niBin

21745C

2I724A

EDS

Page 12

Plate

3—One-half

Size

21705

21705

21741

l54iOE

AHzmrB^^^H2l726

2I703^^^H2I703A

2l72d^^^H2l707

21726

CT

7n^|i^

A

21709

mm

21745

QEZ^

Page 13

Plate

4—One-half

Size

21722

21720

A

A

2I722B

2I720B

2I722D

2I720D

2I720E

21722

2I720L

L

21722

be^q

P

21720

R

Page 14

y

PffHl

Plate

5—One-half

Size

ZI708

21724

21721

21721

fc

2I729A^^H2I723

lhklcfil

21723

A

B

21723

mim

A

B

Page 15

Plate

6—One-fourth

and

One-eighth

Sizes

21293

jslMsMil

C

21733

21704

A

21734

21736

21291

one-«iehih

D

21702

siie

A

one-eighth

sIm

Page 16

LIST

OF

PARTS

Symbol

to

Order

V109

V118

136

318

420

426

18

64

74

77

81

87

93

95

96

97

98

The figures

by

Check

X

Presser

Clamp

Set

Spot

Screw,

Screw,

Set

Spot

Screw,

Set

Tap

Tap

Clamp

Screw,

Lifter

Lifter

and

Screw,

Screw,

Screw,

21726

Screw,

also

Screw,

marked

marked

Lifter

605

A

15430

15430

t

15430 EDriving

Screw,

C

Driving

D

Driving

Driving

D

Lifter

D

Lifter

C

Lifter

C

Lifter

Lifter

Base

A

Cloth

B

Cloth

Cloth

Driving

A

Driving

C

Driving

Driving

Driving

A

Shaft,

Shaft

Shaft

A

Shaft

Driving

22587.

Plate,

Collar

Collar

Renewable

21290

21291

21292

21293

21701W

21702

21702

21703

21703

21703

21704

21705

21705

21707

Driving

22587.

t

See

page

7.

in

the

not

to

Spring

Screw,

for

for

for

throat

for

lifter

for

driving

A,

21728

for

No.

21735

lifter

for

last

be

used

Holder

Regulating

for

feed

presser

driving

plates

lever

presser

lever

driving

are

Clutch

for

for

"J2",

"X2",

Screw,

for

check

for

lifter

cam

Lever

Stud

Lever

Spring

Lever

Spring

for

feed

clutch

Eccentric

Eccentric

Eccentric

Eccentric

Treadle

Treadle

Treadle

Treadle

Treadle

Plate,

Plate,

Plate

Assembly,

Base

Pin

Pin

for

pulling

for

use

for

use

Screws

Eccentric,

Eccentric,

Eccentric,

Eccentric

Eccentric

hardened

Spot

Set

and

Screws

Bearing

Eccentric

Eccentric

Connecting

Connecting

column

refer

only

in

ordering.

Screw

Lock

Screw

clutch

arm

roller

axles

eccentric;

extension

eccentrics;

bar

spring;

also

connection

also

eccentrics;

for

No.

22526

for

No.

22754

clutch

holder.

shaft

bracket

Screw

No.

and

Connecting

Connecting

Connecting

Connecting

Set

Screw

with

with 1 \

No.

four

eleven

seven

Screw

ground,

No.

97.

check

Rod

Rod

Rod

Rod

No.

machine

to

2^

inch

inch

22574.

seven

to

sixteen

to

thirteen

Screw

No.

No.

and

feed

stitches

98.

diameter

98.

clutch

Rod

Rod

14

to

the

plates

Refer

to

pink

Nut...

also

for

Nos.

for

Nos.

and

for

No.

for

21740.

No.

also

. .

shoes

Nut,

left

Nut,

right

Rear

Bearing

Rear

Bearing

95.

sewing

feed

rollers

rollers

per

stitches

stitches

81.

.625

Front

Bearing

Front

Bearing

illustrating

insert

21293

presser

the

for

prices.

21726,

21726

C,

spring

21705

.

thread

thread

Screws

head

inch

per

inch

per

inch

inch

Screws

parts

A

21726,

rest;

No.

No.

Plate

No.

2

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

2

1

2

2

3

g

6

g

__

6

6

3

3

3

6

3

a

3

Page 17

LIST

OF

PARTS

Symbol

to

21708

21709

21710

21711

21712

21713

21713

21713

21714

21715

21716

21717

21718

21718

21720

Order

21719

21720

21720

21720

21720

21720

21720

21721

21721

21722

21722

21722

21722

by

B

D

E

D

C

C

A

B

A

A

B

D

E

L

P

R

A

B

A

B

D

E

The

figures

and

are

Driving

Eccentric

Driving

15430

Driving

15430

D.

Feed

Clutch

Feed

Clutch

Driving

Eccentric

Driving

Nut

Driving

Washer

Feed

Clutch

Feed

Clutch

Feed

Clutch

Feed

Clutch

Feed

Clutch

Feed

Clutch

Check

Clutch

Check

Clutch

Check

Clutch

Check

Clutch

Feed

Clutch

Feed

Clutch

Feed

Clutch

Feed

Clutch

Feed

Clutch

Feed

Roller,

Feed

Roller

Feed

Roller,

Feed

Roller

Feed

Roller,

offset

Feed

Roller

Feed

Roller,

Feed

Roller

Feed

Roller,

Feed

Roller,

Feed

Roller,

Feed

Roller

Throat

Plate,

Throat

Plate,

Throat

Plate

Presser

Roller,

Presser

Roller,

Presser

Roller,

Presser

Roller,

in

the

last

to

be

used

column

Connecting

not

Eccentric

C.

Eccentric

Arm

Arm

Connecting

Clamp

Connecting

Eccentric

Eccentric

Collar

Collar

Shoe,

Shoe

Connecting

Connecting

Screws

hardened

Screw

Key

Holder

Holder

Holder

Sleeve,

Sleeve

Roller

Roller

Roller,

steel,

I'l

Screws

wood fibre,

Screws

No.

steel, 1 j

Screws

No.

wood fibre, 1 j

Screws

No.

steel, 2 j

rubber, 1 j

rubber, 2 j

Screws

No.

for

use

for

use

Screws

steel,

wood fibre,

steel,

wood fibre,

refer

only

in

ordering.

Rod

Connecting

Rod

Rod

Screw

No.

Rod

Rod

Rod

No.

22597.

and

ground;

No.

605

Set

Screw

No.

Clamp

Screw

hardened

Screws

Spring

Spring

hardened

inches

No.

and

No.

Pin

long,

22597.

l|

inches

22571.

inches

long,

22597.

22590.

and

inches

22751.

inches

long,

inches

long, 2 inches

inches

long, 2 inches

22597.

with

2\

if

87.

use

for

use

for

inch

inch

with

use

with

use

with

No.

for

for

to

the

plates

Refer

to

pink

Tube

Nut,

Nut,

74.

Rear

Bearing

Rear

Rear

also

A.

22517

No.

136.

ground

ground

square

long, fine

convex

long,

"V"

concave

feed

rollers

feed

rollers

feed

roller

with

feed

feed

roller

with

feed

illustrating

insert

for

prices.

left

thread,

right

thread.

Ball

Bearing

Bearing

cut

for

A.

teeth

No.

Ball

Ball

21715

corrugated

teeth

with

cut

teeth

between

diameter, flat

diameter, flat

No.

21720 A....

roller

No.

No.

21720 D...

roller

No.

teeth.

the

parts

No.

No.

Stud.

Stud

Stud

D.

face

square

...

face.

face.

21720

21720

..

Plate

No.

B

.

E

15

Page 18

LIST

OF

PARTS

Symbol

to

Order

21722

21722

21722

21723

21723

21723

21723

21724

21724

21725

21726

21726

21727

21728

21729

21731

21733

21733

21734

21735

21736

21740

21741

21745

21745

21745

21745

22517

22517

The figures

by

and

L

Presser

P

Presser

Presser

R

Presser

rollers;

A

Presser

B

Presser

rollers;

C

Presser

Presser

Presser

A

Presser

Presser

Presser

A

Presser

Presser

Presser

Presser

Presser

Presser

No.

Presser

No.

Presser

No.

A

Presser

Presser

Presser

Lifter

A

Lifter

Lifter

Lifter

Lifter

Lifter

Lifter

Lifter

Lifter

Shim, J inch

Shim

Shaft

Clutch

A

Clutch

B

Clutch

C

Clutch

Clamp

A

Screw,

in

the

are

96.

22517.

95.

last

not

to

be

Roller,

steel,

Roller,

rubber,

Roller,

rubber,

Roller

Axle

one

each

Roller

Axle,

Roller

Axle

one

each

Roller

Axle

Roller

Axle

Roller

Axle

Roller

Axle

Roller

Axle

Roller

Hanger,

Roller

Hanger,

Roller

Hanger

Roller

Hanger

Bar,

hardened

Bar

Connection

Bar

Connection

Bar

Connection

Bar

Connection

used

Spring

Spring

Screw

Guide

Bar,

Lever

Casting

Lever

Extension

Lever

Extension

Cam

Shaft

Cam,

hardened

Cam

Clamp

Cam

Spot

Cam

Cam

Screw

Shaft

Shaft

Bracket

Bracket

thick,

Screw

No.

97.

Spacing

Collar

Assembling

Assembling

Assembling

Assembling

Screw,

for

presser

for

cheek

clutch

column

refer

only

in

ordering.

for

use

with

for

use

with

for

use

Assembly,

Nos.

21723

inches

Assembly,

Nos.

21723

2-j-g

inches

Set

Screw

Spring,

for

Spring,

for

Spring

Screw

for I j

for

2\

inch

Spot

Screw

Set

Screw

and

ground,

and

Presser

and

Presser

and

Presser

and

Presser

Pin

No.

hardened

Screw

for

Clamp,

Clamp

Clamp

Clamp

22577.

and

Screws

No.

22811.

No.

96.

Screws

increasing

complete

Locking

Locking

Thumbscrew

bar

connection

holder

to

the

plates

Refer

to

feed

roller

feed

roller

with

feed

roller

for

use

with

A,

21724, 21725,

long

for

use

with

C,

21724

long.

No.

77.

use

with

No.

use

with

No.

inch

rollers

rollers

No.

81.

No.

95.

diameter

Spring

Spring

Spring

Spring

ground,

No.

93.

No.

318.

height

of

Screw

Screw

and

illustrating

pink

insert

for

No.

21720

No.

21720

No.

21720 R..

l|-

inch

28619

2y

inch

A,

21725,

28619....

21723

A

21723

C

.530

inch

Rest

Rest

Spot

Rest

Clamp

Rest

Set

diameter

.319

machine

Wing

Nut

presser

spring

the

parts

prices.

L....

P...

presser

presser

Screw

Screw

Screw

inch.

rest.

Plate

No.

16

Page 19

LIST

OF

PARTS

Symbol

to

Order

22526

22574

22577

22587

22590

22597

22637

22637

22751

22754

22802

22811

29138

29138

29138

29139

by

A

D

A

C

The

dgures

and

are

Screw,

plus

V109

Screw,

for

Screw

Pin,

Screw,

for

Screw,

for

Screw,

for

21720

Screw,

I5

Screw,

if

•

Screw,

for

Screw,

Stop

Screw,

Clamp

Driving

one

each

Driving

one

each

Driving

one

each

Driving

one

each

in

the

last

not

to

be

used

size,

for

cloth

plate

for

presser

driving

feed

clutch

feed

clutch

L,

21720

P,

inches

long,

inches

long,

wood fibre

plus

size,

for

for

lifter

Screw,

for

Eccentric

Nos.

21703

Eccentric

Nos.

21703 A and

Eccentric

Nos.

21703 C and

Eccentric

Nos.

21710

column

refer

only

in

ordering.

throat

plates, ^ inch

spring

eccentric

connecting

sleeve

collar;

21720

R

for

fastening

for

fastening

feed

rollers

cloth

plates,

cam

lifter

cam

Assembly,

and

Assembly,

Assembly,

21707

eleven

seven

21707

Connecting

and

15430 E lapped

to

Refer

also

for

Tap

four

lapped

21707

Rod

the

plates

to

pink

diameter,

rod

bearings

Nos.

21720

machine

machine

No. V 118

to

seven

together

to

sixteen

lapped

to

thirteen

lapped

together

Rear

Bearing

illustrating

insert

for

the

prices.

tap

A,

21720

to

base

plate

to

base

plate

stitches

together

together

to

stitches

to

stitches

to

Assembly;

parts

No.

D,

..

...

inch;

inch;

inch;

Plate

No.

17

Page 20

Union

As

operated

for

in

Tent

Special

Pulling

(•onneetiou

and

Awning

18

Machine

with

Style

Work

7800

C

Page 21

Union

As

operated

Special

in

for

Hemming

Inserting

Pulling

connection

with

Bloomers

Elastic

Machine

Style

7400

and

AG

Page 22

Union

As

operatt'd

Special

in

for

Stitchins

Pulling

connection

Ril>s

to

with

Machine

Style

16500

Ovcrallr!

B

rW-'

Page 23

-"-•a

STITCH

Page 24

Loading...

Loading...