Page 1

INDUSTRIAL

SEWING

flNEST

STYLES

150-260

50-270

QUAUTY

LEWIS.

COLUMBIA

MACH

INES

LIST

OF

PARTS

AND

CATALOG

No.

194-21

UNION

SPECIAL

INSTRUCTIONS

CHICAGO

CORPORATION

Page 2

Union

Special

Wants

Helpbu

to

(mmmiii

Slim

educe

ynum

system

to

and

a

pats

Machine

gm

(lmuon

mi’

lkomnm

requaed,

and

on

Request

233).

out the

fillsinthe

Maintenance

kepiir—prnmme

mirmmntenmnms’

your

Special

maci

ku’epmimg

The

lust

2.37)

their

cost

The

second

repair

costs

Card”

When

top

Cut

sewmmmj

help

imiVi’iitniV

systeom

loi

the

card

are

system

a

of

time

machine

a

Sewing

ml

is

nllm’nnil

lmma(lmmnm’

spot

immailnimmi’s

syst

Records

nm,mctninu’s

ctnllmm

suiqgu’sts Iwo

systemnm

iismmng

utilizes

each

sewiii!J

pulled

is

entered

ill

is

normally

is

desired.

(Form

234),

requires

“Repair

Request

repair

work

the

tsvo

(‘iii

or

inexls’i

s

vanations

‘‘Mactmiimc

a

mniactninm’

from

ttie

QJ4’m-r

_mmrmua

mcOm

Two

and

n,mm

na

mk’imaimim’

1511111

to

sla’i’mI

‘Iron

mm

maRts

the

spaces

used

record

“Machine

a

service,

Card”

started,

is

ii

‘y’tm’mrm

ml

costs:

iimg

ihimnmmnmilly

mnmitimim’

lie

ed

I

oidei,

‘imniplt’

of

a

1

miovidm’d

Mammmtc’nainc

in a

plant.

tile

and

fbi-’

piovided

231

when

more

cards

are used:

the

and givesitto

the

Machine

iiiijmnmiml

lii

11111

rcmnrd

a

‘pails.

mnilntemil

lim’lj)

In

by

Union

When

rm’pan

and

kr’m’ping

in,nnlm’mmimn

logIn

n)m’iatni

ttii’si’

Sl)t

niaimmtm’n,mn

Sla’ciil.

Record’

a

im’paii

date,

ttmecaid

caid

pails

is

of

-j

—

-

detailed

Repair Record”

forelady

parts used

a

“Repair

or

foreman

mechanic.

a

and

information

(Form

their

nid

s

cdii

piohli’mrms,

is

used,

iled.

fills

He

cost,

Maintenance

llii’mnmirplc’lioii

cit

abrini

he

needed

for

when

inventory

local

md

Mactnne Repair

Wliste’vt:r

im’dml(

t’

to

Repair

ami’a’d

wconmmnends

system

downtime

Part

WInk’

mnally

by

toy

Excessive

elinrinated

spare

the

For

free

Union

needless

record

rnutiime

parts.

parts.

is

overall

sample

lists

system

Inventories

keeping

high

that

each

niacliimie

with

Theme

Long

kept

for

Special

tire.

Recoid

is

namirtr’naimcm’

inaintenmimee,

repairs.

manulactumem

of

type

downtimmme

orderly

an

isnolonger

waits

to

a

savings

copies

varietyofthe

a

Representative

3liisd,rti

‘‘

keptmmtIme

used,

tells

To

sewing

for

minimum.

are

the

of

Costs

istlremm

office.

irmanamlenrent

usts.

nminagenient

it

does

littletohelp

alleviate

in—plant

considered.

this

s

establish

machine

and

wasted

inventory

a

needtocannibalize

deliveries

The

costofa

c

-

machine

most

popular

or

write

tiammsteried

now

has

which

situation,

a

formal

they

operate.

hours

of

are

avoided and

parts

::

O0su

record

cards

machines,

direct

to

ttie

an

niacliines

reducethe

Union

parts

by

mechanics

the

most

other

inventory

and

to Union

si

invaluihl’

o’mimmi

downtime

Spv(

iventum

i

commnnly

machines

machine

spare

contact

Special.

isil

ml

y

iii

small

is

part

your

Part

Number

23-338

18-732

29

BL

137-77

126-59

18-634

1733

18-261

21-240

75-251

18-416

6-56

18-643

parts

The

inventory

actual

u®zu

07

,.1

,

11

g,:,

Description

Feed

Dog

Screw

Needles

Cloth

Retainer

Crown

Screw

L

and quantities

of

spare

usage’.

The

parts.Anefficient

nature

Spring

Screw

Spring

Edge

Screw

Needlr

Scre

listed

of

for

for

for

for

Guide

for

above

ihe

for

Feed

Crown

Crown

Spring

Retainer

Bushing

ide

sedle

are intended

inventory

operation

Dog

Guide

(specify size)

sewrng

can

to

only

assist

will

Minimum

youinsetting

be

established

determine

Per

5

actual

Quantity

Machines

1

2

100

1

1

2

1

2

1

1

2

1

1

up

the

according

usage.

initial

Style

Suggested

Part

Number

1

8-307

CS327

44-328

444-330

36-16

1

170

L

18-662

18-71

18-70

810

L

122-C

38

18-292

to

Description

Screw

Screw

Ridge

Yielding

Looper

Screw

Screw

Screw

Screw

Screw

Chaining

Screw

150-270

Minimum

Presser

for

for

Presser

Ridge

Looper

Looper

Looper

Needle

Needle

Finger

Chaining

Disc,

Former

Adjusting

Yoke

Carrier

Clamp

Forming

for

for

for

for

for

for

Spare

Foot

Foot

Left

Finger

Parts

Bracket

Bracket

Sleeve

Lisr

Minimum

Per

Machines

5

2

2

1

1

1

4

2

2

2

4

1

2

Quantity

Page 3

Catalog

No,

194-21

(Supplvm’nl.

ADJUSTING

150—260

Cntalog

to

INSTRUCTIONS

F0R

AND

LIST

OF

Styles

OPERATING

PARTS

No,

150—270

194-9)

Union

Rights

UNION

INDUSTRIAL

First

Copyright

Special

Reserved

SPECIAL

SEWING

CHICAGO

Edition

1974

©

by

Corporation

in

All

Countries

CORPORA

MACHINES

TION

in

U.S.A.

3

December,

Printed

1978

Page 4

Each

tIu

into

machine

This

junction

not

but

identified

are

the

tain

another

of

numbers

or

indenting

by

Always

the

in

The

can

It

References

operator’s

-tvlu

is

catalog

therewith.

on

part

use

first

catalog

also

1O

V

stamped

Style

number,

part

inside

the

column

be

to

position

S

plate

is

150-230

a

by

is

description

its

part

applies

applied

direction,

IDENTIFICATION

‘I

CLL

I

located

the

in

APPLICATION

supplement

a

Only

reference

illustrated

a

when

those

are

description

bracket

number

specifically

with

while

ordering

such

seated

LEWIS

the

on

arm

under

parts

illustrated

number

on

or

under

the

in

discretion

as

machine

head

to

and

the

box.

right,

at

Catalog

which

and

amount

picture

On

the

second

repair

to

the

OF

carries

the

of

the

top

OF

andlisted

this

the

description

column,

parts.

Standard

the

other

to

left,

machine,

MACHINES

machine.

cover.

CATALOG

No.

are

used

reference

required,

plate

copy

front,

a

194-9

the

at

by

page

never

Style

Styles

style

on

having

a

of

back,

number

The

and

Styles

back

of

number

part

Any

component

the

assembly

use

machine

of

machines

of

etc.,

serial

should

150-260

this

the

the

which

number

be

book.

then

is

that

reference

part

reference

as

are

is

used

and

The

used

component

a

is

indicated

is

or

base

listedherein.

this

in

given

stamped

each

of

con

in

150—270,

parts

ob

to

number

part.

number

class.

from

the

Single

Machine,

Line-of-Feed.

justment

pendent

Sides

150-260

150-270

starts.

125

However,

Thread,

of

tacking

similar

(Modified),

pinked,

Seam

The

Use

seconds

Needle

the

of

Ridge

Seam

the

For

hemming

facings

operations

hemming

For

serged

specification

machine

a

at

reference

Single

Travels

Calibrated

Stitch

Forming

on

should

goodrade

100

DESCRIPTION

Curved

Penetration

Length.

Discs

Each

bottoms

the

to

on

bottoms

piped

or

105-EF1-

be

Fahrenheit.

the

to

Needle,

from

Knee

Stitch,

foreparts

medium

edges

oiled

straight

of

oiling

Left

Which

on

on

1

Oiling

diagram

OF

Non-Skip

Right

to

Adjustment,

Lifter

Permits

Equipped

medium

(fronts)

weight

light

(Modified).

twice

and

OILING

mineral

weight

similar

daily,

MACHINES

and

Inserting

for

with

weight

on

fabrics.

fabrics

oil

places

(Fig.

Stitch,

Penetrates

Push

Needle

the

Stationary

fabrics

women’s

Seam

operations

before

with

the

on

will

1)

Chainstitch,

Button

and

medium

specification

(dresses,

the

Saybolt

a

machine

beneficial.

be

at

for

Removing

Penetrate

to

Work

(skirts,

on

light

morning

viscosity

an

Quick

Support

weight

skirts),

weight

and

are

Blind

Angle

Easy

Work.

Alternate

coats,

coats

105—EF1-1

with

afternoon

painted

Stitch

90°

Inde

Plate.

etc.),

fabrics.

90

of

red.

to

Ad

and

raw

to

SPEED

ting

Maximum

direction

recommended

handwheel

of

is

speed

away

for

from

these

the

4

machines

operator.

3000

is

R.

P.

M.

The

opera

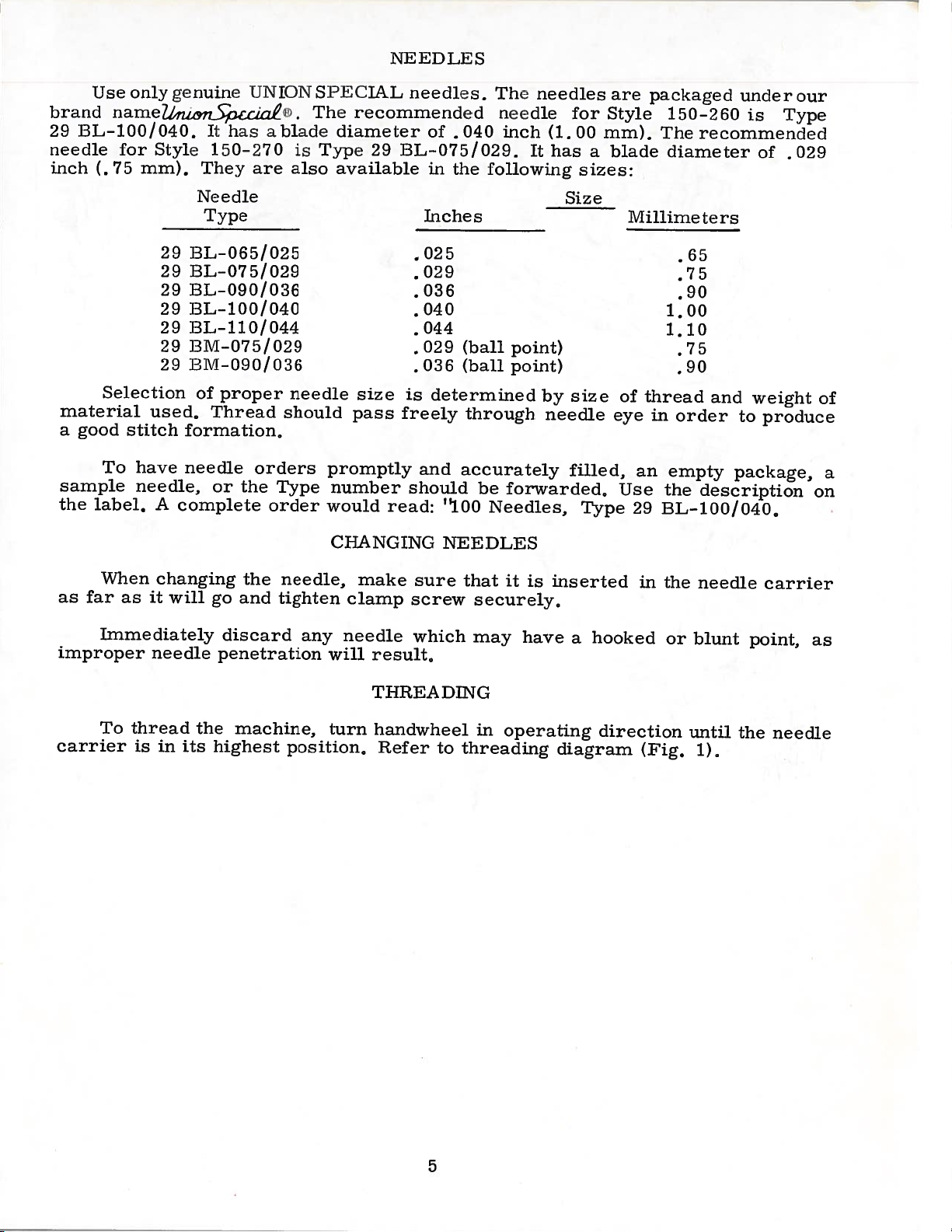

Page 5

Ni

ED

LI

S

Use

brand

29

I3L—l00/040.

needle

inch

(.75

material

good

a

sample

the

label.

onLy

nanieZiunccth

Style

For

mm).

29

29

29

29

29

29

29

Selection

used.

stitch

have

To

needle,

A

genuine

It

has

150-270

They

Needle

Type

HL—065/025

BL—075/029

13L—090/036

BL—100/040

BL-110/044

BM—075/029

HM—090/036

proper

of

Thread

formation,

needle

the

or

complete

UNION

blade

a

are

also

needle

should

orders

Type

order

SPECIAL

The

Type

is

promptly

number

would

CHANGING

recommended

diameter

29

available

size

pass

read:

needles.

.

040

of

13L—075/029,

in

the

following

Inches

.025

.029

.036

.040

.044

.029

.036

is

freely

should

(ballpoint)

(ballpoint)

determined

through

and

accurately

be

“100

NEEDLES

The

needle

inch

It

forwarded,

Needles,

needles

Cor

(1.

has

Size

size

by

needle

filled,

00

a

sizes:

Type

are

packaged

Style

mm).

blade

lVlillimeters

thread

of

eye

an

Use

29

150—260

The

recommended

diameter

.65

.75

.90

1.00

1.10

.75

.90

and

in

order

empty

the

description

BL—100/040,

under

is

of

weight

to

produce

package,

our

Type

.029

of

a

on

When

far

as

Immediately

improper

To

carrier

as

thread

is

changing

it

will

needle

its

in

and

go

discard

penetration

the

machine,

highest

the

needle,

tighten

any

position,

needle

will

turn

make

clamp

result,

THREA

handwheel

Refer

sure

screw

which

to

that

DING

threading

it

securely,

may

in

operating

is

have

inserted

a

hooked

diagram

in

direction

(Fig.

the

or

needle

blunt

until

1).

point,

the

carrier

as

needle

5

Page 6

Page 7

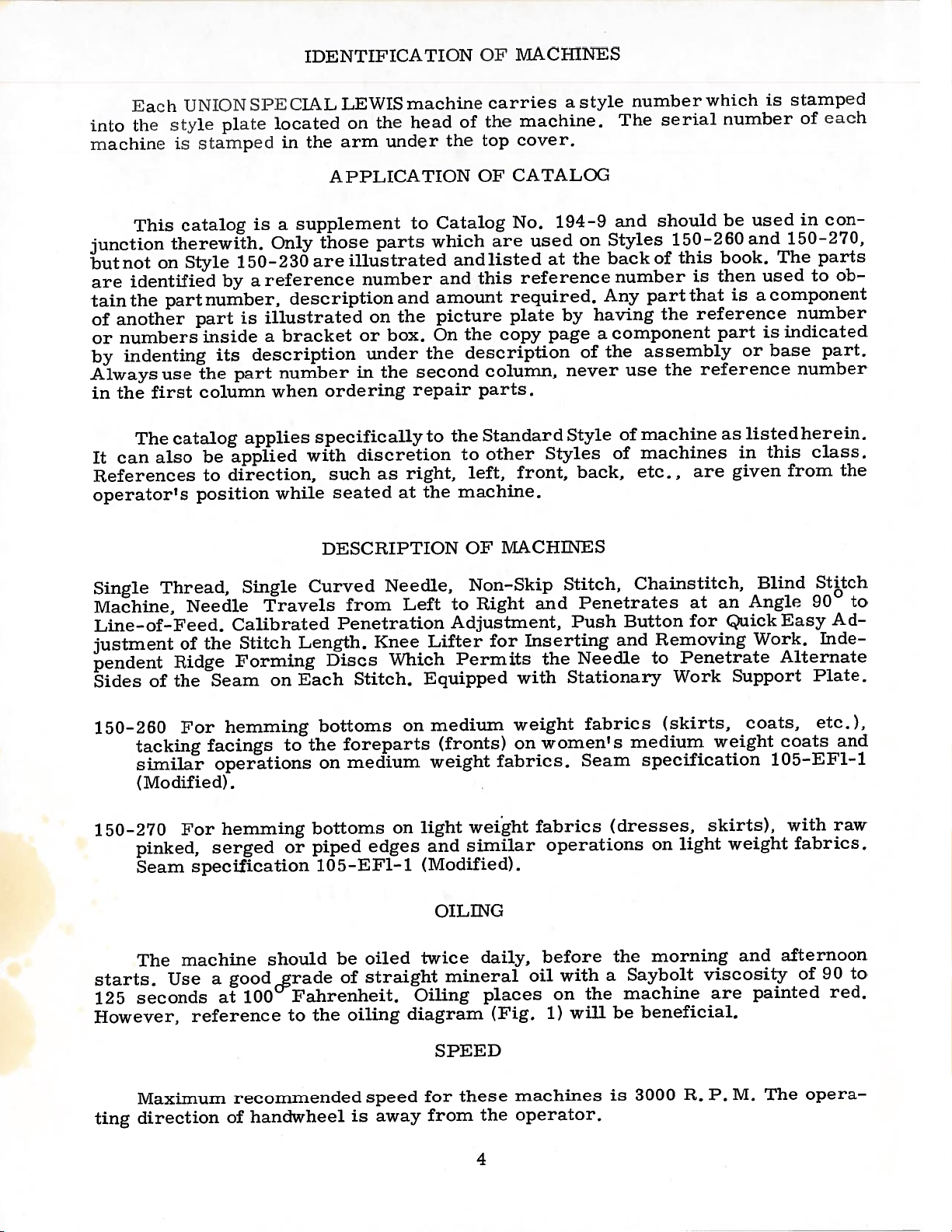

i\

DJUSTING

RESSER

P

FOOT

ADJUSTING

TO

NEE

DLE

foot

A

view

which

the

of

are

presser

referred

to

foot

in

(Fig.

this

and

is

2)

subsequent

shown

to

illustrate

adjustments.

I)

the

various

parts

of

the

B

N

.

R

T

‘“1

F

•

I

\

K

I’_

/

M

Fig.

2

Below

A

B

-

C

-

D

-

E

-

F

-

0

-

H

-

J

-

K

-

L

-

M

-

N

-

P

-

-

Q

R

-

-

Needle

Cloth

Needle

Looper

Radius

Chaining

Crown

Cloth

Eccentric

Eccentric

Eccentric

Cloth

Knurled

Set

Spring

Set

is

screw

screw

the

key

guide

opening

track

opening

run-out

finger

retainer

guide

adjusting

adjusting

stud

stud

stud

to

the

edge

set

sleeve

labeling

screws

screw

(for

(for

as

left

right

shown

cloth

cloth

in

Fig.

retainer)

retainer)

2,

S

-

Edge

T

-

Looper

guide

guard

7

Fig.

3

Page 8

A1)JUSTING

Insert

carrier

the

right

the

of

and

needle

and

needle

P’

‘:$1/

.ff

Fig.

attempted.

PRESSER

new

a

securely

point

that

so

/

lies

7

4

needle

contacts

the

in

B

/

FOOT

tighten

needle

the

of

span

proper

the

the

remains

right

to

needle

needle

(A,

the

screws

foot

the

little

a

After

further

NEEDLE

TO

clamp

needle

between

side

move

and

track

To

Fig.

heads

up,

presser

screws

and

type

screw.

guide

contact

in

the

the

of

the

to

the

(C).

accomplish

on

3)

not

do

on

(B)

retighten

foot

time,

at

a

adjustment

(Continued)

size,

Set

Fig.

(A,

with

center

cloth

right,

needle

these

top

of

contact

side

the

these

up.

to

on

(B)

as

the

opening.

play

guide

the

Adjust

obtain

the

of

far

presser

when

2)

the

the

of

should

until

adjustments,

presser

brackets,

the

each

of

screws

the

the

sides

top

the

will

it

as

foot

traveling

needle

cloth

guide

opening

the

As

develop

the

foot

bracket,

just

(B)

screws

top

aforementioned

have

screws

go

to

needle

needle

brackets,

Loosen

been

into

the

from

until

(B)

between

reaches

loosen

move

enough

(A)

tightened,

(A)

needle

the

needle

left

the

and

continues

screws

so

upper

the

presser

to

equally,

settings.

should

so

to

point

the

the

the

that

hold

no

be

SETTING

Turn

needle

with

the

needle

radius

of

travel

the

following

Turn

needle

ing

(B,

screw

hole

Turn

needle

the

sults,

is

located

needle

seated

NEEDLE

the

left

run-out

of

manner.

the

is

Fig,

in

the

handwheel

eccentric

against

is

2)

point

point,

eye

the

carrier

CAUTION:

handwheel

at

the

side

of

right

at

edge

needle

the

handwheel

flushwith

in

the

needle

point

at

at

is

Fig.

When

the

STROKE

in

of

left

looper

stroke,

of

(E).

will

in

the

presser

crank

(A,

in

operating

its

extreme

ball

6

adjusting

needle

operating

stroke.

opening

If

have

operating

right

foot.

(accessible

Fig.

stud

4)

(A,

shaft

should

this

to

side

in

right

the

crank.

direction

should

It

(D,

is

not

adjusted

be

direction

the

of

Loosen

top

direction

end

Fig.

needle

Fig.

be

cloth

the

through

the

of

of

so

5)

marks

viewed

ball

back

screw

needle

of

carrier

rotate

setting.

be

needle

away

side

ary

above

until

be

2).

the

to

the

until

clamp

head).

until

travel.

that

the

set

eccentric

the

flush

The

top

case,

in

the

the

open

the

the

its

in

in

is

stud

near

and

point

looper

clamp

carrier

Also,

front

is

from

presser

of

slightly

to

adjustments

Remove

slot

the

Fig.

located

the

recheck

in

to

flush

vertical

ball

vertical

is

ball

5.

top.

relation

opening.

screw

as

needle

the

back

to

foot.

retard

stud,

head

stud

The

in

Retighten

the

required

so

.003

wall

It

obtain

to

make

Fig

cover

and

are

needle

the

position

to

Loosen

(C,

carrier

the

inch

may

or

5

the

down,

eccentric

head,

the

the

Fig.

for

side

(.076

the

at

be

advance

desired

sure

and

punch

at

clamp

of

left

needle

3)

above

should

of

necess

that

turn

as

the

the

side

and

the

mm)

right

the

re

it

8

Page 9

shank

holder.

groove

Insert

corresponds

In

and

the

the

on

looper

left

the

with

end

looper

LOOPER

in

its

flat

the

of

crank

T11VI

holder

on

holder

mainshaft

(B),

INC

so

there

ANIDA

that

and

is

(A,

isatiming

DJUSTME

the

seated

Fig.

flat

6)

is

on

in

a‘VTT

its

the

line.

NT

I

groove

Fig.

(A,

that

so

groove

“V’

T

an

approximate

ting

is

over

the

of

mm)

prong

no

by

long

-.—

•

\‘.-

•

and

(E)

secured

in

its

the

the

7)

Turn

direction

the

loopershould

away

the

of

more

prong.

I

A

3

moving

by

handwheel

mainshaft

in

timing

in

the

until

spot

from

looper

than

The

Fig.

rotating

the

setting,

in

the

1/32

long

the

looper

line

coincides

mainshaft

Again

the point

needle.

the

be

from

left

should

inch

prong

8

adjusting

the

sleeve,

in

operating

is

at

crank

(See

of

3/64 to 5/64

end

of

clear

(.79

looper

E)

bottom.

(B)

with the

Fig.

turn

the

At

this

the

the

mm)

.

sleeve

direction

Loosen

position

and

6).

the

handwheel

prong

long

time,

inch

needle

chaining

and

point

should

the

rotation

of

the

looper

on

its

the

looper,

adjustment

pulation

andthe

6)

looper

laterally

vertical

ment

is

in

right

This

the

eye.

cross

should

not

looper

opening

return

of

adjusting

or

secured

or

out.

until

two

of

(1.19

finger

come

the

looper

and

the

edge

is

in

the

long

The

the

be

the

of

should

in

stroke

midway

the

of

looper

also

height

Vertical

the

“V’

T

screws

crank

of

the

merely

opera

looper

prong

to

1.98

short

Fig.

(F,

needle

close

in

contact

handwheel,

the

looper

holder

sleeve

provides

adjustment.

loosening

by

2)

slightly

the

to

with

clear

the

presserfoot

should

between

is

adjusting

connecting

positions

height

or

of

needle

right

enter

the

secured

limited

a

the

-

Fig.

the

presser

higher

it.

On

the

and

the

prongs.

sleeve

rod

Lateral

clamp

adjustment

—

7

than the

spot,

continuing

short

side

the

needle

crotch

by

(C,

(D).

the

looper

amount

adjust—

foot

prong

of

The

mani

Fig.

The

screw

but

the

of

of

is

The

greater

the

to

Fig.

ing

6)

the

screw

amount

adjusting

adjustment

As

when

inch

the

8)

when

end

depth

on

of

point

(4.

the

the

clamp

may

be

for

shorter

back

of

looper

extentthan

spot

on

the

connecting

and

connecting

of

height

sleeve

of

the

needle

of

76

mm)

ofafull

right

feed

the

slot

screw

necessary

the

feed

of

the

connecting

both

needle

side

bar

in

(H,

number

holder

the

needle,

rod,

adjustment

as

previously

the

travels

behind

tooth,

of

is

the stud

Fig,

to

rotate

of

dog

slot

connecting

adjusting

initial

(D),

rod

rolling

rod

lock

nut to

is

described,

connecting rod

SETTING

is

needle.

the

all

from

flush

The

head.

the

right

with

Feed

feed

way

should

and

the

position

punch

6)

stitches.

in

the

presser

rod

sleeve.

adjustment

clamp

the

looper

maintain

required,

and

to

right

dog

dog

is

The

slot

towards

be

towards

stud

marks

CAUTION:

also

If

screw

though

adjusting

FEED

left,

side

should

adjusted

in

the

foot.

9

adjusts

the

to

it

looper

can

(G)

the

can

the

be

final

the

be

made

in

desired

desired

secured

is

connecting

setting

sleeve,

DOG

feed

dog

opening

the

of

cloth

depress

means

by

eccentric

operator

the

operator.

as

required, retighten

down

Feed

in

dog

stud

looper

radically

feed

stud

and

to

must

by

height.

height.

by

involves

should

of

(B)

the

To

obtaina

not

vertically,

out

loosening

rod

Retighten

rotating

contact

and

feed

plates

two

screws

should

punch

position

clamp

graze

but

adjustment,

of

the

yoke

if

only

and

a

the

coordinated

a

feed

dog

is

approximately

(A,

be

horizontal

marks

stud,

screw.

full

tooth

looper

to

nut

turn—

clamp

slight

looper

plates

3/16

Fig.

at

the

loosen

depth

or

the

a

(F,

It

Page 10

SETTING

FEEL)

PLATES

Pressure

back

turning

ate

pensate

the

directlyunder

3

to

of

the

springs

for

Fig.

number

stitches

8

cylinder.

the

nuts

which

varying

A

9

corresponding

on

the

clockwise

the

indicator.

per

feed

Turning

should

thicknesses

from

plates

Feed

1/32

operating

CHANGING

the

arm

the

arm

erals

the

knob

ism.

inch.

plates

them

the

acts

be

adjusted

There

moving

plate

inch

The

While

must

should drop

holder

(.79

position

stitch

of

and

which

down

to

the

Release

is

controlled

reverse.

material

of

be enough

when

mm)

STITCH

length

machine

the

observe

indicate

which

holding

desired

knob, The

l-wo

by

counterclockwise

Each

so

the

uniformly

adjusting

and

the

that

and

pressure

needle

from

locked

LENGTH

regulated

is

near

feed

the

the

number

will

engage

knob

the

amount

cause

work

stitch

nuts

feed

tensions

makes

when

screws

table

nuts

by

the

indicator

down,

of

Fig.

(A,

increases

plate

head.

of

inaslot

range

is

on

the

work

the

applied

penetration.

its

cylinder

the

Fig,

(D,

with

(E).

the

by

Open

on

stitches per

turn

stitches per

of

the

the

located

9)

the

controlledby

plates

feed

to

to

keep

is

should

3)

the

work

knob

the

in

(B,

the

top

shaft

the

feed

handwheel

inch

machine

tension

separ

will

uniformly.

the

material

The

depressed.

table

Fig.

cover

with

inch.

mechan

appears

is

in

com

feed

be

4)

num

Press

until

from

the

and

set

in

on

on

These

forming

type.

The

between

ing

disc,

Style

the

of

height

compensate

disc

material,

material,

“right”

Two

The

the

The

The

is

150-270.

work

of

machines

disc

is

“right”

right

right

left

height

sufficiently

side

for

Style

ridge

dial

knobs

hand

table

hand

left

the

for differences

The

a

ridge

The

forming

which,

hand

the

of

left

SETTING

are

“solid”

forming

cloth

of

150-260.

‘left”

disc

control

knob,

dial

in

dial

knob,

ridge forming

ridge

high

hand

that

disc

RIDGE

equipped

type,

disc

opening

This

ridge forming

without

the

located

turn,

located

in

the

forming

the

is

with

while

should

in

measurement

height

raises

number

discs

needle

set

FORMING

two

the

presser

disc

contacting,

adjustment

on

the

or

at

the

disc

independently

is

just

so

that

ridge

right

be

foot

should

arm

lowers

left

piys

of

set

penetrates

the

set

ridge

to

and

should

for

of

the

of

end

of

at

the

needle

DISCS

forming

measure

be

both

the

machine,

both

of

material

factory

discs.

forming

3/32 inch

the

right

1/8

as

Styles.

work

the

top

penetrates

inch

close

forming

right,

being

so

be

set

ridge forming

ridge

the

of

the

just

disc

side

adjusts

table,

that

ply

The

is

of

(3.

as

and

sewn.

the

of

a

(2.38

ridge

17

possible

discs.

the

discs.

adjusts

three

one

left

‘rielding”

form

mm),

position

used

is

right

plys

ply of

ridge

mm)

for

to

the

to

hand

of

An

Mounted

spring

depth

additional

in

actuated

needle

of

the

adjustment

presser

crown

penetration

foot

(G,

is provided

and

Fig.

from

located

2),

the

With

top

over

this

side

10

with

the

device,

of

the

the

ridge

presser

right

it

yielding

former

is

possible

ridge

isacompensating

to

foot.

former,

regulate

the

Page 11

SETTING

RIDGE

FORIVILNG

DISCS

(Continued)

The

:nmterial

the point

t:ravel.

from

crossing

When

insert

the

crown

the

set

All

further

screw

To

screw

To

adjusting

the

nut.

Pressure

forming

in

the

compensating

Because

the

(luring

of

top

the

penetration,

of

the

of

seams,

making

folded

right

materialcomparable

that

so

ridge

adjustments

located

adjust

in

the

counterclockwise.

increase

screw

is

directly

disc

bottom

adjusting

by

of

same

full

this

work.

will

the

it

former

the

crown

the

clockwise,

spring

travel

the

condition,

cause

preliminary

does

should

crown

spring

applied

the

(A,

the

in

the

of

crown

the

Any

variation

ridge

the

to

not

contact

height

so

be

of

the

presser

for

more penetration

For

less

pressure

counterclockwise

to

Allen

Fig,

head

10).

crown

ridge

is

set

needle

former

penetration

weight

the

the

that

made

by

penetration,

on

the

the

yielding

screw

insures

former,

to

will

in

work.

the

using

foot,

crown,

come

always

thickness

to

yield.

setting

material

of

By

needle

the

of

turn

for

ridge

located

continual

As

the

to

a

positive

penetrate

of

of

using

penetrates

knurled

the

needle,

the

turn

less

contact

ridge

the

the

tobe

the

screw

the

pressure,

with

former

stop

the

work,

right

hemmed

right-hand

the

desired

head crown

turn

clockwise.

screw

in

the

travels

in

its

same

such

ridge

and

dial

adjusting

the

adjusting

the

center

Retighten

fold

upward

distance

as

when

former,

raise

knob,

depth.

lock

of

to

of

crease

the

1.

2.

3.

Should

right

Rotate

to

the

Remove

Lift

in

the

dial

over

Fig.

the

hand

the

shaft.

the

it become

height

dial

right

end

of

screw

dial

dial

seat,

Rotate

stationary

11

of

range,

hand

its

knob

the

dial,

travel.

(A,

but

necessary

discs

proceed

in

Fig,

that

so

so

the

dial

stop

4.

Replace

Refinements

be

made

To

disc

loosen

the

slotted

sired

beyond the

the

and

11)

its

that

its

in the

pin and

by

increase

beyond

the

direction,

to

increase

as

follows:

required

spring

stop

key

required

the

spring

adjusting

the

two

stud

pin

disengages

slot

dial

of

or

limits

locking

located

Retighten

or

limits

direction,

(B).

remains

direction

reengages,

and

screw.

this

adjustment,

the

decrease

of

screws

in

de

of

push

the

the

screws.

from

the

engaged with

until

within

rod

stop

the

height

left-hand

located

center

in

of

Fig.

stationary

its

stop

any

screw

of

dial

range,

the

the

dial

the

the

range,

(A,

dial

10

stop

key

pin

Fig.

left-hand

and

in

the

in

passes

may

12).

simply

turn

de

pin

the

The

the

TABLE

position

to

the work

tension

TENSION

of

the

table

on

the

ridge

by

right

forming

the

large

discs

coil

ridge forming

is

spring

disc.

fixed

in

WORK

applied

trols

11

in

the

the

work

base

of

table.

the

The

machine

tension

con

Page 12

The

small

Fig.

STARTING

coil

10).

tension

spring

H

‘1

Fig.

TO

WORK

the

on

located

12

OPERATE

left

in

3LE

TA]

ridge

the

forming

under

creased,

sewn,

Fig,

ion,

hand

Turning

counterclockwise

TENSION

side

Tension

by

For

13).

counterclockwise

disc

(Continued)

disc

of

onboth

depending

following

the

right

Turning

tension,

screw

independently

is

left

the

on

hand

nut

clockwise

acts

end

discs

the

adjustments:

disc

clockwise

acts

adjust

the

of

can

weight

tension,

the

screw

reverse.

controlled

work

the

increased

be

material

of

increases

reverse.

increases

adjust

(B,

table

or

nut

For

Fig.

tension,

by

(B,

de

being

(A,

tens

left

10).

a

Thread

gram

2.

Move

dog

the

guide

3.

Adjust

penetrate

the

left

4.

Adjust

(B)

the

is

no

tration.

eccentric

(M)

Tn-line-of-feed

eccentric

machme

(Fig.

knee

the

with

right

the

on

needle

required

hand

crown

the

of

ridge

penetrating

will

loop

Lateral

which

1).

press

folded

ridge

front

penetration.

folded

the

direction.

knob

dial

presser

forming

form,

adjusting

fixed

is

adjusting

accordance

in

to

edge

forming

of

in

Fig.

(G,

foot,

discs

material,

the

adjustment

to

adjustment

right

of

the

edge

Check

the

2)

resulting

studs

eccentric

studs

threading

with

andinsertworkunder

the

material

and

disc

presser

Sew

at

same

and

close

as

firmly

to

(K

(K

the

is

against

foot.

few

a

desired

penetration

manner.

cloth

to

the

if

skipped

in

secured

is

and

L)

stud

made

and

L).

stitches

retainer

the

hold

material

laterally

(K)

by

directly

depth,

needle

the

stitches

by

also

loosening

the

at

work

loosening

dia

feed

over

edge

and

turn

the

(H),

as

carried

is

to

moves

inspect.

the

single

located

possible

the

on

and

desired

laterally

screws

the

If

right

of

ply

in

and

discs

along

improper

screws

position.

(J)

j.

Fig.

needile

hand

fabric

the

while

with

(J)

with

and

cloth

set

needle

same.

3

13

does

dial

and

relative

the

the

and

Cloth

turning

not

knob

adjust

opening

needle

needle,

pene

moving

guide

the

in

to

Tension

adjusting

Ridge

Tension

adjusting

adjusting

sired

on

screw

Forming

on

sleeve

stud

tension

the

the

right

Discs”.

(L)

and

(N)

left

(Q).

in

retighten

hand

and

hand

Loosen

position.

the

spring

cloth

the

set

left

actuated

screw

retainer

set

Turn

set

screw

spring

screws.

12

(P).

crown

can

Refer

be

and

(J)

adjusting

varied

controlled

is

adjustment

to

set

by

screw

sleeve

turning

(R)

(Q)

by

under

while

to

the

the

secure

knurled

“Setting

spring

holding

de

Page 13

fJ

5

t:ht

forming

retainer

assure

ting

6.

Removingwork.

withdrawn

work

stitch.

edge

the

the

with

guide

folded

disc.

while

that

machine,

from

a

cloth

quick

STI\

(S,

edge

Looper

sewing

retainer

To

the

pull

RTfN(

Fig.

of

hold

remove

material,

the

guard

over

the

away

has

2)

material

maximum

cannot

folded

work

fromyou,

TO

(T)

push

OPERATE

a

only

is

should

flip

edge

after

the

lateral

guided

be

thickness

up

into

of

the

stitching,

knee

in

order

(Continued)

adjustment

directly

set

so

material,

of

path

the

material

see

press

break

to

to

as

over

that

the

not

of

the

against

the

and

the

to

the

right

should

contact

yet

looper.

needle

thread

right

the

and

low

and

be

hand

the

enough

In

edge

is

entirely

remove

lock

set

ridge

cloth

opera

guide.

so

to

the

the

13

Page 14

14

Page 15

The

on

parts

Styles

LIILIStI’ateCl

150—260

and

C)fl

pjt

150—270,

14

and

but

described

not

used

on

on

this

Style

page,

150—2

represent

30,

improved

the

parts

machines.

that

are

used

Those

150—230,

Catalog

Use

Reference

descriptions,

Ref.

No.

1

—

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

19A

20

21

22

-

23

24

25

26

27

28

29

30

31

32

-

33

34

35

36

37

38

38A

39

40

41

42

parts

150—260

Part

405—587

405—588

137—77

122—C38

1081

41358

LS330

1733

126-59

79077

22560

12934

444-330-1

444-330

9653

22845

22894

999—143

22799

24—331

24-332

shown

No,

numbers

indicate

PRESSER

No.

17—87

21—240

18—292

6—56

18-643

18-416

16—214

L

8—141

18—989

75—251

A

73

17—180

44-332

44—331

39—149

73

A

5-587

5-588

18—261

L

18-1109

22—317

21—300

A

A

44-330

A

P

21-433

21-445

99—355

U

in

ard

194—9

that

phantom

1.50—270.

for

are

the

FOOT,

Presser

Presser

Eccentric

Collar

Screw

Spring,

Crown

Screw

Knurled

Pin

Spring

Screw,

Nut,

Yielding

Yielding

Ridge

Pin

Screw

Set

Ball

Spring,

Spring,

Ridge

Screw

Feed

Feed

viewS

all

parts

inside

are

Foot

Foot

Eccentric

Spring

Retainer

Screw

Chaining

Needle

Screw

Set

Screw

Bushing,

Screw

Disc

Screw

Washer

Edge

Set

Screw

Screw

Cloth

Cloth

Screw

Presser

Presser

Ridge

Ridge

Screw

Plate,

Plate,

and

not

a

components

RIDGE

Assembly,

Assembly,

Finger

Guide

spring

Guard,

Guide

Stud

Guide,

Guide,

Foot,

Foot,

retaining

Adjusting

spring

locking

Former

Former

Forming

for

for

Former

left

right

bearing

illustrated

bracket

FORMING

Stud

marked

for

for

tension

No.

No,

Holder

or

a

of

tensioning

No.

No.

main

main

Screw

Assembly,

Assembly,

Disc,

444-330

444-330-1

15

no

reference

box

complete

DISC

Description

for

for

!A

t

405-587

405-588

section,

section,

adjusting

marked

or

on

Style

Style

described

the

part

AND

150—260

150—270

for

for

for

for

numbers

picture

or

FEED

No.

No.

Style

Style

here.

plate

assembly.

PLATES

405-587

405—588

150-260

150-270

are

common

and

have

to

Styles

indented

Amt.

Req.

2

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Page 16

L E

V

WORLD’S

ATLANTA,

BOSTON,

CHICAGO,

DALLAS,

LOS

FINEST

UNION

facilities

aid

equipment

Special

tory

promptly

tion,

serve

ANGELES,

QUALITY

*

SPECIAL

throughout

in

you

for

representatives

trained

and

thereisa

you.

Check

GA.

MASS.

ILL.

TEXAS

CAL.

maintains

selection

the

your

are

and

efficiently.

Union

with

INDUSTRIAL

sales

world.

the

of

particular

and

service

abletoserve

Whatever

Special

him

today.

MONTREAL,

TORONTO,

BRUSSELS,

LEICESTER,

LONDON,

SEWING

service

and

These

the

operation.

offices

right

men

your

your

sewing

Union

are

needs

loca

Representative

CANADA

CANADA

BELGIUM

ENGLAND

ENGLAND

MACHINES

will

fac

to

NEW

YORK,

PHILADELPHIA,

UNION

400

N.

N.

PA.

Representatives

industrial

SPECIAL

FRANKLIN

Y.

and

distributors

Cities

throughout

ST., CHICAGO,

PARIS,

STUTTGART,

in

the

all

world.

FRANCE

GERMANY

important

CORPORATION

ILL.

60610

Loading...

Loading...