Page 1

FINEST

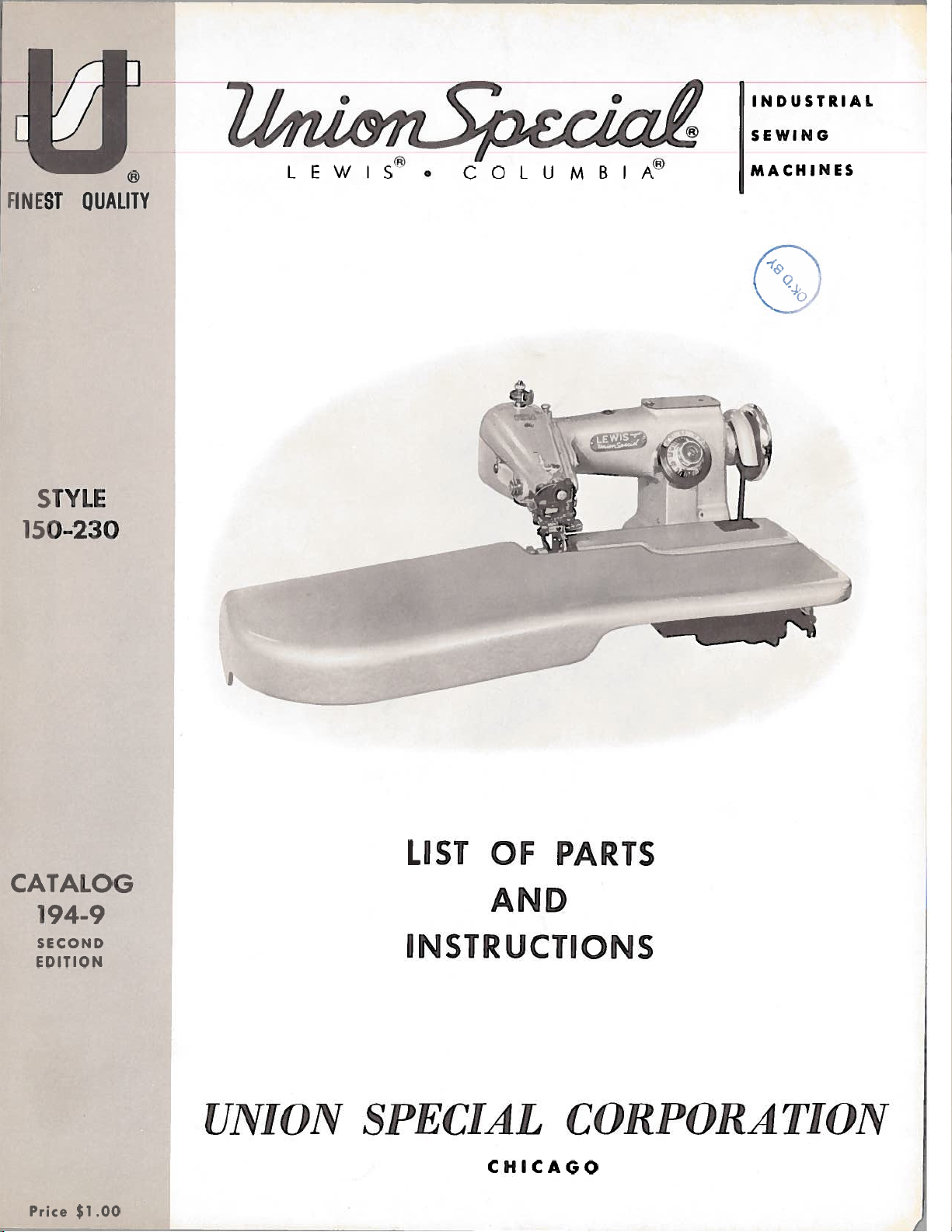

STYLE

150-230

()

QUALITY

liz.c,it...

1

becaz.e

LEWIS

.

COLUMBIA®

I

INDUSTRIAL

MACHINES

SEWING

OJ

\%_

CATALOG

194-9

SECOND

EDITION

LIST

OF

PARTS

AND

INSTRUCTIONS

J

UNION

Price

$1.00

SPECIAL

CHOCAGO

CORPORATION

Page 2

Catalog

No.

194-9

ADJUSTING

INST

LIST

Style

U

R

FOR

AND

OF

IONS

CT

PARTS

150-230

OPERATING

Union

Rights

UNION

INDUSTRIAL

Second

©1961

Special

Reserved

SPECIAL

SEWING

CHICAGO

Printed

Edition

by

Corporation

in

All

Countries

CORPORATION

MACHINES

US.A.

in

2

September,

1977

Page 3

FOREWORD

Style

machine.

ability.

It

enable

machines.

illustrate

Union

cooperate

is

the

150-230

All

parts

our

constant

customer

The

and

describle

Special

witU

is

are

to

following

representatives

you

to

Union

made

aim

secure

the

plan

to

all

pages

parts

and

Special

by

precision

furnish

possible

contain

estimate

Corporationis

for

Style

will

UNION

methods

carefully

advantages

valuable

150-230.

be

found

requirements.

SPECIAL

latest

insuring

prepared

from

operating

in

all

blindstitch

complete

information

the

use

of

and

adjusting

manufacturing

CORPORA

Engineering

face

interchange

UNION

tacking

which

SPECIAL

data,

centers,

TION

Department

will

and

to

3

Page 4

lI)1N’rIl’I(ArION

()[

IV)

/\C’)

uN

)‘S

Each

stamped

I1Iej(I

COV(F.

This

direction,

operator’s

The

Style

tacking

light

weight

shape.

which

stitch.

The

starts.

to

125

UNION

in

catalog

operating

150-230

the

This

permit

Equipped

machine

Use

seconds

style

the

Lii

such

position

inside

coats.

is

the

good

a

SPECIAL

plate

iiunthui’

applies

right

as

while

direction

a

is

facings

Stitches

accomplished

needle

with

should

gade

100

at

LEWIS

the

on

each

ol

APPLICATION

specifically

left,

and

seated

of

DESCRIPTION

to

needle,

the

single

catch

by

penetrate

to

stationary

oiled

be

straight

of

Fahrenheit.

machine

head

machine

front

the

at

hanclwheei

the

non-skip

front

alternately

independently

work

OILING

twice

mineral

the

of

is

OF

to

and

machine.

Ot

or

alternate

support

daily,

carries

machine.

stamped

CATALOG

Style

150-

back,

is

MAChINE

stitch,

forepart

on

yielding

plate.

before

oil

away

body

sides

of

in

230.

etc.

of

the

a

a

style

the

,

blind

women’s

and

ridge

of

morhing

Saybolt

arm

All

are

from

fold

the

number

stitch

under

references

taken

the

machine

medium

hold

to

forming

seam

and

viscosity

which

the

from

operator.

coat

discs

each

on

afternoon

of

is

to)

to

the

for

and

in

90

Most

the

fact

diagram

The

Use

under

The

blade

a

sizes:

Selection

of

material

produce

To

a

sample

tion

29

on

BL-l00/040”.

the

df

they

Page

on

recommended

only

brand

our

recommended

diameter

used.

a

good

have

needle

needle,

the

oiling

are

genuine

name

of

proper

stitch

label.

painted

13

will

.

of

Thread

orders

or

A

places

red.

be

operating

UNION

lnincia®.

needle

inch

040

Needle

29

BL—065/025

29

BL—075/029

29

BL—090/036

29

BL-110f044

needle

should

formation.

Type

the

complete

on

However,

beneficial.

SPECIAL

for

(1.

Type

size

promptly

number

the

speed

NEEDL

this

00

is

pass

order

machine

SPEED

needles.

machine

mm).

determined

freely

accurately

and

should

are

reference

this

of

ES

is

It

be

would

readily

machine

Type

is

also

by

through

forwarded.

read:

to

The

available

Size

025

.

.029

036

.

.044

size

filled,

identified

oiling

the

needles

29

BL-100/040.

of

needle

“100

is

thread

an

and

3000

are

in

eye

empty

Use

Needles,

because

the

and

in

container,

the

threading

P.

R.

packaged

It

following

weight

order

descrip

Type

of

M.

has

to

4

Page 5

as

When

far

as

changing

it

will

needle,

o,

and

CFIANGIN(J

make

tighten

sure

clamp

NEEDLES

that

it

screw

is

inserted

securely.

in

the

tieccile

carrier

lmmediately

improper

To

thread

needle

carrier

Refer

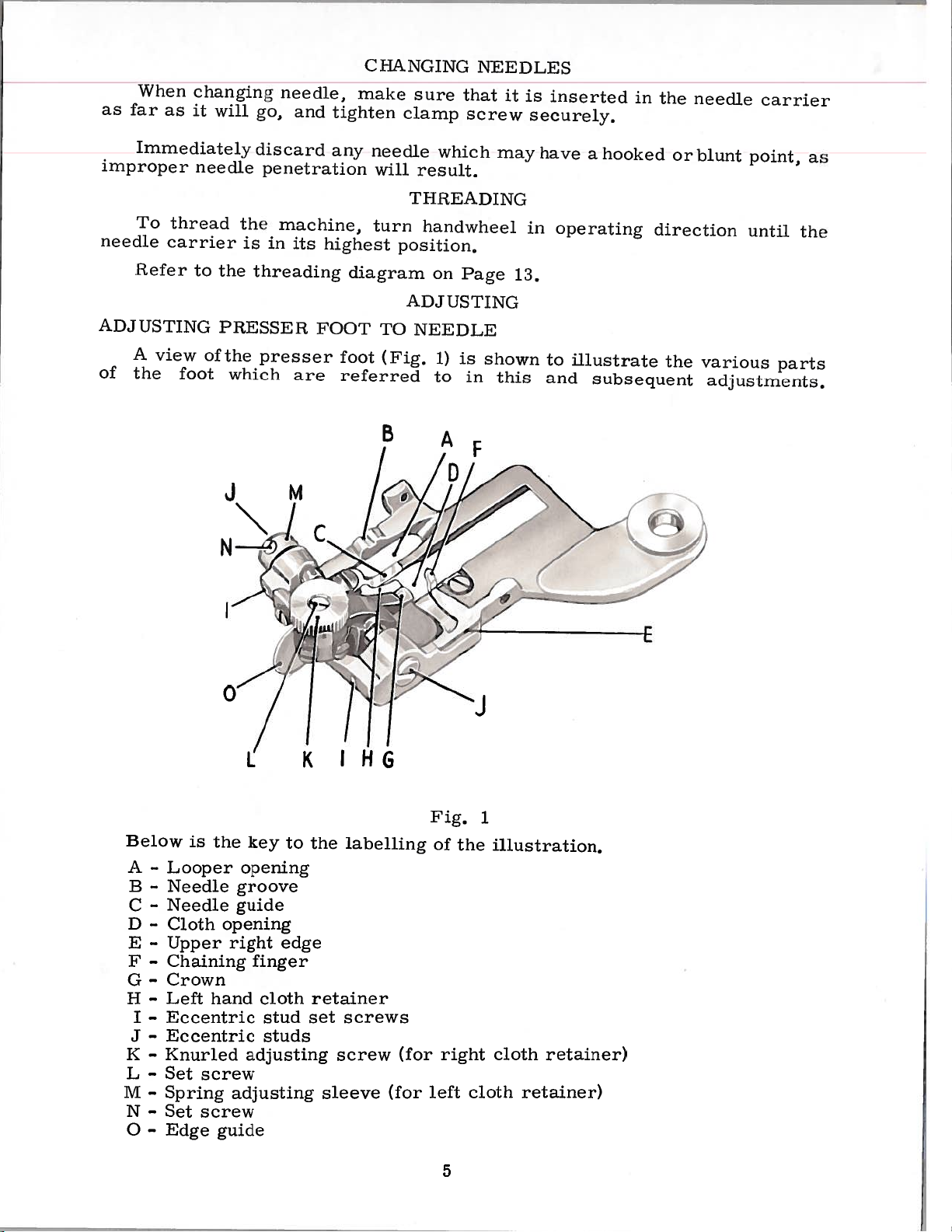

ADJUSTING

A

view

of

the

needle

to

foot

the

is

the

PRESSER

of

the

which

JM/

N

discard

penetration

machine,

in

its

threading

presser

are

any

highest

FOOT

foot

referred

C

needle

will

tu

diagram

TO

(Fig,

B

which

result,

Til

READING

en

handwheel

position,

on

ADJUSTING

NEEDLE

1)

to

Page

is

in

may

13.

shown

this

have

in

to

and

a

hooked

operating

illustrate

subsequent

or

blunt point,

direction

the

until

various

adjustments.

as

the

parts

Below

-

A

-

B

-

C

D

-

-

E

-

F

-

G

-

H

-

I

-

J

-

K

L

-

M

-

-

N

-

0

the

is

Looper

Needle

Needle

Cloth

Upper

Chaining

Crown

hand

Left

Eccentric

Eccentric

Knurled

Set

screw

Spring

Set

screw

Edge

L

key

opening

groove

guide

opening

right

finger

adjusting

adjusting

guide

cloth

stud

studs

to

edge

K

the

retainer

set

sleeve

I

HG

labelling

screws

screw

(for

(for

Fig.

of

right

left

1

the

illustration,

cloth

cloth

retainer)

retainer)

5

Page 6

AiZLJ

u;’ircc;

the

size

clamp

proper

rn-a

I

‘IWI,

(i

a

rt

securety

and

needle

new

o[

tighten

(Continued)

and

type

screw,

as

far

as

will

go

it

needle

the

in

in

a

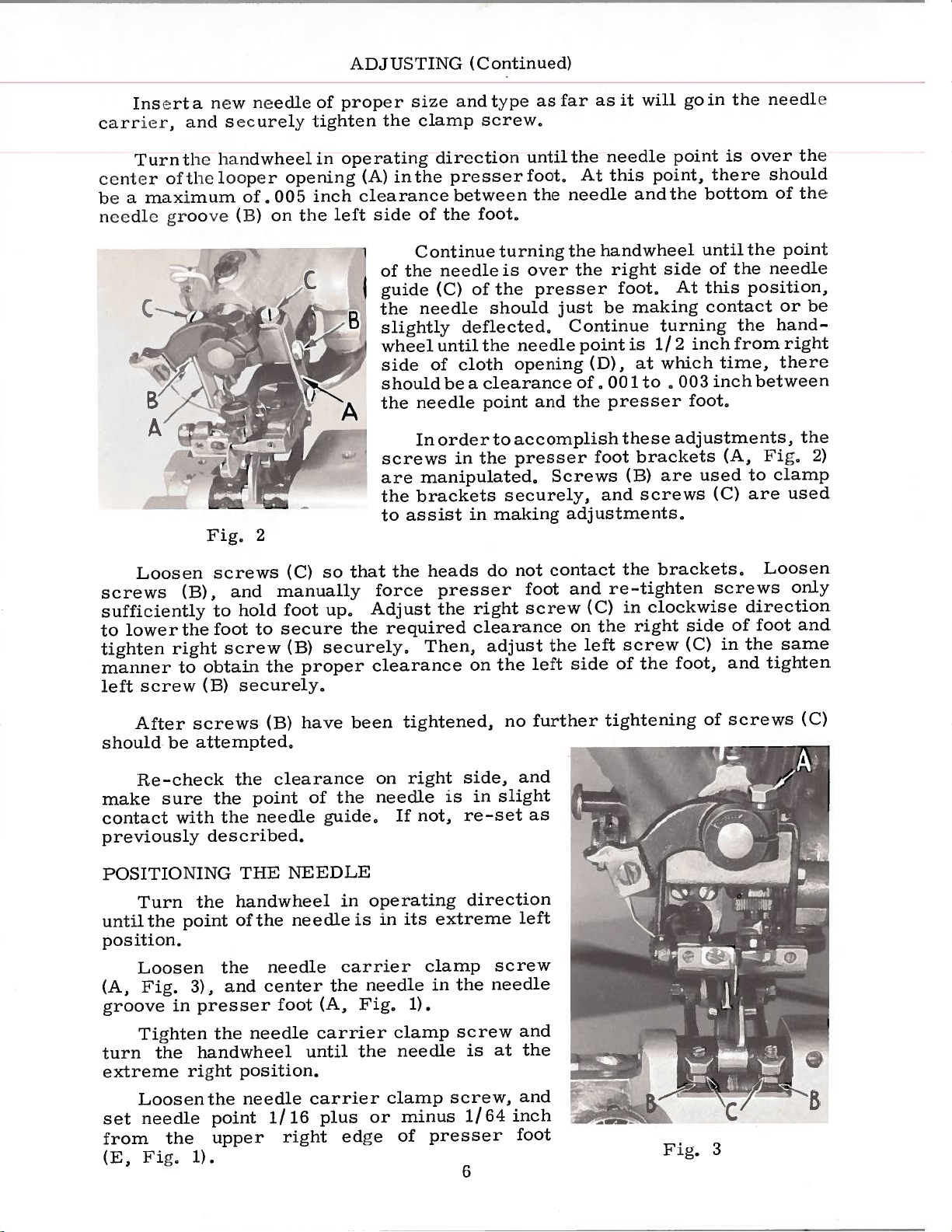

2

maxim

i9w

7,.

((‘nh’

he

iieedie

Loosen

screws

sufficiently

lower

to

tighten

manner

screw

left

tin’

l,in’

oh

groove

(B),

the

right

to

iiandwhiee

looper

of

uni

(13)

Fig.

screws

and

hold

to

foot

screw

obtain

securely,

(B)

(JO

,

On

2

manually

to

the

i.

opening

5

inch

the

C

(C)

foot

secure

(B)

proper

iii

operating

clearance

ie[t

B

that

so

up,

the

securely,

(A)inthe

of

side

Continue

the

of

guide

needle

the

slightly

wheel

side

should

needle

the

In

screws

manipulated,

are

brackets

the

assist

to

the

force

Adjust

required

clearance

direction

presser

between

the

needle

(C)

until

of

be

order

in

heads

presser

the

Then,

foot,

turning

is

the

of

should

deflected,

the

cloth

a

clearance

point

to

the

securely,

making

in

do

right

clearance

adjust

on

the

the

until

foot,

needle

the

the

over

presser

just

Continue

needle

opening

the

and

accomplish

presser

Screws

adjustments,

contact

not

and

foot

screw

on

the

side

left

At

handwheel

the

be

point

(D),

of,

foot

and

(C)

the

left

needle

point,

this

and

right

foot,

making

is

1/

at

to

001

presser

these

brackets

(B)

screws

the

re-tighten

in

clockwise

right

screw

the

of

poit

the

bottom

until

side

this

At

contact

turning

inch

2

which

,

003

foot,

adjustments,

used

are

brackets,

side

(C)

foot,

is

it

the

the

of

time,

inch

(A,

(C)

screws

of

in

and

over

reshonid

the

position,

the

from

between

Fig,

to

are

Loosen

direction

foot and

the

tighten

of

point

needle

or

hand—

right

there

clamp

used

only

same

the

the

be

the

2)

After

should

make

contact

be

Re-check

sure

with

previously

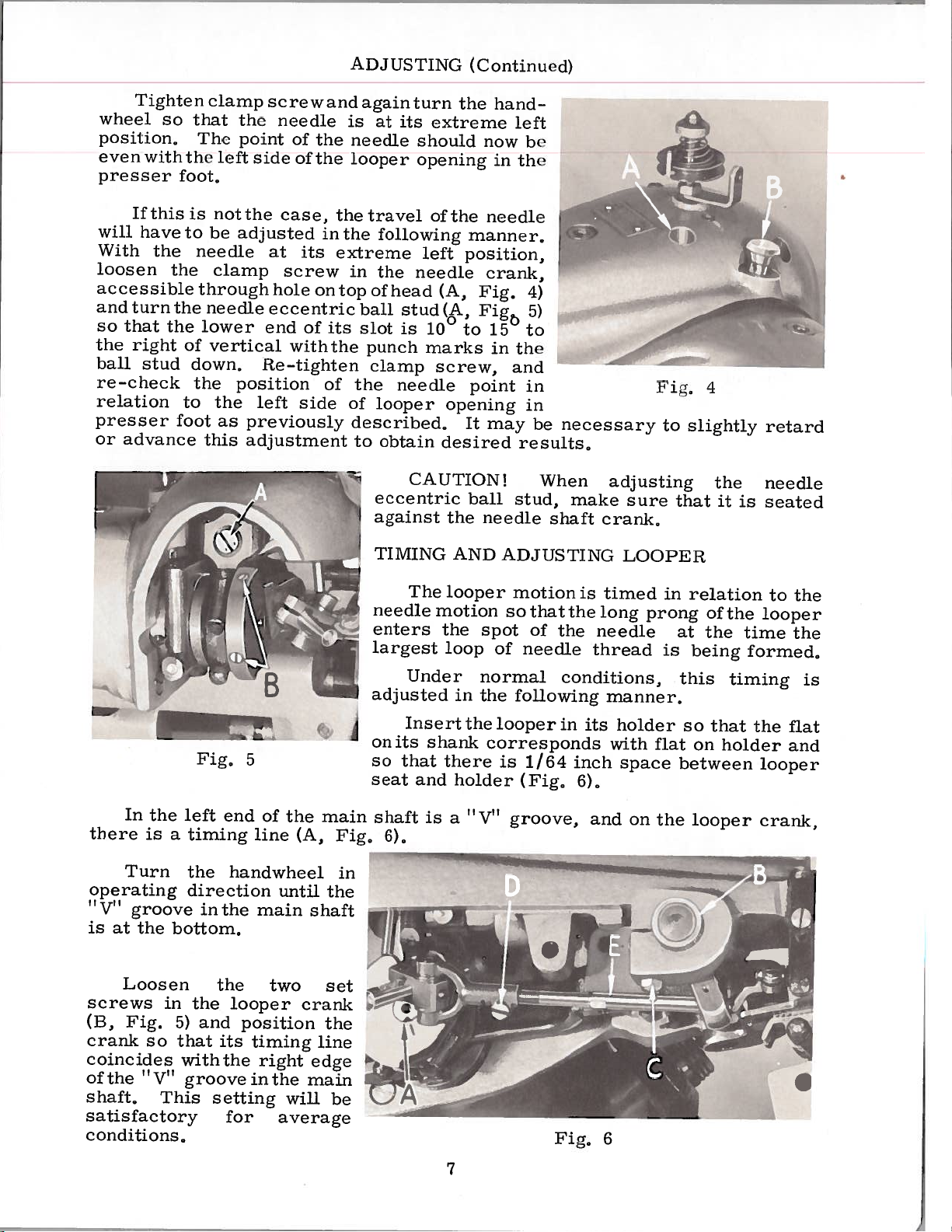

POSITIONING

Turn

point

the

until

position.

Loosen

Fig.

(A,

groove

turn

extreme

in

Tighten

the

right

Loosenthe

needle

set

from

(E,

the

Fig,

screws

attempted,

the

the

the

described.

THE

handwheel

the

of

the

and

3),

presser

the

handwheel

position.

point

upper

1).

(B)

point

needle

the

needle

center

needle

needle

1/16

have

clearance

of

NEEDLE

needle

foot

(A,

carrier

until

carrier

plus

right

the

guide,

in

carrier

the

edge

been

on

needle

operating

in

is

needle

Fig,

the

or

tightened,

right

not,

If

its

1).

clamp

needle

clamp

minus

of

is

extreme

clamp

in

screw,

presser

side,

in

re-set

direction

the

screw

is

1/64

6

no

and

slight

left

screw

needle

and

at

and

inch

foot

further

as

the

tightening

Fig,

of

3

screws

(C)

B

Page 7

rIj.l

wlieet

position,

even

with

presser

If

will

have

With

loosen

accessible

and

turn

so

that

the

right

ball

stud

re—check

relation

presser

or

advance

SO

this

the

the

the

ten

the

foot,

to

the

of

to

foot

clamp

that

The

is

not

be

needle

clamp

through

needle

lower

vertical

down,

the

the

this

the

point

left

the

adjusted

position

as

previously

adjustment

screw

needle

of

side

of

case,

at

screw

hole

eccentric

end

withthe

Re-tighten

left

side

its

of

ADJUSTING

and

is

the

needle

the

looper

the

in

the

extreme

in

on

top

its

of

the

of

described,

to

again

at

travel

following

the

of

head

ball

slot

punch

clamp

looper

obtain

turn

its

should

opening

left

needle

stud

is

10

marks

needle

the

extreme

of

the

manner,

position,

(A,

(,

to

screw,

opening

It

desired

(Continued)

hand

left

now

in

the

needle

crank,

Eig.

Fig

15

the

in

and

point

may

results,

—

he

4)

5)

to

in

in

be

necessary

Fig,

to

4

slightly

retard

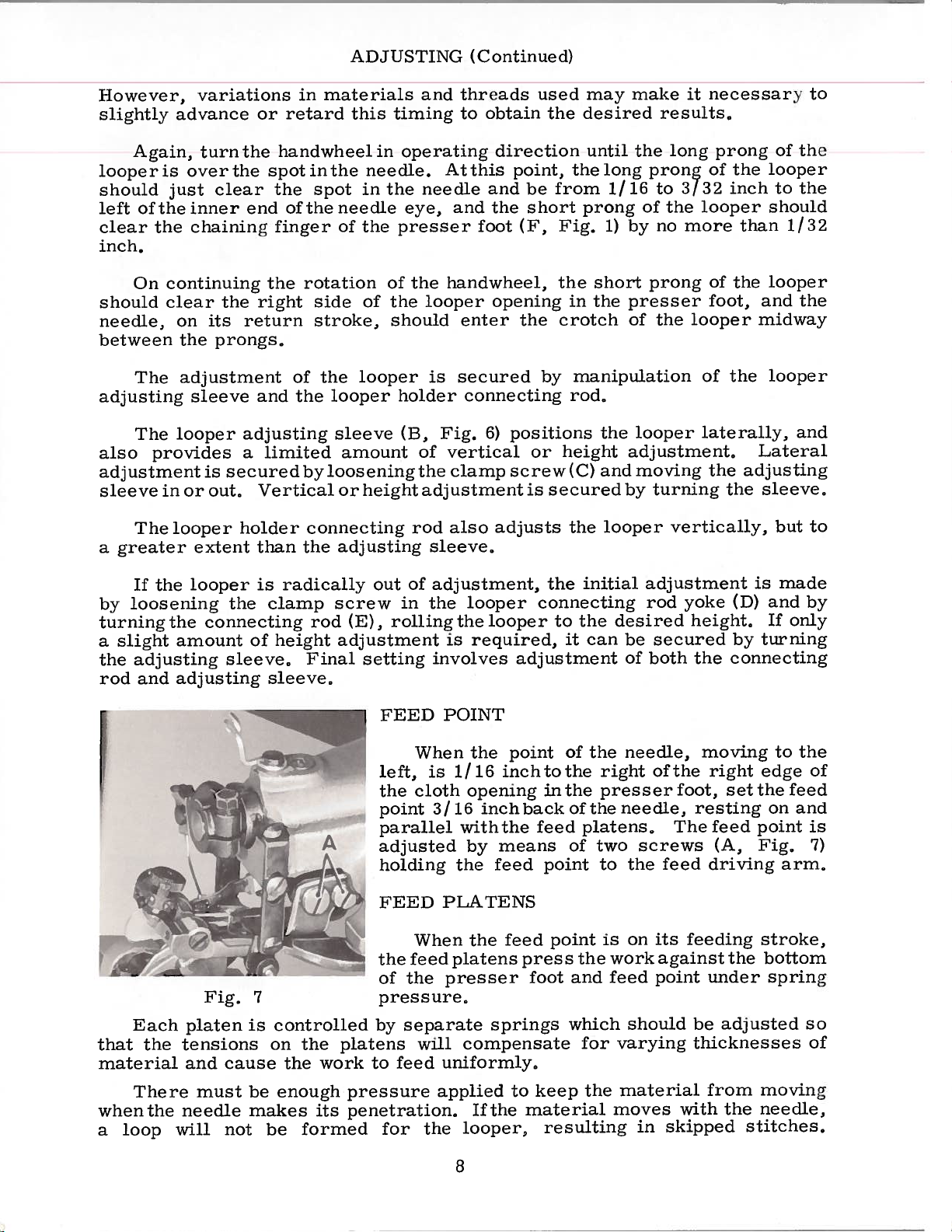

In

there

Turn

operating

“

V’

T

groove

is

the

at

the

is

Ic’c’\

Fig,

left

a

timing

the

direction

inthe

bottom,

5

end

of

line

handwheel

until

main

the

(A,

..J

(.

main

the

shaft

Fig,

in

eccentric

against

TIMING

needle

enters

largest

adjusted

4

on

so

seat

shaft

CAUTION!

The

Under

Insert

its

that

and

is

6),

the

AND

looper

motion

the

loop

shank

there

a

ball

needle

spot

normal

in

the

the

corresponds

holder

“Vu

When

stud,

shaft

ADJUSTING

motionis

sothatthe

of

the

of

needle

conditions,

following

looper

is

groove,

in

1/64

(Fig,

make

thread

its

inch

6),

and

adjusting

sure

crank,

LOOPER

timed

long

needle

manner,

holder

with

space

on

in

prong

is

flat

the

that

relation

of

at

the

being

this

so

that

on

between

looper

the

it

the

timing

holder

needle

is

seated

to

looper

time

formed,

the

looper

crank,

the

the

is

flat

and

Loosen

screws

Fig.

(B,

crank

coincides

of

shaft,

satisfactory

conditions,

the

so

“V’

in

This

the

and

5)

that

withthe

groove

the

looper

position

its

setting

for

two

timing

right

inthe

average

will

set

crank

the

line

edge

main

be

Fig,

7

6

Page 8

A1)JIJSTING

(Continued)

however,

tl

sI

igh

Again,

loope

should

Ic

clear

inc

i’

of

ft

the

h.

On

should

needle,

between

The

adjusting

The

also

provides

adjustment

sleeve

The

greater

a

ad

over

is

just

inne

the

chaining

continuing

clear

on

the

adjustment

sleeve

looper

in

or

looper

extent

variallons

vance

the

turn

the

clear

r

end

the

its

return

prongs,

adjusting

a

secured

is

out,

holder

or

retard

handwheel

spot

the

of

finger

the

right

of

and

the

limited

Vertical

than

in

materials

thi.s

in

the

spot

needle

the

of

rotation

side

stroke,

the

looper

sleeve

amount

loosening

by

orheight

connecting

adjusting

the

in

needle,

in

the

the

of

of

looper

and

timing

operating

needle

eye,

presser

the

the

looper

should

holder

(B,

of

the

adjustment

rod

threads

to

At

this

and

haridwheel,

enter

secured

is

connecting

Fig,

vertical

clamp

also

sleeve,

obtain

cli

and

the

foot

opening

6)

adjusts

used

the

rection

point,

from

be

short

(F,

the

by

positions

or

screw

secured

is

may

des

until

long

the

1/

prong

Fig.

the

crotch

1)

short

in

the

manipulation

rod,

the

height

and

(C)

the

looper

make

ireci

results,

the

pron

16

to

of

no

by

prong

presser

of

the

looper

adjustment,

moving

turning

by

necessary

it

long

of

3732

looper

the

more

of

foot,

looper

of

laterally,

the

vertically,

prong

the

inch

than

the

the

the

of

looper

to

should

1/32

looper

and

midway

looper

Lateral

adjusting

sleeve,

but

to

the

the

the

and

to

If

loosening

by

turningthe

slight

a

adjusting

the

and

rod

Each

that

the

material

There

when

a

the

loop

the

amount

adjusting

will

looper

connecting

Fig.

platen

tensions

and

cause

must

needle

not

is

clamp

the

of

height

sleeve,

sleeve,

7

is controlled

on

be

enough

makes

be

radically

screw

rod

adjustment

Final setting

A

I

platens

the

work

the

its

formed

out

of

in

rollingthe

(E),

FEED

left,

the

point

parallel

adjusted

holding

FEED

the

feed

the

of

pressure,

separate

by

feed

to

pressure

penetration,

for

adjustment,

the

is

involves

POINT

When

is

1/16

cloth

3/16

the

PLATENS

When

platens

presser

will

uniformly,

applied

the

looper

looper

required,

adjustment

the

point

inchtothe

opening

inchback

the

with

means

by

feed

feed

the

press

springs

compensate

to

If

the

looper,

the

connecting

to

it

of

inthe

of

feed

of

point

point

foot

which

keep

material

resulting

initial

the

can

the

right

presser

the

platens,

two

to

the

and

for

the

desired

be

of

needle,

needle,

the

on

is

work

feed

should

varying

material

moves

adjustment

rod

yoke

secured

both

of

the

foot,

The

screws

feed

feeding

its

against

point

with

skipped

in

(D)

height,

by

connecting

the

moving

right

setthe

resting

feed

(A,

driving

the

under

adjusted

be

thicknesses

from

the

stitches,

made

is

and

If

turning

to

edge

on

point

Fig,

arm,

stroke,

bottom

spring

moving

needle,

by

only

the

of

feed

and

is

7)

so

of

8

Page 9

A

I)J

LISTING

(Continued)

Cht’ck

penetvatt’s

P

the

tWo

‘I’urn[Iig

coititer

The

the

work

This

carrier

nuts

(C)

inch

from

ing

position.

STITCH

The

near

the

shaft

down

turn

the

the

stitch.

desired

knob.

RIDGE

iessu

nuts

theni

clockwise

feed

table

adjustment

adjusting

and

\verk

LENGTH

stitch

head.

with

numerals

which

handwheel

amount

The

FORMING

to

see

materiaL

I(

on

tii

the

platens

is

posjtion

table

length

will

As

you

stitch

that

the

)aek

ctock\V

acts

depressed.

screws

Open

engage

turn,

of

stitches

range

DISCS

teed

feed

should

screws

with

is

the

which

away

p

platens

ol

the

ise

the

is

made

(13,

the

regulated

top

a

slot

from

observe

of

atens

work

increases

reverse.

drop

Fig,

so

work

cover

indicate

in

you

per

the

machine

ctanip

is

tti)

uniformly

by

3).

that

table

by

the

the

inch

cotitrottud

te

the

the

feed

Loosen

they

the

on

the

the

feed

to

lengthen

indicator

appears

a

pce

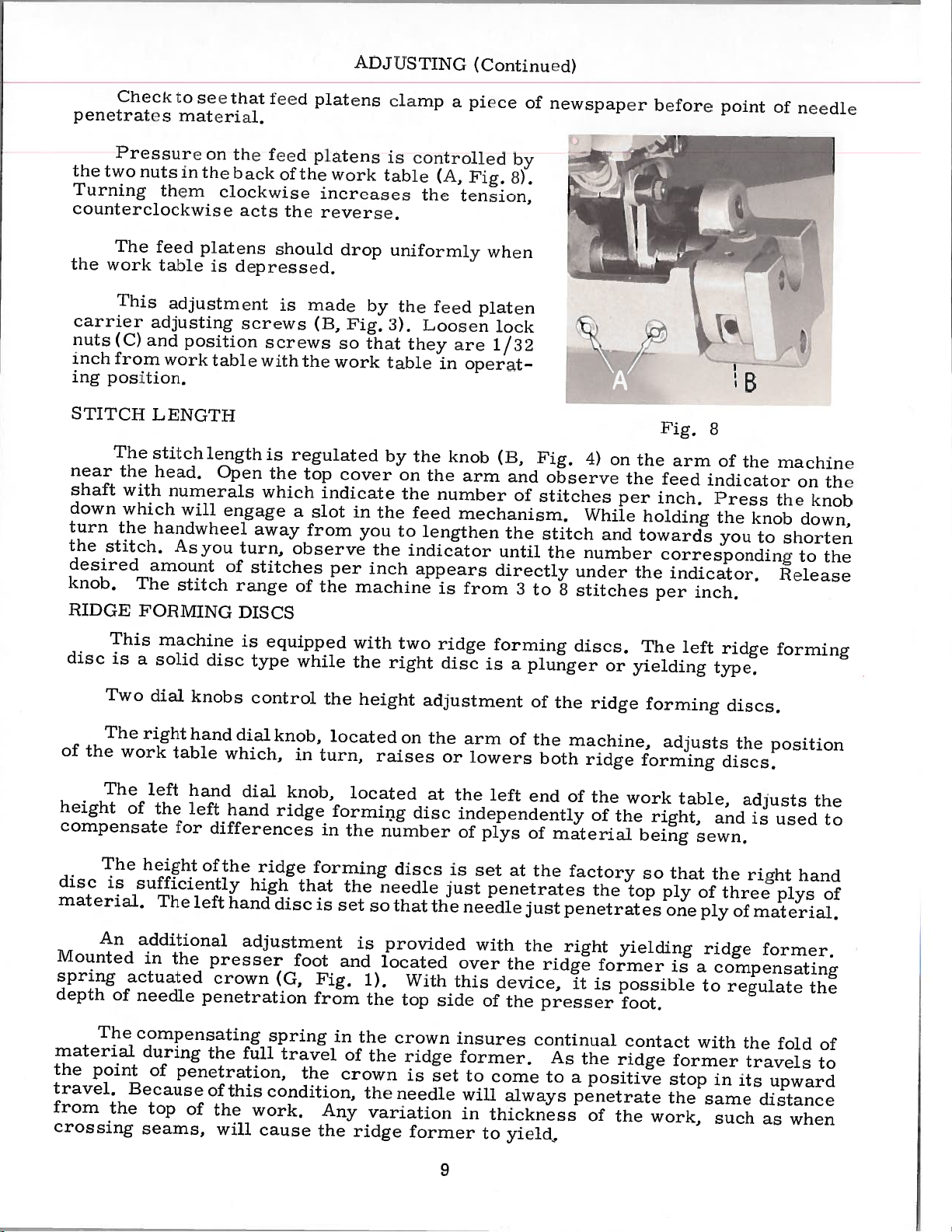

(A,

Pig.

tension,

platen

are

in

operat

knob

arm

number

mechanism.

from

is

by

ii).

vhen

lock

1/32

(13,

and

of

the

until

directly

3

of

newspaper

Fig.

observe

stitches

stitch

the

to

under

8

stitches

4)

on

per

While

and

number

before

r

Fig.

the

the

feed

inch.

holding

towards

corresponding

the

indicator.

per

‘1

arm

point

8

of

indicator

Press

the

you

inch.

the

knob

o[

machine

the

to

Release

necdte

on

knob

down,

shorten

to

the

the

This

disc

is

Two

The

of

the

The

height

compensate

The

disc

is

material.

An

Mounted

spring

depth

The

material

the

point

travel.

from

the

crossing

machine

a

solid

dial

right

work

left

of

the

height

sufficiently

The

additional

in

actuated

of

needle

compensating

during

of

Because

top

seams,

disc

knobs

hand

table

which,

hand

left

hand

for

differences

of

the

left

hand

the

presser

crown

penetration

the

penetration,

of

this

of

the

will

is

equipped

type

control

dial

knob,

dial

knob,

ridge

ridge

high

disc

adjustment

(G,

spring

full

travel

condition,

work.

cause

while

in

forming

that

foot

from

the

the

located

turn,

forming

in

is

set

Fig.

in

Any

the

with

the

height

located

the

the

is

and

1).

the

the

of

the

crown

the

variation

ridge

two

right

on

raises

number

discs

needle

so

that

provided

located

top

crown

needle

ridge

disc

adjustment

the

or

at

disc

the

With

side

ridge

is

set

former

forming

is

a

arm

of

lowers

the

left

independently

of

plys

is

set

at

just

penetrates

needle

with

over

this

device,

of

the

the

insures

former.

to

come

will

always

in

thickness

to

yield.

plunger

of

the

the

both

end

of

material

the

just

the

ridge

presser

continual

As

to

discs.

or

ridge

machine,

ridge

of

the

of

the

factory

the

penetrates

right

yielding

former

it

is

possible

the

ridge

a

positive

penetrate

of

the

The

yielding

forming

forming

work

right,

being

so

top

foot.

contact

work,

left

adjusts

table,

that

ply

one

is

former

stop

the

ridge

type,

discs.

the

discs.

adjusts

and

is

sewn.

the

right

of

three

ply

of

material.

ridge

a

compensating

to

regulate

with

the

travels

in

its

same

such

forming

position

used

hand

plys

former.

fold

upward

distance

as

when

the

to

of

the

of

to

9

Page 10

A

I).)

LS1:ING

(Coititued)

plunger

there

the

of

yond

Fig.

of

it

the

is

with

inch

the

become

dial

shaft.

the

Pressure

rod

3/32

is

head

Should

the

limits

1.

Rotate

Remove

2.

Liftthedialknohsothatits

3.

in

dial

over

Replace

4.

9

directly

the

clearance

plunger

the

of

right

screw

seat,

stationary

screw

upper

necessary

right

hand

Rotate

applied

shaft.

(A,

but

and

nut.

between

hand

dial,

Fig.

so

the

stop

spring.

\Vhen

the

ol

comparabte

ime

and

work.

right

the

made

tocated

ridge

desired

To

needle,

For

less

To

turn

clockwise,

the

to

Generally

increase

to

dial

in

and

9)

stop

that

its

in

dial

pin

by

the

the

range,

the

the

and

right

By

using

in

adjust

turn

increase

yielding

key

making

rL(lge

the

to

crew

the

using

former

depth.

knurled

the

crown

the

the

time

peneti’ation,

screw

in

counterclockwise

the

of

or

the

decrease

top

iiroceed

required

spring

pin

(B).

disengages

remains

slot

required

dial

the

preliminary

the

fluinei,

weight

so

n

right—hand

the

height

All

of

crown

adjusting

the

the

ridge

correct

plunger

direction,

direction

reengages.

that

so

further

beach

the

for

turn

spring

center

forming

follows:

as

from

insert

material

of

it

that

crown

pros

more

screw

the

pressure

for

pressure

holder

height

the

to

the

engaged

until

penetration

fetched

does

the

not

dial

needle

adjustments

adjusting

foot.

ser

penetration

counterclockwise.

screw

adjusting

the

of

less

by

disc

is

and

of

end

the

stationary

with

stop

its

material.

hemmed

he

to

contact

knob,

penetrates

should

clockwise.

the

on

pressure.

adjusting

obtained

the

underside

discs

the

of

its

key

the

pin

setting

set

screw

of

crown,

screw

travel.

stop

in

passes

the

the

he

the

the

when

be

pin

the

Refinements

push

rod

To

height

limits

the

simply

located

ted

stud

in

dial

tighten

Lateral

forming

moving

The

discs

distant

opening

adjustment

hexagonal

two

inthe

base

correct

increase

the

of

of

loosen

in

the

located

the

screws.

discs

the

from

in

position.

stop

left-hand

the

the

dial

desired

adjustment

work

should

the

the

made

is

and

this

of

screw

or

left-hand

two

and

the

in

accomplished

is

table

be

sides

presser

by

screws

sliding

adjustment,

(A,

decrease

disc

dial

locking

turn

center

direction.

of

right

spaced

of

foot.

loosening

(B,

work

Fig.

the

the

the

Fig.

table

10).

beyond

range,

screws

slot

of

Re-

ridge

left.

or

equi

cloth

This

the

the

the

10)

by

to

within

any

range,

may

Fig.

be

made

10

by

adjusting

the

Page 11

1)1

A

\V()

iii

tah[e

control.s

depentty

the

Fig.

[ISTIN(

I

I

TIi

the

by

The

under

8).

(Continued)

TA

e

pos

woi.k

the

large

the

tension

controlLed

side

I

Lt

tabto.

tension

ion

TENSIC)N

of

tI’er

TJie

coil

spring

on

on

the

by

of

the

the

left

a

left

idge

tension

right

ridge

small

in

end

for

the

ridge

coil

of

ni

Lug

appli

base

forming

spring

the

discs

ccl

of

the

forming

work

to

disc

located

table

is

the

nachiie

is

iixc(

work

disc.

in—

in

(H,

disc

tension,

counterclockwise

Thread

(1)

(2)

Move

(3)

edge

edge

Adjust

not

in

of

guide

penetrate

the

adjust

(4)

Adjust

located

as

close

firmly

If

the

material

skipped

g.

adjust

machine

knee

the

needle

required

left

cloth

in

to

hold

stitches

press

material

on

the

hand

retainer

the

the

the

screw

acts

the

in

accordance

to

the

front

penetration.

folded

direction.

dial

cloth

needle

work

is

carried

and

1

(B,

reverse.

STARTING

right

directly

of

edge

knob

and

opening

as

possible

on

the

improper

fension

creased,

sewn,

by

For

11).

Ttirning

counterclockwise

Fig.

8).

with

and

insert

over

the

presser

Sew

a

at

the

Check

in

the

same

crown.

of

The

the

and

discs

along

while

with

needle

on

depending

the

following

right

Turning

TO

OPERATE

threading

work

the

right

foot.

few

stitches

desired

penetration

manner.

cloth

presser

set

the

the

needle,

penetration.

both

hand

nut

screw

under

ridge

depth,

retainer

foot,

relative

needle

discs

on

disc

clockwise

acts

diagram,

feed

and

at

no

can

the

weight

adjustments:

tension,

the

reverse.

clockwise

pointS

forming

inspect.

turn

the

the

single

and

must

to

the

penetrating

is

loop

at

will

Page

crown

all

ridge

be

increased

of

adjust

increases

increases

13.

with

disc

If

right

piy

times

forming

form,

material

For

the

and

the

hand

of

(G,

the

(A,

nut

tension,

left

tension,

folded

against

needle

dial

fabric

H,

Fig.

be

adjusted

discs

material.

resulting

or

being

hand

edge

does

knob

de—

Fig.

the

and

1),

to

in

Lateral

tric

Adjustment

eccentric

Tension

adjusting

Forming

Tension

sleeve

sition.

tighten

adjustment

adjusting

on

Discs.

on

(M).

Turn

the

studs

in

adjusting

the

screw

left

Loosen

spring

two

line

right

set

(N)

hand

is

(J)

of

studs

hand

and

retainer

set

adjusting

screws.

secured

laterally

feed

(J).

the

screws

is

made

spring

set

by

to

screw

can

(I

sleeve

loosening

desired

by

loosening

actuated

(L).

be

varied

&

N)

(M)

while

to

two

position.

two

crown

Refer

by

holding

secure

11

screws

is

to

turning

(I)

screws

controlled

adjustment

the

adjusting

desired

and

(I)

spring

tension,

moving

and

by

the

under

stud

turning

knurled

adjusting

(J)

and

eccen

the

HRidge

in

po

re

Page 12

STARTING

TO

OPERATE

(Continued)

should

right

of

with

catalog

various

actual

listing

required

indenting

by

4124-27

1213

18-74

1170

back

the

This

edge

parts.

be

Adjust

(5)

and

the

edge

Removing

(6)

withdrawn

work

stitch.

ILLUSTRATIONS

This

views

in

found

pieces

the

in

dicated

44

45

46

47

The

the

this

part

of

their

a

Numbers

position

ordering

Component

It

will

reason

complete

At

book.

number

guide.

he

set

hand

material

the

work.

from

a

diuick

has

sections

position

of

the

in

the

in

the

of

L

L

is

sub-assembly

is

that

parts

noted

that

of

will

known.

part

their

replacement

the

so

ridge

To

the

pull

been

in

parts

particular

first

Always

of

Looper

the

in

book

facilitate

The

edge

the

that

forming

against

remove

material,

ORDERING

of

the

with

column

in

the

sub-assemblies

descriptions

will

work

away

arranged

the

mechanism

machine.

their

illustration.

the

use

Carrier

Clamp

Spot

Screw

above

of

should

be

locating

IDENTIFYING PARTS

guide

folded

disc.

edge

the

push

from

view

are

part

Example:

Screw

Screw

example

these

be

found

edge

after

the

you in

REPAIR

to

simplify

On

parts

being

reference

number

which

under

Ball

parts

ordered.

a

the

(0,

[rig.

of

the

In

operating

guide.

stitching,

knee

order

are

shown

the

page

numbers,

shown.

Reference

can

description

the

Joint

that

the

individually

numerical

illustration

1)

material

press

to

PARTS

ordering

opposite

numbers

listed

be

ball

only

has

the

machine,

that

see

to the

break

so

that

description

only,

number

the

in

furnished

of

and

is

index

and

of

description

is

the

right,

the

repair

the

the

second

the

the

not

all

a

lateral

guided

hold

needle

and

thread

parts.

parts

illustration

and

merely

and

should

column.

for

repairs

main

strap

recommended,

the

parts

adjustment

directly

the

entirely

is

remove

lock

and

Exploded

may

be

will

number

the

indicate

never

subassembly.

are

when

be

are

not

shown

only

over

folded

the

the

seen

be

of

used

in

1

1

1

2

listed.

so

in

the

Where

Part

numbers

Success

UNION

poration,

ing

to

Maximum

Genuine

mark

forwarded

otherwise

is

Prices

SPECIAL

its

most

the

efficiency

your

directed.

the

construction

represent

in

the

subsidiaries

approved

needles

guarantee

are

net

b.

f.

o.

USE

operation

Needles

and

are

cash

shipping

A

the

same

GENUINE

and

and

scientific

durability

packaged

the

of

and

charge

permits,

NEEDLES

of

these

Repair

authorized

highest

subject

point.

is

part,

made

each

regardless

machines

Parts

principles,

assured.

are

labels

with

quality

TERMS

to

Parcel

to

part

AND

as

REPAIR

furnished

distributors.

and

marked

in

material

change

Post

cover

postage

is

of

can

are

without

shipments

12

PARTS

the

by

with

with

are

stamped

catalog

secured

be

They

made

ZnZn...pcciaI®

workmanship.

and

notice.

and

insurance.

in

are

its

which

only

Union

designed

utmost

All

part

they

with

Special

.

This

shipments

insured

number.

appear.

genuine

Cor

accord

precision.

trade

are

unless

Page 13

Page 14

11

14

Page 15

IV[AIN

FRAME,

BUSI-IINGS,

COVERS

A

ND

MISCELLANEOUS

PARTS

Ref.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

Part

No.

1

2

3

4

5

6

7

8

9

No.

16—39

41-49

LS314

125-23

61-30

18-565

41-42

468—23—1

1160L

468-23

1183

1132

20—60

61-46

18-768

110-401

125-23

16-148

61—32

61—25

426—47

20—79

16-194

LS75

26—47

1081

32—107

18-330

125—23

16—386

18-764

1197

1220

1221

32—36

18-38

155—9

125—23

416—374

1195

CS331

1197

18-768

97—56

18-C94-1

18-664

22-149

18—768

97-51

16—279

32—262

L

L

L

L

L

L

L

8—89

L

Bushing

Thread

Screw

Oil

Cup

Oil

Tub

Scre

Thread

Tension

Nut

Tension

Tension

Tension

Thumb

Tub

Oil

Screw

Model

Oil

Cup

Bushing

Oil

Tub

Oil

Tub

Stitch

Nut

Bushing

Spring

Plunger

Set

Screw

Cover

Screw

Oil

Cup

Main

Plug

Screw

Set

Screw

Spring

Cover

Screw

Indicator

Oil

Cup

Main

SetScrew

Screw

Belt

Guard

Screw

Set

Screw

Name

Screw’

Set

Screw

Taper

Screw

Name

Bushing

Bottom

Guid

Guidc

Staff,

Plat

Adjusting

Plat

Shaft

Screw

Washe

Plat

Shaft

Plate

Pin

Plate

Cover

complel

Staff,

Dis

Spring

Nut

Bushing,

Bushing,

with

Plunger,

left

right

Dc s

hook

cription

complet

Ami,.

Req.

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

6

1

1

3

1

2

1

1

1

15

Page 16

8

6

I

16

32

Page 17

Rn.

10

11

12

13

14

15

16

17

Ill

19

20

21

t22

23

24

25

26

27

28

29

30

31

32

32A

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

52A

53

54

55

56

57

58

59

61

62

63

*64

*65

*66

67

*

Component

For

For

Nit.

I

2

3

4

5

6

7

8

9

use

use

I

22559

1192

1025

1031

1005

22653

449-27

4124-27

1213

1170L

4118-15

1170

29BL—lOO/040

4118-24

810

439—7

SB15

1243L

l333L

part

on

machines

on

Style

St

‘I

Ne.

448—135

48—135

16—321

18—737

137—19

666—170

17—149

447—141

666—239

660—204

18-492

40—199

45-351

137—19

33—149

18—674

149—16

79—31

21—213

18—767

23—327

23—338

40-126

18—732

44

6-118

18—751

17—114

17—150

14-432

57-56

39—92

139-10

27-221

18—C97

115-118

18-738

18-71

22-8

L

18-74

70-53

17-146

18-662

L

20—31

36-16

L

30—52

22—9

18-70

14-14

48-105

18-702

of

150-230

1)

L

L

L

L

B—B

No.

447-141,

prior

Looper

Set

Oil

Oil

Stud

Needle

Feed

Oil

Feed

Screw

Stitch

Ball

Spriri

Screw

Feed

Feed

Shakeproof

Screw

Feed

Eccentric

Stud

Main

Handwheel

Collar

Counterweight

Drive

Set

Looper

Set

Looper

Pi

Looper

Sleeve,

Stud

Screw

Looper

Nutfor4ll8—15

Loope

Needle

Needle

Colla

Needle

and

to

improved

PEED,

Driving

Crank

Bushing

Screw

Wick

Wick

Drive

Wick

Oil

Screw,

1,0,?

Ring

Spot

Fiber

Driving

Wick

Driving

Regulator

Point

Point

Driving

Screw

Shaft

Set

Screw

Set

Screw

Spot

Scre’,

Set

Scre

Gea

Scre’,

Carrier

Clamp

Scre’,

Carrier

ClampScrew

Carrier

Clamp

SpotScrew

Screw

for

Carrier

Scre

Carrier,

Screw

NeedleClam

P1

ClampScrei

Set

Screw

Carrier

Needle

Scre’,

Spot

Scre’.

Screw

Ref.

after

machines.

LOOPER

Retainer

for

Screw,

Washer

Retainer

Washe

Lever

Stud

Screw

Screw

looper

Carrier

No.

improved

Crank,

Eccentric

connecting

for

Lever

Eccentric,

Balance

Yoke

Yok

Ball

ball

Shaft

complete

Shaft

Shaft

B

AN!)

eccentric

Link

Block

Joint

joint

Style

N

PVDI

complete

Connection,

rod

.250

inch

adjustment

Crank

150-230

P

I

)Il[VING

I’aei’ipI

complete

throw

machines.

PA

RI’S

A

en

niL

hint.

I

1

2

1

1

4

1

1

1

1

2

1

3

1

1

1

1

1

I

2

‘2

1

1

1

1

1

1

2

1

2

1

1

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

17

Page 18

6

1

43

42

18

Page 19

h’IlliI.)

P1

/\lliS,

I1IDC3Ii

ICt)R\/llNC

AND

DRIVING

PARTS

PcI.

—_No•

HA

jill

:2

3

5

7

3)

10

11

12

13

14

15

16

17

18

19

20

21

±22

23

24

25

t25A

26

27

28

29

1:30

t3OA

t3OB

t30C

t30D

t30E

t30F

:r3l

32

33

±34

t34A

±35

t35A

36

37

38

39

40

41

42

43

44

t46

I

‘a

it

No•

I•’ted

Plate

is-sso

9$3—3h)

11—505

22—326

113—749

20—35

6

24—321

10—910

24—322

39—136

20—129

19—628

21—248

10—579

113—634

140—16

14-503

20—141

18—1065

21—70

79—31

13-500

4149—18

44—328

44—321

69—C19

18-C889

48—69

48—184

18—710

14-506

1284L

1022

L

44-C257

444-322

44-322

21—433

20—122

99-348

heed

‘cod

Shalt

Peed

Screw

Nut

Food

Screw

Food

Spacing

Nut

Scrow

Spring

Screw

Sot

Screw

Ridge

Shaft

Adjusting

Adjusting

Sprbg

Ball

Set

Screw

Regulator,

Ridge

Ridge

Slide

Screw

Ridge

Ridge

Screw

Driving

Collar

Screw

Ridge

Yielding

Yielding

Spring

Nut

Frame

Plate,

Plato,

Block

18—633

1246L

l304L

1306L

14-504

14-521

448-C132

48-182

18—497

17—C141

47-131

39-C13OB

18-C94-2

33-C143

27-C149

18-C215-1

14-C147

1284L

1022

L

Pin

Link

Screw

Shaft,

Shaft,

Ridge

Ridge

Screw

Stud

Connecting

Collar

SetScrew

Eccentric,

Driven

Screw

Shaft

Collar

Set

Forming

Forming

I’latc

‘late

‘late

Cotlar

Forming

Nut

Screw

Forming

Forming

Forming

Forming

Shaft,

Forming

Ridge

Set

for

right

for

right

Gear

Screw

IIiildtij’

Iluldei’,

IIulcIoi’,

Iloldcr

left

right

for

Ridge

Screw

Rod

.

240

Disc

adjusting

Disc,

Disc,

Disc

Disc

left

for

Disc,

Forming

ridge

ridge

Disc

Disc

inch

I

)usci:iptain

—

tuft

ii,

lit

lIinic

Cradle

left

left

Crank

Crank

ridge

right

Forming

forming

forming

Crank

Crank

throw

Pin

left

ridge

forming

Assembly,

Plunger

forming

disc

assembly

disc

disc

right

And.

I3eij.

2

1

1

1

2

2

1

2

1

1

2

2

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2or3

1

3

1

2

1

1

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

2

2

1

1

3

1

2

1

For

For

t

use

use

on

on

machines

Style

150-230

prior

to

and

improved

after

machines.

improved

Style

150-230

19

machines.

Page 20

17

50

20

Page 21

\‘OIl.

APHON

A

NI)

SliI’Cl[

DIPI’IL

INCtFLA’I’OH

PARTS

Ref.

10

11

12

1

14

15

16

17

18

10

20

21

22

23

24

25

26

27

28

20

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

No.

5

(5

7

U

3

I

No.

028

1

8—

1

21-40

itt—:o

.11

149—30

21—237

70—31

22—C2l4—4

8-ClOO

1

1H—100’1

22-296

4107—58

18-768

110—

22-C21

22—316

115-Cl

45-Cl50

22-Cl

22—C214—1

2l-C54

47l-C544

71—Cl

22-C2l4-4

7l—Cl33

14-96

1

32—296

61—49

18-960

6258

1025

18-330

32—291

183—36

16-394

16—397

20—34

18—564

1

18-129

18—126

70—28

18-493

21—C153

1388

1025

14-507

1003 L

45-203

40-C213-2

22—C137

71—107

131—C163—1

18-C884

20—C117

:

:32

8-C944

L

8—C94—1

L

L

4-4

13

51—1

B

34

Screw

Siiich

Screw

Ad1tistjn1r

SqLlare

Stitch

Stitch

Stitch

hinge

Pu

Work

Knuckle

Work

Screw

Snap

Oil

Set

Spring

Set

Scre

Cover

Work

Nut

Stitch

Knuckle

Work

Work

Knee

Stitch

Collar

Knee

Set

Screw

Knee

Washe

Cotter

Stitch

“S’

Work

Nut

I

)epi.Ii

Plunger

Spring

13u11

Pu—

I[ead

Depth

Screw

Regulator

Pin

P11

Depth

Depth

Pu

Table

Assembly

Spring

Pin

Spring

Table Pivot

Cover

Tub

Screw

Screw

Apron

Ridge

Ridge

Depth

Assembly

Table

Table

Press

Screw

Depth

Set

Screw

Lift

Shaft

Lift

Lever

Pin

Depth

hook

Table

Regulator

Regulator

Scre

Pu—

Regulator

Regulator

Regulator

Tension

Tension

Tension

Forming

Forming

Regulator

Pivot

Pivot

Rod

Regulator

Regulator

Tension

Plate

Sleev

Spring

Shani

Knuckl

Shaft

Shaft

Shaft

Set

Shaft

Shaft

Adjusting

I)vsc

I\

not)

1lange,

Block

Leve

Bushing,

Shaft

Scre

Lock

Bearing

Shaft

Shaft

iipton

Assen-ibly

Bushing,

Stop

Screw

Spring

complet

Scre

Scre’

Screw

left

right

An-it

Req.

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

2

1

1

1

1

1

1

1

21

Page 22

£17

Page 23

lIiHSSKH

POOl’,

\\OHF.

Sll’I’OHT

(‘I

Al

P

ANt)

A(’(’lNSO(l[ES

*

(((‘I:.

No.

±5

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

I

‘a

it

No.

1

2

3

4

6

7

8

0

10—307

(‘5327

50—160

1(76

405—572—2

405—576—3

17—87

18—634

21—300

21—62

22—317

13—1074

21—240

137—77

126—54

126—57

1733

13—261

5—576

5—532

17—111

LS330

75—251

1351

lO8lL

16—214

18—416

18—643

6—56

122—C38

18—292

4-141

18—533

50—211

18—939

CS320—1/2

854L

14—256

54484

71—87

660—168

4129—18

129—18

22508

144—27

413

1405L

21201

652—16

18—955

110—323

18—768

144—28

403-11

5C303

Srr’w

I

Iliarket

Screw

I’i’rssei’

((5

hoot,

loot,

sri’

I’leeeotnic

Screw

Set

Spring,

S3ing,

Pin

IkinniecI

Spring

(or

for

Aclusting

Retainer

Crown,

L

L

(‘town,

Spiint

Screw

Presser

Presser

Stud

Set

Edge

Screw

for

Cur

loot,

Screw

Guide

Screw

I3usIiin,

spring

SetScrew

Screw

Needle

Chaining

Guide

hAnger

Screw

Work

Set

iN

Screw

Bracket

Support

Plate

Screw

Set

Screw

Screw

Stud

C

Stud

Knee

Knee

Knee

Press

Press

Press

Knee

Rod

Plate

Pad,

Press

Screw

PeltPad

Oil

Can

Open

End

Screw

Wrench

Driver

Washe

Stove

Regulator

Eolt,

for

Plate

Screw

Work

Thread

Wood

Apron

Screw,

Insolator

Stand

for

roioptete

compLete

Html

No.

No.

No.

No.

‘out,

Cushion

complete

Pad

holding

thread

l)rsri’iptioo

405-576-2

405—576—3

Screw

405—576—2

405—576—3

main

section,

main

section,

tensioning

machine

stand

No.

for

for

to

table

No.

405—576—2

405—576—3

‘1

llrq.

1

4

4

1

2

1

1

1

mt.

2

4

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

1

1

1

1

1

1

1

1

1

1

*

Furnished

For

For

t

use

use

on

on

with

machines

Style

machine

150-230

prior

not

hut

to

improved

and

shown

after

on

improved

machines.

picture

plate.

Style

150-230

23

machines.

Page 24

B

I;HIC

NV

I

I

‘art

No.

Page

No.

‘sit

No.

AL

Page

No.

INDEX

OF

Part

No.

A Il

1’S

P

I

‘aie

No.

I’az

No.

Page

No.

4-141

5—502

6—56

8—09

14-14

11—96

11-ElI?

11—256

11—432

14—503

14-504

14—

505

14—506

14—307

14—521

SKiS

16—39

16—149

16—194

16—214

16279

16—321

16—386

16—394

16—397

17—87

17—111

17—114

17—C141

17—146

17-149

17-150

18—38

18—70

18—71

18—74

18—C94—1

18-C94—2

18—C97

18—C100

18—126

18—129

18—C215—i.

18—261

18—292

18—307 23

18—330

18—416

18—492

18-493

18—497

500

1818—533

18—564

18—565

18—579 19

18—628

18—633

18—

634

18—643

18—662

18—664

18—674

18—702

18—710

732

18—

.3

23

3

23

15

17

1

19

17

19

10

19

19

21

17

is

15

15

23

1;)

17

15

21

21

23

23

17

19

17

17

17

15

17

17

17

15,21

19

17

21

21

21

. .

.19

23

23

21

15,

23

17

21

19

19

23

21

15

19

19

23

19,

23

17

15

17

17

19

17

737

10—

11—733

10-749

19—751

18—764

18—767

18—768

18—COOl

18—0189

18—918

18—939

18—C944

18—955

18—960

18—1028

18—1064

18—1065

18—1074

20—31

20—34

20—35

20-60

20—79

20—C117

20-122

20-129

20-141

21—C54

B

21—62

21—70

21—C153

21—213

21—

237

21—240

21—248

21—300

21-404

21—433

22—8

22—9

22—C137

22—149

22—C151—1

22—C214-1

22-C214—4

22—296

22—316

22—317

22—326

23—327

23—338

24—321

24—322

26—47

27-C149

27—221

29BL—100/040

30—52

32—36

32-107

32—262

32—291

32—296

33—C143

33—149

36—16

39—92

...

17

17

19

17

15

17

15,21,

23

21

19

19

23

21

23

21

21

21

19

23

17

21

19

15

15

21

19

19

19

21

23

19

21

17

21

23

19

23

21

19

17

17

21

15

21

21

21

21

21

23

19

17

17

19

19

15

19

17

.17

17

15

15

15

21

21

19

17

17

17

39—C130

39—136

40—126

40-199

40—C213-2

41—42

41—49

44-C257

44-321

44-322

44—328

45—C150

45-203

45—351

47—131

48-69

48-105

48—135

48—182

48-184

50-160

50-211

57—56

61—25

61—30

61—32

61—46

61—49

69—C19

70-28

70-53

71—87

71—107

71—C133

71—C134

75—251

LS75

79—31

97—51

97—56

99—342

99-348

99-349

99—350

110—323

110—401

115—C113

115—118

122—C38

125—23

126—54

126—57

129—18

131—C163—1

137—19

137—77

139—10

140-16

144—27

144-28

149—16

149—30

155—9

183—36

II

A

,.19

,,19

.17

.17

.21

.15

.15

.19

.19

.19

.19

.21

.21

.17

.19

.19

.17

23

23

21

15

21

17

19

19

23

23

17

is

15

15

15

21

19

21

17

23

21

21

21

23

15

17,

21

15

15

19

19

19

19

21,

15

21

17

23

15

23

23

23

21

17

23

17

19

17

19,

23

SC303

24314

1

CS320—1/2

CS327

124330

CS331

403—li

405—576—2

405—576—3

413

416—374

426—47

439—7

444

—322

446—118

447—141

448—Cl

448—135

449—27

468—23

468—23—1

471-C544

652—16

660—168

660—204

666-170

666—239

810L

854L

876L

1003L

1005L

1022L

L

1025

1031L

1081

L

1132

L

1160L

1170L

1183L

1192

L

1195L

1197

L

1213L

1220L

1221

L

1243L

1246L

1284L

1304L

1306L

1333L

1351

L

1388L

1405L

1733L

4107—58

4118—15

4118—24

4124—27

4129—18

4149—18

4149—30

6258

21201

22508

B

22559

22653

B—8

C

54484

23

15

23

23

3

15

23

23

23

23

15

15

17

19

i7

17

32

19

17

17

15

15

21

23

23

17

17

17

17

23

23

21

17

19

17,21

17

15,23

15

15

17

15

17

15

15

17

15

15

17

19

19

19

19

17

23

21

23

23

21

17

17

17

23

19

21

21

23

23

17

17

23

24

Page 25

Here

are

Oil

for

Specifications

Union

Sewing

Specification

roleum

mended

machines.

roleum

white

1.

For

mount.

roleum

high

mitters.

3.

Where

used.

UNION

SPECIFICATION

Viscosity

Flash

Pour

Color

Neutralization

Viscosity

(D&D

Compounding

Copper

*Anline

*Used

viscosity

oil,

for

Specification

oil,

viscosity

withamaximum

or

use

where

Specification

viscosity

oil,

Specification

quality

grease

is

similar

It

3

No.

SPECIAL

S.S.U. at

(Mm.)

(Max.)

A.S.T.M.

Index

Mm.)

Corrosion

No.

with

Buna

oiling

all

freedom

300

for

to

greaseisnot

100°F

(Max.)

(Max.)

No.

(Max.)

N

Rubber

Special

Machines

quality

a

174

specifies

100

seconds

applications

175

specifies

100

seconds

A.S.T.M.

specifies

87

seconds at

specifies

100

use

commercial

NO.

“0”

from

in

obtainable,

90-125 90-125

0.10

None

175-225 175-225

high

at

100°F.

on

high

a

at

color

stainingispara

oil

a

high

100°F.

general

a

ball

bearings

N.L.G.l.,

174

350 350

20 20

3

0.10

85 85 85

1A

Retainers

Recom

high

quality

100°F.,

number

quality

purpose

and

grease

No.2may

175

300-350

1

None None

1A 1A

speed

water

trans

87

350

20

0.10

175-225

pet

pet

pet

of

No.

3

NOTE

meeting

essential.

be

These

and

separate.

NOTE

shall

not

fINEST

1:

above

These

Oxidation

1.

2.

Rust

3.

Lubricity

4.

Anti-oxidants

Film

5.

additives

removable

2:

Oils

be

not

Extreme

1.

2.

Tackiness

Lead

3.

4.

Detergents

/

QUALITY

Ihe

used

of

use

inhibitors

strength

containing

soap

non-corrosive

classification

may

include:

inhibitors

additives

additives

must

be

by

at

any

pressure

or

adhesive

additives

UNION

completely

wick

the

following

time:

additives—corrosive

SPECIAL

CORPORATION

additives

is

desirable

solubleinthe

feeding nor

additives

type

in

but

shall

additives

oils

not

oil

they

Page 26

Union

Special

Wants

to

Helpibu

union

Sp(’(idl

educe

your

system

to

parts

and

a

Machine

Repami—pionuo’

nip

(lnion

I

arid