Page 1

0

installing

Sewing

SPECIAL

Heads

List

Catalog

Third

and

in

including

of

Parts

No.

Edition

MACHINE

CHICAGO

Operating

Class

43

14500

COMPANY

Page 2

Page 3

Catalog

INSTRUCTIONS

FOR

No.

43

INSTALLING

The

parts

furnished

Rights

at

Union

Reserved

AND

SEWING

CLASS

listed

list

Third

HEADS

IN

14500

in

this

prices

Edition

Copyright

by

Special

Machine

in

OPERATING

catalog

for

repairs

1939

Co,

All

Countries

are

only.

^ >

November,

MACHINE

INDUSTRIAL

•

1965

CHICAGO

".I,:

PrinJ,ed

COMPANY

SEWING

in

U.

S.

MACHINES

A

Page 4

The

build

The

information

possible

Union

one

the

name

is a synonym

It

is

economies

Specials.

Dimensioned

gladly

furnished

allocating

opportunity

In

given

14500,

Filled

the

for

including a list

The

following

Bag

dominating

best

industrial

our

constant

that

will

and

drawings

to

assist

pages

to

space.

which

floor

installing

catalogs

Closing

Machines

FOREWORD

idea

for

aim

enable

advantages

mill

engineers

Our

in

solving

follow,

and

operating

of

back

sewing

of

machines

"Superlative

to

furnish

the

customer

accruing

of

any

of

our

for

engineers

your

detailed

the

parts.

and

prints

will

be

furnished

"Union

Special"

in

Excellence".

carefully

to

from

equipment

their

will

welcome

sewing

instructions

sewing

applying

the

world.

prepared

is

secure

the

all

use

will

convenience

an

problems.

are

heads

on

in

to

our

request:

to

of

be

in

Class

Catalog

lating

Base

Machines

Catalog

Type

Class

Catalog

Machine

14500.

Catalog

Machines

14500.

Catalog

Style

3218

Catalog

Machines

(drawing

Catalog

Machine

No.

Catalog

Catalog

Form

Photo

3238

Machine

357.

for

sewing

20200.

No.

to

Machine

in

No.

Machine

14500.

No.

Style

No.

in

No.

20100

Q).

No.

in

No.

No.

Style

Q).

No.

Style

No.

Engineering

prints

29.

List

the

sewing

Style

Class

42

D.

Style

43

E.

20100 D and

43

F.

Class

43

G.

D,

with

43

H.

Class

5090

43

J.

20100

43

K.

21800

45.

List

heads

of

parts

of

Parts

head

20100

20500.

transmitter

H,

Instructions

21800 C and

Instructions

sewing

Instructions

20200

Assembly

list

and

drawing

of

Sub-assembly

20500,

with

Q).

Assembly

H,

Assembly

C.

and

in

Class

for

Union

drawing

with

description

Department

Victor

Special

and

and

the

for

sewing

for

for

sewing

parts

drawing

list

list

drawing

14500.

Adjusting

Machines

Machine

information

on

the

Heavy

Duty

assembling

heads

assembling

heads

in

Class

assembling

heads

of

in

Junior

(drawing

of

of

of

of

of

Heavy.Duty

parts

Fixed

parts

(drawing

Table

of

needles.

in

Company

Instructions

re

Fixed

Table

in

Junior

Victor

Class

Machine

No.

Base

Type

Class

Engineering

-3-

Department

J

Page 5

A

each

and

letters

lij-^OO

When

is

style

sewing

special.

H,

only

merely

Example;

number

head.

Those

suffixed

Style

minor

suffixed

1/4.500

IDENTIFICATION

is

stamped

Style

which

but

never

numbers

changes

containing

to

the

HZ.

OF

in

numbers

are

standard

contain

are

made

respective

SEV/INC

the

are

the

in a steuidard

HEADS

name

classified

have

the

letter

lei.ter

standard

plate

one

"Z",

"Z"

style

attached

as

standard

or

more

are

machine a "Z"

to

Example:

special.

number.

STANDARD

14500 DSewing

fabric;

stitch

inch,

F

Sewing

weight

14500

locked

to

inch,

H

Sewing

14500

fabr'ic;

stitch

inch,

R

Sewing

weight

14500

iocKed

to

inch,

friction

associated

motor.

A

14500

sewing

tion

READY

accurately

denced

apparatus,

wise

arrive

special

Z

Class

component

This

catalog

heads

to

TO

."■lefore

by

the

OPERATE

the

as

special

shipment,

adjusted

with

given a thorough

at

their

STYLES

Head,

short

Type

standard

Head,

fabric;

stitch

standard

Head,

long

Type

standard

Head,

fabric;

stitch

standard

drive

parts,

style,

14500,

parts.

APPLICATION

applies

listed.

sewing

test

sample

the

destination

OF

for

length

401,

lengths

for

short

Type

for

length

401,

length

for

Icng

Type

pulley,

but

each

and

sewing

test.

SEWING

closing

needle

stitch

closing

length

i+Ol,

length

closing

needle

stitch

four

closing

length

401,

length

1/4

H.P.,

similar

differing

OF

only

to

It

can

heads

INSTALLING

sewing

carefully

left

in

head

Packed

ready

HEADS

bags

Type

IN

made

range-three

four

and

eight

bags

made

needle

stitch

range

stitch

four

bags

Type

to

bags

needle

four

range

to

made

l44,

three

inch.

made

range

to

suspended

friction

to

the

standard

in

one

CATALOG

the

standard

also

be

Class

is

inspected.

machine.

by

skilled

for

service.

applied

in

head

the

operating

CLASS

14500

frcrri

double

to

to

from

Type

light

eight

inch.

medium

124,

12/4,

three

inch.

from

heavy

double

to

eight

frcri

heavy

Type

li4r»

three

inch.

Includes

support,

drive

or

14500,

thorougi-.iy

on

styles

more

styles

with

This

Each

fabric,

hands,

weight

locked

to

double

to

eight

weight

locked

to

double

to

eight

cable

a

and

electric

in

of

its

of

discre

run

is

in,

evi

complete

is

like

they

-4-

L

Page 6

CAUTION

Carefully

taken

from

The

operator

ends

and

no

provided

threading

placed

No.

stituting

drawing

harm

to

it

The

sewing

in

20162 D and

equipment

the

Junior

Duty

Types

conveyor

substituted

SIMPLICITY

Union

cient

the

OILING

in

followed

of

the

oiled

It

twice

in

Inexperienced

Specials,

in

oiling

work,

The

accompanying

the

sewing

in a surprisingly

missing

needle

by

pressing

is

important

daily.

note

the

shipping

can

use

is

the

the

turned

head

turn

diagram.

operative

!<.

spare

sewing

Fixed

Class

Class

in

one

screws

21800,

the

with

and

in

and

and

head.

any

place.

lever,

that

INSTALLING

the

threading

box.

the

new

machine

in

ASSEMBLING

is

packed

(Cont'd)

of

Do

not

thread advantageously

thread

the

into

pulley

direction

separately.

position, A quick

No.

sewing

heads

Base

20500,

minute.

operators

with

threading

diagram

This

and

at

the

ball

the

head, is

Types

and

Thus

OPERATING

little

sequence

short

Ball

other

with

sewing

22825,

in

Class

in

the

the

quickly

practice

the

shows

time

valves

locations.

the

head

the

withdraw

the

one

or

indicated

change

for

convenience

included

1/^500,

Class

Table

spare

adapt

machine

the

various

once

memorized

without

are

placed

end

of

be

thoroughly

sewing

head

the

by

machine.

two

revolutions,

It

can

adapter

as

standard

furnished

20100,

Types

sewing

soon

the

with

head

themselves

become

and

in

oiling

the

at

The

bearings

the

oil

when

threads.

tying

It

on

the

be

the

will

easily

plate

in

sub

with

Heavy

12

inch

can

be

to

profi

handling

places

can

be

possibility

two

ends

are

can

spout.

oiled

do

of

USE

AN

OIL

These

Spec,

The

following

tory

85

for

and

the

appearing

The

be

are

bearings,

oiled

each 8 hours

provided

EQUIVALENT

oils

possess

brands

sewing

on

our

Viscosity

Socony

The

Texaco

Standard

at

TO

comply

AN

with

absolutely

of

oil

head.

These

recommended

Oil

Vacuum

all

Company's

Oil

Company's

Oil

Company's

other

than

of

operation.

important

S.A.E.

Union

have

#10

Special

no

compounding

been

oils

list

of

"V" - Dynamo

Company's

"Cetus"

"Polarine

those

in

bearings.

-5-

W.

Machine

materials.

found

to

are

lubricants

be

only a few

#F566i

Oil

Arctic

Convenient

the

"C"

Light".

sewing

grease

Company

satisfac

of

Medium

Heavy

head

those

should

cups

Page 7

OPEHATING

(Cont'd)

OILING

Style

lubricated

pression

the

lack

should

quired

or

CLEANING

(Cont'd)

The

20100 K and

resistance

of

be

oftener

its

equivalent

Accumulated

makes

possible.

necessary

air

by

ing

SETTING

spot

tending

up

the

tion

the

Due

or a steam

with

oil.

In

submerging

equal

It

milled

into

right,

of

wrench

it

sewing

cup,

attention,

with

head

solid

which,

of

screwed

than

necessary

to

the

to

corrosive

clean

Jet,

fertilizer

the

parts

of

THE

NEEDLE

has

two

grooves; a short

out

from

the

the

adjacent

the

needle

and

so

stitches.

No.

Il6,

transmitter

the

Heavy

oil

through a hollow

once a week

the

grease

the

pulleys

up

immediately.

once a month.

in

consistency

lint

and

to

keep

the

sewing

and

subsequently

plants,

sewing

shank

that

head

kerosene

to

to

bar

as

the

Then

the

furnished

Duty

is

dust

the

action

head

the

each

and

the

eye.

It

will

eye

tighten

for

on

the

styles

should

noticeable.

run

hot,

Refilling

No. 5 Arctic

will

fill

quickly

sewing

in

head

salt

each

spray

corrosive

night

machine

groove

eye,

and a long

Insert

go

be

the

the

with

purpose.

will

Fixed

Base

in

Class

shaft

be

screwed

If,

the

compression

will

the

absorb

as

blocks,

day

with

the

cleas

the

action

in a vessel

oil.

terminating

the

the

in

long

line

needle

Machine

20500

from a com--

through

Cup

up

not

Grease,

is

until

cup

be

re

requirements.

oil,

which

as

it

is

compressed

working

is

groove

needle

with

clamp

parts

avoided

contain

in

a

ex

as

groove

the

nut

far

to

direc

with

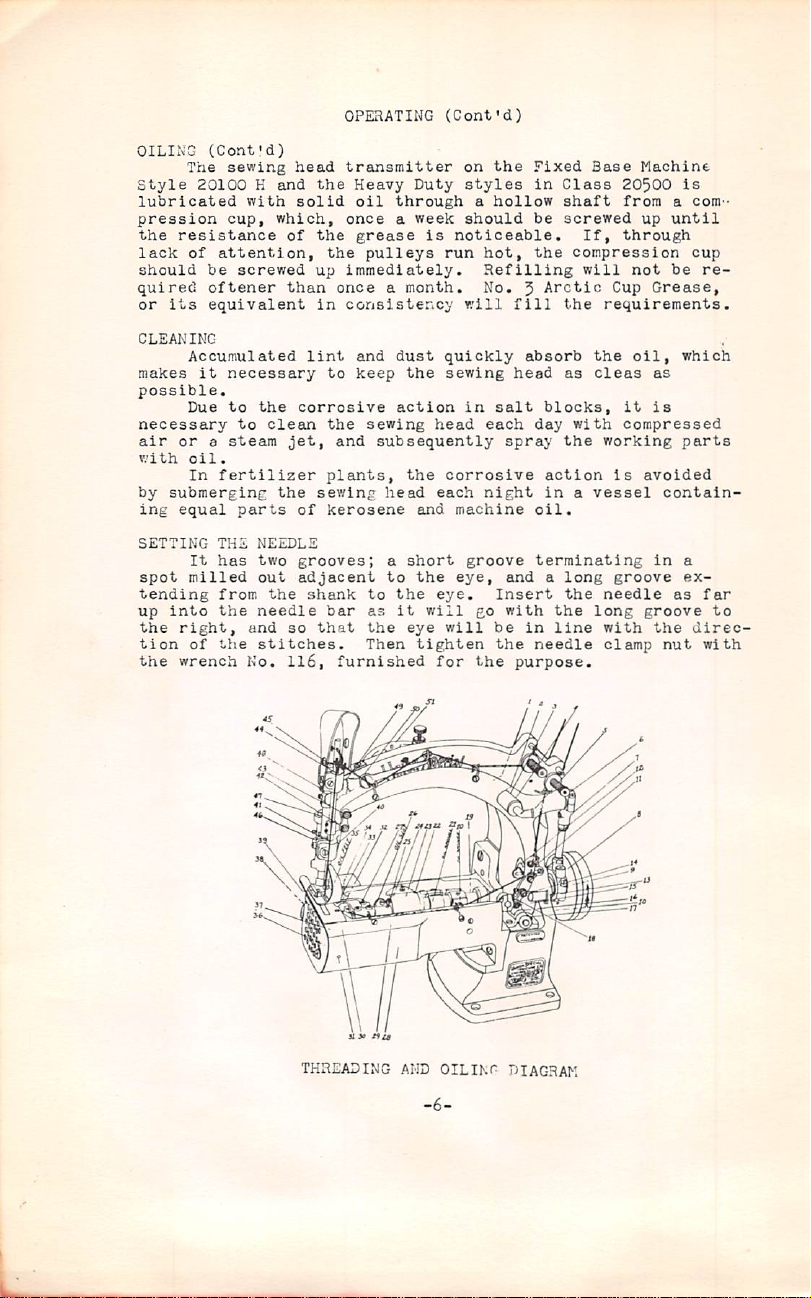

THREADING

AMD

OILING

-6-

DIAGRAM

Page 8

THREAD

liNG

Carry

thread

gram.

circumstances

the

tension

stand

The

the

two

posts

thread

eyelets,

threads

should

in

CP2RATi::C

upwardly

and

then

should

the

thread

threading

cCont'd)

from

proceed

not

cross

be

between

the

cones,

as

each

turned

the

throujvh

shown

in

the

other.

completely

tension

discs.

the

dia

Under

around

no

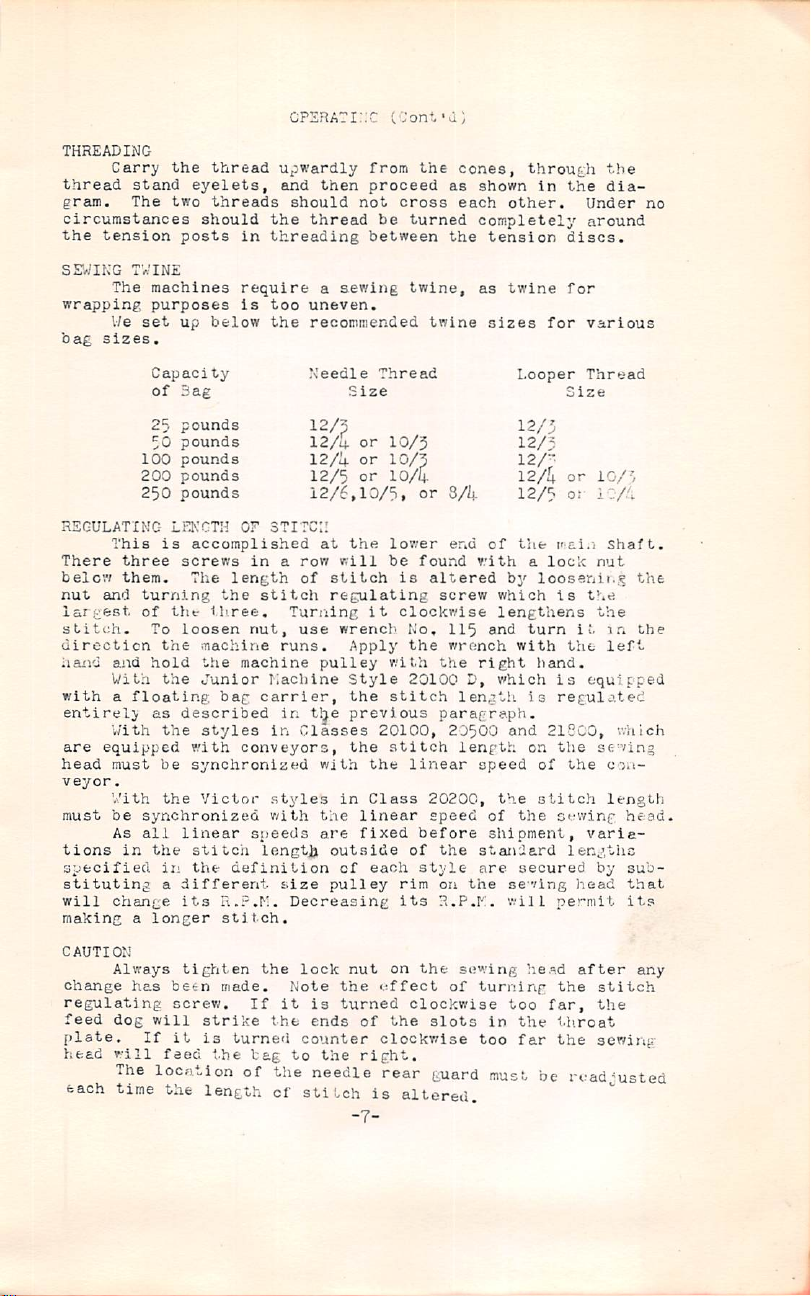

sr^JIKG

wrapping

bag

Tt'INE

The

I7e

sizes.

machines

purposes

set

up

require a sewing

is

below

Capacity

of

3ag

25

pounds

50

pounds

100

pounds

200

pounds

250

pounds

RSGULATIKC-

This

There

below

nut

and

largest

stitch.

direction

iiaiid

and

With

with a floating

entirely

v;ith

are

equipped

head

must

veyor.

Vith

must

be

As

tions

specified

stituting a different

will

change

making a longer

CAUTION

Always

change

regulating

feed

plate.

head

each

Li^'CTH

is

three

screws

them.

turning

of

the

To

loosen

the

hold

the

as

described

the

be

the

synchronized

all

linear

in

the

ir;

its

tigliten

has

been

screw.

dog

will

If

it

will

feed

The

location

time

the

07

accomplished

The

length

the

l.h.ree.

machlrie

the

machine

Junior

bag

styles

with

conveyors,

synchronized

Victor

stitcii

the

definition

u.F.M.

stitch.

made.

strike

is

turned

the

of

length

too

uneven.

the

recommended

N'eedle

12/^

12/y.

12/m.

12/5

12/6,10/5,

STITC:;

in a row

of

stitch

Turiilng

nut,

use

runs.

Tiachine

carrier,

in

t^e

in

Classes

styles

with

speeds

lengtjb

size

Decreasing

the

lock

Note

If

it

the

counter

tag

to

the

of

stitch

Thread

Size

or

10/3

or

IO/3

or

10/4

at

the

will

stitch

regulating

it

wrench

Apply

pulley

Style

the

previous

20100,

the

the

in

Class

linear

fixed

outside

of

each

pulley

stitch

with

the

are

nut

the

is

ends

ctffect

turned

of

clockwise

the

right.

needle

rear

is

-7-

twine,

twine

or

3/4

lower

end

be

found

is

altered

screw

clockwise

No,

II5

the

wrench

with

the

20100

stitch

lenjth

paragraph.

ZO'^QO

length

linear

2020C,

speed

before

of

the

style

rim

on

its

R.P.K.

on

the

sowing

of

clockwise

the

slots

guard

altered.

as

twine

for

sizes

for

hooper

Size

12/5

12/^

12/--

l2/k

or

12/5

or

of

the

with a lock

lengthens

and

right

D,

speed

of

shipment, varia

standard

are

the

turning

In

too

must

rain

by

loosenit.,^

which

is

turn

with

liand.

which

is

is

regulated

and

21GC0,

on

the

of

the

stitch

the

cnving

secured

se'ving

will

permit

head

the

too

far,

the

throat

far

the

be

it

the

the

lengths

head

readjusted

various

Thread

10/v

iO//;

shaft.

nut

the

the

the

in

left

equipped

which

se'ving

con

length

head.

by

sub

that

its

after

any

stitch

the

sewing-

the

Page 9

SUGGESTIONS

V.'hen a machine

apparently

the

following:

(1)

Note

respect

move

(2)

See

that

is

consistent

the

(5)

(ii)

(5)

(6)

(7)

fabric,

See

that

cient

Try a new

Clean

The

throat

which

remedied

of

emery

If

the

it

may

re-adJustment,

TYPE

NW.3ERS

Each

former

finish

diameter

midway

needle

is

the

below.

the

Type

the

The

styles

needle.

denotes

and

between

sheuik.

complete

Set

No.

124

Round

spotted,

in

good

carefully

as

directed,

any

lint

the

tension

the

to

tension

steady

needle.

and

oil

plate

will

cause

by

smoothing

cloth.

foregoing

be

assumed

AND

needle

of

type

SIZES

has a type

the

other

details.

the

blade,

the

Collectively

symbol.

numbers

of

machines

opposite

shank,

nickel

OPERATING

fails

repair,

whether

which

with

its

it.

the

machine

needle

breaking

measures

that

and

the

kind

shank

of

covered

each

round

plated.

to

work

delay

the

especially

may

have

on

the

strength,

on

the

hole

out

the

spare

NEEDLES

number

of

point,

The

measured

and

eye,

the

the

needles

type

Description

point,

(Cont'd)

satisfactorily,

can

be

machine

needle

looper

thoroughly.

of

the

fail

sewing

latter

in

type

by

number

is

at

the

accumulated.

thread

and

thread

may

have

the

threads.

hole

with a narrow

to

relieve

head

head

should

and a size

shank,

denotes

thousandths

and

is

number

most

this

is

short

length,

avoided

by

threaded

tensions,

is

yet

avoids

is

become

This

tlie

needs a general

be

substituted.

number.

length,

the

of

stamped

eind

size

commonly

catalog

are

the

descripLion

double

though

checking

in

every

and

re

as

tight

puckering

barely

suffi

roughened,

can

be

strip

difficulty,

The

groove,

largest

an

inch

in

the

number

used

in

listed

groove,

as

of

145

l44

APPLICATION

listed

number

vRound

long

Round

short

The

styles

herein.

of

shank,

point,double

shank,

point,

OF

TYPE

of

Set

the

needle

round

point,

groove,

round

point.

double

NUIi3ERS

machines

opposite

generally

groove,

covered

each

used.

No. 2 bag,

spotted,

No. 2 bag,

spotted,

style

by

nickel

this

number

long

length,

plated.

long

length,

nickel

catalog

is

the

plated.

are

type

Page 10

APPLICATION

OF

TYPE

NEEDLES

NUMBERS

(Cont'd)

(Cont'd)

Machine

Style

No.

14500

D

14500

F

14500

H

14500

R

ORDERING

To

empty

should

order

.080".

PLATES

trations

component

the

sizes,

these

LIST

cription

Always

ing.

have

package, a sample

be

given.

would

Grouped

of

parts

mechanism.

When a given

only

pieces,

OF

PARTS

Turning

of

check

It

is

When a part

covered

description.

nuts,

part.

parts

by

For

convenience

and

similar

(-) A dash

denotes

orders

read

as

together

parts

that

one

illustration

it

is

from

each

part

the

symbol

not

necessary

is

this

catalog,

in

the

Type

Needles

promptly

needle,

See

marks

follows:

ORDERING

according

similar

go

together

design

the

articles

the

absence

of

necessary

plates

and

against

used

or

no

in

ordering,

"plate

Nos.

used

124

124

lii4

14^

and

accurately

or

on

packages.

"100

REPAIR

to

in

appearance,

in

part

is

is

usually

that

to

its

the

principal

its

to

furnish

can

be

specific

are

repeated

number"

of

an

illustration.

of

the

type

An

Needles

scale

PARTS

the

made

Type

will

and

same

in

shown.

the

size

list

of

uses

description

the

plate

used

in

use

is

minor

parts

after

column

filled,

and

size

the

intelligent

1/^4

Size

be

found

to

some

subdivisions

two

or

more

In

be

parts,

ordering

specified.

the

will

be

before

number.

all

sewing

mentioned

such

as

each

major

of

the

list

numbers

illus

extent,

of

des

found.

order

heads

in

the

screws,

of

($) A double

denotes

separately.

IDENTIFflNG

with

with

similar

the

that

Where

its

an

identification

in

All

catalog

PARTS

the

part

appeareuice.

part

dagger

the

component

construction

number.

numbers

in

which

in

the

parts

permits,

Some

of

letter

represent

they

appear.

"symbol

cannot

the

smaller

to

distinguish

the

-9-

each

same

to

order

be

furnished

part

parts

part,

by"

is

stamped

are

them

from

regardless

column

stamped

parts

of

Page 11

ORDERING

SUPPLIES

All

supplies,

fasteners,

stone,

promptly

USE

be

Needles

Special

Obviously,

reputation

best

to

the

made

efficiency

screw

furnished.

GENUINE

Success

secured

only

and

Machine

of

goods

obtainable.

most

with

and

it

approved

the

Genuine

marked

stamped

trade

in

materials

VmianSfMxicdl

with

mark

is

REPAIR

including

transmitter

drivers,

NEEDLES

in

the

operation

by

the

Repair

is

to

Parts

Company

Union

taps

use

our

Specials

They

scientific

utmost

durability

needles

the

Union

your

and

workmanship.

precision.

are

are

.

Genuine

Special

guarantee

PARTS

belting,

lubricant,

and

AND

of

of

genuine

as

furnished

or

interest

by

are

(Cont'd)

belt

powdered

reamers

REPAIR

these

its

to

furnishing

designed

principles,

The

assured.

packaged

repair

trade

of

the

highest

hooks,

belt

oil

will

be

PARTS

machines

Union

by

the

subsidiaries.

maintain

can

Special

Union

the

the

very

according

and

are

maximum

with

mark.

labels

parts

are

Each

quality

TERMS

Prices

notice.

point.

otherwise

postage

are

net

cashand

All

shipments

Parcel

Post

are

shipments

directed. A charge

and

insurance.

-10-

subject

forwarded

to

are

is

change

f,

insured

made

o.

b,

without

shipping

unless

to

cover

Page 12

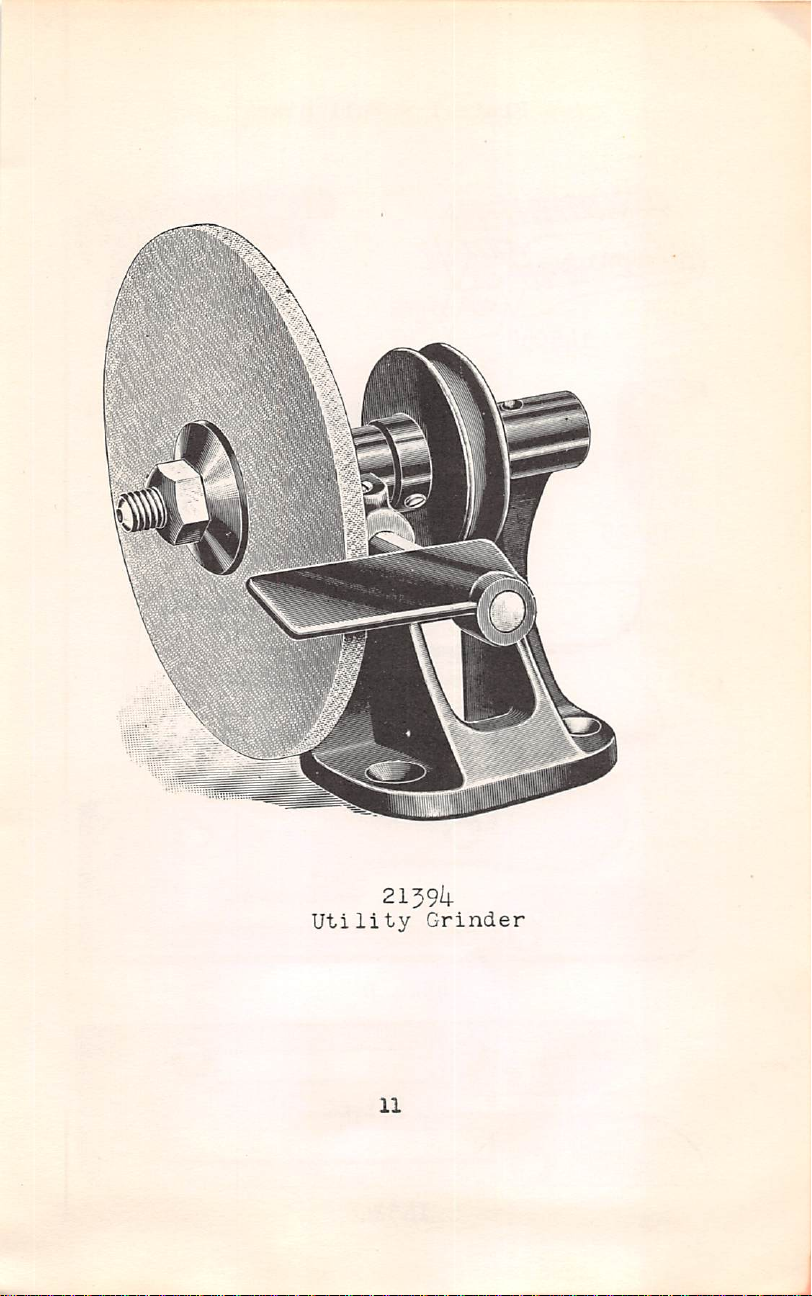

i

2159^

Utility

Grinder

11

Page 13

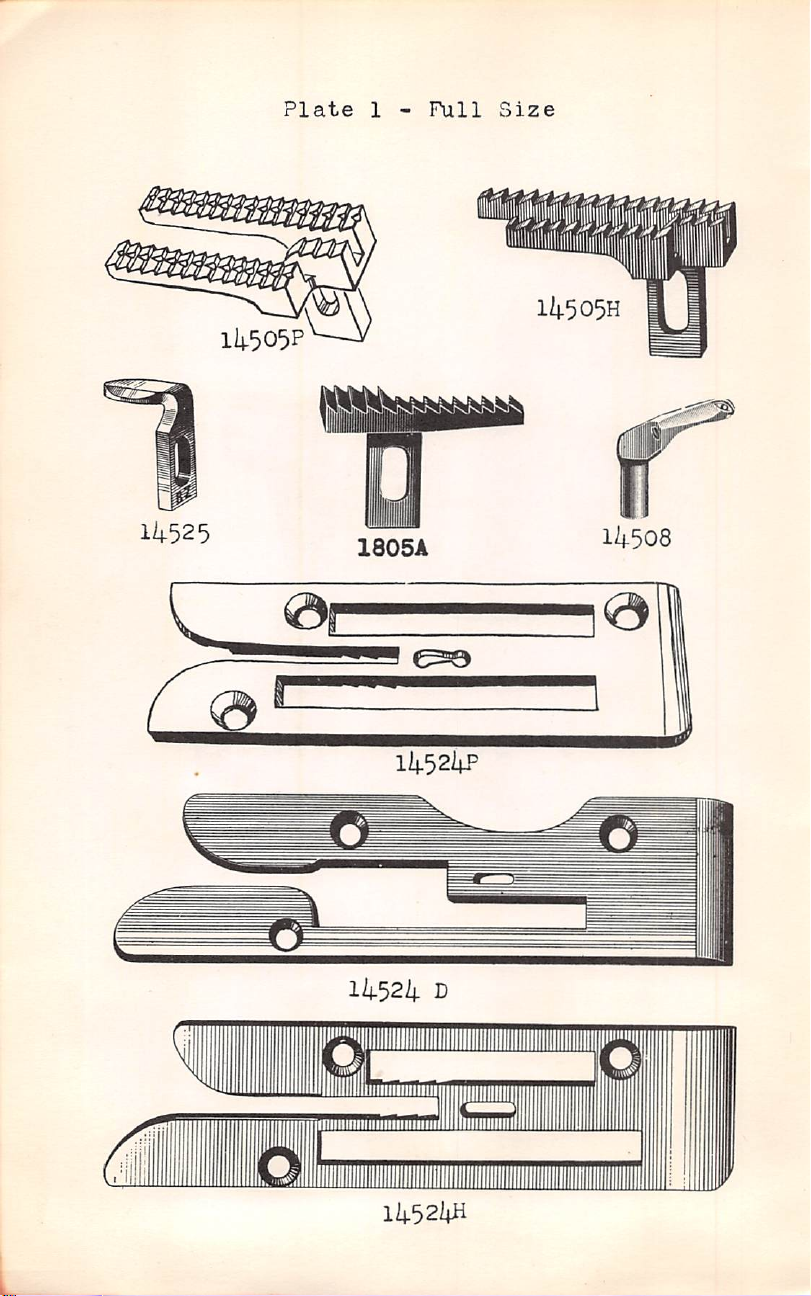

1W05P

Plate

1 - Full

Size

1^505H

14-525

1805A

14524P

14524

14508

D

I4524H

Page 14

15493A

Plate 2 -

Full

Size

ikb^O

B

14577P

li).527F

14520D

14520P

J

Page 15

Plate

3 - Full

Size

89

77

78

32586A

f

33788

2252ij.

88A

22526

98

22580

95

_

22550

96 A 23525

72

259

87 U 98

94

s

22560

22570

9SA

25CC

86

9

32563

73

91

22591

s

96

98a

90

81

85

8

97

22528

22597

2251S

226^2F-Zk

93

22517

22597A

£2569

22596

32571

97

ISO

A

Page 16

-7

22540

Plate k -

15445

22587

22572A

22509

Full

535

141

Size

22795

22794

^0549

22592

14076

80464

555

82

11261A

I7B

1^20

22823

64

A

313

1279

22825A

010

55

19155

Page 17

Plate

5 ~ Full

Size

7947

15430C

109

50

B

37L

15430D

21210

37R

12957

21210

A

2558

13

652

E

21212

258

21104H

C-9

267

A

107

015

64B

129640

12865

a

112613

5

U)

522

1230B

666-1

11658 L 1286B

W

666-6

110-1

110-2

4io/j.6g

^

55172D

llO-o

41078b

1349

426

Page 18

Plate

6 - Full

Size

ll|.56i4Xi

29066B

lk5i^2A

Li

llt-515A

15498

14598

N

5^4

1W72

o

lk565

3

14530

II4.53O

A

llj-578

Page 19

21225

SPECIFY

MEASUREMENT

Plate

7 - Full

Size

21351

21351

h2(ik

21565

A

1361A

13873

21361

21362

WA15

202A

15498R

1286 1286

16

399

V109

A

I23OD

11614

1806

A

21113

B

3^^90

C

14544

Page 20

TA

nc

55

Plate

8 - One-half

l5k30L

Size

118

B

u

21207

116

534

115

21104

21388

R

C

21104

21145

E

21755

A

Page 21

Plate

Q - One-half

Size

1275A

54

54

A

1275E

125OA

14585A

1275F

15442

1275H

B

14585B

1275J

15442

c

15450M

29089F

29089G

Page 22

9274

523

Plate

14545

10 - One-half

14550

Size

172

555

62c

154960

69T

21113

14546

A

14570

60A

14531

1250c

5OD

14653

Page 23

lil-582J

Plate

11 - One-half

Size

151^-98

E

15498X

Page 24

Plate

12 - One-half

168

X

Size

ai

1/+2C

145I4-7A

291

145413

lk566

14559A

14555

21582E

Page 25

Plate

15 - One-third

ih-Slk

Size

1I4-5I4-5

lU5ij-8

ilj-514-9

114.671

a

11670

A

316

14522

Page 26

Plate

21582C-26

215820-5!^

li4. - One-fourth

Size

21201

21208

21202

21582E

21205A

21304

413

21203

Page 27

Plate

15 - One-fourth

Size

Y801

Y

506

Specify

Size

Specify

Y505

Speoify

Size

Y505

Y800

Size

Y501

Spaolfy

Size

YSOS

2ll0i^.

Specify

l!v598

A

29165B

Length

B

Page 28

20162D

Plate

21104D

16 - One-eighth

Size

21150s

14540

14581

211150

21104G

2il04K

2110i|.T

E1104F

d

01-19

Page 29

Plate

17 - Three-fourths

Size

lk59Q

KNIFE

GRINDER

Page 30

LIST

OF

PARTS

010

011

G12

Glk

015

WA15

016

01-19

TA54

TA55

Symbol

to

Order

5

16

17

B

18

20

25

B

25

S

25

cc

55

54

56

G

37

L

37

R

59

47

48

50

D

52

A

54

54

A

56

60

A

60

A-322

6o

A-325

60

A-328

60

A-351

60

a-554

By

The

figures

plates

used

Main

Thumb

No.

Pulley,

Pulley

No.

Pulley

Pulley

Stop

Feed

Emery

Feed

" "

Pressure

Feed

Screw,

"

Clamp

Looper

"

Upper

Looper

"

Frame

Needle

"

"

"

"

"

Hand

••

Needle

Presser

in

illustrating

in

ordering.Refer

Shaft

Collar

Screw,

14598

for

for

knife

Spindle,

136)-

---------------Spindle

Spindle

Watch-

Crank

Crank

Crank

----------------

Link

Wheel,

Stud

Pump

Stud

for

cylinder

for

knife

14582

Screw,

for

*

J

for

Rocker

"

Looper

Connecting

Connecting

«

Looper

Lever

Bar

Lever

No.

Lever

Tally

Thread

Stud

" "

(screw

Thread

98

Link,

" "

Tachometer, 4 speed

12000

R.P.M.

Clamp

Bar,

Nut-

standard

for

"

"

"

"

"

" standard

inch

" steuidard

inch

" standard

inch

" standard

" standard

the

last

column

the

parts

to

pink

(screw

holding

No.

knives

grinder

for

knife

Washer,

Nut,

Ferrule

--------------

Nut;

Oil

Washer,

for

for

knife

knife

----------

grinder-

also

Can, 1 1/2

also

cover

housing,

driven

Stud-

"

Rod

knife

------------

Nut-

Rod

Nut,

n

ti

Guide

Nut

-----------

Washer-

No.

88

A)

Eyelet,

A)

lowerupper-

---------------

---------

---------

type,

-------------

diameter

Style

14500

diameter

------------

diameter

------------

diameter

------------

diameter

diameter

refer

only

bo

and

are

insert

nob

for

the

to

be

prices.

95)- - - - in

grinder

(screw

grinder

knife

No.

98)-

(screw

grinder-

grinder

------

for

No.

11654

pints

capacity

for

No.

spring- - - - -

also

for

14580

No.

-------

Ball

Joint

lower,

thread - - - - -

upper,

thread

---------

---------

left

right

- - - - -

--------

lower

(screw

90

to

.319

inch,

D

plus

.003

plus

,006

plus

.009

plus

.012

plus

.015

- -

Plate

No.

-

4

-

11

11

-

5

5

7

7

11

4

5

16

5

-

5

5

2

5

5

10

-

2

9

9

8

5

-

10

-29-

Page 31

^mbol

to

Order

By

The

figures

plates

used

in

in

the

illustrating

ordering.Refer

last

the

column

parts

to

pink

refer

and

ere

insert

only

not

for

to

the

to

be

prices.

Plate

No.

61

62

62

62

62

62

62

6k

6k

69

72

7:?

77

78

81

82

86

87

88

88

89

90

91

95

95

94

95

96

96

97

97

c

C

C-522

C-525

C-528

c-551

c-55^^.

A

B

T

u

A

A

A

A

Presser

screw,

Presser

"

"

"

"

"

" Spring

" Spring

Filler

closing

Set

Screw,

"

"

"

" fillister

"

Spot

Screw,

Set

" headless,

Screw,

"

"

Screw,

1066.

Set

Screw,

142

Screw,

14545,

for

Clamp

Screw,

15495

Screw,

friction

Screw,

c,

No.

Screw,

Set

Screw,

also

Set

Screw,

Ill,

Spot

Screw,

"

Screw,

"

Bar

Connection

left.

Guide

" "

n n

" "

"

It

14598

for

No,

Cord

Cone

frames

for

for

link

for

for

regulating

for

knife

for

iieedle

for

2558,

for

14552-

for

14550

for

frame

14566

for

for

knife

A

for

grinder

washer

for

needle

for

No.

for

172,

555.

for

« for

1W74

for

supporting

for

looper

also

for

No.

77)-

Bar,

n

Regulating

A

Regulating

14598

Support

in

looper

looper

pin,

feed

setting

feed

------------

stsindard

standard

.005

inch-

standard

.006

inch-

standard

.009

inch-

standard

.012

inch

standard

.015

inch

A------------

Pin,

Class

eccentric

-------------

head,

also

for

needle

lift

length

bar,

gauge

take-up

also

thread

Screw,

Screw

21800

for

arm

12865, 14555,

(screw,right,

needle

feed

bar;

rocker;

looper

thread

----------------

presser

lubricating

feet

swinging

---------------

thread

l4575~

main

557

looper

feed

take-up

-------------

shaft

collar;

avoid

lift

cam;

feed

connecting

No.

15442

C----------

-50-

diameter

diameter

---------

diameter

---------

diameter

---------

diameter

diameter

also

Lock

for

use

-------fork- - -

for

needle

No.

6l

lever

---------

of

stitch- - - - -

on

knife

wire - - - - -

for

Nos.

14578

also

for

also

for

take-up;

---------

felt,

frame

pivot

wire

also

eccentric-

also

dogs

--------

rod

ball

No.

.519

plus

plus

plus

plus

plus

for

Nut,

on

lever

C-

link

Nos.

Nos.

also

for

88,

inch

- -

No.

also

bag

- -

- - - -

pin

grinder

6l

C,

also

for

No.

pin

post;

for

Nos.

- - - -

No.

joints;

6

10

—

—

—

—

—

4

5

10

-

5

5

5

3

3

4

3

5

5

5

5

3

3

5

3

3

5

3

5

3

5

Page 32

LIST

OF

FASTo

Symbol

to

Order

107

108

109

VI09

110-1

110-2

110-5

111

115

116

118

156

142

154

156

158

162

168

168

172

202

258

267

291

299

504

516

By

98

98

Screw,

A

"

Tension

"

"

B

Tap,

Tension

filler

Tension

looper

Tension

needle

14500

Tension

Styles

(screw

Wrench,

connecting

Wrench,

needle

3

Thread

Clamp

grinder;

Cylinder

Needle

c

"

" Lever

"

"

" Bar

Fresser

14500

X

Fresser

Tension

Style

Needle

Nut,

Swinging

grinder

Looper

" Differential

Feed

Looper

The

figures

plates

illustrating

used

in

ordering.Refer

for

looper

Nos.

Gil,

for

needle

No.

157Spring

Regulating

Disc

marked

''J-2",

Spring,

cord

Spring,

thread-

Spring,

thread

P,

14500

Thread

14500

No.

95)

single

rod

single

clamp

Tweezers-

Screw,

for

also

Thread

Thread

"

Buffer,

" Ball-

" Thread

Connection-

Spring,

H,

14500

Spring,

Thread

14500 P (screw

Thread

for

lower

Frame

(screw

Rock

Shaft

Crank

Stud

Avoid

Shaft,

in

the

last

column

the

parts

to

rock

shaft

267,

14545

lever

Ferrule

.026

on

Style

.028

----------------

.040

on

R

Eyelet,

D,

14500

----------------

end,

nuts-

end,

nut

----------------

pulley

for

Eyelet

Controller

for

R

for

Eyelet,

thread

-------------

Nut

-------------

for

screw

inch

14500

inch

inch

Styles

with

F,

5/8

inch

-------------

9/52

---------------

spindle

No.

15498

(screw

■

wood

Eyelet

-------------

Styles

Style

with

Mo.

Take-up

looper

Pivot

Cap

Pin

No.

Collar

Rocker

(screw

98)

V/ire

connecting

------------

(screw

standard

refer

and

pinK

insert

collar;

eyelets;

No.

diameter

diameter

diameter

14500

F,

two

holes,

1450O

opening,

Inch

opening,

on

J-

No,

Lever

Screw

n

Rack

86

fibre-

(screw

14500

14500

F-

three

95)

---------

Post

(screw

Collar,

No.

Pin

---------

No,

22565)-

diameter

only

arr.

not

for

also

22526

wire,

wire,

wire,

1450O

H,

ifooo

for

knife

--------

98

A)-

------

(screw

A)

-----

--------

------

No.

98

D,

l45O0

-------

holes,

rod

ball

for

knife

22580) - -

.407

to

the

to

be

prices.

for

also

for

- - - -

for

for

for

H,

- for

R

looper

for

- - - -

No.

A)- - -

F,

for

No.

94)

Joint

- - - - inch

Flate

Mo.

>

«

5

2

4

-

12

6

4

2

6

12

12

10

7

5

5

-

12

7

6

15

-51-

Page 33

LIST

OF

PARTS

Symbol

to

Order

516-408

516-410

516-415

516-416

518

555

555

557

415

416

420

426

426

Y5OI-257

Y5O5-519

Y505-522

Y505-525

Y505-528

y505-55l

Y505-407

Y505-410

Y505-415

Y505-416

Y505-419

Y506-550

522

525

524

525

652

666-1

666-6

Y800

Y801

Y802

1066

$1250

1250

By

Looper

Screw,

Tension

on

Tension

overall 2 1/8

Tension

overall 1 7/16

Oil

B

Lifter

A

E3q>ansion

Cylinder

c-9

Shake-Proof

Oil

" "

Taper

"

"

Feed

A

Needle

No.

B

Needle

The

plates

used

"

"

Style

Can

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

"

Cup,

Reamer,

Lift

22587)

figures

Avoid

for

Lever

Lever

Lever

in

illustrating

in

ordering.Refer

the

Shaft,

"

"

"

"

"

cylinder-

Post, 2 5/8

14500

Thread

Eyelet,

inches,

Thread

Eyelet,

inches

Casting

« Stud

" Spring-

" "

Reamer,

for

" for

guide

« size

" size

" size

" size

"

for

looper

" size

" size

" size

" size

" for

Cover

Spring

" Bolt

"

for

for

"

" for

Link

" Spring - --

"

Lock.

Washer,

needle

upper

for

lever

for

frame

needle

Pin

Connecting

Connecting

last

column

the

parts

to

pink

standard

.001

standard

.005

standard

,006

standard

.009

--------------

inches

inch-

inch

inch-

inch-

with

for

with

diameter

diameter

diameter

diameter

long,

one

Style

one

(screw

--------------

--------------

Pin-

needle

bar,

presser

bar,

size

.522

inch

.525

inch

.528

inch

.551

feed

inch

drive

avoid

.410

inch

.415

inch

.416

inch

.419

inch

main

shaft,

(screw

Knob

lever

main

Collar

for

stud

shaft

end

of

end

of

lever

(screw

Rod

Front

Rod

Front

No.

needle

refer

only

and

are

insert

not

for

to

to

prices.

plus

---------

plus

plus

---------

plus

---------

for

filler

hole,

length

14500 P (screw

hole,

No.

bar

length

95) - -

size

.257

and

presser

,519

inch-

--------

--------

--------

shaft

and

shaftjsize

--------

--------

--------

--------

size

.550

25

B)

-

--

---------

- - - - -

--

bar

eyelets

bearing

needle

needle

link

pins - «

No.

88)

lever

lever

Bearing

Bearing

the

be

-

cord

- - -

inch

- -

.407

inch

--

--

- - -

stud

stud

- -

- - -

(screw

Valve

Plate

No.

4

4

10

2

14

5

7

15

15

15

15

15

15

15

15

15

15

15

15

5

10

8

4

5

5

-

5

15

15

15

5

fsee

Page

9"^

~

Page 34

LIST

OF

PARTS

Symbol

to

Order

1250

1230

1275

1275

1275

1275

1275

1279

1280-

1286

1286

1286

1349

1361

1805

1806

The

By

C

plates

used

Needle

thread,

15450

Needle

(screw

Needle

Needle

viz;

specify

represents a stud

Needle

viz:

amount.

plus

Needle

tion,

plus

stud

Needle

tion,

.006)

(.003,

.001)

(.012,

.001)

Specify

first

1275

inch

section^

.006

LEVER

Needle

Note:

Before

lever

from

compound

Needle

H

"

"

"

Tension

Presser

Feed

Dog,

" Lift

figures

Lever

D)

Lever

Lever

Lever

.001,

Lever

,001,

in

illuatreting

in

ordering.Refer

Connecting

No.

15450

Connecting

No.

22586

Stud,

Stud,

.002,

plus

amount.

Stud,

.002,

Example:

.005

inch

Lever

Stud,

viz:

.001, .002,

amount.

plus

.005

Lever

Stud,

viz:

(.001,

(.002,

.001)

(.006,

.002)

(.018,

and

J-005-006

on

plus

LET/ER

FRAME

.001)

(.003,

.002)

(.012,

.002)

amounts,

1275

inch

on

section

Lever

and a needle

the

Lever

Spring,

Spring

FRAME

Stud

lapping

stud

has

been

Ball

II

n

" Link

1286

" Link

No.

" Link

Pin-

for

Style

Cam

(spot

the

last

coluna

the

to

Rod

0,

nut,

Rod

A)

--------------

taper

plus

size

refer

parts

and

pink

insert

Tube

ri^t

Front

bearing,

on

.OO3, .006, .012,

Example:

plus

.005

inch

plus

size

.003»

1275

on

LEVER

plus

Example:

inch

on

plus

.002)

(.002,

.002)

(.006,

.003)

(.018,

section

represents a stud

section

J-OO6-OO3

section

(screw

and

for

No.

Felt

No.

the

lever

replace

washed

Stud

II

Pin

Assembly;

A,

1286

Pin

(set

77,

set

Pin

Spring

needle

---------------

on

.006

inch;

F-003

size

.003i

1275

EACH

size

represents a stud

section

equal

.006

H-O03

section

unequal

(.001,

.003)

(.003,

.003)

(.012,

.003)

arranged

last.

and

.006

represents a stud

and

22886

15450

bearing

stud

it

after

cut.

Clamp

Bolt

II

n

B,

12964

screw,

screw,

(screw

thread

14500 D (screw

screw

No.

155!

96

mly

not

for

to

to

prices.

left

are

(nut,

thread.

Bearing

standard

FRAME

section,

.018

I275

E-003

on

FRAME

LEVER

section,

specify

--------

on

EACH

inch;

represents

------

on

.003)

each

(.001,

(.002,

.006)

(.012,

.006)

(.018,

FRAME

section

Example:

plus

inch

.003

B)

.003

on

inch

-------

L

of a needle

remove

one

the

the

--------

Nut

------

each

C,

22560

fillister

headless

No.

2256O)-

on

Style

No.

22596)

A)--

the

be

No.

Valve

inch;

plus

sec

specify

sec

.006)

(.006,

.001)

(.018,

.006).

LEVER

plus

on

felt

lapping

Nos.

head

No.

78)

Plate

No.

10

7

9

a

-

Page 35

LIST

OF

PA^TS

Symbol

to

Order

2558

7947

9274

10549

11261

11261

11614

11658

1:11654

11670

12554

12865

■ 12875

12957

12964

lli076

lh505

14505

14508

14515

14515

14520

14520

14522

14522-

14522-

14524

14524

14524

14525

14527

14529

;i4550

14550

14551

tSee

By

A

B

L

A

.

£

c

H

P

A

D

■555

-536

D

H

P

F

B

A

B

Page

The

figures

plates

illustrating

used

in

ordering.Refer

Needle

Feed

Knife

Tension

ing

Creink

Thread

Collar;

Bar

" Double

Post, 1 7/8

'

Looper

Knife

Looper

Avoid

Bar

Connecting

(washer

nut

No.

"T"

Screw,

Needle

Feed

Needle

Cylinder

Needle

Cylinder

Feed

lock

Bar

washer

Bar

Bar

Lever

Dog,

Shaft

End

End

14500 R (screw

Feed

Dog,

Looper

Looper

Needle

Presser

Presser

Main

Throat

Throat

Needle

Presser

(screw

Rocker

Lever-

Foot,

No.

91,

Foot,

No.

91,

Shaft,

"

"

"

"

Plate,

"

"

"

"

Plate

Guard,

Foot,

14500 R (clamp

No.

22794)

Cylinder,

14500

Note:

pairs

Needle

Needle

Presser

are

(screw

Styles

H,

This

Thread

No.

Thread

Bar,

14500

in

the

last

coltimn

the

parts

to

pink

Controller

also

Link

Nut - -- -- -- -- --

Shaft

Support

Ball

for

Lever

No.

Pin

Joint

inches

" Ferrule,

Eccentric

C-pring-

No.

58

18

for

sewing

Thread

No.

Collar

Bushing

Guard

Link

Guard

for

Styles

for

Style

No.

----------------

----------------

for

hinge

screw

for

hinge

screw

standard

standard

standard

for

for

14500

for

Screw

marked

for

for

Styles

5^/64

(spot

-

-- -- --

Rod

Ball

G,

bearing

head-

Eyelet

6^2

(screw

C-9)-

(screw

(clamp

Spring

Pin

Ball-

Pivot

No.

14500

22596)

Stud

14500 P (screw

75)

------------

Style

14500 D (clamp

No.

Style

14500 P (clamp

Ko.

diameter

diametei-

diameter

Style

14500

Styles

14500

R

Style

No.

14500

22524

"3Z"

Styles

screw

14500

No.

14500

14500 R (screw

part

is

made

l4l)

standard

furnished

at

fectory.

Controller

--------------

Controller

F,

14500

-54-

Lever

Lever

diameter

H,

refer

and

are

insert

9274

---------

Stud,

long

inch

screw

Joint,

screw

-

-

---------

No.

screw

Washer-

---------

--------

F,

14500

22795)-

22794)-

plus

plus

D-------

P----

(screw

9I,

D,

14500

No.

5^8)- - -

only

14500

only

to

not

to

for

prices.

Rack

Support

(screw

front

-------

long-

No.

--

-- --

upper

No.

- - - - -

No.

22768,

88)- - - - -

No.

22569)-

------

H,

No.

------

------

.550

inch - -

.005

.006

F,

14500

No.

22596)

F,

14500

hinge

screw

F,

when

Assembly

Eyelet

.519

inch,

F,

l4500

the

be

No.88)

--

- - -

- -

96)-

97

A,

22596)

screw

screw

inch

inch

H,

H,

- - -

re

- - - for

R

Plate

»o.

5

5

10

4

4

-

5

-

7

-

5

9

15

2

5

-

7

5

1

X

1

✓

O

14

2

-

1-

6

2

10

Page 36

LIST

OF

PARTS

Symbol

to

Order

14531

14531

14531

14531

14531

14536

14539

14540

14541

145^4^

14545

14544

14545

14546

14546

14546

14546

14547

14548

14548

14548

14548

14548'

14549

14550

14552

14555

14556

ti4564

14565

14566

14570

14575

14577

-See

Page

By

-522

-325

-528

-531

-354

-5

22

-3

25

-528

•4

08

•410

■413

•416

D

Looper

Looper

Freune

Stitch

Main

Knife,

9

The

figures

plates

illustrating

used

in

ordering.Refer

Presser Bar,

"

" standard

"

" standard

"

" standard

"

Needle

Cylinder

No.

Cylinder

Feed

Feed

Feed

rear,

Feed

" Rocker

"

"

"

"

"

" standard

Thread

End

14076)

Cover

Bar

(set

Lift

Link

Lift

Link

No.

Bar

Shaft

" Shaft, 4 15/16

" Shaft,

" Shaft,

••

" Drive

diameter

" Drive

" Drive

" Drive

" Drive

* Crank

clamp

' Crank

' Lift

"

Cam

Differential

Connecting

No.

258

A,

Looper

Regulating

Shaft

stationary

"

driven,

14500

In

the

last

the

standard

Take-up

Guard

98)-

(screw

standard

screw

Pin

-------

(washer

No,

(screw,

No.

standard

.Q05

inch

standard

.006

inch-

Shaft,

.009

standard

inch-

Knife

Shaft, 6 1/8

.407

(clamp

Pin

Fork

inch-

standard

standard

standard

standard

lock

(screw

Shoe

Hooker

Shaft,

Shaft,

Shaft,

Shaft,

Link

screw

Link

"

Rod

bearing

Thread

screw

Take-up

Screw

Bushing,

H,

upper-

(screw

for

Styles

14500 R (screw

-35-

column

parts

to

pink

diameter

diameter

diameter

diameter

diameter

Wire

88)-

89)

diameter

------------

------------

Rocker

inches

-----------

screw

nut

No.

No.

(screw

"

Support

22517)

Ball

Joint,

No.

Guard

----------

No.

14500

refer

and

are

insert

plus

plus

plus

plus

plus

(screw

No.

12957

---------

front,

------

----------

inches

.519

diameter

diameter

diameter

Arm

long,

diameter

diameter

diameter

diameter

No.

22572

7947)-

89)

No,

(screw

97

(screw

(screw

94)

-------

D,

No.

only

to

not

to

for

prices.

.005

.006

.009

.012

.015

No.

87

E.

stud

No.

89,

long,

inch- - - -

plus

plus

plus

(screw

standard

plus

.001

plus

.005

plus

.006

plus

,009

A,

- - - - -

-----88

A)

88)-

(screw

(nut

- - - - -

90) - -

No.

CC)- - -

- - -

90)

F,

No.

lower

A)

No.

14500

25

the

be

inch-

inch-

inch-

inch-

inch-

U)-

No.

- -

No.

«

12

16

12

10

13

10

12

13

13

10

6

12

12

6

6

12

10

2

Plate

No.

6

7

Page 37

LIST

PA^TS

Symbol

to

Order

By

ik^n

11^578

1^4-580

14581

14582

14585

14585

14598

14598

14598

14^55

14671

14672

1W74

15430

15450

15450

+15430

154i42

tl5hh2

15^43

15^4-95

15498

15498

15498

15498

15498

15498

15498

The

plates

used

Knife,

p

Knife

" Lubricating

" Housing

j

Needle

"

A

" Lever

B

Knife

A

Knife

B

No.

Looper

57

L,

Looper

adjusting

Looper

Feed

Lift

screw

Needle

c

Needle

D

Needle

L

Nos.

Needle

M

No.

Knife

B

Nos.

c

Knife

"

Filler

A

lower

Grinder

E

"

G

"

H

"

J

"

K

"

L

Knife

N

(screw

figures

Bar

No.

in

illustrating

in

ordering.Refer

driven,

Bar

Lever

Styles

for

(screw

20)

(screw

Guard

Eccentric,

14500

the

No.

(screw

Eccentric,

Styles

No.

Grinder,

Grinder

14500

22597)

complete-

Swinging

22591,stop

nut

Ho.

Grinder

22516)

Connecting

Avoid

Avoid

Lever

Lever

Lever

1275

Lever

22587)

Bar

15(442

Bar

" "

Cord

Setting

6l|.B)---------------

Swinging

nut,

right

Eccentric

screw

Eccentric

Cam

No.

needle

Head,

Swinging

Swinging

(screw

Swinging

screw

Swinging

Fork

96

Connecting

Connecting

Connecting

A,

Connecting

Double

c,

Double

Guide,

for

grinder

No.

" "

Gauge,

Ho.

86)

A,

1275

10349,

bar

No.

No.

----------------

last

column

the

parts

to

Style

88)

Felt

(screw

No.

No.

throw

D,

14500 F (screw

throw

H,

14500

Frame

screw

No.64

Frame

Rod

(nut,

thread.

Fork

No.

22592)

Fork

(set

clamp

screw

screw

Rod

Rod

Rod

E,

1275

Rod

Ball

Joint

15ii43

Ball

Joint

«

"

attaches

lug

(screw

knife

Frame

grinder

Pivot

14598-

Frame

Pivot

95

A)

Frame

Frame

Adjusting

136)

-------------

Adjusting

stop

for

refer

only

and

pink

14500

------------

25

arc

insert

PCscrew

No.

3)

---------

25

S)-

for

95,

.588

.654

P,

14500 R (screw

-----------(set

screw

A,stop

Top

Plate

left

thread.

No.

57

R)

(set

screw

----------

Shoe

(screw

No.

22580,

No,

22592)

Tube

Nut,

Tube

Nut,

Tube

Felt;

F,

1275

Rear

Bearing

Assembly;

Shell(screw

Ball

Stud,

to

sewing

No.

95)- - - - - -

No.

Pin,

Pin

Friction

Sleeve

Thumb

grinder

for

-----------

------------

Pin

knife

to

not

to

prices.

No.25

washer

------Inch,

No.

inch,

screw

(screw

No.

left

right

also

H,

1275

one

rear

head

14598-

knife

Screw

No.

the

be

for

22597)

for

Ho.

check

No.

72,

No.

spot

- - -

for

J-

(screw

each

No.97

at

- -

Washer

(clamp

14598

CC)

A)

- -

Plate

No.

6

16

11

9

17

15

6

10

15

6

-

13

5

5

-

2

-

11

10

7

+oee

Page

9

-36-

Page 38

LIST

CF

PARTS

Symbol

to

Or-ier

By

15498

19155

20162

21104

21104

21104

21104

21104

2110ii

21104

211o4

21104

21104

21104

21104

21105

21113

21113

21115

21130

21145

21201

21202

21203

21204

21205

21207

21208

21210

21210

F

D

3-2

3-5

B-9

3-20

c

D

2

F

c-

K

K

T

J

A

B

c

s

A

A

The

plates

used

Dust

Guard,

• I

0.

Feed

Lift

Sewing.

Ko.

Thread

"

"

Filler

use

20200,

Thread

"

"

"

Thread

support

frames

Thread

cone

Thread

No.

22632

Thread

shoulder

Thread

"

"

Filler

Filler

ing

frames

Cone,

Screw

"

"

"

"

"

"

Looper

"

figures

in

illustrating

in

ordering.Refer

for

22570)

22823)

on

- -

Link

Read

Pin

Quick

---

Stand

Rod, 2 inches

" "

" "

Cord

Support

bag

closing

20500

Stand

(screw

Hod

support

" Seat-

"

"

" "

Stand

seat

pin,

for

in

Classes

Stand

Seat

support

Stand

Stand

Stand

pin

V.'lre,

r-24)

Rod,

------------------

Wire

" "

" "

Cord

Guide

Cord

Cone

wood,

Driver,

in

for

9/64

overall 7 5/8

"

7/52

overall

"

"

"

13/64

overall

9/32

overall

3/8

overall

"

"

Collar,

7/64

" .020

overall 2 1/2

Set,

.o4o

the

lest

column

parts

pink

Adapter

refer

and

ore

insert

ICo.

the

knife

-

Change

to

crir.der

long

22509)

five

inrihes

22509)

nine

inches

22509)

Rod,

frames

No.

Connection;

rod

— — — — — — - —

Connecticn

Pad-

Pin;

also

use

on

'

long

--

long

20

inches

in

Classes

22509) - - - - -

also

(screw

---------

filler

filled

20100, 20200,

Pin

Nut,

nut

sixteen

seven

Kyelet

also

------------

inches

inches

long,

-----------

Extension, 6 inches

(screw

Coupling

Wire

Support,

Classes

thread

inch

Kg,

22632

(screw

------------

for

use

20100,

stand

-----

round

20200,

blade,

inches

inch

inch

inch

inch

inch

three

Irr-'^

tnch

round

11

15

round

15

round

l4

round