Page 1

Service and Parts Manual

Page 2

U-LINE CORPORATION LIMITED WARRANTY FOR MODULAR 3000 SERIES PRODUCTS

1.U-Line Corporation ("U-Line") warrants each U-Line Modular 3000 Series product to be free from defects in materials and workmanship

for a period of two years from the date of purchase. U-Line further warrants the sealed system (consisting of the compressor, the

condenser, the evaporator, the hot gas bypass valve, the dryer and the connecting tube) in each U-Line product to be free from defects in

materials and workmanship for a period of five years from the date of purchase.

2.During the initial two year warranty period for all U-Line Modular 3000 Series products U-Line shall: (1) repair any product or replace

any part of a product; and (2) for all Domestic U-Line Modular 3000 Series products sold and serviced in the United States (including

Alaska and Hawaii) and Canada, U-Line shall be responsible for the labor costs performed by a U-Line authorized service company,

incurred in connection with the replacement of any defective part. During years two through five of the warranty period for the sealed

system, U-Line shall: (1) at U-Line's option repair or replace any part of the sealed system; and (2) for all Domestic U-Line Modular 3000

Series products sold and serviced in the United States (including Alaska and Hawaii) and Canada, U-Line shall be responsible for the labor

costs incurred in connection with the replacement of any defective part of the sealed system. All other charges, including transportation

charges for replacements under this warranty and labor costs not specifically covered by this warranty, shall be the responsibility of the

purchaser. This warranty extends only to the original purchaser of the U-Line product. The registration Card included with the product

should be promptly completed by you and mailed back to U-Line or you can register on-line at www.u-lineservice.com.

3.The following conditions are excluded from this limited warranty: damage caused by outdoor use; use of cleaners other than the

recommended stainless steel cleaners and U-Line Clear Ice Maker cleaner; installation charges; damages caused by disasters or acts of God,

such as fire, floods, wind and lightning; damages incurred or resulting from shipping, improper installation, unauthorized modification, or

misuse/abuse of the product; customer education calls; food loss and spoilage; door and water level adjustments (except during the first 30

days from the date of installation); defrosting the product; adjusting the controls; door reversal; and cleaning the condenser.

4.U-Lines' Outdoor Limited Warranty, set forth in this Paragraph 4, shall apply to U-Line models deemed suitable for outdoor use by

Underwriters Laboratory ("UL") as noted in the U-Line Product Catalog, U-Line's website and/or on the serial tag located inside the

product. Exposure to temperatures below freezing may cause damage to the product. Damage resulting to the product (and/or the

surroundings) caused by this exposure is not covered under this warranty. Such models shall continue to be covered by the warranty terms

set forth in Paragraphs 1 and 2 above, to the extent such models:

A.Are subjected to temperatures between 50 and 100 degrees Fahrenheit. Although these products will function in ambient temperatures

below 50 degrees and above 100 degrees Fahrenheit, performance may decline. Performance degradation due to operating above or below

the designated ambient temperature range is not a manufacturing defect and any issues resulting from exposure to higher temperatures,

such as spoiled food or low ice production, are not covered under this warranty policy; and/or

B.Come into contact with rain by virtue of outdoor use. Exposure to other sources of water shall also cause this warranty to be void,

including flooding of the area in proximity of the unit greater than 1/8" deep in water, hurricanes, splashing of pool water, or directing a

spray from a hose or similar device into and around the unit.

5.If a product defect is discovered during the applicable warranty period, you must promptly notify either U-Line at P.O. Box 245040,

Milwaukee, Wisconsin 53224 or at 800-779-2547 or the dealer from whom you purchased the product. In no event shall such notification

be received later than 30 days after the expiration of the applicable warranty period. U-Line may require that defective parts be returned,

at your expense, to U-Line's factory in Milwaukee, Wisconsin, for inspection. Any action by you for breach of warranty must be

commenced within two years after the applicable warranty period.

6.THIS LIMITED WARRANTY IS IN LIEU OF ANY AND ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, ALL OF

WHICH ARE DISCLAIMED. U-Line's sole liability and your exclusive remedy under this warranty is set forth in the paragraphs above. ULine shall have no liability whatsoever for any incidental, consequential or special damages arising from the sale, use or installation of the

product or from any other cause whatsoever, whether based on warranty (express or implied) or otherwise based on contract, tort or any

other theory of liability.

7.Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential

damages, so the above limitations may not apply to you. This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

U-Line Warranty

Page 3

PRODUCT LIABILITY POLICY

Field service technicians are authorized to make an initial assessment. If in the servicer’s judgment the damage is the result of a product

defect, the product would be removed and returned to U-Line in an unaltered condition. The dealer would then be authorized to

permanently replace the end-user’s product at no cost to the end-user. Please call U-Line immediately at 800-779-2547 to initiate the RA

and product exchange process.

If in the servicer’s judgment the damage is the result of installation issues (water connection/drain, etc.), the consumer would be so notified

and the correction would be made by the servicer or installer without requiring removal of the product. Any claim for damages should be

directed to the original installer.

Any U-Line unit involved in an alleged property damage claim must remain unaltered and unrepaired, for evaluation. No service or

repairs should be performed on any unit suspected to be involved in a property damage situation. If a unit has been altered or repaired in

the field prior to U-Line’s evaluation, any claim for damage may be declined.

If the unit in question is a U-Line CLR or CLRCO with a drain pump, both the unit and the drain pump (regardless of the manufacturer)

must be returned to U-Line Corporation.

To complete the damage claim process for the customer, please obtain the following and forward to U-Line at onlineservice@U-Line.com,

fax to 414-354-5696 or mail to the address below.

Pictures of the unit, installation and any alleged property damage.

Inquire when the problem first appeared, any prior problems with the product and provide a brief description of the

alleged damages.

To expedite the claim process, U-Line will need two damage repair estimates.

Reference the RA number and customer name when providing this information.

If a unit is returned to U-Line, this evaluation will take approximately ten business days. No field service company is authorized to

perform this evaluation. When a Return Authorization Number is issued, and the unit has been boxed in a U-Line carton, U-Line

should be contacted and then will make arrangements for shipping, or designate a truck line to have the unit shipped freight collect.

If U-Line’s evaluation finds the unit, (or U-Line P60 pump) to be defective, causing the property damage, the damage claim will be reviewed

by the U-Line Customer Assurance Department.

If U-Line’s evaluation finds the unit not to be defective, does not repeat a failure or does not leak any water from the U-Line unit or U-Line

P60 pump, all claims for damage will be declined.

When a product evaluation is needed, it is the customer’s responsibility to assure that the unit is returned for evaluation. If the customer

fails to do so, or has the unit repaired in the field prior to U-Line’s evaluation, any claim for damage will be declined.

8900 N. 55th St. • P.O. Box 245040

Milwaukee, WI 53224-9540

414/354-0300 • Fax: 414/354-7905

Website: www.u-line.com

Leaders In Quality Undercounter Refrigeration

U-Line Service

Page 4

Table Of Contents

General Information

Troubleshooting

Parts View & Listing

Safety Alert Definitions.........................................................................................................................................1

General Precautions............................................................................................................................................. 1

Models Covered.....................................................................................................................................................2

Warranty Claims Procedure ...............................................................................................................................3

Proof of Purchase...................................................................................................................................................3

Serial Number ........................................................................................................................................................4

Model Number Format .......................................................................................................................................4

Replacement Parts ................................................................................................................................................5

Thermistors.............................................................................................................................................................6

Thermistor Calibration.........................................................................................................................................6

Viewing Temperature............................................................................................................................................6

Air Flow....................................................................................................................................................................7

Initial Startup ...........................................................................................................................................................7

OLED Electronic Control Display .....................................................................................................................7

Adjusting Temperature Settings ........................................................................................................................7

Interior Lighting .....................................................................................................................................................8

Customer Menu .....................................................................................................................................................8

Service Menu.........................................................................................................................................................10

Electronic Control Quick Guide .............................................................................................. 16

USB Communication...........................................................................................................................................17

Convection Cooling ............................................................................................................................................19

Door Alignment and Adjustment.....................................................................................................................20

Customer Call Guide..........................................................................................................................................21

Compressor Information ...................................................................................................................................23

Thermistors ..........................................................................................................................................................24

Thermistor Failure...............................................................................................................................................24

Reed Switch...........................................................................................................................................................24

Compressors .......................................................................................................................................................24

Refrigeration System Diagnosis Guide............................................................................................................25

Fault System Diagnosis Guide ..........................................................................................................................26

3018RF ..................................................................................................................................................................27

3018RGL ...............................................................................................................................................................29

3018WC ...............................................................................................................................................................31

Wiring Diagrams .................................................................................................................................................33

All Models .............................................................................................................................................................33

Page 5

THIS PAGE INTENTIONALLY LEFT BLANK

U-Line Service

Page 6

General Information

IMPORTANT

IMPORTANT

DANGER

WARN ING

CAUTION

DANGER

WARN ING

WARN ING

CAUTION

IMPORTANT

IMPORTANT

General Information

• PLEASE READ all instructions before installing,

operating, or servicing the appliance.

• Proper installation procedures must be followed when

completing an installation or relocation of a unit. An

INSTALLATION GUIDE for the unit, providing complete

installation information is available from U-Line

Corporation direct. Consult the installation guide before

any installation begins. U-Line contact information

appears on the rear cover of this guide.

• This unit requires connection to a dedicated 15 Amp

grounded (three-prong), polarized receptacle, installed

by a qualified electrician, compliant with applicable

electrical codes.

Safety Alert Definitions

Throughout this guide are safety items labeled with a Danger,

Warning or Caution based on the risk type:

Danger means that failure to follow this safety statement will

result in severe personal injury or death.

General Precautions

Use this appliance for its intended purpose only and follow these

general precautions with those listed throughout this guide:

RISK OF CHILD ENTRAPMENT. Before you throw away your

old refrigerator or freezer, take off the doors and leave shelves

in place so children may not easily climb inside.

• SHOCK HAZARD - Electrical Grounding Required.

• Never attempt to repair or perform maintenance on the

unit until the electricity has been disconnected.

• Never remove the round grounding prong from the plug

and never use a two-prong grounding adaptor.

• Altering, cutting of power cord, removal of power cord,

removal of power plug, or direct wiring can cause serious

injury, fire and or loss of property and or life, and will void

the warranty.

• Never use an extension cord to connect power to the

unit.

• Always keep your working area dry.

Install provided Anti-Tip kit. Serious personal injury could

occur.

Warning means that failure to follow this safety

statement could result in serious personal injury,

property or equipment damage. or death.

Caution means that failure to follow this safety statement

may result in minor or moderate personal injury, property

or equipment damage.

• Use care when moving and handling the unit. Use gloves

to prevent personal injury from sharp edges.

• If your model requires defrosting, DO NOT use an ice

pick or other sharp instrument to help speed up

defrosting. These instruments can puncture the inner

lining or damage the cooling unit. DO NOT use any type

of heater to defrost. Using a heater to speed up

defrosting can cause personal injury and damage to the

inner lining.

• Do not lift unit by door handle.

• Never install or operate the unit behind closed doors. Be

sure front grille is free of obstruction. Obstructing free

airflow can cause the unit to malfunction and will void the

warranty.

• Failure to clean the condenser every six months can

cause the unit to malfunction. This could void the

warranty.

• Allow unit temperature to stabilize for 24 hours before

use.

• Do not Block any internal Fans

Use only genuine U-Line replacement parts. Imitation parts

can damage the unit, affect its operation or performance

and may void the warranty.

1U-Line Service

Page 7

General Information

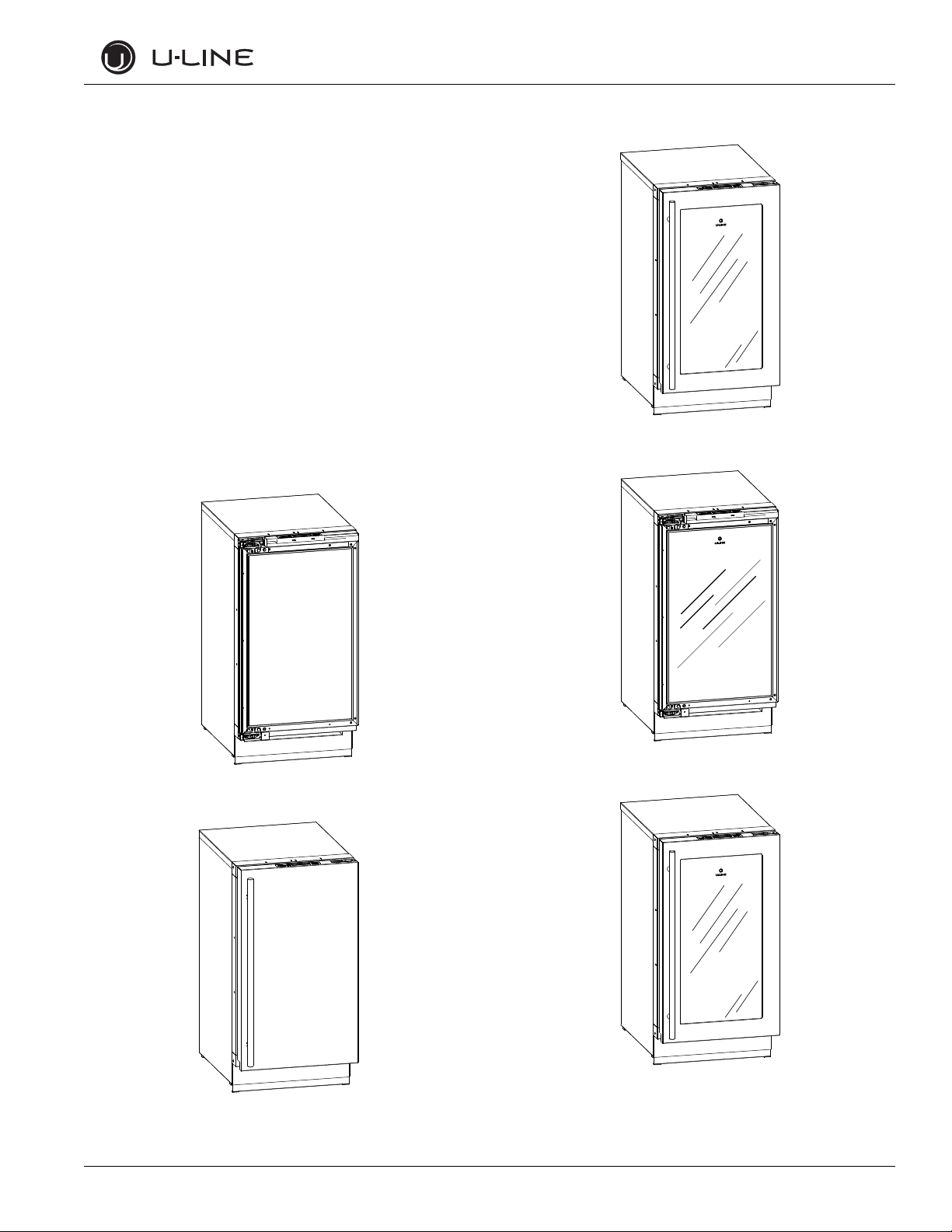

Models Covered

This guide covers the following models:

U-3018RFOL-00 U-3045RFOL-00

U-3018RFOL-01 U-3045RFOL-01

U-3018RFS-00 U-3045RFS-00

U-3018RFS-01 U-3045RFS-01

U-3018RGLOL-00 U-3045RGLOL-00

U-3018RGLOL-01 U-3045RGLOL-01

U-3018RGLS-00 U-3045RGLS-00

U-3018RGLS-01 U-3045RGLS-01

U-3018WCOL-00 U-3045WCOL-00

U-3018WCOL-01 U-3045WCOL-01

U-3018WCS-00 U-3045WCS-00

U-3018WCS-01 U-3045WCS-01

U-3018RFOL

U-3018RGLS

U-3018WCOL

U-3018RFS

U-3018WCS

U-Line Service 2

Page 8

General Information

IMPORTANT

IMPORTANT

Warranty Claims Procedure

Warranty claims must be filed within 60 days after the

completion of the service call

When submitting claims for warranty payment, please

follow these guidelines.

You can use any form you would normally use to bill your customer

(your own computer generated form, Narda, USA, etc.). Claims can

also be filed on-line at www.u-lineservice.com.

The model and serial number MUST be on the claims. Claims will

not be paid without a model and serial number.

If you used a part in your repair, you MUST put the part number, the

invoice number and where the part came from. Claims will be

returned without this information.

If you work on more than one unit per service call please submit a

separate claim for each unit.

We track all defects through warranty claims, so please be specific on

what the repair was. If it is a system leak, please specify where the

leak was.

Please be sure the claim is legible. If the claim form cannot be read, it

will be returned, unpaid.

Remember: Door and water level adjustments are 30 day

warranties only.

If you are changing out a unit please supply the model and serial

number of both units (the unit being replaced and the new unit) and

the R.A. number.

Occasionally the customer does not return their warranty cards. In

this case we use the date the unit was shipped to our distributor for

a beginning warranty date. This may cause the claim to be rejected

for a proof of purchase. If you want to check on a purchase date, you

may contact the U-Line Corporation Customer Assurance

Department at 1-800-779-2547. This will allow you to get a proof of

purchase, if needed, before you submit the claim.

At U-Line, parts and labor claims are paid separately. Included in

labor are freon and recovery charges, all other parts are handled by

the parts department. We require that some parts be returned to us,

so we may return them to our vendor. It will be noted on your

packing list if we require you to return the part. If a part is to be

returned please include a copy of the packing list and a copy of your

claim. If the part was purchased at one of our part distributors, you

must handle the part warranty with that company. For labor payment

please send a readable copy of your claim to U-Line Corporation,

P.O. Box 245040, Milwaukee WI, 53224-9540, or fax it to 414-354-

5696. Claims can also be filed on-line at www.u-lineservice.com.

Proof of Purchase

Proof of Purchase and/or Proof of Install is an important part of the

warranty claim process. Sometimes it is difficult to obtain a proper

Proof of Purchase/Proof of Install for a number of different reasons:

• The customer does not have a copy (only the original).

• The customer has only their copy of the final Walk Through or

sign-off of new construction.

• Other valid reasons that prevent your technician from leaving the

job site with a suitable Proof of Purchase/ Proof of Install.

We understand the problem and have modified our Proof of Purchase

policy to help you in these situations.

Effective immediately, if a copy of the Proof of Purchase/Proof of

Install is not available at the site, the technician should record the

following information on the Labor Invoice:

• The name of the selling Dealer

• The date of purchase/installation

• The Order or Invoice number (if available)

• The type of document they saw, i.e. Store Receipt, Closing Papers,

Sign-Off of Building Permit, Final Walk Through, etc.

If we have this information on the Labor Invoice, and we have the

other information that is needed (correct Serial Number, type of

repair, time spent on repairs, parts used in the repair,

invoice number for the part, etc.), we will be able to process the

invoice for you in a timely manner.

3U-Line Service

Page 9

General Information

IMPORTANTIMPORTANT

0914997-11-XXXX

Year

Month

Factory Internal

Control Number

Shop

Order

U - CO 1175 S - 01

ULN - BI 2115 S - 00

U-LINE FAMILY COLOR SPECIAL

ORDER

U-LINE FAMILYPRODUCT

SERIES

PRODUCT

SERIES

COLOR

SPECIAL

ORDER

U-LINE

U-LINE

U-LINE

FAMILY

FAMILY

FAMILY

PRODUCT

SERIES

PRODUCT

SERIES

PRODUCT

SERIES

COLOR

COLOR

COLOR

SPECIAL

ORDER

SPECIAL

ORDER

SPECIAL

ORDER

U - 2275 DWRW OL - 00

U - 2175 RC GOL - 00

U - CLRCO 2175 S - 41

Serial Number

Starting October 2009, U-Line Corporation went to a 13

digit serial number. Anything before that date will have 12

digits.

The serial number is divided into four segments. A typical serial

number is 0914997-11-0005. (Figure 1)

Number

The first two digits of the first segment, 09, represents the year the

unit was made.

The next four/five digits of the first segment, 14997, represent the

shop order number. Order number 14997 is assigned for the

Model CLRCO2175B-40 units.

The next two digit segment, 11, represents the month the unit was

made.

The last four digit segment, XXXX, is a factory internal control

number used at U-Line Corporation.

Serial Number (Electronic)

The 3000 series contains an electronic serial number assigned to

the main control board. The electronic control serial number and

the unit serial number are tied together at the factory. To obtain

the electronic serial number access “Help” in the customer service

menu. See “Help” on page

10.

Model Number Format

A typical model number would be, U-2175RCGOL-00. The model

number is broken into 5 segments. (Figure 2)

• U- or ULN- This signifies a U-Line Product.

• Family The family is the type of unit. Currently there

are nine families. Refrigerators, Wine Captains, Beverage Centers, Combo Ice Makers, Clear Ice Makers,

Manual Defrost Ice Makers, ADA Units, Outdoor

Units and Freezers.

• Product Series: U-Lines current product series

includes 95, 98, SP18, 1095, 29, 10xx, 11xx, 21xx ,

22xx, and 30xx.

• Color The color segment includes color along with

information that is important to the unit and the way

it is used. As an example, the model U-2175RCGOL00, is part of the family of refrigerators, product series

2175. The “C” following the “R” tells us this is a con

vection cool unit with an evaporator fan motor. The

“GOL” tells us the unit is black with a glass door

requiring an overlay panel. (all glass door overlay units

are black)

• Special Order These numbers tells us if the unit is a

SS door with a left hand hinge, (01) a CLR with a

pump, (40) or a marine or RV product. (03)

-

U-Line Service 4

Page 10

General Information

Replacement Parts

How to Order Replacement Parts

1. Refer to Service Parts and locate the illustration(s) for the model

you are servicing.

2. Locate the desired part to be serviced and note the item number

assigned to it.

3. Locate the item number within the parts list. Note the full

description and the corresponding part number. If this is for a

warranty unit, indicate and record the model and serial numbers.

4. When ordering parts, it will be necessary to supply Model

Number, Serial Number, Part Number, Part Description and in

some cases Color or Voltage.

All warranty parts will be shipped at no charge as long as warranty

status has been confirmed. If we require that a part be returned to Uline, you will be informed at the time the order is placed. It will be

noted on your packing list if we require you to return a part or if you

may field scrap it. If U-Line requires a defective part to be returned, a

prepaid shipping label will be included with your new replacement

part. When returning parts enclose a copy of your packing list and a

copy of your labor claim, showing the model and serial number, and

tag or label the part with the nature of the defect.

Our warranty records may not match the customer's information. In

this case, a proof of purchase will be required. If you do not have the

proof of purchase at the time the order is placed, the part will be

sent net 15 days, charged to a Visa or Master Card if you don't have

an open account with U-Line Corporation. When the proof of

purchase is provided, we will credit your account.

5. Parts may be ordered on-line, by FAX or phone:

www.U-LineService.com

onlineparts@u-line.com

FAX Number (414) 354-7905

Phone Number (414) 354-0300 or (800) 779-2547;

REPLACEMENT PARTS: Use only genuine U-Line replacement

parts. The use of non-U-Line parts can reduce ice rate, cause water

to overflow from ice maker mold, damage the unit, and can void the

warranty.

5U-Line Service

Page 11

IMPORTANT

IMPORTANT

All relay and thermistor information can be found on the

IMPORTANT

IMPORTANT

Electronic Control Quick Guide.

Thermistors

There are 2 thermistors used with the 3018 models.

• Zone Thermistor - Located on the right hand wall and is used to

maintain temperature.

• Evap Thermistor - Located on the back of the evaporator plate

and is used during defrost. Normal defrosting is based on a time

and temperature scale. Defrost ends if the evaporator thermistor

reaches stop point (42°) or maximum time, (90 minutes)

whichever comes first.

• Ambient Thermistor - Located in the base of the unit on the

condenser and is used to monitor ambient air temperatures.

Thermistor Calibration

While thermistors generally do not require calibration, over time

contact corrosion and or element wear may make calibration

necessary.

General Information

Viewing Temperature

Note: The display shows set point NOT the actual temperature.

The 3000 series is equipped with an advanced electronic display and

control. Thermistor readings can be obtained through both the

customer and service menu. The customer menu will display readings

with offsets adjustments taken into consideration. It is important to

note that the system will use adjusted readings when determining

cooling and defrost cycles. The service menu will display the actual

thermistor reading while disregarding offsets.

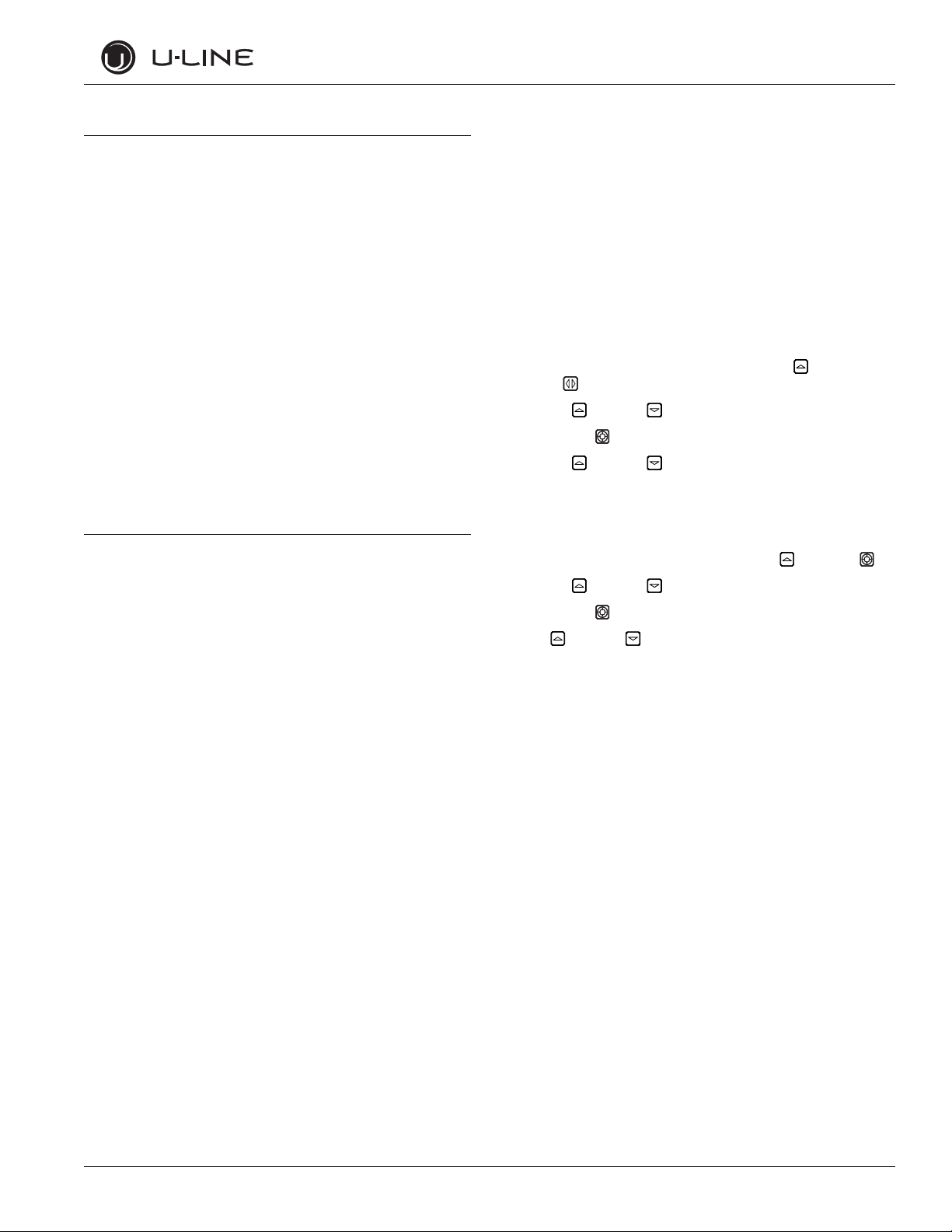

Customer Menu:

To view the adjusted temperature of each available thermistor, follow

the steps below.

1. Initiate the customer menu by holding both up

toggle

2. Use Up or Down to scroll to “Actual Temperatures”.

3. Press select .

4. Use Up or Down to scroll through available information

Service Menu

and zone

If a thermistor reports a temperature difference in excess

of 4°F, the thermistor should be replaced.

Calibration

To calibrate a thermistor one must first prepare an ice-bath of

crushed ice and water in a suitable container. Allow the ice bath

temperature to stabilize for at least 5 minutes before beginning.

1. Make certain the offset for the thermistor to be tested is set to 0.

See “Offsets” on page

2. Fully submerge the thermistor to be calibrated in the prepared ice

bath. It is important the thermistor is surrounded only by the ice

bath and is not touching any walls of the container.

3. View temperature through the customer menu, see “Customer

Menu” under “Viewing Temperature” on page 6.

4. The thermistor should read 32°F. If different, record difference. If

difference is greater then 4°, replace thermistor.

5. Adjust thermistor offset, see “Offsets” on page 12.

6. Repeat step 3 and confirm the new reading is 32°F.

12

To view the actual temperature without having the offsets taken into

consideration, follow the steps below.

1. Initiate the service menu by holding both up

2. Use Up or Down to scroll to “Actual Temperatures”.

3. Press select .

Use Up or Down to scroll through available information

and select

U-Line Service 6

Page 12

General Information

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANT

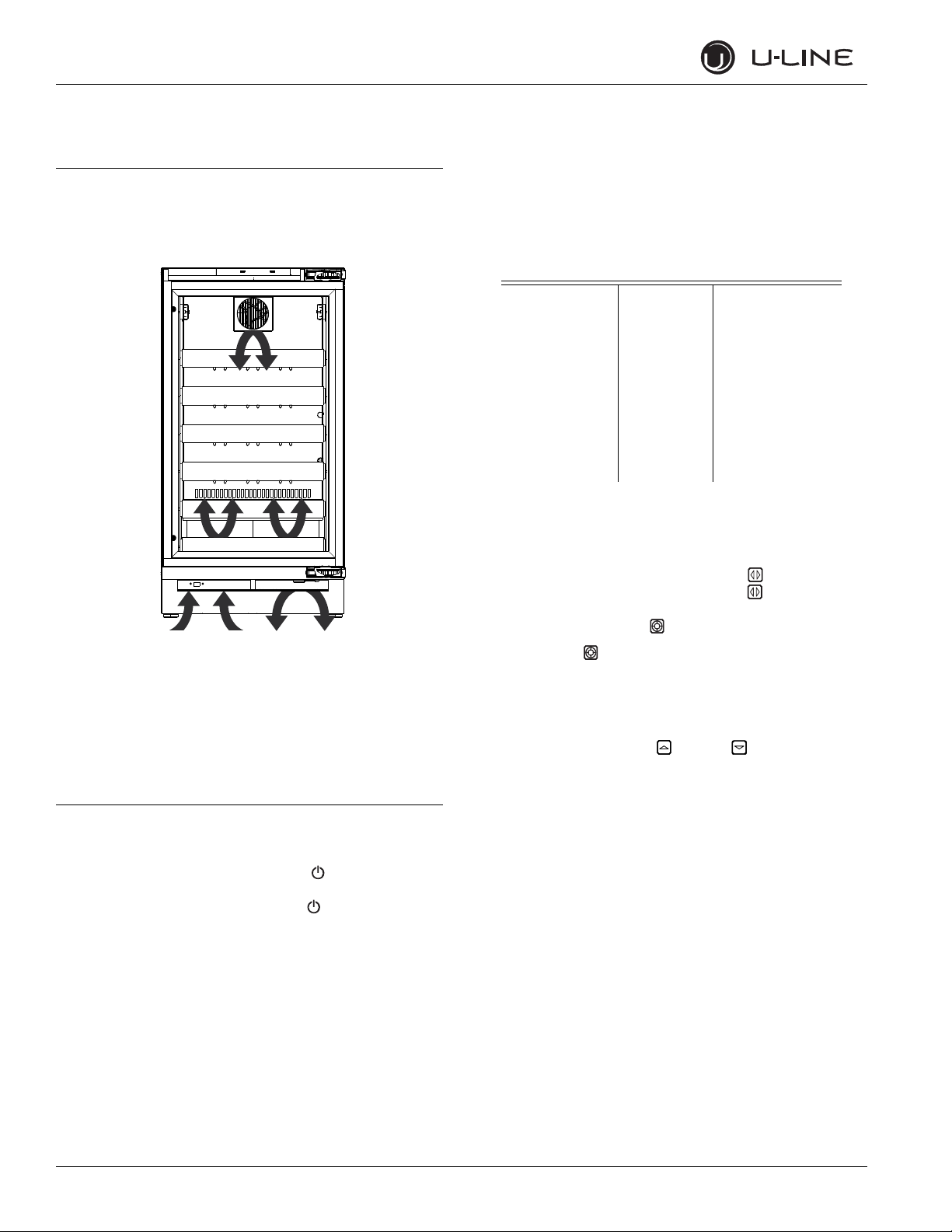

Door Removed For Illustration Purposes

Internal Air Flow And Unit Ventilation Diagram

Air Flow

The unit requires proper air flow to perform at its highest

efficiency. Do not block the front grille, internal fans or vents

at any time, or the unit will not perform as expected. Do not

install the unit behind a door.

Initial Startup

All U-Line controls are preset at the factory. Initial startup requires

no adjustments.

Adjusting Temperature Settings

Each zone has a Series of Zone Settings with a default value for each

setting. Each Zone Setting can be further customized by fine tuning

the temperature set point. See the table below for a description of

each Zone and Zone temperature ranges. Zone selection will vary by

model.

Zone Settings Chart

Setting Default (°F) Range (°F)

Red Wine 55° 55° - 65°

White Wine 50° 45° - 55°

Sparkling Wine 45° 38° - 50°

Beverage 38° 34° - 65°

Market 38° 34° - 40°

Root 50° 45° - 55°

Pantry 42° 34° - 70°

Deli 36° 34° - 40°

The 3036 Models have two independently controlled zones. Each

zone may have its own Zone and set point. The 3018 models have a

single zone. Available Zones Settings will vary with model.

1. In order to adjust temperatures in the 3036 you must first select a

Zone to adjust. To select, press Zone Toggle . The left side

Zone Setting will flash. Pressing Zone Toggle again will select

the right side and the right side Zone Setting will flash. For 3018

Models simply press Select to activate Zone Setting mode.

2. Pressing Select will cycle through each available zones.

Reference the Zone Settings Chart on

default set point and range.

3. Once you have selected your desired Zone Setting the default set

temperature will display. You may further fine tune the

temperature by pressing Up

pg 3

for each Setting’s

or Down .

U-Line recommends allowing the unit to run overnight

before loading refrigerator with product.

To turn the unit off, press and hold POWER for 5 seconds and

release. The display will show a countdown to switching the unit off.

To power the unit on simply press POWER

immediately switch on.

and the unit will

OLED Electronic Control Display

Digital Display.

The 3000 Series units are controlled by a feature rich, advanced

OLED display control unit. The control panel allows adjustment to

temperature set point, access to Energy Saver Mode, internal

temperature readings, and many other features.

7U-Line Service

Page 13

General Information

Up

Select

Down

U-Select Lighting

Power

Up

Select

Down

WELCOME TO THE

CUSTOMER MENU. USE

UP/DOWN ARROWS TO

SCROLL SETTINGS.

Up

Select

Down

3036 Model Display Shown

RETURN TO MENU

ACTUAL TEMPS

LEFT ZONE = 38°F

RIGHT ZONE = 38°F

WHITE WINE

5500 FF

OO

Up

Select

Down

Power

Energy Saver Mode

Indicator

Interior Lighting

U-Line 3000 Series unit uses a state of the art theatre style LED

lighting system.

Note: Lighting system is designed to fade in and out when switching

states.

1. To begin, press U-Select Lighting to enter the lighting menu.

2. Use Up or Down to cycle through each available brightness

setting; Low, Medium, or High.

3. Use U-Select Lighting to cycle through each available timer

setting. Selections include “On With Door”, “On 3 Hours”, “On 6

Hours”, or “On 24 Hours”.

4. To exit, press Select or simply wait for the menu to time out.

Customer Menu

Actual Temps

The Actual Temps option displays the actual temperature of each

zone, evaporator, as well as ambient temperature.

1 . To v ie w A ct u a l Te m p s f i r st s e le c t A c t u a l Te mp s f ro m t h e

customer menu.

2. Use Up or Down to scroll through available information.

3. To exit, Select

Return to Menu.

Energy Saver

The 3000 Series of U-Line undercounter refrigeration appliances

contain a feature rich customer menu. The Customer Menu allows

access to a series of advanced features including Energy Saver Mode,

Sabbath mode, Actual Temp readings as well as a method to restore

factory defaults.

1. To access the Customer Menu hold down both Up and Select

for 5 seconds.

2. Use Up or Down to scroll through available selections.

3. Use Select to enter selected sub-menu.

4. To exit Customer menu, Use Down to scroll to the bottom of

the display and use Select to Select “Exit.”

Energy Saver mode reduces overall energy consumption by altering

user set point, differential, lighting and tone settings. When in Energy

Saver mode a small leaf icon will be displayed on the main screen.

1. To enter Energy Saver first select Energy Saver from the

Customer Menu.

2. Use Down to select “Off” in the menu.

3. Press Select .

4. Use Up or Down to change the selection from Off to On.

5. Press Select to confirm your selection.

6. To exit Energy Saver mode simply return to the Customer Menu,

Select Energy Saver mode and change “On” to “Off”.

U-Line Service 8

Page 14

General Information

Up

Select

Down

RETURN TO MENU

SABBATH MODE

OFF

Up

Select

Down

RETURN TO MENU

LANGUAGES

ENGLISH

Up

Select

Down

RETURN TO MENU

SOUND LEVEL

HIGH

Up

Select

Down

RETURN TO MENU

FARENHEIT/CELSIUS

DEGREES = °F

Sabbath Mode

The U-line 3000 Series of models offer a Sabbath mode for users

who celebrate certain Sabbaths. Sabbath mode disables system

responses to user initiated activities and all external functions;

including lighting, display and audible alarms. The unit will still

maintain internal temperatures and set points.

1. To enter Sabbath Mode, select Sabbath Mode from the Customer

Menu.

2. Use Down to select “Off”.

3. Press Select , “Off ” will begin to flash.

4. Use Up or Down to change “Off ” to “On”.

5. Press Select to Confirm your selection.

The Display will fade out as the unit enters Sabbath Mode. Sabbath

remains active until the Power Button is pushed.

Sound Level

Audible alarms and alert tones support four different Sound Level

settings, High, Medium, Low, and Off.

To select a new sound level, enter the Sound Level menu from the

Customer Menu.

1. Use

Up or Down

to select the current sound level.

2. Press Select , the current setting will begin to flash.

3. Use Up or Down to select a different level.

4. Use Select to confirm your choice.

Fahrenheit / Celsius

Languages

The U-Line 3000 Series of models supports a number of Display

Languages including English, Spanish, French and German.

To Change Display Language select Languages from the Customer

Menu.

1. Use Down to select “English”.

2. Press Select , “English” will begin to flash.

3. Use Up or Down to cycle through the available Languages.

4. Press Select to confirm you choice.

Temperature and Set point information can be displayed in either

Fahrenheit or Celsius.

To change from Fahrenheit to Celsius enter the Fahrenheit / Celsius

menu from within the Customer Menu.

1. Use

Down

to select “Degrees”.

2. Press Select . The selection will begin to flash.

3. Use Up or Down to select between °F (Fahrenheit) or °C

(Celsius).

4. Press Select to confirm your choice.

9U-Line Service

Page 15

General Information

Up

Select

Down

RETURN TO MENU

Help

Model 3018WC

1-800-779-2547

Up

Select

Down

RETURN TO MENU

ACTUAL TEMPS

ZONE = 37°

EVAP = 52°

Up

Select

Down

RETURN TO MENU

ALL ERRORS

NO COMM 0

ZONE T OPEN 0

Help

To access the Help menu select Help from the Customer Menu. Use

the Up or Down to scroll through available information. The

Help screen displays the following.

•Model.

• U-Line Contact Phone Number.

•Software version.

• Serial Number.

To exit the Help menu use Up to select “Return to Menu” and

press Select to confirm.

Service Menu

In addition to a feature rich customer menu, the 3000 series also

offers a service menu with the ability to fine tune and monitor unit

operation.

To initiate the Service menu holed both Up and Zone Toggle

for a few seconds.

Actual Temps

The Actual Temp option in the service menu will display raw

thermistor readings without calculating offsets.

1. Use Down to select “Actual Temps”.

2. Press Select

3. Use Up and

readings.

To exit the Actual Temps menu use Up to select “Return to

Menu” and press Select to confirm.

Down to scroll through available thermistor

All Errors

The All Errors option keeps record of any system errors. When an

error occurs it is recorded to all errors. The number next to the

error idicates the number of recorded instances. Errors in the log

may not be currently active. The error log memory is non volatile and

is persistent should power be lost and restored to the unit. See

below for a list of logged errors and their respective descriptions.

ID Description Solution

Unit lost

No Comm

communication to the

display

Zone T

Open

Evap T Open

Amb Thrm

Open

Zone T

Short

Evap T Short

Amb Thrm

Short

Te m p H i

6H+

Te m p H i

12H+

Te m p L o

6H+

Te m p L o

12H+

Zone thermistor circuit

open.

Evaporator thermistor

circuit open.

Ambient thermistor

circuit open.

Zone thermistor circuit

shorted.

Evaporator thermistor

circuit shorted.

Ambient thermistor

circuit shorted

Zone temperature +10°

over set point for over 6

hours.

Zone temperature +10°

over set point for over

12 hours.

Zone temperature -10°

under set point for over

6 hours.

Zone temperature -10°

under set point for over

12 hours.

Door Open 5MDoor switch open for

more then 5 minutes.

To access All Errors follow the steps below.

Check display cable.

Replace if necessary.

Check connection. Replace

if necessary

Check connection. Replace

if necessary

Check connection. Replace

if necessary

Check connection. Replace

if necessary

Check connection. Replace

if necessary

Check connection. Replace

if necessary

Check compressor,

evaporator fan and related

relays and DC outputs.

Check compressor,

evaporator fan and related

relays and DC outputs.

Check compressor,

evaporator fan and related

relays and DC outputs.

Check compressor,

evaporator fan and related

relays and DC outputs.

Check reed switch and

connection.

1. Use Down to select “All Errors”.

2. Press Select

3. Use Up and

Down to scroll through available information.

U-Line Service 10

Page 16

General Information

Up

Select

Down

RETURN TO MENU

RELAY STATUS

MULL COND DEF LVLV

OFF OFF OFF OFF

Up

Select

Down

RETURN TO MENU

RELAY TOGGLE

MULL OFF

COND OFF

To clear the error log use Down to select “Clear Errors” and

press Select to confirm.

To exit the Actual Temps menu use Up to select “Return to

Menu” and press Select to confirm.

Relay Status

Relay status displays the current state of each relay. While all available

relays are displayed, only a portion are used.

ID Description Status

Mull Mullion Heater Not Used

Cond Condenser Fan Not Used

Def Defrost Valve Not Used

LV LV Left Vale Not Used

RVLV Right Valve Not Used

Pan Pan heater Not Used

Comp Compressor Used

Note: The Cond (Condenser Fan) will switch state with the

compressor relay, however the condenser fan is actually powered

through a DC switch and is independent of the Cond relay.

Condenser fan status can be viewed through the “Output” service

menu option.

To access Relay Status

1. Use Down to select “Relay Status”.

2. Press Select

3. Use Up and

To exit the Relay Status simply press Select to exit.

Down to scroll through available information.

Relay Toggle

Relay toggle is used to manually switch the state of each relay to test

for proper operation. In addition to the AC relays, DC switches may

also be toggled. Relay toggle can also be used to force the unit into a

particular state. For example, to force a 3018 / 3045 into a cooling

cycle activate Comp, F1, and F3.

ID Description Ty p e

Mull Mullion Heater (Not Used) AC

Cond Fan (Not Used) AC

Def Defrost Valve (Not Used) AC

LV LV Left Vale (3036 / 3090 Only) AC

RVLV Right Valve (3036 / 3090 Only) AC

Pan Pan heater (Not Used) AC

Comp Compressor AC

F1 Evaporator Fan DC

F2 Evaporator Fan (3036 / 3090 Only) DC

F3 Condenser Fan DC

L1 Cabinet Lighting DC

L2 Cabinet Lighting (3036 / 3090 Only) DC

To a cc e s s R e la y To g gl e

4. Use Down to select “Relay Toggle”.

5. Press Select

6. Use Up and

7. Press Select to toggle

To exit the Actual Temps menu use Up to select “Return to

Menu” and press Select to confirm.

Down to scroll through each option.

11 U-Line Service

Page 17

General Information

Up

Select

Down

RETURN TO MENU

INPUT STATUS

DOOR OPEN

IN2 OPEN

Up

Select

Down

RETURN TO MENU

OUTPUTS

EVAP FAN=0%

CONDENSER FAN=0%

Up

Select

Down

RETURN TO MENU

OFFSETS

ZONE = 1°F

EVAP = 1°F

Up

Select

Down

RETURN TO MENU

SELF TEST

NO ERRORS

try “RELAY TOGGLE”

Input Status

Input status displays the current state of each available input as well as

the current USB connection state.

ID Description States

Door Door Switch Open - Closed

IN2 Input 2 - Not Used Open

Test Input Factory Test Input Open

USB USB Connection State Flash - Com Port

Note: USB status show current connection state. In order to make a

successful connection USB connection type must be properly set in

“USB Port” under the service menu.

To access Input Status

1. Use Down to select “Input Status”.

2. Press Select

3. Use Up and

Down to scroll through available information.

To exit the Input Status menu use Up to select “Return to Menu”

and press Select to confirm.

Outputs

Offsets.

Offsets are used to adjust or correct thermistor readings. Offset

values are added to the current thermistor reading and are then used

by the control board to determine cooling and defrost cycle times.

Offsets have a range of +/- 10°F. Corrected values may be viewed

through the customer “All Temps” menu or TTY output.

To access Offsets

1. Use Down to select “Offsets”.

2. Press Select

3. Use Up and

Down to scroll through available thermistors.

To change offset

4. Press Select

5. use Up

6. Press Select

, the selected thermistor will begin to flash

or Down to modify offset value

to confirm setting

To exit the Offset menu use Up to select “Return to Menu” and

press Select to confirm.

Self Test

Outputs is used to monitor the state of DC outputs.

ID Description States

Evap Fan Evaporator Fan 0 - 100%

Condenser Fan Condenser Fan 0 - 100%

Light Interior Lighting Off - Low - Med - High

To access Outputs

1. Use Down to select “Outputs”.

2. Press Select

3. Use Up and

To exit the Input Status menu use Up to select “Return to Menu”

and press Select to confirm

Down to scroll through available information.

U-Line Service 12

Self test is used to initiate a self diagnostic report. Any system faults

will be displayed under Self test. If no errors are present “no errors”

will be displayed and the main control board is functioning properly. If

an error is listed attempt to correct it before changing control board.

See troubleshooting for tips on correcting errors.

To access Self Test

1. Use Down to select “Self Test”.

2. Press Select

3. Use Up and

Down to scroll through available information.

To exit the Self Test use Up to select “Return to Menu” and press

Select to confirm.

Page 18

General Information

Up

Select

Down

RETURN TO MENU

DIFFERENTIALS

ZONE = 1°F

45° Set Point

1° Differential

2° Differential

3° Differential

Up

Select

Down

RETURN TO MENU

SET POINTS

ZONE = 38°F

EVAP = 42°F

Up

Select

Down

RETURN TO MENU

FACTORY DEFAULT

RESTORE?

Differentials

Differentials are used to determine the maximum variation from set

point and have a range of 0 through 10. The table below shows the

effect of differentials on cooling cycles with a set point of 45°

Note: Air temperature does not reflect product temperatures. .

Differential Cycle Start Cycle End

0 46° 44°

1 47° 43°

2 48° 42°

3 49° 41°

4 50° 40°

5 51° 39°

The graph below shows a unit’s cooling cycle over time with various

differentials

Set Points

The Set points menu allows has options to modify both the Zone and

Evap set points. Changes to the zone set point will be reflected on

the main screen. Changes to the evap set point alter the temperature

the evaporator needs to meet during a defrost cycle.

To access Set Points

1. Use Down to select “Set Points”.

2. Press Select

3. Use Up and

To c ha n ge s e t po i nt

4. Press Select

5. use Up

6. Press Select

To exit the Set Points menu use Up to select “Return to Menu”

and press Select to confirm.

Down to scroll through available set points.

, the selected set point will begin to flash

or Down to modify the value

to confirm setting

Factory Default

Factory Default will restore all settings to their factory default.

To access Factory Default

1. Use Down to select “Factory Default”.

2. Press Select

To restore settings to their factory default.

3. Use

4. “Restore?” will change to “Restoring...” while settings are restored.

To exit Factory Default use Up to select “Return to Menu” and

press Select to confirm.

Down to select “Restore?” and press

Select

When restoration is complete, “Restoring...” will return to

“Restore”.

13 U-Line Service

Page 19

General Information

Up

Select

Down

RETURN TO MENU

RE-SELECT MODEL #

3018R

Up

Select

Down

RETURN TO MENU

FAN DELAY

FAN DELAY ON = 1

FAN DELAY OFF = 2

Up

Select

Down

RETURN TO MENU

USB PORT

PC Link

Re-Select Model

Re-Select Model allows the units model information to be modified.

Changing the units model completely reprograms available zones,

relay assignments, dc output assignments etc.

To access Re-Select Model

1. Use Down to select “Re-Select Model”.

2. Press Select

To alter model setting.

3. Use

Down to select “Model=” and

press Select . “Model”

will begin to flash.

4. Press Up

or Down to scroll through each available model.

5. Press Select to confirm.

To exit Re-Select Model use Up to select “Return to Menu” and

press Select to confirm.

Fan Delay

To alter fan settings.

3. Use

4. Press Up

Down to select either “Fan Delay On” or “Fan Delay

Off” and

press Select . The chosen option will begin to flash.

or Down to change settings.

5. Press Select to confirm.

To exit Fan Delay use Up to select “Return to Menu” and press

Select to confirm.

USB Port

The USB Port menu option allows the selection of a communication

mode. The 3000 Series can communicate either via TTY to a PC or

log diagnostic information directly to a USB flash disk.

ID Communication

PC Link PC TTY

Flash USB Flash Drive

To access USB Port

1. Use Down to select “USB Port”.

The Fan Delay menu option allows the modification of fan run times

during a cooling cycle. In order to allow time for the evaporator to

properly cool, the evaporator fan is delayed from starting with the

cooling cycle for a given amount of time. In order to remove as much

warmth as possible from the cabinet the evaporator will continue to

run at the end of the cooling cycle for a given amount of time.

Fan Delay On=

“Fan Delay On” is the amount of time in minutes the fan will be

delayed from starting from the beginning of a cooling cycle.

Fan Delay Off=

“Fan Delay Off” is the amount of time in minutes the fan will

continue to run at the end of a cooling cycle.

To access Fan Delay

1. Use Down to select “Fan Delay”.

2. Press Select

2. Press Select

To alter communication settings.

3. Use

4. Press Up

Down to select the current setting and press Select

or Down to change settings.

.

5. Press Select to confirm.

To exit “USB Port” use Up to select “Return to Menu” and press

Select to confirm.

U-Line Service 14

Page 20

General Information

Up

Select

Down

RETURN TO MENU

SHOWROOM MODE

OFF

Showroom Mode

Showroom displays a number of features and allows the unit to be

powered on without running the cooling system.

To toggle showroom mode

1. Use Down to select “Showroom Mode”.

2. Press Select

3. Use

Down to select “Off” and

begin to flash.

4. Press Up

or Down to toggle between off and on.

5. Press Select to confirm.

press Select . “Off” will

If set to “on” showroom mode will begin immediately. To exit

showroom mode press and release Power

To exit the showroom mode menu use Up to select “Return to

Menu” and press Select to confirm.

15 U-Line Service

Page 21

Electronic Control Quick Guide

OFF

RED WINE

55 F

OO

RED WINE

55 F

O

RED WINE

55 F

O

SET

U-SELECT LIGHTING

DOOR ONLY

LIGHTING

LEVEL

HIGH

Ta s k Press Display Comment

Power ON/OFF

General Information

Display will begin a 5 second

countdown To Power Off.

Select Zone

(3036 Models Only)

Select Zone

Ty p e

Fine Tune Temperature

Set Point

Adjust Cabinet Lighting

Display will show The selected zone.

Zone will flash during selection.

Continue to press Select button to

cycle through all available zones.

Set will appear while adjusting set

point.

Use Light button to scroll through

light settings. See Page 8 for more

detailed instructions.

U-Line Service 16

Page 22

General Information

USB Communication

The 3000 series uses an advanced USB logging feature for system

logging and diagnostics. The controller outputs 36 separate data

points per second to either a USB flash disk or transmits over USB

via TTY to a client PC. To prepare the unit for logging, first verify the

USB port is set to the proper configuration. See “USB Port” on page

14 for information on configuring the USB port.

Flash Mode:

Suitable for logging directly to a USB flash disk.

PC Link Mode:

Suitable for communicating directly with another PC via USB.

USB Communication (Flash)

The main control can host a wide range of flash disks up to a max

capacity of 8GB. After verifying the USB port is set to “Flash” simply

insert a flash disk in to the USB port located above the grille. The

flash disk activity light (located on the flash disk) will begin flashing

immediately as data is recorded to the drive. Data is recorded in one

second increments and is only limited by the capacity of the flash disk.

The system will create a file named “uline.csv” on the flash disk. In

the event the file already exists, new data will automatically be

appended to the end of the existing file. The file is output in a comma

delineated text format and may be viewed in a wide variety of simple

text readers or spreadsheet programs.

For information on identifying each data point, see the

“Communication Data” table on page 18.

USB Communication (PC Link)

Data can be transmitted directly to a client PC via a serial

connection. Verify the USB port is set to “PC Link”. Use a Type A to

Type A male to male USB cable to connect the system to a

Windows® compatible PC. It is necessary to install communication

drivers to the client PC. Drivers may be downloaded at

www.u-lineservice.com. Establish a connection using a Telnet / TTY

terminal application. U-Line recommends PuTTY. PuTTY is available

for download at www.u-lineservice.com. Once the connection is

established, the controller will output a series of 36 data points in 1

second increments. For information on identifying each data point,

see the “Communication Data” table on page

18.

17 U-Line Service

Page 23

General Information

Communication Data ID Table

Field 1 2 3 4 5 6 7 8 9 10

ID

Sample

Data

Field 11 12 13 14 15 16 17 18 19 20

ID

Sample

Data

Field 21 22 23 24 25 26 27 28 29 30

ID

Sample

Data

Time

Live

1525 36 --- 5 --- 85 111 Beverage 34 1

Zone

Offset

0 0 --- --- --- 2 --- --- --- ---

Relay 7

Indicator

7 1 --- 3 0 --- --- --- --- 45

Zone

Te m p

Evap

Offset

Evap Fan

Indicator

Not

Used

Door

Indicator

Not

Used

Evap

Te m p

Not

Used

Cond Fan

Indicator

Not

Used

Relay 1

Indicator

Light

Level

Ambient

Te m p

Relay 2

Indicator

Not

Used

Proc

Te m p

Relay 3

Indicator

Energy

Saver

Zone

ID

Relay 4

Indicator

Sabbath

Set

Point

Relay 5

Indicator

Power

Indicator

Differential

Relay 6

Indicator

Comp

Timer

Field 31 32 33 34 35 36

ID

Sample

Data

Comp

Cumulative

500 --- 0 0 0 0

Field Value Field Value

1 Time in seconds since unit plugged in. 19 Relay 5 (unassigned). “5” = active, “---” = inactive.

2 Temperature of Zone in °F/°C. 20 Relay 6 (unassigned). “6” = active, “---” = inactive.

3 Not used. 21 Compressor relay. “7” = active, “---” = inactive.

4 Evaporator temperature in °F/°C. 22 Evaporator fan. “1” = active, “---” = inactive.

5 Not used. 23 Not used.

6 Ambient temperature in base of unit °F/°C. 24 Condensor fan. “3” = active, “---” = inactive.

7 Board processor temperature. 25 LED intensity, provided in %.

8 Zone identification tag. 26 Not used.

9 Zone set point in °F/°C. 27 Energy Saver mode indicator. “E” = active.

10 Differential value in °F/°C. 28 Sabbath mode indicator. “S” = active.

11 Zone offset value in °F/°C. 29 Soft power indicator. “P” = unit in “On” mode.

12 Evaporator offset value in °F/C. 30 Compressor state change timer, in seconds.

13 Door status indicator. “L” = Open “---” = closed. 31 Compressor cumulative run time, in seconds.

14 Not used. 32 Max remaining defrost time, in seconds.

15 Relay 1 (unassigned). “1” = active, “---” = inactive. 33 Evaporator fan state change timer, in seconds.

16 Relay 2 (unassigned). “2” = active, “---” = inactive. 34 Not used.

17 Relay 3 (unassigned). “3” = “active”, “---” = inactive. 35 Cumulative time spent in limp mode, in seconds.

18 Relay 4 (unassigned). “4” = “active”, “---” = inactive. 36 Not used.

Defrost

Timer

Fan 1

Timer

Not

Used

Limp

Timer

Not

Used

Note: Relay 2 will cycle with relay 7, this is considered normal.

U-Line Service 18

Page 24

General Information

IMPORTANT

IMPORTANT

Upper

Back Panel

Fan

Electrical

Connection

Evaporator Plate

Screws

Convection Cooling

All 3000 series units are equipped with an advanced convection

cooling system. Convection cooling stabilizes cabinet temperature,

cools product faster and increases energy efficiency.

Evaporator Fan

The evaporator fan is responsible for circulating warm are from the

refrigeration zone, pass the evaporator and back into the refrigerated

zone,

The evaporator fan is factory set to have a 1 minute delay at the

beginning of a cooling cycle. This delay gives the evaporator time to

cool properly before warm air is passed over it. The fan will continue

to run for an additional 2 minutes at the end of a cooling cycle. Fan

delay times can be modified through the service menu. See “Fan

Delay” on page

Evaporator fan operation is also determined by door switch state. If

the door switch circuit opens the fan will stop. When the door

switch circuit is closed the fan will either continue running with the

cooling cycle, or if not currently cooling the fan will run for 1 minute

to circulate air and clear any condensation that may have appeared on

glass doors and shelves.

Note: If the unit is set to sabbath mode the evaporator fan will no

longer respond to the state of the door switch.

In order to operate efficiently the evaporator fan blade and vents

should be unobstructed and free of any dust build up.

Evaporator Fan Replacement

14.

5. Remove insulating foam from refrigerant line pass-through hole.

6. Remove internal shelving, bins, or wine racks.

7. Remove shelf clips, rack, or bin mounting rails.

8. Remove thermistor cover.

9. Remove two evaporator plate screws from top of evaporator

plate.

10. Grasp evaporator fan shroud and gently pull plate away from the

rear of the unit.

11. While pulling the evaporator plate clear of the unit, it may be

necessary to use your free hand to manipulate the fan plug end

through the pass-through hole.

12. Remove the 4 screws mounting the fan shroud to the evaporator

plate.

Should the evaporator fan need to be replaced follow the steps

below.

1. Remove any product from the unit.

2. Disconnect power to the unit.

3. Remove upper back panel.

4. Disconnect fan electrical connection

13. Remove and replace fan. Take special care to properly route fan

wire.

Fan must be oriented to pull air in through lower evaporator

plate vents and push air out at fan mounting location.

14. Installation is the reverse of removal. Before replacing back panel

fill refrigerant line pass-through hole with sealant gum.

19 U-Line Service

Page 25

General Information

IMPORTANT

IMPORTANT

WARN ING

Wrap Screws

Cable Arm

Step 1

Step 2

Door Top

Door Bottom

Press Tab Down

T-25 Torx Screw

T-25 Torx Screw

Door Alignment and Adjustment

Align and adjust the door if it is not level, or is not sealing properly. If

the door is not sealed the unit may not cool properly, or excessive

frost may form in the interior.

Properly aligned, the door’s gasket should be firmly in

contact with the cabinet all the way around the door (no

gaps). Carefully examine the door’s gasket to assure that it is

firmly in contact with the cabinet. Also make sure the door

gasket is not pinched on the hinge side of the door.

• Do not attempt to use the door to raise or pivot the

unit. This would put excessive stress on the hinge system.

• Pay special attention to the Cable Arm. Make sure not to

over extend or damage it during door alignment

Stainless Models (Removing Wrap)

15. Open door completely

16. Use a short phillips head screw driver to remove wrap screws

from bottom of the door.

17. Remove the two wrap screws from the bottom of the stainless

steel door wrap.

19. The Wrap hinges on top of the door. Carefully pull wrap away and

then up

. See Below.

20. Remove cable from display by pressing the release pin on the cable

connector.

18. Gently pull bottom of wrap away from door.

Alignment and Adjustment

1. Using a T-25 Torx Bit,

loosen each pair of torx

head screws on both the

upper and lower hinge

plate.

2. Square and align door as

necessary

3. Tighten Torx head screws

on hinge

4. If necessary re-install

Stainless steel wrap.

U-Line Service 20

Page 26

Troubleshooting

Troubleshooting

Customer Call Guide

The following guide has been developed to help answer frequently asked questions. It can be used by persons scheduling service calls. These are

things the customer should consider before scheduling a service call.

Concern Response

The unit is not cold enough. • Are you familiar with the factory temperature specifications for

the unit? Many factors can cause these temperatures to vary;

ambient temperature, application, amount of use (number of

times and length of time the door or drawers are opened and

closed), etc

• Is the door or drawers sealing properly? If the door or drawer is

not sealed properly, it allows heat into the unit. U-Line’s war

ranty is 30 days for door or drawer adjustments.

• Has the door or drawers been left open? The unit will issues an

audible tone if the door/drawer has been left open for longer

than 5 minutes.

• Is the condenser clean? U-Line’s warranty does not cover clean-

ing the condenser.

• Is the unit behind closed doors or the grille restricted? The front

grille must be free of obstruction.

• Is the unit in an application of heavy usage? Heavy usage or high

ambient temperatures will cause a unit to frost up.

• Did you try adjusting the temperature to a colder level? Adjust

to a colder level. Be sure to allow 24 hours between temperature

control adjustments.

Temperature is too cold. • Check actual temperature versus set-point.

• Did you try adjusting the temperature to a warmer level? Adjust

to a warmer level and allow 24 hours between temperature con

trol adjustments.

Product is freezing. • What is the temperature set at?

• Do not allow products to lean against the evaporator at the back

wall.

The unit is frosting up. • Are you familiar with the defrost technology of the unit?

• Is the door or drawers sealing properly? If the door or drawer is

not sealing properly, it allows heat/humidity into the unit. U-

Line’s warranty is 30 days for door/drawer adjustments.

• Has the door/drawers been left open?

• Is the unit in an application of heavy usage? Heavy usage or high

ambient temperatures will cause a unit to frost up.

-

-

21 U-Line Service

Page 27

Troubleshooting

CAUTION

Never attempt to repair or perform maintenance on the unit until the main electrical power has been disconnected from the

unit.

Cause Remedy

Compressor overheating

1. Condenser air flow restricted.

2. Condenser fan blade obstructed.

3. Condenser fan motor stalled.

4. Compressor inoperable.

Compressor will not stop operating.

1. Temperature set too cold.

2. Control inoperable.

3. Control sensing bulb not sensing temperature.

4. Evaporator fan stalled.

Excessive frost buildup.

1. Door gasket not sealing properly.

2. Door out of alignment

3. Light stays on when door is closed.

4. Warm air leaking into cabinet from back.

Noisy.

1. Copper refrigeration tube touching cabinet.

2. Evaporator fan blade touching cover.

3. Condenser fan obstruction (wiring, foam insulation,

packaging material).

Ice Buildup in drain trough or drain problem

1. Obstructed drain cup or tube.

2. Kinked drain tube.

3. Drain trough spout and drain cup not aligned

1. Remove restriction (clean condenser and grille).

2. Remove blade restriction

3. Replace fan motor

4. Replace compressor

1. Adjust temperature warmer.

2. Replace control.

3. Check bulb/thermistor for location and ohms.

4. Remove obstruction or replace motor.

1. Adjust door or replace door gasket.

2. Adjust door hinges/pivot plates.

3. Repair or adjust light bracket/magnet.

4. Seal holes in the foam to prevent warm air entering the unit.

1. Carefully adjust tubing.

2. Adjust fan mounting or shroud.

3. Remove obstruction.

1. Check and clear drain tube.

2. Reroute drain tube.

3. Align drain trough and drain cup.

U-Line Service 22

Page 28

Troubleshooting

CAPILLARY TUBE

DRYER

CONDENSER

COMPRESSOR

EVAPORATOR

Compressor Information

Cooling process

Refrigerant is pumped from the compressor to the condenser as a

high pressure, high temperature vapor.

As the refrigerant cools in the high pressure condenser, the vapor

condenses to liquid. During this phase change, a great amount of heat

is rejected with the help of the condenser fan.

The liquid then flows to the dryer where it is strained and filtered.

From the dryer, the refrigerant flows through the capillary tube which

meters the liquid refrigerant to the evaporator.

The pressure of the refrigerant is reduced to the evaporating or low

side pressure.

The reduction of pressure on the liquid refrigerant causes it to boil

or vaporize until it reaches saturation temperature. As the low

temperature refrigerant passes through the evaporator coil, it

continues to absorb a lot of heat, causing the boiling action to

continue until the refrigerant is completely vaporized. It is during this

phase that the most heat is absorbed (the cooling takes place) in the

refrigerator.

The refrigerant vapor leaving the evaporator travels through the

suction line to the compressor inlet. The compressor takes the low

pressure vapor and compresses it, increasing both pressure and

temperature. The hot high pressure gas is pumped out the discharge

line and into the condenser. The cycle continues

23 U-Line Service

Page 29

Troubleshooting

DANGER

Magnet Close To Switch

(Door Closed)

(Switch Closed)

Magnet Away From Switch

(Door Open)

(Switch Open)

C

S

R

OVERLOAD PROTECTOR

STARTING RELAY

CAPACITOR

RELAY COVER

Thermistors

Thermistors are used for various temperature readings. Thermistor

provide reliable temperature readings using a resistance which varies

based on surrounding temperatures. If a faulty thermistor is

suspected it may be tested using an accurate ohmmeter. In an ice bath

(32°F) resistance should measure 16.1 kilohms,

5K Ohms - 70°F ambient.

16.1K Ohms - 32°F ambient

Thermistor Failure

Zone Thermistor

If the zone thermistor fails the unit will continue to operate on a

preset time interval of 10 minutes on and 30 minutes off. The unit

will otherwise operate normally. The error will be displayed on

the main display and “Self Test” and logged in “All Errors”.

Evaporator Thermistor

If the evaporator thermistor fails the unit will rely on a preset

defrost timer during defrost cycles. The unit will otherwise

operate normally. Evaporator thermistor errors are hidden from

the display and recorded in “All Errors” and displayed in “Self

Te s t ” m o d e s .

Ambient Thermistor

The ambient thermistor is mainly used for diagnostics. If the

thermistor fails the unit will operate normally.

Reed Switch

A reed switch is used to monitor door state. The switch side is

mounted under the cabinet and the magnet is mounted to the cable

arm. When the door is closed magnetic force pulls the reed to its

contact and closes the circuit which turns the light and display off.

When the door is open the reed pulls away from the contact and

opens the circuit. If the door or drawers are left open for longer than

5 minutes, the switch will trigger an error code and set an audible

.

warning

Compressors

Electrocution can cause death or serious injury. Burns from hot

or cold surfaces can cause serious injury. Take precautions when

servicing this unit.

• Disconnect the power source.

• Do not stand in standing water when working around

electrical appliances.

• Make sure the surfaces you touch are not hot or frozen.

• Do not touch a bare circuit board unless you are wearing

an anti-static wrist strap that is grounded to an electrical

ground or grounded water pipe.

• Handle circuit boards carefully and avoid touching

components

To measure the start winding resistance, measure across the C and S

pins.

To measure the run winding resistance, measure across the C and R

pins.

Also check S to R and you should get the sum of the run and start

windings.

To ensure the windings are not shorted, check the S and R to ground.

70077 70084

EMU30HSC EMU30HER

Voltage 115 220-240

Frequency 60 50-60

LRA 5.5 8.2

FLA 1.0 .76

Start Winding 7.0 39.1

Run Winding 8.4 24.6

Overload 71009 71031

Relay 71010 71030

Capacitor 71013 N/A

U-Line Service 24

Page 30

Troubleshooting

Refrigeration System Diagnosis Guide

System

Condition

Normal Normal

Overcharge

Undercharge

Partial

Restriction

Complete

Restriction

No Gas

Suction

Pressure

Higher than

Lower than

Somewhat lower

than normal -

in vacuum

normal

normal

In deep

vacuum

0 PSIG

to 25"

Suction

Line

Slightly below

room

temperature

Very co l d -

may frost heavily

Warm -

near room

temperature

Warm -

near room

temperature

Room

temperature

(cool)

Room

temperature

(cool)

Compressor

Discharge

Very hot Very hot Warm Cold Normal

Slightly warm to

hot

Hot Warm Warm

Very ho t

Room

temperature

(cool)

Cool to hot

Condenser Capillary

Hot to warm Cool Cold

Top passes warm

lower passes cool

(near room

temperature due

to liquid

Room

temperature

(cool)

Room

temperature

(cool)

Tube

Room

temperature

(cool) or colder

Room

temperature

(cool)

Room

temperature

(cool)

Evaporator Wattage

Extremely cold

near inlet - outlet

below room

temperature

Extremely cold

near inlet -outlet

below room

temperature

backing up

No refrigeration

No refrigeration

Higher than

normal

Lower than

normal

Lower than

normal

Lower than

normal

Lower than

normal

25 U-Line Service

Page 31

Fault System Diagnosis Guide

Error Solution 1 Solution 2 Solution 3

Inspect the UI data cable for

No Comm

Zone T Open

Evap T Open

Amb Thrm Open

Zone T Short

Evap T Short

Amb Thrm Short

Te m p Hi 6 H +

Temp Hi 12H+

Te m p Lo 6 H +

Te m p L o 12 H +

Door Open 5M Verify door closes properly.

continuity. Replace if necessary.

he main control board and UI.

Inspect zone thermistor connection.

Replace if necessary.

Inspect evaporator thermistor

connection. Replace if necessary.

Inspect ambient thermistor

connection. Replace if necessary

Inspect thermistor cable for pinch

points or damage. Replace if