U-Line U-2015RB-00 Service Manual

Service and Parts Manual

M

A

D

E

I

N

T

H

E

U

S

A

For Models

• CO2075FF • 2075R • 2075WC • BI•2015

• 2075RF • 2015R • 2015WC • CLR2060

• Combo U-CO29FF

U-Line Corporation U-Line Corporation

8900 North 55th Street PO Box 245040

Milwaukee, WI 53223 Milwaukee, WI 53224-9540

www.U-LineService.com

Phone (414) 354-0300 • FAX (414) 354-7905

Service & Parts Tech Lines Phone (800) 779-2547 • FAX (414) 354-5696

INTRODUCTION

Three generations of pride and quality manufacturing and design improvements are built into all U-Line

products. The result: U-Line leads the market with innovative technology and superior craftsmanship.

This manual contains specific instructions for servicing the U-Line Échelon Products which include these

models:

INTRODUCTION

Design ■Features ■Performance

• CO2075FF

• 2075RF

• Combo U-CO29FF

• 2075R

• 2015R

• 2075WC

• 2015WC

•BI•

2015

• CLR2060 Clear

Icemaker

Potential Problems With HFC-134A

This Service Manual has been written to cover product manufactured with HFC-134a. HFC-134A compressors will be received with a synthetic based ester oil charge. The hygroscopic (water attraction) property of

ester oil is many times greater than that of the mineral oils previously used with CFC-12. High system

moisture causes the formation of acids and alcohol which can damage the compressor. Systems should not

be left open for more than fifteen (15) minutes at any time as humidity from the air will enter system. To

assure system dehydration, the system should be pulled down to 100 microns and vacuum pump oil (mineral oil) must not be allowed to enter the system.

Cleanliness of the system will be extremely important. The presence of residues (chlorinated or greasy

residues, mineral oil, or impurities) can lead to capillary tube restrictions, oil return problems and compressor damage. Flux must not

be used on brazed joints.

You can check for the latest service related information at U-LineService.com.

The Technical Knowledge base is continuously updated and can be accessed

24/7.

IMPORTANT

2

INTRODUCTION

Design ■Features ■Performance

This is the safety alert symbol. It is used to alert you to potential personal injury hazards.

Obey all safety messages that follow this symbol to avoid possible injury or death.

!

DANGER indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

!

DANGER

!

WARNING indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

!

WARNING

!

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury.

!

CAUTION used without the safety alert symbol indicates a potentially hazardous situation

which, if not avoided, may result in property damage.

IMPORTANT indicates installation, operation or maintenance information which is important

but not hazard-related.

IMPORTANT

TABLE OF CONTENTS

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Serial Number Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Warranty Claims Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Proof of Purchase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Parts Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Échelon™ Door Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Screening Calls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Guide For Screening Calls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

CO2075FF/2075RF/Origins Combo U-CO29FF Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Compressor/Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Compressor Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

U-Line Frost Free Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Typical Frost Free Airflow Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Refrigeration System Diagnosis Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

CO2075FF and U-CO29FF Ice Maker Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Ice Maker Diagnosis Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Replacing Ice Maker Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Replacing Mold and Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

CO2075FF Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

U-CO29FF Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

2075RF Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

CO2075FF Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Model 402-CO2075FF Icemaker Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Model U-CO29FF – 2002 Design Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Model U-CO29FF & Icemaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Model 402-CO29FF Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Model 2075RF Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

2075R/2015R Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Compressor/Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Compressor Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Refrigeration System Diagnosis Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

2075R/2015R Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

2075R Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

2015R Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

INTRODUCTION

3

Design ■Features ■Performance

2075WC/2015WC Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Compressor/Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Compressor Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Refrigeration System Diagnosis Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

2075WC/2015WC Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

2075WC Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

2015WC Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

BI

•2015 Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Compressor/Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Compressor Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Temperature Control Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Limit Switch Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Refrigeration System-Normal Vapor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Refrigeration System Diagnosis Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Ice Maker Diagnosis Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Ice Maker Operating Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

BI

•

2015 Cycle Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

BI•2015 Replacing Ice Maker Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

BI

•2015 Replacing Mold and Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

BI•

2015 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

BI

•2015 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Model 402-BI•2015 Ice Maker Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

CLR2060 Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Compressor Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Leveling and Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Gravity Drain Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Connecting a Drain Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Automatic Clean Cycle Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

New CLR2060 Control Board Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Low Side Pressure Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Refrigeration System Diagnostic Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Ice Thickness Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Ice Production Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

CLR2060 Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

CLR2060 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

INTRODUCTION

4

Design ■Features ■Performance

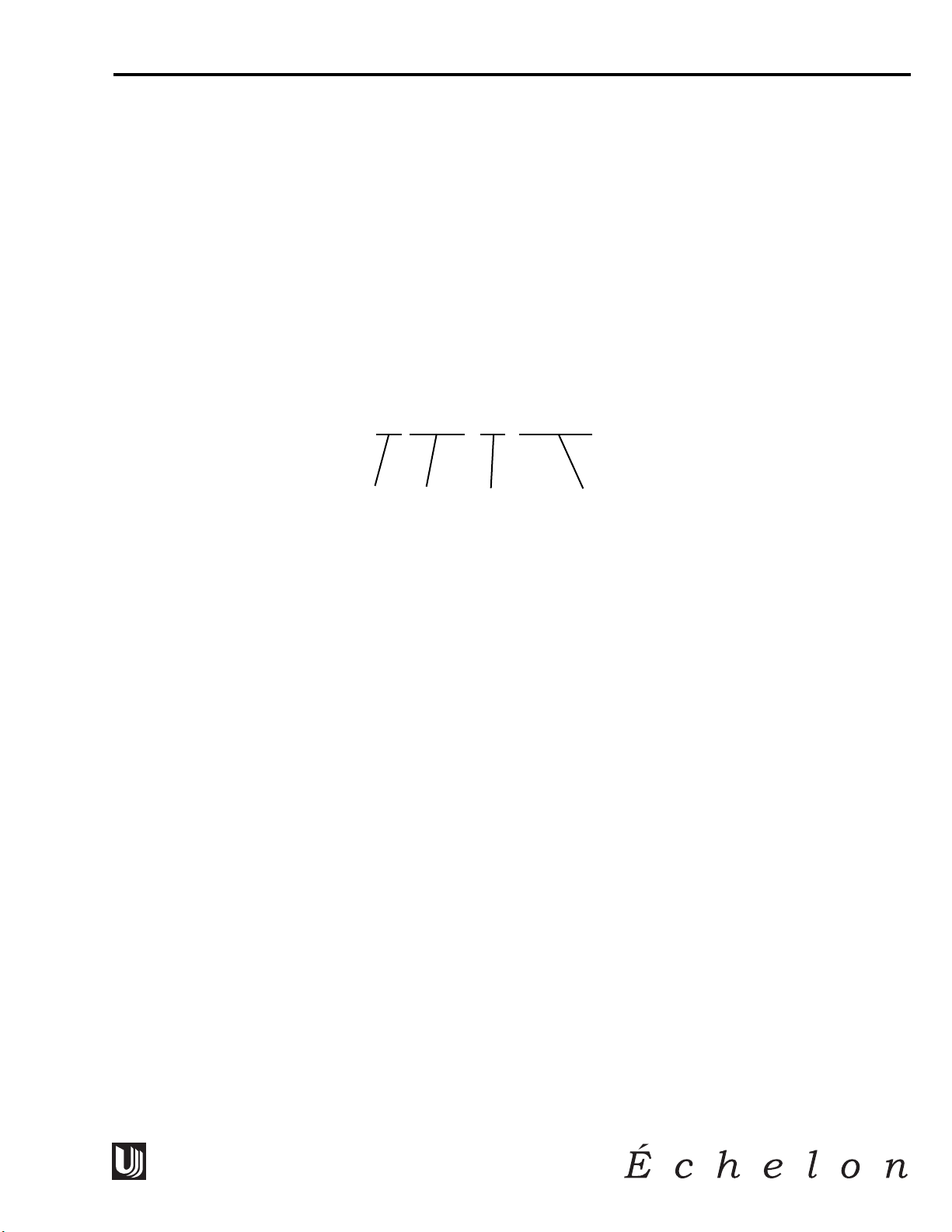

SERIAL NUMBER FORMAT

The serial number is divided into four segments. A typical serial number is 013520-03-0433.

The first two digits of the first segment, 01, represents the year the unit was made.

The next four digits of the first segment, 3520, represents the shop order number. Order number 3520 is

assigned for the Model 75R White-00 units.

The second two digit segment, 03, represents the month the unit was made.

The third four digit segment, XXXX, is a factory internal control number used at U-Line Corporation.

GENERAL INFORMATION

5

Design ■Features ■Performance

013520-03-XXXX

Year

Shop

Order

Number

Month

Factory Internal

Control Number

LIMITED WARRANTY

U-Line Corporation warrants each U-Line product to be free from defects in materials and workmanship

for a period of one year from the date of purchase; and warrants the sealed system (consisting of the compressor, the condenser, the evaporator, the hot gas bypass valve, the dryer and the connecting tubing) in

each U-Line product to be free from defects in materials and workmanship for a period of five years from

the date of purchase. During the initial one-year warranty period for all U-Line products U-Line shall: (1)

at U-Line’s option, repair any product or replace any part of a product that breaches this warranty; and (2)

for all Marine, RV and Domestic U-Line products sold and serviced in the United States (including Alaska

and Hawaii) and Canada, U-Line shall cover the labor costs incurred in connection with the replacement

of any defective part. During years two through five of the warranty period for the sealed system, U-Line

shall: (1) repair or replace any part of the sealed system that breaches this warranty; and (2) for all

Marine, RV and Domestic U-Line products sold and serviced in the United States (including Alaska and

Hawaii) and Canada, U-Line shall cover the labor costs incurred in connection with the replacement of

any defective part of the sealed system. All other charges, including transportation charges for replacements under this warranty and labor costs not specifically covered by this warranty, shall be borne by you.

This warranty is extended only to the original purchaser of the U-Line product. The Product Registration

Card included with the product should be promptly completed by you and mailed back to U-Line or you

can register on-line at www.U-LineService.com.

The following are excluded from this limited warranty: installation charges; damages caused by disasters or

acts of God, such as fire, floods, wind and lightening; damages incurred or resulting from shipping,

improper installation, unauthorized modification, or misuse/abuse of the product; customer education

calls; food loss/spoilage; door and water level adjustments (except during the first 90 days from the date of

purchase); defrosting the product; adjusting the controls; door reversal; or cleaning the condenser.

If a product defect is discovered during the applicable warranty period, you must promptly notify either the

dealer from whom you purchased the product or U-Line at P.O. Box 23220, Milwaukee, Wisconsin 53223

or at 414-354-0300. In no event shall such notification be received later than 30 days after the expiration

of the applicable warranty period. U-Line may require that defective parts be returned, at your expense, to

U-Line’s factory in Milwaukee, Wisconsin, for inspection. Any action by you for breach of warranty must

be commenced within one year after the expiration of the applicable warranty period.

This limited warranty is in lieu of any other warranty, express or implied, including, but not limited to

any implied warranty of merchantability or fitness for a particular purpose; provided however, that to

the extent required by law, implied warranties are included but do not extend beyond the duration of the

express warranty first set forth above. U-Line’s sole liability and your exclusive remedy under this warranty is set forth in the initial paragraph above. U-Line shall have no liability whatsoever for any incidental, consequential or special damages arising from the sale, use or installation of the product or from any

other cause whatsoever, whether based on warranty (express or implied) or otherwise based on contract,

tort or any other theory of liability.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation

of incidental or consequential damages, so the above limitations may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

GENERAL INFORMATION

6

Design ■Features ■Performance

7

WARRANTY CLAIMS PROCEDURE

When submitting claims for warranty payment, please follow these guidelines.

You can use any form you would normally use to bill your customer (your own computer generated form,

Narda, USA, etc.).

The model and serial number MUST be on the claims. Claims will not be paid without a model and serial

number.

If you work on more than one unit per service call please submit a separate claim for each unit.

We track all defects through warranty claims, so please be specific on what the repair was. If it is a system

leak, please specify where the leak was.

Please be sure the claim is legible. If the claim form cannot be read, it will be returned, unpaid.

U-Line will not cover part or labor claims for the replacement of a complete ice maker assembly. All ice

maker parts are available as replacement parts and are stocked in our inventory. Remember: we do not

pay customer education calls. Door and water level adjustments are 90 day warranties only.

If you are changing out a unit please supply the model and serial number of both units (the unit being

replaced and the new unit) and the R.A. number.

Occasionally the customer does not return their warranty cards. In this case we use the date the unit was

shipped to our distributor for a beginning warranty date. This may cause the claim to be rejected for a

proof of purchase. If you want to check on a purchase date, you may contact the U-Line Corporation

Customer Assurance Department at 1-800-779-2547. This will allow you to get a proof of purchase, if

needed, before you submit the claim.

At U-Line, parts and labor claims are paid separately. Included in labor are freon and recovery charges, all

other parts are handled by the parts department. We require that some parts be returned to us, so we may

return them to our vendor. It will be noted on your packing list if we require you to return the part. If a

part is to be returned please include a copy of the packing list and a copy of your claim. If the part was

purchased at one of our part distributors, you must handle the part warranty with that company. For labor

payment please send a readable copy of your claim to U-Line Corporation, P.O. Box 245040, Milwaukee

WI, 53224-9540, for warranty payment.

GENERAL INFORMATION

Design ■Features ■Performance

PROOF OF PURCHASE

Proof of Purchase and/or Proof of Install is an important part of the warranty claim process. Sometimes it is

difficult to obtain a proper Proof of Purchase/Install for a number of different reasons:

• The customer does not have a copy (only the original).

• The customer has only their copy of the final Walk Through or sign-off of new construction.

• Other valid reasons that prevent your technician from leaving the job site with a suitable Proof of

Purchase/Install.

We understand the problem and have modified our Proof of Purchase policy to help you in these situations.

Effective immediately, if a copy of the Proof of Purchase/Install is not available at the site, the technician

should record the following information on the Labor Invoice:

• The name of the selling Dealer

• The date of purchase/installation

• The Order or Invoice number (if available)

• The type of document they saw, i.e. Store Receipt, Closing Papers, Sign-Off of Building Permit,

Final Walk Through, etc.

If we have this information on the Labor Invoice, and we have the other information that is needed

(correct Serial Number, type of repair, time spent on repairs, etc.), we will be able to process the

invoice for you in a timely manner.

GENERAL INFORMATION

8

Design ■Features ■Performance

9

PARTS LISTING

How to Order Replacement Parts

1. Locate the illustration(s) for the model you are servicing.

2. Refer to the area where the desired part would be installed, locate the part and note the item number

assigned to it.

3. Locate the item number in the left column of the parts listing which is on the next page from the product illustration. Note the full description and the corresponding part number. If this is for a warranty

unit, please indicate and record the model and serial numbers.

4. When ordering parts, it will be necessary to supply us with Model Number, Serial Number, Part

Number, Part Description and in some cases Color or Voltage.

5. U-Line requires the return of the parts listed below if replaced under warranty.

GENERAL INFORMATION

Design ■Features ■Performance

• Fan motors (condenser and evaporator)

•Temperature controls

•Water solenoid valves

• Pumps

• Control boards

• Ice maker motors

• Bypass solenoids

• Compressors (two years old or less - lines

soldered closed)

All warranty parts will be shipped at no charge as long as warranty status has been confirmed. We require

that some parts be returned to us, so we may return them to our vendor. It will be noted on your packing

list if we require you to return a part or if you may field scrap it. If U-Line requires a defective part to be

returned, a prepaid shipping label will be included with your new replacement part. When returning parts

please enclose a copy of your packing list and a copy of your labor claim, showing the model and serial

number, and tag or label the part with the nature of the defect.

Our warranty records may not match the customer’s information. In this case a proof of purchase will be

required. If you do not have the proof of purchase at the time the order is placed, the part will be sent net

15 days (COD if you don’t have an open account with U-Line Corporation). When the proof of purchase is

provided we will credit your account (a check will be sent if the part was sent COD).

6. Parts may be ordered by FAX, phone or on-line:

FAX Number (414) 354-7905

Phone Number (414) 354-0300 or (414) 354-7885; press 3

www.U-LineService.com

To expedite parts shipments, FAX all parts orders to: (414) 354-7905. Copy the FAX Parts Order Form,

located in the back of this manual, when placing an order.

7. Effective immediately, U-Line will not pay warranty claims for the replacement of a complete ice

maker assembly. Complete ice maker assembly replacement is not necessary because all ice maker

parts are available as replacement parts and are stocked in our inventory.

REPLACEMENT PARTS: Use only genuine U-Line replacement parts. The use of non-U-Line parts can

reduce ice rate, cause water to overflow from ice maker mold, damage the unit, and may void the

warranty.

10

Design ■Features ■Performance

SAFETY PRECAUTIONS

Do not attempt to service or repair the unit until you have read the entire procedure. Safety items throughout this manual are labeled with Danger, Warning or Caution.

GENERAL INFORMATION

Risk of child entrapment. Before you throw away an old refrigerator or freezer: Take off the

doors, leave shelves in place so that children may not easily climb inside.

!

DANGER

!

• Never attempt to repair or perform maintenance on the unit until the electricity has

been disconnected.

• Altering, cutting of power cord, removal of power cord, removal of power plug, or

direct wiring can cause serious injury, fire and/or loss of property and/or life and

will void the warranty.

!

DANGER

!

•Do not lift unit by door handle.

• Never use an ice pick or other sharp instrument to help speed up defrosting. These

instruments can puncture the inner lining or damage the cooling unit.

• Failure to clean the condenser every three months can cause the unit to malfunction. This

could void the warranty.

•Never install the unit behind closed doors. Be sure front grille is free of obstruction.

Obstructing free air flow can cause the unit to malfunction, and may void the warranty.

GENERAL INFORMATION

11

Design ■Features ■Performance

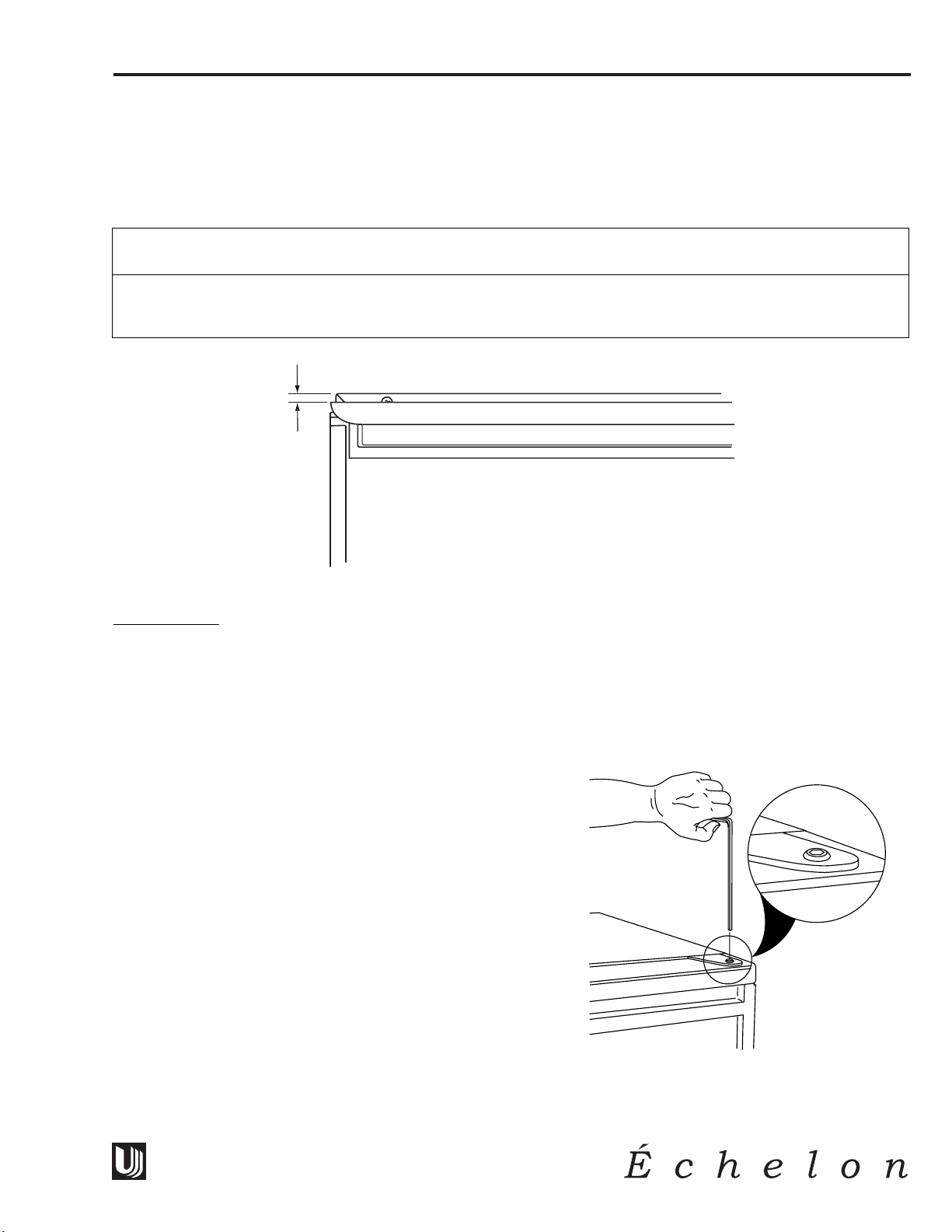

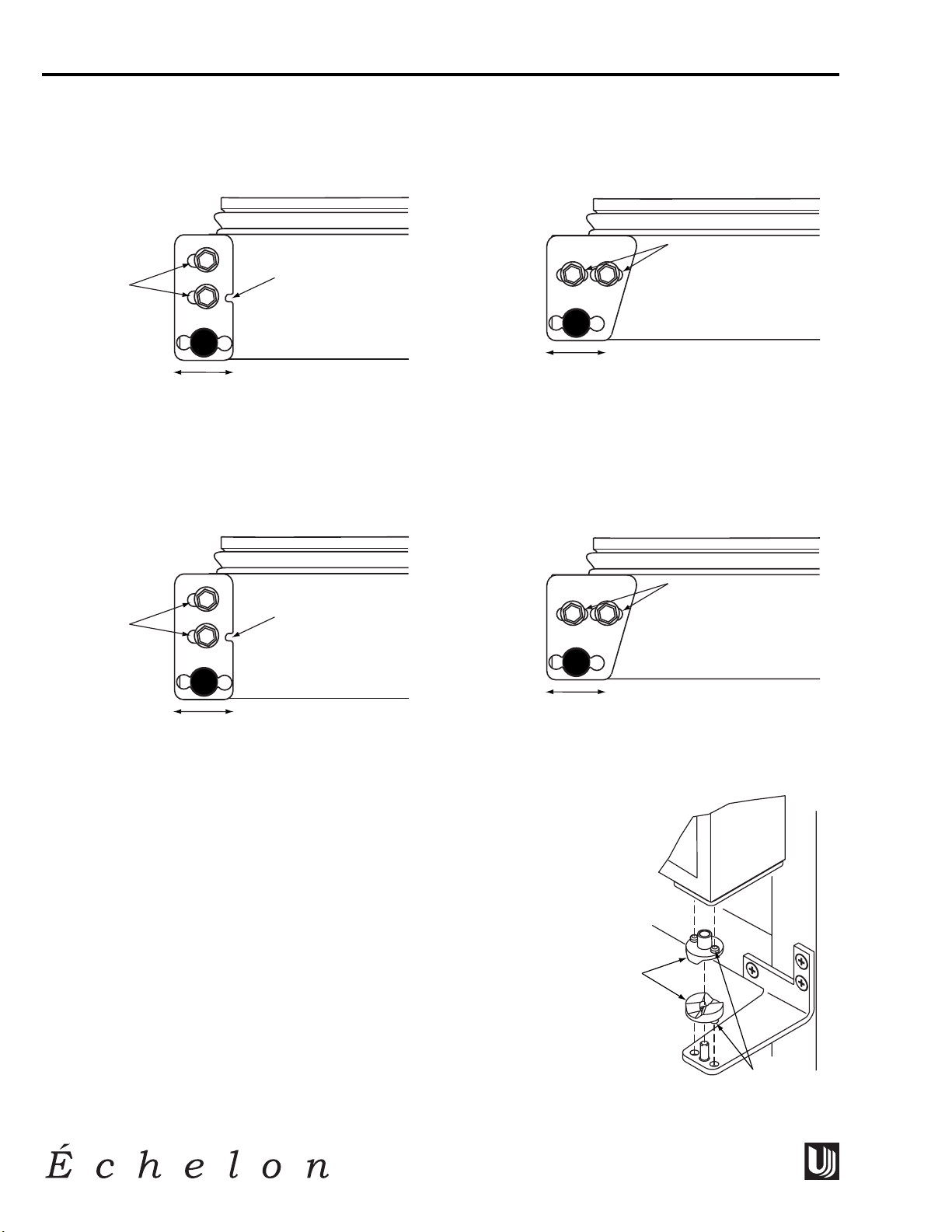

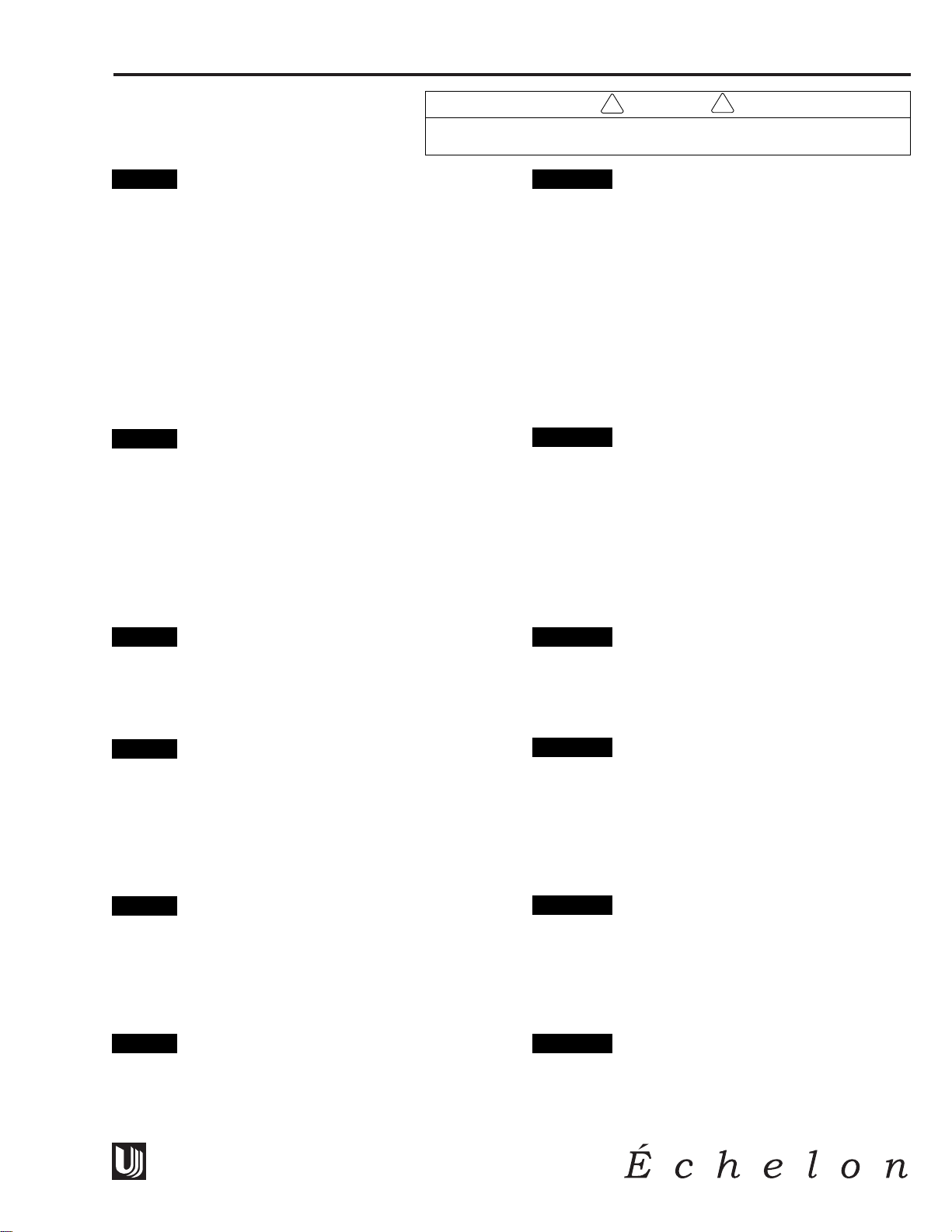

ÉCHELON™ DOOR ADJUSTMENT

All Échelon™ model doors are aligned at the factory before shipment. Occasional re-adjustment may be

necessary, especially if an Overlay Panel is installed. The following procedure will correct for up to 1/4"

alignment.

T

o adjust door:

1. Compare the top edge of the door (opposite the hinges) to the top edge of the cabinet and note the

type (up or down) of adjustment needed.

2. Remove the top hinge pivot pin with a 7/64" hex wrench (see Figure 2) and lift door off bottom hinge

pin. Be careful not to lose door closer inserts (see Figure 5).

Note: The hinge plate on some Échelon™ models does not

have the holes slotted for adjustment. New hinge

plates are available from U-Line Customer Service.

3. With door upside-down, inspect the bottom hinge plate

mounting holes.

a. If your plate has slotted mounting holes, loosen

but do not remove the two hinge plate screws.

b. If your plate does not have slotted mounting

holes, remove the old plate and install the new

plate with the notch to the inside of the door

(see Figure 3).

The door should never be flush with the top of the cabinet. Even when level, the top edge of

the door will be 1/8" below the top of the cabinet (see Figure 1).

IMPORTANT

Figure 1

Figure 2

1/8"

DOOR001

UL310

4. If door edge opposite the hinges needs to move up, move plate toward outside of door. If door edge

needs to move down, move plate toward inside of door (see Figure 3). Repeat until top edge of door is

parallel with top of cabinet and tighten screws securely.

5. If you have an older model, you must slot the door frame to accommodate the door closer boss. Using

the bottom hinge plate pivot hole as a guide, slot the frame hole by using an 11/32" drill.

6. After adjustment is complete, remove the door closers from the bottom hinge,

clean thoroughly and apply petroleum jelly to the mating surfaces of the

closers (see Figure 5). Be sure that bosses on closers align with holes in

hinge and hinge plate. Mount door and install top hinge pivot pin.

GENERAL INFORMATION

12

Design ■Features ■Performance

Figure 3

Figure 4

UL312

DOOR

CLOSER

INSERTS

BOSS

Figure 5

SLOTTED

SLOTTED

MOUNTING

HOLES

DOOR EDGE

RAISE

OUTSIDE

NOTCH

ALL MODELS

EXCEPT WINE CAPTAIN

LOWER

OUTSIDE

DOOR EDGE

RAISE

OUTSIDE

DOOR EDGE

LOWER

OUTSIDE

DOOR EDGE

MOUNTING

HOLES

ALL WINE

CAPTAIN MODELS

DOOR003

SLOTTED

MOUNTING

HOLES

DOOR EDGE

RAISE

OUTSIDE

DOOR EDGE

NOTCH

ALL MODELS

EXCEPT WINE CAPTAIN

LOWER

OUTSIDE

RAISE

OUTSIDE

DOOR EDGE

LOWER

OUTSIDE

DOOR EDGE

SLOTTED

MOUNTING

HOLES

ALL WINE

CAPTAIN MODELS

DOOR003

SCREENING CALLS

13

Design ■Features ■Performance

GUIDE FOR SCREENING CALLS

U-line’s warranty does not cover customer education calls. It has been reported that as high as 50% of all

service calls performed are customer education calls.

The following guide has been developed to help screen calls on the most common customer education

issues. It can be used by persons scheduling service calls. Questions to ask before scheduling a service

call:

The unit is not cold enough!

• Are you familiar with the factory specifications for this unit? (Many factors can cause these figures to

vary: ambient temperature, application, amount of use, etc.)

Model Numbers Approximate Temperatures

2075WC, 2015WC 60° top rack /55° middle/ 45° bottom

2075R, 2015R 38°

2075RF 38° fresh food, 0° freezer

CO2075FF, U-CO29FF 38° fresh food

• Is the door sealing properly? If the door is not sealed properly, it allows heat into the unit. U-Line’s warranty is 90 days for door adjustments.

• Is the condenser clean? U-Line’s warranty does not cover cleaning the condenser.

• Is the unit behind closed doors? The unit must have free air flow to the front grille.

• Did you try turning the temperature control colder? Turning the control knob clockwise is colder. Be

sure to allow 24 hours between temperature control adjustments.

• For Wine Captain Units Only - Is the light on constantly to display the wine? If the light is on

constantly, this could cause the unit to run warmer.

The unit is frosting up!

• Are you familiar with the defrost technology of the unit?

Defrost Technology Model Numbers

Manual Defrost BI•2015

Cycle Defrost 2075R, 2015R, 2075WC, 2015WC

Frost Free CO2075FF, 2075RF, U-CO29FF

• Is the door sealing properly? U-Line's warranty is 90 days for door adjustments.

• Has the door been left open?

• Is the unit in an application of heavy usage? Heavy usage or high ambient temperatures will cause a

unit to frost up.

The light on my Wine Captain never shuts off!

• Did you turn the ON/OFF switch near the base of the unit? The ON/OFF switch is for the light

operation only. When the switch is in the OFF position, the light will turn on only when the door is

open. When the switch is in the ON position, the light will be on constantly to display the wine. To

shut the unit OFF, turn the temperature control all the way counterclockwise.

CUSTOMER

COMPLAINT

CUSTOMER

COMPLAINT

CUSTOMER

COMPLAINT

SCREENING CALLS

14

Design ■Features ■Performance

The ice cubes are sticking together! - U-CO29FF, CO2075FF and BI•2015

Models Only

• BI•2015 Model Only - Does the unit need to be defrosted?

• Is the door sealing properly? This could cause the ice cubes to stick together.

• Have you tried to shake the ice bucket? If the ice sits without being used, it will tend to stick together.

Shaking the bucket will usually break apart the ice cubes. If the ice has been sitting for a long time, we

recommend dumping the bucket and making fresh ice.

• CO2075FF, U-CO29FF - Turn freezer control colder.

Water is leaking out of the unit! - U-CO29FF, CO2075FF and BI•2015

Models Only

• Have you checked the connection at the water solenoid valve? U-Line’s warranty does not cover

installation adjustments.

No ice or not enough ice! - U-CO29FF, CO2075FF, BI•2015 and CLR2060

Models Only

• Are you aware of the factory specifications for ice production?

Model # Approx. Daily Ice Rate Approx. Ice Storage

CO2075FF, U-CO29FF 8 lbs. 13 lbs. bucket

CLR2060 60 lbs. 35 lbs. bucket

BI•2015 25 lbs. 25 lbs. bucket

• Is the ice maker bin arm down? When the arm is up, it will not make ice.

• Is the door sealing properly? U-Line’s warranty is 90 days for door adjustments.

• Does the water level need to be adjusted? U-Line’s warranty is 90 days for water level adjustments.

• BI•2015 Model Only - Is the temperature control set to the warmest setting? The unit will produce the

most ice when set at the warmest setting. Let the unit run overnight.

• CO2075FF, U-CO29FF - Turn freezer control colder.

My cubes are wet - CLR2060 Model Only

• The storage bin that holds the ice is not refrigerated. The cubes in the bin are slowly melting down.

The bin will maintain a temperature of 32 to 34 degrees.

The floor is very warm in front of my CLR2060 Model

• The unit is designed for a built-in application, so the warm air will discharge out the bottom of the unit

below the door. There is a safety feature built into the control board that will shut the unit down if the

warm air cannot be dissipated.

No ice, water pours into the trough and down into the drain - CLR2060

Model Only

• The standpipe needs to be inserted into the drain hole of the water trough to maintain the proper level

of water inside the trough.

CUSTOMER

COMPLAINT

CUSTOMER

COMPLAINT

CUSTOMER

COMPLAINT

CUSTOMER

COMPLAINT

CUSTOMER

COMPLAINT

CUSTOMER

COMPLAINT

SCREENING CALLS

15

Design ■Features ■Performance

When I turn the unit on, all I get is water fill - CLR2060 Model Only

• Check to be sure switch is in ice mode.

•Once the unit is turned on, there will be a three minute water fill. This will assure that a fresh batch of

water has filled the trough. If water flows more than three minutes a service call will be required.

My ice does not come out in a perfect cube shape - CLR2060 Model Only

• The manner in which the ice is made causes a small hole or “dimple” to appear on the front or top of

the cube. Increasing or decreasing the time of the freeze cycle will adjust the size of the dimple. A

service company will need to make this adjustment.

The cubes do not fall into bin as individual cubes - CLR2060 Model Only

• Normal - You can use the scoop to break apart.

Not enough ice is stored in the bin - CLR2060 Model Only

• Check the level of the unit.

CUSTOMER

COMPLAINT

CUSTOMER

COMPLAINT

CUSTOMER

COMPLAINT

CUSTOMER

COMPLAINT

NOTES

SCREENING CALLS

16

Design ■Features ■Performance

17

Design ■Features ■Performance

COMPRESSOR/ELECTRICAL SPECIFICATIONS

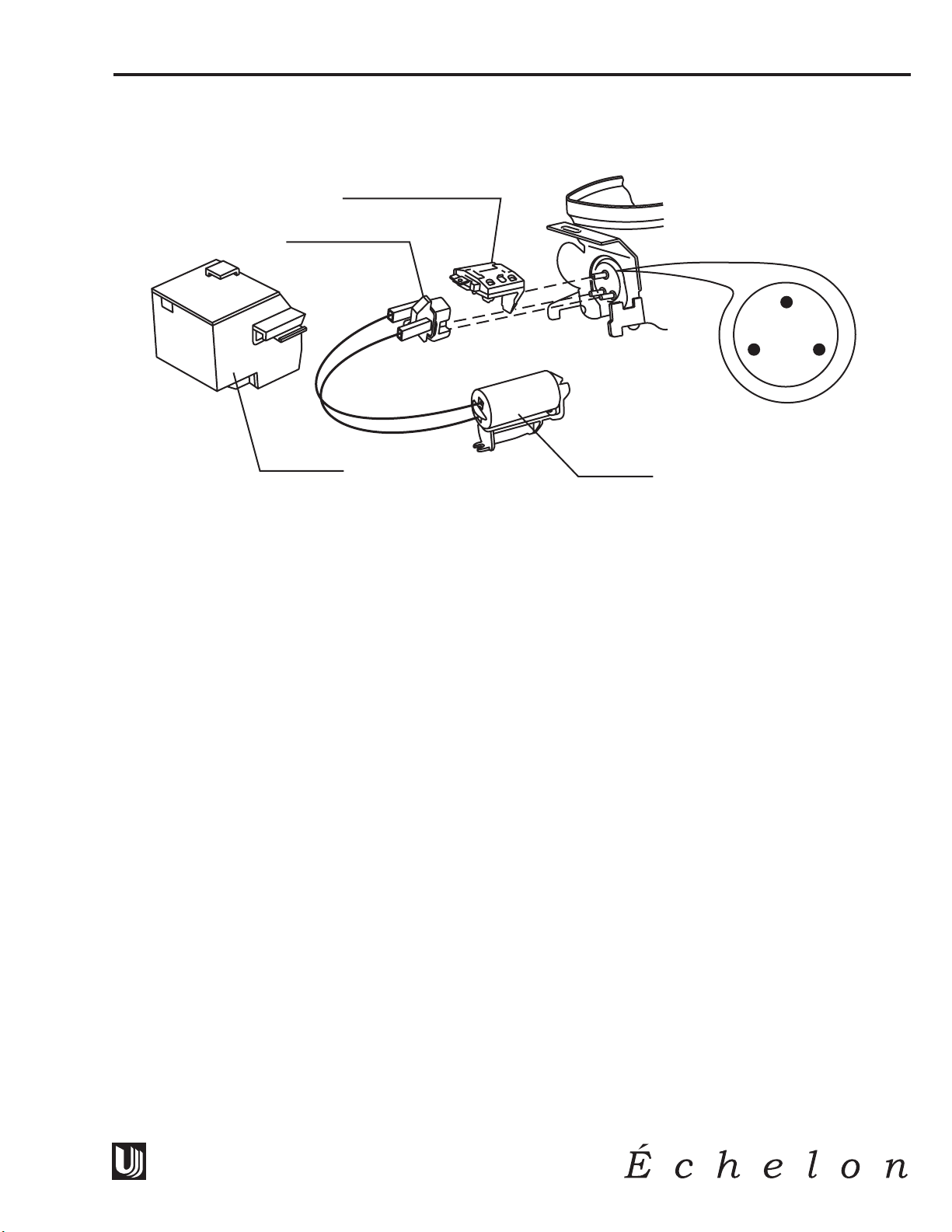

COMPRESSOR PINS

To measure start winding resistance, measure across the C-S pins.

To measure run winding resistance, measure across the C-R pins. Ensure that pins C and R are not shorted

to ground.

Specifications

EMU45HSC Start Winding Resistance: 5.60 OHMS

EMU45HSC Run Winding Resistance: 6.70 OHMS

115 VOLT Ice Maker Heater Resistance: 80 OHMS

115 VOLT Water Valve Coil Resistance: 335 OHMS

115 VOLT Drain Pan Heater 630-661 OHMS

C

S

R

OVERLOAD PROTECTOR

STARTING RELAY

CAPACITOR

RELAY COVER

UL183-3.1

CO2075FF/2075RF & U-CO29FF MODELS

18

Design ■Features ■Performance

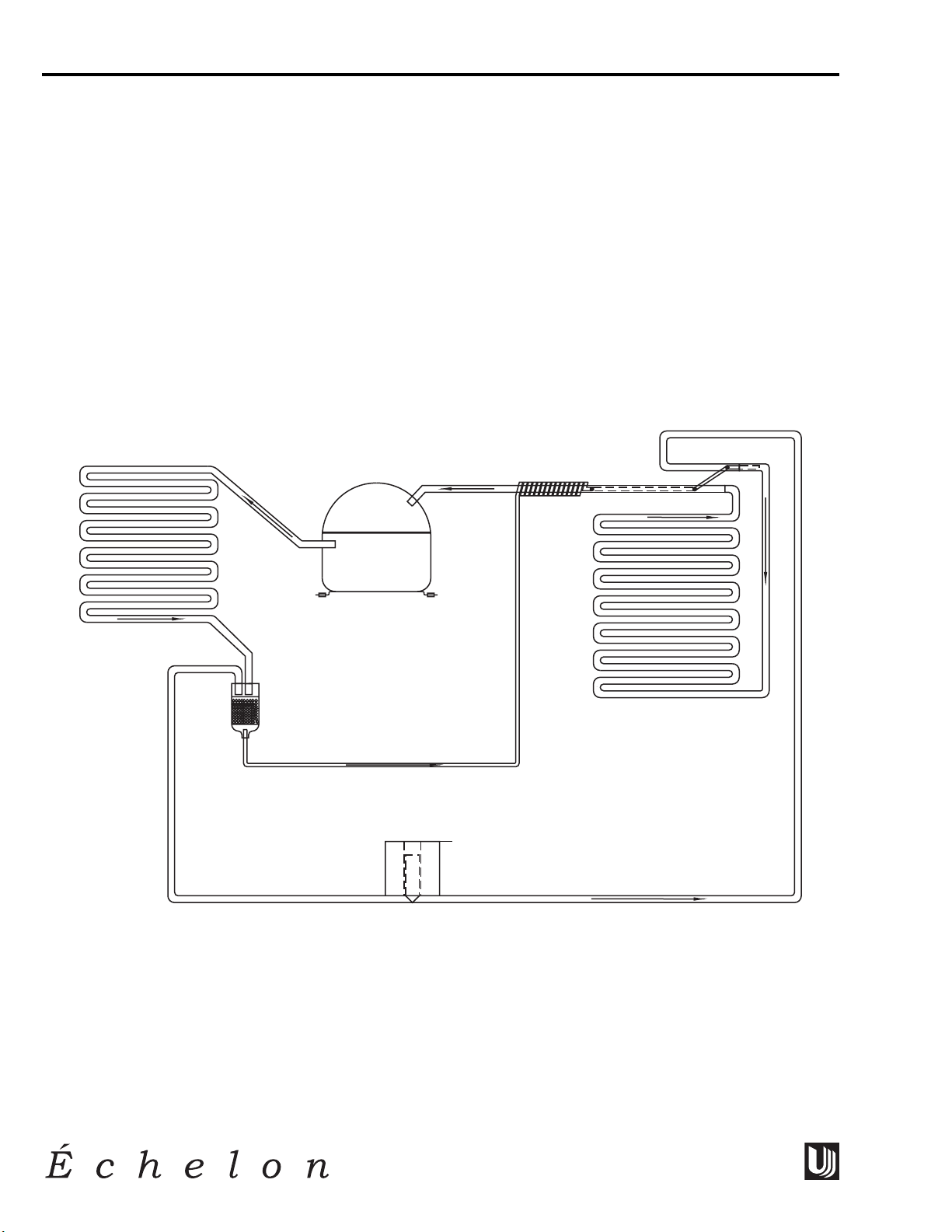

U-LINE FROST FREE REFRIGERATION SYSTEM

Cooling Mode:

• Bypass solenoid valve closed

• Evaporator fan operating

• Refrigerant flows through capillary tube

• Normal vapor/compression cycle refrigeration

•Drain heater off

Defrost Mode:

• Bypass solenoid valve open

• Refrigerant flows through bypass system

•Vapor flows from condenser to evaporator without a phase change

• Drain heater on

CO2075FF/2075RF & U-CO29FF MODELS

CONDENSER

DRYER

COMPRESSOR

FLOW WHEN SOLENOID

VALVE IS CLOSED

CAPILLARY TUBE

SOLENOID VALVE

EVAPORATOR

FLOW WHEN SOLENOID

VALVE IS OPEN

UL183-2

19

Design ■Features ■Performance

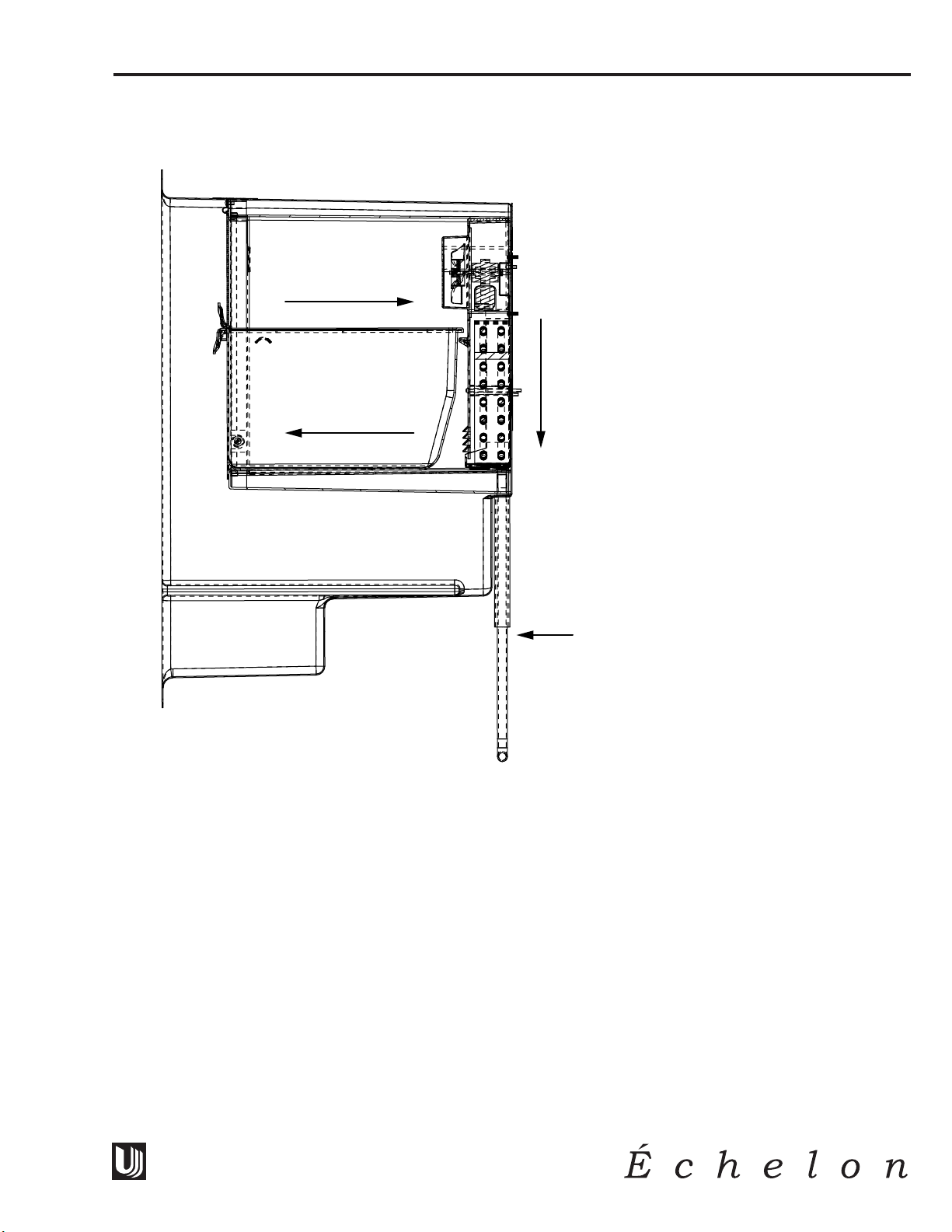

TYPICAL FROST FREE AIRFLOW CONFIGURATION

CO2075FF/2075RF & U-CO29FF MODELS

Air flow in at

evaporator blade

Air passes though

Air flow out at

evaporator outlet

fin tube evaporator

Condensate drains down past the

evaporator, into drain pan, and into

condensate pan through drain hose. The

drain trough is warmed during defrost by

contact with evaporator fins and drain

heater attached to the drain pan.

U-LINE1015

20

Design

■

Features

■

Performance

CO2075FF/2075RF & U-CO29FF MODELS

System Suction Suction Compressor Condenser Capillary Evaporator Wattage

Condition Pressure Line Discharge Tube

Normal Normal Slightly below Very hot Very hot Warm Cold Normal

room

temperature

Overcharge Higher than Very cold Slightly warm Hot to warm Cool Cold Higher than

normal may frost to hot normal

heavily

Undercharge Lower than Warm - near Hot Warm Warm Extremely cold Lower than

normal room near inlet - normal

temperature outlet

below room

temperature

Partial Somewhat Warm - near Very hot Top passes Room Extremely cold Lower than

Restriction lower than room warm - temperature near inlet - normal

normal-in temperature lower passes (cool) or outlet

vacuum cool colder below room

(near room temperature

temperature) backing up

due to liquid

Complete In deep Room Room Room Room No Lower than

Restriction vacuum temperature temperature temperature temperature refrigeration normal

(cool) (cool) (cool) (cool)

No 0 PSIG Room Cool Room Room No Lower than

Gas to temperature to temperature temperature refrigeration normal

25" (cool) hot (cool) (cool)

REFRIGERATION SYSTEM DIAGNOSIS GUIDE

21

Design ■Features ■Performance

CO2075FF AND U-CO29FF ICE MAKER OPERATION

Note: The refrigeration system operates independently of the ice maker. This is a new design for U-Line.

All other U-Line ice makers use a double throw control system where the unit is either in a freeze

mode or harvest mode. In the CO2075FF and the U-CO29FF the refrigeration system will cycle on

and off depending on the temperature of the freezer. In most cases this means the refrigeration

system will be operating during the ice making and harvest modes. If the freezer control is set too

warm the refrigeration system may cycle off during ice making mode, slowing the ice production

rate. If this happens adjust the freezer control colder.

Ice Maker Operating Cycles

1. Freeze Cycle

A. Ice maker thermostat (located behind grille) open.

B. Freezer control closed and refrigeration system is operating.

2. Harvest Cycle-1

A. Ice maker thermostat closed.

B. Refrigeration system operating.

C. If bin arm is up the harvest will not initiate.

D. Power goes through the bin switch to the ice maker motor and mold heater.

3. Harvest Cycle-2

A. Ice maker ejector blades reach 2:00 position and cam depresses the hold switch.

B. Ejector blades stall on ice and ice maker motor pulsates until mold heater warms and ice releases.

C. Refrigeration system operating.

4. Water Fill Cycle

A. Ice maker blades reach approximately 10:00 position and cam depresses the water fill switch.

B. Power to the water valve. Ice maker mold fills.

C. Refrigeration system operating.

5. Eject Cycle

A. Ejector blades push ice into bucket and stop at 12:00 position.

B. Ice maker temperature control opens.

C. Refrigeration system still operating.

CO2075FF/2075RF & U-CO29FF MODELS

22

Design ■Features ■Performance

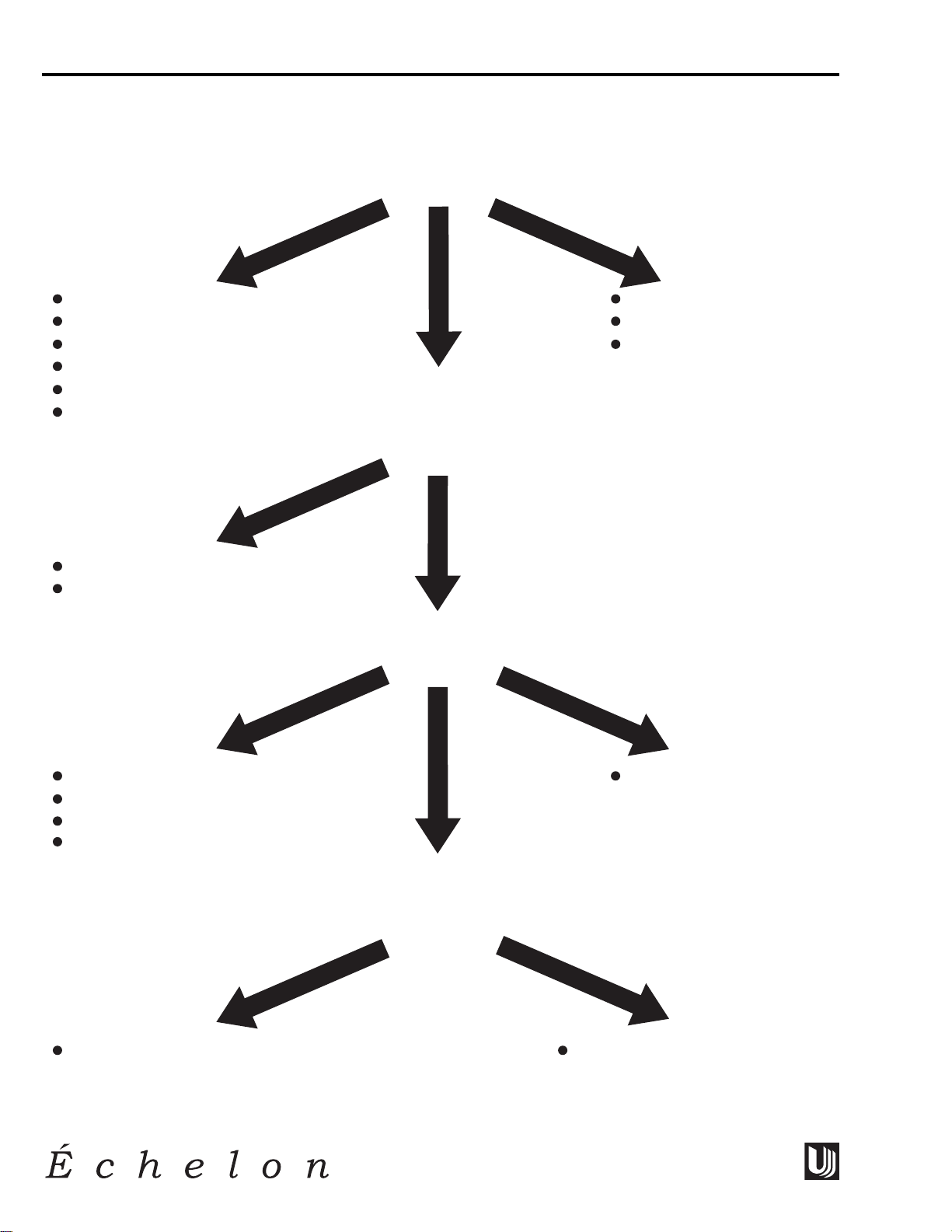

ICE MAKER DIAGNOSIS FLOW CHART

CO2075FF/2075RF & U-CO29FF MODELS

DOES THE UNIT REFRIGERATE?

INTERMITTENT

NO

Sealed System Leak

Electrical Failure

Compressor Failure

Fan Motor Failure

Defrost System Failure

Freezer Control Open

Ice Maker Control Failure

Bin Switch Failure

EVERYWHERE

YES

DOES THE UNIT HARVEST ICE

IF THE EJECTOR BLADES ARE

MOVED BY HAND OR WITH A

WRENCH ?

YES

NO

WHERE DO THE

EJECTOR BLADES

STOP?

AT 3:00

Low V oltage

Voltage Drop

Wiring

Ice Motor Failure

Hold Switch Failure

Limit Switch Failure

Binding Cam/Ejector

Water Switch Failure

AT 12:00

IS THERE VOL T A GE A T THE

WATER SOLENOID VALVE

TERMINALS DURING HARVEST?

YES

NO

Mold Heater Failure

Water Solenoid Valve Failure

U-LINE1005

23

Design ■Features ■Performance

CO2075FF/2075RF & U-CO29FF MODELS

DO NOT service the unit until the main electrical power has

been disconnected.

!

DANGER

!

TROUBLESHOOTING

1. Will not eject ice (water frozen)

Cause

a. Icemaker control setting too cold.

b. Icemaker control defective (contacts open).

c. Bin switch defective.

d. Limit switch defective.

e. Ice maker assembly motor stalled.

f. Broken wire in ice maker circuit.

g. Dirty condenser.

h. Door gasket not sealing.

i. Refrigerant leak causing slight undercharge.

2. Will not fill with water

Cause

a. No water supply to unit.

b. Water switch defective.

c. Solenoid valve defective.

d. Fill tube frozen.

e. Broken wire in water fill circuit.

f. Fill tube kinked.

g. Inlet screen on water valve obstructed.

3. Will not stop making ice

Cause

a. Bin switch defective.

b. Bin arm not raising up completely.

4. Water will not stop filling

Cause

a. Water switch defective.

b. Solenoid valve defective.

c. Stalled ice maker motor.

d. Icemaker temperature control defective. Ice maker

is in continuous harvest cycle (contacts closed).

5. Ejector blades will not stop turning

Cause

a. Water switch defective (closed).

b. Hold switch defective.

c. Defective wiring.

d. Short in mold heater.

6. Low ice production

Cause

a. Icemaker control set too cold.

Remedy

a. Adjust icemaker control warmer

(counterclockwise).

b. Replace icemaker control.

c. Replace bin switch.

d. Replace limit switch.

e. Replace motor.

f. Replace defective wiring.

g. Clean condenser.

h. Replace gasket of fix obstruction.

i. Find and repair leak/replace refrigerant.

Remedy

a. Open water supply connection.

b. Replace switch.

c. Replace valve.

d. Replace solenoid valve and defrost the fill tube.

e. Replace defective wiring.

f. Straighten out tube.

g. Clean or replace valve.

Remedy

a. Replace bin switch.

b. Lubricate pivot point, loosen bin arm lever

screw, or replace bent bin arm.

Remedy

a. Replace switch.

b. Replace solenoid valve.

c. Replace motor and solenoid valve.

d. Replace icemaker temperature control.

Remedy

a. Replace water switch

b. Replace hold switch.

c. Repair or replace wiring.

d. Replace heater.

Remedy

a. Adjust icemaker control warmer

(counterclockwise).

24

Design ■Features ■Performance

CO2075FF/2075RF & U-CO29FF MODELS

b. Fan motor stalled.

c. Ice cubes too large.

d. Dirty condenser.

e. Bypass valve stuck open.

7. Not freezing (compressor and fans are

operating)

Cause

a. Little or no frost pattern on evaporator.

b. Bypass valve stuck open.

8. Not freezing (compressor not operating fans operating)

Cause

a. Relay defective.

b. Overload defective (open).

c. Compressor defective.

9. Not freezing (compressor and fans not

operating)

Cause

a. On-off switch defective (open).

b. Hold switch defective (open).

c. Freezer control defective (open).

d. Broken wire in compressor circuit.

e. Power cord not plugged in.

f. On-off switch in off position (FF only).

g. Freezer control in off position.

h. Ejector blades not in the freeze position (12:00).

10. Compressor overheating

Cause

a. Condenser air flow restricted.

b. Condenser fan blade obstructed.

c. Condenser fan motor stalled.

d. Defective compressor.

11. Compressor will not stop operating

Cause

a. Freezer control set too cold.

b. Freezer control defective (contacts will not open).

c. Control sensing bulb not sensing freezer

temperature.

d. Evaporator fan stalled.

12. Water leak (under unit)

Cause

a. Water supply line leaking at solenoid valve inlet.

b. Water line leaking at solenoid valve outlet.

c. Water line leaking at fill tube.

b. Replace fan motor.

c. Lower water fill adjustment.

d. Clean condenser.

e. Replace bypass valve.

Remedy

a. Check for sealed system leak or restriction.

b. Replace bypass valve.

Remedy

a. Replace relay.

b. Replace overload.

c. Replace compressor.

Remedy

a. Replace on-off switch.

b. Replace hold switch.

c. Replace freezer control.

d. Repair or replace wiring.

e. Plug in power cord.

f. Put switch in on position.

g. Rotate freezer control knob clockwise.

h. Manually advance the ejector blades to the

12:00 position (test ice maker and limit switch).

Remedy

a. Remove restriction (clean condenser and grille).

b. Remove blade restriction.

c. Replace fan motor.

d. Replace compressor.

Remedy

a. Adjust freezer control warmer (counterclockwise).

b. Replace freezer control.

c. Fully insert bulb into well tube on side of freezer,

routing bulb away from compressor discharge tube.

d. Remove obstruction or replace motor.

Remedy

a. Tighten or replace fitting.

b. Replace water line and fitting.

c. Tighten clamp on fill tube or replace fill tube

assembly.

25

Design ■Features ■Performance

CO2075FF/2075RF & U-CO29FF MODELS

d. Defrost drain line not in drain pan.

e. Crack in water line.

13. Water leak (inside unit)

Cause

a. Ice maker assembly fill cup obstructed.

b. Fill ice cup and fill tube out of alignment.

c. Water level too high.

d. Defrost drain plugged.

14. Excessive frost build-up

Cause

a. Door gasket not sealing properly.

b. Door out of alignment.

c. Water soaked cabinet insulation.

d. Light stays on when door is closed.

15. Noisy

Cause

a. Copper refrigeration tube touching cabinet.

b. Fan blade touching shroud.

c. Fan blade obstruction (wiring, foam insulation,

packaging material).

16. Ice build-up in drain trough or drainage

problem.

Cause

a. Obstructed drain cup or tube.

b. Evaporator not touching drain trough.

c. Kinked drain tube.

d. Drain trough spout and drain cup not aligned.

17. Unit will not defrost

Cause

a. Bypass valve not vertical (will not operate).

b. Bypass coil defective.

c. Defrost timer defective.

d. Bypass valve defective.

18. Fresh food temperature too cold

Cause

a. Ice bucket not fully inserted.

b. Freezer temperature control set too cold.

d. Position drain line in drain pan.

e. Replace water line.

Remedy

a. Remove obstruction.

b. Align fill tube and fill cup.

c. Adjust water level.

d. Ice in drain trough (refer to #16).

Remedy

a. Adjust door hinges or replace door gasket.

b. Align door hinges.

c. Replace foamed cabinet assembly

(factory repair only).

d. Repair or adjust light bracket.

Remedy

a. Carefully adjust tubing.

b. Adjust fan mounting or shroud.

c. Remove obstruction.

Remedy

a. Clear obstruction.

b. Reposition evaporator to contact drain trough

along entire length.

c. Reposition drain tube.

d. Align drain trough and drain cup.

Remedy

a. Align bypass valve and coil assembly.

b. Replace bypass valve.

c. Replace defrost timer.

d. Replace bypass valve.

Remedy

a. Push ice bucket in place.

b. Adjust freezer control to warmer setting

(counterclockwise).

26

Design ■Features ■Performance

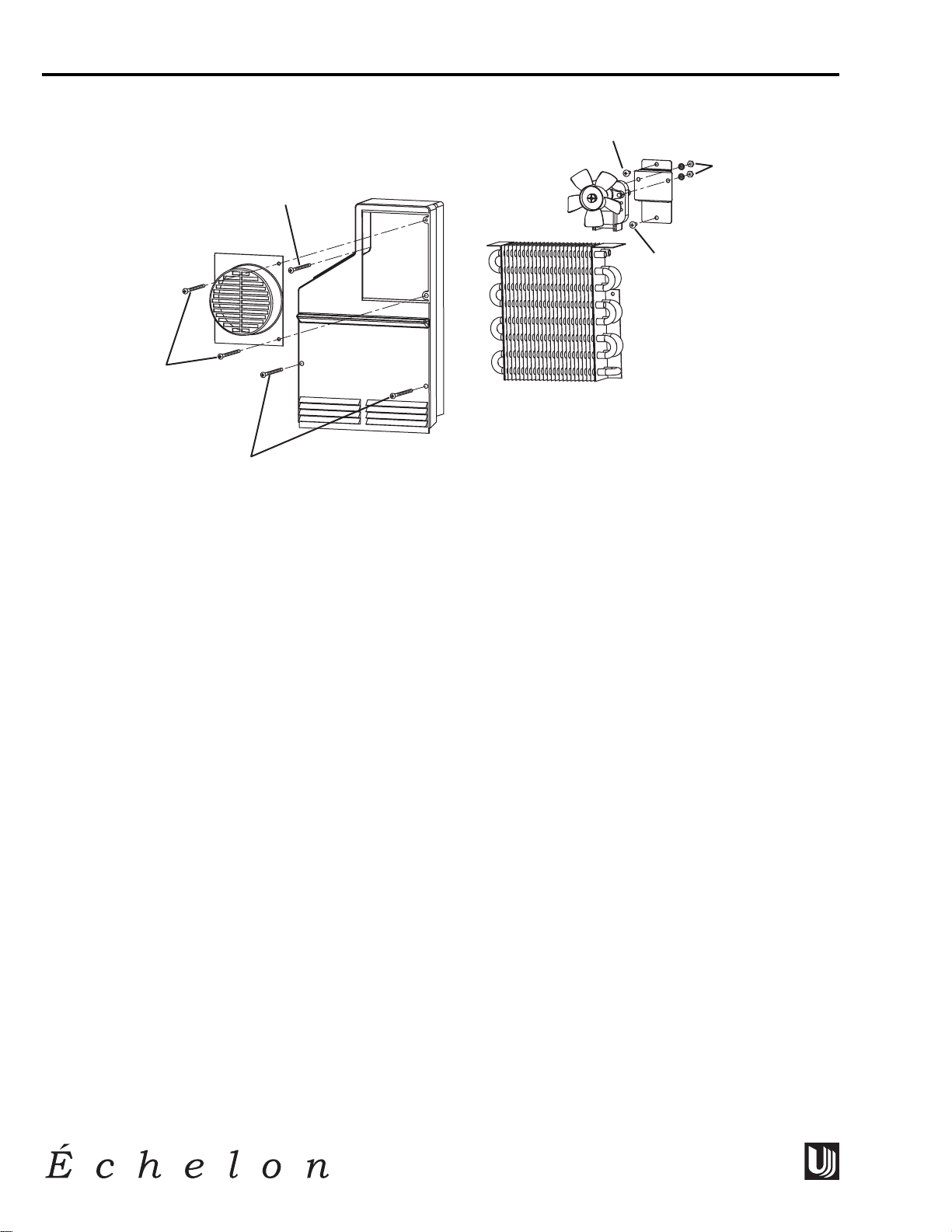

DISASSEMBLY PROCEDURES

Note: Échelon models do not require removal of the ice maker or freezer housing to access the fan

motor, drain or evaporator.

To replace evaporator fan motor:

1. Disconnect unit from power source.

2. Remove 2 screws (1) from fan cover.

3. Remove 2 screws (2) holding fan bracket to liner.

4. Unplug fan connection.

5. Remove 2 nuts (3) holding the fan to the fan bracket.

6. Replace with new fan.

7. Plug in the fan connection.

8. Re-install fan bracket to liner making sure the fan wires are tucked behind the fan bracket.

9. Re-install unit and test.

To access evaporator or drain:

1. Disconnect unit from power source.

2. Remove 2 screws (1) from fan cover.

3. Remove 3 screws (4) from evaporator cover.

4. To remove, pull evaporator cover forward and turn.

1

4

4

2

2

3

U-LINE1004

CO2075FF/2075RF & U-CO29FF MODELS

27

Design ■Features ■Performance

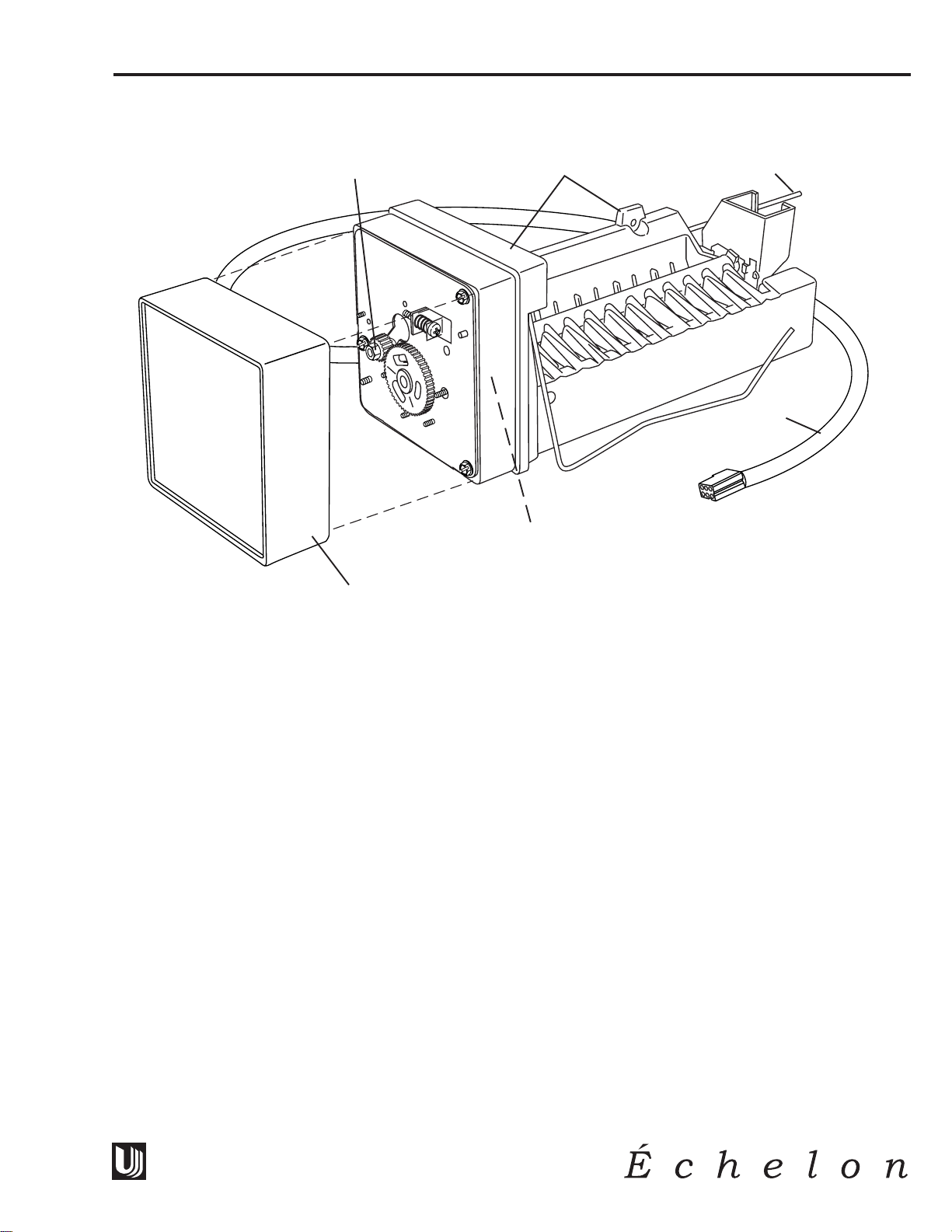

REPLACING ICE MAKER ASSEMBLY

1. Unplug unit.

2. Disconnect ice maker wire harness at plug (1).

3. Remove control capillary tube from sensing tube on ice maker assembly (2).

4. Remove water inlet tube.

5. Remove front cover (3).

6. Advance ejector blade to the 3 o’clock position by turning the 5/16" hex head on the small brass

gear counterclockwise (4).

7. Remove three screws from wall of freezer housing (5).

8. Remove ice maker assembly.

9. Install new ice maker assembly.

10. Reconnect plug.

11. Insert control capillary tube into ice maker sensing tube.

12. Insert water inlet tube.

13. Apply Permagum

®

to all exit holes.

14. Install back panel.

15. Plug in unit and test.

1

2

5

4

5

3

U-LINE1001

CO2075FF/2075RF & U-CO29FF MODELS

28

Design ■Features ■Performance

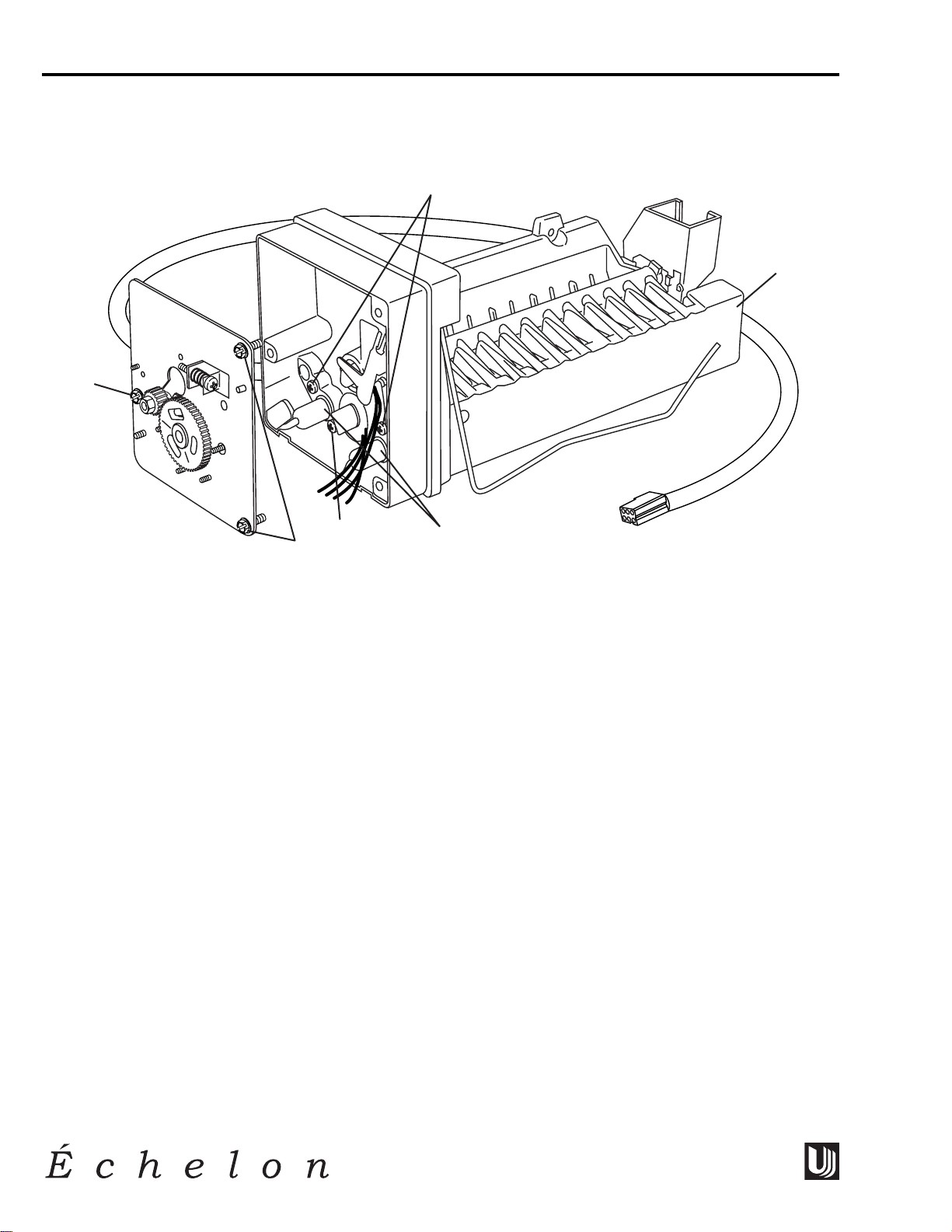

REPLACING MOLD AND HEATER

1. Remove ice maker assembly. Refer to REPLACING ICE MAKER ASSEMBLY.

2. Remove one stripper screw (1) and stripper.

3. Remove three face plate screws (2) and face plate.

4. Remove one screw (3) and detach limit switch from mold.

5. Detach heater leads (4).

6. Remove two screws (5) and mold from support housing.

7. To assemble, replace parts in reverse order.

8. Install the ice maker assembly.

1

2

4

5

3

2

U-LINE1002

CO2075FF/2075RF & U-CO29FF MODELS

29

Design ■Features ■Performance

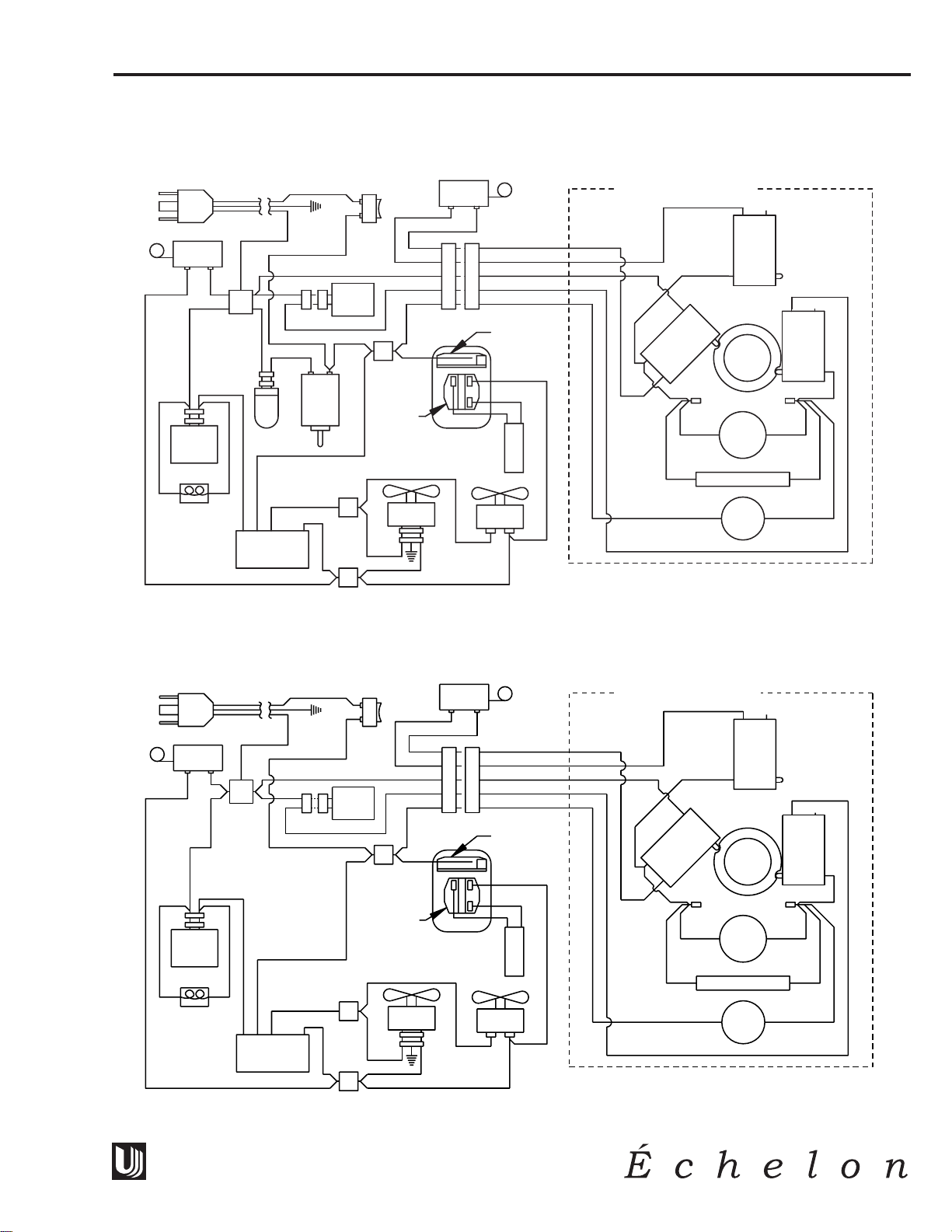

COMBO 2075FF WIRING DIAGRAM

U-CO29FF WIRING DIAGRAM

EMBRACO

WHITE

BLUE

COMPRESSOR

CAPACITOR

ICEMAKER

CONTROL

BLACK

WHITE

POWER CORD ASSEMBLY

GREEN

GROUND

BLACK-HOT

(SMOOTH)

BLACK-NEUTRAL

(RIBBED)

WHITE

BLACK

DOOR

LAMP

L

A

M

P

SWITCH

OVERLOAD

BLACK

ROCKER

SWITCH

FREEZER

CONTROL

BLACK

BLACK

BLACK

RED

YELLOW

BROWN

WHITE

BYPASS

VALVE

TIMER

EVAP

FAN

WATER

VALVE

WHITE

BLACK

WHITE

WHITE

BLACK

BLACK

BLACK

PURPLE

WHITE

BLUE

BLACK

PURPLE

PURPLE

3 RPM

MOTOR

LIMIT

SW

MOLD HEATER

C

NO NC

BIN

SW

NC NO

WATER

SW

C

CAM

NC

NO

C

HOLD

SW

ORANGE

RED

WHITE

BLACK BLACK

BLACK

ORANGE ORANGE

YELLOW

WHITE

BROWN

ICEMAKER ASSEMBLY

RED

YELLOW

BROWN

WHITE

BLACK

21 4 3

DEFROST

HEATER

BROWN

BLACK

BLUE

COND

FAN

5 PIN CONNECTOR

BROWN

RELAY

BLACK

U-LINE42130

CO2075FF/2075RF & U-CO29FF MODELS

POWER CORD ASSEMBLY

WATER

VALVE

BLACK

ROCKER

SWITCH

BLACK

PURPLE

YELLOW

WHITE

BROWN

BLACK

BLACK

RELAY

EVAP

FAN

PURPLE

BLACK-HOT

(SMOOTH)

BLACK

PURPLE

TIMER

GREEN

GROUND

BROWN

WHITE

BLACK-NEUTRAL

(RIBBED)

FREEZER

CONTROL

WHITE WHITE

BLUE

WHITE

BYPASS

VALVE

WHITE

DEFROST

HEATER

BLUE BLUE

BLACK

BLACK

21 4 3

ICEMAKER

CONTROL

RED

5 PIN CONNECTOR

COMPRESSOR

YELLOW

RED

WHITE

BROWN

BLACK

EMBRACO

BLACK

OVERLOAD

WHITE

BLACK

CAPACITOR

WHITE

COND

FAN

ICEMAKER ASSEMBLY

ORANGE

WHITE

C

HOLD

SW

NO

NC

YELLOW

ORANGE ORANGE

BLACK BLACK

MOLD HEATER

BLACK BLACK

RED

3 RPM

MOTOR

LIMIT

NO NC

BIN

SW

C

CAM

SW

BROWN

NC NO

WATER

SW

C

BLACK

BROWN

U-LINE42180

Loading...

Loading...