Page 1

QUICK START GUIDE

Outdoor Collection

30607 Rev_A

Page 2

QUICK START GUIDE

u-line.com

WELCOME TO U-LINE

Congratulations on your U-Line purchase. Your product comes from a company with over five decades of premium modular

ice making, refrigeration, and wine preservation experience. U-Line continues to be the American leader, delivering versatility

and flexibility for multiple applications including residential, light commercial, outdoor and marine use. U-Line’s complete

®

product collection includes Wine Captain

Makers, Glass & Solid Door Refrigerators, Drawer Models, Freezers, Combo

U-Line has captivated those with an appreciation for the finer things with exceptional functionality, style, inspired innovations

and attention to even the smallest details. We are known and respected for our unwavering dedication to product design,

quality and selection. U-Line is headquartered in Milwaukee, Wisconsin and has shipped product to five continents for over

two decades and is proud to have the opportunity to ship to you.

PRODUCT INFORMATION

Looking for additional information on your product? User Guides, Spec Sheets, CAD Drawings, Compliance Documentation,

and Product Warranty information are all available for reference and download at u-line.com.

Models, Beverage Centers, Clear Ice Machines, Nugget Ice Machines, Crescent Ice

®

Models, and more.

PROPERTY DAMAGE / INJURY CONCERNS

In the unlikely event property damage or personal injury is suspected related to a U-Line product, please take the following

steps:

1. U-Line Customer Care must be contacted immediately at +1.800.779.2547.

2. Service or repairs performed on the unit without prior written approval from U-Line is not permitted. If the unit has been

altered or repaired in the field without prior written approval from U-Line, claims will not be eligible.

GENERAL INQUIRIES

U-Line Corporation

8900 N. 55th Street

Milwaukee, Wisconsin 53223 USA

Monday - Friday 8:00 am to 4:30 pm CST

T: +1.414.354.0300

F: +1.414.354.7905

Email: sales@u-line.com

u-line.com

SERVICE & PARTS ASSISTANCE

Monday - Friday 8:00 am to 4:30 pm CST

T: +1.800.779.2547

F: +1.414.354.5696

Service Email: onlineservice@u-line.com

Parts Email: onlineparts@u-line.com

CONNECT WITH US

Designed, engineered and assembled in WI, USA

2

Page 3

QUICK START GUIDE

plus

eligible

1

warrantywarranty

This Quick Start Guide covers the basics of installation and general use of your product.

CONTENTS

Safety and Warning 4

Environmental Requirements 5

Electrical 5

Water Hookup 6

Drain 9

Door Swing 10

Door Adjustments 11

General Installation 17

u-line.com

Control Operation 18

First Use 22

Ice 23

Cleaning 26

Warranty

For more details, see the complete User Guide & Service Manual on u-line.com.

30

This product is eligible for an additional one-year warranty at no charge when you register your product on

u-line.com. See complete warranty for details.

3

Page 4

QUICK START GUIDE

u-line.com

Safety and Warning

Please read all instructions before installing,

operating, or servicing the appliance.

Use this appliance for its intended purpose only and follow

these general precautions with those listed throughout this

guide:

SAFETY ALERT DEFINITIONS

Throughout this guide are safety items labeled with a

Danger, Warning or Caution based on the risk type:

DANGER

!

Danger means that failure to follow this safety

statement will result in severe personal injury or

death.

DANGER

!

Your product may contain R600a (Isobutane)

which is a flammable hydrocarbon. To confirm,

check serial tag inside of unit. It is safe for

regular use. Do not use sharp objects to expedite

defrosting. Do not service without consulting the

“R600a specifications” section included in the

User Guide. Do not damage the refrigerant

circuit.

WARNING

!

Service must be done by factory authorized

service personnel. Any parts shall be replaced

with like components. Failure to comply could

increase the risk of possible ignition due to

incorrect parts or improper service.

WARNING

!

Warning means that failure to follow this safety

statement could result in serious personal injury

or death.

CAUTION

!

Caution means that failure to follow this safety

statement may result in minor or moderate

personal injury, property or equipment damage.

CALIFORNIA PROPOSITION 65

This product contains chemicals known to the

state of California to cause cancer and birth

defects or other reproductive harm.

www.P65warnings.CA.gov

4

Page 5

QUICK START GUIDE

u-line.com

Environmental Requirements

This unit is designed to operate between 50°F (10°C) and

100°F (38°C). Higher ambient temperatures may reduce

the unit’s ability to reach low temperatures and/or reduce

ice production on applicable models.

For best performance, keep the unit out of direct sunlight

and away from heat generating equipment.

In climates where high humidity and dew points are

present, condensation may appear on outside surfaces.

This is considered normal. The condensation will

evaporate when the humidity drops.

CAUTION

!

Damages caused by ambient temperatures of

40°F (4°C) or below are not covered by the

warranty.

Electrical

WARNING

!

SHOCK HAZARD — Electrical Grounding

Required. Never attempt to repair or perform

maintenance on the unit until the electricity has

been disconnected.

Never remove the round grounding prong from

the plug and never use a two-prong grounding

adapter.

Altering, cutting or removing power cord,

removing power plug, or direct wiring can cause

serious injury, fire, loss of property and/or life,

and will void the warranty.

Never use an extension cord to connect power to

the unit.

Always keep your working area dry.

Electrical installation must observe all state and

local codes. This unit requires connection to a

grounded (three-prong), polarized receptacle

that has been placed by a qualified electrician.

The unit requires a grounded and polarized 115 VAC,

60 Hz, 15A power supply (normal household current). An

individual, properly grounded branch circuit or circuit

breaker is recommended. A GFCI (ground fault circuit

interrupter) is usually not required for fixed location

appliances and is not recommended for your unit because

it could be prone to nuisance tripping. However, be sure

to consult your local codes.

5

Page 6

QUICK START GUIDE

u-line.com

Water Hookup

PREPARE PLUMBING

The water valve uses a standard 1/4" (6.35 mm)

compression fitting. U-Line recommends using accessory

water hook up kit – part # 80-54674-00. The kit includes a

10' (3 m) braided flexible water supply line and a brass

hose fitting.

CAUTION

!

Plumbing installation must observe all state and

local codes. All water and drain connections

MUST BE made by a licensed/qualified plumbing

contractor. Failure to follow recommendations

and instructions may result in damage and/or

harm.

Water Supply Connection

CAUTION

!

Do not use any plastic water supply line. The line

is under pressure at all times. Plastic may crack

or rupture with age and cause damage to your

home.

Do not use tape or joint compound when

attaching a braided flexible water supply line

that includes a rubber gasket. The gasket

provides an adequate seal – other materials

could cause blockage of the valve.

Failure to follow recommendations and

instructions may result in damage and/or harm,

flooding or void the product warranty.

Use new hose set. Do not reuse old hose set.

When connecting the water supply, please note the

following:

• Before installing the unit and connecting to the cold

water supply, review the local plumbing codes.

• The water pressure should be between 20 and 120 psi

(138 and 827 kPa).

• The water line MUST have a shut-off valve in the

supply line.

• The water line should be looped into 2 coils. This will

allow the unit to be removed for cleaning and servicing.

Make certain that the tubing is not pinched or damaged

during installation.

WARNING

!

CAUTION

!

Turn off water supply and disconnect electrical

supply to unit prior to installation.

Use caution when handling back panel. The

edges could be sharp.

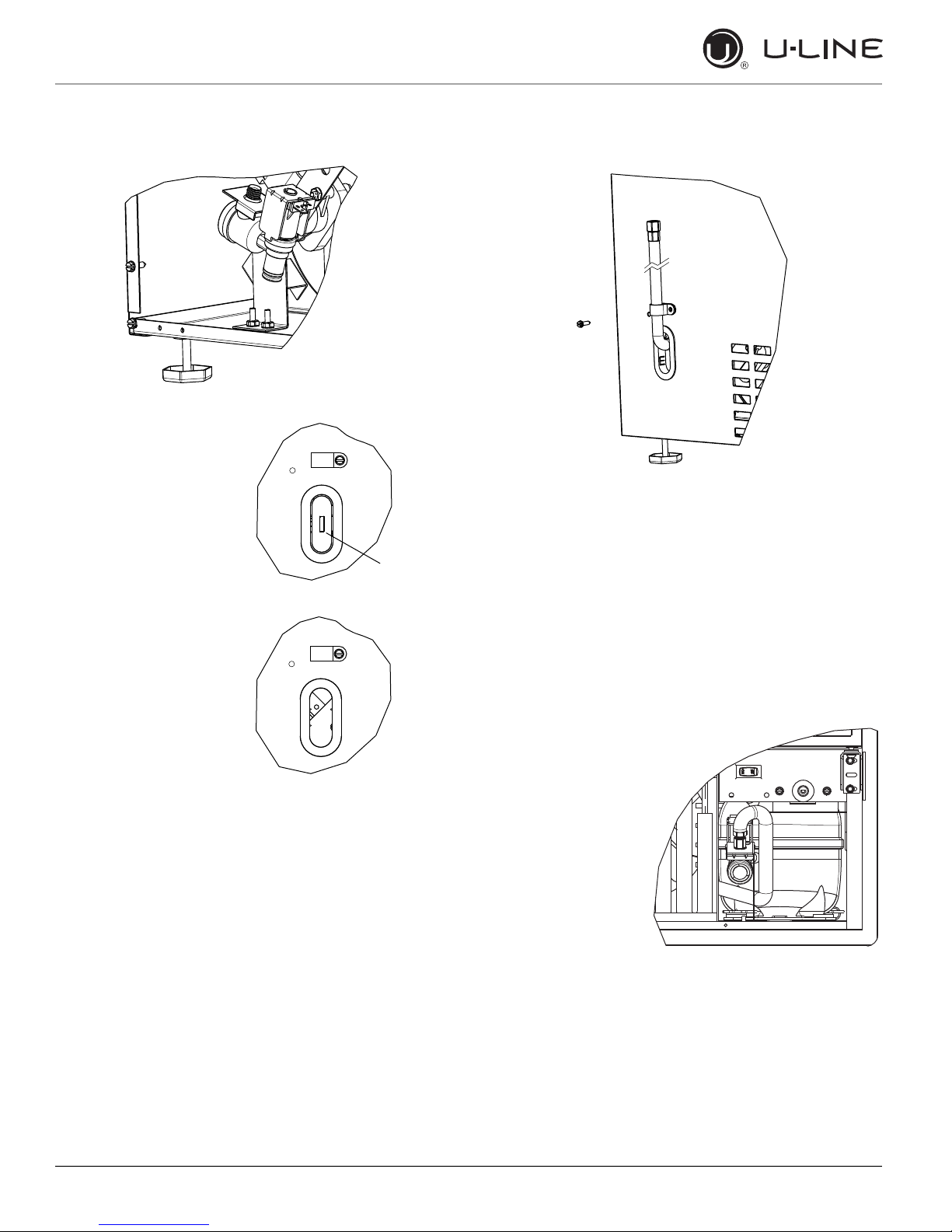

CRESCENT ICE MAKERS

1. Turn off water supply and disconnect electrical supply

to product prior to attempting installation.

2. Remove the back panel.

Connect to potable water supply only.

6

Page 7

QUICK START GUIDE

Remove

ZLWKɠDW

r

u-line.com

3. Locate water valve inlet.

4. Break away filler feature

in bushing with flat

screwdriver.

5. Thread water line

through back panel hole

(with bushing).

screwdrive

9. Install retaining clip.

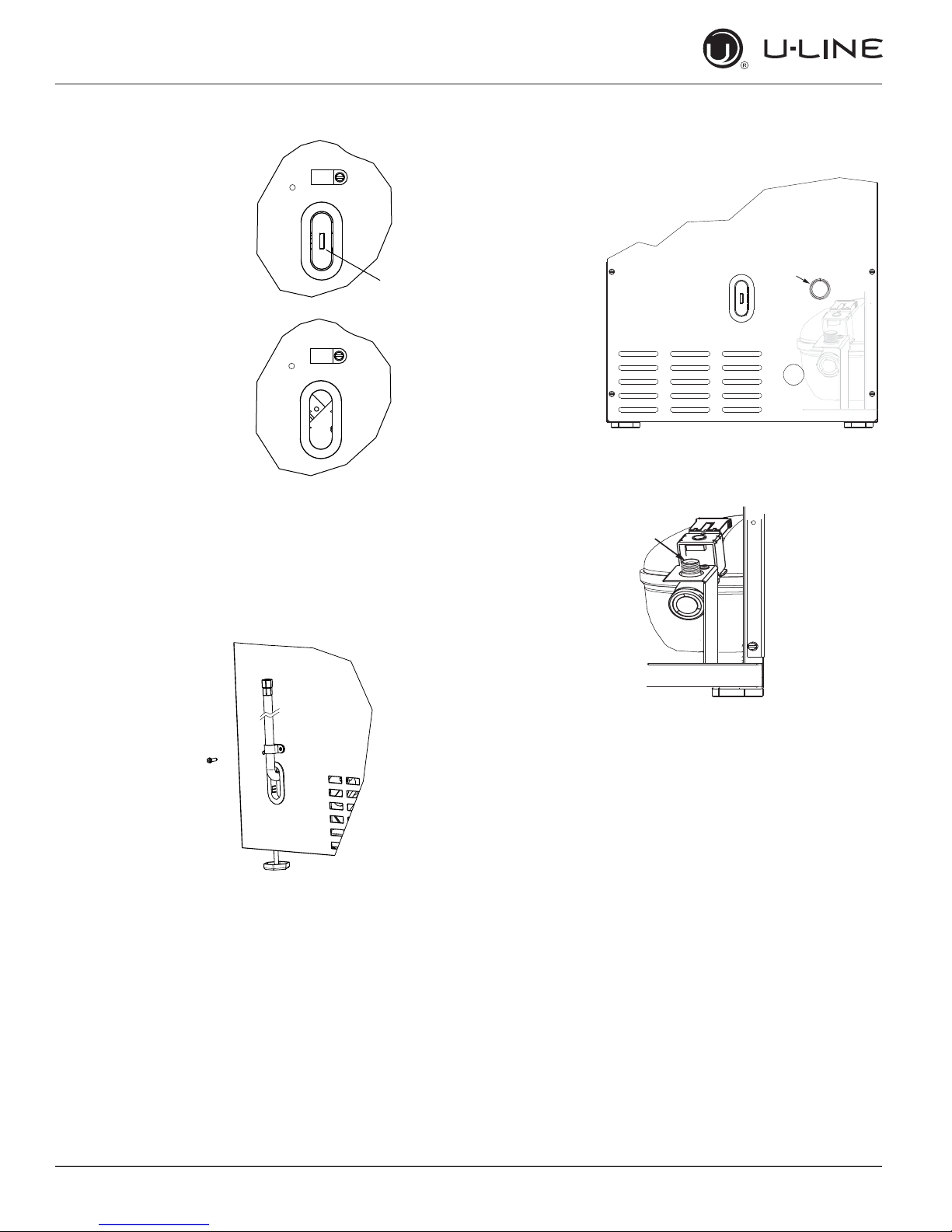

CLEAR ICE MACHINES

1. Turn off water supply and disconnect electrical supply

to product prior to attempting installation.

2. Remove the grille/access panel in the front and the

back panel.

6. Locate water valve inlet

and connect to valve.

7. Turn on water supply

and check for leaks.

8. Reinstall back panel.

3. Locate water

valve in the front

of the unit and

thread water

supply line

through.

Route the water

supply line

through the unit

so it does not

come into contact with any internal components

other than the solenoid valve. Normal operation

creates some vibration. A water supply line

contacting an internal component or cabinet wall

can cause excessive noise during operation or

damage to the line.

7

Page 8

QUICK START GUIDE

Remove

ZLWKɠDW

r

4

3

u-line.com

4. On the back panel,

break away filler feature

in bushing with flat

screwdriver.

5. Thread water line

through back panel hole

(with bushing) and

connect to cold water

supply line.

6. Turn on water supply and check for leaks.

3. Thread water line through back panel hole (with

bushing).

screwdrive

4. Locate water valve inlet and connect to valve.

7. Reinstall back panel and grille/front access panel.

8. Install retaining

clip.

NUGGET ICE MACHINES

1. Turn off water supply and disconnect electrical supply

to product prior to attempting installation.

5. Turn on water supply and check for leaks.

6. Reinstall back panel.

2. Remove the back panel.

8

Page 9

QUICK START GUIDE

Normal

Proper Drain

With Trap

Poor Drainage, Water Will Back Up

With Trap and Vent

u-line.com

Drain

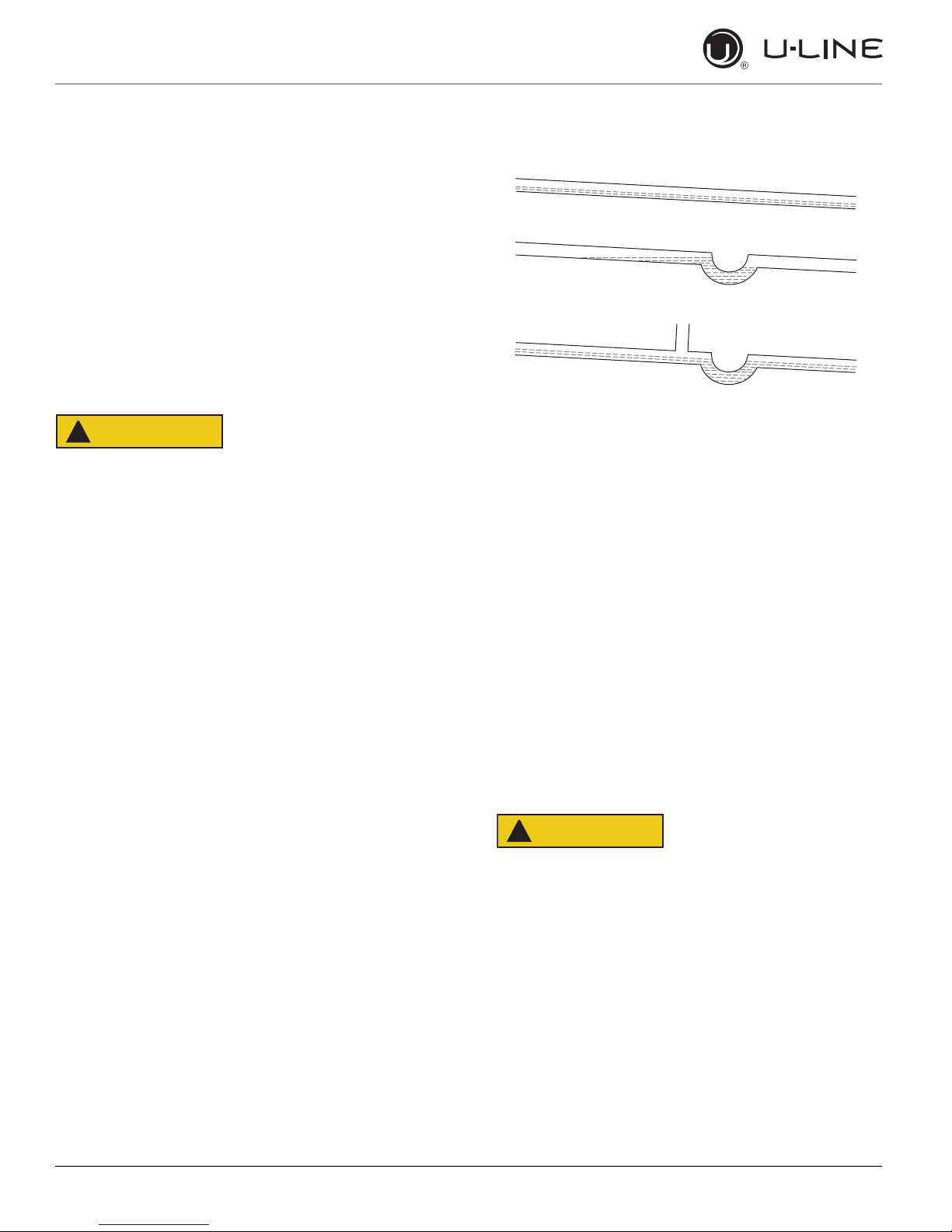

CLEAR ICE AND NUGGET ICE MACHINES ONLY

Model numbers including “CL” or “NB” do not include a

factory installed drain pump.

Model numbers including “CP” or “NP” include a factory

installed drain pump.

DRAIN CONNECTION

CAUTION

!

If your U-Line unit did not come with a factory

installed drain pump you must use a gravity

style drain connection. For assistance in

determining if your unit has a pump please

contact U-Line. The floor drain must be large

enough to accommodate drainage from all

attached drains. Follow these guidelines when

installing drain lines to prevent water from

flowing back into the ice maker storage bin and/

or potentially flowing onto the floor, which may

result in personal injury or property damage.

GRAVITY DRAIN

Proper Drain

A gravity drain may be used if:

Drain line has at least a 1" drop per 48" (approximately

2 cm drop per 100 cm) of run.

Drain line does not create traps and is vented per local

code.

1. Cut the pre-installed drain tube to length.

2. Connect to your local plumbing per the local code.

Drain can NOT be located directly below the unit.

Unit has a solid base that will not allow the unit

to drain below itself.

There is a possibility that hose connections may

have loosened during shipment.

Verify all connections and fittings are free from

leaks.

3. If necessary, insulate drain line to prevent

condensation.

CAUTION

!

Failure to connect water supply or drain line

connections properly can result in personal

injury and property damage. Gravity drain

connections must be routed downward from the

rest of the unit at the rate of 1/4" per foot (1 cm

per 50 cm).

9

Page 10

QUICK START GUIDE

Cold

Water

Hot

Water

Waste

Waste

6KXW2ɞ

Valve

Stand Pipe

P60 Pump Required

Air Gap

(Optional Hook-Up)

Cold

Water

Hot

Water

Waste

6KXW2ɞ

Valve

Disposal Assembly

P60 Pump Required

Waste

Cold

Water

6KXW2ɞ

Valve

Hot

Water

Air Gap

(Optional Hook-Up)

Y-Branch Tailpiece

P60 Pump Required

Wall

90°

Door Swing

2-1/8" Min.

(54 mm)

FACTORY INSTALLED DRAIN PUMP

If your drain line will run up to a stand pipe, disposal or

spigot assembly, or does not otherwise meet the

requirements for a gravity drain, you may have ordered a

pre-installed U-Line P60 drain pump.

If you need to install a P60 drain pump into your unit, see

DRAIN PUMP section in the User Manual.

See below for typical installations requiring a drain pump.

u-line.com

The maximum lift for the P60 drain pump is

10 feet. This must be done as close to the rear of

the unit as possible.

Door Swing

Units have a zero clearance for the door to open 90°,

when installed adjacent to cabinets.

Stainless Steel models require 2-1/8" (54 mm) door

clearance to accommodate the handle if installed next to a

wall.

10

Page 11

QUICK START GUIDE

Hinge Cover

u-line.com

Door Adjustments

CRESCENT ICE MAKERS

HINGE COVER

Hinge cover included with the literature bag is optional.

To install hinge cover:

Press hinge cover squarely over hinge

DOOR ALIGNMENT AND ADJUSTMENT

5. Tighten bottom hinge screws.

6. Tighten top hinge screws and replace hinge cover.

REVERSING THE DOOR

Location of the unit may make it desirable to mount the

door on the opposite side of the cabinet.

The hinge hardware will be removed and reinstalled on the

opposite side of the cabinet.

TO REVERSE THE DOOR

Align and adjust the door if it is not level or is not sealing

properly. If the door is not sealed, the unit may not cool

properly, or excessive frost may form in the interior.

Properly aligned, the door’s gasket should be

firmly in contact with the cabinet all the way

around the door (no gaps). Carefully examine

the door’s gasket to ensure that it is firmly in

contact with the cabinet. Also make sure the

door gasket is not pinched on the hinge side of

the door.

To align and adjust the door:

1. Gently pry off hinge cover from top of unit.

2. Loosen (do not remove) top and bottom hinge screws

using a Torx T-25 screwdriver on the top and a 1/4”

socket on the bottom.

3. Align door squarely with cabinet.

Remove top hinge and door:

1. Remove hinge cover from top of unit.

2. Hold door to keep it from falling.

3. Remove top hinge from cabinet using a Torx T-25

screwdriver to remove three screws. Set aside.

4. Make sure gasket is firmly in contact with cabinet all

the way around the door (no gaps).

11

Page 12

QUICK START GUIDE

Top Hinge

Right Side

Top Hinge

Left Side

Pivot

Screw

4. Remove door by tilting forward and lifting door off

bottom hinge. Retain shoulder washers; they will be

reused.

5. Remove three screws from hinge holes on the opposite

side. Reinstall into holes where the hinge was

removed. Take care not to scratch cabinet.

Remove bottom hinge:

1. Remove bottom hinge from cabinet using 1/4” socket.

u-line.com

Install top hinge and door:

1. Remove pivot screw from hinge, flip hinge over, and

install the pivot screw in the same hole from the

opposite surface.

2. Remove corresponding screws on opposite side of

cabinet. On some models there may be a nut behind

one or both screws on either side.

Install bottom hinge:

Install two or three screws, depending on model. Replace

nuts if used.

Prepare door for reinstallation:

1. Remove gasket.

o

2. Rotate gasket 180

and press firmly into the gasket

channel starting at the corners..

2. On the opposite side, align edge of the hinge with the

outer edge of the unit; leave screws loose to allow door

to fit under hinge.

3. Lift the door onto the bottom hinge.

4. Tighten three hinge screws and replace hinge cover.

Align and adjust the door:

Align and adjust the door (see DOOR ALIGNMENT AND

ADJUSTMENT).

12

Page 13

QUICK START GUIDE

Hinge Cover

u-line.com

Door Adjustments

15” REFRIGERATORS AND CLEAR ICE MACHINES

HINGE COVER

Hinge cover included with the literature bag is optional.

To install hinge cover:

Press hinge cover squarely over hinge

DOOR ALIGNMENT AND ADJUSTMENT

5. Tighten bottom hinge screws.

6. Tighten top hinge screws and replace hinge cover.

REVERSING THE DOOR

Location of the unit may make it desirable to mount the

door on the opposite side of the cabinet.

The hinge hardware will be removed and reinstalled on the

opposite side of the cabinet.

TO REVERSE THE DOOR

Align and adjust the door if it is not level or is not sealing

properly. If the door is not sealed, the unit may not cool

properly, or excessive frost may form in the interior.

Properly aligned, the door’s gasket should be

firmly in contact with the cabinet all the way

around the door (no gaps). Carefully examine

the door’s gasket to ensure that it is firmly in

contact with the cabinet. Also make sure the

door gasket is not pinched on the hinge side of

the door.

To align and adjust the door:

1. Gently pry off hinge cover from top of unit.

2. Loosen (do not remove) top and bottom hinge screws

using a Torx T-25 screwdriver on the top and a 1/4”

socket on the bottom.

3. Align door squarely with cabinet.

4. Make sure gasket is firmly in contact with cabinet all

the way around the door (no gaps).

Remove top hinge and door:

1. Remove hinge cover from top of unit.

2. Hold door to keep it from falling.

3. Remove top hinge from cabinet using a Torx T-25

screwdriver to remove three screws. Set aside.

4. Remove door by tilting forward and lifting door off

bottom hinge. Retain shoulder washers; they will be

reused.

5. Remove three screws from hinge holes on the opposite

side. Reinstall into holes where the hinge was

removed. Take care not to scratch cabinet.

13

Page 14

QUICK START GUIDE

Top Hinge

Right Side

Top Hinge

Left Side

Pivot

Screw

u-line.com

Remove bottom hinge:

1. Remove bottom hinge from cabinet using 1/4” socket.

2. Remove corresponding screws on opposite side of

cabinet. On some models there may be a nut behind

one or both screws on either side.

Install bottom hinge:

Install two or three screws, depending on model. Replace

nuts if used.

Install top hinge and door:

1. Remove pivot screw from hinge, flip hinge over, and

install the pivot screw in the same hole from the

opposite surface.

Prepare door for reinstallation:

1. Remove gasket. This will reveal mounting holes for the

magnet assembly.

2. Remove magnet assembly from door with T-10 TORX

driver. Be sure to only remove the two screws holding

the assembly to the door. Reinstall on the opposite end

of the door.

o

3. Rotate gasket 180

, aligning notch with magnet

assembly and pressing firmly into the gasket channel

starting at the corners.

2. On the opposite side, align edge of the hinge with the

outer edge of the unit; leave screws loose to allow door

to fit under hinge.

3. Lift the door onto the bottom hinge.

4. Tighten three hinge screws and replace hinge cover.

Align and adjust the door:

Align and adjust the door (see DOOR ALIGNMENT AND

ADJUSTMENT).

14

Page 15

QUICK START GUIDE

Hinge Cover

u-line.com

Door Adjustments

24” MODELS AND NUGGET ICE MACHINES

HINGE COVER

Hinge cover included with the literature bag is optional.

To install hinge cover:

1. Press hinge cover squarely over hinge.

6. Tighten top hinge screws and replace hinge cover.

REVERSING THE DOOR

Location of the unit may make it desirable to mount the

door on the opposite side of the cabinet.

The hinge hardware will be removed and reinstalled on the

opposite side of the cabinet.

TO REVERSE THE DOOR

DOOR ALIGNMENT AND ADJUSTMENT

Align and adjust the door if it is not level or is not sealing

properly. If the door is not sealed, the unit may not cool

properly, or excessive frost may form in the interior.

Properly aligned, the door’s gasket should be

firmly in contact with the cabinet all the way

around the door (no gaps). Carefully examine

the door’s gasket to ensure that it is firmly in

contact with the cabinet. Also make sure the

door gasket is not pinched on the hinge side of

the door.

To align and adjust the door:

1. Gently pry off hinge cover from top of unit.

2. Loosen (do not remove) top and bottom hinge screws

using a Torx T-25 screwdriver.

3. Align door squarely with cabinet.

Remove grille:

Remove the grille

Remove top hinge and door:

1. Hold door to keep it from falling.

2. Remove top hinge from cabinet using a Torx T-25

screwdriver to remove three screws. Set aside and

save for possible future use.

4. Make sure gasket is firmly in contact with cabinet all

the way around the door (no gaps).

5. Tighten bottom hinge screws.

15

Page 16

QUICK START GUIDE

3. Remove door by tilting forward and lifting door off

bottom hinge. Retain shoulder washers; they will be

reused.

4. Remove three screws from hinge holes on the opposite

side. Reinstall into holes where the hinge was

removed. (If utilizing supplied screw cover, install just

one screw.)

u-line.com

Prepare door for reinstallation:

1. Remove gasket. This will reveal mounting holes for the

magnet assembly.

2. Remove magnet assembly from door with T-10 TORX

driver. Be sure to only remove the two screws holding

the assembly to the door. Reinstall on the opposite end

of the door.

3. Rotate gasket 180°, aligning notch with magnet

assembly and pressing firmly into the gasket channel

starting at the corners.

4. Rotate door 180° to reverse.

Install top hinge and door:

Remove bottom hinge:

1. Remove bottom hinge from cabinet using a T-10 TORX

screw driver to remove three screws.

2. Remove corresponding screws on opposite side of

cabinet. On some models there may be a nut behind

one or both screws on either side.

Install bottom hinge:

Install two or three screws, depending on model. Replace

nuts if used.

1. Install hinge with longer straight edge aligned to

outside edge of cabinet. Do not tighten.

2. Lift the door on to the bottom hinge.

3. Align edge of the hinge with the outer edge of the unit.

4. Tighten three hinge screws.

Align and adjust the door:

Align and adjust the door (see DOOR ALIGNMENT AND

ADJUSTMENT).

Install grille and top covers

16

Page 17

QUICK START GUIDE

1

Turn to Adjust

u-line.com

General Installation

LEVELING INFORMATION

1. Use a level to

confirm the unit is

level. Level should

be placed along top

edge and side edge

as shown.

2. If the unit is not level, adjust the legs on the corners of

the unit as necessary.

INSTALLATION

1. Plug in the power/electrical cord.

2. Gently push the unit into position. Be careful not to

entangle the cord or water and drain lines, if

applicable.

3. Re-check the leveling, from front to back and side to

side. Make any necessary adjustments. The unit’s top

surface should be approximately 1/8" (3 mm) below

the countertop.

4. Install the anti-tip bracket.

5. Remove interior packing material and wipe out the

inside of the unit with a clean, water-dampened cloth.

3. Confirm the unit is level after each adjustment and

repeat the previous steps until the unit is level.

INSTALLATION TIP

If the room floor is higher than the floor in the cutout

opening, adjust the rear legs to achieve a total unit rear

height of 1/8" (3 mm) less than the opening’s rear height.

Shorten the unit height in the front by adjusting the front

legs. This allows the unit to be gently tipped into the

opening. Readjust the front legs to level the unit after it is

correctly positioned in the opening.

17

Page 18

QUICK START GUIDE

Control Operation

REFRIGERATORS

CONTROL FUNCTION GUIDE

FUNCTION COMMAND NOTES

ON/OFF Press and hold for 5 seconds Unit will turn ON or OFF

u-line.com

Press and release to leave interior

Leave interior light on

Adjust temperature Press or and release

o

Toggle between

Enable Sabbath Mode

Disable Sabbath Mode Press and release Display and interior light return to normal operation

This unit is Star-K certified. See www.star-k.org for more details

DOOR ALERT NOTIFICATION

When the door is left open for more than 5 minutes:

• A tone will sound for several seconds every minute

F / oC Hold and for 5 seconds The display will change units

light on for 3 hours; press again to

deactivate

Press and hold for 5 seconds and

release.

After 3 hours, factory default is restored; light will turn

on when door is open

When the display is flashing, press or to adjust

the set point temperature. Note: temperature

displayed is the actual temperature inside unit

o

F / oC symbol will flash briefly after 5 seconds.

The

Interior light and display will go dark and remain so

until user resets mode - unit continues to operate

will appear in display

•

Close door to silence alert and reset

18

Page 19

QUICK START GUIDE

Control Operation

CLEAR ICE MACHINES

CONTROL FUNCTION GUIDE

FUNCTION COMMAND NOTES

ON/OFF Press and release Unit will immediately turn ON or OFF

Adjust ice thickness See “Ice” section

o

F / oC symbol will flash briefly after 5 seconds.

The

Interior light and display will go dark and remain so

until user resets mode - unit continues to operate

Enable Sabbath Mode

Press and hold for 5 seconds and

release

u-line.com

Disable Sabbath Mode Press and release Display and interior light return to normal operation

Silent Mode (ice

production suspended for

3 hours)

Clean Mode See “Cleaning” section

This unit is Star-K certified. See www.star-k.org for more details.

Hold

and Display will countdown the hours: 3H, 2H, 1H

19

Page 20

QUICK START GUIDE

Control Operation

CONVERTIBLE FREEZER

CONTROL FUNCTION GUIDE

FUNCTION COMMAND NOTES

ON/OFF Press and release Unit will immediately turn ON or OFF

u-line.com

Press and release to leave interior

Leave interior light on

Adjust Temperature Press or and release

o

Toggle between

Toggle between Freezer/

Refrigerator

Enable Sabbath Mode

Disable Sabbath Mode Press and release Display and interior light return to normal operation

This unit is Star-K certified. See www.star-k.org for more details.

DOOR ALERT NOTIFICATION

When the door is left open for more than 5 minutes:

F / oC Hold and for 5 seconds The display will change units

light on for 12 hours; press again to

deactivate

Hold for 5 seconds

Press and hold for 5 seconds and

release

After 12 hours, factory default is restored; light will

turn on when door is open

When the display is flashing, press or to

adjust the set point temperature. Note: temperature

displayed is the actual temperature inside unit

Unit will “beep” and display will show the default set

point for Refrigerator/Freezer

o

F / oC symbol will flash briefly after 5 seconds.

The

Interior light and display will go dark and remain so

until user resets mode - unit continues to operate

• A tone will sound for several seconds every minute

• will appear in display

Close door to silence alert and reset.

20

Page 21

QUICK START GUIDE

Control Operation

NUGGET ICE MACHINES

CONTROL FUNCTION GUIDE

FUNCTION COMMAND NOTES

ON/OFF Press and release Unit will immediately turn ON or OFF.

o

F / oC symbol will flash briefly after 5 seconds.

The

Interior light and display will go dark and remain so

until user resets mode - unit continues to operate.

Enable Sabbath Mode

Press and hold for 5 seconds and

release.

u-line.com

Disable Sabbath Mode Press and release. Display and interior light return to normal operation.

Clean Mode See “Cleaning” section

This unit is Star-K certified. See www.star-k.org

DOOR ALERT NOTIFICATION

When the door is left open for more than 30 minutes:

• Ice production will cease

• A tone will sound for several seconds every minute

• will appear in display

Close door to silence alert and reset (Ice production will resume if bin sensor is not satisfied)

for more details.

21

Page 22

QUICK START GUIDE

OFF

ON

u-line.com

First Use

CRESCENT ICE MAKERS

Initial startup requires no adjustments.

U-Line recommends discarding the ice produced

during the first two to three hours of operation

to avoid possible dirt or scale that may dislodge

from the water line.

To turn the unit on or off:

Press the rocker switch located inside the door on the

front panel, or behind the grille.

CONVERTIBLE FREEZER

Initial startup requires no adjustments. If the unit was

turned off, press and the unit will immediately switch

on. To turn off, press and release. See CONTROL

OPERATION section for more details.

Temperature displayed reflects actual

temperature inside unit.

If the temperature displayed is different than selected, the

unit is progressing towards the selected temperature. Time

to reach set point varies based upon ambient temperature,

temperature of product loaded, door openings, etc. U-Line

recommends allowing the unit to reach set point before

loading.

Approximate time required (empty unit) when converting

between refrigerator and freezer:

REFRIGERATORS

Initial startup requires no adjustments. If the unit was

turned off, press and hold for 5 seconds to turn unit

on. See “Control Operation” section for more details.

Temperature displayed reflects actual

temperature inside unit.

If the temperature displayed is different than selected, the

unit is progressing towards the selected temperature. Time

to reach set point varies based upon ambient temperature,

temperature of product loaded, door openings, etc. U-Line

recommends allowing the unit to reach set point before

loading.

• 38ºF to 0ºF - 1 hour

• 0ºF to 38ºF - 4 hours

CLEAR ICE AND NUGGET ICE MACHINES

Initial startup requires no adjustments. See CONTROL

OPERATION section for more details.

U-Line recommends discarding the ice produced

during the first two to three hours of operation

to avoid possible dirt or scale that may dislodge

from the water line.

When plugged in, the unit will begin operating under the

factory default settings. If the unit was turned off during

installation, simply press and the unit will immediately

switch on. To turn the unit off, press and release.

22

Page 23

QUICK START GUIDE

1

2

OFF

ON

u-line.com

Ice

CRESCENT ICE MAKERS

ICE MAKER OPERATION

When the ice bucket is full, the ice making mechanism will

shut off. However, the refrigeration system will continue

to cool and maintain the ice supply.

Do not place cans or bottles in the ice

compartment because they will freeze.

During periods of limited use or high ambient

temperatures, it is common for cubes to fuse together.

Gently shake the bucket to break apart cubes. If not using

the ice maker regularly, empty the ice bucket periodically

to ensure fresh cubes.

It is normal for cubes to appear cloudy. The cause is air

trapped in the water because of fast freezing. It is not

caused by the health, taste or chemical make up of the

water. It is the same air that is in every glass of water you

drink.

Remove the ice bucket for emptying and cleaning. To

remove the ice bucket, raise the bin arm and remove the

bucket from the ice compartment. Use the ice bucket for

ice storage only.

ICE MAKER ADJUSTMENT

Ice Cube Thickness Adjustment

Interval - As Required

To turn off ice production: Raise the bin arm into

an upright and locked position. The unit will preserve

temperature for ice storage.

If not intending to use the ice maker, turn the

water supply valve off. It is also important to

raise the bin arm of the ice maker (see above).

Failure to raise the bin arm may result in damage

to the water valve.

Certain sounds are normal during the unit’s operation. You

may hear the compressor or fan motor, the water valve,

or ice dropping into the ice bucket.

CAUTION

!

NEVER use an ice pick, knife or other sharp

instrument to separate cubes. Shake the ice

bucket instead.

On ice maker equipped models, adjust the cube size by

changing water amount injected into the ice maker

assembly as follows:

1. Remove the ice maker assembly cover (1).

2. Find the adjusting screw on the ice maker assembly

control box (2). The adjusting screw is just below the

minus (-) and plus (+) signs on the control box.

23

Page 24

QUICK START GUIDE

C

O

L

D

E

R

3

1

2

7/8"

7/8"

(22 mm)

CAUTION

!

u-line.com

CLEAR ICE MACHINES

Too large of an adjustment to the screw can

cause the water to overflow the ice maker and

can cause property damage.

3. Turn the adjusting screw toward the minus (-) sign

(clockwise) for smaller cubes or toward the plus (+)

sign (counterclockwise) for larger cubes.

4. Install the ice maker assembly cover.

ADJUSTING ICE HARVEST

1. Remove the front grille

2. Using a flat tip screwdriver, turn the adjusting screw

(3) a small increment clockwise for a COLDER setting

(slower ice production) or counterclockwise for a

WARMER setting (faster ice production).

ICE CUBE THICKNESS ADJUSTMENT

Ice thickness adjustment should only be made

one increment at a time. Allow ice maker

production to stabilize for 24 hours before

rechecking ice thickness.

Ice is produced in layers resulting in a clear cube. Ice in

bin may develop surface frost which disappears when cube

is placed in liquid.

Ice cubes in any given batch will vary, so it is necessary

to choose cubes from the sample area for comparison

when making adjustments.

The ice cube thickness is factory set for best overall

performance. The factory setting is designed to maintain

an ice bridge of approximately 1/16" to 1/8" (1.6 mm to

3.2 mm) under normal conditions, resulting in a dimple of

approximately 1/4" to 1/2" (6.4 mm to 12.7 mm) in

depth. A fuller cube with less of a dimple results in a

thicker ice bridge. As the ice bridge becomes thicker, the

tendency for the cubes to stay together as a slab

increases. A bridge thicker than 1/8" (3.2 mm) may cause

cubes to overfill the ice bucket.

Warmer Colder

3. Reinstall the front grille (two screws).

32 ice cubes are formed on a 4 x 8 slab during each cycle.

Each cycle takes approximately 15-20 minutes at the

default cube thickness (0).

(22 mm)

ICE BRIDGE

24

DIMPLES

Page 25

QUICK START GUIDE

THINNER BRIDGE

THICKER BRIDGE

DEEPER DIMPLE

SHALLOWER DIMPLE

1/4" TO 1/2"

(6.4 mm to 12.7 mm)

DIMPLE

1/16" TO 1/8"

(1.6 mm to 3.2 mm)

ICE BRIDGE

Cube Details

Factory Default Setting - 0

< 0

SETTING

> 0

SET

TING

u-line.com

Your clear ice machine is preset to produce ice between

the optimal dimensions illustrated below:

NUGGET ICE MACHINES

The Nugget Ice Machine produces cylindrical bits of

3

compressed ice approximately

/4” x 1/2”.

Ice is produced until the machine senses the bin is full. As

ice slowly melts in the bin, the level of ice drops and ice

production resumes. This ensures a constant supply of

fresh ice is always available.

Ice thickness adjustments are made using the control

panel as follows:

1. To enter the thickness adjustment mode:

• Press and hold for 5 seconds.

• The display will switch to “0” to confirm the

thickness adjustment mode has been selected.

The factory setting is “0”. Use to raise the setting and

thicken the ice bridge, or to lower the setting to thin

the ice bridge.

Ice cubes in any given batch will vary, so it is necessary

to choose cubes from the sample area for comparison

when making adjustments.

25

Page 26

QUICK START GUIDE

Evaporator cover

Standpipe

Evaporator

Water trough

u-line.com

Cleaning

CLEAR ICE MACHINE CLEANING CYCLE

Your U-Line clear ice machine has an automatic clean

alert function. Cleaning cycles should be run as notified.

Otherwise, to maintain operational efficiency the unit

should be cleaned every three months. Depending on

water conditions, more frequent cleaning may be

necessary. If the ice machine requires more frequent

cleaning, consult a plumber to test the water quality and

recommend appropriate treatment.

CAUTION

!

Wear rubber gloves and safety goggles and/or

face shield when handling Ice Machine Cleaner.

NOTICE

Use only U-Line Ice Machine Cleaner (Part No.

80-54081-00), available from your dealer or

direct from your local parts distributor. To locate

a parts distributor near you, visit u-line.com. It

is a violation of federal law to use this solution in

a manner inconsistent with its labeling. Use of

any other cleaner can ruin the finish of the

evaporator and will void the warranty. Read and

understand all labels printed on the package

before use.

CAUTION

!

Never use anything

to force ice from the

evaporator. Damage

may result.

1. Turn the ice

machine off and

allow any ice to melt

off of the

evaporator.

2. Remove all ice from the storage bin.

3. Remove evaporator cover.

4. Remove the standpipe by lifting it up while using a

slight back and forth motion to loosen it from the drain

hole. The water in the reservoir will flow down the

drain.

5. Re-install the standpipe into the water trough.

U-Line Ice Machine Cleaner is used to remove lime scale

and other mineral deposits. Refer to the following steps to

initiate the self-cleaning cycle.

6. Clean the Interior Bin as follows:

• Dilute one packet of U-Line Ice Machine Cleaner

into two quarts of water.

26

Page 27

QUICK START GUIDE

Brush

u-line.com

• Using a sponge or cloth, clean interior of ice bin,

tubing and door. This cleaner will remove all mineral

deposits and other contaminants from the surfaces.

• Using a bottle brush, clean out the trough drain tube

and pump tubing where needed.

7. Turn unit on by pressing

NOTICE

Discard all ice produced in the first harvest.

Should power to the unit be interrupted during

the self-clean cycle, it will be necessary to

repeat the complete cleaning cycle after power

is restored.

REFRESH KIT

Due to variations in water quality or inadequate

maintenance your unit may become excessively coated in

lime scale or calcium. U-Line offers a cost effective

refresh kit which replaces many interior components and

will return your unit to like new condition. Refresh kits

may be ordered from your local distributor and installed

by your local service company. For information on your

local distributor or service company please visit

www.u-line.com.

8. Place the unit into CLEAN mode by holding for

5 seconds.

9. When water begins flowing over the evaporator

(approximately 3 minutes), pour 1 packet of CLR

cleaner into the water trough. The cleaning process will

last approximately 45 minutes.

10.Dilute 1 tablespoon bleach in 1 gallon of warm water.

Apply this solution to the entire inside of the storage

area. Then rinse thoroughly with water.

The unit will resume operation approximately 15 minutes

after the automated cleaning process is completed. The

water fill valve will energize, fill the water reservoir, and

shut-off after three minutes. The compressor begins to

operate and water flows over the evaporator assembly (ice

mold). Initially, the water flow may not be uniform,

causing uneven sized cubes or water to spill into the ice

storage bin. This is a normal situation that will correct

itself within the first 24 hours of operation.

NUGGET ICE MACHINE CLEANING CYCLE

This ice machine has an automatic clean alert function.

The control will indicate

every six months with normal use, reminding you to clean

your unit. When

continue. Depending on water conditions, more frequent

cleaning may be necessary. Cleaning removes lime scale,

other mineral deposits, and sanitizes the machine. Poor

ice quality and reduced ice output are signs that cleaning

is necessary. If the machine consistently requires more

frequent cleaning, consult a plumber to test the water

quality and recommend appropriate treatment.

Under normal conditions cleaning should be

done when the display shows

initiate a cleaning cycle at any time by pressing

and holding the clean button for 10 seconds.

will appear in the display indicating the start of

the cleaning process.

CL is displayed, ice production will

CL in the display, approximately

CL. You may

0 1

27

Page 28

QUICK START GUIDE

Cl

Ice

Dispenser

Tube

Vent Tube

Cleaning Tube

and Funnel

u-line.com

You may override CL in the display without cleaning by

pressing and holding the up, down, & light button for 10

seconds.

reminder

month cycle. Failure to clean may reduce the quality and

quantity of ice produced. Once the clean cycle begins, it

can be canceled by pressing three times. Press once

more to start making ice. The clean cycle will

automatically cancel if user fails to activate control at

steps 2, 3b, and 5b within 2 hours.

Required for cleaning:

Need more cleaner? Visit u-line.com.

ICE will scroll in the display and the cleaning

(CL) will be reset for another approximate six

Hose and funnel – provided with unit

Bucket and cleaning sponge

Clean water

SafeCLEAN Plus™ Cleaner (Part No. 80-55266-00)

– included with unit

c. Remove all ice in bin

d. Remove any ice protruding from the ice dispenser

tube

e. Insert the end of the cleaning tube into the ice

dispenser; slowly pour in approximately 1 quart of

hot water. This will melt ice inside the dispenser

tube. It is normal for some water to flow out of

the ice dispenser tube and exit from the vent tube

while pouring. Omit this step if no ice is in the ice

dispenser tube.

CAUTION

!

Use only SafeCLEAN PlusTM Cleaner. Use of any

other cleaner may damage the finish of the

evaporator and will void the warranty.

Follow safety and handling instructions printed

on the SafeCLEAN Plus

NOTICE:

For 3 Class models only

remain in place during the cleaning process.

Cleaning Process (approximate time: 40 minutes)

TM

bottle.

: the water filter must

1. Press and Hold for 5 - 10 seconds

a. 0 1 will appear in the display

b. Remove access shield

2. Press and release

a.

02 will appear in the display

b. Mix 4 ounces of SafeCLEAN Plus™ with 2 quarts of

water

3. Wait until

a. Using the funnel and cleaning tube, slowly pour

3

tube. Air and some water will exit the vent tube.

Remove cleaning tube.

b. Press and release

4.

04 will appear in the display

a. The machine will circulate the solution, cleaning

and sanitizing the internal components, for

approximately 20 minutes

b. While the machine is circulating the cleaning

solution, use the remaining cleaning solution and a

sponge to wipe down the inside of the ice bin and

scoop. Rinse thoroughly with clean water

5. When

sound, indicating the cleaning phase is complete

a. Using the hose and funnel, slowly pour 1.5 quarts

(48 oz.) of clean water into the ice dispenser tube

Air and some water will exit the vent tube

03 appears in the display

/4 of the cleaning solution into the dispenser

05 appears in the display, 3 soft tones will

8

2

Page 29

QUICK START GUIDE

b. Press and release

6.

06 will appear in the display

a. Reinstall shield and close door - no further action is

required

b. The machine will circulate water and perform a

series of final rinses for approximately 15 minutes.

The unit will resume making ice - indicated by 3 soft

tones and

ICE scrolling in the display.

u-line.com

9

2

Page 30

U-Line Corporation (U-Line) Limited Warranty

One Year Limited Warranty

For one year from the date of original purchase, this U-Line product warranty covers all parts and labor to repair or replace any part of the

product that proves to be defective in materials or workmanship. For products installed and used for normal residential use, material

cosmetic defects are included in this warranty, with coverage limited to 60 days from the date of original purchase. All service provided by ULine under the above warranty must be performed by U-Line factory authorized service, unless otherwise specified by U-Line. Service

provided during normal business hours.

Available Second Year Limited Warranty

Beyond the standard one year warranty outlined above, U-Line offers an extension of the one year warranty coverage for an additional

second year from the date of purchase, free of charge. To take advantage of this second year warranty, you must register your product with

U-Line within two months from the date of purchase at u-line.com providing proof of purchase.

Five Year Sealed System Limited Warranty

For five years from the date of original purchase, U-Line will repair or replace the following parts, labor not included, that prove to be

defective in materials or workmanship: compressor, condenser, evaporator, drier, and all connecting tubing. All service provided by U-Line

under the above warranty must be performed by U-Line factory authorized service, unless otherwise specified by U-Line. Service provided

during normal business hours.

Terms

These warranties apply only to products installed in any one of the fifty states of the United States, the District of Columbia, or the ten

provinces of Canada. The warranties do not cover any parts or labor to correct any defect caused by negligence, accident or improper use,

maintenance, installation, service, repair, acts of God, fire, flood or other natural disasters. The product must be installed, operated, and

maintained in accordance with the U-Line User Guide.

The remedies described above for each warranty are the only ones that U-Line will provide, either under these warranties or under any

warranty arising by operation of law. U-Line will not be responsible for any consequential or incidental damages arising from the breach of

these warranties or any other warranty, whether express, implied, or statutory. Some states do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation or exclusion may not apply to you. These warranties give you specific legal

rights, and you may also have other rights which vary from state to state.

Any warranty that may be implied in connection with your purchase or use of the product, including any warranty of merchantability or any

warranty fit for a particular purpose is limited to the duration of these warranties, and only extends to five years in duration for the parts

described in the section related to the five year limited warranty above. Some states do not allow limitations on how long an implied warranty

lasts, so the above limitations may not apply to you.

• The warranties only apply to the original purchaser and are non-transferable.

• The second year and five year warranties cover products installed and used for normal residential or designated marine use only.

• The warranties apply to units operated outside only if designed for outdoor use by model and serial number.

• Replacement water filters, light bulbs, and other consumable parts are not covered by these warranties.

• The start of U-Line’s obligation is limited to four years after the shipment date from U-Line.

• In-home instruction on how to use your product is not covered by these warranties.

• Food, beverage, and medicine loss are not covered by these warranties.

• If the product is located in an area where U-Line factory authorized service is not available, you may be responsible for a trip charge

or you may be required to bring the product to a U-Line factory authorized service location at your own expense.

• Units purchased after use as floor displays, and/or certified reconditioned units, are covered by the limited one year warranty only and

no coverage is provided for cosmetic defects

• Signal issues related to Wi-Fi connectivity are not covered by these warranties.

For parts and service assistance, or to find U-Line factory authorized service near you, contact U-Line:

8900 N. 55th Street, Milwaukee, WI 53223 • u-line.com • onlineservice@u-line.com • +1.800.779.2547

Copyright © 2014/2017 U-Line Corporation. All Rights Reserved. | Publication Number 30379 | 08/2018 Rev. M

30

Loading...

Loading...