Page 1

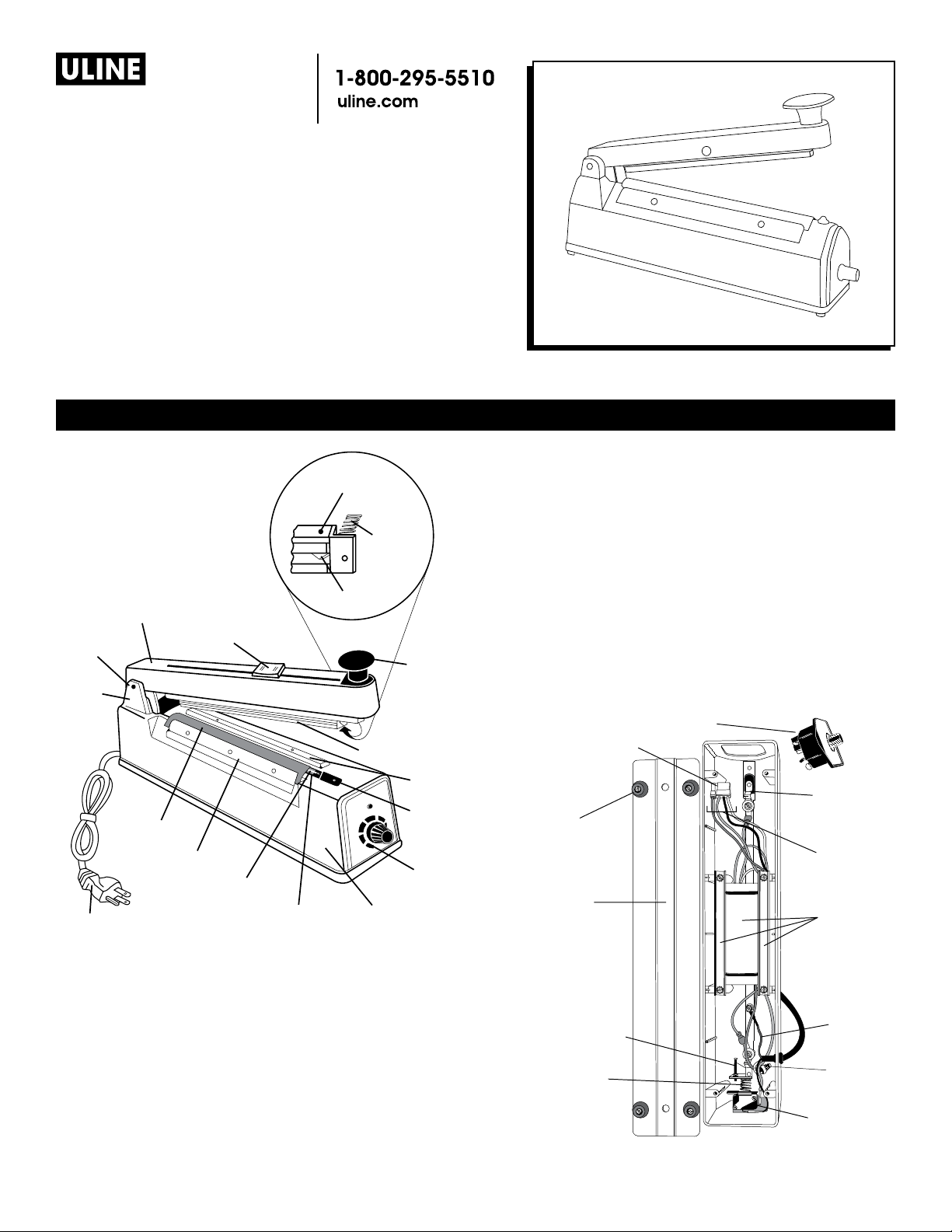

H-161, H-163, H-190

BOTTOM VIEW

Timer Assembly

H-293, H-306, H-458

H-963, H-1029, H-1252

Impulse sealers

Para Español, vea páginas 5-8.

Pour le français, consulter les pages 9-12.

PARTS

Sealing Arm

Hinge Pin

Hinge

Bracket

Power Cord

Bracket Assembly

Teflon Cover

Front Metal Plate

Heating Element

SEALING ARM

(H-161, H-293, H-963

and H-1252 only)

Cutting Blade

(H-161, H-293, H-963

and H-1252 only)

Lower Teflon Tape

Pressure Plate

Assembly

Pressure

Plate

Spring

Cutting Blade

Rubber Pressure Pad

π

5

4

3

2

1

Sealer Body

Handle Knob

Rear Metal

Plate

Heating

6

Element

Cover

Timer Assembly

Timer Connector

Plug

Rubber Foot

Base Plate

Bow

Spring

Assembly

Internal

Wiring

Transformer

& Support

Brackets

Microswitch

Adjustment

Screw

Arm Return

Ground

Wire

(green)

Wire Nut

Spring

Microswitch

Assembly

PAGE 1 OF 12 0314 IH-161

Page 2

OPERATING INSTRUCTIONS

1. Plug the power cord into the outlet and set the timer

knob to the thickness of the materials to be sealed.

(See Recommended Settings Table)

2. Put poly bag on the sealing platform and push down

the sealing arm. The sealer will automatically control

the seal time.

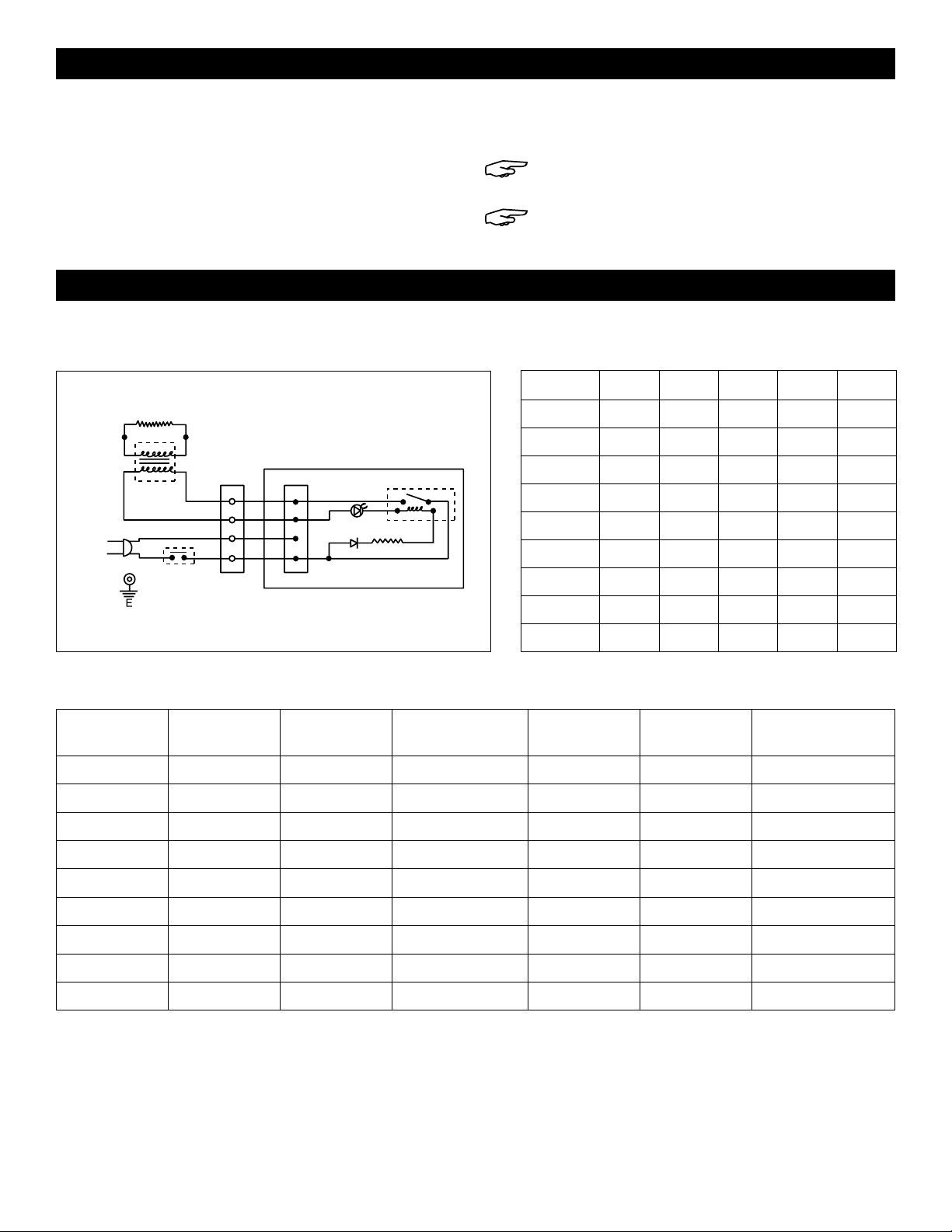

SPECIFICATIONS

Heating Element

Transformer

Relay DC24V

Sealing Light

D

Timer

R

Source

N

L

Microswitch

Connector

Control P.C.B

3. After 1 to 2 seconds, slide the cutter to trim the bag.

(Only on H-161 and H-293) Release the sealing arm.

NOTE: The higher the number on the dial, the

longer the heat sealing time.

NOTE: Sealing is complete when the light

turns off.

RECOMMENDED SETTINGSCONNECTION DIAGRAM

SEALER 1 MIL 2 MIL 3 MIL 4 MIL 6 MIL

H-161 3 3 3 4 5

H-163 3 3 3 4 5

H-190 3 3 3.5 4 5.5

H-293 3 3 3.5 4 5.5

H-306 3 3 3.5 4 5.5

H-458 3 3 3 4 5

H-963 3 3 3.5 4 5

H-1029 3 3 3.5 4 5.5

H-1252 3 3 3.5 4 5

SEALER SPECIFICATIONS

MODEL SOURCE IMPULSE

POWER

H-161 120 V 410 W 8" 6 Mil 7.7 lb s . 3.2 x 15 x 6.3"

H-163 120 V 410 W 8" 6 Mil 5.8 lbs. 3.2 x 12.6 x 5.9"

H-190 120 V 580 W 12" 6 Mil 8.5 lbs. 3.3 x 17.8 x 7.4"

H-293 120 V 580 W 12 " 6 Mil 10.1 lbs. 3.2 x 17.9 x 7.4"

H-306 120 V 670 W 16" 6 Mil 9.9 lbs. 3 x 21 x 7"

H-458 120 V 160 W 4" 6 Mil 3.7 lbs. 2.8 x 8.3 x 5.9"

H-963 120 V 670 W 16" 6 Mil 11.9 l b s . 3.2 x 21.8 x 7.3"

H-1029 120 V 870 W 20" 6 Mil 13 l bs. 4.5 x 28 x 7.8"

H-1252 120 V 870 W 20" 6 Mil 13 lb s. 3.2 x 25.9 x 7.4"

MAX. SEAL

LENGTH

MAX. SEAL

THICKNESS

WEIGHT DIMENSIONS

PAGE 2 OF 12 0314 IH-161

Page 3

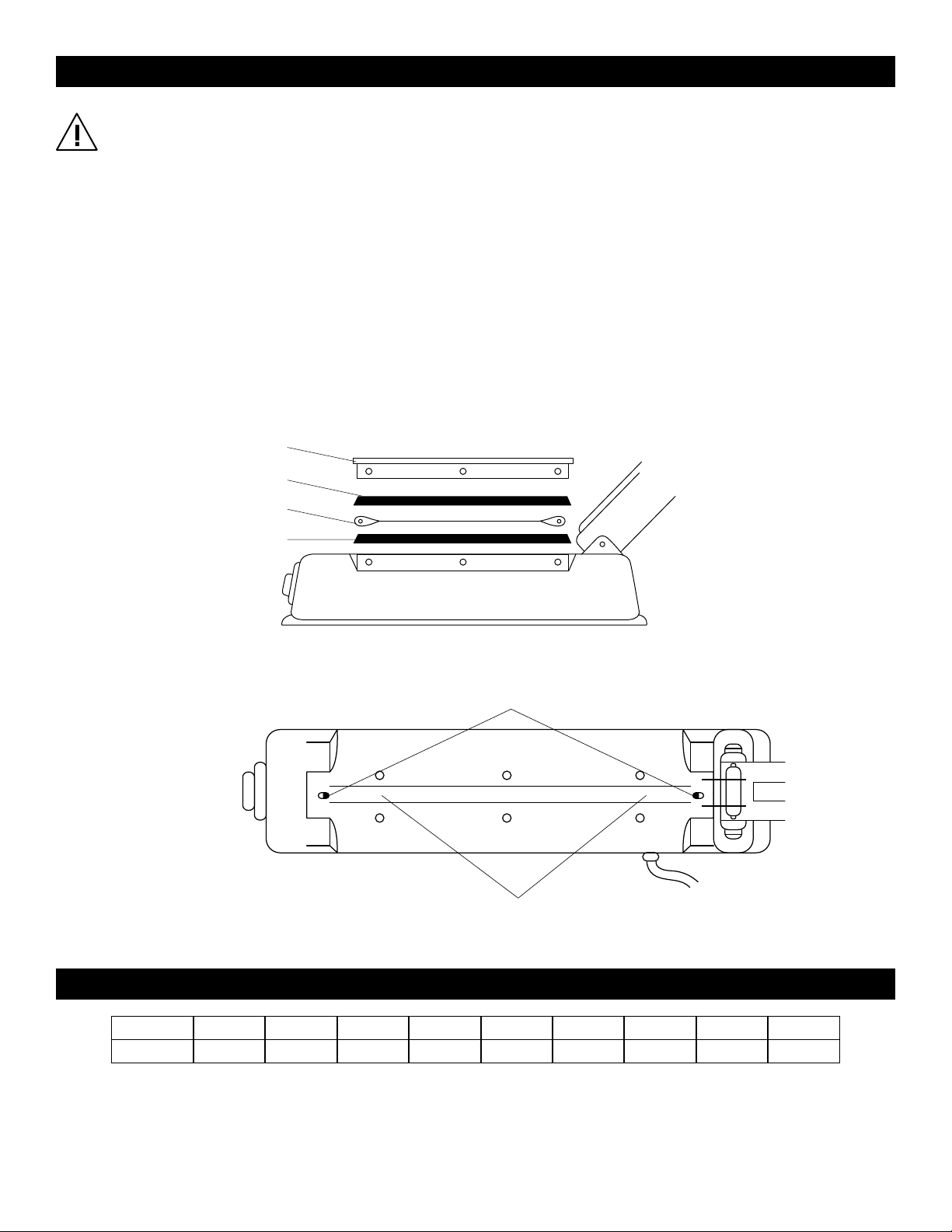

TAPE AND HEATING ELEMENT REPLACEMENT INSTRUCTIONS

CAUTION! Unplug sealer from socket before

proceeding.

1. Remove screws along with the cover plates (A)

and top teflon cover (B). Remove element (C) from

terminal posts. (See Figure 1)

2. If bottom adhesive teflon tape (D) is worn, burned or

ripped, it needs to be changed. Teflon tape keeps

the element insulated from the sealer housing to

ensure proper sealer operation. (See Figure 1)

If this tape is not worn, go to step 5.

3. After removal of metal cover plates, teflon tapes

and element, clean sealing surface (E) with cleaner

until free of glue and debris. Adhesive remover is

recommended. (See Figure 2)

A

B

C

D

4. Peel off backing of adhesive teflon tape. Apply

evenly onto sealer. Excess tape should extend all

the way to the terminal posts (F). If the element

touches any metal, the sealer will short out.

(See Figure 2)

5. Attach new heating element.

6. Reassemble in reverse of step 1. Teflon cover must

be flush against the sealer before replacing cover

plates.

SIDE VIEW

MODEL

REPAIR KIT

Figure 1

F

TOP VIEW

Figure 2

E

REPLACEMENT PARTS

H-161 H-163 H-190 H-293 H-306 H-458 H-963 H-1029 H-1252

H-495 H-164 H-191 H-294 H-307 H-471 H-964 H-1042 H -1253

PAGE 3 OF 12 0314 IH-161

Page 4

ADDITIONAL INFORMATION

• Always keep the sealing platform clean.

• Do not use water to clean the sealing platform.

• A short circuit will occur if the bottom teflon cloth

strip wears out. Each time you replace the heating

element or the top teflon cover, check the bottom

teflon tape for wear and damage.

• Only use ULINE replacement parts.

• A worn rubber pressure pad (under the handle) will

influence the quality of the seats. The rubber pad

should be periodically checked for uneven wear.

CAUTION! To provide continued protection

against risk of electric shock, connect to

properly grounded outlets only.

• If the bag seal is damaged or broken, it is because

the heating time is too long. Reset the timer knob to a

lower number.

• If the plastic bag sticks to the sealing arm, it was

because there was not enough cooling time. Keep

the arm down for a longer period of time after the

light turns off.

• It is okay to leave the unit plugged in. The unit is off

unless the sealing arm is down.

• Information regarding potential risks of fire, electric

shock, or injury to persons that are capable of

occurring due to use of the product. The instructions

shall caution the user to place the product and

connected cord so that it is not likely that the product

will be overturned.

• Information regarding the potential risks of electric

shock due to overfilling, the replacement of a lamp,

or cleaning the product without disconnecting the

power-supply cord.

• Instructions regarding the cleaning of the product,

including any necessity for disassembly (and

reassembly).

• Close supervision is required when this product is used

near children.

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-800-295- 5510

PAGE 4 OF 12 0314 IH-161

uline.com

Page 5

H-161, H-163, H-190

π

2

1

3

4

5

6

Brazo de Sellado

Ensamble del

Soporte de la

Navaja de Corte

(H-161, H-293, H-963 y

H-1252 solamente)

Perilla de la Asa

VISTA INFERIOR DEL

BRAZO DE SELLADO

(H-161, H-293, H-963 y

H-1252 solamente)

Almohadilla de

Goma de Presión

Placa de

Metal Posterior

Ensamble del

Temporizador

Cuerpo de la

Selladora

Resistencia

Placa de Metal Frontal

Cubierta de Teflón

Cable

Pasador

de Bisagra

Soporte

de Bisagra

Cinta Inferior

de Teflón

Cubierta de

la Resistencia

Ensamble de la

Placa de Presión

Resorte de

la Placa de

Presión

Navaja de Corte

Ensamble del

H-293, H-306, H-458

H-963, H-1029, H-1252

SELLADORAS

DE IMPULSO

01-80 0 -295-5510

uline.mx

PARTES

Enchufe del

Temporizador

Pata de Goma

Placa de

la Base

Tornillo de

PAGE 5 OF 12 0314 IH-161

Ajuste del

Microinterruptor

Resorte

del Brazo

Temporizador

Ensamble

del Resorte

Cableado

Interno

Transformador

y Soportes

Cable

de Tierra

(verde)

Tuerca

para Cable

Ensamble del

Microinterruptor

Page 6

FUNCIONAMIENTO

1. Enchufe el cable al tomacorriente y configure el

temporizador de acuerdo al material que va a sellar.

(Vea Tabla de Configuraciones Recomendadas)

2. Coloque una bolsa de polietileno en la plataforma

de sellado y presione hacia abajo el brazo de

sellado. La selladora automáticamente controlará

el tiempo de sellado.

ESPECIFICACIONES

DIAGRAMA DE CONEXIÓN

Resistencia

Transformador

Relevador DC24V

Luz de Sellado

D

Temporizador

R

Fuente

N

L

Microinterruptor

Conector

Control P.C.B.

3. Después de 1 a 2 segundos, deslice la navaja para

cortar la bolsa (solo en H-161 y H-293). Libere el brazo

de sellado.

NOTA: Mientras mayor sea el número en

el temporizador, mayor será el tiempo del

termosellado.

NOTA: El sellado termina cuando la luz se apaga.

CONFIGURACIONES RECOMENDADAS

SELLADORA 1 MIL 2 MIL 3 MIL 4 MIL 6 MIL

H-161 3 3 3 4 5

H-163 3 3 3 4 5

H-190 3 3 3.5 4 5.5

H-293 3 3 3.5 4 5.5

H-306 3 3 3.5 4 5.5

H-458 3 3 3 4 5

H-963 3 3 3.5 4 5

H-1029 3 3 3.5 4 5.5

ESPECIFICACIONES DE LA SELLADORA

MODELO FUENTE POTENCIA DE

IMPULSO

H-161 120 V 410 W 20 cm (8") 6 Mil 3.5 kg (7.7 lbs.) 8.1 x 38.1 x 16 cm

H-163 120 V 410 W 20 cm (8") 6 Mil 2.6 kg (5.8 lbs.) 8.1 x 32 x 15 cm

H-190 120 V 580 W 30 cm (12") 6 Mil 3.9 kg (8.5 lbs.) 8.4 x 45.2 x 18.8 cm

H-293 120 V 580 W 30 cm (12") 6 Mil 4.6 kg (10.1 lbs.) 8.1 x 45.5 x 18.8 cm

H-306 120 V 670 W 40 cm (16") 6 Mil 4.5 kg (9.9 lbs.) 7.6 x 53.3 x 17.8 cm

H-458 120 V 160 W 10 cm (4") 6 Mil 1.7 kg (3.7 lbs.) 7.1 x 21.1 x 15 cm

H-963 12 0 V 670 W 40 cm (16") 6 Mil 5.4 kg (11.9 lbs.) 8.1 x 55.4 x 18.5 cm

H-1029 120 V 870 W 52 cm (20") 6 Mil 5.9 kg (13 lbs.) 11.4 x 71.1 x 19.8 cm

LARGO MÁX. DE

SELLADO

H-1252 3 3 3.5 4 5

GROSOR MÁX.

PESO DIMENSIONES

DE SELLADO

(3.2 x 15 x 6.3")

(3.2 x 12.6 x 5.9")

(3.3 x 17.8 x 7.4")

(3.2 x 17.9 x 7.4")

(3 x 21 x 7")

(2.8 x 8.3 x 5.9")

(3.2 x 21.8 x 7.3")

(4.5 x 28 x 7.8")

H-1252 120 V 870 W 52 cm (20") 6 Mil 5.9 kg (13 lbs.) 8.1 x 25.8 x 18.8 cm

PAGE 6 OF 12 0314 IH-161

(3.2 x 25.9 x 7.4")

Page 7

INSTRUCCIONES PARA CAMBIO DE CINTA Y RESISTENCIA DE REPUESTO

¡PRECAUCIÓN! Desconecte la selladora del

enchufe antes de proceder.

1. Retire los tornillos a lo largo con las placas de la

cubierta (A) y la cubierta superior de teflón (B).

Retire la resistencia (C) de los postes terminales.

(Vea Diagrama 1)

2. Si la cinta adhesiva de teflón inferior (D) está

desgastada, quemada o rota, necesita cambiarse.

La cinta de teflón mantiene aislada la resistencia

de la cubierta de la selladora para asegurar el

funcionamiento adecuado de la selladora. (Vea

Diagrama 1) Si esta cinta no está desgastada, vaya

al paso 5.

A

B

C

D

3. Después de retirar las placas de metal de la

cubierta, cintas de teflón y resistencia, limpie la

superficie de sellado (E) con limpiador hasta quedar

libre de pegamento y residuos. Se recomienda un

removedor de adhesivo. (Vea Diagrama 2)

4. Despegue el respaldo de la cinta adhesiva de

teflón. Aplique de manera uniforme encima de la

selladora. El exceso de cinta deberá extenderse a

hasta llegar a los postes terminales (F). Si la

resistencia toca cualquier metal, la selladora hará

corto circuito. (Vea Diagrama 2)

5. Coloque una nueva resistencia.

6. Ensamble de nuevo a la inversa del paso 1. La

cubierta de teflón debe quedar al ras de la selladora

antes de reemplazar las placas de la cubierta.

VISTA LATERAL

MODELO

KIT DE REPARACIÓN

Diagrama 1

F

VISTA SUPERIOR

Diagrama 2

E

PARTES DE REPUESTO

H-161 H-163 H-190 H-293 H-306 H-458 H-963 H-1029 H -1252

H-495 H-164 H-191 H-294 H-307 H-471 H-964 H-1042 H-1253

PAGE 7 OF 12 0314 IH-161

Page 8

INFORMACIÓN ADICIONAL

• Siempre mantenga la plataforma de sellado limpia.

• No utilice agua para limpiar la plataforma de sellado.

• Si la tira inferior de teflón está desgastada

ocasionará un cortcircuito. Cada vez que

reemplace la resistencia o la cubierta superior de

teflón, revise la cinta inferior de teflón para ver si

está desgastada o dañada.

• Solamente utilice partes de repuesto ULINE.

• Si la almohadilla de goma de presión (abajo del

brazo) está desgastada esta afectará la calidad

del sellado. La almohadilla de goma debe ser

revisada periódicamente por desgaste.

PRECAUCIÓN: Para proveer protección

continua contra el riesgo de una descarga

eléctrica, conecte solo a tomacorrientes

aterrizados correctamente.

• Si se daña o rompe el sellado de la bolsa, es porque

el tiempo de sellado es muy prolongado. Reconfigure

el temporizador en un número menor.

• Si la bolsa de plástico se adhiere al brazo de sellado,

es porque no tuvo tiempo suficiente de enfriamiento.

Deje el brazo abajo por un periodo mayor de tiempo

después de que la luz se apague.

• Está bien dejar la unidad conectada. La unidad

está apagada a menos que el brazo de sellado esté

abajo.

• Información referente a los riesgos potenciales de

incendio, choque eléctrico, o lesiones a las personas

que pudieran ocurrir debido al uso del producto. Las

instrucciones deben advertir al usuario para colocar

el producto y conectar el cable de manera que el

producto no se voltee.

• Información referente a los riesgos potenciales

de choque eléctrico debido al llenado excesivo,

reemplazar una luz, o limpiar el producto sin

desconectar el cable.

• Instrucciones referentes a la limpieza del producto,

incluyendo cualquier necesidad de desarmarlo (y

ensamblarlo de nuevo).

• Requiere supervisión directa cuando este producto

sea utilizado cerca de niños.

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

01-800-295-5510

PAGE 8 OF 12 0314 IH-161

uline.mx

Page 9

H-161, H-163, H-190

Montage de

H-293, H-306, H-458

H-963, H-1029, H-1252

SoudeuSe à impulSion

1-800-295-5510

uline.ca

PIÈCES

VUE DU DESSOUS

BRAS DE SOUDAGE

(H-161, H-293, H-963

et H-1252 uniquement)

Lame de coupe

Montage du support

(H-161, H-293, H-963

et H-1252 uniquement)

Bras de soudage

Axe de

charnière

Charnière

Support

Protection

en téflon

Plaque

métallique

avant

Cordon d’alimentation

Plaque de

pression Montage

Lame de coupe

π

4

3

2

Élément

chauffant

Corps soudant

Ruban en téflon inférieur

Ressort de

la plaque

de pression

Bouton de

la poignée

Tampon de

pression en

caoutchouc

Plaque

métallique

arrière

5

6

Élément

1

chauffant

couvercle

Montage de

la minuterie

Connecteur de

minuterie prise

Pied en

caoutchouc

Plaque

de base

Microrupteur

Réglage vis

la minuterie

Arc ressort

montage

Câblage interne

Transformateur

et supports

Filde mise

à la terre

(vert)

Rappel de

bras ressort

Connecteur

de fils

Microrupteur

Montage

PAGE 9 OF 12 0314 IH-161

Page 10

INSTRUCTIONS D’UTILISATION

1. Branchez le cordon d’alimentation et réglez le bouton

de la minuterie selon l’épaisseur des matériaux à

souder. (Voir le tableau des paramètres recommandés)

2. Mettez le sac de polyéthylène sur la plateforme de

soudage et abaissez le bras de soudage. La soudeuse

contrôle automatiquement le temps de soudage.

SPÉCIFICATIONS

Élément chauffant

Transformateur

Relais 24V c.c.

Voyant de soudage

D

Minuterie

R

Source

N

L

Microrupteur

Connecteur

Contrôle P.C.B

3. Après 1 à 2 secondes, faites glisser le dispositif de

coupe pour découper le sac. (Seulement sur H-161 et

H-293) Desserrez le bras de soudage.

REMARQUE : Plus le chiffre sur le cadran est

important, plus la durée de soudage thermique

est longue.

REMARQUE : Le soudage est terminé lorsque le

voyant s’éteint.

PARAMÈTRES RECOMMANDÉSSCHÉMA DE RACCORDEMENT

SOUDEUSE 1 MIL 2 MIL 3 MIL 4 MIL 6 MIL

H-161 3 3 3 4 5

H-163 3 3 3 4 5

H-190 3 3 3.5 4 5.5

H-293 3 3 3.5 4 5.5

H-306 3 3 3.5 4 5.5

H-458 3 3 3 4 5

H-963 3 3 3.5 4 5

H-1029 3 3 3.5 4 5.5

H-1252 3 3 3.5 4 5

SPÉCIFICATIONS DE LA SOUDEUSE

MODÈLE SOURCE PUISSANCE

D’IMPULSION

H-161 120 V 410 W 20 cm (8 po) 6 Mil 3,5 kg (7,7 lbs.) 8,1 x 38,1 x 16 cm

H-163 120 V 410 W 20 cm (8 po) 6 Mil 2,6 kg (5,8 lbs.) 8,1 x 32 x 15 cm

H-190 120 V 580 W 30 cm (12 po) 6 Mil 3,9 kg (8,5 lbs.) 8,4 x 45,2 x 18,8 cm

H-293 120 V 580 W 30 cm (12 po) 6 Mil 4,6 kg (10,1 lbs.) 8,1 x 45,5 x 18,8 cm

H-306 120 V 670 W 40 cm (16 po) 6 Mil 4,5 kg (9,9 lbs.) 7,6 x 53,3 x 17,8 cm

H-458 120 V 160 W 10 cm (4 po) 6 Mil 1,7 kg (3,7 lbs.) 7,1 x 21,1 x 15 cm

H-963 12 0 V 670 W 40 cm (16 po) 6 Mil 5,4 kg (11,9 lbs.) 8,1 x 55,4 x 18,5 cm

H-1029 12 0 V 870 W 52 cm (20 po) 6 Mil 5,9 kg (13 lbs.) 11,4 x 71,1 x 19,8 cm

H-1252 120 V 870 W 52 cm (20 po) 6 Mil 5,9 kg (13 lbs.) 8,1 x 25,8 x 18,8 cm

MAX. LONGUEUR

DE LA SOUDURE

MAX. ÉPAISSEUR

DE LA SOUDURE

POIDS DIMENSIONS

(3,2 x 15 x 6,3 po)

(3,2 x 12,6 x 5,9 po)

(3,3 x 17,8 x 7,4 po)

(3,2 x 17,9 x 7,4 po)

(3 x 21 x 7 po)

(2,8 x 8,3 x 5,9 po)

(3,2 x 21,8 x 7,3 po)

(4,5 x 28 x 7,8 po)

(3,2 x 25,9 x 7,4 po)

PAGE 10 OF 12 0314 IH-161

Page 11

INSTRUCTIONS POUR LE REMPLACEMENT DU RUBAN ET DE L’ÉLÉMENT CHAUFFANT

MISE EN GARDE! Débranchez la soudeuse de la

prise de courant avant de procéder.

1. Retirez les vis ainsi que les plaques de protection

(A) et la protection en téflon supérieure (B). Retirez

l’élément (C) des bornes de branchement.

(Voir figure 1)

2. Si le ruban adhésif en téflon inférieur (D) est usé,

brûlé ou déchiré, il doit être changé. Le ruban en

téflon isole l’élément du boîtier de la soudeuse pour

assurer le bon fonctionnement de la soudeuse.

(Voir Figure 1) Si cette bande n’est pas usée, passez

à l’étape 5.

3. Après avoir retiré les plaques de protection

métalliques, les rubans en téflon et l’élément,

nettoyez la surface de soudage (E) avec un

nettoyant jusqu’à l’élimination de la colle et des

débris. Un dissolvant d’adhésif est recommandé.

(Voir figure 2)

A

B

4. Retirez la pellicule protectrice du ruban adhésif en

téflon. Appliquez uniformément sur la soudeuse. Le

ruban en excès doit s’étendre jusqu’aux bornes de

branchement (F). Si l’élément entre en contact avec

quoi que ce soit de métallique, la soudeuse se

court-circuite. (Voir figure 2)

5. Fixez le nouvel élément chauffant.

6. Remontez dans le sens inverse de l’étape 1. Il faut

niveler la protection en téflon contre la soudeuse

avant de replacer les plaques de protection.

VUE LATÉRALE

C

D

Figure 1

Figure 2

F

VUE DE

DESSUS

E

PIÈCES DE RECHANGE

MODÈLE

TROUSSE DE

RÉPARATION

PAGE 11 OF 12 0314 IH-161

H-161 H-163 H-190 H-293 H-306 H-458 H-963 H-1029 H -1252

H-495 H-164 H-191 H-294 H-307 H-471 H-964 H-1042 H-1253

Page 12

RENSEIGNEMENTS SUPPLÉMENTAIRES

• Veillez à ce que la plateforme de soudage soit

toujours propre.

• N’utilisez pas d’eau pour nettoyer la plateforme de

soudage.

• En cas d’usure de la bande inférieure de tissu en

téflon, un court-circuit se produit. Chaque fois que

vous remplacez l’élément chauffant ou la protection

en téflon supérieure, vérifiez que le ruban en téflon

inférieur n’est ni usé ni endommagé.

• Utilisez uniquement des pièces de rechange ULINE.

• Un tampon de pression en caoutchouc usé (sous

la poignée) influera sur la qualité des soudures. Le

tampon en caoutchouc doit être vérifié régulièrement

afin de repérer les usures irrégulières.

MISE EN GARDE! Pour garantir une protection

continue contre les risques d’électrocution, ne

branchez qu’à une prise mise correctement à la

terre.

• Si la soudure du sac est endommagée ou cassée,

cela signifie que le temps de chauffage est trop

long. Réglez le bouton de la minuterie sur un nombre

inférieur.

• Si le sac en plastique colle au bras de soudage,

cela signifie que le temps de refroidissement n’est

pas assez long. Maintenez le bras vers le bas plus

longtemps une fois le voyant éteint.

• L’unité peut rester branchée. L’unité est éteinte à moins

que le bras de soudage ne soit vers le bas.

• Renseignements concernant les risques d’incendie,

d’électrocution ou de blessures aux personnes

susceptibles de se produire lors de l’utilisation du

produit. Les instructions doivent avertir l’utilisateur de

placer le produit et le cordon branché de sorte que

le produit ne risque pas d’être renversé.

• Renseignements concernant les risques

d’électrocution dus à un remplissage excessif, au

remplacement d’une lampe ou au nettoyage du

produit sans débrancher le cordon d’alimentation.

• Instructions concernant le nettoyage du produit,

y compris tout besoin de démontage (et de

remontage).

• Une surveillance étroite est nécessaire lorsque ce

produit est utilisé à proximité d’enfants.

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-800-295- 5510

PAGE 12 OF 12 0314 IH-161

uline.ca

Loading...

Loading...