Page 1

Para Español, vea páginas 8-14.

Pour le français, consulter les pages 15-21.

π H-951

SHRINK TUNNEL

1-800-295-5510

uline.com

SPECIFICATIONS

MACHINE SPECIFICATIONS

MODEL PP 1606-20

Chamber Size Width: 16"

Height: 6"

Length: 20"

Volts 110

Amperage 20

Phase Si ng le 1/0

Weight 250 lbs.

PLACEMENT:

Determine where to place the shrink tunnel. Here are

some things to keep in mind:

• A power source with low voltage protection.

Machine will not operate properly if voltage is

too low.

• Avoid drafty areas. Heat may be drawn away from

machine and affect performance.

WARNING! Only authorized or trained

personnel should operate the Shrink Tunnel.

Do not tamper with electrical wiring. Always

switch off machine and disconnect power

before maintenance, cleaning or repairs.

Keep hands away from moving conveyors and

other moving parts.

DO NOT operate this machine without all

covers and guards in place. Severe injury may

result.

Heat-sealing arms and jaws become hot

after a period of use. Keep hands away while

machine is in operation.

Do not modify this machine in any way.

Modifying the Shrink Tunnel will void any

warranties.

Some plastic films used for sealing and

shrinking may release hazardous fumes

at high temperatures. Provide adequate

ventilation at all times.

Unplug the Shrink Tunnel when not in use.

IMPORTANT! Read this manual carefully

to familiarize yourself with the controls

and operation of this Shrink Tunnel before

installation or use. Keep this manual in a safe

place for future reference.

PAGE 1 OF 21 0421 IH-951

Page 2

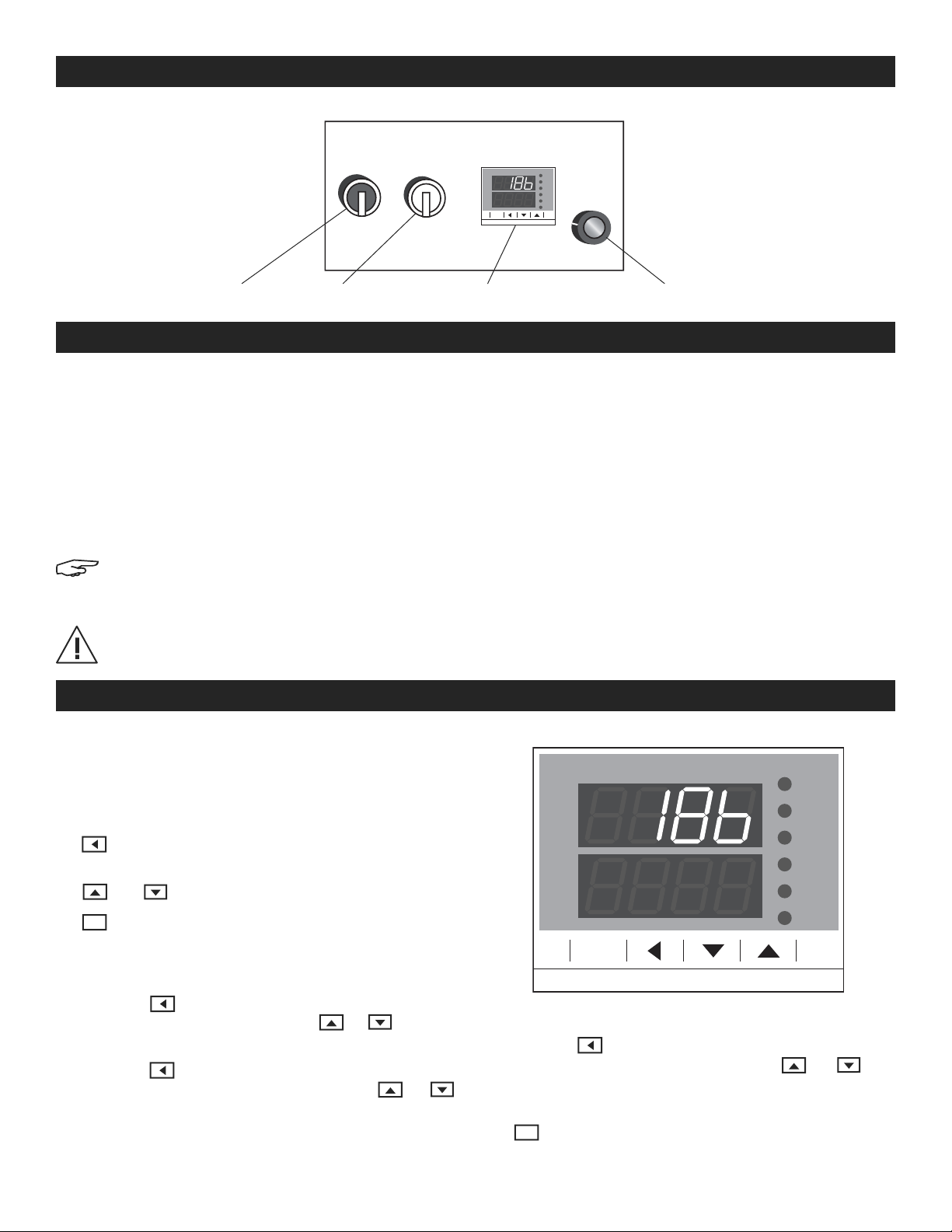

OPERATOR CONTROLS

POWER

Power Switch Heater Switch Temperature Control Conveyor Speed Control

HEATER

ONOFF

ONOFF

TEMPERATURE

PV

SV

SET

TARE FY400

OUT2

AT

AL1

CONVEYOR

AL2

PRO

3

4

2

1

OPERATION

1. Cut the two strappings from rollers prior to first use.

2. Turn power switch on. This starts machine and cooling fan.

3. Turn heater switch on. This starts the blower, conveyor motors and heater.

4. Set conveyor speed. Set the conveyor knob between 1 and 3 until user determines the exact conveyor speed

needed, based on package size and sealer speed. Factory setting is 2.

5. Set shrink temperature. Use the temperature control to set desired temperature. Adjust the temperature higher or

lower as needed. Machine requires about 30 minutes to reach the set temperature. Factory setting is 325ºF.

NOTE: The appropriate conveyor speed and heat setting for shrink wrapping your product will vary based

on type, thickness and brand of shrink film. We recommend shrink wrapping with the manufacturer settings

first and adjusting to suit needs.

CAUTION! When turning the tunnel off, remember to turn off heater switch FIRST. The tunnel automatically

shuts off at about 180ºF. Then user can turn the power switch OFF.

TEMPERATURE CONTROL

1. PV (Present Value) = Shows current operating

temperature of the machine.

2. SV (Set Value) = Shows the temperature you set for the

PV

machine.

3. Moves indicator on SV display so you can set the

temperature.

SV

4. and adjust the number up or down

SET

5. Set button selects the temperature as the set

value.

TO ADJUST THE SET TEMPERATURE:

SET

TARE FY400

1. Press the key. SV display flashes in 1st column.

While number is flashing, use the or keys to

your first desired number

2. Press the key to move the indicator 1 place to

the left. While number is flashing, use the or

keys to your second desired number.

3. Press the key to move the indicator 1 place to the

left. While number is flashing, use the or

keys to your third desired number.

4. Once the desired temperature is displayed, press the

SET

key. This saves the temperature you entered as

the Set Temperature.

PAGE 2 OF 21 0421 IH-951

OUT1

OUT2

AT

AL1

AL2

PRO

Page 3

MAINTENANCE

To keep the Shrink Tunnel operating efficiently perform

the following:

• Monthly – Lubricate the conveyor chains with high

temperature oil. Apply with a brush or spray with

conveyor running slowly.

• Regularly inspect the silicone covering on the tunnel

rollers. Make sure no film is wrapped around rollers,

this could cause packages to stick.

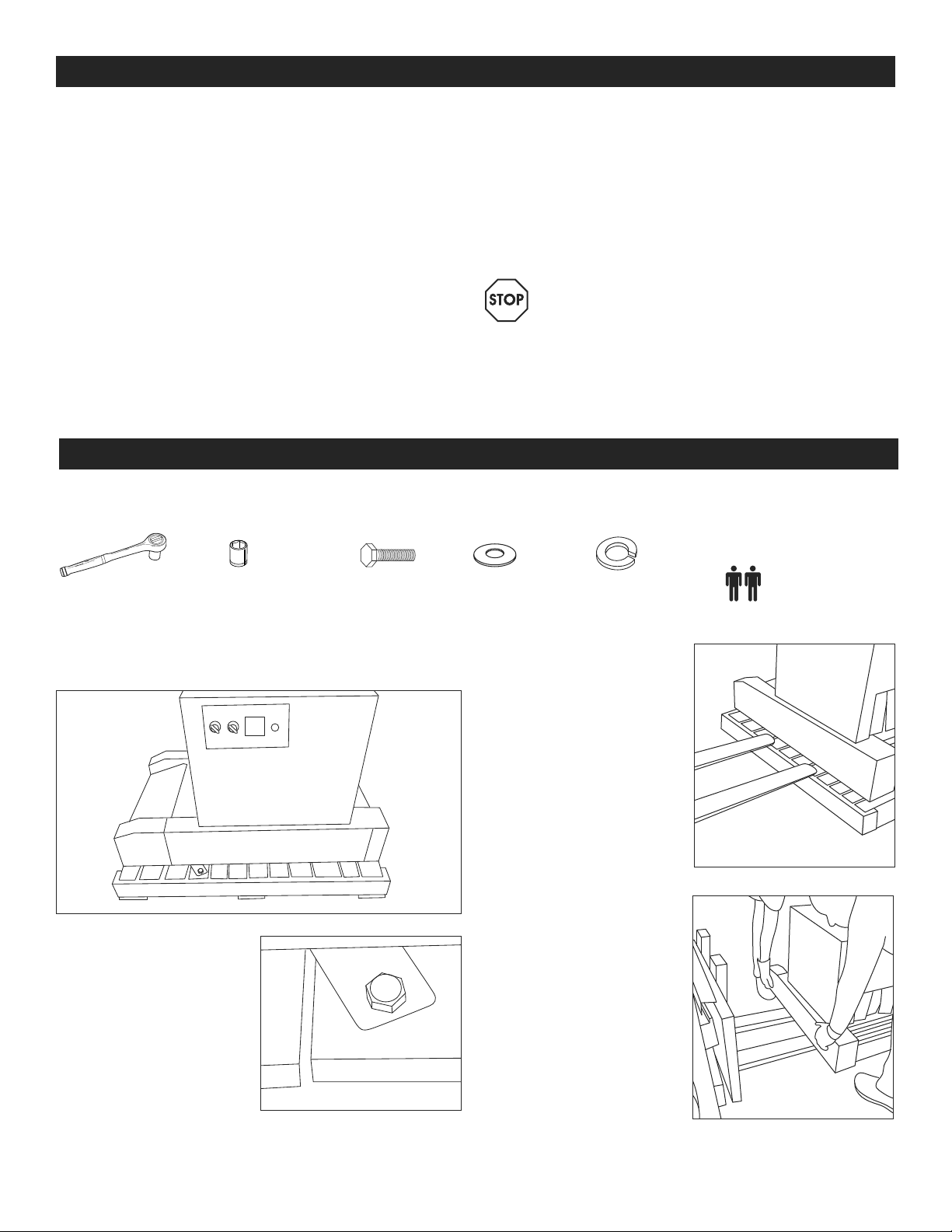

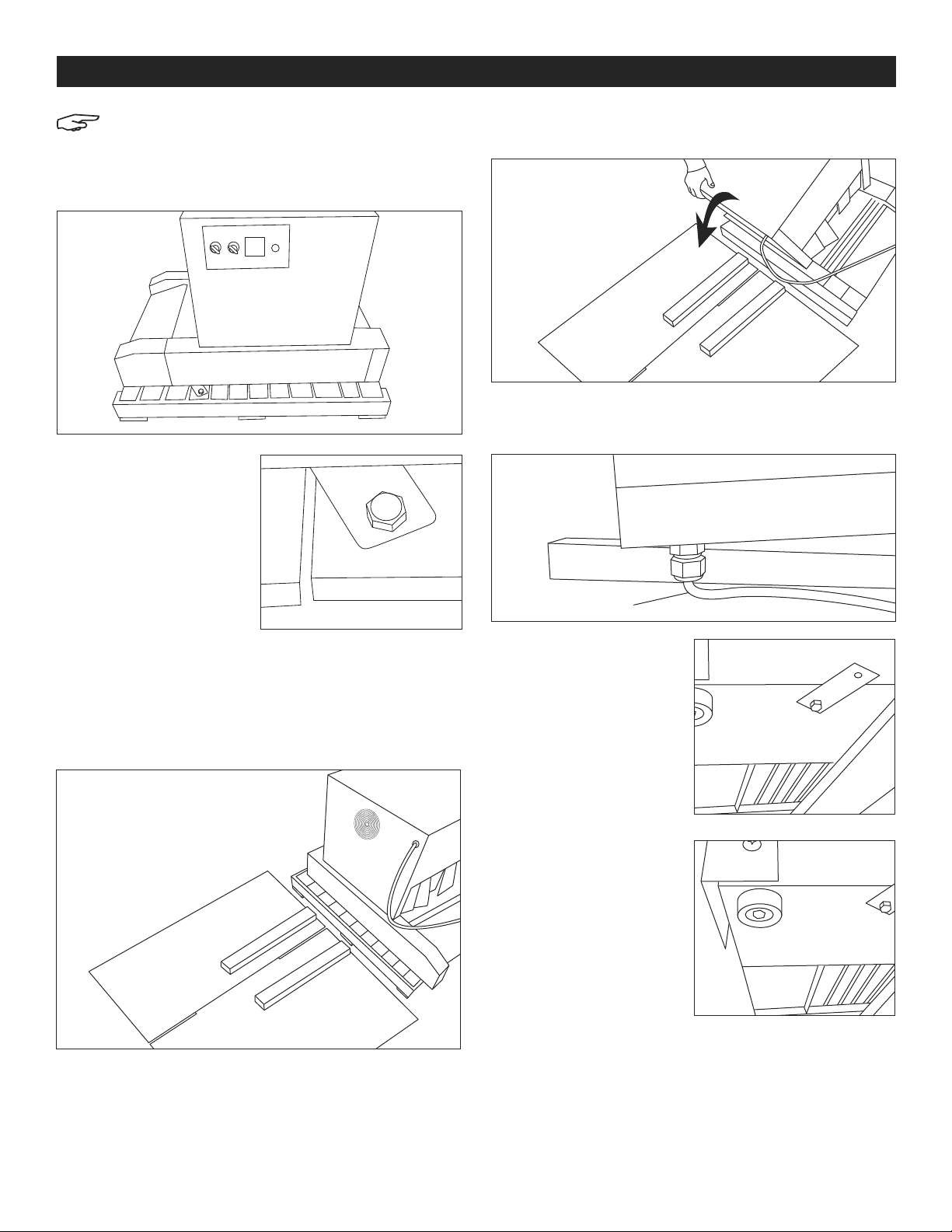

INSTALLING LEG KIT USING FORKLIFT

TOOLS NEEDED

INCLUDED HARDWARE

TO CLEAN:

1. Run conveyor until the affected rollers are inside the

heat chamber.

2. Let the heater soften the film residue on the rollers.

3. Advance the conveyor to stop the rollers outside the

heat chamber.

WARNING! Make sure conveyor is stopped

before placing hands or tools in the conveyor

area.

4. Remove the film residue with a dull blunt-edged tool

such as plastic putty knife. DO NOT use sharp tools or

instruments, you may nick the silicone covering and

have to replace it.

Socket Wrench

10 mm Socket

13 mm Socket

Bolt x 12

1. Remove outer corrugated box from pallet.

(See Figure 1)

Figure 1

2. Using 13 mm socket,

remove two bolts that

secure shrink tunnel to

pallet. (See Figure 2)

Washer x 12 Locking Washer x 12

3. Place forklift in front of

shrink tunnel with the

forks close together.

(See Figure 3)

4. With two people, lift

and slide tunnel onto

the forks. Once unit

is secured, raise the

forks upward to a

comfortable working

height. (See Figure 4)

Two Person Assembly

Recommended

Figure 3

Figure 4

Figure 2

PAGE 3 OF 21 0421 IH-951

Page 4

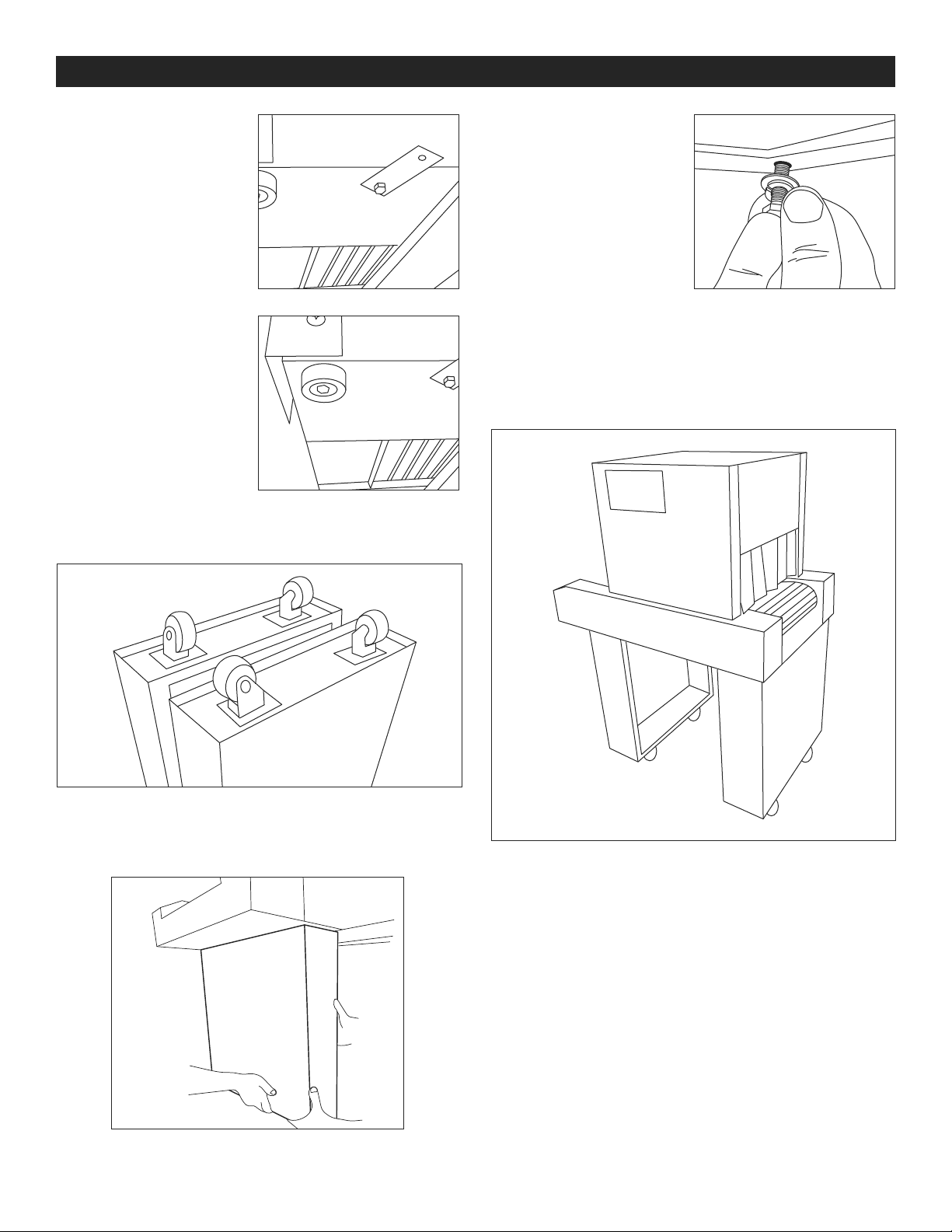

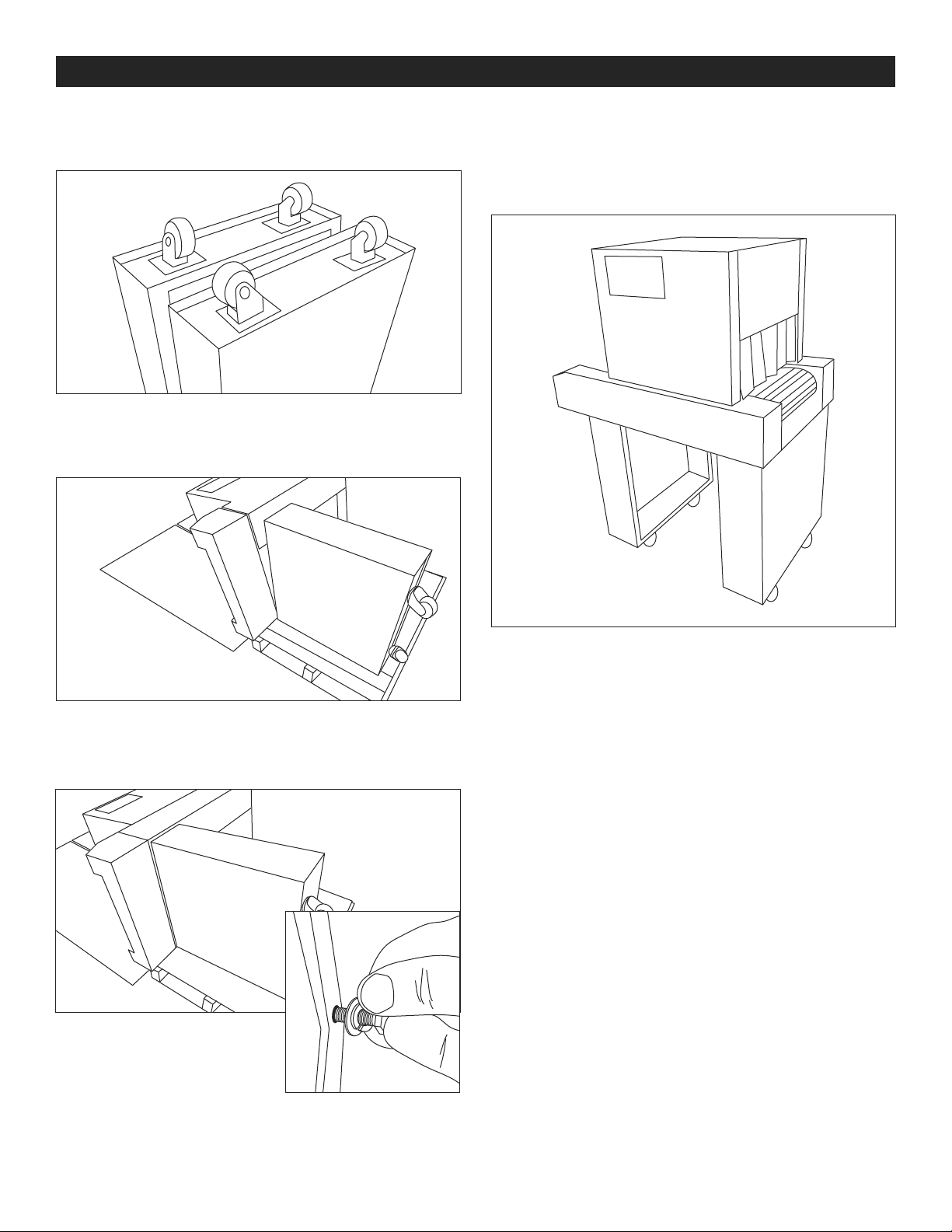

INSTALLING LEG KIT USING FORKLIFT CONTINUED

5. Using 10 mm socket,

remove two metal

Figure 5

straps that secured the

tunnel to pallet.

(See Figure 5)

6. Using 10 mm socket,

Figure 6

remove four rubber

bumpers. (See Figure 6)

7. Remove leg set and included hardware from box.

(See Figure 7)

9. Secure leg to tunnel

with six bolts, three in

Figure 9

each corner.

(See Figure 9)

10. Repeat step 8 and 9 with the other leg.

11. Lower forklift till shrink tunnel is resting on the ground.

Remove forks from unit.

12. Finished unit with legs. (See Figure 10)

Figure 10

Figure 7

8. Hold one leg up to the bottom of tunnel. Make sure

the leg panel is facing outward and along the width

of tunnel. (See Figure 8)

Figure 8

Leg

PAGE 4 OF 21 0421 IH-951

Page 5

INSTALLING LEG KIT WITHOUT FORKLIFT

NOTE: You will need two 2 x 4" wood planks for

this process.

1. Remove outer corrugated box from pallet.

(See Figure 11)

Fig ur e 11

2. Using 13 mm socket,

remove two bolts that

secure shrink tunnel

to

pallet. (See Figure 12)

5. Rest the shrink tunnel on the planks, exposing the

bottom of tunnel. (See Figure 14)

Fi gure 14

6. With tunnel resting on its backside, make sure power

cord is free from damage. (See Figure 15)

Figure 15

Figure 12

3. Place corrugated flat sheet or blanket on the

3. Place corrugated flat

floor toward the backside of shrink tunnel.

sheet or blanket on the floor toward the backside of

(See Figure 13)

shrink tunnel. (See Figure 13)

4. Place two 2 x 4" wood planks perpendicular to the

tunnel as shown. (See Figure 13)

Figure 13

Power Cord

7. Using 10 mm socket,

remove two metal

straps that secured the

tunnel to pallet.

(See Figure 16)

8. Using 10 mm socket,

remove four rubber

bumpers.

(See Figure 17)

Figu re 16

Fig u re 17

PAGE 5 OF 21 0421 IH-951

Page 6

INSTALLING LEG KIT WITHOUT FORKLIFT CONTINUED

9. Remove leg set and included hardware from box.

(See Figure 18)

Figu re 18

10. Place leg on top of pallet. Make sure the leg panel

faces outward and along the width of tunnel.

(See Figure 19)

Figu re 19

12. Repeat steps 10 and 11 with the other leg.

13. With two people, lift shrink tunnel upright.

14. Finished unit with legs. (See Figure 21)

Figure 21

11. Secure leg to tunnel with six bolts, six washers and six

lock washers. Use three on each corner.

(See Figure 20)

Figure 20

PAGE 6 OF 21 0421 IH-951

Page 7

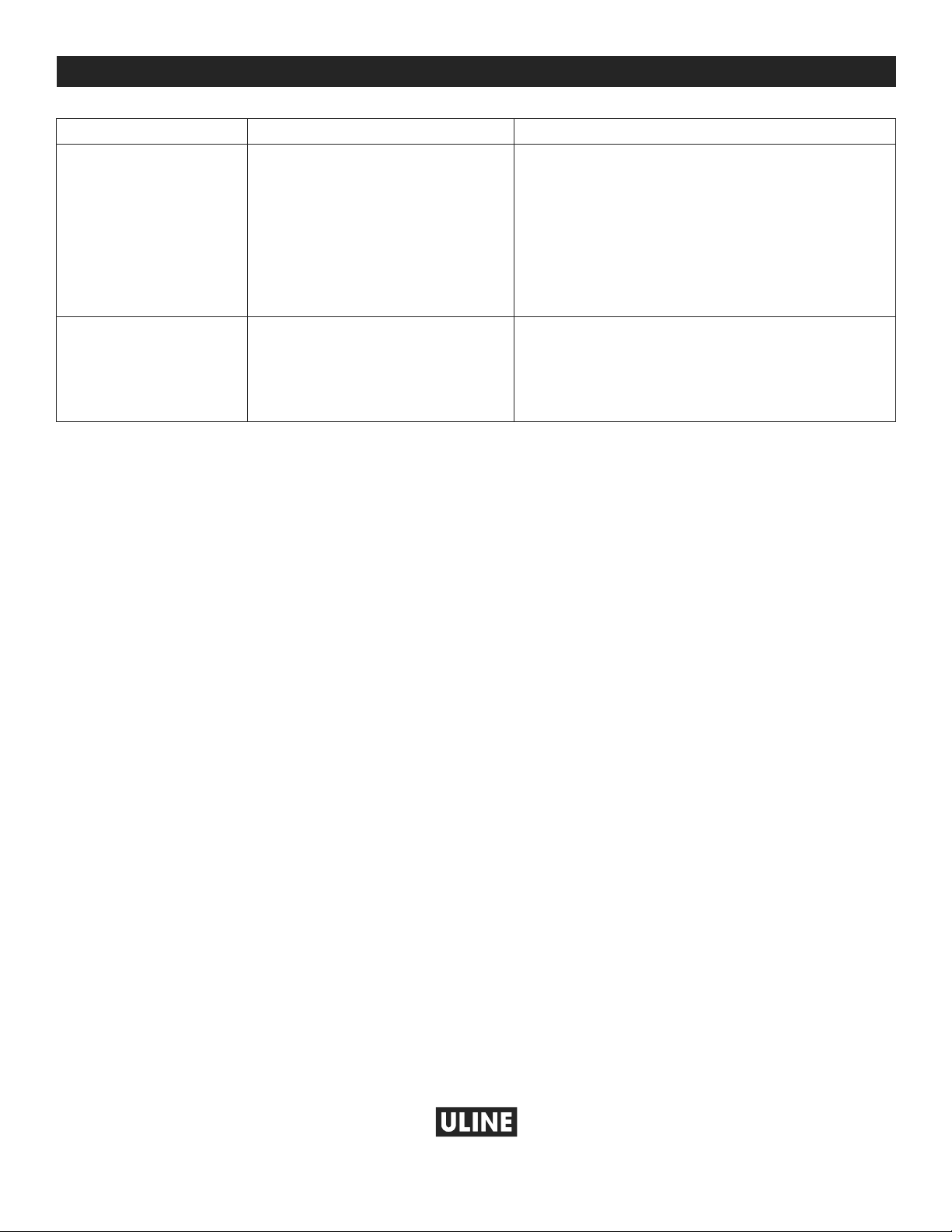

TROUBLESHOOTING

1

0

uline.com

OPERATING ISSUE CAUSES RECOMMENDATIONS

Conveyor not working

No air flow

Machine not powered correctly. Check power switch is ON and power cord is

plugged into or wired to power.

Check that main power is ON.

Check fuse: Remove Top Panel (12 screws).

Check fuse (F5 1 Amp fuse) between wires 11 and

16. Check fuse with fuse tester or multi-meter.

Replace fuse if bad.

Bad fuse. Check fuse: Remove top panel (12 screws).

Check fuse (F1 20 Amp fuse) betweeen wires 4

and 6. Check fuse with fuse tester or

multi-meter. Replace fuse if bad.

-800-295-551

PAGE 7 OF 21 0421 IH-951

Page 8

π H-951

TÚNEL

TERMOENCOGIBLE

800-295-5510

uline.mx

ESPECIFICACIONES

ESPECIFICACIONES DE LA MÁQUINA

MODELO PP 1606-20

Tamaño de la

Cámara

Voltios 110

Amperaje 20

Fase Monofásica 1/0

Peso 113.4 kg (250 lbs.)

Ancho: 40.6 cm (16")

Alto: 15.2 cm (6")

Longitud: 50.8 cm (20")

UBICACIÓN:

Determine dónde colocará el Túnel Termoencogible.

Estas son algunas consideraciones para tomar en

cuenta:

• Una fuente de energía con protección para bajo

voltaje. La máquina no funcionará correctamente si

el voltaje es demasiado bajo.

• Evitar zonas con corrientes de aire. Puede que

la máquina pierda calor y que esto afecte el

rendimiento.

¡ADVERTENCIA! Solamente el personal

autorizado o capacitado debe operar el túnel

termoencogible.

No altere el cableado eléctrico. Apague

siempre la máquina y desconéctela del

tomacorriente antes de realizar tareas de

mantenimiento, limpieza o reparaciones.

Mantenga las manos alejadas de las bandas

transportadoras y otras piezas móviles.

No opere esta máquina sin todas las cubiertas

y los protectores. Puede ocasionar lesiones

graves.

Los brazos y las mordazas de sellado se

calientan a altas temperaturas después de un

periodo de uso. Mantenga las manos alejadas

mientras la máquina esté en funcionamiento.

No modifique esta máquina de ninguna

manera. La modificación del Túnel

Termoencogible anulará cualquier garantía.

Puede que algunas de las películas plásticas

utilizadas para sellar y encoger despidan vapores

peligrosos a altas temperaturas. Disponga de una

ventilación adecuada en todo momento.

Desconecte el Túnel Termoencogible cuando

no esté en uso.

¡IMPORTANTE! Lea cuidadosamente este

manual para familiarizarse con los controles y el

funcionamiento de este Túnel Termoencogible

antes de instalarlo o utilizarlo. Conserve este

manual en un lugar seguro para referencia futura.

PAGE 8 OF 21 0421 IH-951

Page 9

CONTROLES DEL OPERADOR

TEMPERATURE

PV

SV

SET

TARE FY400

Control de

OUT2

AT

AL1

CONVEYOR

AL2

PRO

3

4

2

1

Control de la Velocidad de la

Banda Transportada

Interruptor

de Encendido

POWER

Interruptor

del Calentador

HEATER

ONOFF

ONOFF

Temperatura

FUNCIONAMIENTO

1. Corte las dos tiras de fleje de los rodillos antes del primer uso.

2. Encienda el interruptor. Esto enciende la máquina y el ventilador de enfriamiento.

3. Encienda el interruptor del calentador. Esto enciende el soplador, los motores de la banda transportadora y el

calentador.

4. Configure la velocidad de la banda transportadora. Ajuste la perilla entre 1 y 3 hasta que el usuario determine

la velocidad exacta y necesaria de la banda transportadora, según el tamaño del paquete y la velocidad del

sellador. El ajuste de fábrica es 2.

5. Establezca la temperatura de encogimiento. Use el control de temperatura para establecer la temperatura

deseada. Suba o baje la temperatura según sea necesario. La máquina requiere unos 30 minutos para alcanzar

la temperatura establecida. El ajuste de fábrica es de 163°C (325ºF).

Nota: La velocidad de la banda y el ajuste de calor adecuados para envolver su producto cambiarán

según el tipo, grosor y marca de la película termoencogible. Recomendamos envolver con la película

termoencogible siguiendo la configuración del fabricante primero y ajustarla según las necesidades

¡PRECAUCIÓN! Cuando apague el túnel, recuerde PRIMERO apagar el interruptor del calentador. El

túnel se apaga aproximadamente a los 82°C (180ºF). Luego, el usuario puede apagar el interruptor de

encendido.

CONTROL DE TEMPERATURA

1. PV (Valor Actual) = Muestra la temperatura de

funcionamiento actual de la máquina.

2. SV (Configurar Valor) = Muestra la temperatura que

configuró para la máquina.

3. Mueve el indicador de la pantalla SV de forma

que pueda establecer la temperatura.

4. y permiten ajustar el número hacia arriba o

hacia abajo.

SET

5. El botón "Set" selecciona la temperatura como

valor establecido.

AJUSTAR LA TEMPERATURA

PV

OUT1

OUT2

AT

SV

AL1

AL2

PRO

SET

TARE FY400

1. Presione la tecla . En la pantalla SV parpadea

la primera columna. Mientras el número parpadea,

use las teclas o para fijar el primer número

deseado.

PAGE 9 OF 21 0421 IH-951

2. Presione la tecla

para mover el indicador

una posición a la izquierda. Mientras el número

parpadea, use las teclas o

para fijar el

segundo número deseado.

Page 10

CONTINUACIÓN DE CONTROL DE TEMPERATURA

3. Presione la tecla para mover el indicador

una posición a la izquierda. Mientras el número

parpadea, use las teclas o para fijar el

tercer número deseado.

MANTENIMIENTO

Para mantener el Túnel Termoencogible funcionando

de forma eficiente, haga lo siguiente:

• Mensualmente – Lubrique las cadenas de la banda

transportadora con aceite para altas temperaturas.

Aplíquelo con una brocha o un rociador con la

banda transportadora funcionando a velocidad

lenta.

• Inspeccione regularmente la cubierta de silicón

de los rodillos del túnel. Asegúrese de que no hay

película enrollada en los rodillos, puesto que podría

causar que los paquetes se adhieran.

4. Una vez que se muestre la temperatura deseada,

presione la tecla .Esto guarda la temperatura

SET

que ha introducido como Temperatura

Configurada.

LIMPIEZA:

1. Haga funcionar la banda transportadora hasta que

los rodillos afectados queden dentro de la cámara

de calor.

2. Deje que el calefactor ablande los residuos de

película de los rodillos.

3. Haga avanzar la banda transportadora y deténgala

cuando los rodillos queden fuera de la cámara de

calor.

¡ADVERTENCIA! Asegúrese de que la banda

transportadora se haya detenido antes de

colocar las manos o herramientas en el área

de la banda.

4. Quite los residuos de la película con una

herramienta sin filo, como una espátula de plástico.

NO use herramientas o instrumentos afilados que

puedan dañar la cubierta de silicón ya que tendría

que reemplazarla.

INSTALACIÓN DEL KIT DE PATAS UTILIZANDO MONTACARGAS

HERRAMIENTAS NECESARIAS

Llave de Dado

1. Retire la caja de cartón externa de la tarima.

(Vea Diagrama 1)

Diagrama 1

Dado de 10 mm

Dado de 13 mm

TORNILLERÍA INCLUIDA

12 Pernos

12 Rondanas 12 Rondanas de

Bloqueo

Se recomienda

armar entre dos

personas

2. Utilizando un dado de 13 mm, retire dos pernos que

fijan el túnel termoencogible a la tarima.

(Vea Diagrama 2)

Diagrama 2

PAGE 10 OF 21 0421 IH-951

Page 11

CONTINUACIÓN DE LA INSTALACIÓN DEL KIT DE PATAS UTILIZANDO MONTACARGAS

3. Coloque el

montacargas al frente

del túnel

termoencogible con

las horquillas muy

juntas.

(Vea Diagrama 3)

4. Entre dos personas,

levanten y deslicen el

túnel hacia las

horquillas. Una vez

que la unidad quede

fija, levante las

horquillas hacia arriba

a una altura de

trabajo cómoda.

(Vea Diagrama 4)

5. Utilizando un dado

de 10 mm, retire

las dos tiras de

metal que fijan el

túnel a la tarima.

(Vea Diagrama 5)

6. Utilizando un dado de

10 mm, retire los cuatro

topes de caucho.

(Vea Diagrama 6)

Diagrama 3

Diagrama 4

Diagrama 5

Diagrama 6

8. Mantenga una pata al fondo de la base del túnel.

Asegúrese de que el panel de la pata esté

orientado hacia afuera y a lo largo del ancho del

túnel. (Vea Diagrama 8)

Diagrama 8

Pata

9. Fije la pata al túnel

con seis pernos, tres en

Diagrama 9

cada esquina.

(Vea Diagrama 9)

10. Repita los pasos 8 y 9

con la otra pata.

11. Baje el montacargas

hasta que el túnel termoencogible descanse sobre

el suelo. Retire las horquillas de la unidad.

12. Unidad terminada con patas. (Vea Diagrama 10)

Diagrama 10

7. Retire el set de patas y la tornillería incluida de la

caja. (Vea Diagrama 7)

Diagrama 7

PAGE 11 OF 21 0421 IH-951

Page 12

INSTALACIÓN DEL KIT DE PATAS SIN USAR MONTACARGAS

NOTA: Necesitará dos tablas de madera de

2 x 4" para este proceso.

1. Retire la caja de cartón externa de la tarima.

(Vea Diagrama 11)

Diagrama 11

2. Utilizando un dado

de 13 mm, retire dos

pernos que fijan el

túnel termoencogible

a

la tarima.

(Vea Diagrama 12)

5. Ponga el túnel termoencogible encima de las

tablas con la base del túnel expuesta.

(Vea Diagrama 14)

Diagrama 14

6. Con el túnel recargado sobre su parte posterior,

asegúrese de que el cable eléctrico no esté

dañado. (Vea Diagrama 15)

Diagrama 15

Diagrama 12

3. Coloque una lámina

3. Coloque una lámina plana corrugada o una

plana corrugada o una manta en el suelo hacia la

manta en el suelo hacia la parte posterior del

parte posterior del túnel termoencogible.

túnel termoencogible. (Vea Diagrama 13)

4. Coloque dos tablas de madera de 2 x 4"

perpendiculares al túnel como se muestra.

(Vea Diagrama 13)

Diagrama 13

Cable Eléctrico

7. Utilizando un dado de

10 mm, retire las dos

tiras de metal que fijan

el túnel a la tarima.

(Vea Diagrama 16)

8. Utilizando un dado de

10 mm, retire los cuatro

topes de caucho.

(Vea Diagrama 17)

Diagrama 16

Diagrama 17

PAGE 12 OF 21 0421 IH-951

Page 13

CONTINUACIÓN DE INSTALACIÓN DEL KIT DE PATAS SIN USAR MONTACARGAS

9. Retire el set de patas y la tornillería incluida de la

caja. (Vea Diagrama 18)

Diagrama 18

10. Coloque la pata encima de la tarima. Asegúrese

de que el panel de la pata esté orientado hacia

afuera y a lo largo del ancho del túnel.

(Vea Diagrama 19)

Diagrama 19

12. Repita los pasos 10 y 11 con la otra pata.

13. Entre dos personas, levanten el túnel

termoencogible hasta que quede erguido.

14. Unidad terminada con patas. (Vea Diagrama 21)

Diagrama 21

11. Fije la pata al túnel con seis pernos, seis rondanas

y seis rondanas de bloqueo. Use tres en cada

esquina. (Vea Diagrama 20)

Diagrama 20

PAGE 13 OF 21 0421 IH-951

Page 14

SOLUCIÓN DE PROBLEMAS

8

0

uline.mx

PROBLEMA DE OPERACIÓN CAUSAS RECOMENDACIONES

La banda transportadora no

funciona

El aire no circula

La maquina no enciende

correctamente.

Fusible dañado. Verifique el fusible: Retire el panel superior

Verifique que el interruptor esté

encendido y que el cable de

alimentación esté enchufado o

conectado a la corriente eléctrica.

Verifique que la fuente principal esté

encendida.

Verifique el fusible: Retire el panel superior

(12 tornillos). Verifique el fusible (fusible F5

de 1 amperio) entre los cables 11 y 16.

Verifique el fusible con un probador de

fusibles o con un multímetro. Reemplace

el fusible si está dañado.

(12 tornillos).

Verifique el fusible (fusible F1 de 20

amperios) entre los cables 4 y 6. Verifique

el fusible con un probador de fusibles o

con un multímetro. Reemplace el fusible si

está dañado.

00-295-551

PAGE 14 OF 21 0421 IH-951

Page 15

π H-951

TUNNEL DE

RÉTRACTION

1-800-295-5510

uline.ca

SYSTÈME

SPÉCIFICATIONS DE L'APPAREIL

MODÈLE PP 1606-20

Dimensions de la chambre Largeur: 40,6cm (16po)

Hauteur: 15,2 cm (6po)

Longueur: 50,8cm (20po)

Volts 110

Intensité du courant électrique 20

Phase Monophasé 1/0

Poids 113,4kg (250lb)

POSITIONNEMENT:

Identifiez où installer le tunnel de rétraction. Voici quelques

éléments à prendre en compte:

• Une source d'alimentation avec protection contre les

baisses de tension. L'appareil ne fonctionnera pas

correctement si la tension est trop basse.

• Évitez les endroits exposés aux courants d'air. Ceux-ci

peuvent retirer de la chaleur de l'appareil et nuire à son

rendement.

ARRÊT

AVERTISSEMENT! Seul le personnel autorisé ou formé

doit manipuler le tunnel de rétraction.

N'altérez pas le câblage électrique. Éteignez et

débrancher toujours l'appareil avant tout entretien,

nettoyage ou réparation.

Gardez les mains à l'écart des convoyeurs en

marche et de tout autre composant mobile.

N'OPÉREZ PAS cet appareil si les couvercles et

protecteurs ne sont pas tous installés. Cela pourrait

entrainer des blessures graves.

Les bras et les mâchoires thermoscelleurs peuvent

devenir chauds après un certain temps d'utilisation.

Gardez les mains à l'écart de l'appareil durant son

fonctionnement.

Ne modifiez cet appareil d'aucune façon. La

modification du tunnel de rétraction annulera toute

garantie.

À haute température, certaines des pellicules de

plastique utilisées pour le thermoscellage peuvent

produire des vapeurs nocives. Prévoyez une

ventilation adéquate en tout temps.

Débranchez le tunnel de rétraction lorsqu'il n'est

pas utilisé.

IMPORTANT! Veuillez lire attentivement ce manuel

afin de vous familiariser avec les commandes et

l'opération de ce tunnel de rétraction avant son

installation et son utilisation. Conservez ce manuel

dans un endroit sûr pour référence future.

PAGE 15 OF 21 0421 IH-951

Page 16

COMMANDES DE FONCTIONNEMENT

TEMPERATURE

PV

SV

SET

TARE FY400

OUT2

AT

AL1

CONVEYOR

AL2

PRO

3

4

2

1

Commande de

vitesse du convoyeur

Interrupteur

d'alimentation

Interrupteur de

chauffage

POWER

HEATER

ONOFF

ONOFF

Contrôle de la

température

FONCTIONNEMENT

1. Coupez les deux sangles des rouleaux avant la première utilisation.

2. Allumez l'interrupteur d'alimentation. Cela fait démarrer la machine et le ventilateur de refroidissement.

3. Allumez l'interrupteur de chauffage. Ceci fait démarrer le dispositif de soufflerie, les moteurs du convoyeur et le

chauffage.

4. Réglez la vitesse du convoyeur. Déterminez la vitesse de convoyeur nécessaire en réglant le bouton du

convoyeur entre 1 et 3, et ce, en fonction de la taille du paquet et de la vitesse de la scelleuse. Le paramètre

d’usine est de 2.

5. Réglez la température de rétraction. Utilisez le contrôle de température pour sélectionner la température

souhaitée. Augmentez ou diminuez la température selon le besoin. La machine requiert environ 30 minutes pour

atteindre la température sélectionnée. Le paramètre d’usine est de 325 ºF.

REMARQUE : La vitesse de convoyeur et le réglage de la chaleur appropriés pour la rétraction de

l'emballage de votre produit varient en fonction du type, de l'épaisseur et de la marque du film

rétractable. Il est fortement recommandé d'utiliser en premier les réglages du fabricant, puis de les

adapter à vos besoins.

MISE EN GARDE! Lorsque vous éteignez le tunnel, l'interrupteur de chauffage doit être éteint en PREMIER.

Le tunnel s'éteint automatiquement à environ 180 ºF. L'utilisateur peut alors éteindre l'interrupteur

d'alimentation.

CONTRÔLE DE LA TEMPÉRATURE

1. PV (température actuelle)= Affiche la température de

service actuelle de l'appareil.

2. SV (température désirée)= Affiche la température à

PV

laquelle vous avez réglé l'appareil.

3. Déplace l'indicateur sur l'affichage SV afin de vous

permettre de régler la température.

SV

4. et règlent le nombre vers le haut ou le bas.

SET

5. La touche « Set » sélectionne la température en tant

que valeur de consigne.

SET

POUR AJUSTER LA TEMPERATURE DÉSIRÉE :

1. Appuyez sur la touche . La 1re colonne de l'affichage

SV clignote. Pendant que le chiffre clignote, réglez le

premier chiffre au nombre voulu à l'aide de la touche

ou .

2. Appuyez sur la touche pour déplacer l'indicateur

d'une colonne vers la gauche. Pendant que le chiffre

clignote, réglez le second chiffre au nombre voulu à l'aide

de la touche ou .

PAGE 16 OF 21 0421 IH-951

3. Appuyez sur la touche pour déplacer l'indicateur

4. Dès que la température voulue est affichée, appuyez sur la

TARE FY400

d'une colonne vers la gauche. Pendant que le chiffre

clignote, réglez le troisième chiffre au nombre voulu à

l'aide de la touche .

touche . Ceci confirme la température que vous avez

SET

sélectionnée en tant que point de consigne.

OUT1

OUT2

AT

AL1

AL2

PRO

Page 17

ENTRETIEN

Pour maintenir l'état de fonctionnement efficace du

tunnel de rétraction, effectuez l'entretien suivant:

• Mensuellement: lubrifiez les chaînes du convoyeur avec

de l'huile haute température. Appliquez-la avec un

pinceau ou vaporisez-la avec le convoyeur fonctionnant

lentement.

• Inspectez régulièrement le revêtement de silicone des

rouleaux du tunnel. Assurez-vous que les rouleaux ne sont

pas recouverts de pellicule, car cela peut empêcher les

colis d'avancer.

NETTOYAGE :

1. Faites fonctionner le convoyeur jusqu'à ce que les

rouleaux touchés se situent à l'intérieur de la chambre de

chaleur.

2. Laissez le réchauffeur ramollir la pellicule résiduelle

entourant les rouleaux.

3. Avancez le convoyeur afin de stopper les rouleaux à la

sortie de la chambre de chaleur.

AVERTISSEMENT! Assurez-vous que le convoyeur est

ARRÊT

arrêté avant de placer les mains ou des outils dans

la zone du convoyeur.

4. Retirez les résidus de film avec un outil émoussé, tel

qu'un couteau à mastiquer en plastique. N'utilisez

PAS d'outils ou d'instruments coupants, vous risquez

d'entailler le revêtement en silicone et de devoir le

remplacer.

INSTALLATION DES PIEDS AVEC UN CHARIOT ÉLÉVATEUR

OUTILS REQUIS MATÉRIEL D'INSTALLATION INCLUS

Clé à douille

Douille de 10 mm

Douille de 13 mm

Boulon x 12

1. Retirez l'emballage de carton ondulé de la palette.

(Voir Figure 1)

Figure 1

2. Retirez les deux

boulons qui

maintiennent le tunnel

de rétraction à la

palette à l'aide de la

douille de 13 mm.

(Voir Figure 2)

Figure 2

Rondelle x 12 Rondelle de blocage

x 12

3. Placez le chariotélévateur, fourches

rapprochées, devant le

tunnel de rétractation.

(Voir Figure 3)

4. Soulevez et faites

glisser le tunnel sur

les fourches. Cette

opération nécessite

deux personnes.

Lorsque l'unité est

solidement en place,

soulevez les fourches à

une hauteur de travail

confortable.

(Voir Figure 4)

Montage à

deux personnes

conseillé

Figure 3

Figure 4

PAGE 17 OF 21 0421 IH-951

Page 18

INSTALLATION DES PIEDS AVEC UN CHARIOT ÉLÉVATEUR (SUITE)

5. Retirez les deux

languettes métalliques

Figure 5

qui maintiennent le

tunnel de rétraction

à la palette à l'aide

de la douille de

10 mm. (Voir Figure 5)

6. Retirez ensuite

les quatre butoirs en

Figure 6

caoutchouc en

utilisant la même

douille. (Voir Figure 6)

7. Retirez les pieds et le matériel d'installation de la

boîte. (Voir Figure 7)

9. Fixez le pied au tunnel

Figure 9

en utilisant six boulons,

trois dans chaque coin.

(Voir Figure 9)

10. Répétez les étapes 8 et 9 pour l'autre pied.

11. Abaissez le chariot-élévateur jusqu'à ce que le

tunnel de rétraction repose sur le sol. Retirez les

fourches de l'unité.

12. Produit fini muni de pieds (Voir Figure 10)

Figure 10

Figure 7

8. Tenez un des pieds en position verticale en dessous

du tunnel. Assurez-vous que le côté panneau du

pied soit orienté vers l'extérieur et dans la largeur du

tunnel. (Voir Figure 8)

Figure 8

Pied

PAGE 18 OF 21 0421 IH-951

Page 19

INSTALLATION DES PIEDS SANS CHARIOT ÉLÉVATEUR

REMARQUE : Pour cette opération, vous aurez

besoin de deux planches en bois de 2 x 4 po.

1. Retirez l'emballage de carton ondulé de la palette.

(Voir Figure 11)

Fig ur e 11

2. Retirez les deux

boulons qui

maintiennent le tunnel

de rétraction

palette

à l'aide de la

douille de 13 mm.

à la

(Voir Figure 12)

5. Faites reposer le tunnel sur les planches, exposant

ainsi le dessous du tunnel. (Voir Figure 14)

Fi gure 14

6. Lorsque le tunnel repose sur le côté, assurez-vous

que le cordon d'alimentation ne se trouve pas

entravé. (Voir Figure 15)

Figure 15

Figure 12

3. Placez une feuille de

3. Placez une feuille de carton ondulé ou une

carton ondulé ou une couverture sur le sol vers

couverture sur le sol vers l'arrière du tunnel.

l'arrière du tunnel.

(Voir Figure 13)

4. Placez deux planches en bois de 2 x 4 po à la

perpendiculaire du tunnel comme illustré.

(Voir Figure 13)

Figure 13

Cordon d'alimentation

7. Retirez les deux

languettes métalliques

qui maintiennent le

tunnel de rétraction à

la palette à l'aide de

la douille de 10 mm.

(Voir Figure 16)

8. Retirez ensuite les

quatre butoirs en

caoutchouc en

utilisant la même

douille. (Voir Figure 17)

Figu re 16

Fig u re 17

PAGE 19 OF 21 0421 IH-951

Page 20

INSTALLATION DES PIEDS SANS CHARIOT ÉLÉVATEUR (SUITE)

9. Retirez les pieds et le matériel d'installation de la

boîte. (Voir Figure 18)

Figu re 18

10. Placez le pied sur la palette. Assurez-vous que le

côté panneau du pied soit orienté vers l'extérieur et

dans la largeur du tunnel. (Voir Figure 19)

Figu re 19

12. Répétez les étapes 10 et 11 avec l'autre pied.

13. Redressez le tunnel à l'aide d'une autre personne.

14. Produit fini muni de pieds. (Voir Figure 21)

Figure 21

11. Fixez le pied au tunnel en utilisant six boulons, six

rondelles et six rondelles de blocage. Utilisez-en trois

sur chaque coin. (Voir Figure 20)

Figure 20

PAGE 20 OF 21 0421 IH-951

Page 21

DÉPANNAGE

1

0

uline.ca

PROBLÈME DE FONCTIONNEMENT CAUSES RECOMMANDATIONS

Le convoyeur ne fonctionne pas

Aucun débit d'air

La machine n'est pas

alimentée correctement.

Fusible défectueux. Vérifiez le fusible : retirez le panneau

Vérifiez que l'interrupteur d'alimentation est

allumé et que le cordon d'alimentation est

branché ou câblé à une source de courant.

Vérifiez que l'alimentation principale est en

marche.

Vérifiez le fusible : retirez le panneau

supérieur (12 vis). Vérifiez le fusible (fusible

F5, 1 ampère) entre les fils 11 et 16. Vérifiez

le fusible avec un testeur de fusibles ou

un multimètre. Remplacez le fusible s'il est

défectueux.

supérieur (12 vis).

Vérifiez le fusible (fusible F1, 20 ampères)

entre les fils 4 et 6. Vérifiez le fusible avec

un testeur de fusibles ou un multimètre.

Remplacez le fusible s'il est défectueux.

-800-295-551

PAGE 21 OF 21 0421 IH-951

Loading...

Loading...