Page 1

Para Español, vea páginas 10-18.

Pour le français, consulter les pages 19-27.

H-7241

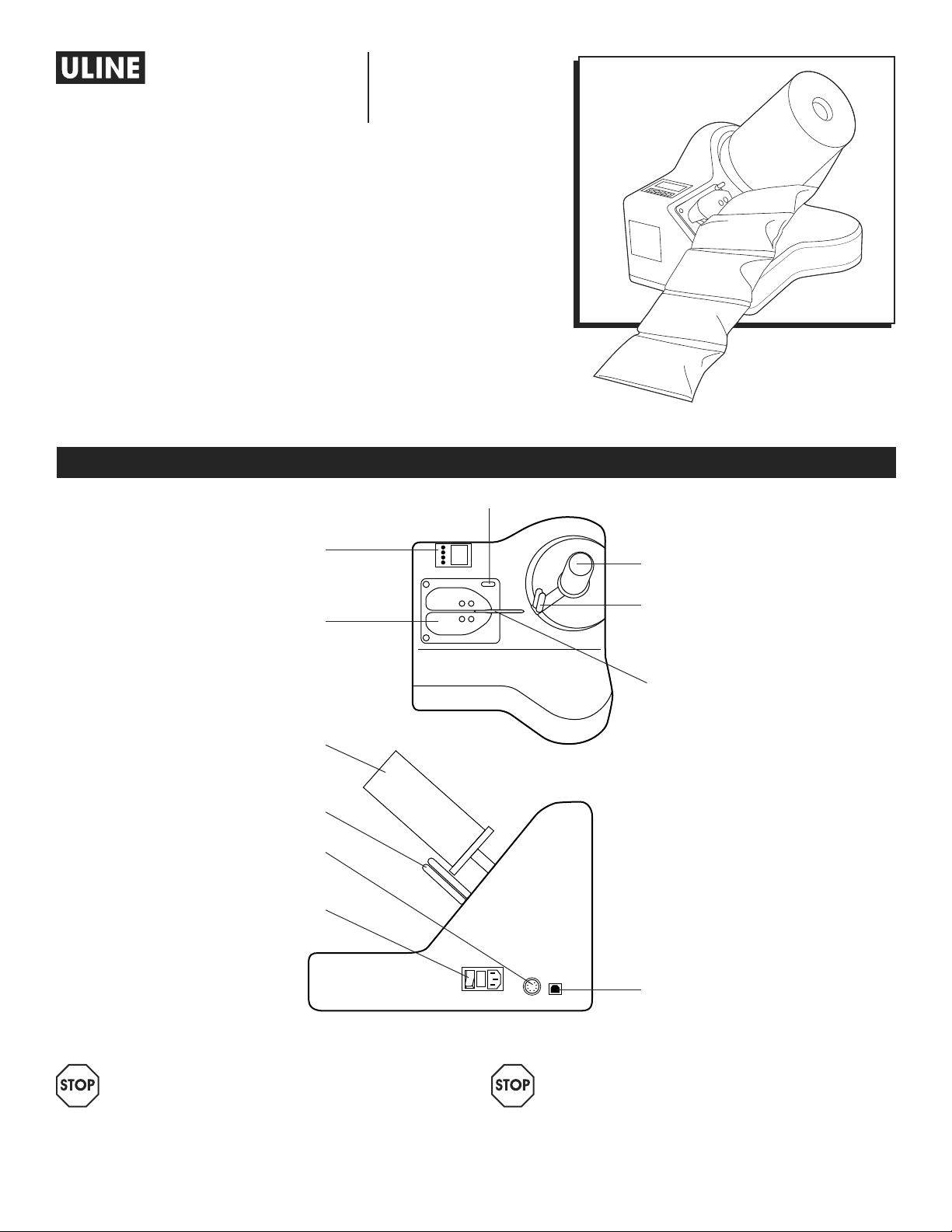

AIR CUSHION MACHINE

BOX CONTENTS

• Air Cushion Machine

• Film Roll Holder

• Spacing Gauge

• Maintenance Kit

• Power Cord

• User Manual

1-800-295- 5510

uline.com

PARTS

Unlock Knob

Control Panel

Sealing Unit

(Includes Teflon® Belts)

Film Roll Holder

Guide Bar

External Input

Connection

Main Power Switch

and Power Socket

Film Roll Holder

Guide Bar

Air Injector

USB-B Connector

WARNING! Please read and understand

instructions fully before operating the

Uline Air Cushion machine.

PAGE 1 OF 27 0621 I H-7241

WARNING! To guarantee personal safety,

the following instructions must be carefully

observed.

Page 2

SAFETY

WORK AREA

• Keep the work area clean and well lit.

• Place the machine on a flat, dry surface.

• Do not operate machine in explosive atmospheres,

such as in the presence of flammable liquids, gases

or dust. Do not place flammable materials in, on or

around the machine.

ELECTRICAL SAFETY

• The power plug must match the outlet and the outlet

must be appropriately grounded. Do not modify

the plug in any way. Do not use adapter plugs or

extension cords.

• Do not expose the machine to wet conditions.

• For installation and maintenance work, the machine

must always be turned off by the main switch and be

disconnected from the main power connection.

• All safety, protective measures and facilities must be

applied and maintained in accordance with IEC

instructions.

PERSONAL SAFETY

• Prevent accidental starting. Ensure the switch is in the

off position before plugging in.

• There is an extremely sharp knife blade under the

air injector assembly. Strictly adhere to the blade

replacement instructions on page 8.

USE AND CARE

• Switch machine off and disconnect the plug from

the power source before performing any operation

to the machine. This includes replacing film,

cleaning or maintenance.

• The machine requires periodic cleaning. Check for

misalignment or binding of moving parts, broken

parts and any other condition that may affect the

operation. Do not operate a damaged machine.

• This system was designed for processing a specific

film type. In order to guarantee smooth function,

only replace with Uline Air Cushion Machine film.

• In emergency situations, turn the power switch

off. The machine will be switched off within a few

seconds (when indicator is turned off completely).

After eliminating the emergency situation or fault,

the machine can be switched on again according

to the user manual.

STORAGE

Store device only under the following conditions:

• Outdoor storage is prohibited.

• The device must only be stored in dry rooms.

• Keep dry and dust-free.

• Protect from massive heat, like radiators.

• The film is sealed by using a heated wire that is

located under a Teflon® belt. This wire gets very

hot and may cause burns if touched. Switch the

machine off and allow the wire 2-3 minutes to

cool before performing any operation exposing

the wire. Follow provided instructions, page 7, for

replacement of Teflon® belts.

PAGE 2 OF 27 0621 I H-7241

Page 3

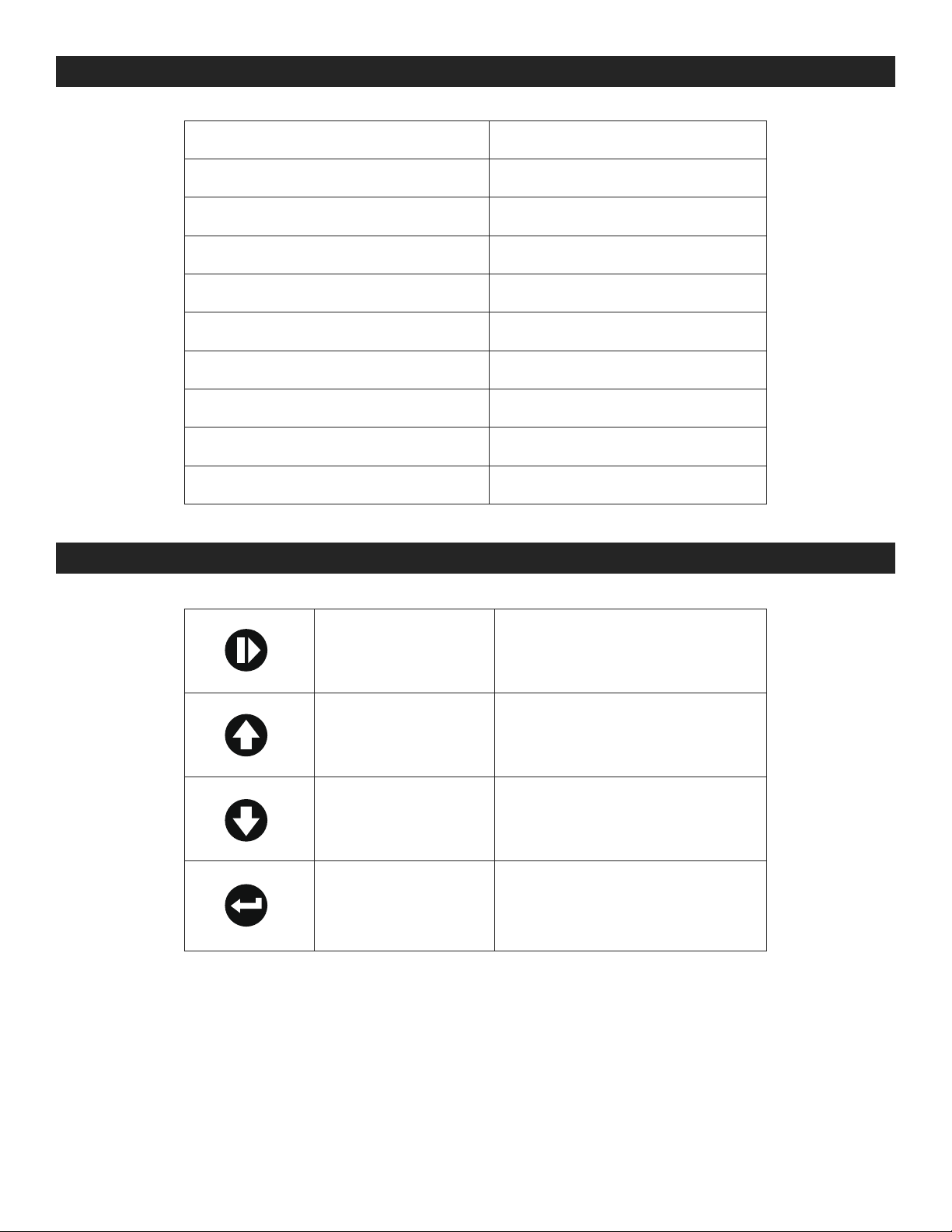

TECHNICAL SPECIFICATIONS

Voltage 95 – 250 VAC; 50/60 Hz

Power Consumption (max.) 97 W

Power Consumption 76 W

Power Consumption (stand-by mode) 6.2 W

Recommended Main Fuse 3.15 AMP

Dimensions 14⁄ x 14⁄"

Height 13"

Transport Speed ~33 LFM

Weight 15.65 lbs.

Sound Pressure Level 52 db

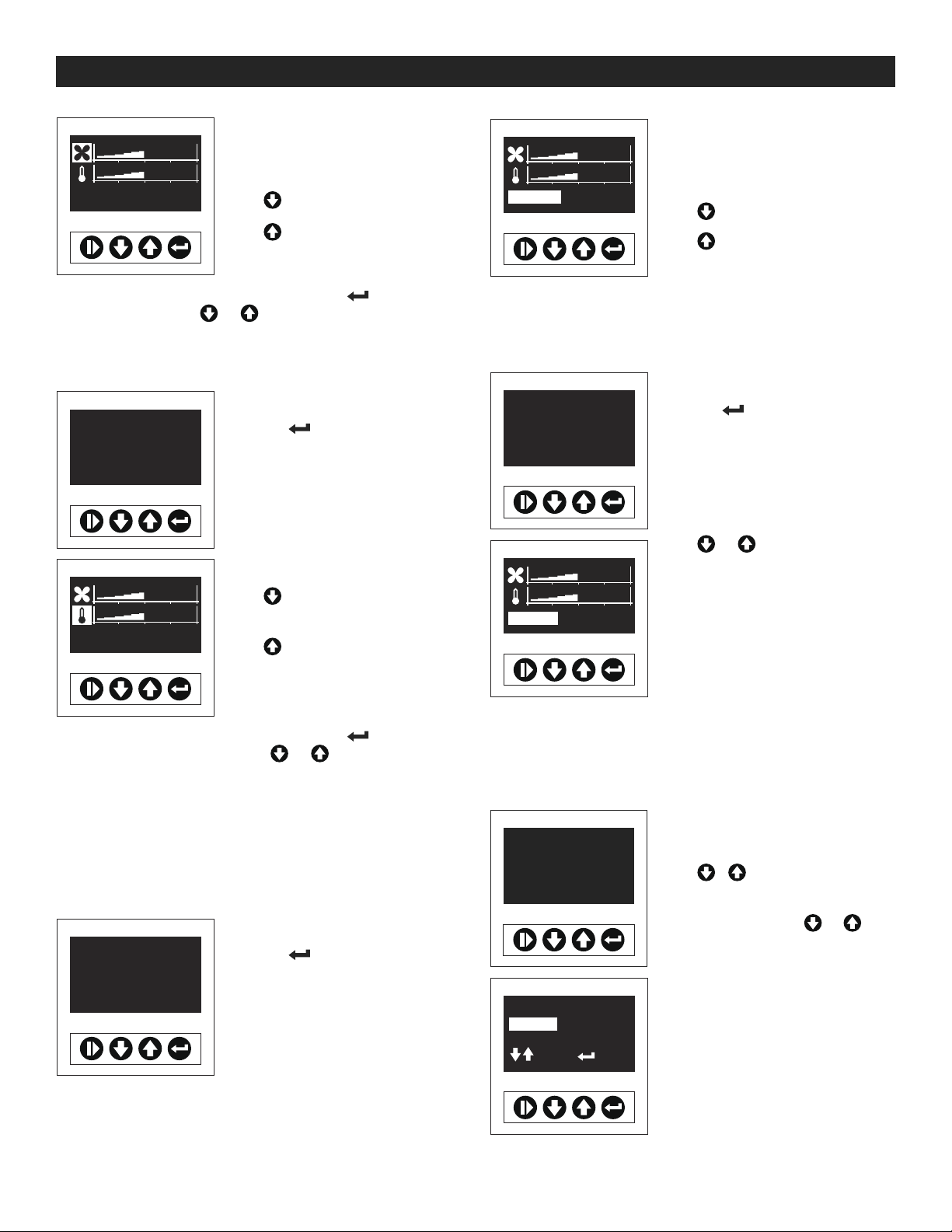

KEYPAD FUNCTIONS

Start/Stop Button • Starts or stops the machine

Arrow up

Arrow down

Enter Button

• Increases the value

• Scrolls up

• Decreases the value

• Scrolls down

• Confirms

• Enter menu

• Enter menu item

PAGE 3 OF 27 0621 I H-7241

Page 4

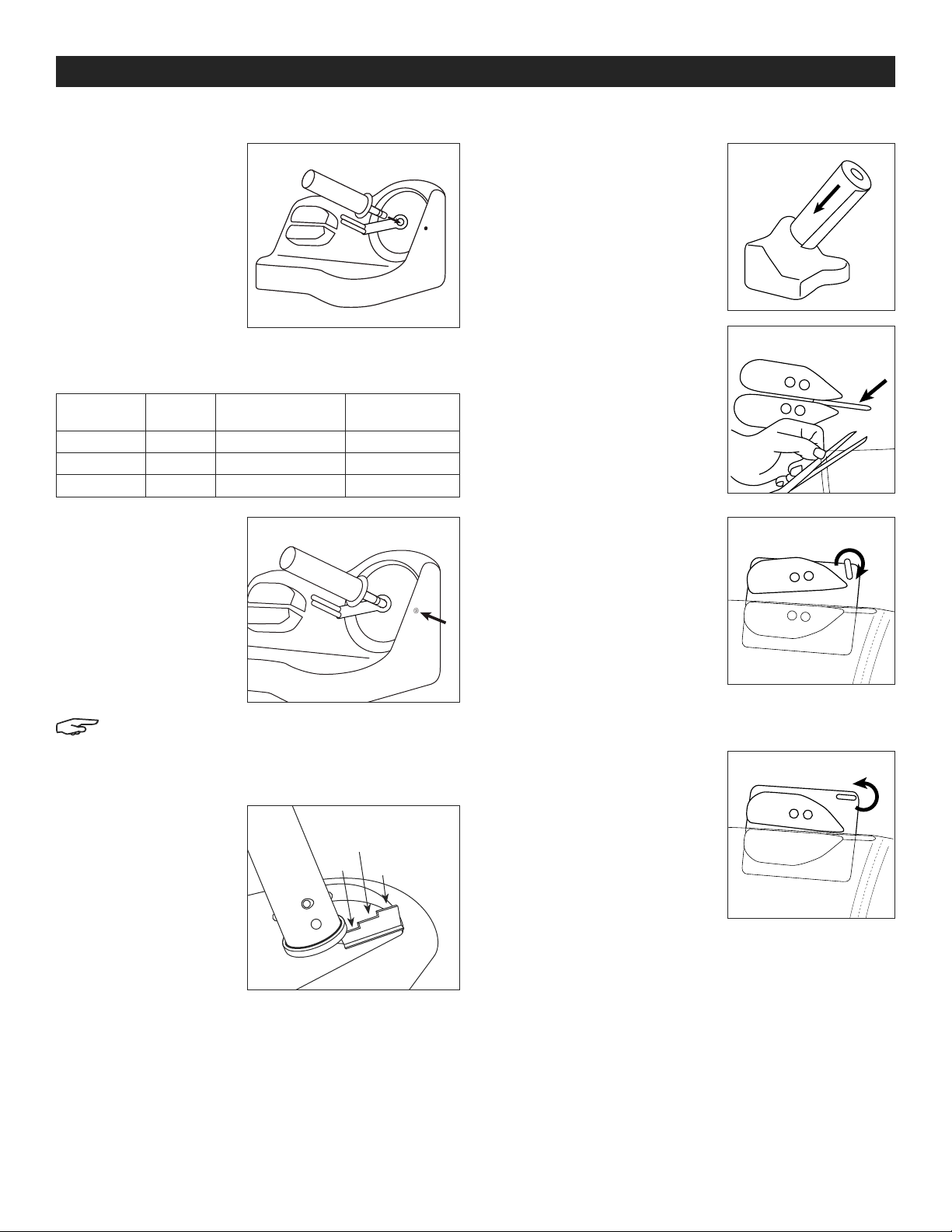

SETTING UP THE DEVICE

ASSEMBLY OF THE FILM ROLL HOLDER

1. Remove the machine

and the blue film roll

shaft from the box.

Insert the metal part

into hole on the front

side of the machine.

(See Figure 1)

Uline Air Cushion Machine films are available in three

different options:

DESCRIPTION

Air Pillows S-22467 8 x 4" 11/ 16"

Air Cushion S-22468 1⁄ x 9 x 13" 1/2"

Bubble Film S-22469 3/4 x 6 x 13" 1/2 "

ULINE

PART NO.

2. Adjust the film roll

holder to fit desired

film type by loosening

the screw on the right

side of the machine

with included Allen

wrench. Gently

tighten screw to

secure. (See Figure 2)

NOTE: Screw on right side of machine is set into

machine housing. It should be loosened and

tightened to adjust film roll holder and does

not need to be removed for this process.

3. Using the included

spacing gauge can

help find the right

setting for each film

type. (See Figure 3)

Figure 1 Figure 4

CUSHION SIZE SPACING GUIDE

Figure 2

Figure 3

11/ 16"

1/2"

15/16"

LOADING A FILM ROLL

1. Slide the film roll onto the

film roll holder. Ensure that

the film is oriented to unwind

from the underside of the

roll. (See Figure 4)

2. There is a gap between

the edge of the film and

the perforations. Cut a little

corner off the film gap.

(See Figure 5)

3. Turn the unlock knob

clockwise to unlock the top

sealing unit. Slide the film

between the guide bars

and thread the gap on

the film through the black

nozzle and between the

sealing units. Ensure the

film cuts on the blade, and

advance the film all the

way through the sealing units. (See Figure 6)

4. Turn unlock knob

counterclockwise to lock

the top sealing unit. Always

make sure that the knob is

locked before operating the

machine. (See Figure 7)

Figure 5

Figure 6

Figure 7

• Air Pillows = 11/16"

• Air Cushion = 1/2"

• Bubble Film = 1/2"

4. Tighten screw to

secure film roll holder.

PAGE 4 OF 27 0621 I H-7241

Page 5

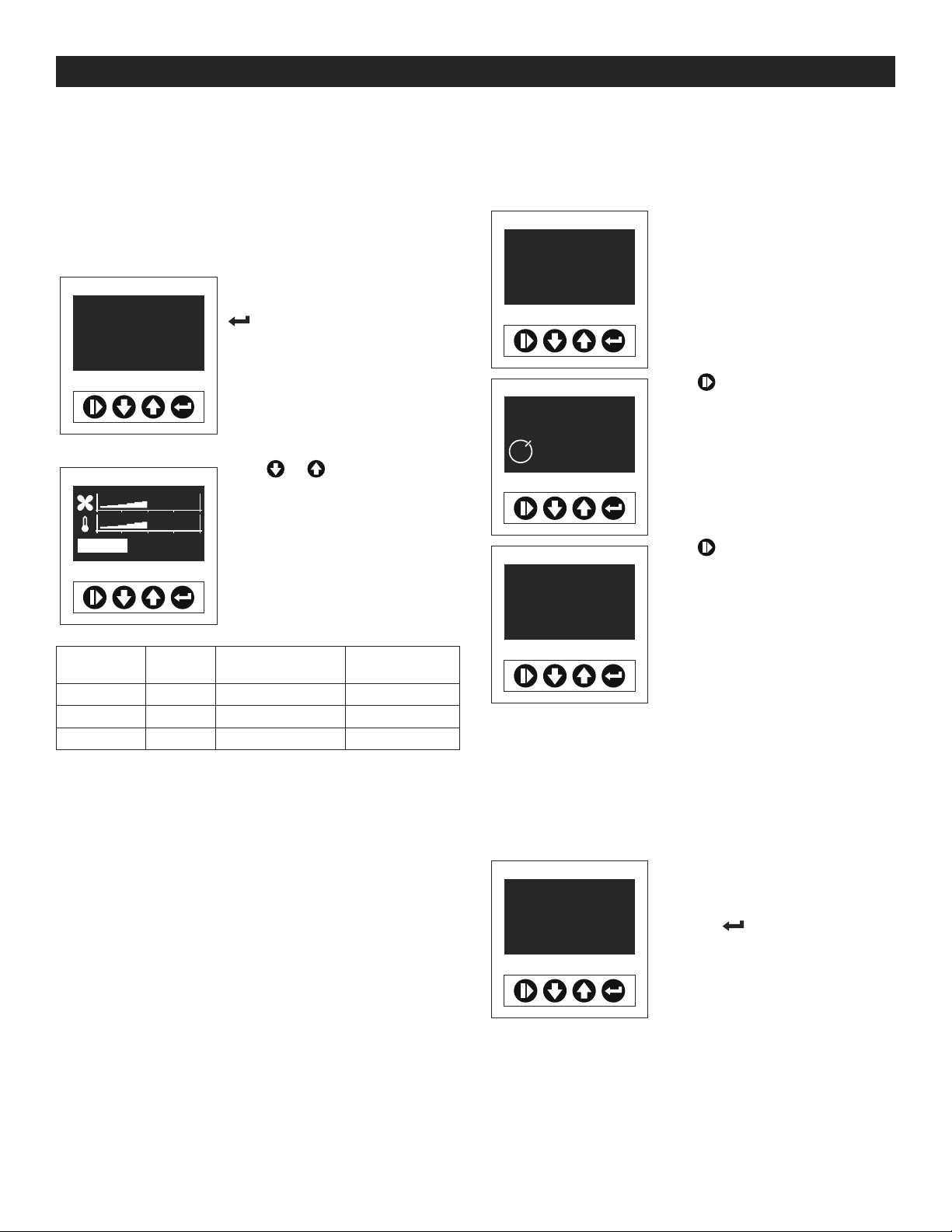

SETTING UP THE DEVICE CONTINUED

POWER SWITCH AND CONNECTIONS

After checking the power supply, the system can be

switched on. The main switch is on position "I."

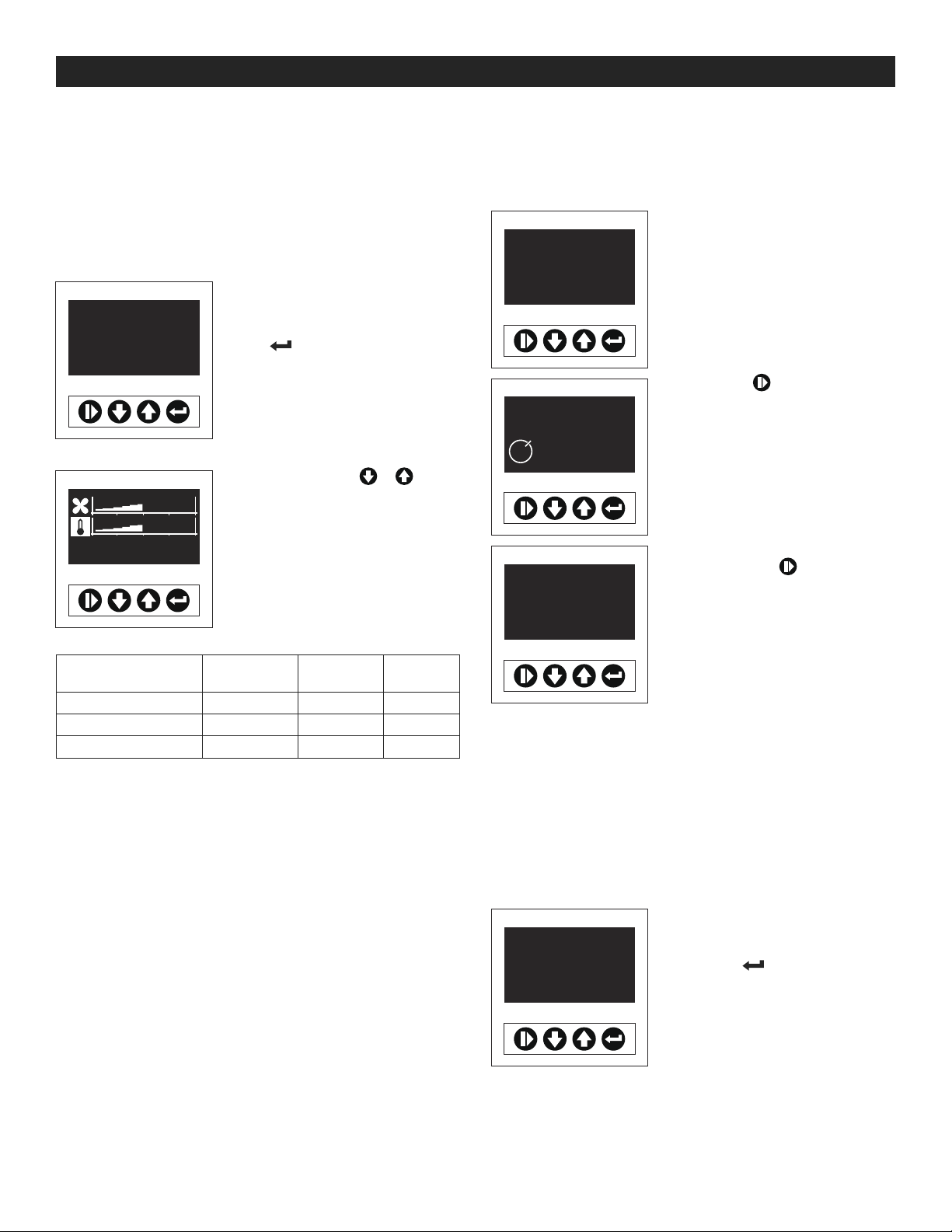

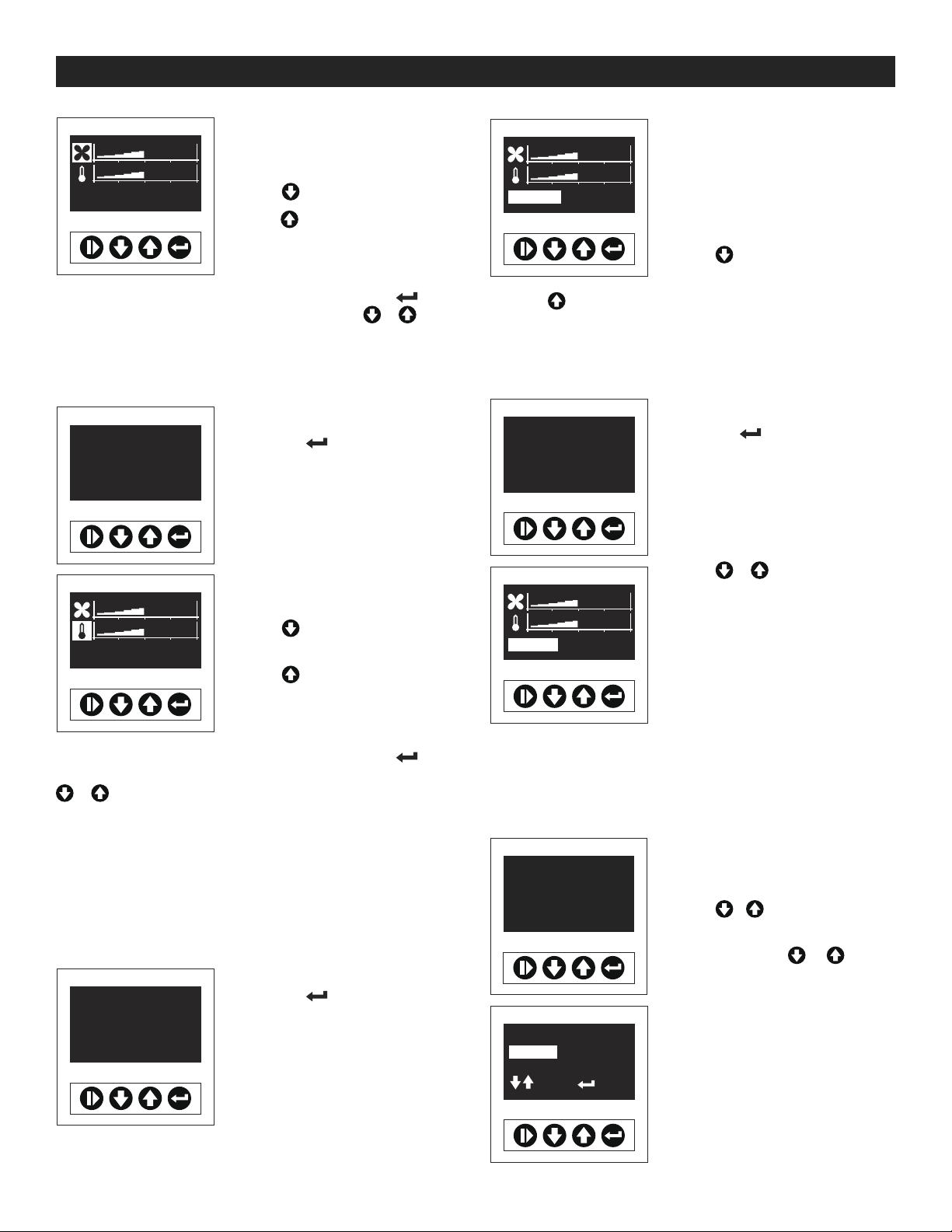

SELECTING INITIAL FILM TYPE

There are three different film types available for

selection when turning on the machine.

Select air pillows, bubble or

Air Pillows

ULINE S-22467

AIRmove

Air Pillows

cushion film options by pressing

six times until film type shows

up.

2

Press or to change the

film type.

START FILM PRODUCTION

Once a menu is selected with its pre-set parameters the

machine is ready to operate. Every menu follows the

same steps:

Machine is ready to start

Air Pillows

ULINE S-22467

Air Pillows

ULINE S-22467

180

Air Pillows

ULINE S-22467

AIRmove

AIRmove

Air Pillows film production.

2

Press to start

Air Pillows film production.

2

Press again to stop

Air Pillows production.

DESCRIPTION

Air Pillows S-22467 8 x 4" 11/ 16"

Air Cushion S-22468 1⁄ x 9 x 13" 1/2"

Bubble Film S-22469 3/4 x 6 x 13" 1/2"

ULINE

PART NO.

CUSHION SIZE SPACING GUIDE

2

AIRmove

HOW TO ADJUST AIR SETTINGS

The chosen film type menus automatically run on the

correct air and temperature settings. You do not need

to adjust machine setting manually, but if the automatic

settings are not optimal, the keypad allows you to

change the following settings:

Display Air Pillows

Air Pillows

ULINE S-22467

AIRmove

Ready to start

Press 1 x for air settings.

2

PAGE 5 OF 27 0621 I H-7241

Page 6

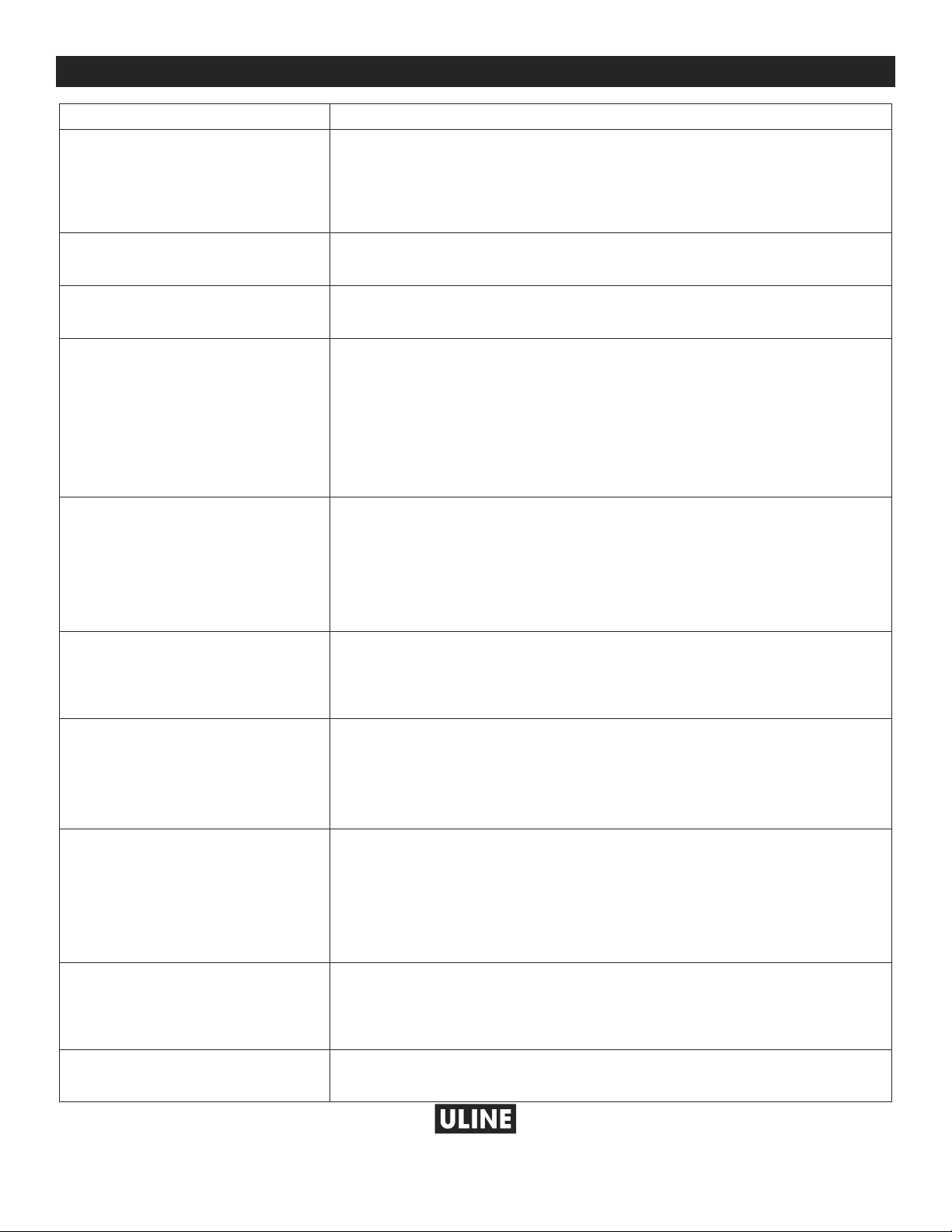

SETTING UP THE DEVICE CONTINUED

Connect_ _ Init_ _

HMI SW 22

Machine SW 1108977017

Reg nr 1

Display air settings

Amount of air is

now adjustable.

Runtime [s] 180

Press to decrease air.

Press to increase air.

Even while the machine is running, press to change

air settings by using or . While the machine is

running, the runtime sign will not show up.

HOW TO ADJUST SEALING TEMPERATURES

Display Air Pillows

Air Pillows

ULINE S-22467

AIRmove

Press 2 x for temperature

settings.

2

Display temperature settings

Change runtime settings

Minimum setting is 1 second.

Runtime [s] 180

Maximum setting is 2,400 seconds.

Press to decrease runtime.

Press to increase runtime.

HOW TO CHANGE FILM TYPE

Changing the menu to a new film type when loading a

different kind of film.

Display Air Pillows

Air Pillows

ULINE S-22467

AIRmove

Press 6 x until film

type shows up.

2

Press or to change the

film type.

Press to decrease

temperature.

Runtime [s] 180

Press to increase

temperature.

Even while the machine is running, press to change

temperature settings by using or . While the

machine is running, the runtime sign will not show up.

HOW TO ADJUST RUNTIME

To produce a desired amount of air pillows, a specific

runtime can be set. Runtime is indicated in seconds,

and its factory setting is 180 seconds. The set runtime will

run down to zero and production will stop.

Display Air Pillows

Air Pillows

ULINE S-22467

AIRmove

Press 3 x to get

the runtime menu.

2

Air Pillows

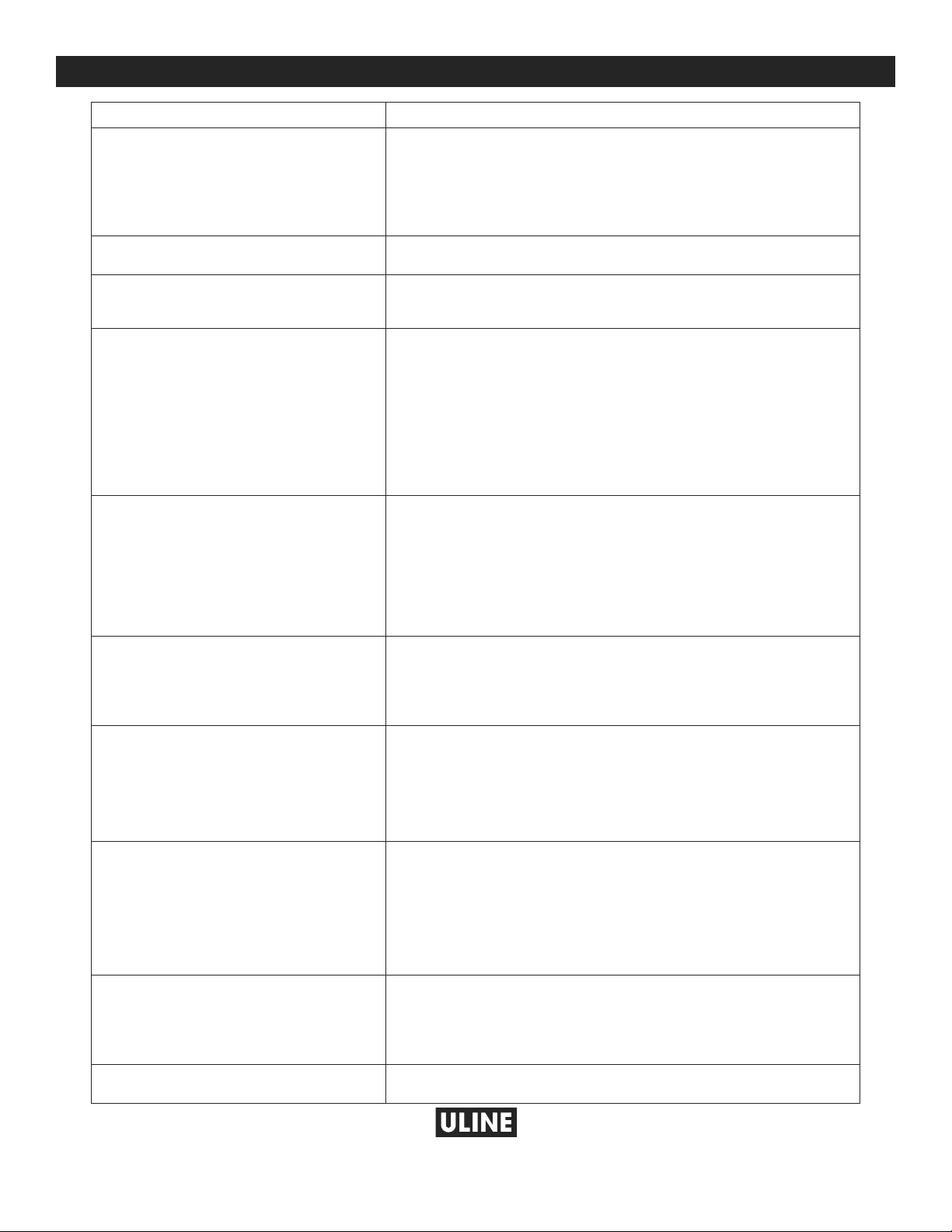

FACTORY SETTINGS

The machine setting enables resetting all choices,

parameters, adjustments and changes back to the

factory settings.

Machine off

Power switch [O] display off

Press and hold while

switching on the machine.

Release the buttons +

when the display runs.

Power switch on

Select Film type

Air Pillows

200mm/8inch

Select Set

Power switch on [I]

All settings have been reset,

proceed with "Selecting Initial

Film Type" again to choose a film

type.

PAGE 6 OF 27 0621 I H-7241

Page 7

MAINTENANCE

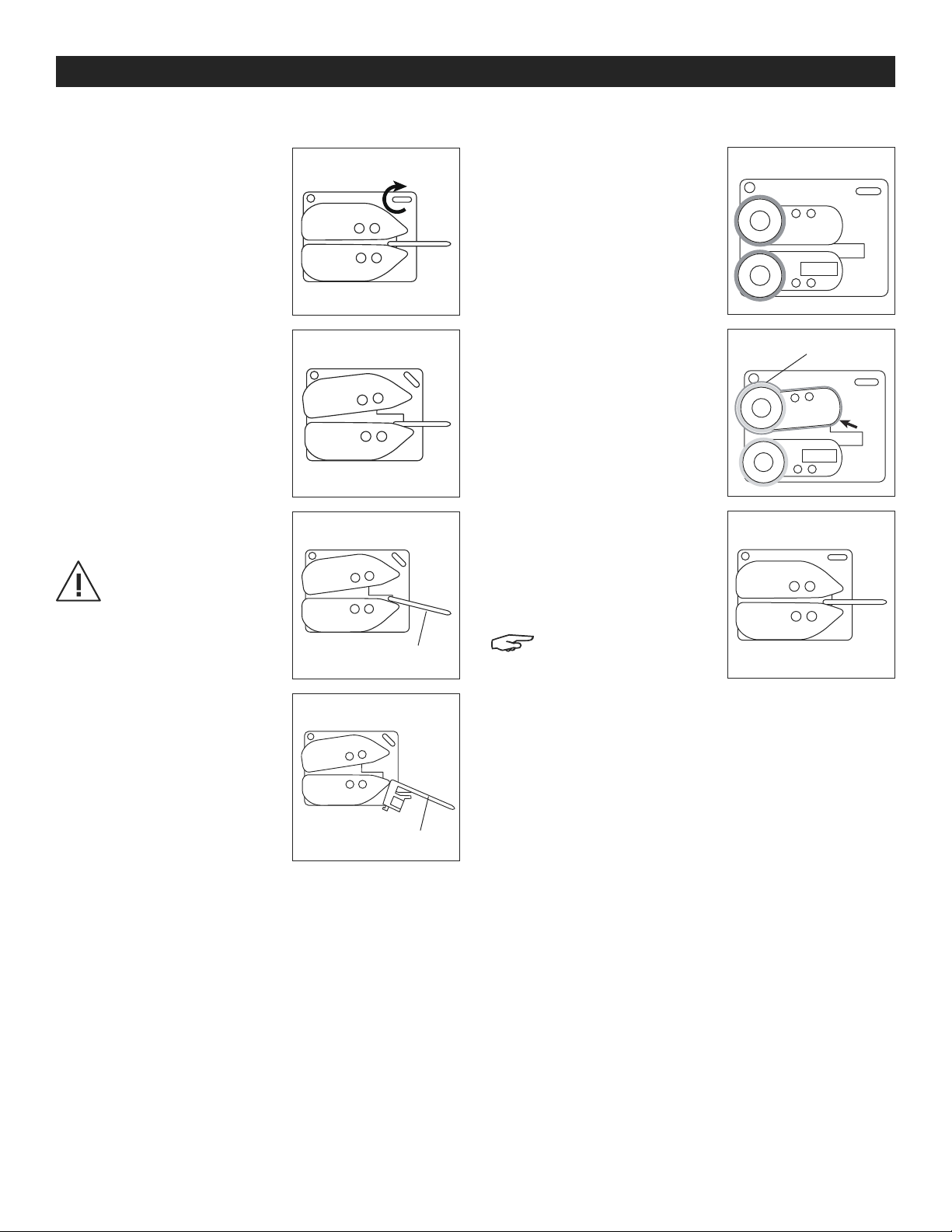

REPLACING THE BLADE

Make sure to disconnect from

the power supply.

1. Turn the locking knob

clockwise to unlock the top

sealing unit. (See Figure 8)

2. Open the top sealing unit.

(See Figure 9)

3. Pull the blade to the right

side. (See Figure 10)

CAUTION! Sharp blade.

Figure 8

Figure 9

Figure 10

CHANGING THE BELTS

1. Remove the blue covers on

both the top and bottom

sealing units using included

Allen key. Ensure the top

sealing unit is unlocked.

(See Figure 12)

2. Push the top sealing unit to

the left.

3. Remove the Teflon® belt

while applying upward

pressure to the top sealing

unit and replace with a new

Teflon® belt. (See Figure 13)

4. Repeat steps 2 and 3 with

the bottom sealing unit.

5. Reattach the blue covers

using the included Allen key

and turn the locking knob

counterclockwise to lock

the top sealing unit.

(See Figure 14)

Figure 12

Figur e 13

Fi gure 14

Teflon Belt

4. Take the blade out of the

machine and insert a new

one. (See Figure 11)

5. Turn the locking knob

counterclockwise to re-lock

the top sealing unit.

Figure 11

Blade

Blade

NOTE: Visit uline.com

to order replacement

injector blades (H-7241INJCT) and teflon belts

(H-7241-TBELT).

PAGE 7 OF 27 0621 I H-7241

Page 8

ERROR CODES

ERROR 20

Calibration out of range

Calibrate seal wire

Turn off and on

ERROR 21

Seal wire

Check connection

Turn off and on

ERROR 22

Temperature not reached

Check seal system

Turn off and on

Calibration out of range.

Calibrate seal wire.

Turn off and on.

Call Uline Customer Service at

1-800-295-5510.

Seal wire.

Check connection.

Turn off and on.

Temperature not reached.

Check seal system.

Turn off and on.

ERROR 30

Seal jaw is not closed

Close jaw

Press start to release

ERROR 31

Transport failure

Check film transport

Press start to release

ERROR 32

Transport motor overload

Check film transport

Press start to release

Seal jaw is not closed.

Only possible if a micro switch is

mounted.

Close jaw.

Press start to release.

Transport failure.

Check film transport.

Press start to release.

Remove and reload film from

seal jaw/injector blade.

Transport motor overload.

Check film transport.

Press start to release.

Remove and reload film from

seal jaw/injector blade.

PAGE 8 OF 27 0621 I H-7241

Page 9

TROUBLESHOOTING

1

0

uline.ca

OPERATING ISSUE RECOMMENDATIONS

No power to machine

No display after power on

Display shown but machine will not start.

Bad film seal

Film seal is stretched.

Check power cord is connected to both machine and outlet.

Check main power switch is on.

Check power fuse.

Check power fuse.

Contact Uline Customer Service at 1-800-295-5510.

Check film type selection.

Turn off machine, check belt/blade position.

Check sealing units are closed and locked.

Check if film roll shaft is in the right position.

Replace belts and blades.

Adjust the temperature.

Check film type selection.

Check if film roll shaft is in the right position.

Adjust the temperature.

Adjust the air flow.

Check if film roll shaft is jammed.

Film does not run through.

Air cushions do not hold air.

Film jams occur frequently.

Film blockage

Film winding around rollers

Check if sealing units are closed and locked.

Check blade placement.

Replace belts and blades.

Film roll is loaded the wrong way.

Check belt/blade position.

Check if film roll shaft is in the right position.

Check if sealing units are closed and locked.

Check film causing blockage.

Check belts and blades. Replace as needed.

Check film and mandrel settings.

Remove and reload film into machine to ensure film is not

jamming up injector.

Check if film roll shaft is jammed.

Remove any film causing blockage.

Check film run on machine.

Remove any film causing blockage.

-800-295-551

PAGE 9 OF 27 0621 I H-7241

Page 10

H-7241

MÁQUINA PARA

ACOJINADO

CONTENIDO DE LA CAJA

• Máquina para Acojinado

• Soporte del Rollo de Película

• Medidor de Espacio

• Kit de Mantenimiento

• Cable Eléctrico

• Manual del Usuario

800-295- 5510

uline.mx

PARTES

Perilla de Desbloqueo

Panel de Control

Unidad de Sellado

(incluye Correas de Teflon®)

Soporte del Rollo de Película

Barra de Guía

Conexión de

Entrada Externa

Interruptor Principal

de Energía y Entrada

de Corriente

Soporte del Rollo de Película

Barra de Guía

Inyector de Aire

Conector USB-B

¡ADVERTENCIA! Lea y comprenda las

instrucciones por completo antes de utilizar la

Máquina para Acojinado Uline.

PAGE 10 OF 27 0621 I H-7241

¡ADVERTENCIA! Para garantizar la seguridad

personal, debe seguir con atención las

siguientes instrucciones.

Page 11

SEGURIDAD

ÁREA DE TRABAJO

• Mantenga el área de trabajo limpia y bien

iluminada.

• Coloque la máquina sobre una superficie plana y

seca.

• No utilice la máquina en ambientes explosivos,

como en presencia de líquidos inflamables, gases

o polvo. No coloque materiales inflamables dentro,

encima o alrededor de la máquina.

SEGURIDAD ELÉCTRICA

• La clavija debe corresponder al enchufe y el

enchufe debe hacer tierra de forma adecuada. No

modifique la clavija de ninguna manera. No utilice

un adaptador de clavijas o extensiones eléctricas.

• No exponga la máquina a condiciones de

humedad.

• Para trabajos de instalación y mantenimiento, la

máquina debe apagarse siempre mediante el

interruptor principal y estar desconectada de la

toma de corriente principal.

• Todas las medidas y facilidades de seguridad

y protección deben aplicarse y mantenerse

conforme a las instrucciones de la IEC (International

Electrotechnical Commission).

SEGURIDAD PERSONAL

• Evite el encendido accidental. Asegúrese de que

el interruptor esté colocado en apagado antes de

enchufar.

USO Y CUIDADO

• Apague la máquina y desconecte el enchufe de la

fuente de energía antes de llevar a cabo cualquier

operación a la máquina. Esto incluye reemplazo de

película, limpieza o mantenimiento.

• La máquina requiere limpieza periódica. Verifique si

hay partes móviles desalineadas o atoradas, partes

rotas, o cualquier otro problema que afecte el

funcionamiento. No utilice una máquina dañada.

• Este sistema fue diseñado para procesar un tipo

específico de película. Para garantizar el buen

funcionamiento, solo reemplace con película para

Máquina para Acojinado Uline.

• En situaciones de emergencia, apague el

interruptor de energía. La máquina se apagará en

unos pocos segundos (cuando el indicador esté

apagado por completo). Luego de eliminar la

situación de emergencia o el defecto, la máquina

se puede encender de nuevo de acuerdo al

manual del usuario.

ALMACENAMIENTO

Almacene el dispositivo solo bajo las siguientes

condiciones:

• El almacenamiento en exteriores está prohibido.

• El dispositivo solo se debe almacenar en

habitaciones secas.

• Mantenga seco y libre de polvo.

• Proteja del calor masivo, como los radiadores.

• Hay una navaja extremadamente filosa por

debajo del ensamble del inyector de aire. Siga

estrictamente las instrucciones de reemplazo de

navajas en la página 17.

• La película se sella utilizando un alambre térmico

localizado debajo de una correa de Teflon®. Este

alambre se pone muy caliente y podría quemar

si se toca. Apague la máquina y permita que el

alambre se enfríe de 2 a 3 minutos antes de llevar

a cabo cualquier operación que exponga el

alambre. Siga las instrucciones incluidas, página 16,

para reemplazar las correas de Teflon®.

PAGE 11 OF 27 0621 I H-7241

Page 12

ESPECIFICACIONES TÉCNICAS

Voltaje 95 – 250 VAC; 50/60 Hz

Consumo de Energía (máx.) 97 W

Consumo de Energía 76 W

Consumo de Energía (modo de espera) 6.2 W

Fusible Principal Recomendado 3.15 AMP

Dimensiones 37.3 x 36.4 cm (14⁄ x 14⁄")

Altura 33 cm (13")

Velocidad de Transporte ~33 LFM

Peso 7.1 kg (15.65 lbs.)

Nivel de Presión Acústica 52 db

FUNCIONES DEL TECLADO

Botón de Encendido/Apagado • Enciende o apaga la máquina

Flecha arriba

Flecha abajo

Botón de Entrada

• Aumenta el valor

• Desplaza hacia arriba

• Reduce el valor

• Desplaza hacia abajo

• Confirma

• Menú de entrada

• Elemento de menú de entrada

PAGE 12 OF 27 0621 I H-7241

Page 13

CONFIGURAR EL DISPOSITIVO

ENSAMBLE DEL SOPORTE DEL ROLLO DE PELÍCULA

1. Remueva la máquina

y el eje azul para

rollo de película

de la caja. Inserte

la pieza de metal

en el orificio en el

lado delantero de la

máquina.

(Vea Diagrama 1)

Las películas para la Máquina para Acojinado Uline

están disponibles en tres opciones diferentes:

DESCRIPCIÓN

Almohadillas de Aire S-22467 8 x 4" 11/ 16"

Acojinado S-22468 1¼ x 9 x 13" 1/2"

Burbuja S-22469 3/4 x 6 x 13" 1/2"

2. Ajuste el soporte

del rollo de película

para que quepa la

película deseada

aflojando el tornillo

en el lateral derecho

de la máquina con

la llave Allen que se

incluye. Apriete el

tornillo suavemente

para fijarlo.

(Vea Diagrama 2)

NOTA: El tornillo en el lado derecho de la

máquina está colocado en la cubierta de

la máquina. Debe aflojarse y apretarse para

ajustar el soporte del rollo de película y no es

necesario quitarlo para este proceso.

3. El uso del medidor de espacio incluido puede

ayudar a encontrar

la configuración

correcta para cada

tipo de película.

(Vea Diagrama 3)

Diagrama 1

NO. DE PARTE

DE ULINE

Diagrama 2

TAMAÑO DE

ACOJINADO

11/ 16"

1/2"

GUÍA DE

ESPACIO

Diagrama 3

15/16"

CARGAR UN ROLLO DE PELÍCULA

1. Deslice la película para

insertarla en el soporte

del rollo de película.

Asegúrese de que la

película esté orientada

para desenrollarse desde la

parte inferior del rollo.

(Vea Diagrama 4)

2. Hay un espacio entre el

borde de la película y

las perforaciones. Corte

un pequeña esquina del

espacio para la película.

(Vea Diagrama 5)

3. Gire la perilla de

desbloqueo en sentido

de las manecillas del

reloj para desbloquear la

unidad superior de sellado.

Deslice la película entre

las unidades de sellado lo

más lejos posible hasta que

sienta resistencia.

(Vea Diagrama 6)

4. Gire la perilla en sentido

contrario a las manecillas

del reloj para desbloquear la

unidad superior de sellado.

Asegúrese siempre de que la

perilla esté bloqueada antes

de operar la máquina.

(Vea Diagrama 7)

Diagrama 4

Diagrama 5

Diagrama 6

Diagrama 7

• Almohadillas

de Aire = 11/16"

• Acojinado = 1/2"

• Burbuja = 1/2"

4. Ajuste el tornillo para

asegurar el soporte del rollo de película.

PAGE 13 OF 27 0621 IH-7241

Page 14

CONTINUACIÓN DE CONFIGURAR EL DISPOSITIVO

INTERRUPTOR DE ENERGÍA Y CONEXIONES

Después de verificar la fuente de energía, el sistema

se puede encender. El interruptor principal está en la

posición "I."

SELECCIONAR EL TIPO DE PELÍCULA INICIAL

Hay tres tipos de películas diferentes para seleccionar

disponibles cuando enciende la máquina.

Seleccione las opciones de

Air Pillows

ULINE S-22467

AIRmove

Runtime [s] 180

almohadillas de aire, burbuja

o acojinado presionando seis

veces hasta que el tipo de

2

película aparezca.

Oprima el símbolo o

para confirmar la opción de

pelicula.

COMENZAR LA PRODUCCIÓN DE PELÍCULA

Una vez que se seleccione un menú con sus

parámeteros preconfigurados, la máquina está lista

para operar. Todo menú sigue los mismos pasos:

La máquina está lista para

Air Pillows

ULINE S-22467

Air Pillows

ULINE S-22467

180

Air Pillows

ULINE S-22467

AIRmove

AIRmove

AIRmove

comenzar la producción de

película Air Pillows.

2

Oprima para comenzar

la producción de película Air

Pillows.

2

Vuelva a oprimir para

detener la producción de

película Air Pillows.

2

DESCRIPCIÓN

Almohadillas de Aire S-22467 8 x 4" 11/ 16"

Acojinado S-22468 1¼ x 9 x 13" 1/2"

Burbuja S-22469 3/4 x 6 x 13" 1/2"

NO. DE PARTE

DE ULINE

TAMAÑO DE

ACOJINADO

GUÍA DE

ESPACIO

CÓMO AJUSTAR LAS CONFIGURACIONES DE AIRE

Los menús de tipo de película escogida funcionan

automáticamente bajo las configuraciones correctas

de aire y temperatura. No se necesita ajustar la

configuración de la máquina manualmente, pero si las

configuraciones automáticas no son óptimas, el teclado

le permite cambiar las siguientes configuraciones:

Visualizar Air Pillows

Air Pillows

ULINE S-22467

AIRmove

Listo para comenzar

Oprima 1 x para

configuración de aire.

2

PAGE 14 OF 27 0621 IH-7241

Page 15

CONTINUACIÓN DE CONFIGURAR EL DISPOSITIVO

Connect_ _ Init_ _

HMI SW 22

Machine SW 1108977017

Reg nr 1

Visualizar configuración de aire

La cantidad de aire

ya es ajustable.

Runtime [s] 180

Oprima para reducir el aire.

Oprima para aumentar el aire.

Aún cuando la máquina esté operando, oprima para

cambiar la configuración de aire utilizando o .

Mientras la máquina esté operando, el signo de tiempo

de ejecución no aparecerá.

CÓMO AJUSTAR TEMPERATURAS PARA SELLAR

Visualizar Air Pillows

Air Pillows

ULINE S-22467

AIRmove

Oprima 2 x para

configuración de temperatura.

2

Visualizar configuración de

temperatura

Cambiar configuración de

tiempo de Ejecución

Configuración mínima es de 1

Runtime [s] 180

segundo.

Configuración máxima es de

2,400 segundos.

Oprima para reducir el tiempo

de ejecución.

Oprima para aumentar el tiempo de ejecución.

CÓMO CAMBIAR EL TIPO DE PELÍCULA

Cambiar el menú a un tipo nuevo de película al cargar

un tipo diferente de película.

Visualizar Air Pillows

Air Pillows

ULINE S-22467

AIRmove

Oprima 6 x hasta que

aparezca el tipo de película.

2

Oprima o para cambiar el

tipo de película.

Oprima para reducir la

Runtime [s] 180

temperatura.

Oprima para aumentar la

temperatura.

Aún cuando la máquina esté operando, oprima

para cambiar la configuración de temperatura utilizando

o . Mientras la máquina esté operando, el signo de

tiempo de ejecución no aparecerá.

CÓMO AJUSTAR EL TIEMPO DE EJECUCIÓN

Para producir una cantidad deseada de acojinado, se

puede fijar un tiempo específico de ejecución. El tiempo

de ejecución se indica en segundos y su configuración

de fábrica es de 180 segundos. El tiempo de ejecución

fijado bajará a cero y cesará la producción.

Visualizar Air Pillows

Air Pillows

ULINE S-22467

AIRmove

Oprima 3 x para ver

el menú de tiempo de ejecución.

2

Air Pillows

CONFIGURACIONES DE FÁBRICA

La configuración de la máquina permite reiniciar todas

las opciones, parámetros, ajustes y cambios y volver a la

configuración de fábrica.

Máquina apagada

Visualización del interruptor de

energía [O] apagada

Oprima y déjelo oprimido

mientas encienda la máquina.

Suelte los botones +

cuando opere la visualización.

Interruptor de energía encendido

Select Film type

Air Pillows

200mm/8inch

Select Set

Interruptor de energía encendido [I]

Todos las configuraciones

fueron reiniciadas prosiga con

"Seleccionar el Tipo Inicial de

Película" de nuevo para escoger

un tipo de película.

PAGE 15 OF 27 0621 I H-7241

Page 16

MANTENIMIENTO

REEMPLAZAR LA NAVAJA

Asegúrese de desconectar de

la fuente de energía.

1. Gire la perilla de bloqueo

en sentido de las

manecillas del reloj para

desbloquear la unidad

superior de sellado.

(Vea Diagrama 8)

2. Abra la unidad superior de

sellado. (Vea Diagrama 9)

3. Jale la navaja hacia el

lado derecho.

(Vea Diagrama 10)

¡PRECAUCIÓN! Navaja

filosa.

4. Saque la navaja de la

máquina e inserte una

nueva. (Vea Diagrama 11)

5. Gire la perilla de bloqueo

en dirección contraria a las

manecillas del reloj para

volver a bloquear la unidad

superior de sellado.

Diagrama 8

Diagrama 9

Diagrama 10

Diagrama 11

Navaja

Navaja

CAMBIAR LAS CORREAS

1. Remueva las cubiertas

azules tanto en la unidad de

sellado superior como en

la inferior utilizando la llave

Allen incluida. Asegúrese de

que la unidad de sellado

superior esté desbloqueada.

(Vea Diagrama 12)

2. Empuje la unidad de

sellado superior hacia la

izquierda.

3. Retire la correa de Teflon®

mientras aplica presión

hacia arriba a la unidad

de sellado superior y

reemplácela con una nueva

correa de Teflon®.

(Vea Diagrama 13)

4. Repita los pasos 2 y 3 con la

unidad de sellado inferior.

5. Vuelva a fijar las cubiertas

azules utilizando la llave

Allen incluida y gire la

perilla en sentido contrario

a las agujas del reloj para

bloquear la unidad superior

de sellado.

(Vea Diagrama 14)

NOTE: Vea uline.mx para ordenar el repuesto

de las navajas del inyector (H-7241-INJCT) y las

correas de teflón (H-7241-TBELT).

Diagrama 12

Diagrama 13

Diagrama 14

Correa de

Teflon®

PAGE 16 OF 27 0621 I H-7241

Page 17

CÓDIGOS DE ERROR

ERROR 20

Calibration out of range

Calibrate seal wire

Turn off and on

ERROR 21

Seal wire

Check connection

Turn off and on

ERROR 22

Temperature not reached

Check seal system

Turn off and on

Calibración fuera de rango.

Calibre el alambre de sellado.

Encienda y apague.

Llame a Servicio a Clientes de

Uline al 800-295-5510.

Alambre de sellado.

Revisar conexión.

Encienda y apague.

No se alcanzó la temperatura.

Revise el sistema de sellado.

Encienda y apague.

ERROR 30

Seal jaw is not closed

Close jaw

Press start to release

ERROR 31

Transport failure

Check film transport

Press start to release

ERROR 32

Transport motor overload

Check film transport

Press start to release

La mordaza de sellado no está

cerrada.

Solo es posible si está instalado

un microinterruptor.

Cierre la mordaza.

Presione iniciar para liberarla.

Falla de transporte.

Revise el transporte de la película.

Presione iniciar para liberar.

Retire y cargue de nuevo la

película para sellar la navaja de

la mordaza/inyector.

Sobrecarga del transporte del

motor.

Verifique el transporte de la

película.

Presione iniciar para liberar.

Retire y cargue de nuevo

la película de mordaza de

sellado/inyector.

PAGE 17 OF 27 0621 I H-7241

Page 18

SOLUCIÓN DE PROBLEMAS

8

0

uline.mx

PROBLEMA DE FUNCIONAMIENTO RECOMENDACIONES

La máquina no recibe corriente

No hay visualización después de

encender

Aparece la visualización pero no

se enciende la máquina.

Sellado pobre de la película

El sellado de la película está

estirado.

Verifique que el cable eléctrico esté conectado tanto a la máquina como

al enchufe.

Verifique que el interruptor principal de energía esté encendido.

Verifique el fusible de energía.

Verifique el fusible de energía.

Comuníquese con Servicio a Clientes de Uline al 800-295-5510.

Verifique la selección de tipo de película.

Apague la máquina, verifique la posición de la correa/navaja.

Verifique que las unidades de sellado estén cerradas y bloqueadas.

Verifique que el eje del rollo de la película esté en la posición correcta.

Reemplace correas y navajas.

Ajuste la temperatura.

Verifique la selección de tipo de película.

Verifique que el eje del rollo de película esté en la posición correcta.

Ajuste la temperatura.

Ajuste el flujo de aire.

Verifica si el eje del rollo de película está atascado.

La película no sale.

El acojinado no almacena aire.

Ocurren atascos de película con

frecuencia.

Obstrucción de película

La película se enrolla alrededor

de los rodillos

Verifique que las unidades de sellado estén cerradas y bloqueadas.

Verifique la colocación de la navaja.

Reemplace correas y navajas.

El rollo de película está cargado en la dirección equivocada.

Verifique la posición de la correa/navaja.

Verifique que el eje del rollo de película esté en la posición correcta.

Verifique que las unidades de sellado estén cerradas y bloqueadas.

Verifique la película que causa la obstrucción.

Revise correas y navajas. Reemplace cuando sea necesario.

Revise la película y la configuración del eje del torno.

Retire y vuelva a cargar la película en la máquina para asegurarse de

que no esté atascada.

Verifique si el eje del rollo de película está atascado.

Remueva cualquier película que cause obstrucción.

Verifique el camino de la película en la máquina.

Remueva cualquier película que cause obstrucción.

00-295-551

PAGE 18 OF 27 0621 I H-7241

Page 19

H-7241

MACHINE À

COUSSIN D'AIR

CONTENU DE LA BOÎTE

• Machine à coussin d'air

• Support de rouleau de film

• Jauge d'espacement

• Ensemble d'entretien

• Cordon d'alimentation

• Manuel de l'utilisateur

1-800-295- 5510

uline.ca

PIÈCES

Bouton de déverrouillage

Panneau de commande

Unité de scellage

(comprend les courroies

en TeflonMD)

Support de rouleau de film

Barre de guidage

Port de connexion

externe

Commutateur

principal et prise de

courant

Support de rouleau de film

Barre de guidage

Injecteur d'air

Connecteur USB-B

ARRÊT ARRÊT

PAGE 19 OF 27 0621 I H-7241

AVERTISSEMENT! Veuillez lire et comprendre

toutes les instructions avant d'utiliser la

machine à coussin d'air Uline.

AVERTISSEMENT! Pour garantir la sécurité

personnelle, il est impératif de respecter les

instructions suivantes.

Page 20

SÉCURITÉ

ZONE DE TRAVAIL

• Maintenez la zone de travail propre et bien éclairée.

• Placez la machine sur une surface plate et sèche.

• N'utilisez pas cette machine dans un environnement

explosif, ou en présence de liquide inflammable,

de gaz ou de poussière. Ne placez aucune matière

inflammable à l'intérieur, sur ou à proximité de la

machine.

SÉCURITÉ ÉLECTRIQUE

• La fiche d'alimentation doit correspondre à la prise

électrique, qui doit être convenablement mise à la

terre. N'apportez aucune modification à la fiche.

N'utilisez pas de fiche d'adaptation ou de rallonge.

• N'exposez pas cette machine à l'humidité.

• Pendant les opérations d'installation et d'entretien, la

machine doit toujours être éteinte et débranchée de

la source d'alimentation principale.

• Toutes les consignes de sécurité et de protection

doivent être observées et maintenues conformément

aux réglementations ICE.

SÉCURITÉ PERSONNELLE

• Empêchez tout démarrage accidentel. Assurez-vous

que le commutateur est en position éteinte avant de

brancher la machine.

• Une lame extrêmement tranchante est située sous

l'injecteur d'air. Adhérez strictement aux instructions

de remplacement de lame à la page 26.

• Le film est scellé par un fil chauffant situé sous la

courroie en TeflonMD. Ce fil devient extrêmement

chaud et peut provoquer des brûlures en cas

de contact. Éteignez la machine et laissez le fil

refroidir pendant 2 ou 3 minutes avant d'effectuer

toute opération où il se trouvera exposé à nu.

Suivez les instructions fournies à la page 25 pour le

remplacement des courroies en TeflonMD.

UTILISATION ET SOIN

• Éteignez la machine et débranchez la fiche de

la source d'alimentation avant d'effectuer toute

opération. Ceci inclut le remplacement du film, le

nettoyage ou l'entretien.

• Cette machine nécessite un nettoyage régulier.

Assurez-vous qu'aucune pièce mobile n'est décalée,

bloquée ou endommagée et que rien ne puisse

affecter le fonctionnement. N'utilisez pas une

machine endommagée.

• Ce système a été conçu pour fonctionner avec

un certain type de film. Afin de garantir un bon

fonctionnement, remplacez uniquement avec le film

Uline pour machine à coussins d'air.

• En cas d'urgence, placez le commutateur en

position arrêt. La machine s'éteindra en quelques

secondes (lorsque l'indicateur est complètement

éteint). Après avoir réglé le problème ou l'urgence,

vous pouvez rallumer la machine selon les

instructions du manuel de l'utilisateur.

RANGEMENT

Ne rangez l'appareil que dans les conditions suivantes :

• Le rangement à l'extérieur est interdit.

• L'appareil ne doit être entreposé que dans une

pièce sèche.

• Conservez au sec et à l'abri de la poussière.

• Protégez des sources de chaleur intense, comme les

radiateurs.

PAGE 20 OF 27 0621 I H-7241

Page 21

SPÉCIFICATIONS TECHNIQUES

Tension 95 à 250 VCA; 50/60 Hz

Consommation électrique (max.) 97 W

Consommation électrique 76 W

Consommation électrique (mode de veille) 6,2 W

Fusible principal recommandé 3,15 A

Dimensions 37,3 x 36,4 cm (14 ⁄ x 14 ⁄ po)

Hauteur 33 cm (13 po)

Vitesse de route ~ 33 pi/m

Poids 7,1 kg (15,65 lb)

Niveau de pression acoustique 52 db

FONCTIONS DU CLAVIER

Touche marche/arrêt • Allume ou éteint la machine

Flèche vers le haut

Flèche vers le bas

Bouton d'entrée

• Augmente la valeur

• Fait défiler vers le haut

• Diminue la valeur

• Fait défiler vers le bas

• Confirme

• Accès au menu

• Accès aux options du menu

PAGE 21 OF 27 0621 I H-7241

Page 22

RÉGLAGE DE L'APPAREIL

MONTAGE DU SUPPORT DE ROULEAU DE FILM

1. Retirez la machine et

l'arbre porte-rouleau

de film bleu de la

boîte. Insérez la partie

métallique dans le

trou situé sur le côté

avant de la machine.

(Voir Figure 1)

Les films pour machines à coussin d'air Uline sont offerts

en trois options différentes :

DESCRIPTION

Coussins d'Air

Coussins d'Air

Film À Bulles

RÉF. ULINE

S-22467 8 x 4 po

S-22468 1 ⁄ x 9 x 13 po 1/2 po

S-22469 3/4 x 6 x 13 po 1/2 po

2. Ajustez le support de

rouleau de film au

type de film désiré

en desserrant la vis

située sur le côté

droit de la machine

à l'aide de la clé

Allen incluse. Serrez

légèrement la vis

pour sécuriser.

(Voir Figure 2)

REMARQUE : La vis située sur le côté droit de la

machine est placée dans son boîtier. Elle doit

être desserrée et serrée pour ajuster le support

de rouleau de film, sans nécessiter son retrait.

3. L'utilisation de la jauge

d'espacement incluse

peut aider à trouver

le bon réglage pour

chaque type de film.

(Voir Figure 3)

Figure 1

TAILLE DU COUSSIN

Figure 2

11/ 16 p o

1/2 po

GUIDE

D'ESPACEMENT

11/ 16 po

Figure 3

15/16 p o

CHARGEMENT DU ROULEAU DE FILM

1. Glissez le film sur le support

de rouleau de film. Assurezvous que le film est orienté

de manière à se dérouler

par le bas. (Voir Figure 4)

2. Il y a un écart entre le bord

supérieur du film et les

perforations. Coupez un

petit coin de film.

(Voir Figure 5)

3. Tournez le bouton de

déverrouillage dans le sens

horaire pour déverrouiller la

partie supérieure de unité

de scellage. Glissez le film

aussi loin que possible entre

les deux unités de scellage

jusqu'à ce que vous sentiez

une résistance. (Voir Figure 6)

4. Tournez le bouton de

déverrouillage dans le sens

antihoraire pour verrouiller

l'unité de scellage

supérieure. Assurez-vous de

toujours verrouiller le bouton

avant d'utiliser la machine.

(Voir Figure 7)

Figure 4

Figure 5

Figure 6

Figure 7

• Coussins

d'air = 11/16 po

• Coussins

d'air = 1/2 po

• Film à bulles = 1/2 po

4. Serrez la vis pour sécuriser le support de rouleau de

film.

PAGE 22 OF 27 0621 I H-7241

Page 23

RÉGLAGE DE L'APPAREIL SUITE

COMMUTATEUR ET CONNEXIONS

Après vérification de la source d'alimentation, vous

pouvez allumer l'appareil. Le commutateur principal est

en position « l ».

SÉLECTION DU TYPE DE FILM INITIAL

Il y a trois types de film offerts lorsque vous allumez la

machine.

Sélectionnez parmi les options

Air Pillows

ULINE S-22467

AIRmove

Select Film type

Air Pillows

200mm/8inch

Select Set

de coussins d'air ou de film à

bulles en appuyant six fois sur

jusqu'à ce que le type de

2

film s'affiche.

Appuyez sur ou pour

confirmer votre sélection de film.

DÉMARRAGE DE LA PRODUCTION

Lorsque vous avez sélectionné un menu et ses

paramètres, la machine est prête à l'emploi. Chaque

menu suit les mêmes étapes :

La machine est prête à démarrer

Air Pillows

ULINE S-22467

Air Pillows

ULINE S-22467

180

Air Pillows

ULINE S-22467

AIRmove

AIRmove

la production de film de

remplissage de vide S.

2

Appuyez sur pour

commencer la production de

film de remplissage de vide S.

2

Appuyez une nouvelle fois sur

pour arrêter la production de

film de remplissage de vide S.

DESCRIPTION

Coussins d'Air

Coussins d'Air

Film À Bulles

RÉF. ULINE

S-22467 8 x 4 po

S-22468 1 ⁄ x 9 x 13 po 1/2 po

S-22469 3/4 x 6 x 13 po 1/2 po

TAILLE DU

COUSSIN

GUIDE

D'ESPACEMENT

11/ 16 po

2

AIRmove

COMMENT AJUSTER LES RÉGLAGES DE L'AIR

Les menus de type de film choisi fonctionnement

automatiquement sur les paramètres d'air et de

température appropriés. Vous n'avez pas besoin

d'ajuster manuellement les paramètres de la

machine, mais si les paramètres automatiques ne

sont pas optimaux, le clavier vous permet de faire les

changements suivants :

Affichage de remplissage de

Air Pillows

ULINE S-22467

AIRmove

vide S

Prête à démarrer

2

Appuyer 1 x sur pour les

paramètres d'air.

PAGE 23 OF 27 0621 I H-7241

Page 24

RÉGLAGE DE L'APPAREIL SUITE

Connect_ _ Init_ _

HMI SW 22

Machine SW 1108977017

Reg nr 1

Affichage des paramètres d'air

La quantité d'air est maintenant

réglable.

Runtime [s] 180

Appuyez sur pour moins d'air.

Appuyez sur pour plus d'air.

Même lorsque la machine est en cours d'utilisation,

appuyez sur pour changer les réglages d'air

en utilisant ou . Lorsque la machine est en

cours d'utilisation, l'affichage de temps d'exécution

(«runtime») n'apparaît pas.

COMMENT AJUSTER LA TEMPÉRATURE DE SCELLAGE

Affichage des coussins d'air

Air Pillows

ULINE S-22467

AIRmove

Runtime [s] 180

Appuyer 2 x sur pour les

paramètres de température.

2

Affichage des paramètres de

température

Appuyez sur pour diminuer la

température.

Appuyez sur pour augmenter

la température.

Changer le réglage de temps

d'exécution

Le réglage minimal est de 1

Runtime [s] 180

seconde.

Le réglage minimal est de 2400

secondes.

Appuyez sur pour diminuer le

temps d'exécution.

Appuyez sur pour augmenter le temps d'exécution.

COMMENT CHANGER LE TYPE DE FILM

Changer le menu à un type de film différent lors du

chargement d'un type de film différent.

Affichage des coussins d'air

Air Pillows

ULINE S-22467

AIRmove

Air Pillows

Appuyez 6 x sur jusqu'à

l'affichage du type de film.

2

Appuyez sur ou pour

changer les type de film.

RÉGLAGES D'USINE

Même lorsque la machine est

en cours d'utilisation, appuyez sur pour changer les

réglages de température en appuyant sur ou .

Lorsque la machine est en cours d'utilisation, l'affichage

de temps d'exécution («runtime») n'apparaît pas.

COMMENT AJUSTER LE TEMPS D'EXÉCUTION

Pour produire une quantité désirée de coussins

d'air, il est possible de régler un temps d'exécution

spécifique. Le temps d'exécution est indiqué en

secondes; le réglage d'usine est de 180 secondes. Le

temps d'exécution préétabli descend vers zéro, et la

production s'arrête.

Affichage des coussins d'air

Air Pillows

ULINE S-22467

AIRmove

PAGE 24 OF 27 0621 I H-7241

Appuyez 3 x sur pour

parvenir au menu de temps

d'exécution.

2

Le réglage de la machine permet de réinitialiser vers le

réglage d'usine tous les choix, paramètres, ajustements

et changements effectués.

Machine éteinte

Affichage du commutateur

éteint [O]

Appuyez sur et maintenez

appuyé tout en allumant la

machine.

Relâchez les boutons + à

l'affichage de l'écran.

Commutateur allumé

Select Film type

Air Pillows

200mm/8inch

Select Set

Commutateur allumé [I]

Tous les paramètres sont

réinitialisés, suivez à nouveau

les instructions de la section

Sélection de type de film initial

pour sélectionner un type de

film.

Page 25

ENTRETIEN

REMPLACEMENT DE LA LAME

Assurez-vous que l'appareil est

débranché de toute source

d'alimentation.

1. Tournez le bouton de

verrouillage dans le sens

horaire pour déverrouiller

l'unité de scellage

supérieure. (Voir Figure 8)

2. Ouvrez l'unité de scellage

supérieure. (Voir Figure 9)

3. Tirez la lame vers le côté

droit. (Voir Figure 10)

MISE EN GARDE! Lame

tranchante

Figure 8

Figure 9

Figure 10

Lame

REMPLACEMENT DES COURROIES

1. Retirez les couvercles

bleus situés sur les unités

de scellage inférieure et

supérieure à l'aide d'une

clé Allen. Assurez-vous

que l'unité de scellage

supérieure est déverrouillée.

(Voir Figure 12)

2. Poussez l'unité de scellage

supérieure vers la gauche.

3. Tout en appuyant sur l'unité

de scellage supérieure,

retirez la courroie en

TeflonMD et remplacez-la

avec une courroie neuve.

(Voir Figure 13)

4. Répétez les étapes 2 et 3

avec l'unité de scellage

inférieure.

5. Replacez les couvercles

bleus à l'aide de la clé

Allen et tournez le bouton

de verrouillage dans le sens

antihoraire pour verrouiller

l'unité de scellage

supérieure. (Voir Figure 14)

Figure 12

Figur e 13

Fi gure 14

Courroie en

MD

Teflon

4. Retirez la lame de la

machine et insérez une

nouvelle lame.

(Voir Figure 11)

5. Tournez le bouton de

verrouillage dans le sens

antihoraire pour verrouiller à

nouveau l'unité de scellage

supérieure.

Figure 1

REMARQUE : veuillez

consulter fr.uline.ca pour commander des

lames d'injecteur (H-7241-INJCT) et des

courroies en téflon (H-7241-TBELT) de rechange.

Lame

PAGE 25 OF 27 0621 I H-7241

Page 26

CODES D'ERREUR

ERROR 20

Calibration out of range

Calibrate seal wire

Turn off and on

ERROR 21

Seal wire

Check connection

Turn off and on

ERROR 22

Temperature not reached

Check seal system

Turn off and on

Étalonnage hors échelle.

Calibrez le fil de scellage.

Éteignez et rallumez l'appareil.

Contactez le service à la

clientèle de Uline au 1 800

295-5510.

Scellez le fil.

Vérifiez la connexion.

Éteignez et rallumez l'appareil.

Température non atteinte.

Vérifiez le système de scellage.

Éteignez et rallumez l'appareil.

ERROR 30

Seal jaw is not closed

Close jaw

Press start to release

ERROR 31

Transport failure

Check film transport

Press start to release

ERROR 32

Transport motor overload

Check film transport

Press start to release

La mâchoire de scellage n'est

pas fermée.

Possible uniquement si un

microrupteur est installé.

Fermez la mâchoire.

Appuyez sur démarrer pour

relâcher.

Panne de transport.

Vérifiez le transport du film.

Appuyez sur démarrer pour

relâcher.

Retirez et rechargez le film de

la mâchoire de scellage/de la

lame de l'injecteur.

Surcharge du moteur de transport.

Vérifiez le transport du film.

Appuyez sur démarrer pour

relâcher.

Retirez et rechargez le film de la

mâchoire de scellage/de la lame

de l'injecteur.

PAGE 26 OF 27 0621 I H-7241

Page 27

DÉPANNAGE

1

0

uline.ca

PROBLÈME DE FONCTIONNEMENT RECOMMANDATIONS

La machine n'est pas alimentée

Aucun affichage après l'allumage

L'affichage apparaît, mais la

machine ne se met pas en marche.

Mauvais scellage du film

Le scellage du film est étiré.

Vérifiez que le cordon d'alimentation est branché dans la

machine et dans la prise de courant.

Vérifiez que le commutateur principal est allumé.

Vérifiez le fusible.

Vérifiez le fusible.

Contactez le service à la clientèle de Uline au 1 800 295-5510.

Vérifiez le type de film sélectionné.

Éteignez la machine, et vérifiez la position de la courroie/lame.

Vérifiez que les unités de scellage sont fermées et verrouillées.

Vérifiez que l'arbre porte-rouleau de film est bien positionné.

Remplacez les courroies et les lames.

Ajustez la température.

Vérifiez le type de film sélectionné.

Vérifiez que l'arbre porte rouleau de film est bien positionné.

Ajustez la température.

Ajustez le débit d'air.

Vérifiez si l'arbre porte rouleau est bloqué.

Le film n'avance pas.

Les coussins d'air ne se gonflent pas.

Le film se bloque fréquemment.

Blocage du film

Le film s'enroule autour des rouleaux

Vérifiez que les unités de scellage sont fermées et verrouillées.

Vérifiez le positionnement de la lame.

Remplacez les courroies et les lames.

Le rouleau de film est installé dans le mauvais sens.

Vérifiez la position de la courroie/lame.

Vérifiez que l'arbre porte rouleau de film est bien positionné.

Vérifiez que les unités de scellage sont fermées et verrouillées.

Inspectez le film provoquant les blocages.

Vérifiez les courroies et les lames. Remplacez-les au besoin.

Vérifiez le film et les réglages du mandrin.

Retirez et rechargez le film dans la machine pour vous assurer

que le film ne bloque pas l'injecteur.

Vérifiez si l'arbre porte rouleau est bloqué.

Retirez tout film provoquant un blocage.

Vérifiez l'avancée du film sur la machine.

Retirez tout film provoquant un blocage.

-800-295-551

PAGE 27 OF 27 0621 I H-7241

Loading...

Loading...