Page 1

Para Español, vea páginas 8-14.

Pour le français, consulter les pages 15-21.

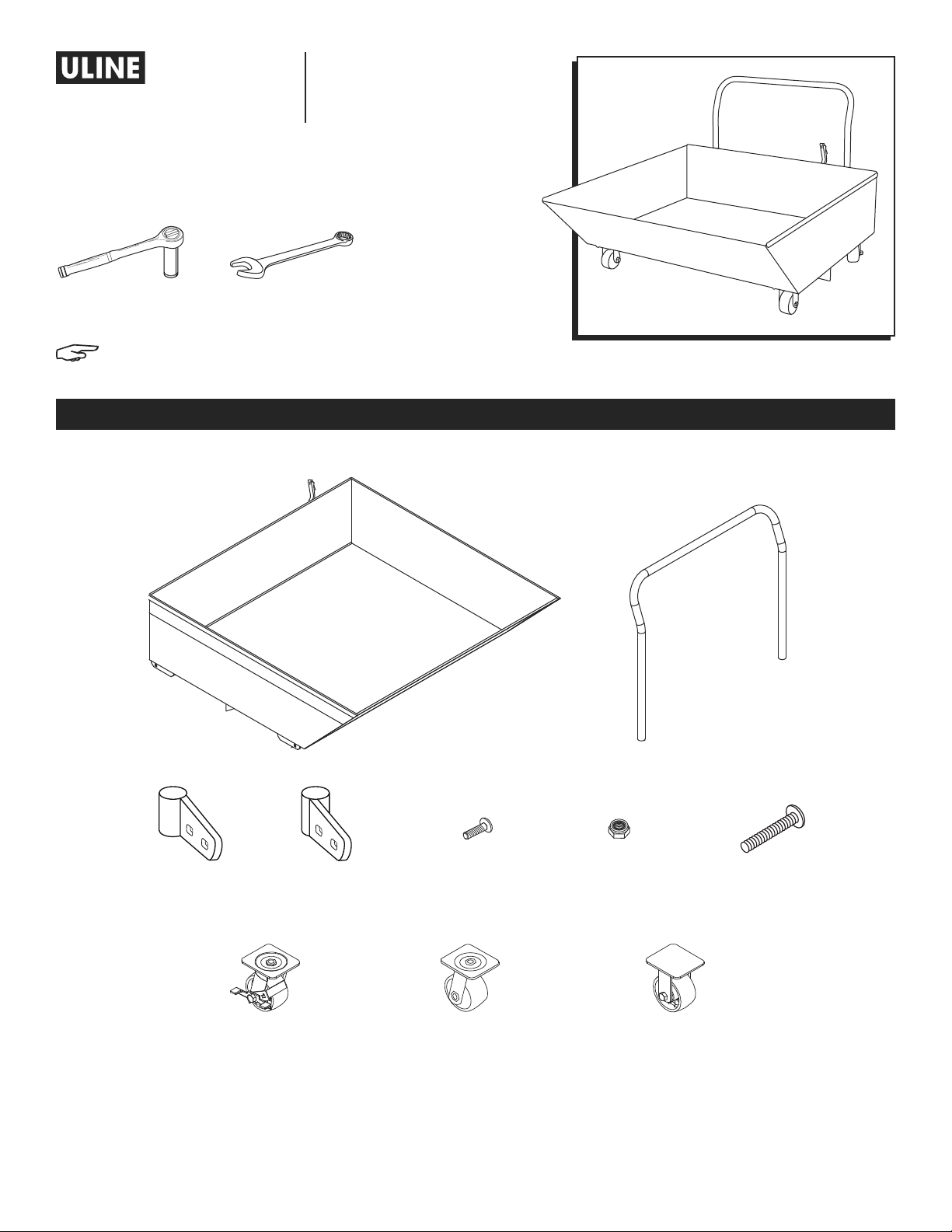

H-5485

LOW PROFILE

DUMPING HOPPER

TOOLS NEEDED

9/16" Deep Well

Socket Wrench

NOTE: Gloves are recommended for assembly.

9/16" Wrench

1-800-295 -5510

uline.com

PARTS

Left Handle

Socket x 1

Right Handle

Socket x 1

Swivel Caster

with Brake x 1

Chute Assembly x 1

3/8" - 16 x 1⁄"

Handle Socket Bolt

x 4

Swivel Caster x 1 Rigid Caster x 2

3/8" Locknut x 8 3/8" - 16 x 5"

Handle x 1

Caster Bolt x 4

PAGE 1 OF 21 0621 IH-5485

Page 2

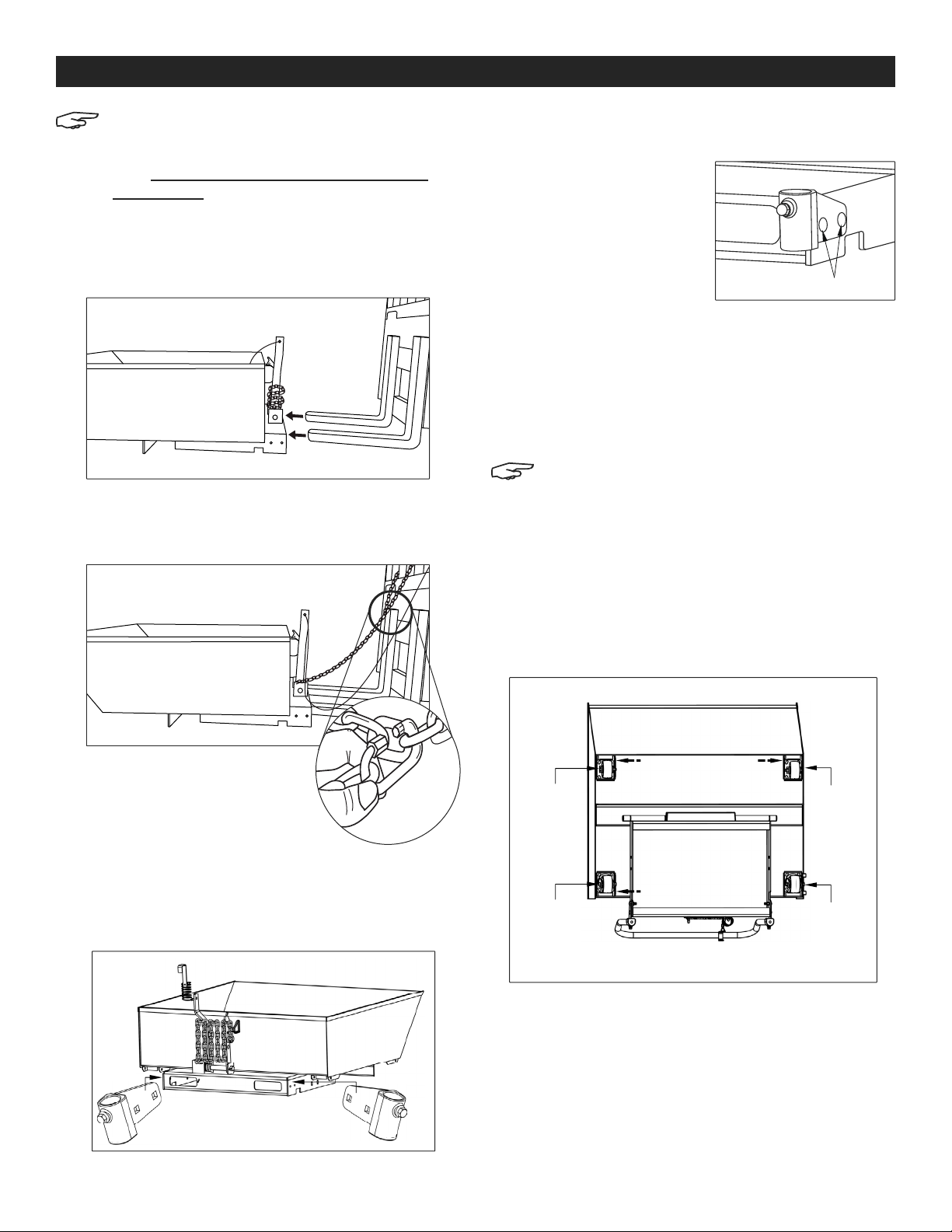

ASSEMBLY

NOTE: Uline recommends raising the hopper

on a forklift for assembly. If a forklift is

not available, tilt dumping hopper on its

side. Make sure hopper is stabilized before

proceeding.

RAISE HOPPER ON FORKLIFT

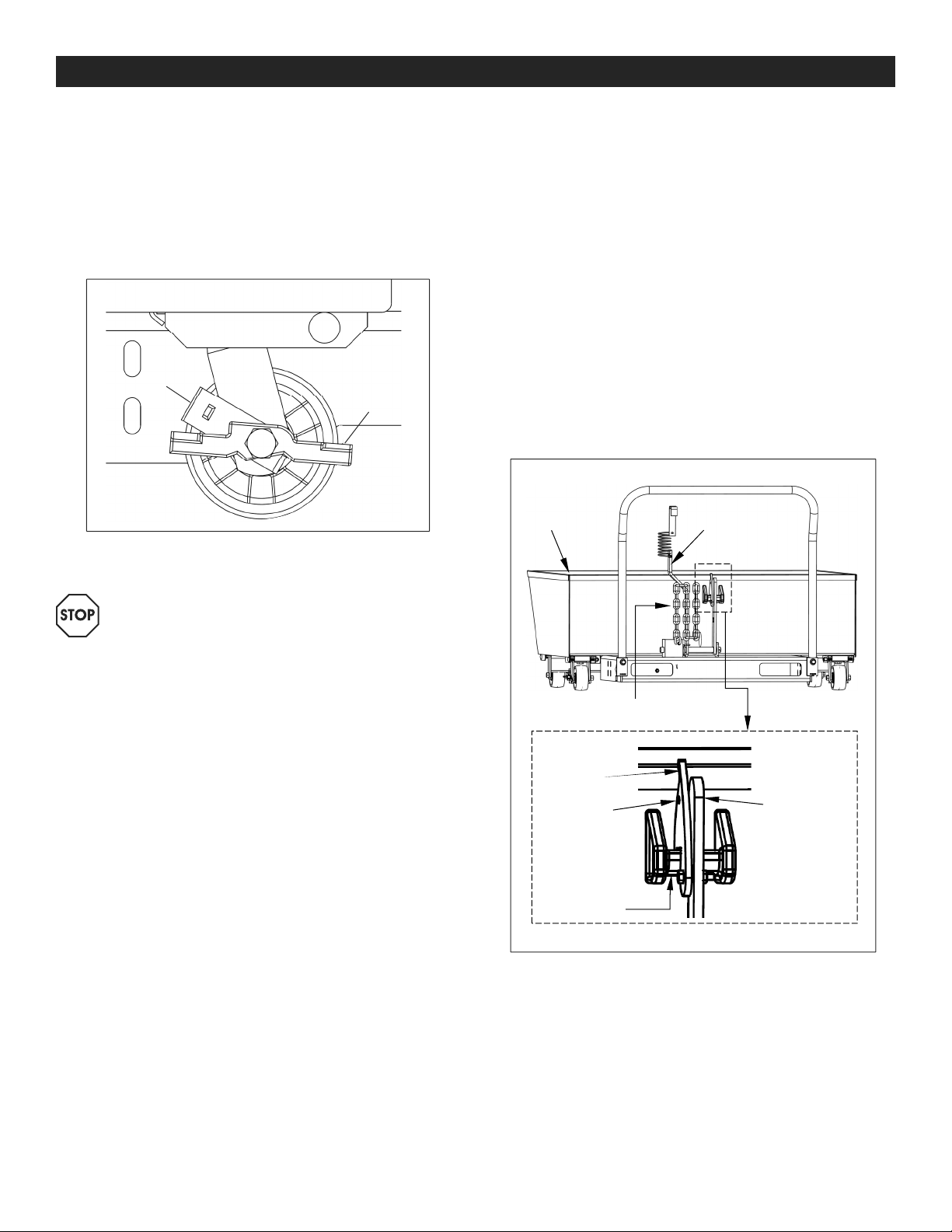

1. Drive lift truck forward until hopper's fork pockets

contact vertical legs of lift truck forks. (See Figure 1)

Figure 1

2. Wrap the safety chain around the fork carriage and

attach the quick link on the chain. There should be

no slack in the chain. (See Figure 2 and Figure 2a).

Figure 2

1. Insert two 3/8-16 x 1½" bolts through the two bolt

holes in the right socket bracket.

2. Slide the bolts through the

two bolt holes on the right

side of the base frame.

(See Figure 4)

3. Secure each bolt with a

3/8" locknut using a 9/16"

deep well socket wrench,

Figure 4

Bolt

but DO NOT TIGHTEN.

4. Repeat steps 1-3 to install the left socket bracket.

ATTACH HANDLE

1. Insert the handle legs into the sockets. Maneuver

handle legs into place until they are all the way into

the socket.

NOTE: Put handle legs into sockets evenly. Do

not put in one at a time.

2. Tighten the set screws on the back of the socket

brackets against the handle legs using a 9/16"

wrench.

ATTACH CASTERS

3. Raise forks to a comfortable

working height.

4. Unlock the latch and dump the

Figure 2a

hopper.

ATTACH HANDLE SOCKET BRACKETS

Attach the socket brackets on either side of the hopper

base. Right socket bracket is offset to the right. Left

socket is offset to the left. (See Figure 3)

Figure 3

Install rigid casters on the front of the hopper and swivel

and swivel with brake casters on the back of the hopper

(See Figure 5).

Figure 5

Rigid

Caster

Swivel

Caster

Rigid

Caster

Swivel

Caster

with

brake

PAGE 2 OF 21 0621 IH-5485

Page 3

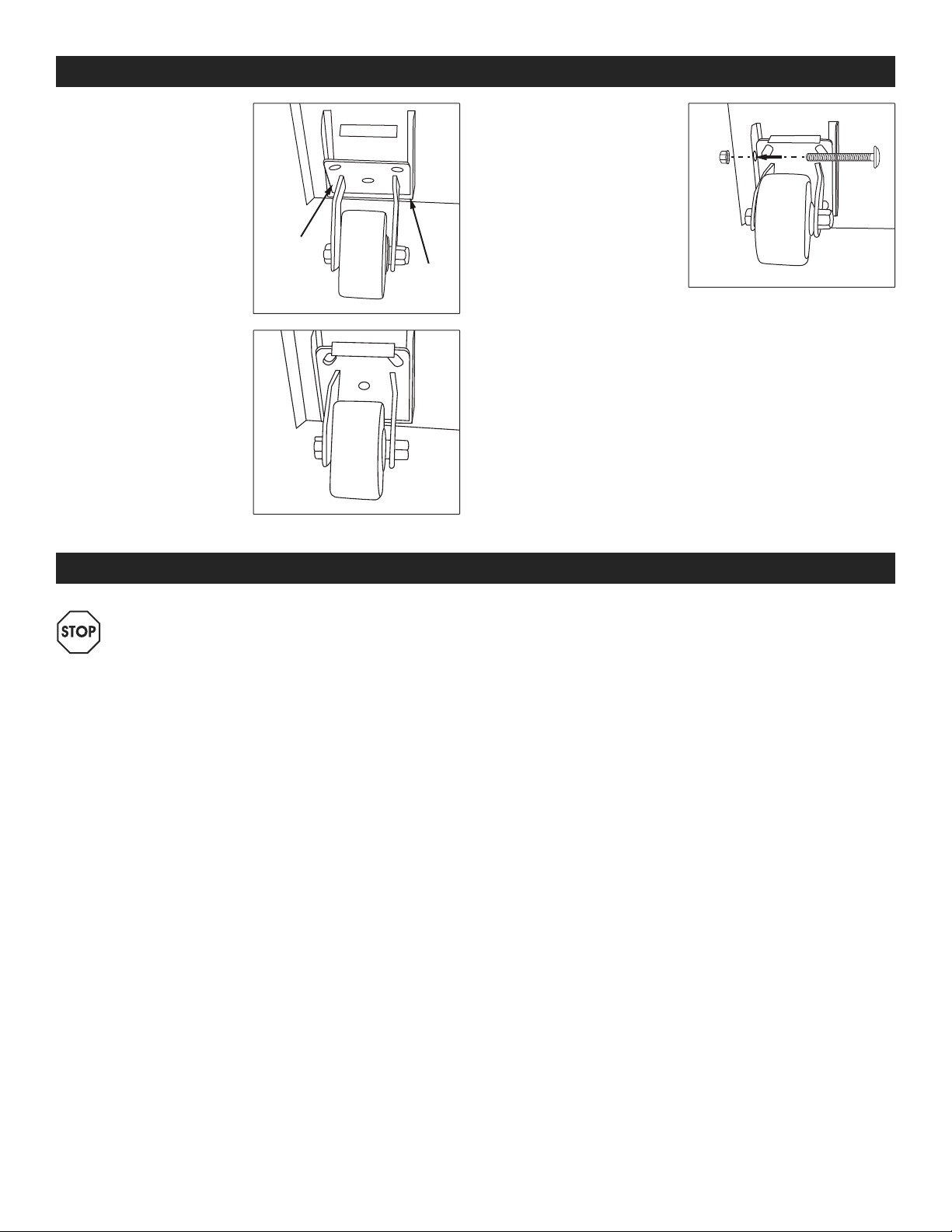

ASSEMBLY CONTINUED

1. Insert one edge of the

caster mounting plate

under the angled

bracket of the caster

mount. (See Figure 6)

2. Press the mounting

plate against the

underside of the

hopper. (See Figure 7)

Mounting

Plate

Figure 6

Figure 7

Angled

Bracket

3. Insert a 3/8-16 x 5" bolt

through the bolt holes

on the inside of the

caster mounting plate.

Secure the bolt with

a 3/8" locknut using a

9/16" wrench.

(See Figure 8)

4. Repeat steps 1-3 for

Figure 8

the remaining casters.

5. Tighten all locknuts.

REMOVE HOPPER FROM FORKLIFT

1. Slowly lower forks and disconnect safety chain.

2. Back lift truck away until forks are free of hopper's

fork pocket.

SAFETY

WARNING! Follow these safety instructions to

avoid any personal injury.

• Do not use a malfunctioning or structurally

damaged hopper. Examples of structural damage

include:

a. damage to the hopper release mechanism (that

allows the hopper to dump);

b. broken fork pocket(s);

c. damaged main connection pin; or

d. broken welds. Inspect the hopper before each

use according to the inspection instructions on

page 6. Do Not use the hopper unless it passes

every part of the inspection.

• DO NOT use the hopper if the safety chain is

damaged or absent.

• DO NOT lift the hopper until it is securely connected

to the carriage of the fork truck with the safety chain.

• DO NOT fill the hopper with a load weighing more

than its capacity (2,000 lb.).

• DO NOT stand beneath or travel under the hopper

at any time. Do not permit any person to stand

beneath or travel under the hopper.

• Hoppers with lifting lugs can be lifted with overhead

hoists and cranes. DO NOT lift a hopper unless the

chute is securely latched to the frame. The hopper

must not be able to rotate while it is suspended.

• DO NOT allow people to ride on or in the hopper.

• DO NOT use the hopper if any product label is

unreadable, damaged, or missing. Contact Uline

Customer Service at 1-800-295-5510 to order

replacement labels.

• Always apply proper (fork) lift truck operation

practices learned during your training program.

Before raising the hopper from the floor, tilt the (forklift)

mast toward the cab of the truck to ensure that the

hopper will not slide towards the tips of the forks.

• DO NOT modify the hopper in any way!

Modifications might make the hopper unsafe to use

and automatically void the limited warranty.

• DO NOT dump the hopper unless every person in the

vicinity is safely behind the forklift truck.

• DO NOT dump the hopper if the forklift is facing

down a slope. Only dump the hopper while parked

on a level surface.

• ALWAYS engage the caster brake when the hopper

is stationary or not in use.

PAGE 3 OF 21 0621 IH-5485

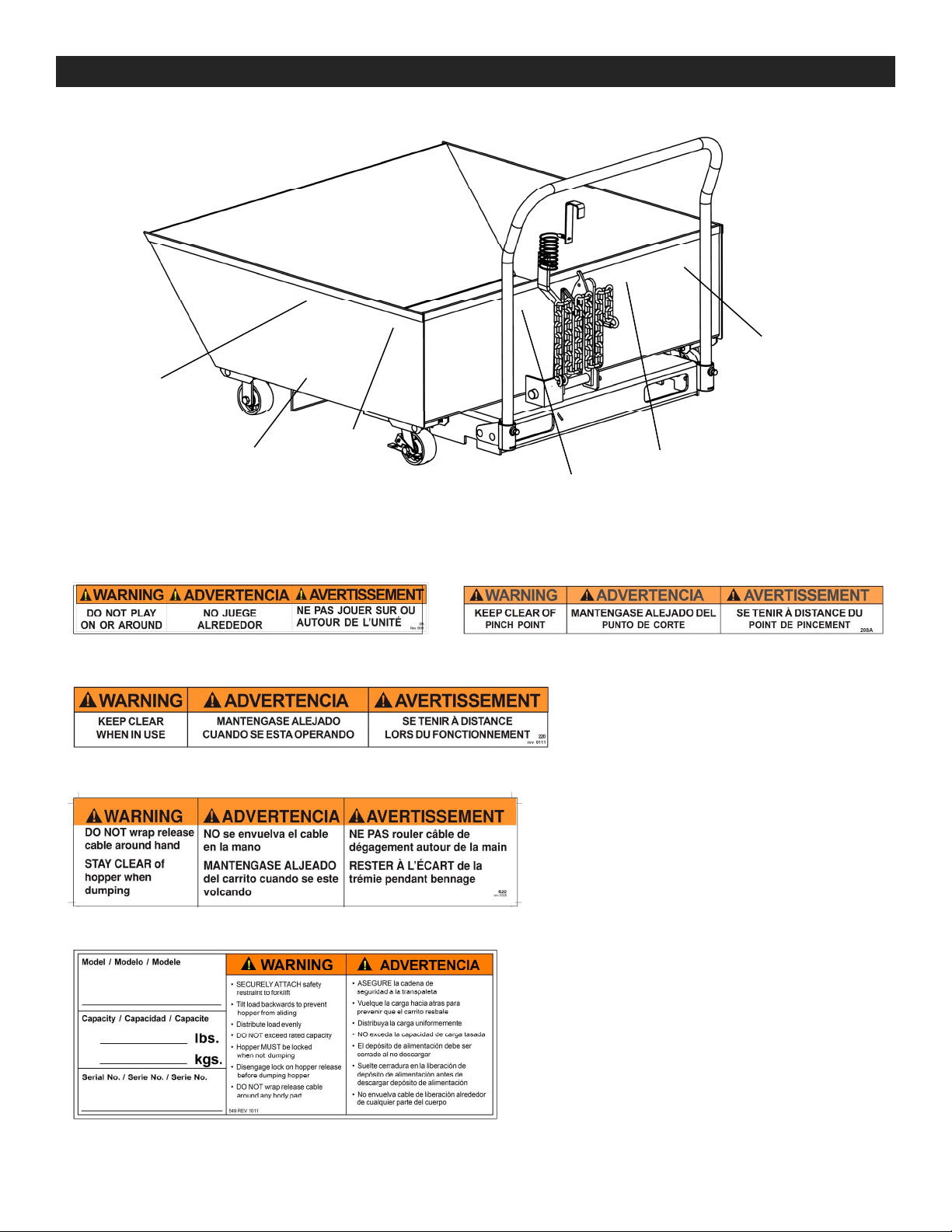

Page 4

WARNING LABELS

E

B

A

A. Label 375 (both sides)

C. Label 220 (both sides)

D. Label 620

B

C

B

D

B. Label 208 (both sides & back)

E. Label 549

PAGE 4 OF 21 0621 IH-5485

Page 5

OPERATING INSTRUCTIONS

CASTER BRAKE

Each hopper has two swiveling casters in the rear, one

of which is equipped with a brake. (See Figure 9)

1. To engage the brake, press the brake lever down.

When the brake is engaged, the wheel will not rotate.

2. To disengage the brake, lift the brake lever up.

Figure 9

Brake

Brake

lever

LOADING

WARNING! Do not exceed the load rating or fill

the hopper above the top of the sides. Serious

personal injury (or property damage) could

result from overloading the hopper.

DUMPING

1. Mount the hopper on the forks of a lift truck and

secure it to the carriage with the safety chain. Wrap

the free end of the chain around the lift carriage;

then fasten the quick link to a link in the chain. The

chain must be taut (no slack) to prevent the hopper

from sliding on the forks.

2. Store the handle of the release cable within reach

of the forklift operator. For example, hook the cable

to the frame of the forklift cab. Make sure that there

is plenty of slack in the cable to avoid accidentally

releasing the chute.

3. The chute cannot dump unless the latch is unlocked.

To unlock the latch, pull the finger tab at the top

end of the latch lock bracket until the bracket

disengages the latch bar (See Figure 10)

Figure 10

Front end of

chute

Manual chute

release lever

Low profile hoppers are designed for indoor and

outdoor use in most industrial and commercial

settings. They should only be used to collect and dump

non-hazardous wastes.

1. Confirm the hopper chute is solidly latched to the

base frame before filling the chute with refuse.

2. When the hopper is stationary, engage the caster

brake.

Finger tab

Latch lock

bracket

Latch bar

Safety chain

Latch lever

PAGE 5 OF 21 0621 IH-5485

Page 6

OPERATING INSTRUCTIONS CONTINUED

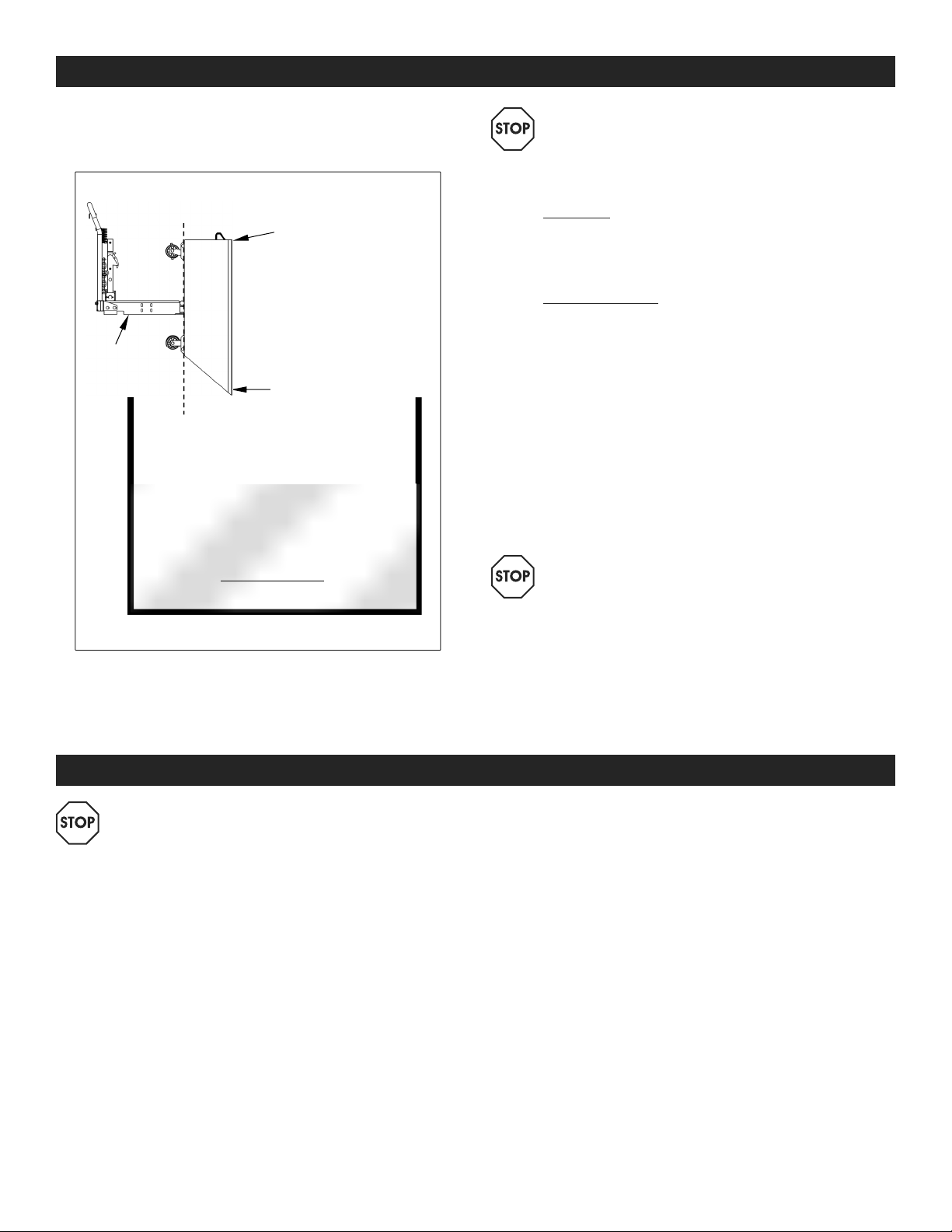

4. Raise the hopper above the dumpster and drive

forward until the dumping axis is clearly over the

inside of the dumpster (See Figure 11).

Fig u r e 11

Back end

of chute

Base

frame

Front end

of chute

Dumping

axis

Waste material

WARNING! DO NOT wrap the release cable

around your hand/fingers or attach the handle

to your clothing!

6. Latch the chute to the base.

a. Manually: Slowly lower the forks until the hopper

rests on the ground. The chute will pivot towards the

frame. Press the back end of the chute onto the

base until the latch lever engages the latch bar.

b. Using the forklift: Raise the fork tips by tilting the

forklift mast toward the cab. Then, back away

from the dumpster. Slowly lower the forks until the

front end of the chute contacts the top of the

side of the dumpster. Continue to slowly lower

the forks until the chute pivots onto the base

frame. You should hear the latch lever snap over

the latch bar. Confirm that the chute is securely

latched by raising the forks. The chute should not

rotate. If necessary, lower the forks completely

and manually latch the chute to the frame.

7. Lock the latch by reversing the process described in

step 3.

WARNING! DO NOT move the hopper until the

latch is locked!

5. Dump the contents of the hopper by releasing the

chute. To release the chute, pull the release cable.

The chute will pivot about the dump axis.

Dumpster (cross-section)

MAINTENANCE

WARNING! If an inspection reveals issues,

restore the hopper to normal operating

condition BEFORE using it again. DO NOT use

a structurally damaged hopper. Structural

damage includes but is not limited to,

cracked welds, warping or deformation of the

chute, pivot points, or the supporting frame,

particularly the fork pockets.

DAILY INSPECTION

Before each use, inspect the following components:

• Release cable – Look for fraying, birdcaging,

thinning.

• Hopper chute or base frame – Check for damage,

deformation, corrosion or severely rusted regions.

• Pivot points – As the chute rotates (after releasing

it), listen for unusual noise and watch for binding as

the chute rotates. Also look for distortion of the axle

points or axle receivers.

• Release/latch mechanisms – Test the chute release

mechanism (lock release, lever assembly). The

torsion spring should cause the lever assembly to

automatically recoil and firmly latch the chute to the

frame.

• Safety chain – Check the chain for damaged links

(broken, cracked, elongated).

PAGE 6 OF 21 0621 IH-5485

Page 7

MAINTENANCE CONTINUED

1

0

uline.com

MONTHLY INSPECTION

Inspect the following components at the least once per

month. Replace any component that is excessively worn

or no longer operates normally:

• Pivot points – Look for excessive wear, warping, or

other damage to the release lever pin, pin brackets,

axle pins and axle receivers. Listen for unusual

noises and watch for irregular movement. Remove

dirt and debris from areas that could affect the

hopper's dumping motion.

• Fasteners (bolt, locknuts, axle pins, cotter pins,

retaining rings) – Inspect for looseness and wear.

• Casters – Check for looseness, excessive wear or

damage to the casters, caster bearings, mounting

brackets and hardware. Confirm that the brake

functions properly.

• Release Mechanism – Verify the mechanisms

function properly:

a. Torsion spring firmly latches the lock release lever

assembly to the chute.

b. The latch lock bracket should seat on the latch

bar unless manually disengaged.

• Chute – Examine the chute. The structure should be

rigid and square without corroded holes or severely

rusted areas.

• Supporting frame – Examine the frame. It should be

rigid and square, welds should be intact and fork

pockets should be square and sound.

• Labels – All labels must be applied to the hopper

in the locations shown in the labeling diagram on

page 4.

WARNING! The end user should understand

the significant difference between necessary

adjustments and repairs, and modification.

Adjustments are simple corrections that restore

the hopper to normal operating condition,

such as tightening loose fasteners, or removing

dirt or other debris from the surface. Repairs

involve removing worn parts and installing new/

replacement parts.

A modification is a change that alters the

hopper from normal operating condition, such

as bending the frame or removing a part

or several parts. NEVER modify the hopper.

Modifications automatically void the Warranty

and might make the hopper unsafe to use.

c. Lever assembly pivots smoothly and securely

engages the latch bar.

-800-295-551

PAGE 7 OF 21 0621 IH-5485

Page 8

H-5485

TOLVA AUTOVACIABLE

DE PERFIL BAJO

HERRAMIENTAS NECESARIAS

800-295 -5510

uline.mx

Llave de Tubo de

Impacto Profundo de

9/16"

NOTA: Se recomienda usar guantes para el ensamble.

Llave Combinada

de 9/16"

PARTES

1 Ensamble de la Tolva

1 Asa

1 Soporte

Izquierdo con

Orificios para

el Asa

PAGE 8 OF 21 0621 IH-5485

1 Soporte

Derecho con

Orificios para

el Asa

1 Rueda

Giratoria con

Freno

4 Pernos de

3/8" - 16 x 1½"

para los Soportes con

Orificios para el Asa

1 Rueda Giratoria 2 Ruedas Fijas

8 Tuercas de

Seguridad de 3/8"

4 Pernos de

3/8" - 16 x 5"

para Rueda

Page 9

ENSAMBLE

NOTA: Uline recomienda elevar la tolva con

un patín hidráulico para ensamblarla. Si no

hay un patín hidráulico disponible, coloque la

tolva sobre un lado. Asegúrese de que la tolva

se encuentre estable antes de comenzar.

ELEVAR LA TOLVA CON UN PATÍN HIDRÁULICO

1. Desplace el patín hidráulico hacia adelante hasta

que las entradas para las horquillas de la tolva

entren de manera recta en las horquillas del patín.

(Diagrama 1)

Diagrama 1

2. Rodee el portador de horquillas con la cadena de

seguridad y coloque el seguro de conexión en

la cadena. La cadena no debe quedar holgada.

(Vea Diagrama 2 y Diagrama 2a)

Diagrama 2

1. Inserte dos pernos de 3/8" - 16 x 1⁄" a través de los

orificios de la derecha de la base del soporte.

2. Deslice los pernos a través

de los orificios en el lado

derecho del armazón de

la base. (Vea Diagrama 4)

3. Asegure cada perno con

una tuerca de seguridad

de 3/8" utilizando una

Diagrama 4

Perno

llave de tubo de impacto

profundo de 9/16", pero NO LOS AJUSTE.

4. Repita los pasos 1-3 para instalar la base del

soporte izquierdo.

INSTALAR EL ASA

1. Inserte las patas del asa en las bases. Maniobre

las patas del asa hasta conseguir que entren por

completo en la base.

NOTA: Coloque las patas del asa en las bases

al mismo tiempo. No coloque una a la vez.

2. Ajuste los tornillos en la parte trasera de las bases

del soporte de tal manera que aprieten las patas

del asa utilizando una llave combinada de 9/16".

3. Eleve las horquillas a una altura

cómoda para trabajar.

4. Quite el seguro y vacie la tolva.

Diagrama

2a

CONECTAR EL ASA EN LAS BASES DEL SOPORTE

Coloque las bases del soporte en cualquier lado de la

base tolva. La base del soporte derecha se encuentra

hacia la derecha. La base del soporte izquierda se

encuentra hacia la izquierda. (Vea Diagrama 3)

Diagrama 3

INSTALAR LAS RUEDAS

Instale las ruedas rígidas en la parte frontal de la tolva

y la giratoria y giratoria con freno en la parte trasera.

(Vea Diagrama 5)

Diagrama 5

Rueda

Rígida

Rueda

Giratoria

Rueda

Rígida

Rueda

Giratoria

con

Freno

PAGE 9 OF 21 0621 IH-5485

Page 10

CONTINUACIÓN DE ENSAMBLE

1. Inserte un borde de la

placa de montaje de

la rueda debajo de

la base angulada de

montaje de la rueda.

(Vea Diagrama 6)

2. Presione la placa de

montaje contra la

parte baja de la tolva.

(Vea Diagrama 7)

Placa de

Montaje

Diagrama 6

Diagrama 7

Base

Angulada

SEGURIDAD

3. Inserte un perno de

3/8" - 16 x 5" a través de

los orificios en la parte

interior de la placa de

montaje de la rueda.

Asegure el perno con

una tuerca de 3/8"

utilizando una llave

combinada de 9/16".

(Vea Diagrama 8)

Diagrama 8

4. Repita los pasos 1-3 para el resto de las ruedas.

5. Ajuste todas las tuercas.

RETIRAR LA TOLVA DEL PATÍN HIDRÁULICO

1. Baje las horquillas lentamente y desconecte la

cadena de seguridad.

2. Mueva el patín hiráulico en reversa hasta que

las horquillas queden libres de la entradas para

horquillas de la tolva.

¡ADVERTENCIA! Siga estas instrucciones de

seguridad para evitar lesiones personales.

• No use una tolva que funcione incorrectamente o

que tenga la estructura dañada. Los ejemplos de

daños en la estructura incluyen:

a. daños en el mecanismo de liberación de la

tolva (que permite que la tolva se autovacíe);

b. abertura(s) de la(s) horquilla(s) dañada(s);

c. clavija de conexión principal dañada; o

d. soldaduras rotas. Inspeccione la tolva antes de

cada uso siguiendo las instrucciones del manual

de inspección en la página 13. NO use la tolva

a menos que haya pasado todas las partes de

la inspección.

• NO use la tolva si la cadena de seguridad está

dañada o falta.

• NO eleve la tolva hasta que esté conectada de

manera segura al armazón de elevación del

montacargas con la cadena de seguridad.

• NO eleve la tolva con una carga cuyo peso sea

superior a su capacidad (907 kg/2,000 lbs.).

• NO se pare ni camine bajo la tolva en ningun

momento. No permita que nadie se pare ni camine

bajo la tolva.

• Las tolvas con acoplador de remolque se pueden

elevar con grúas o polipastos. NO levante la tolva

• NO permita que nadie se suba a la tolva o dentro

de ella.

• NO utilice la tolva en caso de cualquier etiqueta

del producto sea ilegible, esté dañada o haya

desparecido. Contacte a Uline Servicio a Clientes al

1-800-295-5510 para pedir etiquetas adhesivas de

reemplazo.

• Utilice siempre las prácticas de funcionamiento del

montacargas adecuadas aprendidas durante su

programa de capacitación. Antes de elevar la tolva

del suelo, incline el mástil (del montacargas) hacia

la cabina del montacargas para asegurarse de

que la tolva no se deslice hacia las puntas de las

horquillas.

• NO modifique la tolva de ninguna manera! Las

modificaciones podrían hacer que la tolva fuese

poco segura de usar y anularán automáticamente

la garantía limitada.

• NO vacíe la tolva a menos que todas las personas

que haya alrededor estén colocados detrás del

montacargas por su seguridad.

• NO vacíe la tolva en caso de que el montacargas

esté mirando hacia abajo en una cuesta. Vacíe la

tolva únicamente cuando esté estacionado en una

superficie nivelada.

• ACTIVE siempre el freno de la rueda cuando la tolva

esté detenida o no se esté usando.

a menos que la tolva esté bien fijada al armazón.

La tolva no debería poder girar mientras esté

suspendida en el aire.

PAGE 10 OF 21 0621 IH-5485

Page 11

ETIQUETAS ADHESIVAS DE ADVERTENCIA

E

B

A

B

C

A. Etiqueta Adhesiva 375 (ambos lados)

C. Etiqueta Adhesiva 220 (ambos lados)

D. Etiqueta Adhesiva 620

B

D

B. Etiqueta Adhesiva 208 (ambos lados y laterales)

E. Etiqueta Adhesiva 549

PAGE 11 OF 21 0621 IH-5485

Page 12

INSTRUCCIONES DE FUNCIONAMIENTO

RUEDA CON FRENO

Cada tolva cuenta con dos ruedas giratorias en la

parte posterior, una de las cuales está equipada con

un freno. (Vea Diagrama 9)

1. Para activar el freno, presione la palanca del freno

hacia abajo. Cuando el freno esté activado, la

rueda no girará.

2. Para desactivar el freno, levante la palanca del

freno hacia arriba.

Diagrama 9

Freno

Palanca

de Freno

CARGA

¡ADVERTENCIA! No exceda la capacidad

de carga ni llene la tolva por encima de los

laterales. En caso de sobrecargar la tolva,

podrían ocurrir lesiones personales graves

(o daños a la propiedad).

Las tolvas de perfil bajo están diseñadas para usarse

en interiores y exteriores en la mayoría de entornos

industriales y comerciales. Deben usarse únicamente

para recolectar basura o desechos no peligrosos.

1. Confirme que el contenedor de la tolva esté bien

fijado al armazón de la base antes de llenarlo de

desechos.

VACIADO

1. Coloque la tolva sobre las horquillas del

montacargas y fíjela al armazón de elevación con

la cadena de seguridad. Enrolle el extremo libre de

la cadena alrededor del armazón de elevación del

montacargas y luego asegure el broche rápido a

un eslabón de la cadena. La cadena deberá estar

tirante (no floja) para evitar que la tolva se deslice y

se caiga de las horquillas.

2. Guarde el asa del cable de liberación donde

quede a l mano del operador del montacargas. Por

ejemplo, puede enganchar el cable al marco de

la cabina del montacargas. Asegúrese de que hay

suficiente margen de cable flojo para evitar que la

tolva se suelte accidentalmente.

3. La tolva no se puede vaciar a menos que el pestillo

esté desbloqueado. Para desbloquear el pestillo,

jale de la lengüeta para el dedo ubicada en el

extremo superior del soporte del pestillo hasta que

el soporte desbloquee la barra del pestillo

(Vea Diagrama 10)

Diagrama 10

Parte Delantera

de la Tolva

Palanca

de Liberación

Manual de la Tolva

Cadena de Seguridad

Lengüeta

para el Dedo

2. Active siempre el freno de la rueda cuando

la tolva esté detenida.

PAGE 12 OF 21 0621 IH-5485

Soporte

del Pestillo

de Cierre

Barra del Pestillo

Palanca

del Pestillo

Page 13

CONTINUACIÓN DE INSTRUCCIONES DE FUNCIONAMIENTO

4. Eleve la tolva por encima del contenedor y

muévala hacia adelante hasta que el eje de

vaciado esté claramente sobre el interior del

contenedor (Vea Diagrama 11).

Diagrama 11

Extremo

posterior de Tolva

Armazón

de la Base

Extremo Frontal

de la Tolva

Eje de Vaciado

axis

Material de desecho

¡ADVERTENCIA! NO enrolle el cable de

liberación alrededor de su mano/sus dedos o

sujete el asa a su ropa!

6. Fije la tolva a la base.

a. Manualmente: baje lentamente las horquillas

hasta que la tolva descanse sobre el suelo. La

tolva rotará hacia el armazón. Presione el extremo

posterior de la tolva hacia la base hasta que la

palanca del pestillo se enganche a la barra del

pestillo.

b. Usar el patín de elevación: eleve las puntas

de las horquillas inclinando el mástil del patín

de elevación hacia el carrito. Luego, retírese

del contenedor. Baje lentamente las horquillas

hasta que la parte delantera de la tolva entre

en contacto con la parte superior del lateral

del contenedor. Continúe bajando lentamente

las horquillas hasta que la tolva rote sobre el

armazón de la base. Debería escuchar cómo la

palanca del pestillo se traba sobre la barra del

pestillo. Confirme que la tolva está bien fijada

elevando las horquillas. La tolva no debería girar.

En caso de ser necesario, baje las horquillas

completamente y fije la tolva manualmente al

armazón.

Contenedor de basura (corte transversal)

7. Trabe el pestillo repitiendo el proceso descrito en el

paso 3 de manera inversa.

5. Vacíe el contenido de la tolva liberando la misma.

Para liberar la tolva, jale del cable de liberación. La

¡ADVERTENCIA! NO mueva la tolva hasta que el

pestillo esté trabado!

tolva rotará en el eje de vaciado.

¡ADVERTENCIA! En caso de que una inspección

revele problemas, repare la tolva para que

funcione con normalidad ANTES de usarla

de nuevo. NO use una tolva que tenga la

estructura dañada. Una estructura dañada

incluye, pero no se limita a, soldaduras

agrietadas, arqueo o deformación de la tolva,

de los puntos de rotación o del armazón de

soporte, especialmente las aberturas para

horquillas.

INSPECCIÓN DIARIA

Antes de cada uso, inspeccione los siguientes

componentes:

MANTENIMIENTO

• Tolva de vaciado o armazón de la base - Verifique

si existen daños, deformaciones, corrosión o zonas

muy oxidadas.

• Puntos de rotación - Mientras la tolva gira (después

de su liberación), escuche en busca de ruidos

extraños y compruebe las uniones mientras la

tolva gira. También mire si los puntos del eje y los

receptores del eje se han dañado.

• Mecanismos de cierre/liberación - Verifique el

mecanismo de liberación de la tolva (liberación

del pestillo, ensamble de la palanca). El resorte

de torsión debería hacer que el ensamble de la

palanca se recoja automáticamente y fijar la tolva

firmemente al armazón.

• Cable de liberación - Busque señas de pelado,

desmadejado o pérdida de grosor.

• Cadena de seguridad - Verifique si hay eslabones

dañados en la cadena (rotos, agrietados o

vencidos).

PAGE 13 OF 21 0621 IH-5485

Page 14

CONTINUACIÓN DE MANTENIMIENTO

8

0

uline.mx

INSPECCIÓN MENSUAL

Inspeccione los siguientes componentes al menos una

vez al mes. Reemplace cualquier componente que

esté excesivamente desgastado o que ya no funcione

con normalidad:

• Puntos de rotación - Busque señales de desgaste

excesivo, deformación u otros daños que pudiera

haber sufrido la clavija de la palanca de liberación,

los soportes de la clavija, las clavijas del eje y los

receptores del eje. Escuche si hay ruidos inusuales

y observe si ocurren movimientos irregulares. Elimine

la suciedad y los residuos de cualquier zona que

pudieran afectar al movimiento de vaciado de la

tolva.

• Tornillería (perno, tuercas de seguridad, clavijas del

eje, pasadores de chaveta, anillos de retención) Inspecciónelos por si están sueltos o desgastados.

• Ruedas - Verifique si hay holgura, desgaste excesivo

o daño en las ruedas, los baleros de las ruedas, los

soportes de montaje y la tornilería. Confirme que el

freno funcione correctamente.

• Mecanismo de liberación - Verifique que todos los

mecanismos funcionen correctamente:

a. El resorte de torsión sujeta firmemente el

ensamble de la palanca de liberación a la

tolva.

b. El soporte del pestillo de cierre debe quedar

asentado sobre la barra del pestillo a menos

que se desactive manualmente.

• Tolva - Examine la tolva. La estructura deberá ser

rígida y cuadrada, sin orificios con corrosión o

zonas muy oxidadas.

• Armazón de soporte - Examine el armazón. Deberá

ser rígido y cuadrado, las soldaduras deberán estar

intactas y las aberturas de la horquilla deberán ser

cuadradas y robustas.

• Etiquetas adhesivas - Todas las etiquetas adhesivas

deben colocarse en la tolva en las ubicaciones

mostradas en el diagrama de etiquetas en la

página 11.

¡ADVERTENCIA! El usuario final deberá

comprender la diferencia significativa

entre ajustes necesarios, reparaciones y

modificaciones. Los ajustes son simples

correcciones que devuelven la tolva a su

condición de funcionamiento normal, como

por ejemplo apretar tornillería suelta o eliminar

suciedad u otros desechos de la superficie.

Las reparaciones implican quitar partes

desgastadas e instalar partes nuevas/de

reemplazo.

Una modificación es un cambio que altera la

condición de funcionamiento normal de la

tolva, como por ejemplo doblar el armazón

o quitar una o varias partes. No modifique

NUNCA la tolva. Las modificaciones podrían

hacer que la tolva fuese poco segura de usar

y anularán automáticamente la Garantía.

c. El ensamble de la palanca gira bien y activa de

manera segura la barra del pestillo.

00-295-551

PAGE 14 OF 21 0621 IH-5485

Page 15

H-5485

BENNE BASCULANTE

À PROFIL BAS

OUTILS REQUIS

1-800-295 -5510

uline.ca

Clé à douilles

profondes de 9/16 po

REMARQUE : Le port de gants est recommandé durant le

montage.

Clé de 9/16 po

PIÈCES

L'ensemble de la benne x 1

Poignée x1

Support à

emboîture

gauche x 1

avec frein x 1

PAGE 15 OF 21 0621 IH-5485

Support à

emboîture

droit x 1

Roulette

pivotante

Boulon pour support à

emboîture de

3/8 po - 16 x 1 ⁄ po x 4

Roulette

pivotante x1

Écrou freiné

de 3/8 pox8

Boulon pour roulette de

3/8po - 16 x 5 po x 4

Roulette

fixe x2

Page 16

MONTAGE

REMARQUE : Uline recommande de soulever la

benne à l'aide d'un chariot élévateur pour faciliter

le montage. Si vous ne disposez pas d'un chariot

élévateur, inclinez la benne afin qu'elle repose

sur son côté. Assurez-vous de stabiliser la benne

avant de procéder.

SOULEVER LA BENNE AVEC UN CHARIOT ÉLÉVATEUR

1. Faites avancer le chariot élévateur jusqu'à ce que la

fourche rentre complètement dans les entrées de la

benne et que les montants de la fourche soient en

contact avec la benne. (Voir Figure 1)

Figure 1

2. Enfilez la chaîne de sécurité tout autour du châssis de

la fourche et fixez le maillon rapide à la chaîne. La

chaîne doit être bien tendue. (Voir Figures 2 et 2a).

Figure 2

1. Insérez deux boulons de 3/8-16 x 1½ po dans les

trous de boulon dans le support à emboîture droit.

2. Glissez les deux boulons à

travers les deux trous de

boulon du côté droit du

cadre de la base de la

benne. (Voir Figure 4)

3. Fixez les boulons à l'aide

d'un écrou freiné de 3/8

Figure 4

Boulon

po et d'une clé à douilles

profondes de 9/16 po, mais NE SERREZ PAS.

4. Répétez les étapes 1 à 3 pour installer le support à

emboîture gauche.

FIXATION DE LA POIGNÉE

1. Introduisez les deux extrémités de la poignée

dans les emboîtures et assurez-vous de les insérer

complèment.

REMARQUE : Introduisez les deux extrémités de

la poignée en même temps. Ne les introduisez

pas une à la fois.

2. Serrez les vis de pression, se trouvant à l'arrière des

supports à emboîture, contre les extrémités de la

poignée à l'aide d'une clé de 9/16 po.

3. Soulevez la fourche à une hauteur

vous permettant de travailler

Figure 2a

aisément.

4. Déverrouillez le loquet pour faire basculer la benne.

FIXATION DES SUPPORTS À EMBOÎTURE

Fixez un support à emboîture de chaque côté de la base

de la benne. L'emboîture du support droit s'orientera

légèrement vers la droite, et l'emboîture gauche vers la

gauche. (Voir Figure 3)

Figure 3

FIXATION DES ROULETTES

Installez les roulettes fixes à l'avant de la benne et

les roulettes pivotantes, dont l'une dotée d'un frein, à

l'arrière de la benne. (Voir Figure 5)

Figure 5

Roulette

fixe

Roulette

pivotante

Roulette

fixe

Roulette

pivotante

avec

frein

PAGE 16 OF 21 0621 IH-5485

Page 17

MONTAGE SUITE

1. Insérez un bord de

la plaque de fixation

pour roulette sous

l'équerre de fixation

pour roulette.

(Voir Figure 6)

2. Appuyez la plaque

de fixation contre le

dessous de la benne.

(Voir Figure 7)

Plaque de

fixation

Figure 6

Figure 7

Équerre

SÉCURITÉ

3. Introduisez un boulon

de 3/8-16 x 5 po dans

les trous de boulon,

en dessous de la

plaque de fixation

pour roulette. Fixez le

boulon à l'aide d'un

écrou freiné de 3/8 po

et d'une clé de 9/16

po. (Voir Figure 8)

Figure 8

4. Répétez les étapes 1 à 3 pour les roulettes qui

restent.

5. Serrez tous les écrous freinés.

ENLEVER LA BENNE DU CHARIOT ÉLÉVATEUR

1. Abaissez la fourche et retirez la chaîne de sécurité.

2. Reculez le chariot élévateur jusqu'à ce que la

fourche sorte des entrées de la benne.

ARRÊT

sécurité afin d'éviter tout risque de blessures.

• N'utilisez pas une benne défectueuse ou présentant

des dommages structuraux. Les dommages

structuraux peuvent comprendre les exemples

suivants :

a. dommage au mécanisme de dégagement de

la benne (qui permet de vider la benne);

b. entrée(s) pour fourche endomagée(s);

c. broches de connexion principales

endommagées; ou

d. soudures fissurées. Inspectez la benne avant

chaque utilisation selon les procédures

d'inspection à la page 20. N'utilisez pas la

benne à moins qu'elle n'ait été soumise à

chaque étape de l'inspection avec succès.

• N'UTILISEZ PAS la benne si la chaîne de sécurité est

endommagée ou absente.

• NE SOULEVEZ PAS la benne tant qu'elle n'est pas bien

raccordée au chariot élévateur avec la chaîne de

sécurité.

• NE REMPLISSEZ PAS la benne avec une charge

dépassant sa capacité (90,7kg [2000 lb]).

• NE VOUS TENEZ ET NE VOUS DÉPLACEZ jamais sous la

benne. Ne laissez personne se tenir sous la benne.

• Les bennes dotées d'anneaux de levage peuvent

être levées à l'aide d'un monte-charge ou d'une

AVERTISSEMENT! Suivez ces consignes de

grue. NE SOULEVEZ PAS une benne à moins qu'elle ne

soit solidement fixée au cadre. La benne ne doit pas

être en mesure de tourner lorsqu'elle est suspendue.

• NE LAISSEZ personne monter sur ou dans la benne.

• N'UTILISEZ PAS la benne si une des étiquettes du

produit est illisible, endommagée ou manquante.

Communiquez avec Uline au 1 800 295-5510 pour

commander des étiquettes de rechange.

• Lorsque vous utilisez un chariot élévateur, veillez

à toujours appliquer les bonnes pratiques

operationnelles, telles qu'apprises lors de votre

programme de formation. Avant de soulever la

benne du sol, inclinez le mât (du chariot élévateur)

vers la cabine du chariot pour vous assurer que la

benne ne glissera pas vers les pointes de la fourche.

• NE MODIFIEZ la benne d'aucune façon! Toute

modification pourrait rendre la benne dangereuse à

utiliser et annuler automatiquement la garantie limitée.

• NE VIDEZ la benne que si chaque personne à

proximité est en sécurité à l'arrière du chariot

élévateur.

• NE VIDEZ PAS la benne si le chariot élévateur est

orienté vers le bas d'une pente. Videz uniquement

la benne lorsqu'elle est immobilisée sur une surface

plane et d'aplomb.

• ENCLENCHEZ TOUJOURS le frein des roulettes lorsque

la benne est immobile ou inutilisée.

PAGE 17 OF 21 0621 IH- 5485

Page 18

ÉTIQUETTES D'AVERTISSEMENT

E

B

A

B

A. Étiquette 375 (les deux côtés)

C. Étiquette 220 (les deux côtés)

D. Étiquette 620

C

B

D

B. Étiquette 208 (des deux côtés et à l'arrière)

E. Étiquette 549

PAGE 18 OF 21 0621 IH-5485

Page 19

INSTRUCTIONS D'UTILISATION

FREIN DE ROULETTE

Chaque benne est munie de deux roulettes pivotantes

à l'arrière, dont l'une est dotée d'un frein. (VoirFigure9)

1. Pour enclencher le frein, poussez le levier de frein

vers le bas. Une fois le frein enclenché, la roue ne

tournera pas.

2. Pour desserrer le frein, soulevez le levier de frein vers

le haut.

Figure9

Frein

Levier

de frein

CHARGEMENT

AVERTISSEMENT! Ne dépassez pas la charge

ARRÊT

Les bennes à profil bas sont conçues pour être utilisées

à l'intérieur comme à l'extérieur dans la plupart des

milieux industriels et commerciaux. Elles doivent être

utilisées uniquement pour ramasser et déverser des

déchets non dangereux.

1. Assurez-vous que la benne est solidement fixée au

2. Enclenchez le frein des roulettes lorsque la benne

nominale de la benne et ne la remplissez pas

au-dessus de la limite supérieure de ses parois

latérales. De graves blessures corporelles (ou

des dommages matériels) pourraient survenir si

la benne est surchargée.

cadre de la base avant de remplir la benne de

déchets.

est immobile.

VIDANGE

1. Montez la benne sur la fourche d'un chariot

élévateur et fixez-la au chariot à l'aide de la chaîne

de sécurité. Enroulez l'extrémité libre de la chaîne

autour du chariot élévateur; puis fixez le maillon

rapide à un maillon de la chaîne. La chaîne doit

être tendue (aucun jeu) pour empêcher la benne

de glisser sur la fourche.

2. Placez la poignée du câble de dégagement à

portée de main de l'opérateur du chariot élévateur.

Par exemple, accrochez le câble au cadre de la

cabine du chariot élévateur. Assurez-vous qu'il y

a beaucoup de jeu dans le câble pour éviter de

libérer accidentellement la benne.

3. La benne ne peut pas se vider à moins que

le loquet soit déverrouillé. Pour déverrouiller le

loquet, tirez sur la languette annulaire à l'extrémité

supérieure du support de loquet de verrouillage

jusqu'à ce que le support libère la tige de

verrouillage (Voir Figure 10).

Figure10

Avant

de la benne

Levier de

dégagement

manuel de

la benne

Chaîne de sécurité

Languette

annulaire

Support

de loquet de

verrouillage

Tige de

verrouillage

Levier

du loquet

PAGE 19 OF 21 0621 IH-5485

Page 20

INSTRUCTIONS D'UTILISATION SUITE

4. Soulevez la benne au-dessus du conteneur à

déchets et avancez jusqu'à ce que l'axe de

vidange soit bien au-dessus de l'intérieur du

conteneur à déchets (Voir Figure 11).

Figure11

Arrière de

la benne

Cadre de

la base

Avant de

la benne

Axe de

vidange

Déchets

ARRÊT

dégagement autour de votre main ou de vos

doigts ou ne fixez pas la poignée à l'un de vos

vêtements!

6. Fixez la benne à la base.

a. Manuellement: abaissez lentement la fourche

jusqu'à ce que la benne repose au sol. La benne

pivotera vers le cadre. Appuyez l'extrémité arrière

de la benne contre la base jusqu'à ce que le levier

du loquet s'enclenche sur la tige de verrouillage.

b. Utilisation du chariot élévateur: soulevez les

pointes de la fourche en inclinant le mât

du chariot élévateur vers la cabine. Ensuite,

éloignez-vous du conteneur à déchets. Abaissez

lentement la fourche jusqu'à ce que l'avant de

la benne repose sur le rebord du conteneur

à déchets. Continuez d'abaisser lentement la

fourche jusqu'à ce que la benne pivote sur le

cadre de la base. Vous devriez entendre le levier

de verrouillage s'encliqueter sur la tige du loquet.

Assurez-vous que la benne est solidement fixée

en soulevant la fourche. La benne ne doit pas

pivoter. Si nécessaire, abaissez complètement la

fourche et verrouillez manuellement la benne au

cadre.

AVERTISSEMENT! N'enroulez PAS le câble de

Conteneur à déchets (coupe transversale)

5. Videz le contenu de la benne en libérant cette

dernière. Pour libérer la benne, tirez sur le câble

de dégagement. La benne pivotera sur l'axe de

vidange.

AVERTISSEMENT! Si une inspection révèle

ARRÊT

des problèmes, remettez la benne en

état de fonctionnement normal AVANT de

l'utiliser à nouveau. N'utilisez PAS une benne

présentant des dommages structuraux. Les

dommages structuraux comprennent, sans

s'y limiter, les soudures fissurées, l'altération

ou la déformation de la benne, des points

de pivotement, ou du cadre de support, en

particulier les entrées pour fourche.

INSPECTION QUOTIDIENNE

Avant chaque utilisation, inspectez les éléments

suivants:

• Câble de dégagement – Vérifiez s'il y a présence

d'effilochage, de déformation, d'amincissement.

7. Verrouillez le loquet en effectuant à l'inverse la

ARRÊT

ENTRETIEN

• L'ensemble de la benne ou cadre de la base – Vérifiez

• Points de pivotement – Lorsque la benne tourne

• Mécanisme de dégagement/verrouillage – Testez le

• Chaîne de sécurité – Vérifiez la chaîne pour repérer

procédure décrite à l'étape 3.

AVERTISSEMENT! NE déplacez PAS la benne tant

que le loquet n'est pas verrouillé!

s'il y a présence de dommages, de déformation, de

corrosion ou de zones fortement rouillées.

(après l'avoir libérée), écoutez les bruits inhabituels

et repérez tout coinçage. Repérez aussi toute

déformation des points de l'essieu ou des récepteurs

de l'essieu.

mécanisme de dégagement de la benne (dispositif

de dégagement, ensemble du levier). Le ressort de

torsion doit faire reculer automatiquement l'ensemble

du levier et fixer fermement la benne au cadre.

tout maillon endommagé (cassé, fissuré, allongé).

PAGE 20 OF 21 0621 IH-5485

Page 21

ENTRETIEN SUITE

1

0

uline.ca

INSPECTION MENSUELLE

Inspectez les éléments suivants au moins une fois par

mois. Remplacez tout composant qui est trop usé ou ne

fonctionne plus correctement:

• Points de pivotement – Repérez toute usure

excessive, la déformation ou d'autres dommages

à la tige de levier de dégagement, aux supports

de tige, aux clavettes d'essieu et aux récepteurs

de l'essieu. Soyez attentif à tout bruit inhabituel

et repérez tout mouvement irrégulier. Retirez la

saleté et les débris dans les zones où ils pourraient

compromettre le mouvement de bascule de la

benne.

• Fixations (boulons, contre-écrous, clavettes d'essieu,

goupilles, bagues de retenue) – inspectez pour

repérer tout desserrement et usure.

• Roulettes – Repérez tout desserrement, usure

excessive ou dommage aux roulettes, aux

roulements de roulettes, aux supports de fixation

et à la quincaillerie. Assurez-vous que le frein

fonctionne correctement.

• Mécanisme de dégagement – Vérifiez que les

mécanismes fonctionnent correctement:

a. Le ressort de torsion fixe fermement le dispositif

de dégagement et l'ensemble du levier à la

benne;

b. Le support de loquet de verrouillage doit

s'appuyer sur la tige de verrouillage à moins

d'être libéré manuellement;

• Benne – Examinez la benne. La structure doit être

rigide et à angle droit sans perforations ou zones

fortement rouillées.

• Cadre de support – Examinez le cadre. Il doit

être rigide et bien droit, les soudures doivent être

intactes, et les entrées pour fourche doivent être

droites et solides.

• Étiquettes – Toutes les étiquettes doivent être

appliquées sur la benne aux endroits indiqués sur le

schéma d'étiquetage à la page 18.

AVERTISSEMENT! L'utilisateur final doit

ARRÊT

comprendre la différence considérable

qui existe entre les réglages et réparations

nécessaires et la modification. Les réglages

sont de simples ajustements qui remettent

la benne en état de fonctionnement normal,

comme le serrage des fixations desserrées ou

le retrait de la saleté et d'autres débris de la

surface. Les réparations consistent à retirer les

pièces usées et à installer de nouvelles pièces

ou des pièces de rechange.

Une modification est un changement qui

modifie l'état de fonctionnement normal de

la benne, comme la flexion du cadre ou le

retrait d'une pièce ou de plusieurs pièces. NE

MODIFIEZ JAMAIS la benne. Toute modification

annule automatiquement la garantie et

pourrait rendre la benne dangereuse à utiliser.

c. L'ensemble du levier pivote en douceur

et enclenche en toute sécurité la tige de

verrouillage.

-800-295-551

PAGE 21 OF 21 0621 IH-5485

Loading...

Loading...