Para Español, vea páginas 4-6.

Pour le français, consulter les pages 7-9.

H-2721

DELUXE

PALLET TRUCK

1-800-295-5510

uline.com

TECHNICAL DATA

MODEL H-2721

Capacity 7,70 0 lb s .

Max. Fork Height 7.5"

Min. Fork Height 3"

Fork Length 48"

Overall Fork Width 27"

Fork Wheel Diameter 3" Polyurethane

Steering Wheel Diameter 7" Polyurethane

Net Weight 201 lbs.

WARNING! Operator must read and understand

instructions here and on truck prior to use.

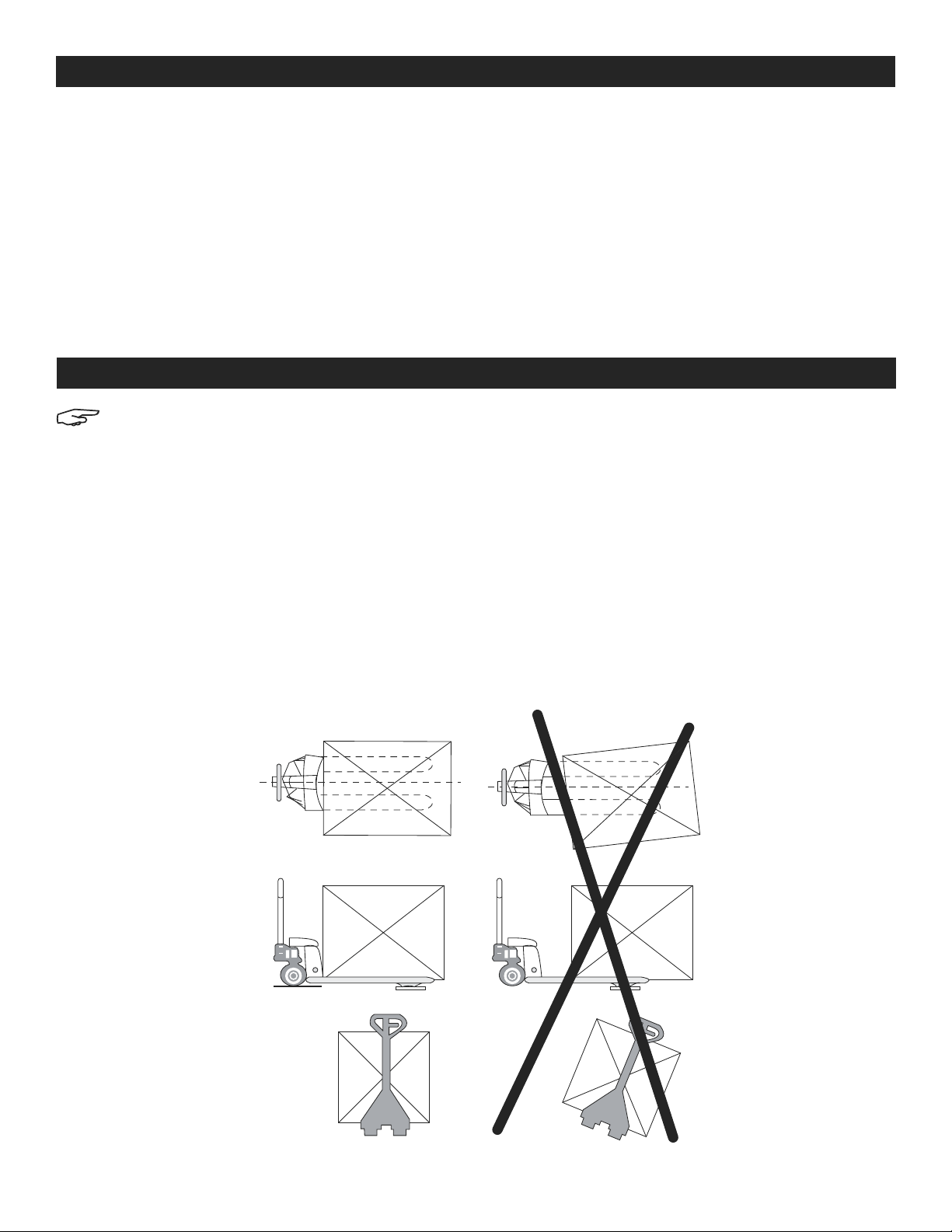

On the handle of the pallet truck, you will find the

control lever which can be set in three positions.

(See Figure 1)

Figure 1

- LOWER = to lower the forks

- NEUTRAL = to move the load

- RAISE = to raise the forks

OPERATION

1. If the forks elevate while pumping in the NEUTRAL

position, turn the setting screw clockwise until

pumping the handle does not raise the forks and

the NEUTRAL position functions correctly.

2. If the forks descend while pumping in the NEUTRAL

position, turn the setting screw counterclockwise

until the forks do not lower.

3. If the forks do not descend when the control lever is in

the LOWER position, turn the setting screw clockwise

until raising the control lever lowers the forks. Then

check the NEUTRAL position as per step 1 and 2.

4. If the forks do not lift while pumping in the RAISE

position, turn the setting screw counterclockwise

until the forks elevate while pumping in the RAISED

position. Then check the NEUTRAL and LOWER

position as per steps 1, 2 and 3.

NOTE: When viewing the truck from the handle

side, the setting screw is located on the right

side of the pump above the right wheel. The

truck will lower faster or slower depending on

how far in or out the screw is adjusted.

PAGE 1 OF 9 0321 IH-2721

MAINTENANCE

OIL

Check the oil level every six months. The oil capacity is

about 0.3L. Restore the fluid level in the reservoir to 5mm

below the top; this must be done with the forks in the

lowered position.

Use the hydraulic oil ISO-VG32 or equivalent. Oil viscosity

should be 30cSt at 104°.

HOW TO EXPEL AIR FROM THE PUMP UNIT

Air may enter the unit over time or when the seals are

SAFETY

NOTE: For safe operation of the Deluxe Pallet

Truck, read all warning signs and instructions

here and on the pallet truck prior to use.

1. Do not operate the truck unless you are familiar with

it and have been trained and authorized to do so.

2. Do not use the truck on sloping ground.

3. Never place any part of your body in the lifting

mechanism or under the forks or load. Do not carry

passengers.

4. We advise that operators wear gloves and safety

shoes.

replaced. To expel the air, lift the control lever to the

LOWER position and move the handle up and down

several times.

DAILY CHECK AND MAINTENANCE

Daily checks of the pallet truck can limit wear and tear

on the unit. Pay special attention to the wheels, the

axles, the handle, the forks and lift and lower control.

LUBRICATION

Use motor oil or grease to lubricate all moveable parts.

5. Do not handle unstable or loosely stacked loads.

6. Do not overload the truck.

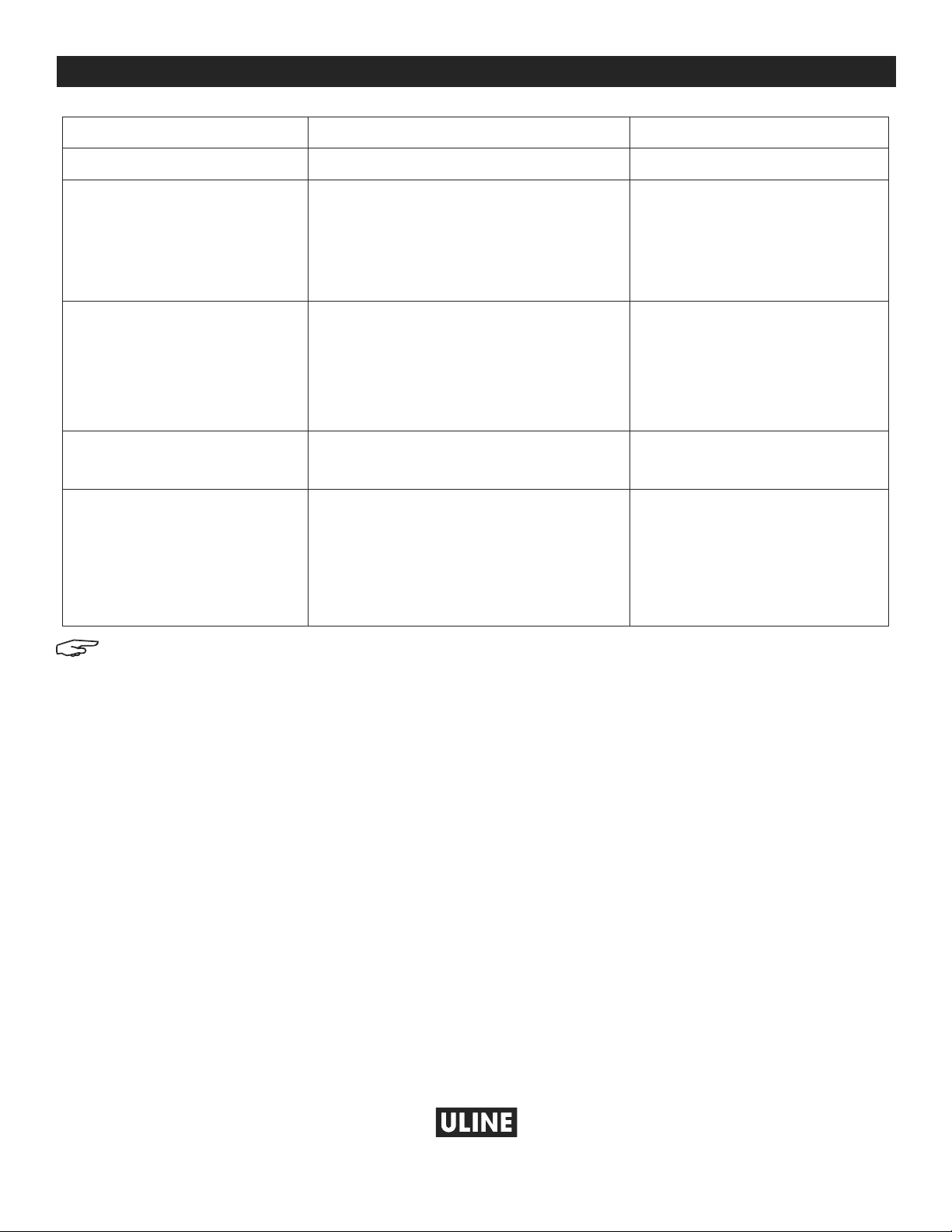

7. Always center loads on the forks, not at the end of

the forks. (See Figure 2)

8. The capacity of the truck assumes an evenly

distributed load with the center of the load being at

the halfway point of the length of the forks.

9. Make sure the length of the forks matches the length

of the pallet load.

10. Lower the forks to lowest height when the truck is not

being used.

Figure 2

PAGE 2 OF 9 0321 IH-2721

A B

TROUBLESHOOTING

1

0

uline.com

OPERATING ISSUE CAUSES RECOMMENDATIONS

The forks do not lift to maximum height. Not enough hydraulic oil. Add more oil.

The forks do not raise. Not enough hydraulic oil.

The oil has impurities.

Discharge valve is out of adjustment.

Air in the hydraulic oil.

The forks do not descend. The rod and the cylinder are deformed

Leaks Seals worn out or damaged.

The forks descend without being

lowered.

from a seriously unbalanced load.

A part has been broken or been deformed

from an unbalanced load.

The setting screw is not in the correct position.

Some parts may be cracked or worn out.

Impurities in the oil cause the discharge valve to fail

to close.

Air in the oil.

Seals worn or damaged.

Discharge valve is out of adjustment.

Add more oil.

Change the oil.

Adjust the setting screw. (As noted in

Operation)

Expel the air. (As noted in Maintenance)

Replace the rod or cylinder.

Repair or replace component.

Adjust the setting screw. (As noted in

Operation)

Replace seals with new ones.

Check and replace with new ones.

Change the oil.

Expel the air. (As noted in Maintenance)

Replace with new ones.

Adjust the setting screw. (As noted in

Operation)

NOTE: Do not attempt to repair the Deluxe Pallet Truck unless you are trained and authorized to do so.

-800-295-551

PAGE 3 OF 9 0321 IH-2721

H-2721

PATÍN HIDRÁULICO

DE ALTA CALIDAD

MODELO H-2721

Capacidad 3,492 kg (7,700 lbs.)

Altura Máx. de Horquilla 19 cm (7.5")

Altura Mín. de Horquilla 7.6 cm (3")

Longitud de Horquilla 121.9 cm (48")

Ancho Total de Horquillas 68.5 cm (27")

Diámetro de Llantas de la Horquilla Poliuretano de 7.6 cm (3")

Diámetro del Volante Poliuretano de 17.8 cm (7")

Peso Neto 91 kg (201 lbs.)

800-295-5510

uline.mx

INFORMACIÓN TÉCNICA

FUNCIONAMIENTO

¡ADVERTENCIA! El operador debe leer y

comprender las instrucciones contenidas aquí

y en el patín antes de darle uso.

En el asa del patín hidráulico encontrará la palanca de

control, la cual puede fijarse en tres posiciones.

(Vea Diagrama 1)

Diagrama 1

- LOWER (BAJAR) = para bajar las horquillas

- NEUTRAL (NEUTRO) = para mover la carga

1. Si las horquillas se elevan mientras se bombea en la

posición NEUTRAL (NEUTRO), gire el tornillo de ajuste

en dirección de las manecillas del reloj hasta que

el bombeo del asa deje de elevar las horquillas y

funcione correctamente la posición NEUTRAL (NEUTRO).

2. Si las horquillas bajan mientras se bombea en la

posición NEUTRAL (NEUTRO), gire el tornillo de ajuste

en dirección contraria a las manecillas del reloj

hasta que las horquillas dejen de bajar.

3. Si las horquillas no bajan cuando la palanca de

control esté en la posición LOWER (BAJAR), gire el

tornillo de ajuste en dirección de las manecillas

del reloj hasta que las horquillas bajen al levantar

la palanca de control. Revise entonces la posición

NEUTRAL (NEUTRO) como se indica en los pasos 1 y 2.

4. Si las horquillas no se elevan mientras se bombea

en la posición RAISE (ELEVAR), gire el tornillo de

ajuste en dirección contraria a las manecillas del

reloj hasta que las horquillas se eleven al bombear

en la posición RAISE (ELEVAR). Revise entonces la

posición NEUTRAL (NEUTRO) y LOWER (BAJAR) como

se indica en los pasos 1, 2 y 3.

- RAISE (ELEVAR) = para elevar las horquillas

PAGE 4 OF 9 0321 IH-2721

NOTA: Al estar viendo el patín del lado de la

asa, el tornillo de ajuste está localizado al

lado derecho de la bomba arriba de la llanta

derecha. El patín bajará más rápido o lento

dependiente de que tan adentro o afuera esté

el tornillo.

MANTENIMIENTO

ACEITE

Revise el nivel de aceite cada seis meses. La

capacidad de aceite es de alrededor de 0.3 L.

Restaure el nivel de fluido en el depósito a 5 mm por

debajo del tope; esto debe hacerse con las horquillas

en la posición LOWER (BAJAR).

Use aceite hidráulico ISO-VG32 o equivalente. La

viscosidad del aceite debe ser 30cSt a 40 °C (104 °F).

CÓMO EXPULSAR AIRE DE LA BOMBA

El aire puede entrar aire a la unidad con el tiempo o

cuando se reemplazan los sellos. Para expulsarlo, levante

SEGURIDAD

NOTA: Para la operación segura del Patín

Hidráulico de Alta Calidad, lea todas las

instrucciones y advertencias de seguridad que

aparecen aquí o en el patín hidráulico antes

de usarlo.

1. No opere el patín a menos que esté familiarizado

con esta máquina y haya recibido capacitación y

autorización para hacerlo.

2. No use el patín en suelo inclinado.

3. Nunca coloque ninguna parte de su cuerpo en el

mecanismo elevador ni debajo de las horquillas o

la carga. No lleve pasajeros.

4. Recomendamos a los operadores usar guantes y

zapatos de seguridad.

la palanca de control a la posición LOWER (BAJAR) y

mueva el asa hacia arriba y abajo varias veces.

REVISIÓN DIARIA Y MANTENIMIENTO

Las revisiones diarias del patín hidráulico pueden limitar

el desgaste de la unidad. Preste especial atención a

las llantas, los ejes, el asa, las horquillas y la palanca

de control para subir o bajar.

LUBRICACIÓN

Use aceite para motor o grasa para lubricar todas las

partes móviles.

5. No maneje cargas inestables ni apiladas sin

asegurarlas.

6. No sobrecargue el patín.

7. Siempre centre las cargas en las horquillas, no en

los extremos de las horquillas. (Vea Diagrama 2)

8. La capacidad del patín supone una carga

distribuida de forma homogénea con el centro de

la carga en el punto medio de la longitud de las

horquillas.

9. Asegúrese de que la longitud de las horquillas

coincida con la de la carga de la tarima.

10. Baje las horquillas a la altura más baja cuando no

se use el patín.

Diagrama 2

PAGE 5 OF 9 0321 IH-2721

A B

SOLUCIÓN DE PROBLEMAS

8

0

uline.mx

PROBLEMA DE FUNCIONAMIENTO CAUSAS RECOMENDACIONES

Las horquillas no suben a la altura

máxima.

Las horquillas no suben. No hay suficiente aceite hidráulico.

Las horquillas no bajan. La varilla y el cilindro se deforman como

Fugas Sellos desgastados o dañados.

Las horquillas descienden sin haberlas

bajado.

No hay suficiente aceite hidráulico. Agregue más aceite.

El aceite tiene impurezas.

La válvula de descarga está fuera de su ajuste.

Aire en el aceite hidráulico.

resultado de una carga que está extremadamente

desbalanceada.

Una parte está rota o deformada como resultado

de una carga desbalanceada.

El tornillo de ajuste no está en la posición correcta.

Algunas partes pueden estar agrietadas o

desgastadas.

Impurezas en el aceite hacen que la válvula de

descarga no se cierre.

Aire en el aceite.

Sellos desgastados o dañados.

La válvula de descarga está fuera de su ajuste.

Agregue más aceite.

Cambie el aceite.

Ajuste el tornillo de ajuste. (Como se

indica en Operación)

Expulse el aire. (Como se indica en

Mantenimiento)

Reemplace la varilla o el cilindro.

Repare o reemplace el componente.

Ajuste el tornillo de ajuste. (Como se

indica en Funcionamiento)

Reemplace los sellos con otros nuevos.

Revise y reemplace con sellos nuevos.

Cambie el aceite.

Expulse el aire. (Como se indica en

Mantenimiento)

Reemplace con partes nuevas.

Ajuste el tornillo de ajuste. (Como se

indica en Funcionamiento)

NOTA: No intente reparar el Patín Hidráulico de Alta Calidad a menos que esté capacitado y autorizado

para hacerlo.

00-295-551

PAGE 6 OF 9 0321 IH-2721

H-2721

TRANSPALETTE

DE LUXE

1-800-295-5510

uline.ca

DONNÉES TECHNIQUES

MODÈLE H-2721

Capacité 3492,7 kg (7 700lb)

Hauteur max. des fourches 19,1cm (7,5po)

Hauteur min. des fourches 7,6 cm (3po)

Longueur des fourches 1,2m (48po)

Largeur totale des fourches 68,6cm (27po)

Diam. des roues des fourches 7,6cm (3 po), polyuréthane

Diam. de la roue directrice 17,8cm (7po), polyuréthane

Poids net 91,2 kg (201lb)

FONCTIONNEMENT

AVERTISSEMENT! L'opérateur doit lire et

comprendre les instructions qui figurent ici et

sur le transpalette avant l'utilisation.

La poignée du transpalette est munie d'un levier de

commande réglable à trois positions. (Voir Figure1)

Figure1

- LOWER (ABAISSER) = pour abaisser les fourches

- NEUTRAL (NEUTRE) = pour déplacer la charge

- RAISE (SOULEVER) = pour soulever les fourches

PAGE 7 OF 9 0321 IH-2721

1. Si les fourches se soulèvent lorsque vous pompez à

la position NEUTRAL, tournez la vis de réglage dans

le sens horaire jusqu'à ce que le pompage de

la poignée ne soulève pas les fourches et que la

position NEUTRAL fonctionne correctement.

2. Si les fourches s'abaissent lorsque vous pompez à la

position NEUTRAL, tournez la vis de réglage dans le

sens antihoraire jusqu'à ce que les fourches cessent

de s’abaisser.

3. Si les fourches ne s'abaissent pas quand le levier

de commande est à la position LOWER, tournez

la vis de réglage dans le sens horaire jusqu'à

ce que le soulèvement du levier de commande

abaisse les fourches. Puis vérifiez la position NEUTRAL

conformément aux étapes1 et 2.

4. Si les fourches ne se soulèvent pas lorsque vous

pompez à la position RAISE, tournez la vis de

réglage dans le sens antihoraire jusqu'à ce que les

fourches se soulèvent avec le levier à la position

RAISE. Ensuite, vérifiez les positions NEUTRAL et LOWER

en suivant les étapes 1, 2et3.

REMARQUE: En visualisant le transpalette

du côté poignée, la vis de réglage se situe

du côté droit de la pompe, au-dessus de la

roue droite. Le transpalette s'abaissera plus

ou moins rapidement selon la profondeur du

réglage de la vis de réglage.

ENTRETIEN

HUILE

Vérifiez le niveau d'huile tous les sixmois. Le volume

maximal d'huile est d'environ 0,3litre. Réglez le niveau de

fluide dans le réservoir à environ 5mm sous le plein entier;

ceci doit être fait les fourches en position abaissée.

Utilisez l'huile hydraulique ISO-VG32 ou un équivalent. La

viscosité de l'huile doit être 30cSt à 40°C (104°F).

COMMENT PURGER L'AIR DE LA POMPE

De l'air peut pénétrer dans la pompe au fil du temps ou

lors du remplacement des joints d'huile. Pour purger l'air,

soulevez le levier de commande à la position LOWER,

SÉCURITÉ

REMARQUE: Pour l'opération sécuritaire du

transpalette de luxe, veuillez lire tous les

avertissements et consignes qui figurent ici et

sur le transpalette avant l'utilisation.

1. N'utilisez pas le transpalette si vous n'avez pas une

bonne connaissance de ce dernier et n’avez pas

été formé ni autorisé pour le faire.

2. N'utilisez pas le transpalette sur une surface en pente.

3. Ne placez jamais une partie de votre corps dans

le mécanisme de levage ou sous la fourche ou la

charge. Ne transportez pas de passagers.

4. Nous conseillons aux opérateurs de porter des gants

et des chaussures de sécurité.

puis déplacez le levier de haut en bas à plusieurs

reprises.

VÉRIFICATION ET ENTRETIEN QUOTIDIENS

La vérification quotidienne du transpalette peut en

limiter l'usure. Portez une attention spéciale aux roues,

aux essieux, à la poignée, aux fourches et au levier de

commande.

LUBRIFICATION

Utilisez de l'huile à moteur ou de la graisse pour lubrifier

toutes les pièces mobiles.

5. Ne manutentionnez jamais de charges instables ou

mal empilées.

6. Ne surchargez pas le transpalette.

7. Positionnez toujours la charge au centre plutôt qu'à

l'extrémité des fourches. (Voir Figure2)

8. La capacité du transpalette est établie avec une

charge uniformément distribuée, avec le centre de

la charge positionné à mi-chemin de la longueur

des fourches.

9. Assurez-vous que la longueur des fourches

correspond à la longueur de la palette transportée.

10. Lorsque vous n'utilisez pas le transpalette, abaissez

les fourches au niveau le plus bas.

Figure2

PAGE 8 OF 9 0321 IH-2721

A B

DÉPANNAGE

1

0

uline.ca

PROBLÈME CAUSES RECOMMANDATIONS

Les fourches ne se soulèvent pas à la

hauteur maximale.

Les fourches ne se soulèvent pas. L'huile hydraulique est insuffisante.

Les fourches ne descendent pas. La tige et le cylindre sont déformés

Fuites Joints d'huile usés ou endommagés.

Les fourches descendent sans

commandement.

L'huile hydraulique est insuffisante. Ajoutez de l'huile.

L'huile contient des impuretés.

Le clapet de refoulement est déréglé.

Il y a de l'air dans l'huile hydraulique.

à la suite du transport d'une charge très

déséquilibrée.

Une pièce a été brisée ou déformée à la suite du

transport d'une charge déséquilibrée.

La vis de réglage n'est pas à la position appropriée.

Certaines pièces peuvent être fissurées ou usées.

Des impuretés contenues dans l'huile empêchent la

fermeture du clapet de refoulement.

Il y a de l'air dans l'huile.

Les joints sont usés ou endommagés.

Le clapet de refoulement est déréglé.

Ajoutez de l'huile.

Changez l'huile.

Réglez la vis de réglage. (de la

façon indiquée dans la section

Fonctionnement)

Purgez l'air. (de la façon indiquée dans

la section Entretien)

Remplacez la tige ou le cylindre.

Réparez ou remplacez le composant.

Réglez la vis de réglage. (de la

façon indiquée dans la section

Fonctionnement)

Remplacez les joints d'huile par des

neufs.

Vérifiez et remplacez par des

composants neufs.

Changez l'huile.

Purgez l'air. (de la façon indiquée dans

la section Entretien)

Remplacez par des joints neufs.

Réglez la vis de réglage. (de la

façon indiquée dans la section

Fonctionnement)

REMARQUE: Ne tentez pas de réparer le transpalette de luxe à moins d'être formé ou autorisé pour le faire.

-800-295-551

PAGE 9 OF 9 0321 IH-2721

Loading...

Loading...