Page 1

π H-2065

DELUXE IMPULSE SEALER

WITH CUTTER

TECHNICAL DATA

Types of films: LDPE, HDPE, PP, PVC, BOPP.

1-800-295 -5510

uline.com

OPERATION

IMPORTANT! Read this manual thoroughly and

familiarize yourself with ALL controls and operating

features. Keep this manual for future reference and

maintenance.

The machine should be located and operated in a

dry room with good ventilation, and away from any

flammable materials and gases.

SETUP

The machine is ready for operation after it is plugged into

an approved 115VAC electrical outlet and the yellow LED

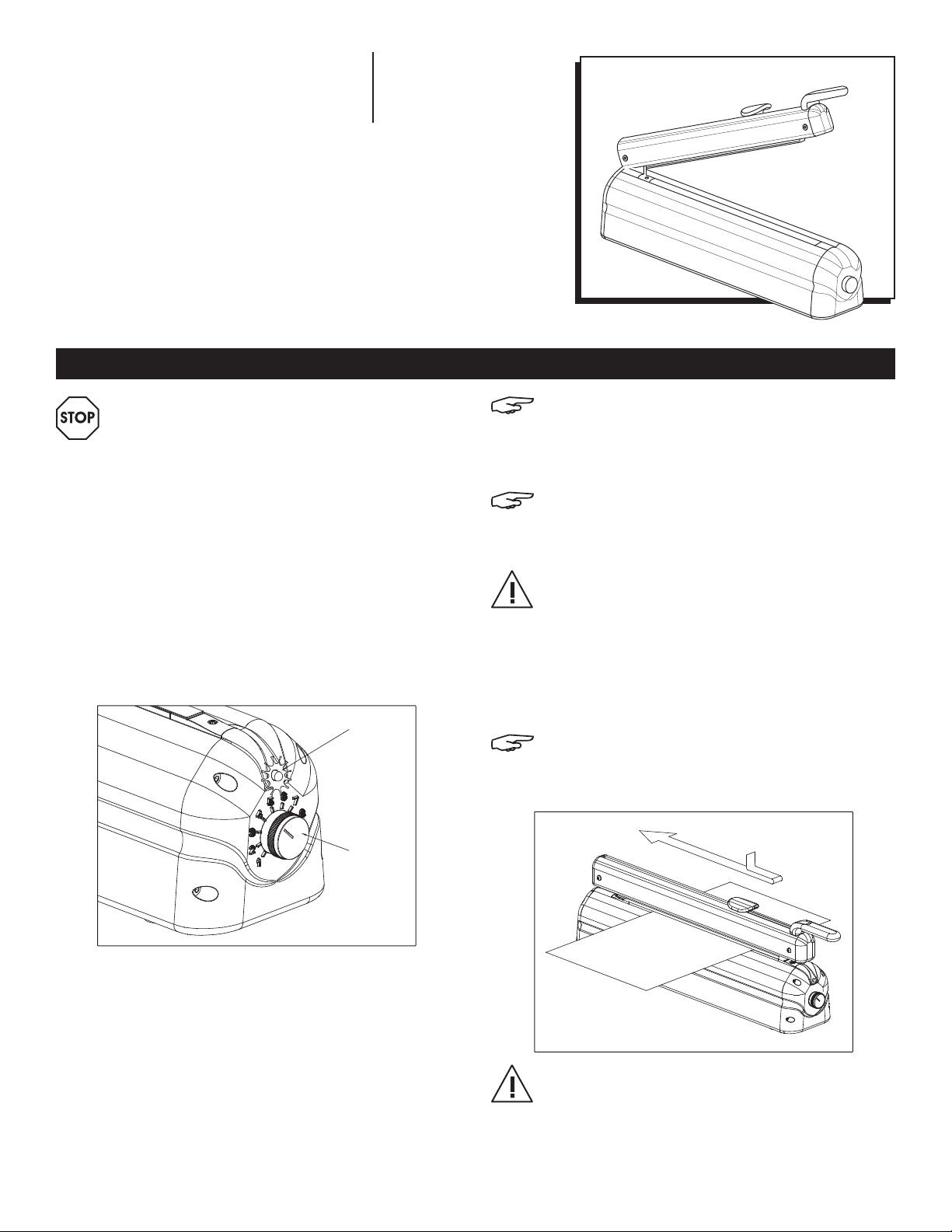

illuminates. (See Figure 1A) Before operation, adjust the

sealing time to match the film’s type and width by conducting

a test sealing:

1. Set regulator button to lowest setting (#1 setting).

(See Figure 1B)

A

B

NOTE: The quality of the seal depends on the

thickness of the film and its composition. Test

sealing should always be conducted at a low

setting. If necessary, sealing time can be increased

in small steps.

NOTE: To achieve the best seal, keep the handle

down for a few seconds after the sealing operation

is complete. This allows the seal to cool down under

pressure and become permanent.

WARNING! Sealing at a higher temperature than

necessary may result in premature wear of parts

and excessive melting of packaging material.

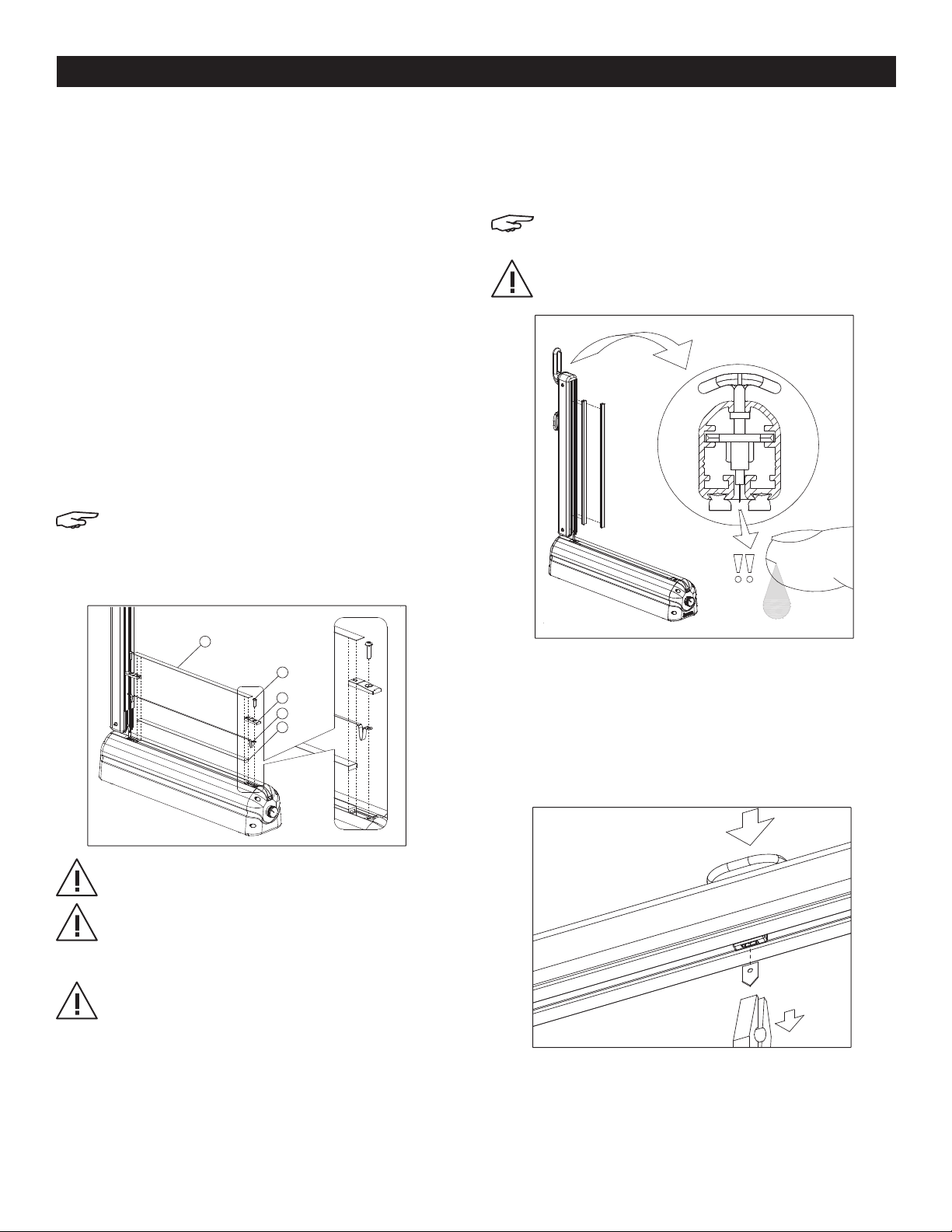

USING THE CUTTING KNIFE

For safety reasons, the knife is secured in position by a spring.

To cut the film, press down on the knife and move it back

and forth.

NOTE: For best results, first press the knife head down

in the middle of the sealed film and slide it back

and forth. This helps prevent film breakage on the

sides. (See Figure 2)

Figure 1

2. Place film between sealing head and sealing electrode.

3. Close sealing head, hold down handle and wait for end

of sealing cycle. LED changes from yellow to red while

machine is sealing.

4. When sealing is complete, LED changes from red to

yellow.

5. Allow seal to cool down for 1-2 seconds and lift handle.

6. If bag is not fully sealed, increase sealing time by turning

regulator button to higher setting and repeat steps 2-5.

PAGE 1 OF 4 0715 IH-2065

Figure 2

WARNING! To prevent injury, never operate the knife

head when the sealing bar is open. Before using,

always ensure that the knife is intact and positioned

correctly.

Page 2

MAINTENANCE

CLEANING

The machine does not require special care. However, it is

advisable to remove any residue from the sealing head and

silicone rubber before it burns on. Use a damp, wet cloth to

clean. Do not use cleaning products that contain solvents.

REPLACING WORN PARTS

Only use Uline replacement parts.

REPLACING THE PTFE TAPE AND SEALING WIRE

To replace the PTFE tape and sealing wire:

1. Remove upper PTFE tape (See Figure 3A) and unscrew

fastening screws on side of sealing electrode.

(See Figure 3B)

2. Remove safety caps from sealing wire tensioning units.

(See Figure 3C)

3. Carefully pull sealing wire up and remove from machine.

(See Figure 3D)

4. Remove PTFE tape attached to machine. (See Figure 3E)

NOTE: When changing the PTFE tape, always ensure

the tape under the sealing wire is intact. While

changing the sealing wire, it is advisable to install

the protective cap backwards on the sealing wire

tensioning unit.

REPLACING THE SILICONE RUBBER

Pull out the damaged or burned silicone rubber from sealing

bar and clip in the new silicone rubber. (See Figure 4)

When installing the silicone rubber, observe the direction of

the profile.

NOTE: It is not necessary to pull the silicone rubber

through the profile. It can be clipped in easily.

WARNING! When changing the silicone rubber, use

caution around the sharp knife in the sealing bar’s

knife assembly. (See Figure 4)

Figure 4

A

B

C

D

E

REPLACING THE KNIFE

To replace a blunt, dull or broken knife:

1. Lift sealing bar and press down on head of knife assembly.

(See Figure 5A)

2. Pull knife out of its housing with pliers. (See Figure 5B)

3. Insert new knife.

Figure 3

Figure 5

A

WARNING! For safety, used or burned PTFE tape

should be replaced immediately.

WARNING! To prevent an electrical short, cut each

side of lower self adhesive PTFE tape 4 mm

(about 1⁄8") longer than the aluminum side panel of

the machine.

WARNING! Never apply tape to the surface of the

sealing wire. It must move freely under the upper

B

PTFE strap. (Only a portion of the upper strap is

treated with adhesive.)

PAGE 2 OF 4 0715 IH-2065

Page 3

MAINTENANCE CONTINUED

REPLACING THE KNIFE ASSEMBLY

To replace a worn or damaged knife assembly:

1. Remove front cap in front side of sealing bar as it opens.

(See Figure 6A)

2. Loosen screws that hold handle and remove.

(See Figure 6B)

3. Detach screws that fasten sealing head. (See Figure 7A)

Figure 6 Figure 7 Figure 8

4. Remove spreader from aluminum profiles. (See Figure 7B)

5. Pull out old knife assembly and replace. (See Figure 8A)

6. Reinstall sealing head by performing steps 1-5 in reverse

order.

NOTE: Always replace the front cap, the machine

will not operate without it.

B

A

A

B

A

TROUBLESHOOTING

A

OPERATING ISSUE RECOMMENDATIONS

LED lamp does not illuminate. Machine does not seal.

LED lamp illuminates yellow but does not change to

red when handle is closed. Machine does not seal.

LED lamp illuminates normally, but machine does

not seal.

Sealing is not acceptable.

Loose handle.

Ensure the machine is connected to an

electrical outlet.

Is the outlet “live?”

Check if the control panel is damaged.

Ensure that sufficient force is used to press

handle down. (Do not press the handle

sideways.)

Is the front cap on the handle? Is the magnet

inside it?

Check if the control panel is damaged.

Unplug from power immediately. Ensure sealing

wire, PTFE tapes and transformer are intact.

Change sealing time with regulator button.

(Sealing time increases proportionally with

thickness of film.)

After sealing, allow 1-2 sec. to cool. (Cooling

time increases proportionally with sealing time.)

Tighten hinge bolts.

Sealing wire heats up immediately when machine is

plugged in.

PAGE 3 OF 4 0715 IH-2065

Check if the control panel is damaged.

Immediately unplug from electrical power and

call Uline at 1-800-295-5510

Page 4

TECHNICAL INFORMATION

TYPE

H-2065 12.60" 11. 81" 11. 81" 20.99 x 3.95 x 6.89 7.9 l b s .

TYPE OF

TRANSFORMER

H-2065 110 /17,6 V 240 w 2,2 a 6 a

SEALING

LENGTH

PRIMARY/SECONDARY

NOMINAL VOLTAGE

MAX. FILM

WIDTH

CUTTING

LENGTH

NOMINAL

ELECTRIC POWER

MACHINE

DIMS

NOMINAL

CURRENT

NET

WEIGHT

USED FUSES

REFERENCE

4

3

2

1

7

8

5

6

13

12

#

DESCRIPTION

1 Main Electric Cable

2 Hinge Bolt

3 Sealing Bar

4 Knife Assembly

5 Handle

6 Front Cap (Magnetic)

7 Silicone Rubber

8 Sealing Unit (Sealing Wire With Upper And Lower Ptfe Tape)

9 Led (Lamp)

10 Regulator Button

11 Front Cover

12 Machine Frame

13 Back Cover

9

10

11

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-800 -295 -5510

PAGE 4 OF 4 0715 IH-2065

uline.com

Loading...

Loading...