Page 1

Para Español, vea páginas 6-10.

Pour le français, consulter les pages 11-15.

H-2034, H-2035

SHRINK TUNNEL

1-800-295 -5510

uline.com

SPECIFICATIONS

IMPORTANT! Read this manual thoroughly

and familiarize yourself with ALL controls and

operating features. Keep this manual for future

reference and maintenance.

Unpacking: Check the machine for damage.

If damage is found, return to Uline.

MACHINE SPECIFICATIONS

• Package Size Capabilities: Tunnel 16 x 8".

• Speed: Will vary with length of package.

• Power Supply: 220 volt, 10 amp mesh belt conveyor.

• Overall Dimensions: 32"L x 27"W x 28"H.

TUNNEL STANDARD FEATURES

• 2,100-Watt tunnel heating power.

• 360-degree air circulation.

MESH BELT CONVEYOR

• Teflon coated mesh belt.

WARNING! Damage to the machinery can

be caused by (but not limited to): electrical

overload, mechanical overload, incorrect

power source, lifting and/or moving the

equipment improperly, and misuse of

assemblies. Any damage from the above

constitutes misuse and/or abuse and we will not

be covered by the manufacturer's warranty.

This manual contains multiple precautionary

notes indicated with the word "CAUTION" and/

or "WARNING". Such notes are used to describe

functions that can cause bodily injury and/or

damage to the machine. Notes marked with

"WARNING" indicate a condition that can cause

harm to a person. Notes marked with "CAUTION"

indicate conditions which can cause damage

to the machine.

It is the employer's responsibility to ensure all

personnel associated with the operation of

this machine are adequately trained in the

operation, safety precautions and potential

hazards of this machinery.

• Speed controlled tunnel conveyor. 0-60 FPM.

WARRANTY

• Full 1-year warranty on parts.

0521 IH-2034PAGE 1 OF 15

Page 2

INSTRUCTIONS

GENERAL

1. H-2034 Shrink Tunnel consists of a tunnel and a

conveyor.

The conveyor is a teflon coated mesh belt.

The mesh belt allows the heated air to shrink the

bottom of the package from the tunnel.

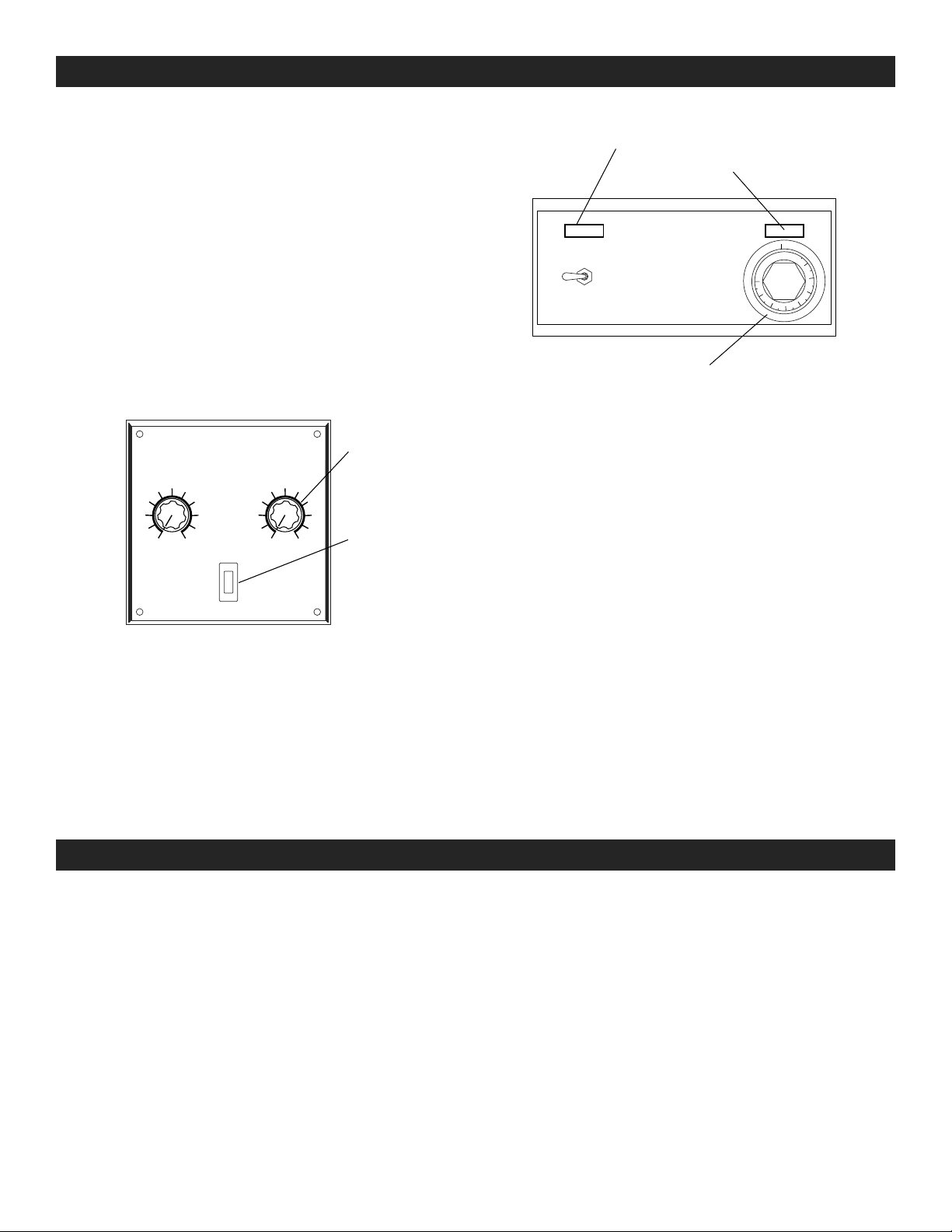

2. There are two control panels for the operation of

the machine. The lower panel controls the conveyor

and the upper panel controls the tunnel.

MACHINE STARTUP

1. Turn on the conveyor using the ON/OFF rocker switch.

The ON/OFF switch will light up. Set the conveyor

speed to "2" on the operator panel. (See Figure 1)

Figure 1

3

2

1

CONVEYOR

SPEED

5

4

6

POWER

MAIN

CONVEYOR

TEMP

5

6

4

7

8

9

3

2

1

RESET

OFF

7

8

9

820HB Only

ON/OFF Switch

Circuit Breaker

Figure 2

Power Light

Heat Indicator Light

OFF

550

500

450

200

ON/OFF

400

250

350

300

Thermostat

4. Set the tunnel temperature to a setting of 325º F

on the tunnel’s operator panel. It will take 20-30

minutes to reach temperature. The heat indicator

light will go off when it has reached temperature.

(See Figure 2)

5. After the initial package has been run through the heat

shrink tunnel, the following adjustments may be made:

a. Increase or decrease the thermostat setting.

b. Increase or decrease the conveyor speed.

2. If the power light is not on, plug in the tunnel.

3. Turn on the tunnel using the ON/OFF switch.

MAINTENANCE

The machine should be inspected on a timely basis to

ensure all is functioning well and in good working order.

There is not much required to keep the machine running

trouble free. The most important area is the seal head.

The following are recommendations for preventative

maintenance on the machine to keep it performing well

over an extended period.

c. Increase or decrease the temperature if

available.

6. Due to the various types of shrinkable films, room

temperatures and voltages, you may have to

experiment with various temperatures and conveyor

speeds, to get the desired shrink. Your film supplier

is familiar with this type of equipment and will be

helpful in determining the best settings for the film

you are using.

MAINTENANCE TIPS

1. Inspect the conveyor belts for wear and

misalignment. If the belts are not tracking properly,

adjust the idler rollers to realign the belts. Replace

worn belts as needed.

2. Lubricate all chain drives every 160 hours of

operation with a bearing grease or chain lubricant.

3. To clean the machine, wipe down the conveyor

belts and other flat surfaces to remove any dirt.

Do not use any type of belt dressing on the

conveyor belts.

0521 IH-2034PAGE 2 OF 15

Page 3

MACHINE COMPONENTS

MAIN FRAME ASSEMBLY

1. The main frame assembly of this machine consists of

the rails, conveyor drive motor, and the operator panel.

TUNNEL CONVEYOR ASSEMBLY MESH BELT

1. T

his assembly consists of the tunnel conveyor belt

as

sembly including the DC gear motor. The belt is

heated by a 500W heat element mounted under

the conveyor pan. The heated belt provides positive

shrink on the bottom of the package. The assembly

also includes belt guides and tracking screws.

TUNNEL CONVEYOR ASSEMBLY HEATED BELT

1. This assembly consists of the heated belt including

the DC gear motor. The belt is heated by a 500W

heating element mounted under the conveyor

pan. The heated belt provides positive shrink on the

bottom of the package. The assembly also includes

belt guides and tracking screws.

TUNNEL ASSEMBLY

1. The tunnel assembly set on the tunnel conveyor

uses heated recirculated air to shrink the film onto

the package. The assembly has its own power cord

and requires a dedicated 20Amp circuit. The blower

motor runs in a counterclockwise direction when

looking at the non-shaft end. (See Figure 2)

ELECTRICAL PANEL ASSEMBLY

1. This assembly is located under the drive roller. Only

a qualified technician should access this assembly.

WARNING! Do not tamper with electrical wiring

unless licensed or trained to do so. Disconnect

main power to the machine before attempting

any electrical service.

2. Electrical schematics can be found in the original

manual.

OPERATOR PANEL ASSEMBLY

1. The operator assembly panel consists of the ON/

OFF switch, adjustment for the conveyor speed and

conveyor temperature if available.

2. The ON/OFF switch also acts as a circuit breaker for

the conveyor system. (See Figure 1)

3. The Conveyor Speed is controlled using a DC Drive

Board (203-61) mounted in the Operator Panel. The

speed can vary from 0 feet per minute to 60 feet

per minute.

4. The Conveyor Temperature is controlled using a

variable voltage supply.

CONSOLE LEG KIT (Optional, see below)

1. ULINE item H-2035.

INSTALLATION AND SETUP

IMPORTANT! Prior to machine set up and

installation the general warnings should be

read and fully understood by all personnel

associated with this machinery.

SET-UP INSTRUCTIONS

1. Remove the tunnel from the crate or box.

Inspect for damage.

2. If available, attach the console stand to the tunnel

conveyor rails. See the enclosed instructions for the

stand. Level the machine using the levelers.

3. Place the tunnel on the conveyor with the operator

panels toward the front.

4. Remove any ties used for shipping.

5. Connect machine to power source. Power supply

for the tunnel should be 220 Volt, 10 Amp grounded

power supply. (Have an electrician install a plug on

the power cord, if you are plugging the tunnel into

an electrical outlet.)

CAUTION! Machine should be grounded in

accordance with local electrical codes.

6. Turn on the power to the conveyor using the ON/OFF

switch. Turn on the tunnel using its ON/OFF switch.

7. Ensure the tunnel conveyor is slowly running.

Ensure the tunnel blower is working. Turn the tunnel

temperature to 325º F. When the tunnel has reached

temperature, check the tracking of the tunnel

conveyor’s belt.

8. Test run a few products through the machine to fine

tune the settings in order to achieve as tight a bag

around the product as practical. This will aid in the

shrink process.

9. When finished, turn the tunnel and conveyor

temperatures off. Wait 15-20 minutes and turn off the

tunnel and conveyor.

0521 IH-2034PAGE 3 OF 15

Page 4

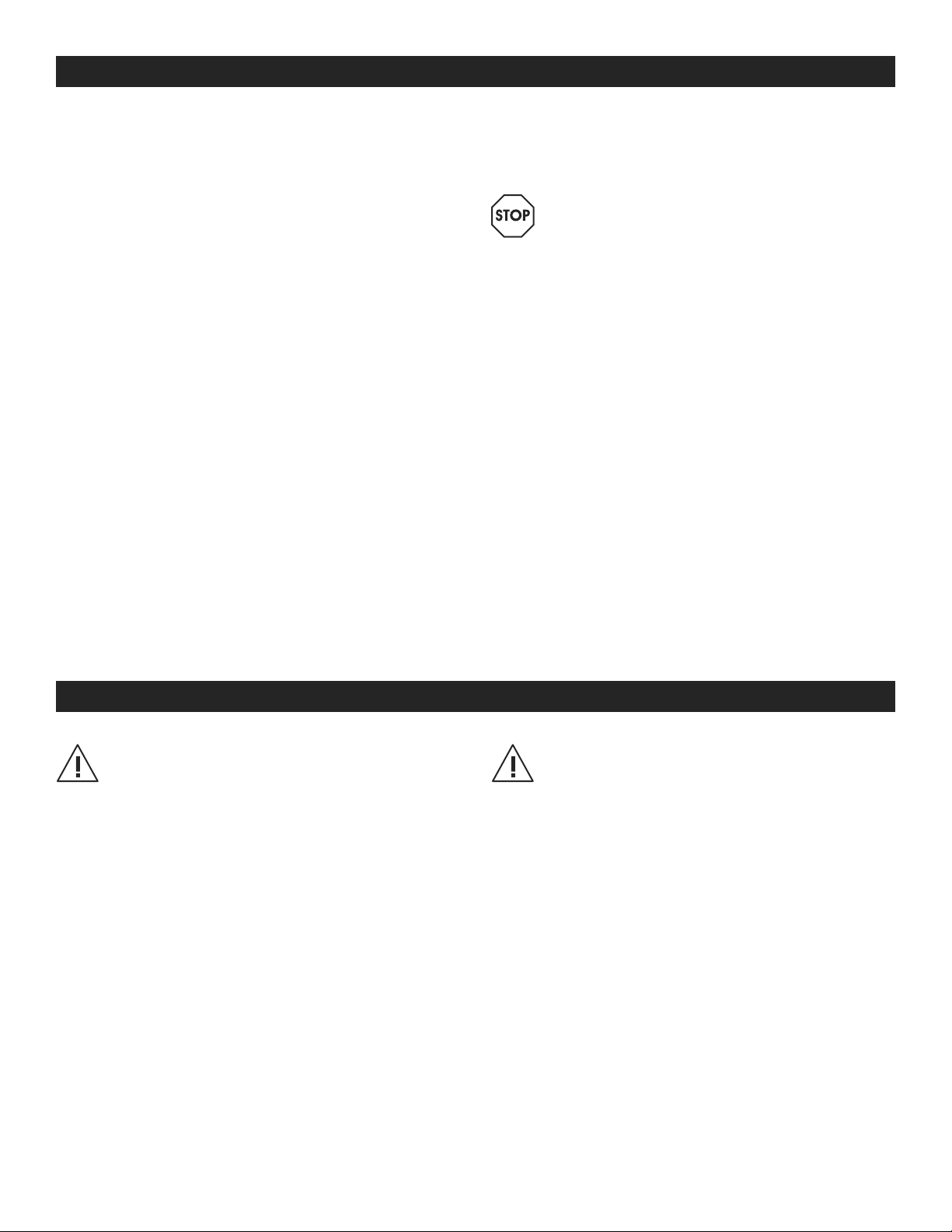

OPTIONAL LEG KIT INSTALLATION AND SETUP

CAUTION! Assembling the leg kit to the

conveyor can be dangerous. Two people or

a mechanical lift device must be used to

position the conveyor above the leg kit until

they are attached.

SET-UP INSTRUCTIONS

1. Remove the leg kit from the crate. Inspect for

damage.

2. To adjust leg length, remove shipping bolts from legs

(1 bolt per leg). Adjust leg length by measuring the

desired height and subtracting 12" to account for

the conveyor and caster height.

3. Place legs upside down on floor. Position shelf on

legs. Insert socket screws through shelf and each leg

from outside (7 places per leg). Tighten screws with

flat washers, lock washers and nuts. Use a socket

wrench. (See Figure 3)

Figure 3

Outside

4. Screw feet into threaded holes provided on bottom

of the shelf. Insert casters into nylon insert next to

feet. (See Figure 4)

Upside Down View

Socket Screw

Figure 4

Hex

Bolt

5. Turn the leg kit right side up. Place conveyor on top

of the leg kit assembly. Insert hex bolts through the

conveyor and leg kit (2 bolts per corner). Tighten

bolts

with flat washers, lock washers and nuts.

(See Figure 5)

Hex

Bolt

Socket Screw

Figure 5

0521 IH-2034PAGE 4 OF 15

Page 5

TROUBLESHOOTING

1

0

uline.com

The following guidelines are intended to ease the

solution of potential problems that may be encountered

during the everyday operations of the machine.

The cause/solution statements are generally arranged

in order of most probable, easiest solution first on up to

more involved, difficult solutions. If all possible solutions

have been tried, the distributor or factory should be

consulted.

OPERATING ISSUE RECOMMENDATIONS

Conveyor does not power on. Check incoming power. The ON/OFF switch should be lit.

Check power supply line.

Check On/Off switch on the operator panel.

Conveyor powers on but

conveyor does not run.

Conveyor powers on

belt does not heat up.

Check the position of the Conveyor Speed Pot.

Check the voltage to the DC Drive board. The incoming voltage should be equal to the line voltage.

Check the voltage from DC Drive Board. The voltage is DC and will vary with the speed pot setting. If

there isn’t output voltage, replace the board, 203-62.

Check the wiring to the motor. Replace the gear motor.

Check the position of the Conveyor Temp Pot.

Check the voltage to the Voltage Controller. The incoming voltage will vary with the speed pot

setting.

Check heat element for continuity. The 220V element has a resistance of 97 ohms. (Note that the

resistance given is a nominal value.)

Tunnel powers on but does not

heat.

Tunnel conveyor not tracking. Check tension roller on assembly (belt will track to tighter side). Be careful not to over tighten.

Check incoming power. 20-amp service is required.

With power removed check if the thermostat is turning on by checking continuity across wires #1

and #3.

Check the resistance of the heating element. The 220V element has a resistance of 23 ohms.

the resistance value given is a nominal value.)

E

nsure the voltage matches the element voltage.

Check the operation of the blower motor.

Check for air leaks around the blower housing and manifolds.

Check for worn belt.

Check the condition of the belt guides. The belt guides should just touch both sides of the belt.

(Note that

-800-295-551

0521 IH-2034PAGE 5 OF 15

Page 6

H-2034, H-2035

TÚNEL TERMOENCOGIBLE

800-295 -5510

uline.mx

ESPECIFICACIONES

¡IMPORTANTE! Lea detenidamente este manual

y familiarícese con TODOS los controles y

características de funcionamiento. Conserve este

manual para referencias futuras y mantenimiento.

Desempaque: Inspeccione la máquina en busca

de daños. Si se encuentra algún daño, regrésela a

Uline.

ESPECIFICACIONES DE LA MÁQUINA

• Capacidades tamaño del paquete: Túnel 40.6 x 20.3 cm

(16 x 8").

• Velocidad: Varía de acuerdo con la longitud

del paquete.

• Suministro de electricidad: Banda transportadora de

malla a 10 amperes, 220 voltios.

• Dimensiones generales: 81.3 cm Largo x 68.6 cm Ancho x

71.1 cm Alto (32" Largo x 27" Ancho x 18" Alto).

CARACTERÍSTICAS ESTÁNDARES DEL TÚNEL

• 2100 vatios de potencia de calefacción del túnel.

• Circulación de aire de 360 grados.

BANDA TRANSPORTADORA DE CORREA DE MALLA

¡ADVERTENCIA! Los daños a la máquina pueden ser

causados por (pero no limitados a): sobrecarga

eléctrica, sobrecarga mecánica, fuente de

alimentación incorrecta, levantar y/o mover el

equipo de manera incorrecta y el uso indebido de

los ensambles. Cualquier daño de los mencionados

anteriormente constituye uso indebido y/o abuso y

no será cubierto por la garantía del fabricante.

Este manual contiene varias notas de precaución

indicadas con la palabra "PRECAUCIÓN" y/o

"ADVERTENCIA". Dichas notas se utilizan para

describir las funciones que pueden causar

lesiones corporales y/o daños a la máquina. Las

notas marcadas con "ADVERTENCIA" indican una

condición que puede causar daño a una persona.

Las notas marcadas con "PRECAUCIÓN" indican

condiciones que pueden causar daños a la

máquina.

Es la responsabilidad del empleador asegurarse de

que todo el personal asociado con la operación

de esta máquina esté debidamente capacitado

en la operación, precauciones de seguridad y los

peligros potenciales de esta maquinaria.

• Correa de malla recubierta de teflón.

• Banda transportadora del túnel con control de velocidad

0-60 FPM.

GARANTÍA

• Garantía total de 1 año en piezas.

0521 IH-2034PAGE 6 OF 15

Page 7

INSTRUCCIONES

Temperatura

de la Banda

Transportada

Interruptor del

GENERALIDADES

1. El túnel termoencogible H-2034 consiste de un túnel y

una banda transportadora. La banda transportadora es

una correa de malla recubierta de teflón. La correa de

malla permite que el aire caliente reduzca el tamaño de

la parte inferior del paquete desde el túnel.

2. Hay dos paneles de control para la operación de

la máquina. El panel inferior controla la banda

transportadora y el panel superior controla el túnel.

ARRANQUE LA MÁQUINA

1. Encienda la banda transportadora con el interruptor

basculante ON/OFF. El interruptor ON/OFF se iluminará.

Ajuste la velocidad de la banda transportadora en "2" en

el panel del operador. (Vea Diagrama 1)

Diagrama 1

Velocidad

de la Banda

Transportada

3

2

1

CONVEYOR

SPEED

5

4

CONVEYOR

TEMP

6

7

8

9

5

6

4

3

2

1

7

8

9

820HB

Solamente

Diagrama 2

Luz de Encendido

Luz Indicadora de Calor

OFF

550

500

450

200

ON/OFF

400

250

350

300

Encendido/

Apagado

Termostato

4. Ajuste la temperatura del túnel a un ajuste de 163ºC

(325ºF) en el panel del operador del túnel. Le tomará

aproximadamente de 20 a 30 minutos alcanzar la

temperatura. La luz indicadora de calor se apagará

cuando se haya alcanzado la temperatura. (Vea

Diagrama 2)

5. Después de que el paquete inicial haya pasado a través

del túnel termoencogible, se pueden hacer los siguientes

ajustes:

RESET

MAIN

POWER

OFF

Circuito de

Encendido/

Apagado

2. Si la luz de encendido está apagada, conecte el túnel.

3. Encienda el túnel con el interruptor ON/OFF.

MANTENIMIENTO

La máquina debe ser inspeccionada de forma oportuna

para garantizar que todo esté en buen estado y funcionando

bien. No se necesita mucho para mantener la máquina

funcionando sin problemas. El área más importante es el

cabezal de sellado. Las siguientes recomendaciones son

para el mantenimiento preventivo de la máquina para que

continúe funcionando bien durante un período prolongado.

a. Aumentar o disminuir el ajuste del termostato.

b. Aumentar o disminuir la velocidad de la banda

transportadora.

c. Aumentar o disminuir la temperatura si está

disponible.

6. Debido a los diversos tipos de películas termoencogibles,

las temperaturas ambiente y voltajes, es posible que

tenga que experimentar con diferentes temperaturas y

velocidades de la banda transportadora para obtener el

encogimiento deseado. Su proveedor de películas está

familiarizado con este tipo de equipos y le ayudará a

determinar la mejor configuración para la película que

está utilizando.

CONSEJOS DE MANTENIMIENTO

1. Inspeccione las correas transportadoras por si presentan

desgaste y desalineación. Si las correas no están

rodando correctamente, ajuste los rodillos locos para

realinearlas. Reemplace las correas desgastadas según

sea necesario.

2. Lubrique todas las transmisiones por correa cada

160 horas de funcionamiento con una grasa para

rodamientos o lubricante de cadenas.

3. Use un paño sobre las correas transportadoras y otras

superficies planas para limpiar la máquina y eliminar

la suciedad. No use ningún tipo de acondicionador de

correas en las correas de la banda transportadora.

0521 IH-2034PAGE 7 OF 15

Page 8

COMPONENTES DE LA MÁQUINA

ENSAMBLE DEL ARMAZÓN PRINCIPAL

1. El ensamble del armazón principal de esta máquina

consiste de los rieles, motor de tracción de la banda

transportadora y el panel del operador.

ENSAMBLE DE LA CORREA DE MALLA DEL TUNEL

DE LA BANDA TRANSPORTADORA

1. Este ensamble consiste en el ensamble de la correa

del tunel, incluyendo el motor de engranaje CC. La

correa se calienta mediante una resistencia a 500 W

montada debajo de la bandeja transportadora. La correa

calentada proporciona un encogimiento positivo en la

parte inferior del paquete. El ensamble incluye también

las guías de la correa y tornillos de seguimiento.

ENSAMBLE DE LA CORREA CALIENTE DEL TUNEL

DE LA BANDA TRANSPORTADORA

1. Este ensamble consiste de la banda calentada incluyendo

el motor de engranaje CC. La correa se calienta mediante

una resistencia a 500 W montada debajo de la bandeja

transportadora. La correa calentada proporciona un

encogimiento positivo en la parte inferior del paquete. El

ensamble incluye también las guías de la correa y tornillos

de seguimiento.

ENSAMBLE DEL TÚNEL

1. El ensamble del túnel situado en la banda

transportadora del túnel usa aire caliente recirculado

para encoger la película sobre el paquete. El ensamble

tiene su propio cable de alimentación y requiere un

circuito dedicado a 20 A. El motor del soplador funciona

en el sentido contrario de las agujas del reloj cuando se

mira en el extremo que no es del eje. (Ver Diagrama 2)

ENSAMBLE DEL PANEL DE ELECTRICIDAD

1. Este ensamble se encuentra ubicado bajo el el rodillo de

tracción. Sólo un técnico calificado debe tener acceso a este

ensamble.

¡ADVERTENCIA! No manipule las conexiones eléctricas

de manera indebida a menos que tenga licencia

o esté capacitado para hacerlo. Desconecte la

alimentación principal de la máquina antes de

realizar cualquier servicio eléctrico.

2. Los esquemas eléctricos se pueden encontrar en el

manual original.

ENSAMBLE DEL PANEL DEL OPERADOR

1. El panel de ensamble del operador consiste en el

interruptor ON/OFF, el ajuste de la velocidad de la

banda transportadora y de la temperatura de la banda

transportadora si está disponible.

2. El interruptor de ENCENDIDO Y APAGADO (ON/OFF)

también actúa como un interruptor para el sistema de la

banda transportadora. (Ver Diagrama 1)

3. La velocidad de la banda transportadora se controla

utilizando un tablero de control CC (203-61) montada

en el panel del operador. La velocidad puede variar de

0 metro por minuto a 18.3 metros por minuto (0 pies por

minuto a 60 pies por minuto).

4. La temperatura de la banda transportadora se controla

mediante el uso de un suministro de voltaje variable.

KIT DE PATAS PARA CONSOLA (Opcional, vea abajo)

1. ULINE artículo H-2035.

INSTALACIÓN Y CONFIGURACIÓN

¡IMPORTANTE! Antes de configurar e instalar la

máquina, se deben leer las advertencias generales

y ser entendidas a cabalidad por parte de todo el

personal asociado con esta maquinaria.

INSTRUCCIONES DE CONFIGURACIÓN

1. Retire el túnel del embalaje o caja.

Inspeccione si hay daños.

2. Si está disponible, conecte el soporte de la consola a

los rieles de la banda transportadora del túnel. Consulte

las instrucciones adjuntas del soporte. Nivele la máquina

con los niveladores.

3. Coloque el túnel en la banda transportadora con los

paneles de operador hacia la parte frontal.

4. Quite las ataduras utilizadas para el envío.

5. Conecte la máquina a la fuente de alimentación. La

fuente de alimentación para el túnel debe ser de 220

voltios, 10 A y estar aterrizada. (Pídale a un electricista

que instale el enchufe en el cable de alimentación, si

va a conectar el tún el a un a toma el éctrica).

¡PRECAUCIÓN! La máquina debe estar conectada a

tierra de acuerdo con los códigos eléctricos locales.

6. Encienda la alimentación de la banda transportadora

con el interruptor ON/OFF. Encienda el túnel con el

interruptor ON/OFF.

7. Asegúrese de que la banda transportadora del túnel esté

funcionando lentamente. Asegúrese de que el soplador

del túnel esté funcionando. Ponga la temperatura del

túnel a 162.8ºC (325ºF). Cuando el túnel haya alcanzado

la temperatura, compruebe el movimiento de la correa

de la banda transportadora del túnel.

8. Haga una prueba de funcionamiento con algunos

productos a través de la máquina para afinar los ajustes a

fin de lograr apretar la bolsa alrededor del producto según

sea práctico. Esto ayudará en el proceso de encogimiento.

9. Cuando termine, apague las temperaturas del túnel y de

la banda transportadora. Espere de 15 a 20 minutos y

apague el túnel y la banda transportadora.

0521 IH-2034PAGE 8 OF 15

Page 9

INSTALACIÓN Y CONFIGURACIÓN DEL KIT DE PATAS OPCIONAL

¡PRECAUCIÓN! Montar el kit de patas a la banda

transportadora puede ser peligroso. Deben trabajar

dos personas o usar un dispositivo mecánico de

elevación para ubicar la banda transportadora

sobre el kit de patas hasta que éstas se hayan fijado.

INSTRUCCIONES DE CONFIGURACIÓN

1. Retire el kit de patas del embalaje. Inspeccione si hay

daños.

2. Para ajustar la longitud de la pata, retire los pernos de

envío de las patas (1 perno por pata). Ajuste la longitud

de la pata midiendo el alto deseado y restándole

30.5 cm (12") para tomar en cuenta la altura de la banda

transportadora y la rueda.

3. Coloque las patas boca abajo en el piso. Posicione

la repisa en las patas. Insterte los tornillos de cabeza

hueca a través de la repisa y cada pata desde afuera

(7 lugares por pata). Apriete los tornillos con arandelas

planas, arandelas de seguridad y tuercas. Use una llave

de dado. (Vea Diagrama 3)

Diagrama 3

Exterior

4. Atornille las patas en los orificios roscados incluidos en la

parte inferior de la repisa. Inserte las ruedas en el inserto

de nylon junto a las patas. (Vea Diagrama 4)

Vista desde abajo

Tornillo de cabeza hueca

Perno

Hexagonal

5. Gire el kit de patas con el lado derecho hacia arriba.

Coloque la banda transportadora encima del ensamble

del kit de patas. Inserte los pernos hexagonales a través

de la banda transportadora y el kit de patas (2 pernos

por esquina). Apriete los pernos con arandelas planas,

arandelas de seguridad y tuercas. (Vea Diagrama 5)

Diagrama 4

Diagrama 5

Perno

Hexagonal

Tornillo de cabeza hueca

0521 IH-2034PAGE 9 OF 15

Page 10

SOLUCIÓN DE PROBLEMAS

8

0

uline.mx

Las siguientes directrices están destinadas a facilitar la

solución de los problemas potenciales que se pueden

presentar durante el funcionamiento cotidiano de la

máquina.

PROBLEMA DE

OPERACIÓN

La banda transportadora no

enciende.

La banda transportadora

enciende, pero la banda

transportadora no funciona.

La banda transportadora

enciende, la correa no se

calienta.

Verifique entrada de electricidad. El interruptor ON/OFF debe estar iluminado.

Verifique la línea de suministro de electricidad.

Verifique el interruptor ON/OFF en el panel del operador.

Verifique la posición del potenciómetro de velocidad de la banda transportadora.

Verifique el voltaje en el tablero de control CC. El voltaje de entrada debe ser igual al voltaje de línea.

Verifique el voltaje saliente del tablero de control CC. El voltaje es de CC y pueden variar con el

ajuste del potenciómetro de velocidad. Si no hay voltaje de salida, reemplace el tablero, 203-62.

Verifique el cableado hacia el motor. Reemplace el motor del mecanismo.

Verifique la posición del potenciómetro de temperatura de la banda transportadora.

Verifique el voltaje al controlador de voltaje. El voltaje de entrada puede variar con el ajuste del

potenciómetro de velocidad.

Verifique la continuidad de la resistencia. El elemento de 220 V tiene una resistencia de 97 ohmios.

(Tenga en cuenta que la resistencia dada es un valor nominal.)

Las declaraciones de causas / soluciones generalmente son

organizadas por orden; comenzando con la solución la más

probable y fácil primero y terminando con las soluciones más

complicadas y difíciles. Si ha intentado todas las soluciones

posibles, debe consultar al distribuidor o la fábrica.

RECOMENDACIONES

El túnel enciende, pero no se

calienta.

La banda transportadora del

túnel no se mueve.

Verifique entrada de electricidad. Se requiere un servicio de 20 A.

Con la electricidad desconectada, verifique si el termostato se enciende al verificar la continuidad a

través de los cables # 1 y # 3.

Verifique la resistencia. El elemento de 220 V tiene una resistencia de 23 ohmios. (Tenga en cuenta

que la resistencia dada es un valor nominal.)

Asegúrese de que el voltaje coincida con el voltaje del elemento.

Verifique el funcionamiento del motor del soplador.

Verifique que no haya fugas de aire alrededor de la carcasa del soplador y los colectores.

Verifique el rodillo tensor en el ensamble (la correa se moverá hacia el lado más apretado). Tenga

cuidado de no apretar demasiado.

Verifique si la correa está desgastada.

Verifique el estado de las guías de la correa. Las guías de las correas apenas deben tocar ambos

lados de la correa.

00-295-551

0521 IH-2034PAGE 10 OF 15

Page 11

H-2034, H-2035

TUNNEL DE RETRACTION

1-800-295 -5510

uline.com

SPÉCIFICATIONS

IMPORTANT! Veuillez lire attentivement ce manuel

et apprendre TOUTES les commandes et fonctions.

Conservez ce manuel pour une référence et

entretien ultérieur.

Déballage : Vérifiez l'état de l'appareil.

En cas de dommage, veuillez le retourner à Uline.

SPÉCIFICATIONS DE L'APPAREIL

• Dimensions de colis acceptables: Tunnel 40,6 x 20,3 cm

(16 x8po).

• Vitesse : Varie selon la longueur du colis.

• Alimentation électrique: Convoyeur à courroie maillée,

220V, 10ampères.

• Dimensionshors-tout: 81,3cm long. x 68,6cm larg. x

71,1cm haut. (32po long. x27po larg. x28pohaut.).

CARACTÉRISTIQUES STANDARDS DU TUNNEL

• Puissance de chauffage du tunnel, 2100Watts.

• Circulation d'air sur 360 degrés.

CONVOYEUR À COURROIE MAILLÉE

• Courroie maillée revêtue de Teflon.

ARRÊT

AVERTISSEMENT! La machinerie peut être

endommagée par, mais non de façon limitative:

une surcharge électrique, une surcharge

mécanique, une source d'alimentation

inappropriée, le soulèvement et/ou déplacement

inapproprié de l'équipement et l'utilisation

inappropriée des ensembles. Tout dommage

venant des éléments décrits ci-dessus sont

conséquences d’une mauvaise utilisation et/ou de

l’abus et ne sera pas couvert par la garantie du

fabricant.

Ce manuel contient de nombreuses remarques

de mise en garde identifiées par les expressions

«MISE EN GARDE» et/ou «AVERTISSEMENT» Les

dites remarques servent à décrire des fonctions qui

peuvent causer des blessures corporelles et/ou des

dommages à l'appareil. Les «AVERTISSEMENTS»

identifient un état qui peut provoquer des blessures

corporelles. Les «MISE EN GARDE» identifient des

états qui peuvent provoquer des dommages à

l'appareil.

L'employeur est responsable d'assurer que tout le

personnel associé à l'utilisation de cet appareil

est correctement formé pour l'utilisation de cet

appareil, ainsi que sur les mesures de sécurité et les

dangers potentiels associés à cet appareil.

• Convoyeur de tunnel à vitesse contrôlée. 0-60pi/min.

GARANTIE

• 1 an complet sur les pièces.

0521 IH-2034PAGE 11 OF 15

Page 12

INSTRUCTIONS

GÉNÉRALITÉS

1. Le tunnel de rétraction H-2034 est composé d'un tunnel

et d'un convoyeur.

Le convoyeur est une courroie maillée

revêtue de Teflon. La courroie maillée permet à de l'air

réchauffé de rétracter le dessous du colis dans le tunnel.

2. L'appareil est contrôlé par deux panneaux de

commande. Le panneau inférieur commande le

convoyeur et le panneau supérieur commande le tunnel.

MISE EN MARCHE DE L'APPAREIL

1. Démarrez le convoyeur à l'aide de l'interrupteur ON/OFF

(marche/arrêt). L'interrupteur ON/OFF s'illuminera. Réglez la

vitesse du convoyeur à "2" sur le panneau de commande

du convoyeur. (Voir Figure1)

Figure 1

3

2

1

CONVEYOR

SPEED

5

4

6

POWER

MAIN

CONVEYOR

TEMP

5

6

4

RESET

3

2

1

OFF

7

8

9

7

8

9

820HB

Seulement

Disjoncteur de

l'interrupteur

Figure 2

Voyant d'alimentation

Voyant de chaleur

OFF

550

500

450

200

ON/OFF

400

250

350

300

Thermostat

4. Réglez la température du tunnel à 163 °C (325 ºF)

sur le panneau de commande du tunnel. Il faudra

20-30 minutes avant que la machine n'atteigne cette

température. L'indicateur de chaleur s'éteindra quand

l'appareil aura atteint la température. (Voir Figure2)

5. Suivant le passage du premier colis dans le tunnel

d'emballage sous film rétractable, vous pouvez effectuer

les réglages suivants:

a. Hausser ou abaisser le réglage du thermostat.

b. Accélérer ou ralentir la vitesse du convoyeur.

c. Hausser ou abaisser la température, si disponible.

2. Si le voyant d'alimentation demeure éteint, branchez

le tunnel.

3. Démarrez le convoyeur à l'aide de l'interrupteur ON/OFF.

ENTRETIEN

L'appareil doit être inspecté régulièrement afin d'assurer

que tout est en bon état et fonctionne correctement. Il suffit

de peu pour assurer le fonctionnement sans problème de

l'appareil. La zone la plus importante est la tête de scellage.

Nous vous présentons ci-dessous des recommandations

d'entretien préventif à exécuter afin d'assurer le rendement

efficace de l'appareil pendant une longue période de temps.

6. Dû aux nombreux types de pellicule thermorétractable,

aux différentes températures ambiantes et aux différentes

intensités électriques, il se peut que vous ayez à

expérimenter avec divers réglages de température et

de vitesse de convoyeur afin d'obtenir la rétractation

voulue. Votre fournisseur de pellicule connaît ce type

d'équipement et pourra vous aider à identifier les bons

réglages pour la pellicule que vous utilisez.

CONSEILS D'ENTRETIEN

1. Inspectez les courroies de convoyeur pour la présence

d'usure et de désalignement. Si les courroies sont

désalignées, alignez-les en réglant les galets-guides.

Remplacez les courroies usées au besoin.

2. Graissez toutes les unités de chaîne avec la graisse à

roulements ou de la graisse à chaîne après toutes les 160

heures d'utilisation.

3. Pour nettoyer l'appareil, essuyez les courroies de

convoyeur et autres surfaces planes afin d'éliminer toute

saleté. N'employez pas de graisse pour courroies sur les

courroies de convoyeur.

0521 IH-2034PAGE 12 OF 15

Page 13

COMPOSANTS DE L'APPAREIL

ENSEMBLE DE CADRE PRINCIPAL

1. L'ensemble de cadre principal de cet appareil se compose

des rails, du moteur d'entraînement du convoyeur et du

panneau de commande.

ENSEMBLE DE COURROIE MAILLÉE DE

CONVOYEUR DE TUNNEL

1. C

et ensemble se compose de la courroie de

convoyeur de tunnel,

CC. La courroie est chauffée par un élément chauffant

de 500W installé sous le bac du convoyeur. La courroie

chauffée rétracte la pellicule sur le dessous du colis.

L'ensemble comprend aussi des guides de courroie et

des vis d alignement.

y compris le moteur à engrenages

ENSEMBLE DE COURROIE CHAUFFÉE DE

CONVOYEUR DE TUNNEL

1. Cet ensemble se compose de la courroie chauffée, y

compris le moteur à engrenages CC. La courroie est

chauffée par un élément chauffant de 500W installé sous

le bac du convoyeur. La courroie chauffée rétracte la

pellicule sur le dessous du colis. L'ensemble comprend

aussi des guides de courroie et des vis d'alignement.

ENSEMBLE DE TUNNEL

1. L'ensemble de tunnel installé sur le convoyeur de tunnel

emploie de l'air réchauffé recyclé pour rétracter la

pellicule sur le colis. L'ensemble possède son propre

cordon d'alimentation et exige un circuit spécialisé de

20ampères. Le moteur de soufflante tourne dans le

sens antihoraire lorsque vu de l'extrémité sans arbre.

(Voir Figure2)

ENSEMBLE DE PANNEAU ÉLECTRIQUE

1. Cet ensemble se situe sous le rouleau d'entraînement.

Seul un technicien qualifié devrait être autorisé à

accéder à cet ensemble.

AVERTISSEMENT! N'altérez pas le câblage

ARRÊT

électrique à moins d'y être officiellement

autorisé ou formé à cette fin. Débranchez la

source d'alimentation principale de l'appareil

avant d'entamer tout entretien électrique.

2. Les schémas électriques figurent dans le manuel original.

ENSEMBLE DE PANNEAU DE COMMANDE

1. L'ensemble de panneau de commande se compose

de l'interrupteur ON/OFF, de la commande de vitesse

du convoyeur et de la température du convoyeur si

disponible.

2. L'interrupteur ON/OFF sert aussi de disjoncteur pour le

système de convoyeur. (Voir Figure1)

3. La vitesse du convoyeur est commandée au moyen d'un

panneau d'entraînement CC (203-61) installé dans le

panneau de commande. La vitesse peut varier de 0 à 60

pieds par minute.

4. La température du convoyeur est commandée au moyen

d'une tension d'aliment ation variable.

TROUSSE DE PATTES DE CONSOLE

(Optionnel, voir ci-dessous)

1. Article ULINE H-2035.

INSTALLATION ET ASSEMBLAGE

IMPORTANT! Avant d'assembler et d'installer

l'appareil, tout le personnel associé à cet appareil

doit lire et comprendre les avertissements généraux.

INSTRUCTIONS D'ASSEMBLAGE

1. Retirez le tunnel de la caisse ou la boîte.

Inspectez pour la présence de dommages.

2. Si disponible, fixez le stand de console aux rails du

convoyeur de tunnel. Voir les instructions comprises pour

le stand. Nivelez l'appareil à l'aide des patins réglables.

3. Positionnez le tunnel sur le convoyeur avec les panneaux

de commande orientés vers l'avant.

4. Retirez toutes les attaches employées pour l'expédition.

5. Branchez l'appareil sur une source d'alimentation. La

source d'alimentation pour le tunnel doit être une source

d'alimentation 220V, 10ampères, mise à la terre. (Si vous

branchez le tunnel dans une prise électrique murale,

faites installer une fiche sur le cordon d'alimentation par

un électricien.)

MISE EN GARDE! L'appareil doit être mis à la terre en

conformité avec les codes électriques locaux.

6. Mettez le convoyeur sous tension à l'aide de l'interrupteur

à bascule ON/OFF (marche/arrêt). Démarrez le convoyeur

à l'aide de son interrupteur ON/OFF.

7. Assurez-vous que le convoyewur fonctionne lentement.

Assurez-vous que la soufflante fonctionne. Réglez la

température du tunnel à 163°C (325°F). Lorsque le

tunnel atteint cette température, vérifiez si la courroie de

convoyeur de tunnel est correctement alignée.

8. Passez quelques produits dans l'appareil afin de mettre

au point les réglages nécessaires pour la meilleure

thermorétraction que possible une pellicule autour du

produit. Ceci contribuera au processus de rétraction.

9. Une fois fini, arrêtez le chauffage du tunnel et du

convoyeur. Patientes de 15 à 20 minutes, puis éteignez le

tunnel et le convoyeur.

0521 IH-2034PAGE 13 OF 15

Page 14

INSTALLATION ET ASSEMBLAGE DE L'ENSEMBLE DES PIEDS OPTIONNEL

IMPORTANT! L'assemblage de l'ensemble des pieds

au convoyeur peut être dangereux. Deux personnes

ou un dispositif de levage mécanique sont

nécessaires pour maintenir le convoyeur au-dessus

de l'ensemble des pieds jusqu'à ce qu’ils soient

attachés.

INSTRUCTIONS D'ASSEMBLAGE

1. Retirez l'ensemble des pieds de la caisse. Inspectez pour

la présence de dommages.

2. Pour ajuster la longueur du pied, retirez les boulons

d'expédition des pieds (1 boulon par pied). Ajustez la

longueur du pied en mesurant la hauteur voulue et

soustrayant 30,5 cm (12 po) pour tenir compte de la

hauteur du convoyeur et des roulettes.

3. Placez les pieds à l'envers sur le plancher. Positionnez la

tablette sur les pieds. Insérez les vis creuses à travers la

tablette et chaque pied à partir de l'extérieur (7 endroits

par pied). Serrez les vis avec des rondelles plates, des

rondelles de blocage et des écrous. Utilisez une clé à

douille. (Voir Figure 3)

Figure3

Extérieur

4. Vissez les pieds dans les trous filetés sous la tablette.

Insérez les roulettes dans l'encastrement de nylon près

des pieds. (Voir Figure 4)

Figure4

Vue à l'envers

Vis creuse

Boulon

hexagonal

5. Retournez l'ensemble des pieds à l'endroit. Placez le

convoyeur sur l'ensemble des pieds. Insérez des boulons

hexagonaux à travers le convoyeur et l'ensemble des

pieds (2 boulons par coin). Serrez les boulons à l'aide de

rondelles plates, de rondelles de blocage et d'écrous.

(Voir Figure 5)

Boulon

hexagonal

Vis creuse

Figure 5

0521 IH-2034PAGE 14 OF 15

Page 15

DÉPANNAGE

1

0

uline.ca

Les directives qui suivent visent à faciliter la résolution des

problèmes potentiels qui peuvent survenir durant l'0utilisation

quotidienne de l'appareil.

PROBLÈME DE

FONCTIONNEMENT

Le convoyeur ne se met pas sous

tension.

Le convoyeur se met sous tension mais

ne fonctionne pas.

Le convoyeur se met sous tension, mais

la courroie ne se réchauffe pas.

Vérifiez l'entrée de l'alimentation. L'interrupteur ON/OFF (marche/arrêt) devrait être illuminé.

Vérifiez le cordon d'alimentation.

Vérifiez l'interrupteur ON/OFF sur le panneau de commande.

Vérifiez la position du potentiomètre de vitesse du convoyeur.

Vérifiez la tension d'alimentation du panneau d'entraînement CC. La tension d'entrée doit être

égale à la tension composée.

Vérifiez la tension de sortie du panneau d'entraînement CC. Il s'agit de tension CC qui variera

selon le réglage du potentiomètre de vitesse du convoyeur. S'il n'existe aucune tension de

sortie, remplacez le panneau d'entraînement, 203-62.

Vérifiez le câblage vers le moteur. Remplacez le moteur à engrenages.

Vérifiez la position du potentiomètre de température du convoyeur.

Vérifiez la tension d'entrée du gradateur de tension. La tension d'entrée variera selon le

réglage du potentiomètre de vitesse.

Vérifiez la continuité de l'élément chauffant. L'élément de 220V possède une résistance de

97ohms. (Veuillez noter que la résistance publiée est une valeur nominale.)

Les affirmations cause/solution sont généralement disposées

avec la solution la plus probable/facile en premier, suivie en

ordre de difficulté ascendante des solutions plus complexes.

Si vous avez essayé toutes les solutions possibles, communiquez avec le distributeur ou l'usine.

RECOMMANDATIONS

Le tunnel se met sous tension mais ne

se réchauffe pas.

Le convoyeur de tunnel est désaligné. Vérifiez le rouleau compensateur de l'ensemble (la courroie se désalignera vers le côté le plus

Vérifiez l'alimentation d'entrée. Une alimentation de 20 ampères est nécessaire.

Avec l'alimentation coupée, vérifiez si le thermostat s'active en contrôlant la continuité entre

les fils n° 1 et n° 3.

Vérifiez la résistance de l'élément chauffant. L'élément de 220V possède une résistance de

23ohms.

A

ssurez-vous que la tension correspond à la tension de l'élément.

Vérifiez le fonctionnement du moteur de soufflante.

Contrôlez la présence de fuites d'air autour du boîtier et des collecteurs d'air de la soufflante.

tendu). Prenez soin de ne pas trop le serrer.

Vérifiez l'usure de la courroie.

Vérifiez l'état des guides de courroie. Les guides de courroie devraient à peine toucher les

deux côtés de la courroie.

(Veuillez noter que la résistance publiée est une valeur nominale.)

-800-295-551

0521 IH-2034PAGE 15 OF 15

Loading...

Loading...