Page 1

π

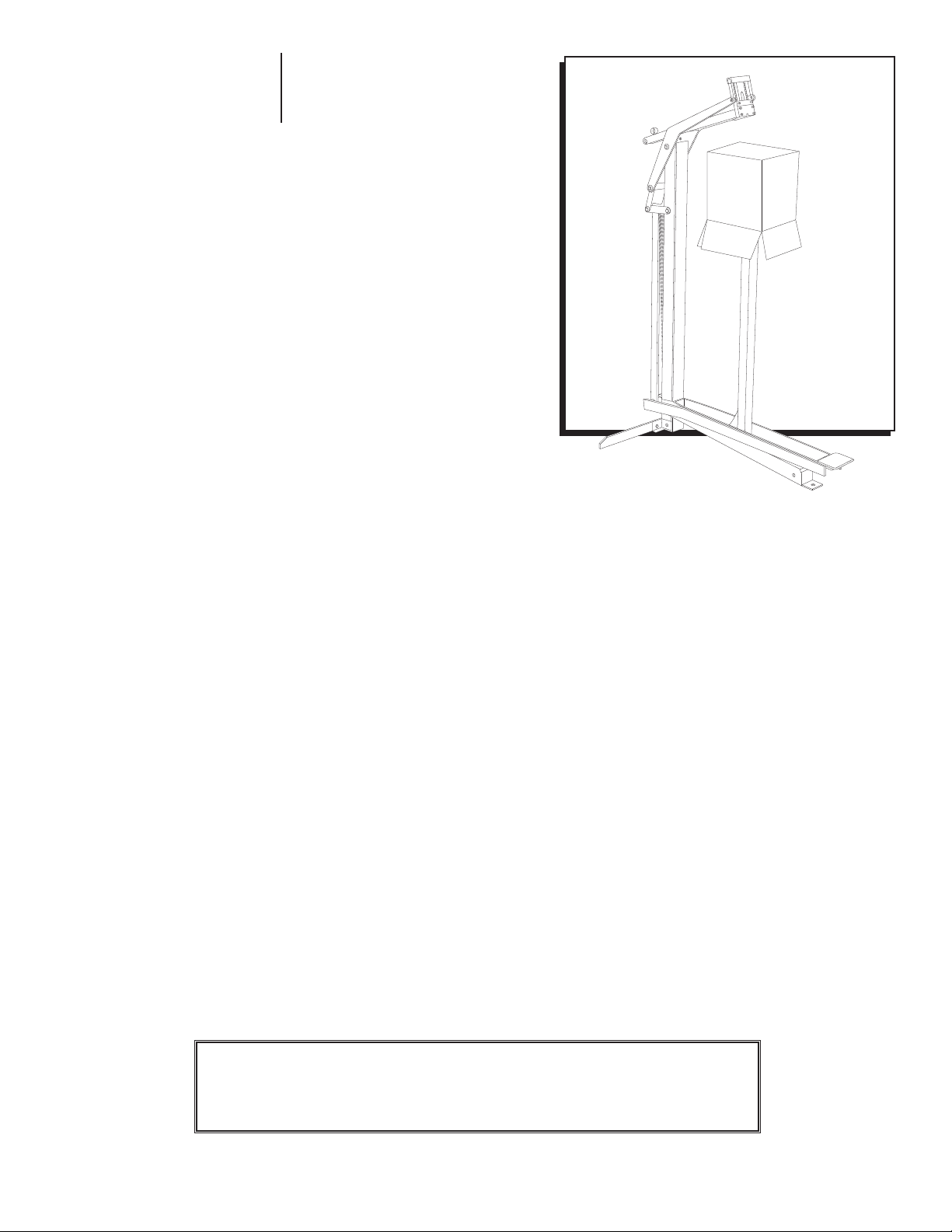

H-1980

FOOT-OPERATED

STAPLER

1-800-295-5510

uline.com

STAPLER SPECIFICATIONS

Dimensions L x W x H: 36 x 24 x 49"

Weight (without fasteners): 66 lbs.

Staple Specification: S-289 C58 Stick

Staple Specification: S-1396 C34 Stick

Staple Capacity: 200 Staples

WARNING!

Before operating this stapler familiarize yourself with the safety

warnings and instructions in this manual. Keep these instructions with

the stapler for future reference. If you have any questions, contact

Uline at 1-800-295-5510.

0813 I H -198 0PAGE 1 OF 6

Page 2

GENERAL INFORMATION

WARNING! It is important that all operators

read, understand, and practice all safety,

operating, and maintenance instructions

before using this unit to reduce risk of bodily

injury to everyone involved.

STAPLE SELECTION/CLINCH

1. Proper staple leg length selection is dependent on

the thickness and quantity of individual material

layers to be fastened. Since the head assembly is

only able to compress the top layer of corrugated

slightly, thicker materials must use longer leg staples

to penetrate all layers sufficiently and supply a

quality closure.

2. A proper clinch is attained when the staple legs are

bent sufficiently to hold the corrugated layers tightly

together without the points tearing back through the

inside corrugate liner. Excessive clinch can cause

loss of holding strength. (See Figure 1)

SAFETY

GENERAL SAFETY

It is important that you read, understand, and practice

all safety, operating, and maintenance instructions

before using this or any other stapling unit to reduce risk

of bodily injury to yourself and others in the work area.

WARNING! Employer must provide

recommended safety protection equipment

for use by operator of this unit. Must enforce

compliance with the operator safety

instructions, all other instructions contained

in this manual, and all applicable OSHA

regulations. Must provide complete training in

safe unit operation for all operators as well as

maintain an instruction manual available for

use by all unit operators.

Figure 1

EXCESSIVE CLINCH

PROPER CLINCH

3. Never operate your unit under the influence of

alcohol or drugs. Do not operate this unit if you are

excessively tired or not feeling well.

4. Do not rush or hurry your work. This may cause injury.

5. Always assume your unit contains fasteners.

6. Maintain a clean, uncluttered work area and use

sufficient lighting for safe unit operation.

7. Use only parts and fasteners recommended by

manufacturer. Others may be dangerous and could

cause your unit to malfunction.

8. Contact the manufacturer before making any

modifications to the unit.

9. Replace unit warning label if missing.

1. Wear Eye Protection. Eye protection which

conforms to American National Standards Institute

Specification ANSI 287.1 and which provides

protection against flying fasteners and debris both

from the front and side shall always be worn by the

operator and others in the work area when loading,

operating, or servicing the unit.

2. Wear Hearing Protection. Ear protection may be

required in work areas which include exposure to

high noise levels which can damage hearing. Both

user and employer should make sure necessary

hearing protection is provided and worn by the

operator and others in the work area.

UNIT LOADING SAFETY

1. Use only genuine fasteners recommended by

manufacturer. Others may be dangerous and could

cause your unit to malfunction.

2. Do not place your hand or any part of your body in

the fastener discharge area.

0813 I H -198 0PAGE 2 OF 6

Page 3

SAFETY (CONTINUED)

UNIT OPERATION SAFETY

1. Always assume unit is loaded. Never discharge

fasteners without corrugated in place. Do not

engage in horseplay or games.

2. Keep your hands and body away from the

discharge area of the unit.

3. Use care when handling unit. Do not pound or

hammer on the unit for any reason. This may

damage the body of unit causing deformations or

cracks which can be dangerous.

4. Wear proper work clothes. Do not wear neck ties,

gloves, or loose-fitting clothing when operating

pneumatic units.

1. Find a suitable place.

2. Open the packaging and stand the machine up.

OPERATING INSTRUCTIONS

UNIT MAINTENANCE SAFETY

1. Only qualified service people shall repair the unit.

2. Always remove fasteners when performing repairs.

Use only authorized spare parts for repair or

replacement.

3. Clean unit daily. A dirty unit may malfunction,

causing injury.

4. Inspect unit regularly for proper operation. Repair or

replace any damaged components at once.

5. Do not modify unit in any way.

ASSEMBLY

3. Use 6 mm Allen wrench and 13 mm wrench to

assemble the balancer (49). (See parts diagram)

4. Assemble the spring (38).

1. Pull pusher backwards until it stops on pusher pivots.

Then rotate pusher into position.

2. Insert 4 sticks of appropriate staples into magazine

from the back. Let the staples slide forward to the

front.

3. Pull pusher back to upright position and gently let

the pusher slide forward against the staples. DO NOT

let the pusher slide forward to engage staples at

high speed. It may deform staples or damage the

machine.

MAINTENANCE

1. Keep the machine clean.

2. Feed oil on every shaft before operating.

CLEARING A JAM

1. Pull the pusher backwards and rotate into position.

Then, remove all the staples.

2. Remove cover A with a 4mm hex wrench.

3. Clear the jam.

4. Put the carton into position.

NOTE: Straighten the center line of the carton

to the cover center line.

5. Press the step board set down by foot until it stoops.

Then release the step board set.

NOTE: If there is not a carton in position, do not

press the step board set down.

4. Assemble cover A.

0813 I H -198 0PAGE 3 OF 6

Page 4

PARTS DIAGRAM

507

511

508

4

504

506

9

14

15

16

512

501

1

2

3

7

502

10

26

519

50

518

27

28

30

24

23

25

21

532

520

11

8

503

530

516

12

20

22

515

517

527

521

39

526

44

38

34

35

29

48

31

33

37

525

3

32

523

49

48

524

46

17

513

533

0813 I H -198 0PAGE 4 OF 6

Page 5

PARTS LIST

# DESCRIPTION QTY. ULINE PART NO. MFG. PART NO.

1 Link 1 2

2 Tube 2 ------------ A00603401

3 Shaft E 2 ------------ A00603201

4 Link 2 2 H-1980-LINK A00600401

7 Driver Seat 1 ------------ A00600703

8 Shaft C 2 H-1980-08 A00600801

9 Driver 1 H-1980-09 A00600905

10 Spring 2 H -1980 -10 A00601002

11 Spring Shaft 1 H-1980-11 A0 0601103A

12 Magazine Seat 1 H-1980 -12 A00601203

14 Cover B 1 ------------ A00601405

15 Shaft D 1 ------------ A00601502

16 Cover A 1 ------------ A00601605

17 Bracket 1 ------------ A00607501

20 Magazine Unit 1 H-1980 -20 CMB-S-32-P3-S

21 Bracket Set 1 ------------ A00602101

22 Nut 2 ------------ A00607101

23 Right Pusher Guide 1 ------------ A00103903A

24 Rod 1 ------------ A00103203

25 Left Pusher Guide 1 ------------ A00103904A

26 Pusher Set 1 H-1980-26 A00103710A

27 Roller 1 H-1980 -27 A00103501

28 Spring 1 H-1980-28 A00602801

29 Link 3-A 2 ------------ A00602901

30 Tube 1 ------------ A00603002

31 Tube 2 ------------ A00603701

32 Shaft E 1 ------------ A00603202

33 Shaft F 1 ------------ A00603302

34 Tube 2 ------------ A00603402

35 Link 4 Set 1 ------------ A00603503A

37 Tube 2 ------------ A00603701

38 Spring 1 ------------ A00603801

39 Body Set 1 ------------ A00603904A

44 Step Board Set 1 ------------ A00604402A

46 Mold 1 ------------ A00604607

48 Shaft G 2 ------------ A00604801

49 Balancer 1 ------------ A00604901

50 Link 3-B 2 ------------ A00602903

501 E-Ring 2 ------------ BA F11 0 02

502 E-Ring 2 H-198 0 - 5 02 BAF10502

503 E-Ring 2 H-198 0 - 5 0 2 BAF10502

------------

A0060 0102

0813 I H -198 0PAGE 5 OF 6

Page 6

PARTS LIST (CONTINUED)

# DESCRIPTION QTY. ULINE PART NO. MFG. PART NO.

504 Hexagonal Socket Head Bolt 2 ------------ BAC0604102

506 Spring Pin 2 ------------ BAA060016

507 E-Ring 2 ------------ BAF10602

508 Hexagonal Socket Head Bolt 6 ------------ BAC0605102

511 Hexagonal Socket Head Bolt 6 ------------ BAC0605082

512 Locknut 1 ------------ BAD01041

513 Hexagonal Socket Flat

Counter Sunk Head Screw

515 Washer 4 ------------ BAE01052

516 Hexagonal Socket Flat

Counter Sunk Head Screw

517 Locknut 2 ------------ BAD02051

518 Spring Pin 1 H -1980-518 BA A040016

519 E-Ring 2 ------------ B A F110 02

520 E-Ring 2 ------------ B AF110 0 2

521 E-Ring 2 ------------ BA F11 0 02

523 Hexagonal Socket Head Bolt 2 ------------ BAC0408202

524 E-Ring 2 ------------ B A F110 02

525 E-Ring 2 ------------ B A F110 02

526 Locknut 2 ------------ BAD01081

527 Wave Washer 2 ------------ BAE03122

530 Spring Pin 4 ------------ BAA040008

532 Wave Washer 2 ------------ BAE03142

533 Hexagonal Socket Round Head Screw 2 ------------ BAC0904082

1 ------------ BAC0204222

2 H-1980 -516 BAC0205162

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-80 0-295-5510

uline.com

0813 I H -198 0PAGE 6 OF 6

Loading...

Loading...