Page 1

Para Español, vea páginas 4-6.

Pour le français, consulter les pages 7-9.

H-1485, H-1486, H-1487

π

H-1783, H-6754

STANDARD LIFT TABLE

1-800 -295-5510

uline.com

TECHNICAL INFORMATION

SPECIFICATIONS H-1485 H-1486 H-1487 H -1783 H-6754

Capacity 330 lbs. 660 lbs. 1,100 l bs. 1,760 lbs . 1,100 lbs.

Height Raised 29" 35" 35" 39.5" 36"

Height Lowered 8.8" 11" 11" 16.5" 12.5"

Table Size 27 x 18 x 2" 32 x 20 x 2" 32 x 20 x 2" 39½ x 20 x 2" 63 x 31.5 x 2"

Total Height 37" 39" 39" 39" 39"

Overall Length 31" 37" 37" 46" 65"

Foot Pedal Cycles to Max Height 25 32 45 56 40

Wheel Diameter 4" 5" 5" 6" 5"

Weight 101 lbs. 165 lbs. 187 lbs. 254 lbs. 296 lbs.

Working Volume of Oil Cylinder 138 ml 164 ml 164 ml 157 m l 200 ml

Oil Capacity 210 ml 250 ml 250 ml 240 ml 300 ml

GENERAL INFORMATION

1. Read all instructions carefully before operating the

lift table.

2. DO NOT overload the lift table and always operate

it within the rated load. Overloading will cause

damage to the lift table and the operator.

3. DO NOT stand or sit on the table to work.

4. DO NOT put hands or feet under the table when

lowering.

5. Apply the brakes while loading to prevent the table

from moving.

6. The load must be distributed uniformly across the

whole table.

7. DO NOT load loose or unstable loads onto the table.

8. DO NOT leave the table loaded for extended

periods of time.

PAGE 1 OF 9 1118 IH-1485

9. DO NOT move the truck while lifting.

10. The table should only be used on flat solid surfaces.

11. Make sure not to overload the table when it is in

the raised position. The safety valve only works as

the table is lifted. Overloading in the raised position

may damage the table.

12. When loading and unloading goods in the raised

position, do not drag loads across the table.

This may cause offset loading and the table may

turn over.

13. When maintaining and repairing the table, the

stand bar should be used to support the fork arm in

order to prevent table from falling. There should not

be a load on table while maintaining and repairing

the table.

Page 2

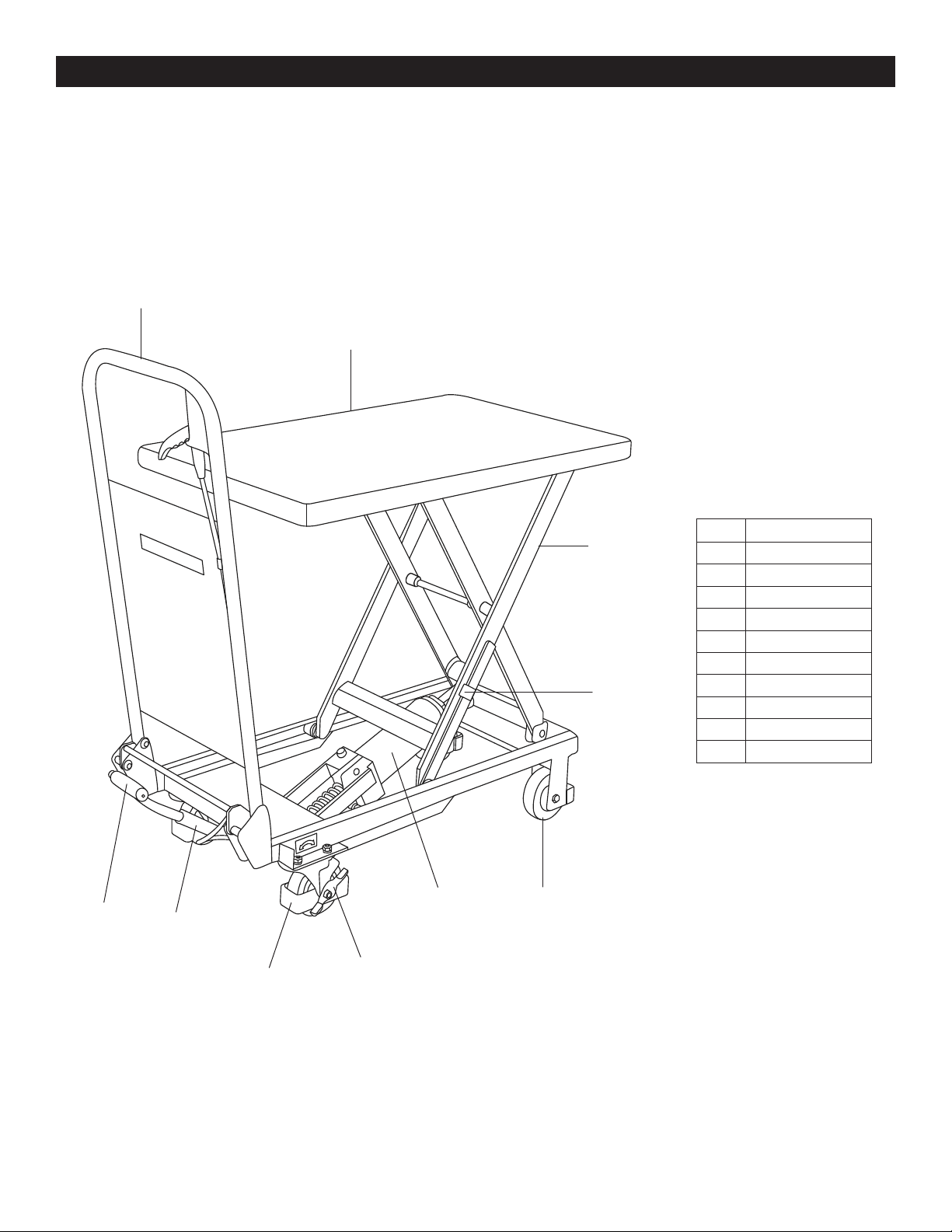

ASSEMBLY

1. These are folding tables. They can only be operated

if the handle is in the upright position.

2. The foot lever is dismantled when shipped. It must be

attached to lift table before operating.

8

1

FOOT LEVER INSTALLATION

Foot lever mounting: insert the foot pedal into the hole

of the square bar. Fix the foot pedal with a

bolt, flat washer a lock washer, and a nut. Tighten the

nut with a wrench.

2

7

# PART NAME

1 Loading Platform

2 Lift Mechanism

3 Hydraulic Cylinder

4 Swivel Caster

5 Rigid Caster

6 Brake

7 Safety Stand Bar

8 Handle

9 Foot Pedal

10 Square Bar

9

PAGE 2 OF 9 1118 IH-1485

10

4

6

3

5

Page 3

MAINTENANCE

It is very important to conduct necessary maintenance

and upkeep so as to prolong the service life and

safety of the lift table. Please check the lift table before

operation accordingly:

1. Check for any distortion or bending of any parts of

the lift table.

2. Check the brake of the truck and the condition of

the wheels.

3. Check for oil leakage in the hydraulic system.

4. Add or fill lubricant to each friction surface before

daily operation.

TROUBLESHOOTING

OPERATING ISSUE CAUSES RECOMMENDATIONS

Does not reach the full lift height.

1) Steel ball of the check-valve is not

fully seating.

2) Firing pin does not allow the steel

ball to fully seat.

3) Low hydraulic oil.

5. If there is any failure, the lift table should be

repaired at once before it is put into use again.

6. Change the hydraulic oil every twelve months.

Choose appropriate hydraulic oil according to the

climate conditions.

7. To change the hydraulic oil:

a. Unscrew sealing screw with a wrench.

b. Lift the hand lever.

c. Twist off screw of the oil plug and fill pump with

hydraulic oil.

1) Clean the valve opening and

replace the steel ball.

2) Adjust the tension rate of the steel

wire connected to the hand lever to

adjust the seating of the firing pin.

3) Add hydraulic oil.

The table rises then descends.

The table board does not descend.

Oil leakage at firing pin.

Oil leakage at pump.

Table will not rise.

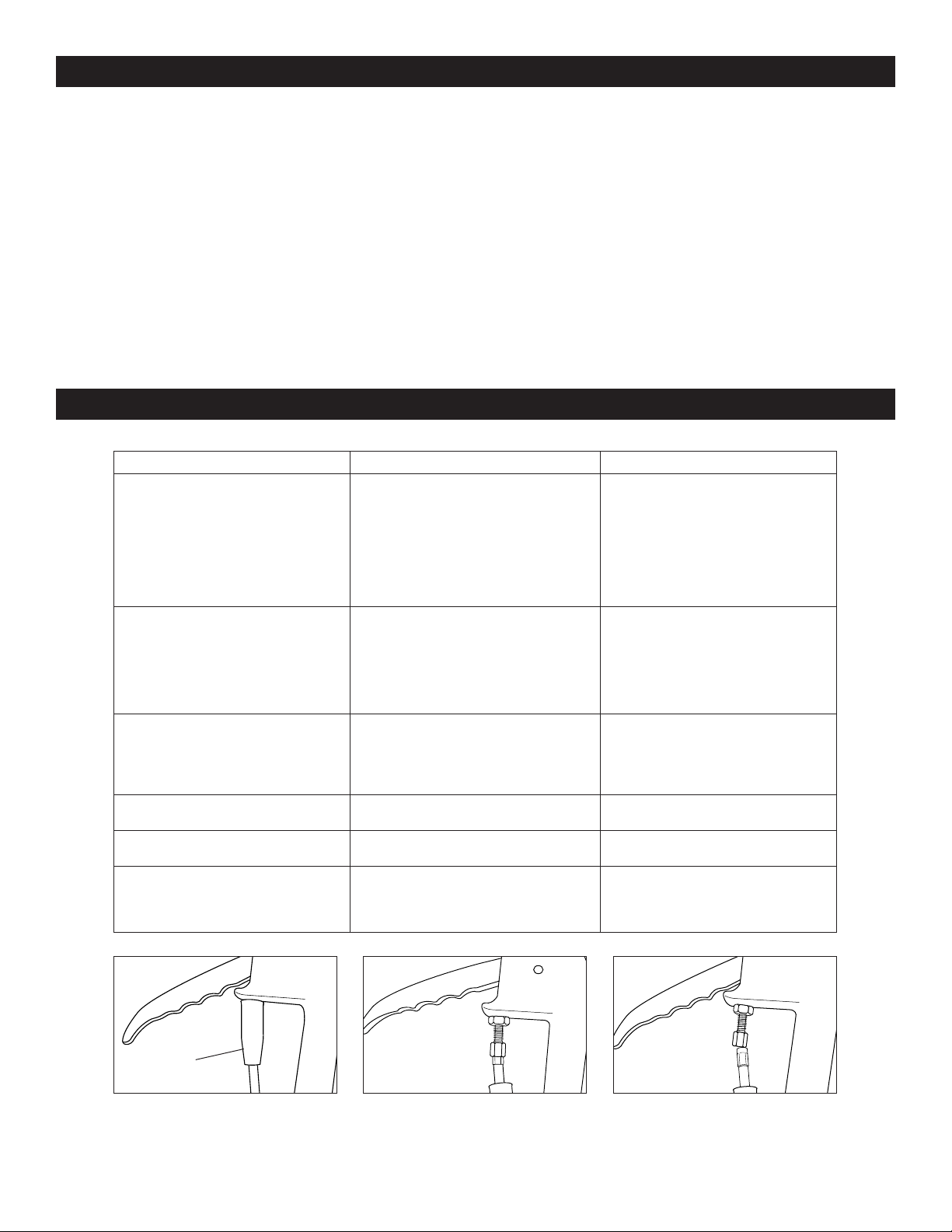

Figure 1 Figure 2 Figure 3

Cable

with Boot

1) Steel ball of the check-valve is not

fully seating.

2) Firing pin does not allow the steel

ball to fully seat.

The travel of the firing pin is not enough

to open the steel ball.

The O-ring is damaged. Change the O-ring.

The seal ring is damaged. Change the seal ring.

Cable may be disconnected. Ensure cable with silver sleeve is

Correct

Cable Insertion

1) Clean the valve opening and

change the steel ball.

2) Adjust the tension rate of the steel

wire connected to the hand lever

to adjust the seating of firing pin.

Adjust the tension rate of the steel

wire rope to make firing pin at

suitable place and apply lubricant

to the pin.

terminating inside of nut.

(See Figures 1-3)

Incorrect

Cable Insertion

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-80 0 -295-5510

PAGE 3 OF 9 1118 IH-1485

uline.com

Page 4

π

H-1783, H-6754

01-800 -295-5510

uline.mx

MESA DE ELEVACIÓN

ESTÁNDAR

INFORMACIÓN TÉCNICA

ESPECIFICACIONES H-1485 H-1486 H-1487 H -1783 H-6754

Capacidad 150 kg (330 lbs.) 300 kg (660 lbs.) 499 kg (1,100 lbs.) 798.3 kg (1,760 lbs.) 499 kg (1,100 lbs.)

Altura Máxima 73.66 cm (29") 88.9 cm (35") 88.9 cm (35") 1 m (39.5") 91.4 cm (36")

Altura Mínima 22.35 cm (8.8") 27.9 cm (11") 27.9 cm (11") 41.9 cm (16.5") 31.75 cm (12.5")

H-1485, H-1486, H-1487

Tamaño de la mesa

Altura total 94 cm (37") 99 cm (39") 99 cm (39") 99 cm (39") 99 cm (39")

Largo general 78.7 cm (31") 94 cm (37") 94 cm (37") 117 cm (46") 165 cm (65")

Ciclos del pedal hasta la altura

máx.

Diámetro de llanta 10.2 cm (4") 12.7 cm (5") 12.7 cm (5") 15.2 cm (6") 12.7 cm (5")

Peso 46 kg (101 lbs.) 75 kg (165 lbs.) 84.82 kg (187 lbs.) 115.1 kg (254 lbs.) 134.26 kg (296 lbs.)

Volumen de funcionamiento del

cilindro de aceite

Capacidad de aceite 210 ml 250 ml 250 ml 240 ml 300 ml

68.6 x 45.7 x 5.1 cm

(27 x 18 x 2")

25 32 45 56 40

138 ml 164 ml 164 ml 157 m l 200 ml

81.3 x 51 x 5.1 cm

(32 x 20 x 2")

81.3 x 51 x 5.1 cm

(32 x 20 x 2")

100.3 x 50.8 x 5.1 cm

(39½ x 20 x 2")

160.02 x 80 x 5.1 cm

(63 x 31.5 x 2")

INFORMACIÓN GENERAL

1. Lea con cuidado todas las instrucciones antes de

utilizar la mesa de elevación.

2. NO sobrecargue la mesa de elevación y hágala

funcionar siempre con el peso indicado. La

sobrecarga causará daños a la mesa de elevación

y al operador.

3. NO se ponga de pie ni se siente en la mesa para

trabajar.

4. NO ponga las manos o los pies debajo de la mesa

al bajarla.

5. Ponga los frenos al cargarla para evitar que la

mesa se desplace.

6. La carga deberá repartirse uniformemente por toda

la mesa.

7. NO cargue pesos sueltos o inestables sobre la mesa.

8. NO deje la mesa cargada durante períodos

prolongados.

PAGE 4 OF 9 1118 IH-1485

9. NO mueva el carrito mientras eleva.

10. La mesa solo debe utilizarse sobre superficies

planas y sólidas.

11. Asegúrese de no sobrecargar la mesa cuando

se encuentre en posición elevada. La válvula de

seguridad solo funciona mientras se eleva la mesa.

Sobrecargar la mesa en posición elevada podría

dañarla.

12. Al cargar o descargar artículos en posición elevada,

no arrastre las cargas a lo largo de la mesa.

Esto puede desequilibrar la carga y la mesa podría

volcarse.

13. Al realizar tareas de mantenimiento y reparación

a la mesa, la barra vertical deberá usarse para

apoyar el brazo de la horquilla y evitar que la mesa

se caiga. No debe haber carga alguna sobre la

mesa mientras se realizan tareas de mantenimiento

o se repara.

Page 5

ENSAMBLE

1. Estas son mesas plegables. Solo pueden funcionar

si el asa está en posición vertical.

2. La palanca de pie se desmonta para el envío.

Debe colocarse en la mesa de elevación antes de

hacerla funcionar.

8

1

COLOCACIÓN DE LA PALANCA DE PIE

Montaje de la palanca de pie: inserte el pedal en el

orificio ubicado en la barra cuadrada. Fije el pedal

con un perno, una rondana plana una rondana de

seguridad y una tuerca. Apriete la tuerca con una llave.

2

7

# NOMBRE DE PARTE

1 Plataforma de Carga

2 Mecanismo de Elevación

3 Cilindro Hidráulico

4 Rueda Giratoria

5 Rueda Rígida

6 Freno

7

8 Asa

9 Pedal

10 Barra Cuadrada

Barra de Soporte

de Seguridad

9

PAGE 5 OF 9 1118 IH-1485

10

4

6

3

5

Page 6

MANTENIMIENTO

Es muy importante realizar el mantenimiento necesario

para prolongar la vida útil y la seguridad de la mesa

de elevación. Por favor, verifique la mesa de elevación

antes de hacerla funcionar:

1. Verifique no haya partes de la mesa de elevación

que se hayan deformado o doblado.

2. Verifique el estado del freno del carrito y de las llantas.

3. Verifique que no haya fugas de aceite en el sistema

hidráulico.

4. Agregue o rellene con lubricante cada una de las

superficies de fricción antes del funcionamiento diario.

SOLUCIÓN DE PROBLEMAS

PROBLEMA DE FUNCIONAMIENTO CAUSAS RECOMENDACIONES

No alcanza la altura máxima de

elevación.

1)

La bola de acero de la válvula de

control no se asienta completamente.

2) El perno de disparo no permite

que la bola de acero se asiente

completamente.

3) El nivel de aceite hidráulico es bajo.

5. En caso de fallos, la mesa de elevación debe

repararse de inmediato antes de volverse a utilizar.

6. Cambie el aceite hidráulico cada doce meses. Elija

el aceite hidráulico adecuado en función de las

condiciones climáticas.

7. Para cambiar el aceite hidráulico:

a. Desatornille el tornillo de sellado con una llave.

b. Levante la palanca de mano.

c. Gire el tornillo del tapón de aceite hasta quitarlo

y llene la bomba con aceite hidráulico.

1) Limpie la abertura de la válvula y

reemplace la bola de acero.

2

) Ajuste la tasa de tensión del

alambre de acero conectado a la

palanca de mano para ajustar el

asiento del perno de disparo

3) Agregue aceite hidráulico.

.

La mesa se eleva y luego

desciende.

La tabla de la mesa no desciende.

Fuga de aceite en el perno de

disparo.

Fuga de aceite en la bomba.

La mesa no se eleva.

Diagrama 1 Diagrama 2 Diagrama 3

1)

La bola de acero de la válvula de

control no se asienta completamente.

2) La clavija de disparo no permite

que la bola de acero se asiente

completamente.

El recorrido del perno de disparo no es

suficiente para abrir la bola de acero.

El anillo-O está dañado. Cambie el anillo-O.

El empaque está dañado. Cambie el empaque.

El cable podría estar desconectado. Asegúrese de que el cable con el

1) Limpie la abertura de la válvula y

cambie la bola de acero.

2) Ajuste la tasa de tensión del

alambre de acero conectado a

la palanca de mano para ajustar

el asiento de la clavija de disparo.

Ajuste la tasa de tensión de la

cuerda del alambre de acero

para colocar la clavija de disparo

en una posición óptima y aplique

lubricante a la clavija.

recubrimiento plateado termine

de la tuerca. (Vea Diagramas 1-3)

dentro

π

Cable

con Cubierta

Conexión

Correcta

del Cable

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

Conexión

Incorrecta

del Cable

01-800-295-5510

PAGE 6 OF 9 1118 IH-1485

uline.mx

Page 7

π

H-1783, H-6754

1-800 -295-5510

uline.ca

TABLE ÉLÉVATRICE

STANDARD

CARACTÉRISTIQUES TECHNIQUES

SPÉCIFICATIONS H-1485 H-1486 H-1487 H -1783 H-6754

Capacité 149,7 kg (330 lb) 299,4 kg (660 lb) 499 kg (1100 lb) 798,3kg (1760 lb) 499 kg (1 100 lb)

Hauteur élevée 73,7cm (29po) 88,9cm (35po) 88,9cm (35po) 100,3cm (39,5po) 91,4 cm (36 po)

Hauteur abaissée 22,4cm (8,8po) 27,9cm (11po) 27,9cm (11po) 41,9cm (16,5po) 31,75 cm (12.5 po)

H-1485, H-1486, H-1487

Dimensions de la table

Hauteur totale 94cm (37po) 99cm (39po) 99cm (39po) 99cm (39po) 99 cm (39 po)

Longueur totale 78,7cm (31po) 94cm (37po) 94cm (37po) 116,8cm (46po) 165 cm (65 po)

Cycles du levier à pied jusqu'à la

hauteur maximale

Diamètre des roues 10,2cm (4po) 12,7cm (5po) 12,7cm (5po) 15,2po (6po) 12,7 cm (5 po)

Poids 45,8kg (101lb) 74,8kg (165lb) 84,8kg (187lb) 115,2kg (254lb) 134,26 kg (296 lb)

Volume fonctionnel du cylindre

à huile

Volume maximal d’huile 210 ml 250 ml 250 ml 240 ml 300 ml

68,6 x 45,7 x 5,1cm

(27 x 18 x 2po)

25 32 45 56 40

138 ml 164 ml 164 m l 157 ml 200 ml

81,3 x 50,8 x 5,1cm

(32 x 20 x 2po)

81,3 x 50,8 x 5,1cm

(32 x 20 x 2po)

100,3 x 50,8 x 5,1cm

(39½ x 20 x 2po)

160,02 x 80 x 5,1 cm

(63 x 31 ½ x 2 po)

RENSEIGNEMENTS GÉNÉRAUX

1. Lisez soigneusement toutes les instructions avant

d'utiliser la table élévatrice.

2. NE surchargez PAS la table élévatrice et respectez

toujours sa charge nominale. Une surcharge risque

d'endommager la table élévatrice et de blesser

l’utilisateur.

3. NE vous tenez PAS debout ou ne vous assoyez pas

sur la table pour travailler.

4. NE placez PAS vos mains ou vos pieds sous la table

en l'abaissant.

5. Appliquez les freins lors du chargement pour

empêcher la table de se déplacer.

6. La charge doit être répartie uniformément sur toute

la table.

7. NE chargez PAS des charges lâches ou instables sur

la table.

8. NE laissez PAS la table chargée pendant de longues

périodes.

PAGE 7 OF 9 1118 IH-1485

9. NE bougez PAS le chariot lors du levage.

10. La table doit être utilisée uniquement sur des

surfaces planes et solides.

11. Assurez-vous de ne pas surcharger la table

lorsqu'elle est en position élevée. La soupape de

sécurité fonctionne uniquement lors du levage. Une

surcharge en position élevée risque d'endommager

la table.

12. Lors du chargement et du déchargement des

marchandises en position élevée, ne traînez pas

les charges sur la table. Cela peut déséquilibrer le

chargement et renverser la table.

13. Lors de l'entretien et la réparation de la table, la

barre de soutien doit être utilisée pour soutenir

le bras de fourche afin d'empêcher la table de

tomber. La table ne doit pas supporter une charge

lors de l'entretien et la réparation de la table.

Page 8

ASSEMBLAGE

1. Ces tables sont pliantes. Elles peuvent seulement

être utilisées si la poignée est en position verticale.

2. Le levier à pied est démonté lors de la livraison.

Il doit être fixé sur la table élévatrice avant son

utilisation.

8

1

INSTALLATION DU LEVIER À PIED

Assemblage du levier à pied : Insérez le levier à pied

dans le trou de la barre carrée. Fixez le levier à pied à

l'aide d'un boulon, d'une rondelle plate, d'une rondelle de

blocage et d'un écrou. Serrez l'écrou à l'aide d'une clé.

2

7

# NOM DE PIÈCES

1 Plate-forme de chargement

2 Mécanisme de levage

3 Cylindre hydraulique

4 Roulette pivotante

5 Roulette fixe

6 Frein

7 Barre de sécurité

8 Poignée

9 Levier à pied

10 Barre carrée

9

PAGE 8 OF 9 1118 IH-1485

10

4

6

3

5

Page 9

ENTRETIEN

Il est très important d'effectuer l'entretien nécessaire

afin de prolonger la durée de vie et la sécurité de la

table élévatrice. Veuillez vérifier les points suivants avant

d’utiliser la table:

1. Assurez-vous que les pièces de la table élévatrice

ne sont pas déformées ou pliées.

2. Vérifiez les freins du chariot et l'état des roues.

3. Vérifiez s'il y a des fuites d'huile dans le système

hydraulique.

4. Lubrifiez chaque surface de frottement avant

l'utilisation quotidienne.

DÉPANNAGE

PROBLÈME CAUSES RECOMMANDATIONS

La table n'atteint pas la hauteur

maximale.

1)

La bille en acier du clapet anti-retour

n’est pas appuyée complètement.

2) La goupille de déclenchement

empêche la bille en acier de

s’appuyer complètement.

3) Le niveau d'huile hydraulique est bas.

5. En cas de défaillance, la table élévatrice doit être

réparée immédiatement avant d'être utilisée de nouveau.

6. Changez l'huile hydraulique tous les douze mois.

Choisissez l'huile hydraulique appropriée en fonction

des conditions climatiques.

7. Pour changer l'huile hydraulique:

a. Dévissez la vis d'étanchéité à l’aide d'une clé.

b. Levez le levier à main.

c. Dévissez la vis du bouchon d'huile et remplissez

la pompe avec de l'huile hydraulique.

1)

Nettoyez l'ouverture de la soupape

et replacez la bille en acier.

2) Réglez le niveau de tension du fil

d'acier relié au levier à main pour

régler l'appui sur la goupille de

déclenchement.

3) Ajoutez de l'huile hydraulique.

La table s'élève puis redescend.

Le plateau de la table ne descend

pas.

Fuites d'huile au niveau de la

goupille de déclenchement.

Fuites d'huile au niveau de la

pompe.

La table ne s'élève pas.

Figure 1 Figure 2 Figure 3

1) La bille en acier du clapet

anti-retour n'est pas appuyée

complètement.

2) La goupille de déclenchement

empêche la bille en acier de

s'appuyer complètement.

La goupille de déclenchement ne se

déplace pas suffisamment pour ouvrir

la bille en acier.

Le joint torique est endommagé. Changez le joint torique.

La bague d'étanchéité est

endommagée.

Le câble est peut-être débranché. Assurez-vous que le câble avec le

1) Nettoyez l'ouverture de la

soupape et changez la bille en

acier.

2) Réglez le niveau de tension du fil

d'acier relié au levier à main pour

régler l'appui sur la goupille de

déclenchement.

Réglez le niveau de tension du câble

en acier pour déplacer la goupille

de déclenchement à l'endroit

approprié et lubrifiez la goupille.

Changez la bague d'étanchéité.

manchon argenté n'excède pas

l'intérieur de l'écrou. (Voir Figures 1-3)

π

Câble

avec gaine

Insertion

adéquate

du câble

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

Insertion

inadéquate

du câble

1-80 0 -295-5510

PAGE 9 OF 9 1118 IH-1485

uline.ca

Loading...

Loading...