Page 1

H-1459

BAG ON A ROLL

SYSTEM

1- 80 0-295 -5510

uline.com

USING THIS MANUAL

READ MANUAL FIRST

IMPORTANT: Please read this manual and

familiarize yourself with the equipment before

use. The manual contains valuable information

about the machine, its operation and the

packaging materials used with it.

SAFETY INFORMATION

This manual contains very important information to

protect both the operator and the machine. Please pay

special attention to the SAFETY WARNINGS.

STOP - Alerts you to dangerous situations or

hazards.

CAUTION - Alerts you to actions and situations

that may affect the machine and its operation.

NOTE - Important information about the

operation and use of the machine.

Serial number ______________ and voltage

marked on the ID plate _______VAC

Please enter the serial number of your machine in the

space provided above. If service in needed, please be

prepared to furnish both the model number and serial

number.

UNPACK AND INSPECT

Remove all packing materials from the machine. Do

not discard packing materials until you are sure there

is no hidden damage. Find the manual and related

hardware supplied with the machine. Carefully examine

the machine for any indications of damage that may

have occurred in transit.

NOTE: If there is any damage, contact ULINE

immediately.

Remember that even minor damage on the outside

of the machine can cause problems with sensitive

components inside the machine.

PAGE 1 OF 7 0621 IH-1459

Page 2

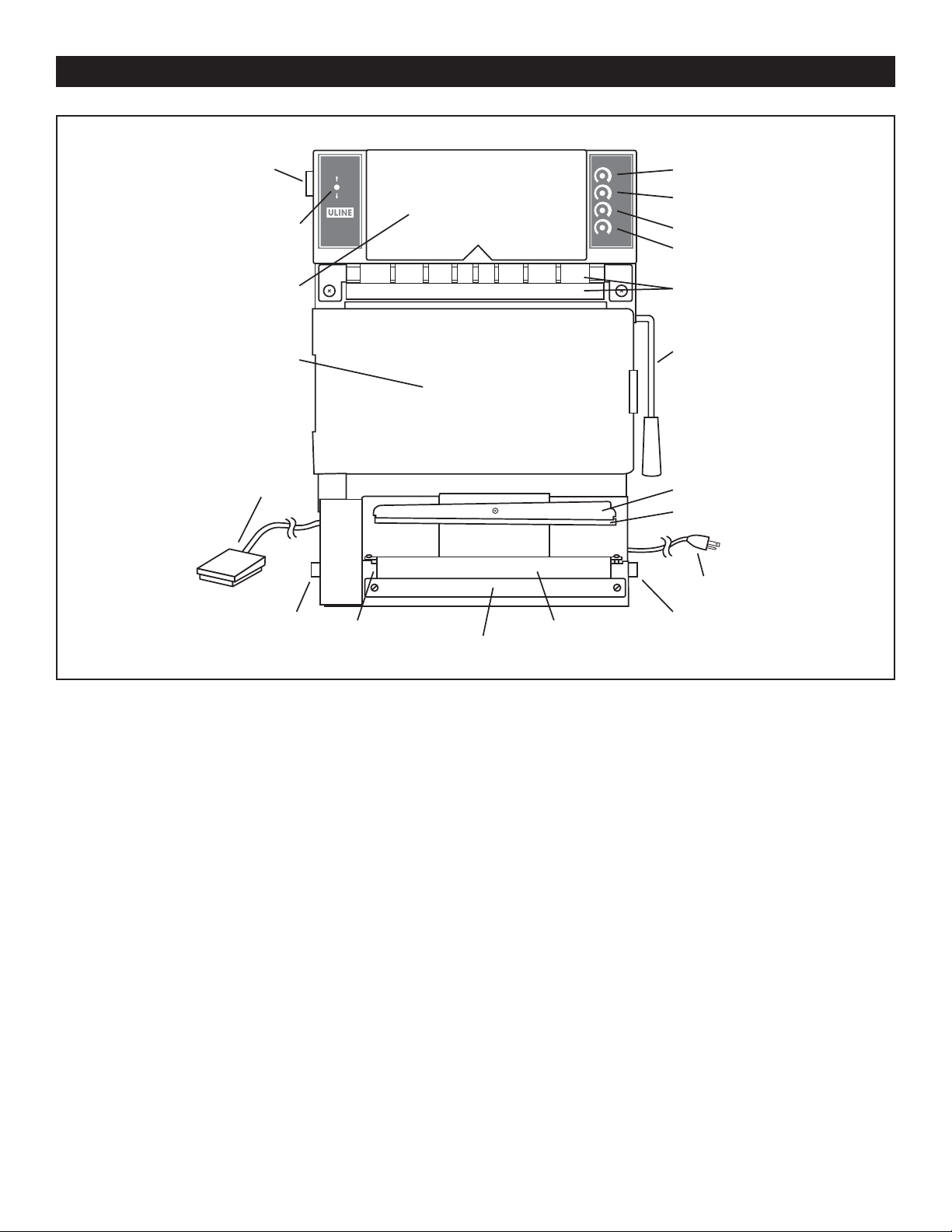

PARTS OF THE MACHINE

Blower Air Flow Knob

Bag Adjust

Air Deflector

Door

Foot Pedal

-

+

+

-

-

+

-

+

Bag Length (Fine)

Bag Length (Coarse)

Seal temp

Cool Cycle

Pinch Rollers

Pinch Roller Lever

Upper Teflon Jaw

Compression Pad

Power Cord

Roller Knob Roller Knob

Lower Jaw

Figure 1: Parts of the Machine

TOP LEFT FRONT PANEL:

• Bag Adjust: Flip up or down to rewind or dispense the

next bag manually.

TOP RIGHT FRONT PANEL:

• Bag Length Fine Adjustment: Clockwise for longer

bags/counterclockwise for shorter bags.

• Bag Length Coarse Adjustment: Clockwise for longer

bags/counterclockwise for shorter bags.

• Seal Heat-Time Adjustment for bag sealer: Clockwise

to increase heating time/counterclockwise to

decrease heating time.

• Cooling-Time Adjustment for bag sealer: Clockwise

to increase cooling time/counterclockwise to

decrease cooling time.

Lower Teflon Jaw

Front Clamp

LOWER BACK PANEL:

• Power Switch: Push ON ( I ), push OFF ( O ).

OTHER CONTROLS:

• Foot Switch: Step on to begin both the heat sealing

and bag dispensing cycles.

• Blower Air Flow Knob: (Top left side) Adjusts airflow to

open bags.

• Pinch Roller Lever: (Right side) Opens and closes

pinch rollers.

• Teflon® Roller Adjustment Knobs: (Right and left

sides) Unroll or rewind the Teflon® cover on the lower

sealing jaw assembly.

PAGE 2 OF 7 0621 IH-1459

Page 3

INSTALLATION DESCRIPTION

ELECTRICAL REQUIREMENTS

CAUTION! Follow local electrical and safety

codes as well as the National Electrical Code

(NEC) and the Occupational Health and Safety

Act (OSHA).

The machine is rated at 110 to 125 volts AC, 50/60

Hz with a ground. At this voltage the unit draws

about 5 amperes. The use of extension cords is not

recommended.

Locate the unit at or near an appropriate electrical

supply. Be certain that the power source conforms to

the machine’s requirements and that the proper gauge

and type of wire is used. Make connections using the

shortest possible runs of wire. Long runs of wire can result

in reduced voltage.

CAUTION! ALWAYS check the specifications

listed on the back of the machine. It shows the

correct operating voltage and amp draw for

this machine.

GROUNDING

For your SAFETY and machine protection, DO NOT

operate without a proper and secure electrical ground.

If a grounded receptacle is not available, use a proper

grounding adapter.

NOTE: All warranties are VOID if the machine

is used with an ungrounded electrical

connection. Never connect a machine to any

power source that exceeds the specified rating.

LOCATION

CAUTION! DO NOT operate this machine in

explosive atmospheres. Do not subject the

machine to wet or corrosive environments.

Keep all flammable and caustic substances

away from the machine at all times.

This self-contained bag-packaging machine dispenses,

opens and seals pre-made, pre-opened bags from

a roll. The chassis is 300 series stainless steel and

is designed as a tabletop unit to be used in the

vertical position. The machine works with pre-made,

pre-opened bags on a roll up to a maximum 12” (30.5

cm) wide and up to 12” (30.5 cm) long. Running longer

than maximum bags may require factory modifications.

Heavy products may also require factory modifications.

NOTE: Continuous pre-made bags-on-a-roll

that are not pre-opened will not work on this

machine.

The Bag On A Roll Machine is extremely safe and easy

to use even by inexperienced operators. There is no

guesswork, and the machine is designed for the SAFETY

of both your operator and your products. If the sealing

jaws encounter anything significantly thicker than the

bag to be sealed, no heat or pressure is applied –

protects operator’s hands and fingers.

The electromagnetic jaw pressure system exerts pressure

only after the sealing jaws close. The adjustable sealing

system provides heating and cooling time to make

consistently strong heat seals. Once the heat-sealing

cycle is complete, the sealing jaws reopen.

HOW THE MACHINE WORKS

1. Install the pre-made, pre-opened bags on a roll in

the machine.

2. Close the pinch rollers.

3. Set the bag length control for the proper time

duration.

4. Set the sealer control for the material to be sealed.

5. Dispense the first bag to the filling position and air

stream blows it open.

Unit is for indoor use only. Select a location close

to where the products being packaged are stored

or manufactured for best workflow. Also consider

whether the operator will sit or stand while using this

machine. Place the unit on a level, sturdy table that can

support the weight of the machine, the products to be

packaged and those already packaged.

PAGE 3 OF 7 0621 IH-1459

6. Place the product(s) into the open bag.

7. Tear off the filled bag at the perforations.

8. Hold the bag flat and place the open mouth of the

bag between the open sealing jaws near the base

of the machine.

9. Depress the electric foot switch.

CAUTION! DO NOT use the electric foot switch

when liquids are on the floor. A dangerous

electric shock might result.

10. The sealing jaws automatically close on the

mouth of the filled bag.

Page 4

11. The automatic sealing cycle begins when the sealer

jaws close fully and the next bag automatically

dispenses into the air stream and opens, ready for

filling.

LOADING BAGS

NOTE: If the brake springs are over-tightened,

the perforations between the bags may

separate while the bags are being dispensed.

If the perforations break, it will require

re-threading the bags through the pinch rollers.

If the brake springs are too loose, the bags

may unwind prematurely.

The front access door is located under the pinch rollers.

Pull handle to open door.

1. If loading for the first time: Locate the core-roll shaft

packed for shipment at the factory in the top foam

end cap.) Proceed to Step 3.

Bag Roll

Non-rotate Pin

Brake Springs

Collar

Thumbscrew

Figure 2: Core-Roll Assembly

Shaft

2. To change rolls (See Figure 2): Remove core-

roll shaft from the holding brackets by pulling

it toward you and slightly upward in one fluid

motion. Note that one end of the core-roll shaft has

a non-rotation pin.

7. With the roll of bags properly placed and centered

in the machine, raise the lever on the right side of

the machine. This releases pressure on the pinch

rollers and allows easy bag threading.

8. Insert the end of the first bag from the roll between

the pinch rollers. Make sure bag is centered with no

wrinkles. (See Figure 3)

9. Pull the bag between the rollers to approximately

the filling position, then lower the lever on the left

side of the machine to close and lock the pinch

rollers on the bag.

SIDE VIEW

ROLLERS

INFLATED

ROLLBAG

DOOR

ROLL OF

PINCH

UN-LOCKED

BAGS

LOCKED

PINCH ROLLER

CONTROL

THUMB

SCREW

LOCKING

COLLAR

3. Loosen the thumbscrew on the end opposite the

non-rotation pin, remove the locking collar and one

brake spring from the core shaft.

4. Slide a roll of bags on the shaft so that the

pre-opened parts of the bags face you.

5. Reinstall the brake spring and collar and place the

roll of bags and the core assembly back

in the machine. Allow the core shaft to slide to the

ends of the holding tracks.

6. Loosen the thumbscrews on the locking collars

and center the roll of bags on the core. Retighten

the thumbscrews so there is slight pressure from the

NOTE: A blower system opens the bags for filling.

This system will not work with some products

such as powders, shredded paper and other

very light products. Very light products get

caught in the airflow and will not go into the

bag properly. Some powders may also stick to

the inner surfaces of the bag in the heat seal

area. This may prevent the bag from sealing

properly during the heat sealing process.SET

THE HEAT CONTROLS

Figure 3: Bag Roll Routing

brake springs against the side plates on the roll of

bags

PAGE 4 OF 7 0621 IH-1459

Page 5

SET THE HEAT CONTROLS

The machine includes one heating element mounted to

the lower jaw of the heat sealer and one spare, taped

inside the front access door. The heating elements

make a Ribbon Seal approximately 12" (30.5 cm) long

by 1/8” (3 mm)

The heat sealer has an adjustable heat-time control that

may be set from 0% to 100%.

1. Set the HEAT SEALING control to indicate

approximately 30%. (See Figure 4)

SEAL

Figure 4

+

Figure 5

-

2. Flip the BAG ADJUST switch to dispense a bag. (See

Figure 5)

3. Tear the bag off along perforation, then position the

mouth of the bag between the seal jaws.

CAUTION! NEVER attempt to heat seal through

the printed area on a bag, as it will cause

sticking and gumming.

NOTE: Use as little heat time as possible to

obtain the necessary results. Overheating

weakens the seal area on the bag and causes

higher maintenance. The heating element

expands and contracts during each sealing

cycle, eventually causing the element to wear

out. When replacing the element, it may be

necessary to readjust the temperature control

timer.

RESIDUAL HEAT – HEAT BUILD UP

The machine is designed to allow sufficient time for

the heating element and sealing compression pad to

cool during the bag dispensing and filling period. It

is not intended for use as a high-speed heat sealer.

Attempting to operate the sealer at speeds beyond its

intended use causes residual heat build-up resulting

in bag seal stretch and melt-through and require early

replacement of the heating element, Teflon® covers

and compression pad.

BAG STOP POSITION ADJUSTMENTS

If the bag in the staging area opens properly, fill it,

tear it off and heat seal it. The next bag dispenses

during the heat-sealing cycle. If the bag does not stop

in the correct position, follow the instructions below. This

is trial-and-error; when using bags of different lengths,

write down the proper settings as you determine them.

The settings will vary slightly from one machine to

another. Initial set-ups may take a few minutes.

4. Depress the foot switch until the sealing cycle starts,

then release. When the sealing cycle is complete,

remove the bag from the Teflon® covered lower

sealer jaw using a left to right or right to left peeling

motion.

INSPECTING THE HEAT SEAL

An acceptable ribbon seal shows the grain of the Teflon®

jaw covers and have a slightly milky appearance. An

acceptable trim seal leaves a fine raised bead at the

end of the bag – no fringe or angel hair.

IF HEAT SEAL IS TOO WEAK

Increase the heat-time setting slightly (clockwise): If the

heat seal does not look complete or if the bag will not

stay closed, repeat the process using another bag until

you are satisfied with the results. Be sure that the seal

area is not coated with a contaminant.

IF HEAT SEAL MELTS THROUGH

Decrease the heat-time setting slightly

(counterclockwise): If the seal melts through, too much

of the bag material extrudes away during sealing, the

top of the bag flops back on itself or if the sealed ends

look shrunken. Repeat testing using another bag until

you are satisfied.

IF BAG STOPS TOO LOW ON THE MACHINE

1. Decrease the BAG LENGTH setting slightly

(counterclockwise). Use the coarse or fine adjusting

control as needed.

2. Flip the BAG ADJUSTMENT switch up or down until the

next bag is in position for filling.

3. Fill, tear off and heat-seal the bag.

4. Repeat until the next bag stops in the proper

position each time.

IF BAG STOPS TOO HIGH ON THE MACHINE

1. Increase the BAG LENGTH setting slightly (clockwise).

Use the coarse or fine adjusting control as needed.

2. Flip the BAG ADJUSTMENT switch up or down until the

next bag is in position for filling.

3. Fill, tear off and heat-seal the bag.

4. Repeat until the next bag stops in the proper

position each time.

PAGE 5 OF 7 0621 IH-1459

Page 6

MAINTENANCE

If you encounter any problems with the Uline

Bag on a Roll System, contact Uline Customer

Service at 1-800-295-5510.

CAUTION! Never attempt to make heat seals

without the lower Teflon® cover over the

heating element and lower sealing jaw.

REPLACING THE LOWER TEFLON® COVER

To replace the lower Teflon® cover roll:

(See Figure 7)

TEFLON®JAW COVERS

Both the upper and lower jaws of the heat sealer are

covered with a Teflon® glass cloth to aid heat sealing

and prevent sticking. Since the heat source is in the

lower jaw it is exposed to greater abuse and is therefore

larger and easily repositioned.

REPLACE UPPER JAW COVER

Replace the upper Teflon® cover if it becomes torn,

burned or the sealed bag sticks to it. It is held in place

by a spring and is easily replaceable.

REPOSITION LOWER JAW COVER

The lower Teflon® cover provides an easily

repositionable sealing surface. The cover is anchored

at one end to a roller held in place by two screws; the

other end passes through a clamp-type retainer on the

face of the machine.

To reposition the lower Teflon® cover:

1. Loosen the two plastic screws holding the clamp.

2. Using either one or both of the knobs located on

the sides of the machine, rotate the roller slightly so

that a new seal area is positioned over the heating

element. (See Figure 6)

1. Loosen the two plastic clamp screws and rotate the

roller knob with one hand while pulling the trailing

end of the Teflon® up with the other until the two

roller mounting screws are visible.

Figure 7: Replacing lower Teflon® cover

2. Remove the two screws (use either a magnetic or

starter screwdriver). Keep the screws for reuse in

mounting the new Teflon® cover roll.

3. Install the new Teflon® cover roll by passing the

mounting screws through the two eyelets and into

the roller. The screws should be snug. Do not overtighten as damage could result.

4. Rotate the roller knob, winding the Teflon® cover

onto the roller. Insert the free end behind the clamp.

To reduce waste, put as little Teflon® beyond the

end of the clamp as possible.

REPLACING COMPRESSION PAD

Over time the silicone rubber compression pad

becomes brittle and pitted and needs to be replaced.

1. Remove the upper Teflon® cover by first removing

Figure 6: Repositioning lower Teflon® cover

3. After repositioning, retighten the clamp using the

same two plastic screws.

4. Tear off the used Teflon® material below the clamp.

Replace the roll when there is no more usable

Teflon®.

PAGE 6 OF 7 0621 IH-1459

the retaining spring. Keep the parts for reuse.

2. Remove the nut and bolt retaining the compression

pad holder. (See Figure 8)

3. Peel off the old compression pad and clean the

area so it’s free of lumps and old adhesive.

Page 7

4. The replacement compression pad has a pressure

HEATING ELEMENT INSTALLATION

1

0

uline.com

sensitive backing. Carefully remove the backing

paper and attach the new compression pad to the

jaw. Be sure that it is flat and has no depressions or

lumps.

5. Reinstall the upper compression pad holder and

Teflon® cover.

Figure 8: Replacing compression pad

HEATING ELEMENT REPLACEMENT

NOTE: The heating element has a top and a

bottom. See Figure 9 for proper positioning and

installation.

NOTE: The seal jaw assembly is spring-loaded

on left end, fixed on right end.

TOP

SIDE VIEW - HEATING ELEMENT

1

REMOVE OR ROLL UP

LOWER TEFLON ASSY.

PRIOR TO STARTING

USE A SMALL SCREW DRIVER

TO COMPRESS THE TENSION

2

SPRING DURING INSTALLATION

RETAINER NUT

SPRING LOADED TERMINATION

BROKEN ELEMENT

BARRIER STRIP

NEW ELEMENT

RETAINER NUT

The heating element expands and contracts during

each sealing cycle and will eventually break over time.

Replace using only Uline heating elements.

Make sure that the machine is turned off and

the power cord is secured before working on

the machine.

Any attempt to use elements designed for use

on another machine or in another application

may not work properly and may cause

damage and/or create a dangerous situation.

Use of non Uline parts will void all warranties.

1. Loosen the two clamp mounting screws and rotate

the roller knobs to rewind the Teflon® onto the roller

to expose the heating element. (See Figure 9)

2. Remove the heating element retaining nuts at each

end of the element (keep for reuse).

3. Remove the old heating element and discard.

4. Inspect the insulator on the lower jaw for signs of

cracks, pits, burn marks, etc.

5. If the insulation material is worn replace it before

installing the new heating element. Remove the

old insulator when necessary, clean the area,

apply a smooth coating of RTV adhesive, install the

replacement insulation and allow it to dry for several

hours before installing the new heating element.

3

NOTE:

REPLACE TEFLON

COVER BEFORE USE

Figure 9: Replacing heating element

6. Place the left end of the new heating element

over the threaded post at the left end of the jaw

assemb l y.

7. Compress the left end of the jaw (spring-loaded)

and place the right end of the heating element over

the fixed threaded post on the right end.

8. Make sure that the heating element is positioned

correctly, is not twisted and lays flat against the

lower jaw.

9. Reinstall the retainer nuts no more than finger-tight.

10. Reinstall the lower Teflon® cover.

PAGE 7 OF 7 0621 IH-1459

-800-295-551

Loading...

Loading...