Page 1

Para Español, vea páginas 6-10.

Pour le français, consulter les pages 11-15.

H-1358, H-1359

MARSH® MANUAL

TAPE DISPENSER

1-800-295-5510

uline.com

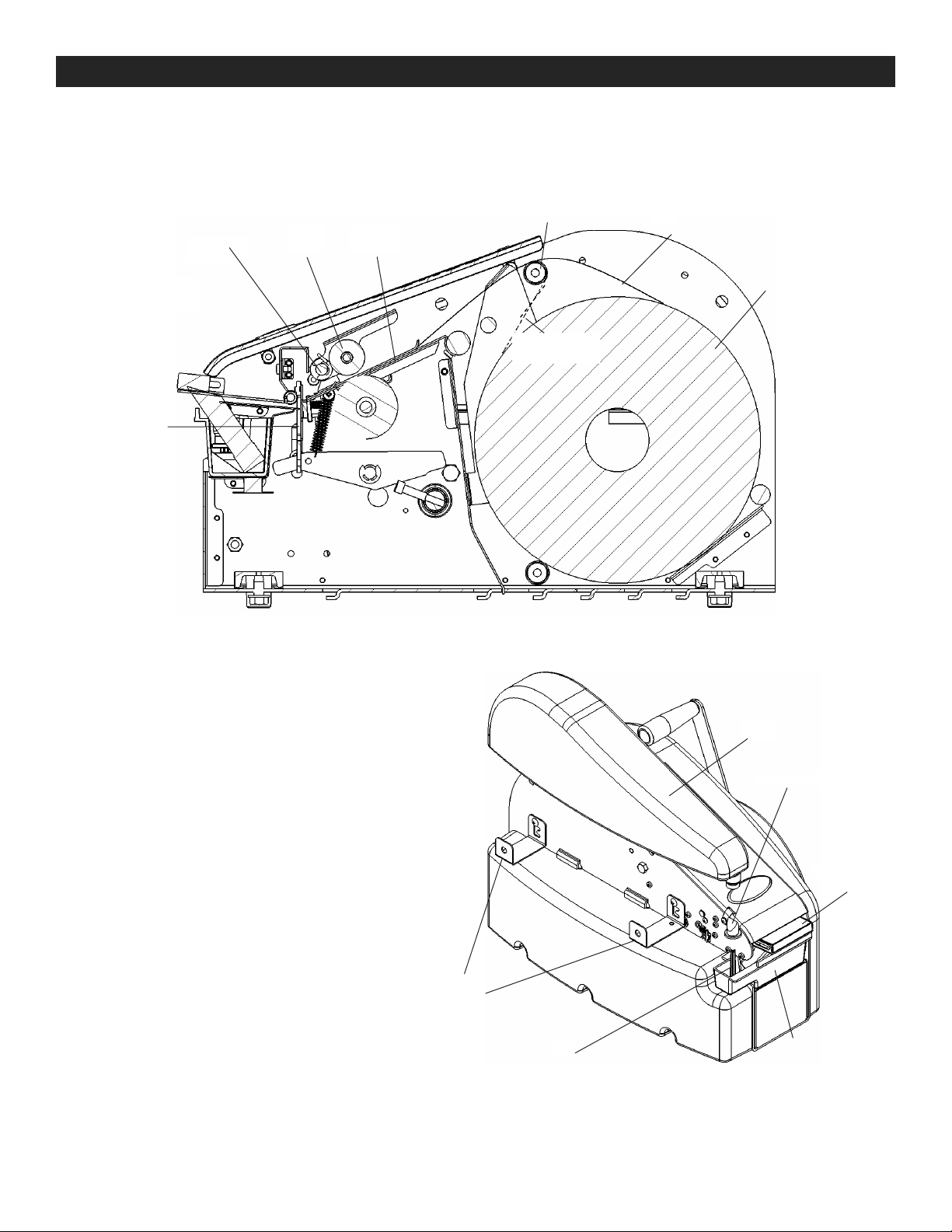

SET-UP INSTRUCTIONS

LOADING TAPE

1. Open the top cover.

2. Insert tape roll. Adjust tape guides with the

tape guide turnbuckle to fit the width of

the tape. Include a 1/8" clearance on both

sides of the tape roll.

(See Figure 1)

3. Remove the pressure plate. (See Figure 1)

Pinch Roller

Top Cover

Figure 1

Pressure Plate

Top Roller

Left Tape

Guide Flap

Tape

Guide

Turnbuckle

Length

Scale

Mechanical

Stop

PAGE 1 OF 15 0521 IH-1358

Page 2

SET-UP INSTRUCTIONS CONTINUED

4. Feed the tape, gummed side down, over the top

roller, under the tape guide flaps, and under the

pinch roller. (See Figure 2)

Cutter

Assembly

Pinch

Roller

Shaft

Pinch

Roller

Pressure

Plate

5. Place the pressure plate over the tape and release

the pinch roller. (See Figure 2)

6. Close the top cover.

Top Roller

Tape

Tape Roll

Gummed

Side of Tape

Figure 2

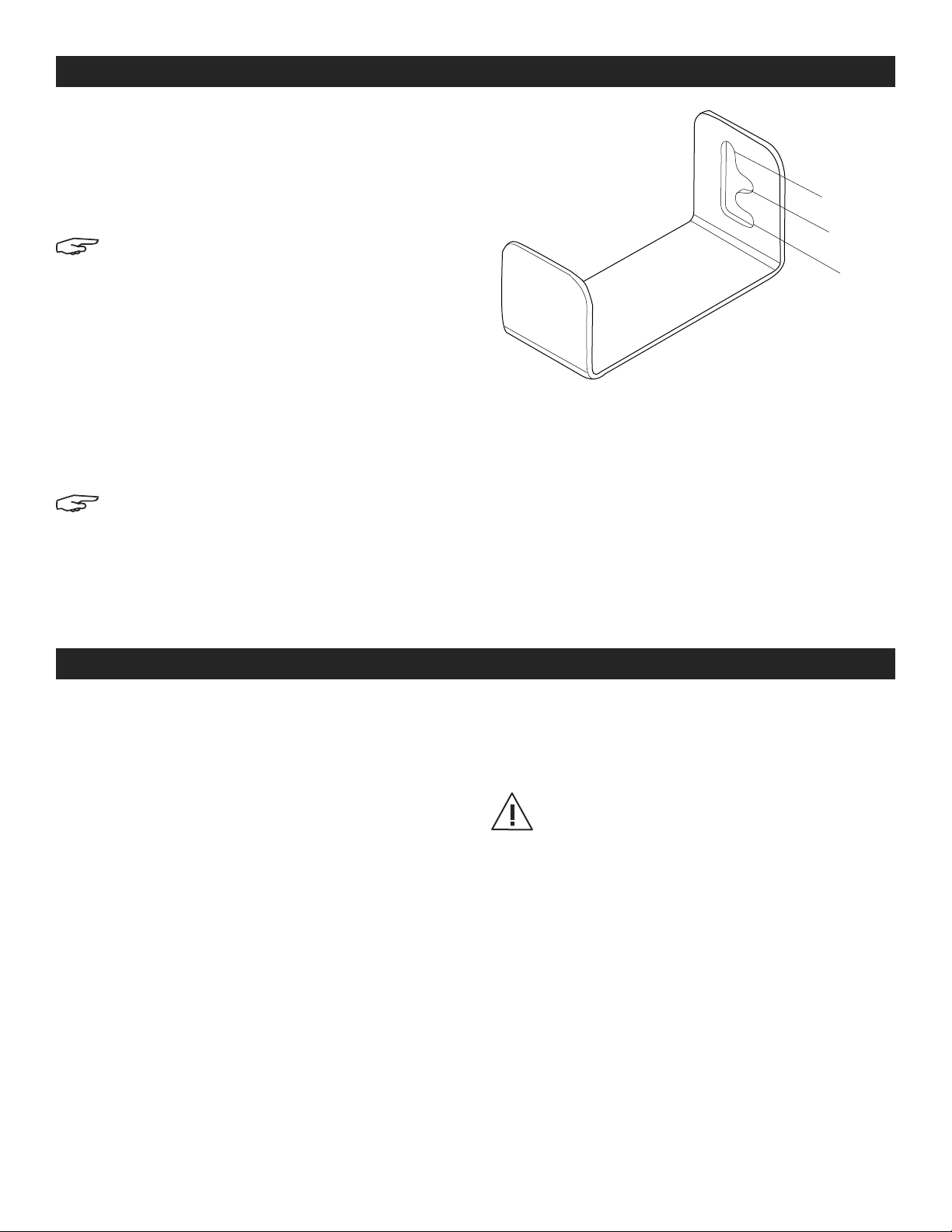

FILLING WATER BOTTLE

1. Remove the water bottle from the dispenser.

(See Figure 3)

2. Remove the duckbill valve from the water

bottle. Fill the water bottle with water.

(See Figure 3)

3. Place the duckbill valve back into the water

bottle.

4. Place the water bottle back onto the

dispenser.

5. Verify that the post in the brush tank is inserted

through the duckbill valve.

Water

Bottle

Brackets

Post

Figure 3

Water

Bottle

Duckbill

Valve

Tape

Weight

Brush

Tank

PAGE 2 OF 15 0521 IH-1358

Page 3

SET-UP INSTRUCTIONS CONTINUED

ADJUSTING BRUSH TANK WATER LEVEL

1. Loosen the screws on the water bottle brackets.

2. Move the water bottle brackets to a position that will

obtain the desired water level in the brush tank. Both

brackets should be in the same position. (See Figure 4)

NOTE: Lightweight tapes should be adjusted to

the low position, heavyweight tapes should be

adjusted to the high position.

3. Tighten the retaining screws on the water bottle

brackets.

ADJUSTING TAPE WEIGHT

1. Loosen the retaining screw.

2. Slide the tape weight forward to apply greater

pressure. Slide the tape weight backwards to apply

less pressure.

NOTE: Lightweight tapes will apply less water on

the tape. Heavyweight tapes will apply more

water on the tape.

Figure 4

LOW

MEDIUM

HIGH

3. Tighten retaining screw.

OPERATING INSTRUCTIONS

1. Pull the operating handle to the desired length on

the scale and release the handle.

2. When the handle returns to resting position, the tape

will be cut.

3. A mechanical stop on the side of the dispenser is

available if a known length will be used repeatedly.

4. The mechanical stop can be moved to the desired

position by loosening the knurled nut a half turn and

sliding up or down in the slot. Retighten knurled nut

once the desired setting has been found.

CAUTION! The knurled nut should never be

removed.

PAGE 3 OF 15 0521 IH-1358

Page 4

MAINTENANCE

NOTE: Little maintenance is required, but

regular cleaning of the brush, brush tank,

cutter mechanism and tape path are

important. Clean the tape dispenser when the

water bottle needs refilling.

CAUTION! For units with power switch or heater:

before performing any maintenance or

repair procedures, turn off power switch and

disconnect from power source.

CLEANING WATER FEED SYSTEM

1. Clean the brush by soaking in warm, soapy water.

Rinse with warm water.

2. Clean the brush tank by rinsing in warm water.

3. Rinse out the water bottle and duckbill valve with

warm water.

CLEANING CUTTER ASSEMBLY

1. Open top cover and remove pressure plate.

2. Remove tape from tape path.

plate back into the machine.

CLEANING TAPE PATH

1. Open top cover and remove pressure plate.

2. Remove tape from tape path.

3. Using compressed air, remove all debris from the

tape path.

4. To remove gum adhesive buildup, use a moist cloth

to wipe down all sheet metal parts within tape

path. This includes the tape channel, pressure plate,

weighted brush tank cover and water tank holder.

5. Place the tape back into the tape path and place

the pressure plate back in the machine.

6. Close the top cover.

3. Using a small amount of non-flammable lubricant,

spray the cutter assembly behind the cutter guard

through the gaps in front and behind the cutter

guard.

4. Place tape back in tape path and place pressure

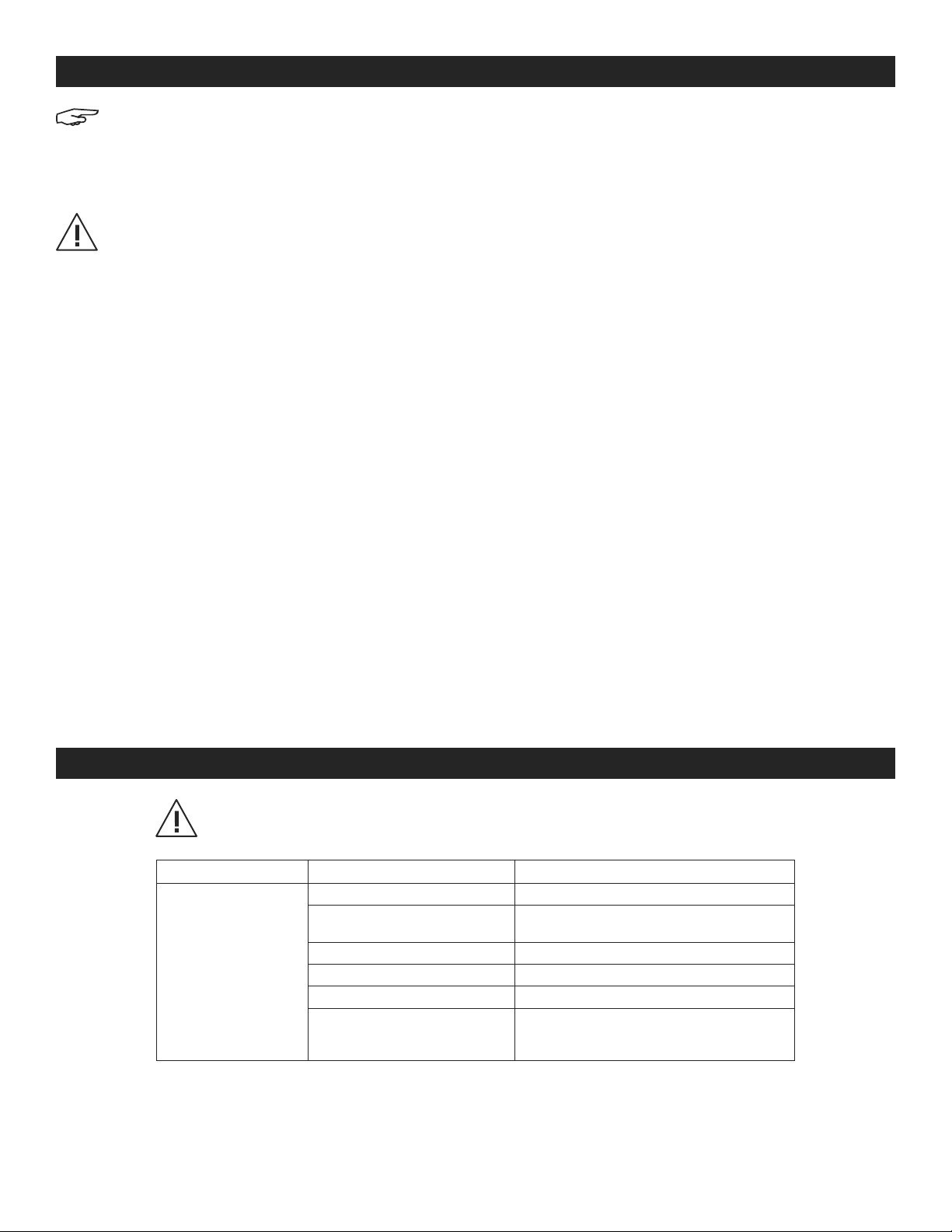

TROUBLESHOOTING

CAUTION! For units with power switch or heater: before performing any

maintenance or repair procedures, turn off power switch and disconnect

from power source.

PROBLEM CAUSE SOLUTION

Tape is jamming,

rearing or won't feed.

Debris is in the tape path. Clean the tape path.

Tape guides are too tight. Adjust the tape guides with the tape guide

Tape is routed incorrectly. Reroute the tape.

Pressure plate is out of the place. Verify the pressure plate is in place.

Too much weight on the brush. Adjust the amount of weight on the brush.

Cutter is not cutting tape. Clean the cutter assembly. If problem

turnbuckle.

persists, contact Uline Customer Service

at 1-800-295-5510.

PAGE 4 OF 15 0521 IH-1358

Page 5

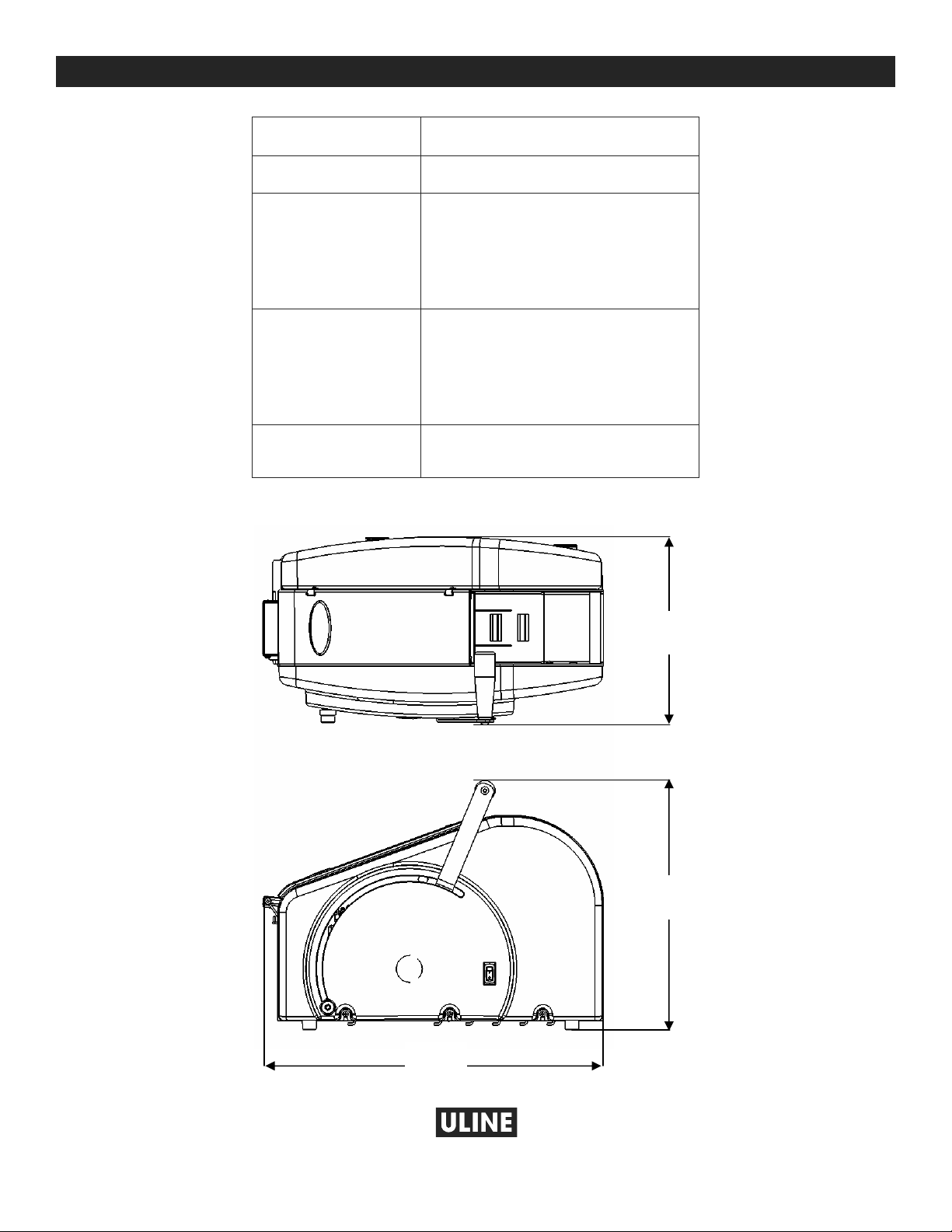

SPECIFICATIONS

1

0

uline.com

SHIPPING WEIGHT 31 LBS. (14.1 KG)

Water Bottle Capacity 70 oz. (2,070 mL)

Tape Dry, gummed tape—paper or reinforced

1 to 3 inches wide (25.4 to 76.2 mm)

Up to 1,000 ft. long (304.8 m)

Up to 9 in. roll diameter (22.86 cm)

Electrical Requirements

(For Units with Heater)

Power Cord Length

(For Units with Heater)

115 volts AC or 220 volts AC

50/60 Hz

4 amps at 115 volts

2 amps at 220 volts 7 ft. (2.3 m)

7 ft. (2.3 m)

10.5"

13.7"

18.9 in

-800-295-551

PAGE 5 OF 15 0521 IH-1358

Page 6

H-1358, H-1359

MARSH®

DESPACHADOR

MANUAL DE CINTA

800-295-5510

uline.mx

INSTRUCCIONES DE CONFIGURACIÓN

CARGAR LA CINTA ADHESIVA

1. Abra la tapa superior.

2. Inserte el rollo de cinta adhesiva. Ajuste

las guías para cinta usando los tornillos

tensores para adaptarlas al ancho de cinta

adhesiva. Deje un margen de 3.22 mm

(1/8") a ambos lados del rollo de cinta.

(Vea Diagrama 1)

3. Quite la placa de presión. (Vea Diagrama 1)

Rodillo de

Presión

Cubierta

Superior

Diagrama 1

Solapa de

la Guía

para Cinta

Izquierda

Placa de

Presión

Rodillo Superior

Tornillo

Tensor

de la Guía

para Cinta

Escala de

Longitud

Tope

Mecánico

PAGE 6 OF 15 0521 IH-1358

Page 7

CONTINUACIÓN DE INSTRUCCIONES DE CONFIGURACIÓN

4. Inserte la cinta, con el lado engomado hacia

abajo, por encima del rodillo, por debajo de las

solapas de las guías para cinta y por debajo del

rodillo de presión. (Vea Diagrama 2)

Ensamble

de la

Cortadora

Eje del

Rodillo de

Presión

Rodillo de

Presión

Placa de

Presión

5. Coloque la placa de presión encima de la cinta y

libere el rodillo de presión. (Vea Diagrama 2)

6. Cierre la tapa superior.

Rodillo Superior

Cinta

Lado

Engomado

de la Cinta

Diagrama 2

Rollo de Cinta

Adhesiva

LLENAR LA BOTELLA PARA AGUA

1. Quite la botella para agua del despachador.

(Vea Diagrama 3)

2. Quite la válvula de pico de pato de la

botella para agua. Llene de agua la botella

para agua. (Vea Diagrama 3)

3. Vuelva a colocar la válvula de pico de pato

dentro de la botella para agua.

4. Vuelva a colocar la botella para agua en el

despachador.

5. Verifique que el poste del tanque del cepillo

esté insertado a través de la válvula de pico

de pato.

Soportes

de la Botella

para Agua

Poste

Diagrama 3

Botella

para Agua

Válvula

de Pico de

Pato

Peso de la

Cinta

Adhesiva

Tanque

del Cepillo

PAGE 7 OF 15 0521 IH-1358

Page 8

CONTINUACIÓN DE INSTRUCCIONES DE CONFIGURACIÓN

AJUSTAR EL NIVEL DE AGUA DEL TANQUE

DEL CEPILLO

1. Afloje los tornillos de los soportes de la botella para

agua.

2. Mueva los soportes de la botella para agua a una

posición que le permita obtener el nivel de agua

deseado en el tanque del cepillo. Ambos soportes

deberán estar en la misma posición. (Vea Diagrama 4)

NOTA: Las cintas ligeras deberán ajustarse

a la posición baja y las cintas pesadas a la

posición alta.

3. Apriete los tornillos de retención de los soportes de

la botella para agua.

AJUSTAR EL PESO DE LA CINTA ADHESIVA

1. Afloje el tornillo de retención.

2. Deslice el peso de la cinta adhesiva hacia

adelante para ejercer más presión. Deslice el

peso de la cinta adhesiva hacia atrás para ejercer

menos presión.

3. Apriete el tornillo de retención.

Diagrama 4

BAJO

LOW

MEDIO

MEDIUM

ALTO

HIGH

NOTA: Las cintas livianas aplicarán menos

agua a la cinta. Las cintas pesadas aplicarán

más agua a la cinta.

INSTRUCCIONES DE FUNCIONAMIENTO

1. Jale del asa hasta el largo deseado en la escala y

libere el asa.

2. Cuando el asa regrese a la posición de descanso,

se cortará la cinta adhesiva.

3. Hay disponible un tope mecánico en el lateral de

despachador en caso de que un largo conocido

se vaya a usar repetidamente.

4. El tope mecánico se puede poner en la posición

deseada aflojando la tuerca estriada media vuelta

y deslizándolo hacia arriba o hacia abajo de la

ranura. Vuelva a apretar la tuerca estriada una vez

que haya encontrado la configuración deseada.

¡PRECAUCIÓN! No quite nunca la tuerca

estriada.

PAGE 8 OF 15 0521 IH-1358

Page 9

MANTENIMIENTO

NOTA: Se requiere poco mantenimiento, pero

es importante que el cepillo, el tanque del

cepillo, el mecanismo de corte y el recorrido

de la cinta se limpien de manera regular.

Limpie el despachador de cinta cuando la

botella para agua necesite rellenarse.

¡PRECAUCIÓN! Para las unidades con un

interruptor de energía o calefactor: antes

de llevar a cabo cualquier procedimiento

de mantenimiento o reparación, apague el

interruptor de energía y desconecte la unidad

de la fuente de alimentación.

LIMPIAR EL SISTEMA DE ALIMENTACIÓN

DE AGUA

1. Limpie el cepillo sumergiéndolo en agua templada

jabonosa. Enjuáguelo con agua templada.

2. Limpie el tanque del cepillo enjuagándolo con

agua templada.

3. Enjuague la botella para agua y la válvula de pico

de pato con agua templada.

3. Usando una pequeña cantidad de lubricante no

inflamable, rocíe el ensamble de la cortadora por

detrás del protector de la cortadora a través de los

huecos de la parte delantera y trasera del protector

de la cortadora.

4. Vuelva a colocar la cinta en el recorrido de la

cinta e inserte de nuevo la placa de presión en la

máquina.

LIMPIAR EL RECORRIDO DE LA CINTA

1. Abra la cubierta superior y quite la placa de

presión.

2. Quite la cinta del recorrido de la cinta.

3. Usando aire comprimido, elimine toda la suciedad

del recorrido de la cinta.

4. Para eliminar la acumulación de adhesivo

engomado, use un paño húmedo para limpiar

todas las partes de láminas de metal del recorrido

de la cinta. Esto incluye el canal de la cinta, la

placa de presión, la cubierta del tanque del cepillo

pesada y el soporte del tanque de agua.

LIMPIAR EL ENSAMBLE DE LA CORTADORA

1. Abra la cubierta superior y quite la placa de

presión.

2. Quite la cinta del recorrido de la cinta.

SOLUCIÓN DE PROBLEMAS

¡PRECAUCIÓN! Para las unidades con un interruptor de energía o calefactor:

antes de llevar a cabo cualquier procedimiento de mantenimiento o

reparación, apague el interruptor de energía y desconecte la unidad de la

fuente de alimentación.

PROBLEMA CAUSA SOLUCIÓN

La cinta adhesiva se

atasca, retrocede o no

se despacha.

Hay suciedad en el recorrido de

la cinta.

Las guías para cinta están

demasiado apretadas.

El recorrido de la cinta es

incorrecto.

La placa de presión está fuera

de su sitio.

Hay demasiado peso sobre el

cepillo.

La cortadora no corta la cinta. Limpie el ensamble de la cortadora. Si el

5. Vuelva a colocar la cinta en el recorrido de la

cinta e inserte de nuevo la placa de presión en la

máquina.

6. Cierre la tapa superior.

Limpie el recorrido de la cinta.

Ajuste las guías para cinta usando los tornillos

tensores.

Corrija el recorrido de la cinta.

Compruebe que la placa de presión esté en

su sitio.

Ajuste la cantidad de peso sobre el cepillo.

problema persiste, contacte con Servicio a

Clientes de Uline llamando al 800-295-5510.

PAGE 9 OF 15 0521 IH-1358

Page 10

ESPECIFICACIONES

8

0

uline.mx

PESO DE ENVÍO 14.1 KG (31 LBS.)

Capacidad de la

botella para agua

Cinta Cinta engomada seca - de papel o reforzada

Requisitos eléctricos

(Para unidades con

calefactor)

Largo del cordón

eléctrico

(Para unidades con

calefactor)

2,070 ml (70 oz.)

Ancho de 25.4 a 76.2 mm (1 a 3 pulgadas)

Largo de hasta 304.8 m (1,000 pies)

Diámetro del rollo de hasta 22.8 cm (9 pulgadas)

115 voltios AC o 220 voltios AC

50/60 Hz

4 amperios a 115 voltios

2 amperios a 220 voltios 2.3 m (7 pies)

2.3 m (7 pies)

48 cm

(18.9")

26.6 cm

(10.5")

34.8 cm

(13.7")

00-295-551

PAGE 10 OF 15 0521 IH-1358

Page 11

H-1358, H-1359

MARSHMD – DÉVIDOIR

MANUEL DE RUBAN

ADHÉSIF

1-800-295-5510

uline.ca

INSTRUCTIONS D'INSTALLATION

CHARGEMENT DU RUBAN ADHÉSIF

1. Ouvrez le capot.

2. Insérez le rouleau de ruban. À l'aide du

tendeur de guide de ruban, réglez les

guides de ruban en fonction de la largeur

du ruban. Laissez un espace de 3,2mm

(1/8po) des deux côtés du rouleau de

ruban. (Voir Figure 1)

3. Retirez la plaque de pression. (Voir Figure1)

Capot

Figure1

Galet

presseur

Rabat

gauche

de guide

de ruban

Plaque de

pression

Rouleau supérieur

Tendeur

de guide

de ruban

Échelle de

longueur

Butée

mécanique

PAGE 11 OF 15 0521 IH-1358

Page 12

INSTRUCTIONS D'INSTALLATION SUITE

4. Faites passer le ruban, le côté gommé vers le bas,

au dessus du rouleau supérieur, en dessous des

rabats de guide de ruban, et en dessous du galet

presseur. (Voir Figure2)

Arbre de

galet presseur

Outil de

coupe

Galet

presseur

Plaque de

pression

5. Placez la plaque de pression sur le ruban et

relâchez le galet presseur. (Voir Figure2)

6. Fermez le capot.

Rouleau

supérieur

Côté gommé

du ruban

Ruban

adhésif

Figure2

Rouleau de

ruban

REMPLISSAGE DE LA BOUTEILLE D'EAU

1. Retirez la bouteille d'eau du dévidoir.

(Voir Figure3)

2. Retirez le clapet à bec de canard de la

bouteille d'eau. Remplissez la bouteille avec

de l'eau. (Voir Figure 3)

3. Remettez le clapet à bec de canard dans la

bouteille d'eau.

4. Remettez la bouteille d'eau sur le dévidoir.

5. Vérifiez que la tige dans le réservoir de la

brosse est insérée à travers le clapet à bec

de canard.

Supports de

bouteille d'eau

Tige

Figure3

Bouteille

d'eau

Clapet à

bec

de canard

Poids du

ruban

Réservoir de

la brosse

PAGE 12 OF 15 0521 IH-1358

Page 13

INSTRUCTIONS D'INSTALLATION SUITE

RÉGLAGE DU NIVEAU D'EAU DU

RÉSERVOIR DE LA BROSSE

1. Desserrez les vis sur les supports de bouteille d'eau.

2. Placez les supports de bouteille d'eau dans une

position permettant d'obtenir le niveau d'eau souhaité

dans le réservoir de la brosse. Les deux supports

doivent être dans la même position. (Voir Figure4)

REMARQUE: Les rubans légers doivent être

réglés en position basse, les rubans lourds

doivent être réglés en position élevée.

3. Serrez les vis de retenue sur les supports de bouteille

d'eau.

RÉGLAGE DU POIDS DU RUBAN

1. Desserrez la vis de retenue.

2. Glissez le poids du ruban vers l'avant pour appliquer

une plus grande pression. Glissez le poids du ruban

vers l'arrière pour appliquer moins de pression.

REMARQUE: Les rubans légers utiliseront moins

d'eau. Les rubans lourds utiliseront plus d'eau.

Figure4

LOW

BAS

MEDIUM

MOYEN

HIGH

ÉLEVÉ

3. Serrez la vis de retenue.

INSTRUCTIONS D'UTILISATION

1. Tirez la poignée d'actionnement jusqu'à la longueur

souhaitée sur l'échelle, puis relâchez la poignée.

2. Lorsque la poignée revient en position de repos, le

ruban est coupé.

3. Si vous utilisez une longueur connue de façon

répétée, une butée mécanique se trouve sur le côté

du distributeur.

4. La butée mécanique peut être déplacée à la

position souhaitée en desserrant l'écrou moleté d'un

demi-tour et en la faisant glisser vers le haut ou vers

le bas dans la fente. Resserrez l'écrou moleté jusqu'à

ce que vous obteniez le réglage souhaité.

MISE EN GARDE! L'écrou moleté ne doit jamais

être retiré.

PAGE 13 OF 15 0521 IH-1358

Page 14

ENTRETIEN

REMARQUE: Le dévidoir ne nécessite que peu

d'entretien, mais il est important d'effectuer un

nettoyage régulier de la brosse, du réservoir

de la brosse, de l'outil de coupe et de la

trajectoire de ruban. Nettoyez le dévidoir de

ruban adhésif lorsque la bouteille d'eau doit

être remplie.

MISE EN GARDE! Pour les unités munies d'un

interrupteur d'alimentation ou d'un élément

chauffant: avant d'effectuer une opération

d'entretien ou de réparation, mettez le dévidoir

hors tension et débranchez-le de la source

d'alimentation.

NETTOYAGE DU SYSTÈME D'ALIMENTATION

D'EAU

1. Nettoyez la brosse en la trempant dans de l'eau

tiède savonneuse. Rincez à l'eau tiède.

2. Nettoyez le réservoir de la brosse en le rinçant à

l'eau tiède.

3. Rincez la bouteille d'eau et le clapet à bec de

canard avec de l'eau tiède.

3. En utilisant une petite quantité de lubrifiant non

inflammable, vaporisez l'outil de coupe derrière le

protecteur de l'outil de coupe à travers les espaces

devant et derrière le protecteur de l'outil de coupe.

4. Remettez le ruban dans la trajectoire de ruban et

replacez la plaque de pression dans l'appareil.

NETTOYAGE DE LA TRAJECTOIRE DE RUBAN

1. Ouvrez le capot et retirez la plaque de pression.

2. Retirez le ruban de la trajectoire de ruban.

3. En utilisant de l'air comprimé, retirez tous les débris

se trouvant sur la trajectoire de ruban.

4. Pour retirer l'accumulation de gomme adhésive,

utilisez un chiffon humide pour essuyer toutes les

pièces en tôle se trouvant dans la trajectoire de

ruban. Inclus la cannelure de ruban, la plaque

de pression, le couvercle du réservoir de la brosse

pondéré et le porte-réservoir d'eau.

5. Remettez le ruban dans la trajectoire de ruban et

replacez la plaque de pression dans l'appareil.

6. Fermez le capot.

NETTOYAGE DE L'OUTIL DE COUPE

1. Ouvrez le capot et retirez la plaque de pression.

2. Retirez le ruban de la trajectoire de ruban.

DÉPANNAGE

MISE EN GARDE! Pour les unités munies d'un interrupteur d'alimentation ou

d'un élément chauffant: avant d'effectuer une opération d'entretien ou de

réparation, mettez le dévidoir hors tension et débranchez-le de la source

d'alimentation.

PROBLÈME CAUSE SOLUTION

Le ruban est coincé,

recule ou ne se

distribue pas.

Des débris se sont accumulés

dans la trajectoire de ruban.

Les guides de ruban sont trop

serrés.

Le ruban n'est pas acheminé

correctement.

La plaque de pression n'est pas

bien placée.

Il y a trop de poids sur la brosse. Réglez la quantité de poids sur la brosse.

L'outil de coupe ne coupe pas

le ruban.

Nettoyez la trajectoire de ruban.

Réglez les guides de ruban à l'aide du

tendeur de guide de ruban.

Réacheminez le ruban.

Vérifiez si la plaque de pression est en

position.

Nettoyez l'outil de coupe. Si le problème

persiste, communiquez avec le service à la

clientèle d'Uline au 1-800-295-5510.

PAGE 14 OF 15 0521 IH-1358

Page 15

SPÉCIFICATIONS

1

0

uline.ca

POIDS D'EXPÉDITION 14,1 KG (31 LB)

Capacité de la

bouteille d'eau

Ruban adhésif Ruban gommé, sec—papier ou renforcé

Exigences électriques

(pour les unités munies

d'un élément chauffant)

Longueur du cordon

d'alimentation

(pour les unités munies

d'un élément chauffant)

2 070 ml (70 oz)

Largeur de 25,4 à 76,2 mm (1 à 3 po)

Longueur jusqu'à 304,8 m (1 000 pi)

Diamètre de rouleau jusqu'à 22,8 cm (9 po)

115 volts c.a. ou 220 volts c.a.

50/60 Hz

4 ampères à 115 volts

2 ampères à 220 volts, 2,3 m (7 pi)

2,3 m (7 pi)

48 cm

(18,9 po)

26,6 cm

(10,5 po)

34,8 cm

(13,7 po)

-800-295-551

PAGE 15 OF 15 0521 IH-1358

Loading...

Loading...