Page 1

H-1030

H-1031

PNEUMATIC ROLL

STAPLER

Para Español, vea páginas 11-20.

Pour le français, consulter les pages 21-30.

1-800-295 -5510

uline.com

STAPLER SPECIFICATIONS

Dimensions (L x H x W): 9 x 9 x 4.5"

Weight (without fasteners): 5.5 lbs.

Compressed Air:

Maximum PSI: 110 psi

Recommended

Operating Pressure: 70–100 psi

Air Co nsumption: 2.4 CFM

Staple Specification: S-860 RR1-58 Roll

Staple Specification: S-861 RR1-34 Roll

Staple Capacity: 1,000 staples

Noise Levels: 89 dBA

WARNING

Before operating this stapler familiarize yourself with the safety warnings and

instructions in this manual. Keep these instructions with the stapler for future

reference. If you have any questions, contact Uline at 1-800-295-5510.

PAGE 1 OF 30 0421 IH-103 0

Page 2

SAFETY INSTRUCTIONS

Connector

Quick

Compressor

GENERAL SAFETY

1. Read the manual and understand all safety

instructions before operating the tool. If you have

questions, contact Uline at 1-800-295-5510.

2. Never use flammable gases as a power source for

the stapler. Only use filtered, compressed air.

3. Never use gasoline or other flammable liquids to

clean the stapler. Vapors left on the stapler could

ignite and cause the tool to explode.

4. Do not exceed 110psi of air pressure when

operating the stapler.

5. Disconnect the stapler from the air supply before

making adjustments, cleaning or clearing jams and

when not in use.

6. Do not pull the trigger when carrying or holding the

stapler.

7. Never carry the stapler by the hose or pull on the

hose to move the stapler.

8. Always wear protective equipment; i.e. safety

glasses, hearing protection and head protection.

9. Do not use a check valve or any other fitting which

allows air to remain in the stapler.

10. Do not place your hand or any other body part in

the staple clinching area or adjustment window

when connecting or disconnecting the air supply.

LUBRICATION & MAINTENANCE

1. Lubricate the stapler prior to initial operation.

2. Disconnect the stapler from the air supply prior to

servicing.

3. Turn the stapler so that the inlet is facing up and put

one drop of high-speed spindle oil, UNOCOL RX22,

or 3-in-1 oil into air inlet. Never use detergent oil or

additives.

4. Operate the tool briefly after adding oil.

5. Wipe off excessive oil at the exhaust. Excessive

oil will damage the O-rings. If inline oiler is used,

manual lubrication through the air inlet is not

required on a daily basis.

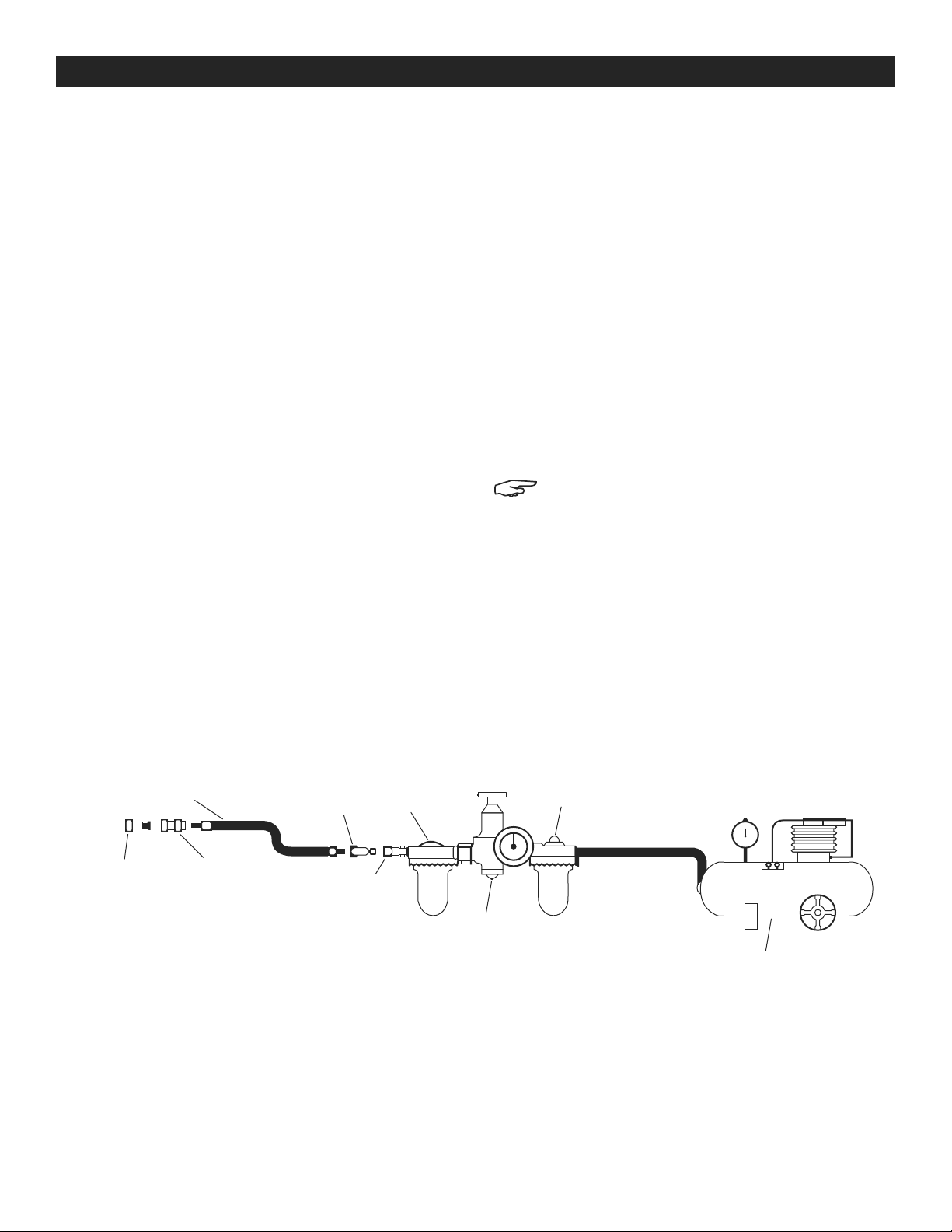

AIR SUPPLY AND CONNECTIONS

NOTE: The following illustration shows the

correct mode of connection to the air supply

system which will increase the efficiency and

life of the stapler.

Many air tool users find it convenient to use an inline

oiler to provide oil circulation through their tool. Check

oil level in the oiler daily.

A filter is recommended on your air compressor. Check

the filter and drain on a daily basis.

11. Never point the stapler at yourself or anyone else.

PAGE 2 OF 30 0421 IH-103 0

Quick

Air Hose

Quick

Coupler

Connector Oiler

Quick

Coupler

Filter

Regulator

Page 3

SAFETY INSTRUCTIONS CONTINUED

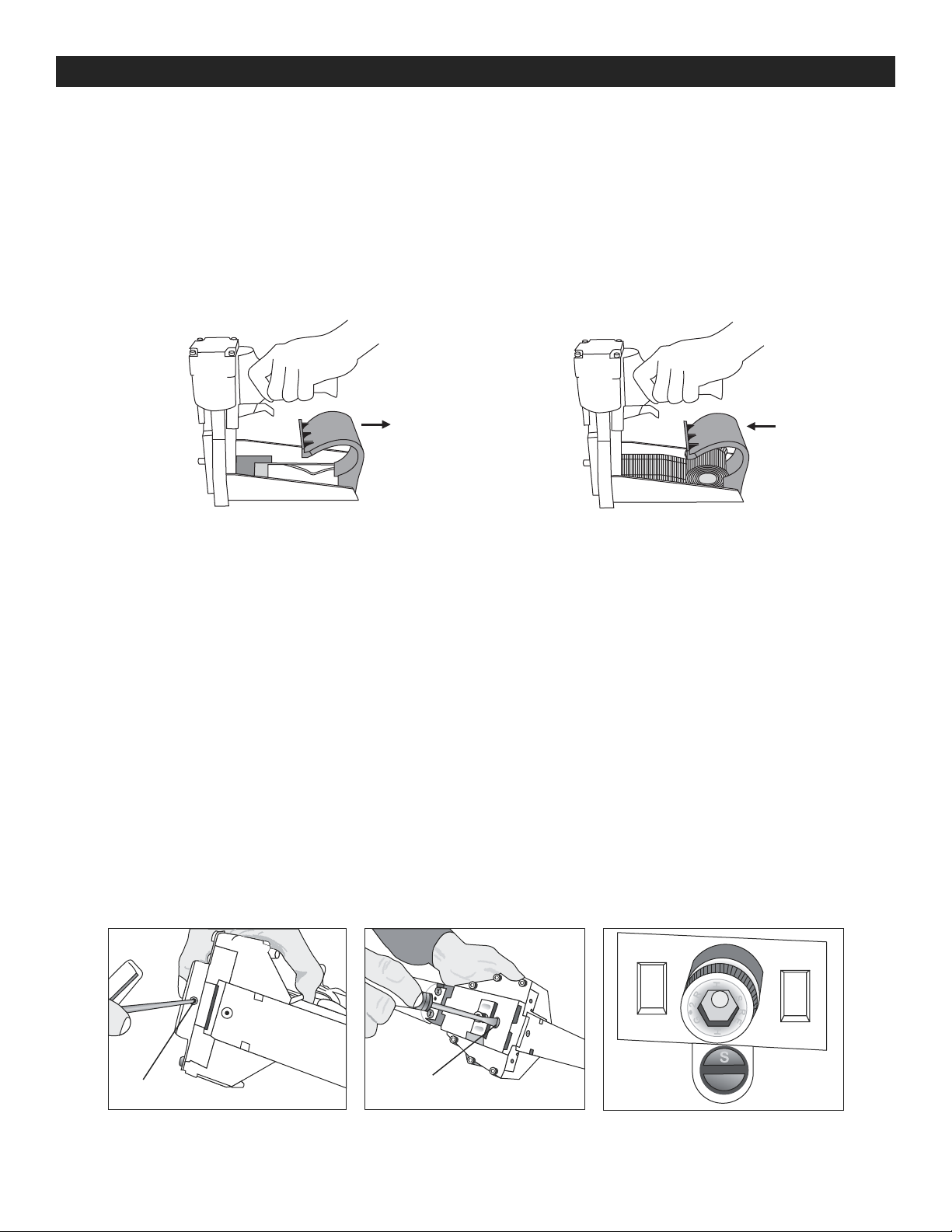

LOADING THE STAPLER

1. Disconnect the air supply.

2. Slightly squeeze the cover back, then pull the top

cover open. (See Figure 1)

3. Place coil staples in magazine. Feed front end

of coil staples into right coil guide, left coil guide

and top guide. Push forward until stopping in driver

guide unit. (See Figure 2)

4. Swing cover closed and squeeze to snap closed.

Check position engagement. (See Figure 2)

Figure 1 Figure 2

STAPLE LEG LENGTH

1. Loosen the set screw on the bottom with a 3mm

Allen wrench. (See Figure 3)

2. Adjust L/S screw with a screwdriver to the desired

setting. (See Figure 4)

a. If you are using 3/4" staples set L up.

b. If you are using 5/8" staples set S up. (See Figure 5)

3. Tighten the set screw on the bottom.

Set Screw

Figure 3 Figure 4 Figure 5

PAGE 3 OF 30 0421 IH-103 0

L/S Screw

L

Page 4

SAFETY INSTRUCTIONS CONTINUED

Loose

No. 4

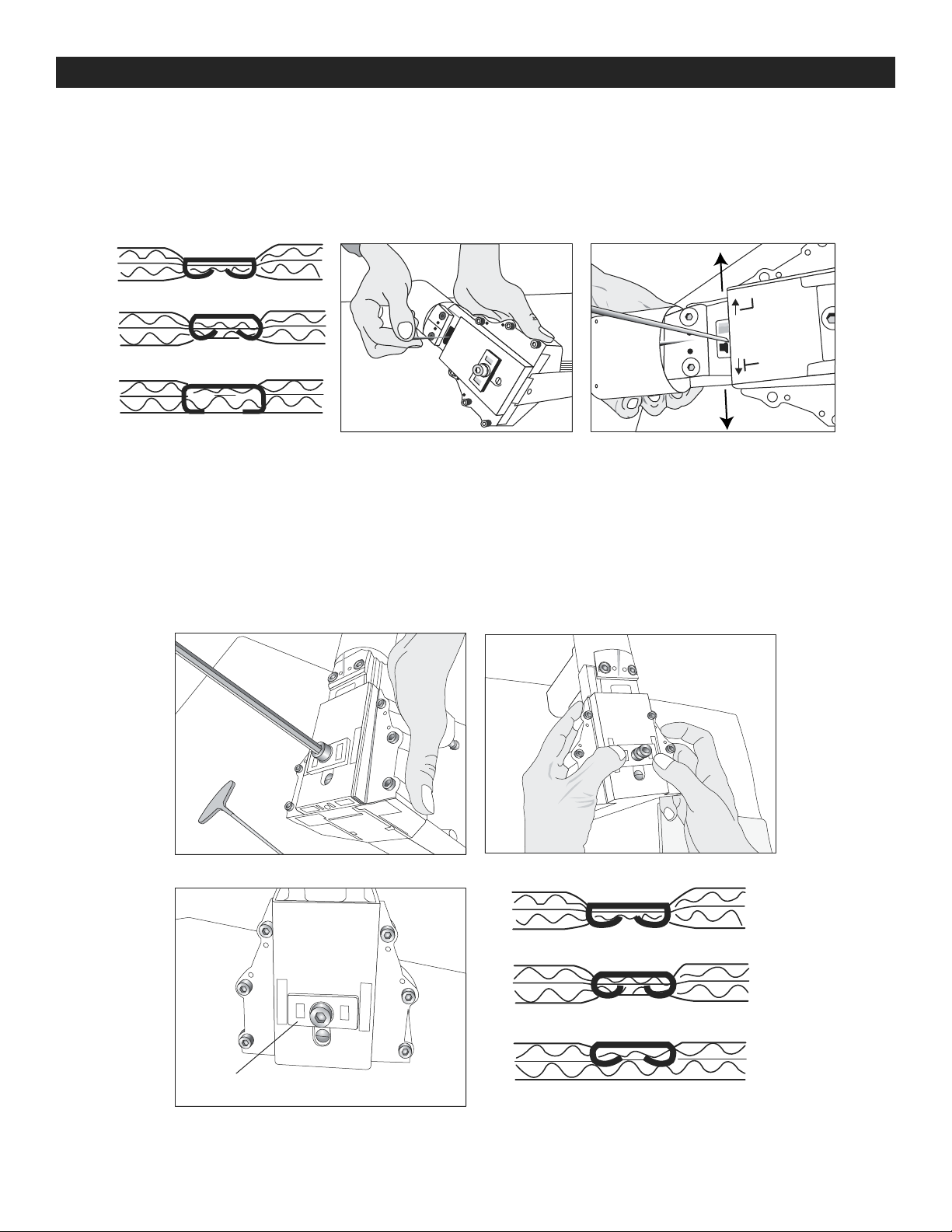

CLINCH ADJUSTMENT

Use 2.5mm Allen wrench and turn collar through window

clockwise to tighten clinch. (See Figure 6)

Tight

Medium

Figure 6

DEPTH ADJUSTMENT

1. Loosen front screw with a 6mm Allen wrench.

(See Figure 7)

2. Push the body up and adjust to the desired depth.

(See Figure 8)

Loosen

Tighten

3. When the top edge of the adjustment plate is at

its highest setting, the teeth are at their shallowest

penetration. (See Figure 9)

4. If set at No. 1 the teeth are at their deepest

penetration. (See Figure 10)

Figure 7

Figure 8

No. 1

No. 2 & 3

Adjustment Plate

Figure 9

PAGE 4 OF 30 0421 IH-103 0

Figure 10

Page 5

OPERATING INSTRUCTIONS

WARNING

1. Protect your eyes and ears.

a. Wear safety glasses with side shields

b. Wear hearing protection.

c. Ensure that anyone in the vicinity wears safety protection.

2. To prevent accidental injuries, never place a hand or any other body part in

the staple clinching area or adjustment window.

3. Never point the stapler towards you or anyone else.

4. Always handle the stapler with care. Never pull the trigger unless tool is ready

for operation.

5. Check and replace any damaged or worn components on the stapler.

1. Add a few drops of oil into the air inlet.

2. Install a quick connect fitting to the stapler.

3. Regulate the air pressure to attain 70–100 psi.

4. Insert the staples into the tool following the loading

instructions.

WARNING

Never use gasoline or other flammable liquids to clean

the stapler. Vapors in the stapler could be ignited by a

spark and cause the stapler to explode.

CLEANING THE STAPLER

1. Disconnect the air supply from the stapler.

2. Remove tar buildup with non-corrosive cleaner.

CAUTION! Do not allow solvent to get into the

cylinder or damage may occur.

5. Reconnect the air hose to the stapler.

6. Grasp the handle with one hand on box in line

with the desired staple location. There is a small

projection on either side of the magazine seat as

an aid in locating the position of the staple.

7. The strongest closure requires staples close to the

ends of the box.

3. Dry the stapler completely before use.

PAGE 5 OF 30 0421 IH-103 0

Page 6

OPERATING INSTRUCTIONS CONTINUED

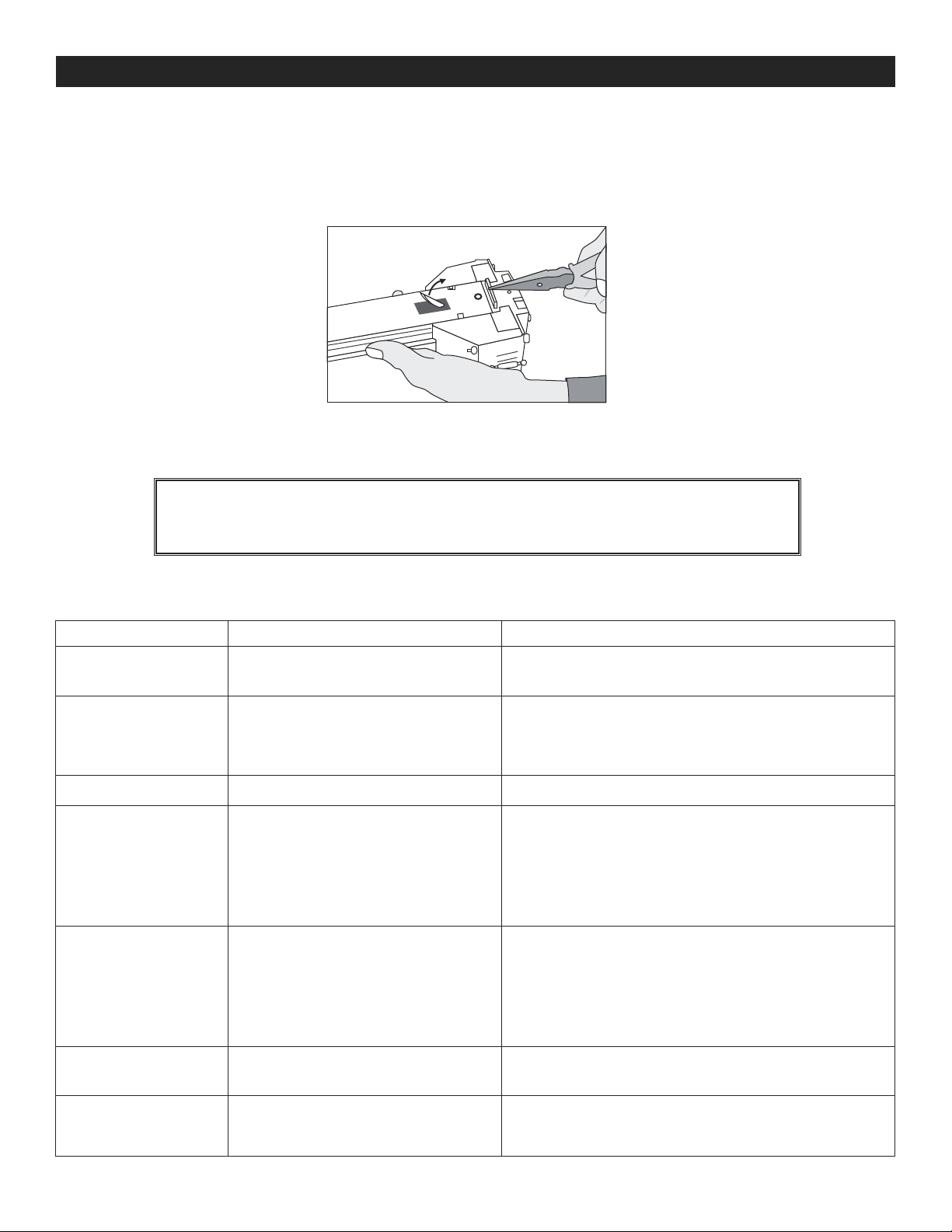

CLEARING A JAM

1. Disconnect air supply.

2. Pull up lever. (See FIgure 11)

Stop using the stapler immediately if any of the following problems occur.

Serious personal injury could occur. Any repairs or replacements must be done

by a qualified person or authorized service center only.

3. Insert needle nose pliers or screw driver to clear jam.

(See Figure 11)

4. Push down lever.

Figu r e 11

WARNING

TROUBLESHOOTING

PROBLEM CAUSE REMEDY

Air leak from trigger O-ring on valve or on tube is

damaged.

Air leak from exhaust

port

Air leak from cylinder Piston rod port O-ring is damaged. Replace O-ring.

Slow & short travel

cycling

Excessive jams 1. Slow & short travel cycle.

O-Ring on valve or on tube is

damaged.

O-Ring on piston is damaged.

Check for loose screw or wear of

parts.

2. Teeth screws are loose.

3. Wrong staple size.

4. Insufficient lubrication.

Replace O-ring.

Replace O-ring.

1. Position eccentric pin and tighten screw.

2. Recheck for maximum efficiency.

a. Adjust pin slightly upward if due to short travel.

b. Adjust pin slightly downward if due to slow cycling.

1. Adjust as noted above.

2. Tighten screws.

3. Check staples.

4. Clean and lubricate.

Uneven clinch Wrong staple size. Check for proper leg length adjustment and

clincher size.

Unclinched staple 1. Teeth are loose or broken.

2. Slow & short travel cycle.

PAGE 6 OF 30 0421 IH-103 0

1. Check & replace teeth as needed.

2. Adjust as noted above.

Page 7

TEETH REPLACEMENT

OPERATING INSTRUCTIONS CONTINUED

1. Loosen screws and nut with an 8mm wrench and

4mm Allen wrench. (See Figure 12)

2. Remove the magazine assembly. (See Figure 13)

Figure 12 Figure 13

3. Loosen screws with 3mm Allen wrench.

(See Figure 14)

4. Change teeth one at a time to prevent reverse

teeth.

Fi g ure 14

PAGE 7 OF 30 0421 IH-103 0

Page 8

DRIVER REPLACEMENT

OPERATING INSTRUCTIONS CONTINUED

1. Disconnect the air supply.

2. Loosen screw and nut with a 8mm spanner wrench

and a 4mm Allen wrench. (See Figure 15)

3. Remove the magazine assembly. (See Figure 16)

4. Loosen the set screw with a 3mm Allen wrench to

unlock the adjusting rod.

Figure 15

5. Slide the linkage mechanism and adjusting rod

simultaneously from the collar. (See Figure 17)

6. Loosen the screws with a 3mm Allen wrench.

(See Figure 18)

7. Take off the spring pin with a hammer and 6mm

straight rod. (See Figure 19)

Magazine Assembly

Figure 16

Figure 17

Figure 19

PAGE 8 OF 30 0421 IH-103 0

Figure 18

Page 9

OPERATING INSTRUCTIONS CONTINUED

VALVE AND TUBE O-RING REPLACEMENT

1. Loosen screws with a flat screw driver. (See Figure 20)

2. Remove spring with needle-nose pliers.

(See Figure 21)

Figure 20

3. Remove C-ring with C-ring pliers. (See Figure 22)

4. Remove valve and tube with needle-nose pliers.

(See Figure 23)

Figure 21

Figure 22

C-ring

Valve and Tube

Figure 23

PAGE 9 OF 30 0421 IH-103 0

Page 10

PISTON REPLACEMENT

1

0

uline.com

OPERATING INSTRUCTIONS CONTINUED

1. Remove screws and nut with 8mm Spanner wrench

and 4 mm Allen wrench. (See Figure 24)

2. Remove magazine assembly. (See Figure 25)

3. Loosen set screw with a 3mm Allen wrench to unlock

the adjusting rod.

4. Slide linkage mechanism and adjusting rod

simultaneously from collar.

5. Loosen collar with a 3mm straight rod to remove the

spring. (See Figure 26)

6. Loosen screw with a 3mm Allen wrench and remove

the block through the window.

7. Loosen screws with a 3mm Allen wrench and remove

the cap. (See Figure 27)

8. Remove the piston assembly with a 10mm Spanner

wrench. (See FIgure 28)

9. Remove piston and replace.

Spring

Figure 24

Figure 27

Cap

Figure 25

Figure 28

Magazine Assembly

Figure 26

Piston Assembly

-800-295-551

PAGE 10 OF 30 0421 IH-103 0

Page 11

H-1030

H-1031

ENGRAPADORA

NEUMÁTICA DE

ROLLO

800-295 -5510

uline.mx

ESPECIFICACIONES DE LA ENGRAPADORA

Dimensiones (LA x AL x AN): 23 x 23 x 11.5 cm

(9 x 9 x 4.5")

Peso (sin cinchos): 2.5 kg (5.5 lbs.)

Aire comprimido:

PSI Máximo: 110 PSI

Presión operativa

Recomendada: 70–100 PSI

Consumo de aire: 0.07 m³/min (2.4 pie³/min)

Especificación de las grapas: S-860 RR1-58 Rollo

Especificación de las grapas: S-861 RR1-34 Rollo

Capacidad de engrapar: 1,000 grapas

Niveles de ruido: 89 dBA

ADVERTENCIA

Familiarícese con las advertencias de seguridad e instrucciones de este

manual antes de utilizar esta engrapadora. Mantenga estas instrucciones

junto con la engrapadora para futuras consultas. Contacte a Servicio a

Clientes al 800-295-5510 si tiene alguna duda.

PAGE 11 OF 30 0421 IH-103 0

Page 12

INSTRUCCIONES DE SEGURIDAD

Conector

Conector

Compresor

SEGURIDAD GENERAL

1. Lea el manual y comprenda todas las instrucciones

de seguridad antes de utilizar la herramienta.

Contacte a Uline al 800-295-5510 si tiene

alguna duda.

2. Nunca utilice gases inflamables como fuente de

energía para la engrapadora. Utilice solamente

aire comprimido filtrado.

3. Nunca use gasolina ni otros líquidos inflamables

para limpiar la engrapadora. Los vapores que

quedan en la engrapadora podrían encenderse y

causar la explosión de la herramienta.

4. No exceda los 110 psi de presión de aire cuando

opere la engrapadora.

5. Desconecte la engrapadora del suministro de aire

antes de hacer ajustes, limpiar o eliminar atascos y

cuando no esté en uso.

6. No jale el gatillo cuando transporte o sujete la

engrapadora.

7. Nunca sostenga la engrapadora por la manguera

ni jale la manguera para mover la engrapadora.

8. Siempre use equipo de protección; por ejemplo,

lentes de seguridad, protección auditiva y

protección de la cabeza.

9. No use una válvula de control ni cualquier otro

conector que permita que el aire permanezca

dentro de la engrapadora.

LUBRICACIÓN Y MANTENIMIENTO

1. Lubrique la engrapadora antes de la operación

inicial.

2. Desconecte la engrapadora del suministro de aire

antes de repararla.

3. Gire la engrapadora de modo que la entrada

quede hacia arriba y ponga una gota de aceite

para husos de alta velocidad, UNOCOL RX22, o

aceite 3-en-1, en la entrada de aire. Nunca utilice

aceite detergente ni aditivos.

4. Opere la herramienta brevemente después de

lubricar.

5. Limpie el exceso de aceite del tubo de escape.

El exceso de aceite puede dañar los anillos-o. Si

se utiliza el engrasador en línea, no es necesario

realizar diariamente la lubricación manual a través

de la entrada de aire.

SUMINISTRO DE AIRE Y CONEXIONES

NOTA: La siguiente ilustración muestra el modo

correcto de conexión al sistema de suministro

de aire, el cual aumentará la eficiencia y la

vida útil de la engrapadora.

A muchos usuarios de herramientas neumáticas les

resulta conveniente utilizar un lubricador de línea para

proporcionar circulación del aceite a través de su

herramienta. Revise el nivel de aceite en el lubricador

diariamente.

10. No coloque las manos ni ninguna otra parte del

cuerpo en la zona de engrapado y remachado ni

en la ventana de ajuste al conectar o desconectar

el suministro de aire.

11. Nunca apunte la engrapadora hacia usted ni

hacia ninguna otra persona.

Manguera de aire

Acople

Rápido

PAGE 12 OF 30 0421 IH-103 0

Rápido

Rápido Lubricador

Acople

Rápido

Se recomienda poner un filtro en su compresor de aire.

Revise el filtro y vacíelo diariamente.

Filtro

Regulador

Page 13

CONTINUACIÓN DE INSTRUCCIONES DE SEGURIDAD

CÓMO CARGAR LA ENGRAPADORA

1. Desconecte el suministro de aire.

2. Apriete ligeramente la cubierta posterior y después

jale para abrir la cubierta superior. (Vea Diagrama

3. Coloque el rollo de grapas en el cargador. Pase el

extremo delantero del rollo de grapas al interior de

las guías de bobina derecha, izquierda y superior.

1)

Empuje hacia adelante hasta que se detenga en la

unidad de guía del impulsor. (Vea Diagrama 2)

4. Cierre la cubierta y apriete para que cierre

a presión. Verifique que se haya enganchado

en su posición. (Vea Diagrama 2)

Diagrama 1

LARGO DE PATA DE LA GRAPA

1. Afloje el tornillo de ajuste de la parte inferior con

una llave Allen de 3 mm. (Vea Diagrama 3)

2. Apriete el tornillo L/S con un destornillador hasta el

ajuste deseado. (Vea Diagrama 4)

a. Si está utilizando grapas de 1.9 cm (3/4"), ajuste L.

b. Si está utilizando grapas de 1.5 cm (5/8"), ajuste S.

(Vea Diagrama 5)

Diagrama 2

3. Apriete el tornillo de ajuste de la parte inferior.

Tornillo de Ajuste

Diagrama 3 Diagrama 4 Diagrama 5

PAGE 13 OF 30 0421 IH-103 0

Tornillo L/S

L

Page 14

No. 4

CONTINUACIÓN DE INSTRUCCIONES DE SEGURIDAD

Flojo

AJUSTE DE REMACHE

Utilice una llave Allen de 2.5 mm y gire el collarín hacia

la derecha a través de la ventana para apretar el

remache. (Vea Diagrama 6)

Apretado

Mediano

Diagrama 6

AJUSTE DE PROFUNDIDAD

1. Afloje el tornillo frontal con una llave Allen de 6 mm.

(Vea Diagrama 7)

2. Empuje el cuerpo hacia arriba y ajuste a la

profundidad deseada.(Vea Diagrama 8)

Aflojar

Apretar

3. Cuando el borde superior de la placa de ajuste

esté en su configuración más alta, los dientes están

en la penetración más superficial. (Vea Diagrama 9)

4. Si está configurado en el No. 1, los dientes están en

su penetración más profunda. (Vea Diagrama 10)

Diagrama 7

Diagrama 8

No. 1

No. 2 & 3

Placa de Ajuste

Diagrama 9

PAGE 14 OF 30 0421 IH-103 0

Diagrama 10

Page 15

FUNCIONAMIENTO

ADVERTENCIA

1. Proteja sus ojos y orejas.

a. Use lentes de seguridad con protección lateral

b. Use protección auditiva.

c. Asegúrese de que cualquier persona en las proximidades lleve protección de

seguridad.

2. Para evitar lesiones accidentales, nunca coloque las manos ni ninguna otra parte

del cuerpo en la zona de engrapado y remachado ni en la ventana de ajuste.

3. Nunca apunte la engrapadora hacia usted ni hacia ninguna otra persona.

4. Siempre manipule la engrapadora con cuidado. Nunca jale el gatillo a menos que

la herramienta esté lista para operar.

5. Revise y reemplace los componentes dañados o desgastados de la engrapadora.

1. Añada unas gotas de aceite en la entrada de aire.

2. Instale un acople de conexión rápida en la

engrapadora.

3. Regule la presión de aire hasta que alcance de 70

a 100 psi.

4. Inserte las grapas en la herramienta siguiendo las

instrucciones de carga.

ADVERTENCIA

Nunca use gasolina ni otros líquidos inflamables para limpiar

la engrapadora. Los vapores de la engrapadora podrían

encenderse con una chispa y causar que la engrapadora estalle.

LIMPIEZA DE LA ENGRAPADORA

1. Desconecte el suministro de aire de la engrapadora.

2. Elimine la acumulación de alquitrán con un limpiador no

corrosivo.

5. Vuelva a conectar la manguera de aire a la

engrapadora.

6. Sujete el asa con una mano y colóquela en la

caja alineando con la ubicación deseada de la

grapa. Hay una proyección pequeña en cada

lado del soporte del cargador que permite ubicar

la posición de la grapa.

7. El cierre más fuerte requiere grapas cerca de los

extremos de la caja.

¡PRECAUCIÓN! No permita que el disolvente entre

en el cilindro. ya que podrían ocurrir daños.

3. Seque la engrapadora completamente antes de su uso.

PAGE 15 OF 30 0421 IH-103 0

Page 16

CONTINUACIÓN DE FUNCIONAMIENTO

ELIMINAR UN ATASCO

1. Desconecte el suministro de aire.

2. Hale la palanca hacia arriba. (Vea Diagrama 11)

Diagrama 11

3. Inserte unas pinzas de punta fina o un destornillador

para eliminar el atasco. (Vea Diagrama 11)

4. Empuje la palanca hacia abajo.

ADVERTENCIA

Deje de usar la engrapadora de inmediato si presenta cualquiera de los siguientes problemas. Podrían

ocurrir lesiones personales graves. Todas las reparaciones o reemplazos deben ser realizados solamente

por una persona calificada o en un centro de servicios autorizado.

SOLUCIÓN DE PROBLEMAS

PROBLEMA CAUSA REMEDIO

Fuga de aire en el

gatillo

Fuga de aire en el

orificio de escape

Fuga de aire en el

cilindro

Ciclos de

desplazamiento

cortos y lentos

Atascos excesivos

El anillo-o de la válvula o en el tubo

está dañado.

El anillo-o de la válvula o en el tubo

está dañado.

El anillo-o del pistón está dañado.

El anillo-o de la varilla de pistón está

dañado.

Verifique que no haya tornillos sueltos

ni piezas desgastadas.

1. Ciclo de desplazamiento corto y lento

2. Los dientes de los tornillos están flojos.

3. Tamaño de la grapa incorrecto.

4. Lubricación insuficiente.

Reemplace el anillo-o.

Reemplace el anillo-o.

Reemplace el anillo-o.

1. Ponga el pasador excéntrico en su posición y

apriete el tornillo.

2. Vuelva a verificar para una máxima eficiencia.

a. Ajuste el pasador ligeramente hacia arriba si se

debe a que el desplazamiento es muy corto.

b. Ajuste el pasador ligeramente hacia abajo si se

debe a que el ciclo es muy lento.

1. Ajuste como se señaló anteriormente.

2. Apriete los tornillos.

3. Revise las grapas.

4. Limpie y lubrique.

Remache irregular

Grapa sin

remache.

PAGE 16 OF 30 0421 IH-103 0

Tamaño de la grapa incorrecto. Verifique el correcto ajuste de la longitud de la

pata y el tamaño del remachador.

1. Los dientes están flojos o rotos.

2. Ciclo de desplazamiento corto y lento

1. Revise y reemplace los dientes según sea necesario.

2. Ajuste como se señaló anteriormente.

Page 17

REEMPLAZO DE DIENTES

CONTINUACIÓN DE FUNCIONAMIENTO

1. Afloje los tornillos y la tuerca con una llave de 8 mm

y una llave Allen de 4 mm. (Vea Diagrama 12)

2. Retire el ensamble del cargador. (Vea Diagrama 13)

Diagrama 12 Diagrama 13

3. Afloje los tornillos con la llave Allen de 3 mm.

(Vea Diagrama 14)

4. Cambie los dientes uno a la vez para no ponerlos

en el orden inverso.

Diagrama 14

PAGE 17 OF 30 0421 IH-103 0

Page 18

CONTINUACIÓN DE FUNCIONAMIENTO

REEMPLAZO DEL IMPULSOR

1. Desconecte el suministro de aire.

2. Afloje el tornillo y la tuerca con una llave de 8 mm y

una llave Allen de 4 mm. (Vea Diagrama 15)

3. Retire el ensamble del cargador. (Vea Diagrama 16)

4. Afloje el tornillo de ajuste con una llave Allen de 3

mm para destrabar la varilla de ajuste.

Diagrama 15

5. Retire el mecanismo de unión y ajuste la varilla

de forma simultánea desde el cuerpo.

(Vea Diagrama 17)

6. Afloje los tornillos con una llave Allen de 3 mm.

(Vea Diagrama 18)

7. Retire el perno con resorte con un martillo y una

varilla recta de 6 mm. (Vea Diagrama 19)

Ensamble del Cargador

Ensamble del Cargador

Diagrama 16

Diagrama 17

Diagrama 19

PAGE 18 OF 30 0421 IH-103 0

Diagrama 18

Page 19

CONTINUACIÓN DE FUNCIONAMIENTO

REEMPLAZAR LA VÁLVULA Y EL TUBO DEL

ANILLO-O

1. Afloje los tornillos con un destornillador plano. (Vea

Diagrama 20)

2. Retire el resorte con pinzas de punta fina.

(Vea Diagrama 21)

3. Retire el anillo-C con pinzas para anillos-C.

(Vea Diagrama 22)

4. Retire la válvula y el tubo con pinzas de punta fina.

(Vea Diagrama 23)

Diagrama 20

Diagrama 22

Anillo-C

Diagrama 21

Válvula y tubo

Diagrama 23

PAGE 19 OF 30 0421 IH-103 0

Page 20

REEMPLAZAR EL PISTÓN

8

0

uline.mx

CONTINUACIÓN DE FUNCIONAMIENTO

1. Retire los tornillos y la tuerca con una llave de 8 mm

y una llave Allen de 4 mm. (Vea Diagrama 24)

2. Retire el ensamble del cargador. (Vea Diagrama 25)

3. Afloje el tornillo de ajuste con una llave Allen de 3

mm para destrabar la varilla de ajuste.

4. Retire el mecanismo de unión y ajuste la varilla de

forma simultánea desde el cuerpo.

5. Afloje el collarín con una varilla recta de 3 mm para

retirar el resorte. (Vea Diagrama 26)

6. Afloje el tornillo con una llave Allen de 3 mm y retire

el bloque a través de la ventana.

7. Afloje los tornillos con una llave Allen de 3 mm y

retire la tapa. (Vea Diagrama 27)

8. Retire el ensamblado de pistón con una llave de 10

mm. (Vea Diagrama 28)

9. Retire el pistón y remplace.

Resorte

Diagrama 24

Diagrama 27

Tapa

Diagrama 25

Diagrama 28

Ensamble del Cargador

Ensamble del Cargador

Ensamble de Pistón

Diagrama 26

00-295-551

PAGE 20 OF 30 0421 IH-103 0

Page 21

H-1030

H-1031

AGRAFEUSE

PNEUMATIQUE

À ROULEAU

1-800-295 -5510

uline.ca

SPÉCIFICATIONS DE L'AGRAFEUSE

Dimensions (long.xhaut.xlarg.) : 23x23x11,5cm

(9x9x4,5po)

Poids (sans agrafes) : 2,5kg (5,5lb)

Air comprimé:

Pression maximum: 6,9bars (110lb/po²)

Pression de service

recommandée: 4,9 à 6,9bars (70 à 100lb/po²)

Débit d'air: 0,07mcm (2,4pcm)

Spécification des agrafes: Rouleau S-860 RR1-58

Spécification des agrafes: Rouleau S-861 RR1-34

Capacité d'agrafes: 1000 agrafes

Volume sonore: 89dBA

AVERTISSEMENT

Avant d'utiliser cette agrafeuse, prenez connaissance des avertissements et

consignes de sécurité qui figurent dans ce manuel. Conservez ces instructions avec l'agrafeuse pour future référence. Pour toutes questions, communiquez avec Uline au 1-800-295-5510.

PAGE 21 OF 30 0421 IH-103 0

Page 22

CONSIGNES DE SÉCURITÉ

branchement

Raccord à

Compresseur

SÉCURITÉ GÉNÉRALE

1. Lisez ce manuel et assurez-vous de comprendre

toutes les consignes de sécurité avant d'utiliser

l'agrafeuse. Pour toute question, communiquez avec

Uline au 1800295-5510.

2. N'alimentez jamais l'agrafeuse avec des gaz

inflammables. Utilisez uniquement de l'air comprimé

filtré.

3. Ne nettoyez jamais l'agrafeuse avec de l'essence ou

autres liquides inflammables. Les vapeurs résiduelles

laissées sur l'agrafeuse peuvent s'enflammer et

provoquer l'explosion de l'agrafeuse.

4. N'opérez pas l'agrafeuse à une pression d'air

supérieure à 6,9bars (110lb/po²).

5. Déconnectez l'agrafeuse de l'alimentation en air

avant d'effectuer des réglages, de la nettoyer,

d'éliminer des obstructions et lorsque vous ne

l'utilisez pas.

6. N'actionnez pas la détente lorsque vous transportez

ou tenez l'agrafeuse.

7. Ne jamais transporter, ni tirer l'agrafeuse par la

conduite d'air.

8. Portez toujours de l'équipement de protection

individuelle; c.-à-d., lunette de sécurité, protection

de l'ouïe et protection pour la tête.

9. N'utilisez aucune soupape de non-retour ou tout

autre raccord qui permet à l'air de demeurer dans

l'agrafeuse.

10. Ne placez pas votre main ou toute autre partie de

votre corps dans la zone de fermeture d'agrafe ou

dans la fenêtre de réglage lors de la connexion ou

la déconnexion de l'alimentation d'air.

LUBRIFICATION ET ENTRETIEN

1. Lubrifiez l'agrafeuse avant son utilisation initiale.

2. Déconnectez l'agrafeuse de la source

d'alimentation d'air avant tout entretien.

3. Tournez l'agrafeuse de façon à orienter l'entrée

vers le haut, puis déposez une (1) goutte d'huile

à broche haute vitesse, UNOCOL RX22, ou huile

3en1, dans l'entrée d'air. N'employez jamais d'huile

de détergent ou d'additifs.

4. Actionnez brièvement l'agrafeuse suivant l'ajout

d'huile.

5. Essuyez l'excès d'huile à l'échappement. L'excès

d'huile endommagera les joints toriques. L'utilisation

d'un huileur en ligne élimine le besoin d'effectuer

une lubrification manuelle quotidienne par l'entrée

d'air.

ALIMENTATION EN AIR ET RACCORDS

REMARQUE: L'illustration ci-dessous présente

le mode de raccordement approprié au

système d'alimentation en air, qui augmentera

l'efficacité et la durée de vie de l'agrafeuse.

Plusieurs utilisateurs d'agrafeuses pneumatiques

trouvent commode d'assurer la circulation d'huile dans

l'agrafeuse au moyen d'un huileur en ligne. Contrôlez le

niveau d'huile dans l'huileur tous les jours.

Il est recommandé de doter votre compresseur d'air

d'un filtre. Contrôlez le filtre et le drain sur une base

quotidienne.

11. Ne pointez jamais l'agrafeuse sur vous-même ou sur

une autre personne.

PAGE 22 OF 30 0421 IH-103 0

Conduite d’air

Raccord à

rapide

Connecteur

rapide

branchement

rapide

Connecteur

rapide

Huileur

Filtre

Régulateur

Page 23

CONSIGNES DE SÉCURITÉ SUITE

CHARGEMENT DE L'AGRAFEUSE

1. Déconnectez l'alimentation d'air.

2. Pincez légèrement le couvercle vers l'arrière, puis

ouvrez le couvercle supérieur. (Voir Figure 1)

3. Placez le rouleau d'agrafes dans le magasin.

Acheminez l'extrémité avant du rouleau d'agrafes

dans le guide droit de rouleau, le guide gauche de

rouleau et le guide supérieur. Poussez vers l'avant

jusqu'à ce qu'elle butte dans le guide de lame de

poussée. (Voir Figure 2)

4. Refermez le couvercle en le comprimant pour

l'enclencher. Vérifiez la position d'engagement.

(Voir FIgure 2)

Figure 1 Figure 2

LONGUEUR DE PATTE D'AGRAFE

1. Desserrez la vis de réglage qui se trouve sous

l'agrafeuse à l'aide d'une clé Allen 3mm.

(Voir Figure3)

2. Ajustez la vis L/S au réglage désiré à l'aide d'un

tournevis. (Voir Figure 4)

a. Si vous utilisez des agrafes de 19mm (3/4 po)

orientez la lettre L vers le haut.

b. Si vous utilisez des agrafes de 16mm (5/8po)

orientez la lettre S vers le haut. (Voir FIgure 5)

3. Serrez la vis de réglage sous l'agrafeuse.

Vis de

réglage

Figure 3 Figure 4 Figure 5

PAGE 23 OF 30 0421 IH-103 0

Vis L/S

L

Page 24

CONSIGNES DE SÉCURITÉ SUITE

Lâche

N° 4

RÉGLAGE DE LA FERMETURE

Serrez la fermeture en tournant le collet dans le sens

horaire à travers la fenêtre à l'aide d'une clé Allen

2,5mm. (Voir Figure 6)

Serrée

Moyenne

Figure 6

RÉGLAGE DE LA PROFONDEUR

1. Desserrez la vis avant à l'aide d'une clé Allen 6mm.

(Voir Figure 7)

2. Poussez le corps vers le haut et réglez l'ensemble à

la profondeur voulue. (Voir Figure 8)

Desserrer

Serrer

3. Quand le rebord supérieur de la plaque de réglage

est à sa position la plus élevée, les dents présentent

la pénétration la moins profonde. (Voir Figure 9)

4. Si réglées au N° 1, les dents présentent la

pénétration la plus profonde. (Voir Figure 10)

Figure 7

Figure 8

N° 1

N° 2 et 3

Plaque de réglage

Plaque de réglage

Figure 9

PAGE 24 OF 30 0421 IH-103 0

Figure 10

Page 25

INSTRUCTIONS D'UTILISATION

AVERTISSEMENT

1. Protégez vos yeux et vos oreilles.

a. Portez des lunettes de sécurité avec écrans latéraux

b. Portez un dispositif de protection de l'ouïe.

c. Assurez-vous que toute personne à proximité porte des dispositifs

de protection.

2. Afin d'éviter toute blessure accidentelle, ne placez jamais une main ou toute

autre partie de votre corps dans la zone de fermeture d'agrafe ou dans la

fenêtre de réglage.

3. Ne pointez jamais l'agrafeuse sur vous-même ou sur une autre personne.

4. Utilisez toujours l'agrafeuse avec précaution. N'actionnez jamais la détente si

l'agrafeuse n'est pas prête à utiliser.

5. Vérifiez et remplacez tout composant usé ou endommagé.

1. Déposez quelques gouttes d'huile dans l'entrée

d'air.

2. Installez un raccord à branchement rapide sur

l'agrafeuse.

3. Régulez la pression d'air pour qu'elle atteigne entre

4,8 et 6,9bars (70 et 100lb/po²).

4. Insérez les agrafes dans l'agrafeuse conformément

aux directives de chargement.

AVERTISSEMENT

Ne nettoyez jamais l'agrafeuse avec de l'essence ou autres

liquides inflammables. Une étincelle pourrait enflammer les

vapeurs résiduelles dans l'agrafeuse et provoquer l'explosion

de l'agrafeuse.

NETTOYAGE DE L'AGRAFEUSE

1. Déconnectez la source d'alimentation d'air de

l'agrafeuse.

2. Éliminez l'accumulation de goudron à l'aide d'un

nettoyant non corrosif.

5. Reconnectez la conduite d'air à l'agrafeuse.

6. Saisissez la poignée avec une main sur la boîte

en ligne avec l'emplacement d'agrafe voulu. Il

existe une petite saillie de part et d'autre de l'assise

de magasin pour aider à localiser la position de

l'agrafe.

7. Pour la fermeture la plus solide, installez les agrafes

près des rebords de la boîte.

MISE EN GARDE! Ne laissez pas le solvant

pénétrer dans le cylindre, cela pourrait

l'endommager.

3. Asséchez bien l'agrafeuse avant de l'utiliser.

PAGE 25 OF 30 0421 IH-103 0

Page 26

INSTRUCTIONS D'UTILISATION SUITE

DÉGAGEMENT D'UNE OBSTRUCTION

1. Déconnectez l'alimentation d'air.

2. Soulevez le levier. (Voir Figure 11)

Figu r e 11

Cessez immédiatement d'utiliser l'agrafeuse si l'un ou l'autre des problèmes suivants se produit.

De graves blessures corporelles pourraient s'en suivre. Tout remplacement ou réparation doit

être réalisé(e) uniquement par une personne qualifiée ou par un centre de service autorisé.

DÉPANNAGE

PROBLÈME CAUSE CORRECTIF

3. Insérez une pince à bec effilé ou un tournevis afin

de dégager l'obstruction. (Voir Figure 11)

4. Abaissez le levier.

AVERTISSEMENT

Fuite d'air au niveau de

la détente

Fuite d'air au niveau de

l'orifice d'échappement

Fuite d'air au niveau

du cylindre

Cyclage lent et course

courte

Nombre excessif

d'obstructions

Le joint torique sur la soupape ou

le tube est endommagé.

Le joint torique sur la soupape ou

le tube est endommagé.

Le joint torique sur le piston est

endommagé.

Le joint torique de l'orifice de tige

de piston est endommagé.

Contrôlez la présence de vis

desserrées ou l'usure des pièces.

1. Cyclage lent et course courte.

2. Vis de dents desserrées.

3. Agrafes de format inapproprié.

4. Lubrification insuffisante.

Remplacez le joint torique.

Remplacez le joint torique.

Remplacez le joint torique.

1. Positionnez la tige excentrique et serrez la vis.

2. Revérifiez afin de confirmer l'efficacité maximale.

a. S'il s'agit d'une course courte, réglez la tige

légèrement vers le haut.

b. S'il s'agit d'un cyclage lent, réglez la tige

légèrement vers le bas.

1. Réglez de la façon décrite ci-dessus.

2. Serrez les vis.

3. Vérifiez les agrafes.

4. Nettoyez et lubrifiez l'agrafeuse.

Fermeture inégale Agrafes de format inapproprié. Vérifiez si les réglages de la longueur des pattes et

du niveau de fermeture sont appropriés.

Agrafe ouverte 1. Dents desserrées ou brisées.

2. Cyclage lent et course courte.

PAGE 26 OF 30 0421 IH-103 0

1. Vérifiez et remplacez les dents au besoin.

2. Réglez de la façon décrite ci-dessus.

Page 27

INSTRUCTIONS D'UTILISATION SUITE

REMPLACEMENT DE DENTS

1. Desserrez les vis et l'écrou à l'aide d'une clé 8mm et

d'une clé Allen 4mm. (Voir Figure 12)

2. Retirez le magasin. (Voir Figure 13)

Figure 12 Figure 13

3. Desserrez les vis à l'aide d'une clé Allen 3mm.

(Voir Figure 14)

4. Remplacez les dents une à la fois afin d'éviter de les

inverser.

Fi g ure 14

PAGE 27 OF 30 0421 IH-103 0

Page 28

INSTRUCTIONS D'UTILISATION SUITE

REMPLACEMENT DE LA PLAQUE

DE POUSSÉE

1. Déconnectez l'alimentation d'air.

2. Desserrez la vis et l'écrou à l'aide d'une tricoise

8mm et d'une clé Allen 4mm. (Voir Figure 15)

3. Retirez le magasin. (Voir Figure 16)

4. Pour déverrouiller la tige de réglage, desserrez la vis

de réglage à l'aide d'une clé Allen 3mm.

5. Glissez simultanément les liens et la tige de réglage

pour les éloigner du collet. (Voir Figure 17)

6. Desserrez les vis à l'aide d'une clé Allen 3mm.

(Voir Figure 18)

7. Retirez la cheville ressort à l'aide d'un marteau et

d'une tige droite de 6mm. (Voir Figure 19)

Figure 15

Figure 17

Ensemble

de magasin

Figure 16

Figure 18

Figure 19

PAGE 28 OF 30 0421 IH-103 0

Page 29

INSTRUCTIONS D'UTILISATION SUITE

REMPLACEMENT DU JOINT TORIQUE DE

SOUPAPE ET TUBE

1. Desserrez les vis à l'aide d'un tournevis à lame plate.

(Voir Figure 20)

2. Retirez le ressort à l'aide d'une pince à bec effilé.

(Voir Figure 21)

3. Retirez l'anneau en C à l'aide d'une pince pour

anneau en C. (Voir Figure 22)

4. Retirez la soupape et le tube à l'aide d'une pince à

bec effilé. (Voir Figure 23)

Figure 20

Figure 22

Anneau en C

Figure 21

Soupape et tube

Figure 23

PAGE 29 OF 30 0421 IH-103 0

Page 30

INSTRUCTIONS D'UTILISATION SUITE

1

0

uline.ca

REMPLACEMENT DU PISTON

1. Retirez les vis et l'écrou à l'aide d'une tricoise 8mm

et d'une clé Allen 4mm. (Voir Figure 24)

2. Retirez le magasin. (Voir Figure 25)

3. Pour déverrouiller la tige de réglage, desserrez la vis

de réglage à l'aide d'une clé Allen 3mm.

4. Glissez simultanément les liens et la tige de réglage

pour les éloigner du collet.

5. Pour retirer le ressort, desserrez le collet à l'aide

d'une clé Allen 3mm. (Voir Figure 26)

6. Desserrez la vis à l'aide d'une clé Allen 3mm et

retirez le bloc par la fenêtre.

7. Desserrez les vis à l'aide d'une clé Allen 3mm et

retirez le couvercle. (Voir Figure 27)

8. Retirez l'ensemble piston à l'aide d'une tricoise

10mm. (Voir FIgure 28)

9. Retirez et remplacez le piston.

Ressort

Figure 24

Figure 27

Couvercle

Figure 25

Figure 28

Ensemble de magasin

Figure 26

Ensemble de piston

-800-295-551

PAGE 30 OF 30 0421 IH-103 0

Loading...

Loading...