Page 1

Para Español, vea páginas 10-18.

Pour le français, consulter les pages 19-27.

H-1020

80" SEMI-AUTOMATIC

STRETCH WRAP MACHINE

1-800-295-5510

uline.com

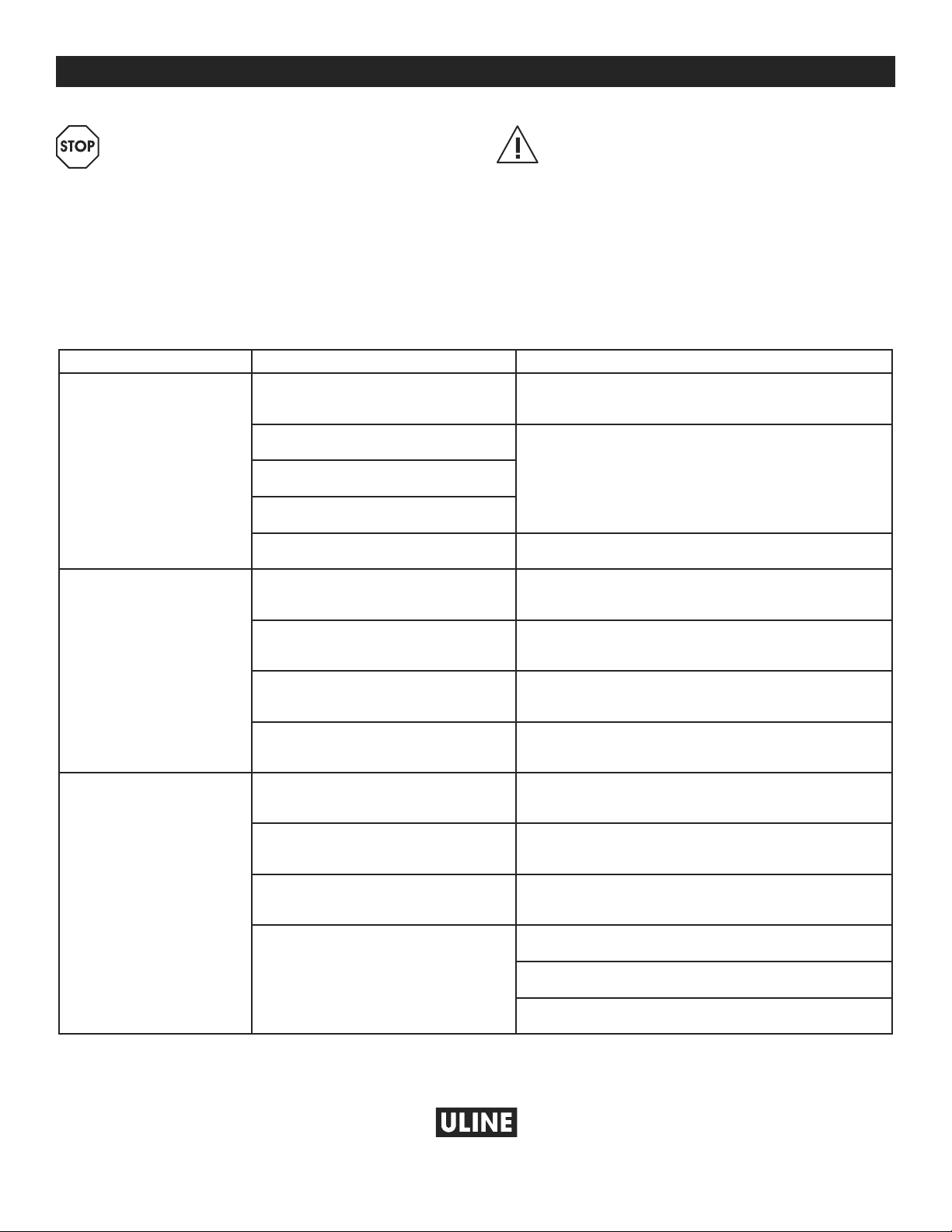

SYSTEM SPECIFICATIONS

MACHINE DIMENSIONS

Length 98"

Width 60"

Height 91"

Turntable Diameter 60"

Turntable Height from Floor 3/"

Wrapping Height 80"

Operation Space 98 x 60 x 91"

Maximum Load Size 52 x 52 x 80"

Approximate Shipping Weight 1175 lb s .

ELECTRICAL SPECIFICATIONS

• 115 VAC, 60 Hz, Single-phase, 15 AMP

TURNTABLE SYSTEM

• 20 loads per hour (spiral)

• 12 RPM turntable maximum speed

• 4,000 lbs. turntable maximum load capacity

FILM CARRIAGE / ELEVATOR SYSTEM

• Adjustable raise and lower speeds

• Automatic height detection photoelectric sensor

FILM DELIVERY SYSTEM

• Infinite / Manual Stretch Adjustment

• 10" Diameter Roll Capacity

• 20" Roll Width Capacity

CAUTION! Motor control equipment and

electronic controllers are connected to

hazardous line voltages. When servicing

drive and controllers, there may be exposed

components with housings or protrusions at or

above line potential. Extreme care should be

taken to protect against shock.

The user is responsible for conforming to all

applicable code requirements with respect to

grounding requirements. Do NOT use extension

cords to operate the equipment.

Disconnect AC input power before checking

components, performing maintenance,

cleaning up, and when the machine is not in

use. Do NOT connect or disconnect wires and

connectors while power is applied to circuit.

Wiring work should be performed only by

qualified personnel. There is a danger of

electric shock or fire.

WARNING! Loose clothing must NOT be worn

while the machine is in operation. Stay clear

of moving parts while the machine is running.

PAGE 1 OF 27 0321 IH-1020

Page 2

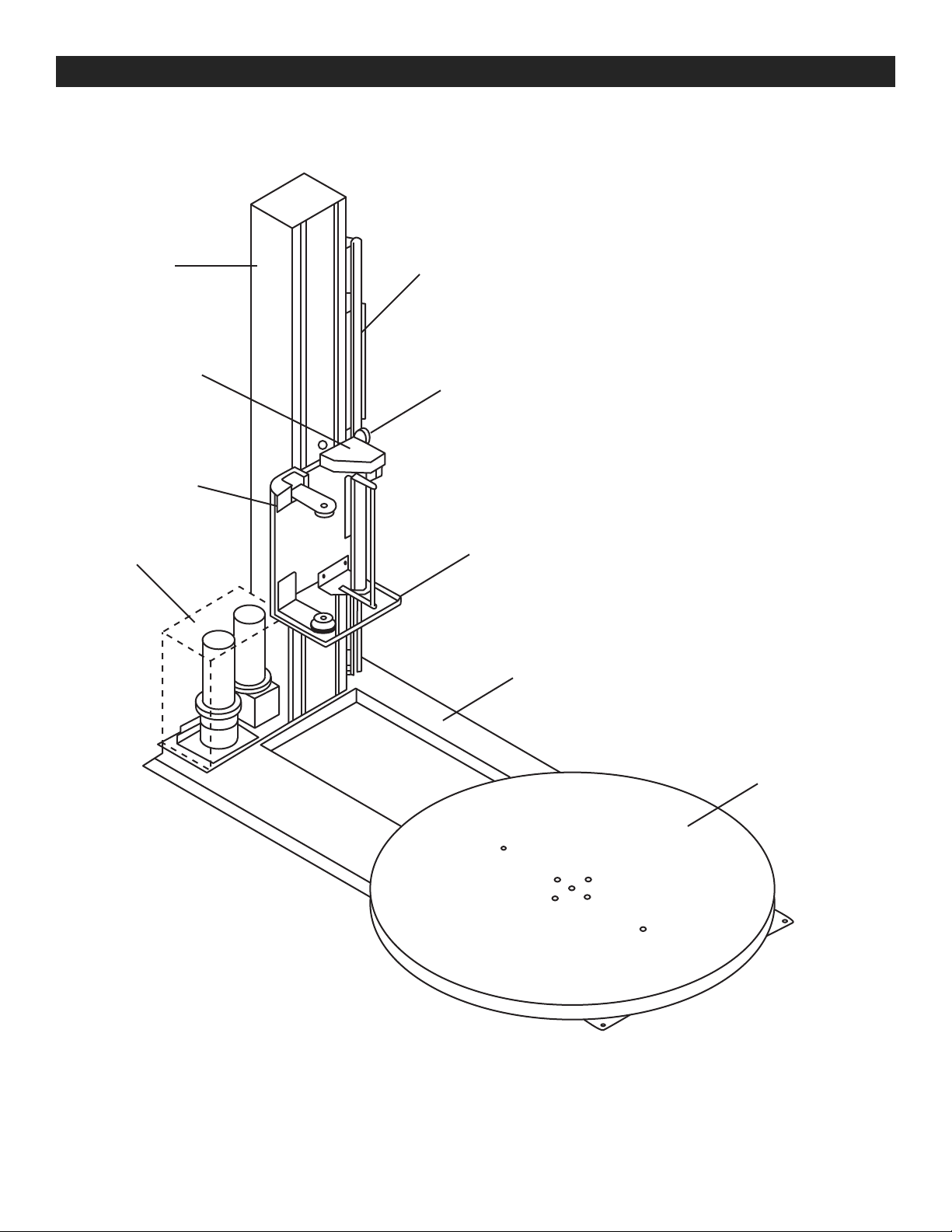

SYSTEM DESCRIPTION

Tower

Stretch Handle

Film Carriage

Motor Box

Control Box

Tension Adjustment Knob

Foot Safety Bar

Seat

Turntable

PAGE 2 OF 27 0321 IH-1020

Page 3

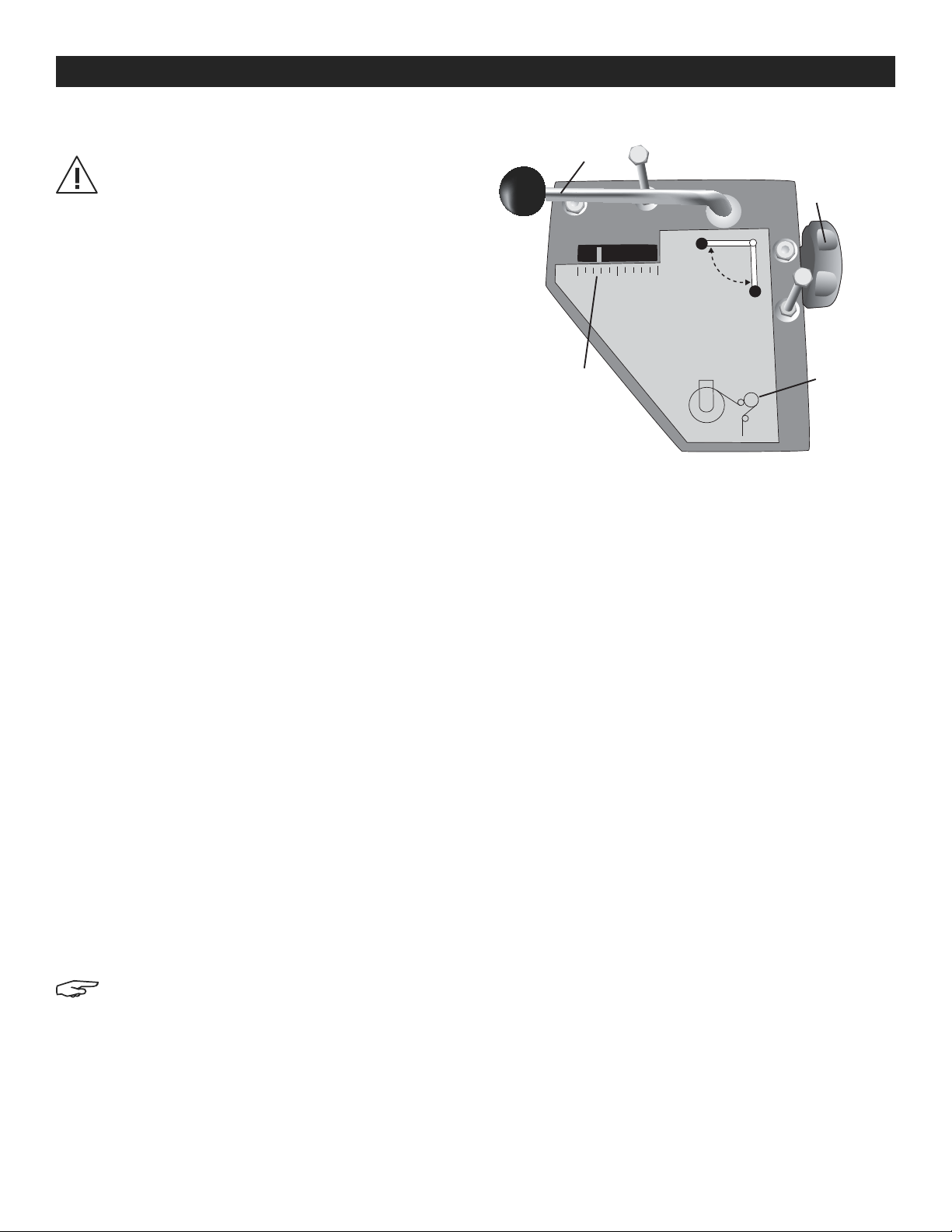

SYSTEM SET-UP

180˚

MACHINE PLACEMENT

Place the Automatic Stretch Wrap Machine close to

an area where you will be wrapping your pallet loads.

Make sure that there is sufficient room to load/unload

the machine and that you do not stretch the wiring

cable. Remember, you will need to provide electrical

service to a 120 VAC, 15-AMP outlet.

FLOOR WEIGHT BEARING TOLERANCE

The floor must be able to bear the weight of the

machine, the weight of the maximum load, plus a

safety factor. The floor must also be able to tolerate

the stress of the machine's operation. If fork trucks

will operate on the same weight bearing area, add

the weight of the trucks to the weight bearing stress

tolerance requirements.

MACHINE SET-UP

1. Place skidded machine close to the designated

wrap area. Remove all shipping fasteners holding

the machine to the pallet. The machine may be

crated with the tower tilted down and the motor

cover front carriage roller removed for shipping

purpose.

2. Place forks of the forklift through the tubes provided

at the rear base of the module, remove the

machine from skids and place it at the designated

wrap area.

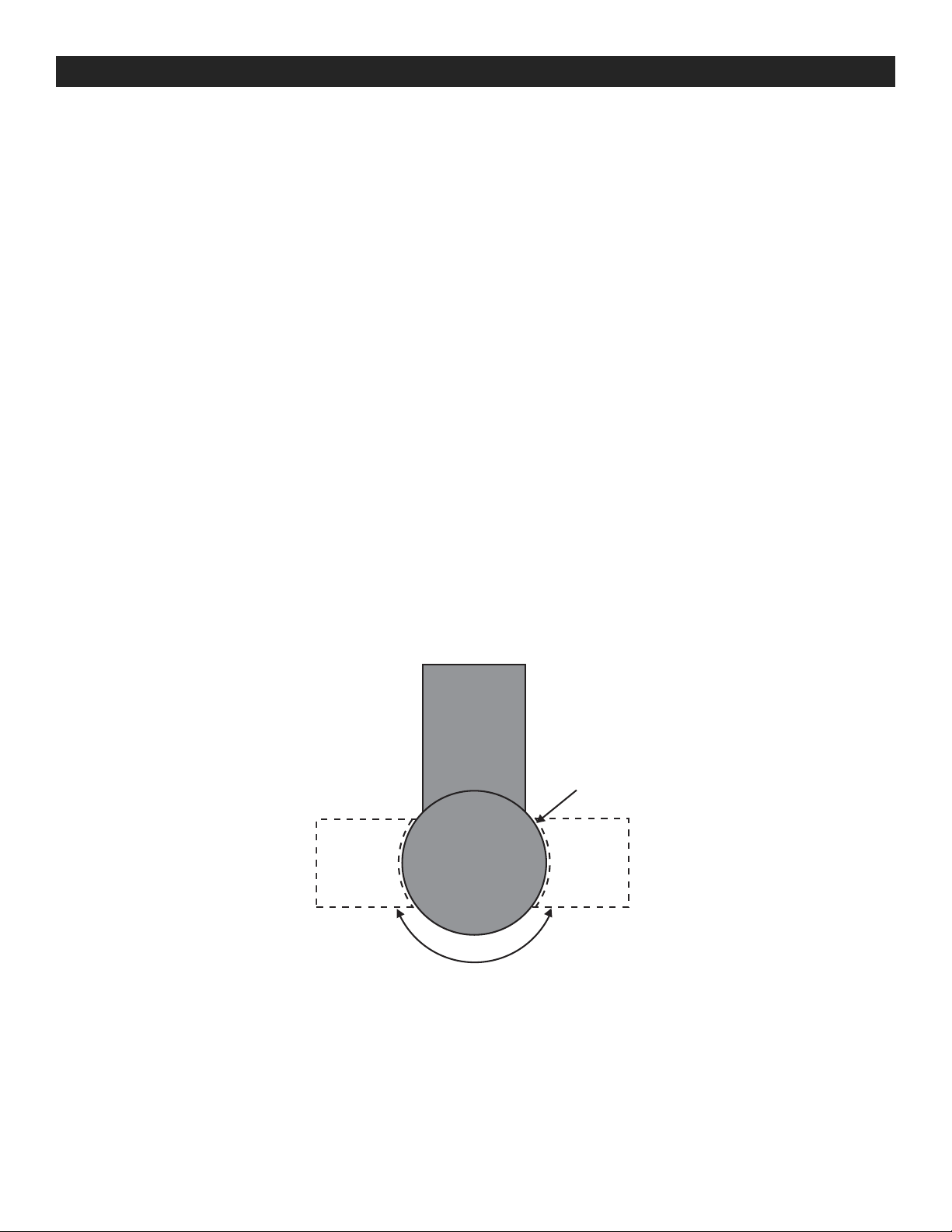

3. If the OPTIONAL ramp (H-1071) is purchased:

Select a ramp position as illustrated below. The

ramp can be positioned anywhere in a 180°

rotation around the front of the turntable. There

should be a 1/4" gap between the turntable and

the ramp. The ramp should be fully supported by

the floor. (See Figure 1)

Figure 1

1/4" Gap

PAGE 3 OF 27 0321 IH-1020

Page 4

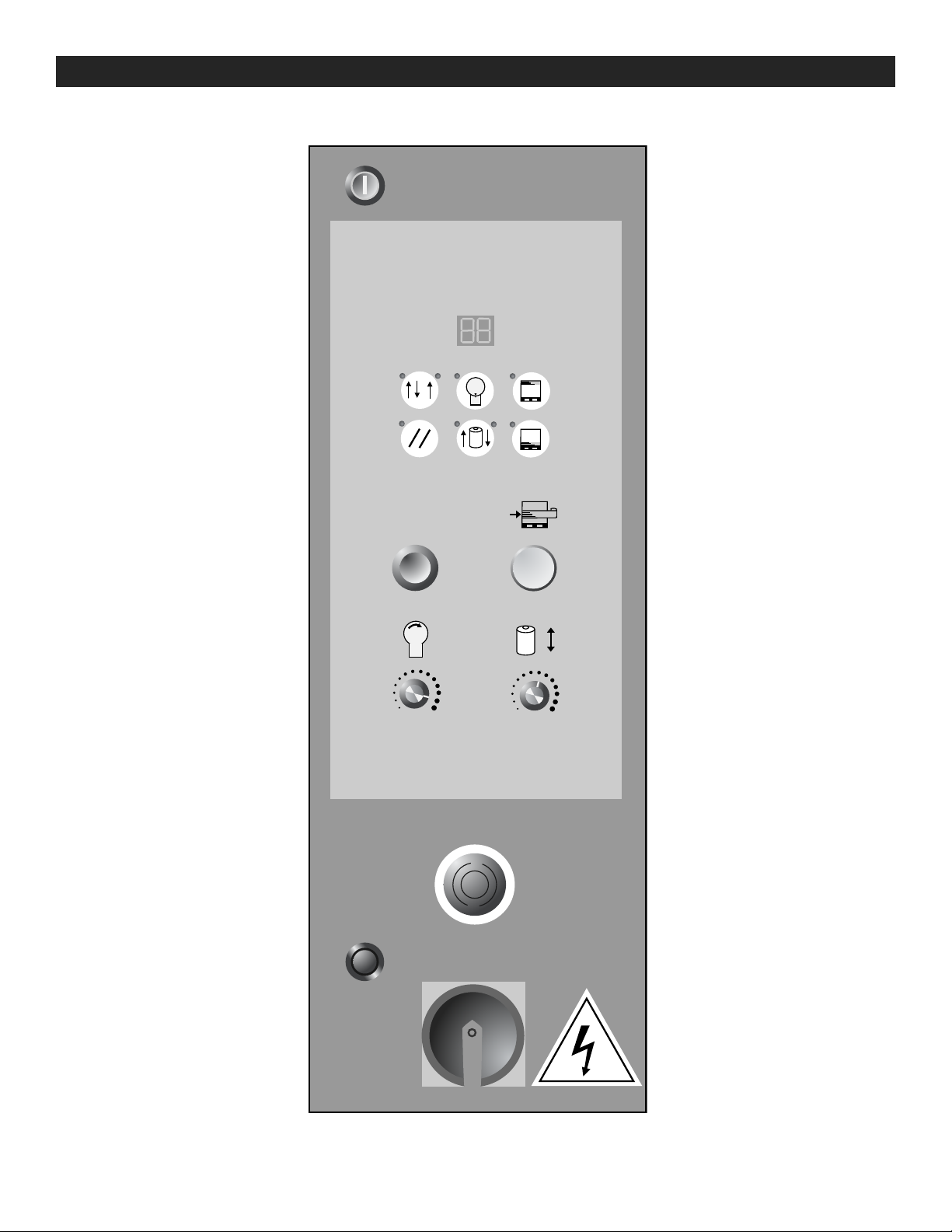

CONTROL BOX

INFO

WRAP

MODES

SYSTEM

RESET

START

TURNTABLE

SPEED

TURNTABLE

JOG

CARRIAGE

JOG

TOP

WRAPS

BOTTOM

WRAPS

BANDING

CARRIAGE

SPEED

PAGE 4 OF 27 0321 IH-1020

Page 5

CONTROL BOX CONTINUED

LED DISPLAY

EO Emergency Stop Condition

- - System is normal

A Mode A Selected

B Mode B Selected

CO Continue operation by pushing START button

S System is in Manual

BUTTONS

WRAPPING MODE A - WRAP UP AND DOWN

The LED on the button's upper left is on. In Mode A, the bottom wrap is applied first, and then

the top wrap follows. The film carriage comes down to its home position after wrapping cycle is

finished.

WRAPPING MODE B - WRAP UP ONLY

The LED on the upper left is on. In Mode B, after a bottom to top wrapping is completed, the

carriage stays on the top. The START button flashes at this point. To resume the operation, push

START. When the carriage reaches the bottom, the START button turns off. Push START button again

to begin a new cycle.

The TURNTABLE JOG button allows you to manually operate the turntable. When this button is

pushed, the light on the button's upper left is on. Push START button to run the table. Pushing

the button again will stop the turntable and the light will turn off. This button may be used in

conjunction with the CARRIAGE JOG button.

The CARRIAGE JOG button allows you to manually operate the carriage. When this button is

pushed, one of the lights on the button's upper right or left is on. The upper left light indicates

that the carriage will go up when the START button is pushed. Conversely, the upper right light

indicates the carriage will go down when the START button is pushed. To pause operation, simply

push this button again. Both indicator lights will go off. This button may be used in conjunction

with the TURNTABLE JOG button.

Push this RESET button, followed by the START button, to reset the system. The turntable will return to

its home position and the carriage will lower.

Push the TOP WRAPS button to select the number of top wraps desired (0 - 9).

PAGE 5 OF 27 0321 IH-1020

Page 6

OPERATOR CONTROLS CONTINUED

Push the BOTTOM WRAPS button to select the number of bottom wraps desired (0 - 9).

Turn the CARRIAGE SPEED adjustment knob clockwise to increase, and counterclockwise to

decrease the carriage speed. This allows you to adjust the overlap of your film.

Turn the TURNTABLE SPEED adjustment knob clockwise to increase, and counterclockwise to

decrease the turntable speed.

The BANDING button is used for applying multi-layer reinforcing wraps in automatic or manual

mode. Push and hold this button: the carriage will stop raising / lowering. When released, the

carriage will resume its movement.

The EMERGENCY STOP button stops the turntable in the event of emergency. This will NOT stop the

turntable instantly. The turntable will coast to a stop, depending on the load's weight, after this

button is pushed.

This switches the main power ON or OFF. Also used to resume operation after power has been shut off.

WARNING! The FOOT SAFETY BAR, located underneath the film carriage, works only when

the machine is ON. When the bar is activated, the main power will shut OFF. Releasing

the bar will re-activate the main power. Push START button to resume the operation.

PAGE 6 OF 27 0321 IH-1020

Page 7

FILM LOADING

Adjustment Knob

Stretch Handle

CAUTION! Be sure EMERGENCY STOP is pushed

in before threading the film and pulled out

when the film is threaded.

MACHINE OPERATION

(Off Position)

Stretch Tension

1. Place the film on the film mandrel.

2. Set the Stretch Handle to the OFF position to release

film tension.

3. Follow the Film Feed Diagram and thread the 6 foot

film tail ALL THE WAY through the rollers.

4. Set the Stretch Handle to the OFF position to release

film tension.

5. Rotate the Stretch Tension Adjustment

Knob clockwise to increase film tension or

counterclockwise to decrease film tension.

6. Attach the film securely to the pallet. Tying the end

of the film in a knot often helps secure the film to

the pallet.

NORMAL SYSTEM START-UP

1. Place the film on the film mandrel.

2. Set the Stretch Handle to the OFF position to release

film tension.

3. Thread the film as instructed and attach it to the

product.

4. Set the desired numbers for top and bottom wrap

counts.

OFF

LESS

500100

STRETCH

Stretch Tension

Indicator

MORE

ON

Film Feed

Diagram

APPLYING REINFORCEMENT WRAPS

1. Press the START button as normal to initiate cycle.

2. As the carriage travels up, press and hold the

BANDING button. The carriage travels up, press and

hold the BANDING button. The carriage will stop

and reinforcing wraps will be applied.

3. Letting go of the BANDING button will resume the

cycle.

5. Select wrapping mode A or B.

6. Press the START button to initiate cycle.

STOP CONDITION

1. In the event of an emergency, press the STOP

button. This cancels the current wrapping cycle and

immediately stops the system.

2. Correct the problem

3. Pull the STOP button out and perform normal system

start-up procedure.

NOTE: After pressing the STOP button, wait for

at least 60 seconds before pulling the button

back out. This will allow the microcontroller

card to completely turn off.

PAGE 7 OF 27 0321 IH-1020

Page 8

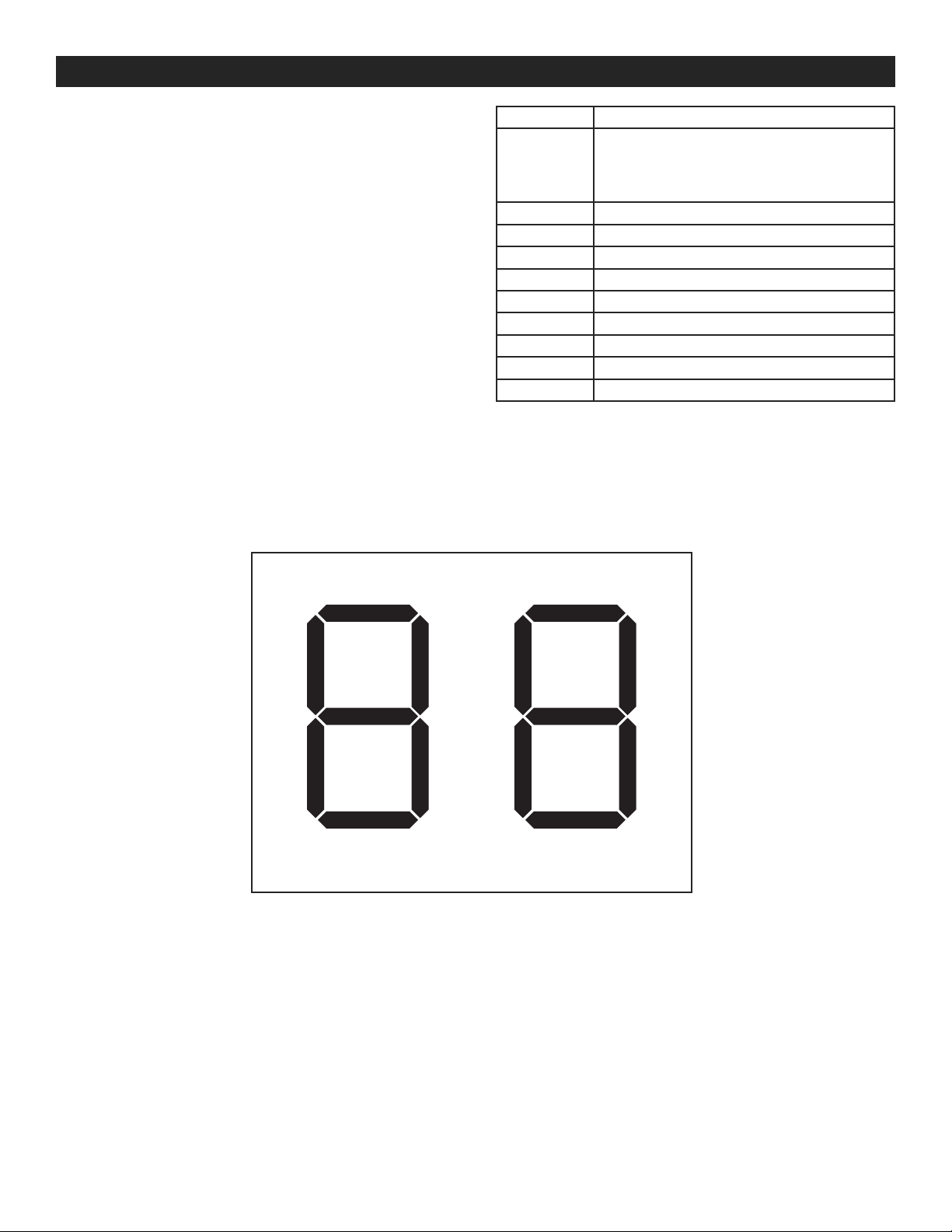

SELF-TEST PROCEDURE

A1

E1

D1

A2

C2

An operator may check the status of the machine

by running a self-test. If the procedure is carried out

properly, the INFO screen will display the location of the

problem(s).

To run the self-test, follow the procedure below:

1. Turn the turntable and carriage speed adjustment

knobs to maximum (clockwise) position.

2. Put a load on the turntable (about 3 feet tall).

3. While holding down the TURNTABLE JOG and

CARRIAGE JOG buttons, turn the main disconnect

switch ON.

4. Release the buttons after the screen shows "EE".

5. Push the START button. The machine will run the test,

which takes approximately 2 minutes.

6. The screen will display the alarm code. Refer to the

table below for code information.

DISPLAY POSSIBLE PROBLEM LOCATION(S)

A1 Film carriage Safety Bar

EMERGENCY STOP button

Electrical enclosure safety switch

B1 Film carriage max upper limit switch

C1 Film carriage max down limit switch

D1 Turntable count/home proximity switch

E1 BANDING push button

F1 START push button

G1 Package height photo sensor

A2 START light

B2 Turntable motor

C2 Carriage motor

F1

G1

B1

C1

B2

PAGE 8 OF 27 0321 IH-1020

Page 9

TROUBLESHOOTING

1

0

uline.com

WARNING! Make sure that only qualified

personnel perform inspection, troubleshooting

and part replacement.

CAUTION! Disconnect all power, including

external control power that may be present,

before servicing the frequency drive

controllers. WAIT for three (3) minutes for the

DC bus capacitors to discharge. The

frequency drive controller's display and/or LEDs

are not accurate indicators of the absence of

DC bus voltage.

OPERATING ISSUE CAUSES RECOMMENDATIONS

Machine not powering on.

Main power is turned off. Check that power is going to the machine. Verify that switch

is turned on.

Machine not plugged into 120VAC outlet. Verify the voltage going to the machine matches the power

supply labels on the power module.

Power supply faulty.

Internal battery not charged.

Film carriage foot engaged. Remove obstruction from Film Carriage foot.

Film carriage malfunctioning.

Turntable is malfunctioning.

FILM CARRIAGE SPEED dial not set high

enough.

Resistance of potentiometer not equal to

5K_ across.

The carriage limit switch lever arm is

obstructed.

Microcontroller card inside electrical

enclosure not turned on.

Turntable speed potentiometer dial not

set high enough.

Resistance of potentiometer not equal to

5K_ across.

Microcontroller card inside electrical

enclosure not turned on.

The turntable motor is not running. Tighten or replace motor wiring as necessary.

Adjust potentiometer towards 100% to set speed.

Tighten wiring, replace dial if necessary.

Remove obstruction and/or clean limit switch head.

Check and switch on the main circuit breaker.

Adjust potentiometer towards 100% to set speed.

Tighten wiring, replace dial if necessary.

Check and switch on main circuit breaker.

Check turntable for mechanical restrictions.

Replace microcontroller or turntable output relay.

-800-295-551

PAGE 9 OF 27 0321 IH-1020

Page 10

H-1020

DESPACHADORA DE

80” AUTOMÁTICA DE

PELÍCULA ELÁSTICA

800-295-5510

uline.mx

ESPECIFICACIONES DEL SISTEMA

DIMENSIONES DE LA MÁQUINA

Largo 249 cm (98")

Ancho 152 cm (60")

Altura 231 cm (91")

Diámetro de Plataforma Giratoria 152 cm (60")

Altura de Plataforma Giratoria desde el Piso 8 cm (3")

Altura para Envolver 203 cm (80")

Espacio de Funcionamiento 249 x 152 x 231 cm

(98 x 60 x 91")

Tamaño Máximo de Carga 132 x 132 x 183 cm

(52 x 52 x 72")

Peso Aproximado del Envío 533 kg (1,175 lbs.)

ESPECIFICACIONES ELÉCTRICAS

• 115 VAC, 60 Hz, Monofásica, 15 AMP

SISTEMA DE PLATAFORMA GIRATORIA

• 20 cargas por hora (espiral)

• 12 RPM de velocidad máxima de plataforma

giratoria

• Capacidad máxima de 4,000 lbs. de carga de la

plataforma giratoria

SISTEMA DEL PORTADOR DE PELÍCULA/ELEVADOR

• Velocidades ajustables para elevación y descenso

• Sensor fotoeléctrico automático para detección de

altura

SISTEMA PARA DESPACHAR LA PELÍCULA

• Ajuste de Película Infinito / Manual

• Capacidad del Rollo de 25 cm (10") de Diámetro

• Capacidad del Rollo de 50 cm (20") de Ancho

¡PRECAUCIÓN! El equipo de control del motor y

los reguladores están conectados a líneas de

voltaje peligrosas. Cuando dé mantenimiento a

la unidad y a los reguladores, los componentes

pueden estar expuestos con cubiertas o salientes

en o por encima de la línea de voltaje. Deberá

tomar precauciones extremas para protegerse

de choques eléctricos.

El usuario es responsable del cumplimiento de

todas las regulaciones relacionadas con la

conexión a tierra. NO use extensiones eléctricas

para operar el equipo.

Desconecte la alimentación de la corriente

directa antes de revisar los componentes, dar

mantenimiento, limpiar, y cuando la máquina

no esté en uso. NO conecte o desconecte

cables y conectores mientras se suministra

energía al circuito.

El cableado debe ser realizado sólo por personal

calificado. Existe el peligro de choque eléctrico

o incendio.

¡ADVERTENCIA! NO debe usar ropa holgada

mientras la máquina esté funcionando.

Manténgase alejado de las partes móviles

mientras la máquina esté operando.

PAGE 10 OF 27 0321 IH-1020

Page 11

DESCRIPCIÓN DEL SISTEMA

Plataforma Giratoria

Torre

Asa de Película

Portador de Película

Caja del Motor

Caja de Control

Perilla para Ajuste de Tensión

Pedal de Seguridad

Soporte

PAGE 11 OF 27 0321 IH-1020

Page 12

180˚

CONFIGURACIÓN DEL SISTEMA

COLOCACIÓN DE LA MÁQUINA

Coloque la Máquina Automática para Película Elástica

cerca del área en donde envolverá sus tarimas de

carga. Asegúrese de que haya suficiente espacio

para cargar/descargar la máquina y que no se estire

el cable de conexión. Recuerde, necesita tener una

salida para un tomacorriente de 120 VAC, 15-AMP.

RESISTENCIA DEL PISO PARA SOSTENER EL PESO

El piso deberá tener la capacidad de sostener el peso

de la máquina, la carga de mayor peso, además

del factor de seguridad. El piso debe también resistir

la presión del funcionamiento de la máquina. Si se

manejarán montacargas en la misma área de soporte

de peso, agregue el peso de los montacargas a los

requerimientos para la resistencia del peso.

INSTALACIÓN DE LA MÁQUINA

1. Coloque la máquina entarimada cerca del área

designada para envoltura. Retire todos los cinchos

que fijan la máquina a la tarima. La máquina

podría haberse empacado con la torre hacia

abajo y sin la cubierta frontal del rodillo portador

para propósitos de envío.

2. Inserte las horquillas del montacargas a través de

los tubos ubicados en la base posterior del módulo,

retire la máquina de las tarimas y colóquela en el

área designada para envolver.

3. Si compra la rampa OPCIONAL (H-1071): Seleccione

una posición para la rampa como se ilustra abajo.

La rampa puede ser posicionada en cualquier

lugar en una rotación de 180° alrededor del

frente de la plataforma giratoria. Debe haber una

separación de 6.3 mm (1/4") entre la plataforma

giratoria y la rampa. La rampa deberá estar

completamente apoyada en el piso.

(Vea Diagrama 1)

Diagrama 1

Separación

de 6.3 mm

(1/4")

PAGE 12 OF 27 0321 IH-1020

Page 13

CAJA DE CONTROL

INFORMACIÓN

MODOS DE

ENVOLTURA

REINICIO

AL SISTEMA

INICIO

VELOCIDAD

DE PLATAFORMA

GIRATORIA

IMPULSO DE

PLATAFORMA

GIRATORIA

IMPULSO

DEL PORTADOR

ENVOLTURA

SUPERIOR

ENVOLTURA

INFERIOR

ATAR CON BANDA

VELOCIDAD

DEL PORTADOR

PAGE 13 OF 27 0321 IH-1020

Page 14

CONTINUACIÓN DE CAJA DE CONTROL

PANTALLA LED

EO Posición de Apagado de Emergencia

- - Sistema Normal

A Modo A Seleccionado

B Modo B Seleccionado

CO Continúe el funcionamiento presionando el botón START

S El Sistema está en Manual

BOTONES

ENVOLTURA EN MODO A – ENVOLTURA POR ARRIBA Y ABAJO

El LED de la parte izquierda superior del botón está encendido. En Modo A, la envoltura se

aplica primero en la parte inferior, y después sigue la envoltura superior. El portador de la

película baja a su posición de inicio después de terminar el ciclo de envoltura.

ENVOLTURA EN MODO B – ENVOLTURA POR ARRIBA SOLAMENTE

El LED en la parte izquierda superior está encendido. En Modo B, después de que la envoltura

desde abajo hasta arriba está completa, el portador permanece en la parte superior. El botón

START parpadea en este punto. Para reiniciar el funcionamiento, presione START. Cuando el

portador llega a la parte inferior, el botón START se apaga. Presione el botón START de nuevo y

empiece el nuevo ciclo.

El botón TURNTABLE JOG le permite operar manualmente la plataforma giratoria. Cuando este

botón es presionado, la luz en la parte izquierda superior del botón se enciende. Presione el

botón START para poner a funcionar la plataforma. Al presionar de nuevo el botón detendrá la

plataforma giratoria y la luz se apagará. Este botón puede utilizarse en conjunto con el botón de

CARRIAGE JOG.

El botón CARRIAGE JOG permite operar manualmente el portador. Cuando este botón es

presionado, una de las luces en la parte superior derecha del botón se enciende. La luz superior

izquierda indica que el portador irá hacia arriba cuando el botón START sea presionado. Por el

contrario, la luz superior derecha indica que el portador irá hacia abajo cuando el botón START

sea presionado. Para pausar la función simplemente presione este botón de nuevo. Ambas luces

indicadoras se apagarán. Este botón puede utilizarse en conjunto con el botón TURNTABLE JOG.

Presione este botón RESET, seguido por el botón START, para reiniciar el sistema. La plataforma

giratoria regresará a su posición de inicio y el portador bajará.

Presione el botón TOP WRAPS para seleccionar el número de envolturas deseadas en la parte

superior (0-9).

PAGE 14 OF 27 0321 IH-1020

Page 15

CONTINUACIÓN DE CAJA DE CONTROL

Presione el botón BOTTOM WRAPS para seleccionar el número de envolturas inferiores deseadas (0-9).

Gire la perilla de ajuste CARRIAGE SPEED en el sentido de las manecillas del reloj para aumentar

la velocidad del portador, y en sentido contrario para disminuirla.

Esto le permite ajustar la superposición de su película.

Gire la perilla de ajuste TURNTABLE SPEED en el sentido de las manecillas del reloj para aumentar

la velocidad de la plataforma giratoria, y en sentido contrario para disminuirla.

El botón BANDING es utilizado para aplicar multicapas para reforzar la envoltura en modo

automático o manual. Presione y sostenga este botón: el portador dejará de subir o bajar.

Cuando lo libere, el portador reanudará su movimiento.

El botón EMERGENCY STOP detiene la plataforma giratoria en caso de emergencia. Esto NO

detendrá la plataforma giratoria inmediatamente. La plataforma giratoria se detendrá por

inercia, dependiendo del peso de la carga, después de que el botón sea presionado.

Este cambia el interruptor principal a Encendido o Apagado. También es utilizado para reiniciar el

funcionamiento después de haberse apagado.

¡PRECAUCIÓN! El PEDAL DE SEGURIDAD, localizado debajo del portador de la película,

trabaja sólo cuando la máquina está Encendida. Cuando la barra es activada, la

corriente principal se apagará. Al liberar el pedal reactivará la corriente principal.

Presione el botón START para reiniciar el funcionamiento.

PAGE 15 OF 27 0321 IH-1020

Page 16

FUNCIONAMIENTO DE LA MÁQUINA

de Alimentación

Asa de Tensión

(Posición Apagado, Off)

CARGAR LA PELÍCULA

¡PRECAUCIÓN! Asegúrese de presionar el

BOTÓN DE EMERGENCIA antes de cargar la

película y liberarlo cuando la película esté

cargada.

1. Coloque la película en el mandril de la película.

2. Mueva el Asa de Tensión a la posición OFF para

liberar la tensión de la película.

3. Siga el Diagrama de Alimentación de la Película

y cargue los 1.80 m (70") de película TODO EL

TRAYECTO a través de los rodillos.

4. Mueva el Asa de Tensión a la posición OFF para

liberar la tensión de la película.

5. Gire la Perilla de Ajuste de Tensión de Película en el

sentido de las manecillas del reloj para aumentar

la tensión de la película o en sentido opuesto para

disminuirla.

Perilla de Ajuste

de Tensión de Película

OFF

LESS

STRETCH

Indicador de

Tensión de Película

500100

MORE

ON

APLICAR ENVOLTURAS DE REFUERZO

Diagrama

de Película

6. Sujete la película a la tarima de manera segura.

Haciendo un nudo en el extremo de la película a

menudo ayuda a asegurarla a la tarima.

ARRANQUE NORMAL DEL SISTEMA

1. Coloque la película en el mandril de la película.

2. Mueva la Asa de la Película a la posición OFF para

liberar la tensión de la película.

3. Coloque la película como se indica y sujétela en el

producto.

4. Configure los números deseados para el conteo de

envolturas superior e inferior.

5. Seleccione el modo de envoltura A o B.

6. Presione el botón de START para iniciar el ciclo.

CASO DE INTERRUPCIÓN

1. En caso de emergencia, presione el botón STOP.

Esto cancela el ciclo de envoltura actual e

inmediatamente detiene el sistema.

2. Corrija el problema.

1. Presione el botón START de manera normal para

iniciar el ciclo.

2. Mientras el portador se mueve hacia arriba,

presione y sostenga el botón BANDING. El portador

se detendrá y las envolturas de refuerzo serán

aplicadas.

3. Liberando el botón BANDING se reanudará el ciclo.

3. Jale el botón STOP y siga el procedimiento de

arranque normal del sistema.

NOTA: Después de presionar el botón STOP,

espere por lo menos 60 segundos antes de

jalar el botón de regreso. Esto permitirá que

la tarjeta del microcontrolador se apague

completamente.

PAGE 16 OF 27 0321 IH-1020

Page 17

PROCEDIMIENTO DE AUTOPRUEBA

A1

E1

D1

A2

C2

Un operador puede revisar el estado de la máquina

corriendo la autoprueba. Si el procedimiento se lleva a

cabo correctamente, la pantalla de INFO mostrará la

ubicación del (los) problema(s).

Para correr la autoprueba, siga el siguiente

procedimiento:

1. Gire las perillas de ajuste de la plataforma giratoria

y el portador a la posición máxima (en sentido de

las manecillas del reloj).

2. Coloque una carga en la plataforma giratoria

(cerca de 1 m (36") de alto).

3. Mientras mantiene presionados los botones

TURNTABLE JOG y CARRIAGE JOG, encienda el

interruptor de desconexión principal.

4. Libere los botones después de que aparezca "EE"

en la pantalla.

5. Presione el botón START. La máquina correrá la

prueba, la cual toma aproximadamente 2 minutos.

6. La pantalla mostrará el código de alarma.

Consulte la tabla de abajo para la información de

códigos.

PANTALLA POSIBLE UBICACIÓN DE PROBLEMA(S)

A1 Barra de Seguridad del Portador de Película.

Botón EMERGENCY STOP

Interruptor de seguridad de la caja eléctrica

B1 Interruptor de límite máximo superior del portador de

película

C1 Interruptor de límite máximo inferior del portador de

película

D1 Interruptor de conteo de plataforma giratoria/cambio

de proximidad

E1 Botón de presión BANDING

F1 Botón de presión START

G1 Foto sensor de altura del paquete

A2 Luz START

B2 Motor de la plataforma giratoria

C2 Motor del portador

F1

G1

B1

C1

B2

PAGE 17 OF 27 0321 IH-1020

Page 18

SOLUCIÓN DE PROBLEMAS

8

0

uline.mx

¡ADVERTENCIA! Asegúrese de que sólo

personal calificado lleve a cabo la

inspección, solución de problemas y

reemplazo de partes.

¡PRECAUCIÓN! Desconecte la corriente,

incluyendo el control externo de corriente que

pudiera estar presente, antes de dar servicio a

los controladores de frecuencia de dirección.

ESPERE tres (3) minutos para que los

capacitores del conector de CD se

descarguen. La pantalla de los controladores

de frecuencia de dirección y/o LEDs no son

adecuados para indicar ausencia de voltaje

del conector de CD.

PROBLEMA DE FUNCIONAMIENTO CAUSAS RECOMENDACIONES

La máquina no enciende.

Falla del portador de película.

La corriente principal está apagada. Revise que la corriente llegue a la máquina.

La máquina no está conectada a un

enchufe de 120VAC.

Falla del suministro de corriente.

La batería interna no está cargada.

El pedal del portador de película está

obstruido.

La perilla de CARRIAGE SPEED de la película

no se configuró a una altura suficiente.

Verifique que el interruptor esté encendido.

Verifique que el voltaje que llega a la máquina

coincida con las etiquetas del suministro de

corriente en el módulo de corriente.

Retire la obstrucción del pedal del Portador de

Película.

Ajuste el potenciómetro al 100% para establecer

la velocidad.

Falla de la plataforma giratoria.

La resistencia del potenciómetro no es igual

a través de 5k.

El brazo nivelador del interruptor de límite

del portador está obstruido.

La tarjeta del microcontrolador dentro de la

caja eléctrica no encendió.

La velocidad de la perilla del potenciómetro

de la plataforma giratoria no está lo

suficientemente alta.

La resistencia del potenciómetro no es igual

a través de 5K_.

La tarjeta del microcontrolador dentro de la

caja eléctrica no encendió.

El motor de la plataforma giratoria no está

corriendo.

Ajuste el cableado, reemplace la perilla si es

necesario.

Retire la obstrucción y/o limpie el cabezal del

interruptor de límite.

Revise y encienda el interruptor de circuito

principal.

Ajustar el potenciómetro al 100% para establecer

la velocidad.

Ajuste el cableado, reemplace la perilla si es

necesario.

Revise y encienda el interruptor de circuito

principal.

Ajuste o reemplace el cableado del motor como se

requiera.

Revise la plataforma giratoria de limitaciones

mecánicas.

Reemplace el microcontrolador o el interruptor de

salida de la plataforma giratoria.

00-295-551

PAGE 18 OF 27 0321 IH-1020

Page 19

H-1020

DISTRIBUTEUR DE FILM

ÉTIRABLE AUTOMATIQUE

DE 80PO (203CM)

SPÉCIFICATIONS DU SYSTÈME

1-800-295-5510

uline.ca

DIMENSIONS DE LA MACHINE

Longueur 249 cm (98 po)

Largeur 152 cm (60 po)

Hauteur 231 cm (91 po)

Diamètre de la plaque tournante 152 cm (60 po)

Hauteur de la plaque à partir du sol 8 cm (3 po)

Hauteur de l'emballage 203 cm (80 po)

Espace de fonctionnement 249 x 152 x 231 cm

(98 x 60 x 91 po)

Taille maximale de la charge 132 x 132 x 183 cm

(52 x 52 x 72 po)

Poids d'expédition approximatif 533 kg ( 1 175 lb)

SPÉCIFICATIONS ÉLECTRIQUES

• 115 V c.a., 60 Hz, monophasé, 15 A

SYSTÈME DE LA PLAQUE TOURNANTE

• 20 charges par heure (spirale)

• Vitesse maximale de la plaque tournante : 12 tr/min

• Capacité de charge maximale de la plaque

tournante : 1,8 T (4 000 lbs.)

CHARIOT PORTE-FILM/SYSTÈME D'ASCENSEUR

• Vitesses d'ascension et de descente réglables

• Détecteur à cellule photoélectrique de mesure de

hauteur automatique

SYSTÈME DE DISTRIBUTION DE FILMS

• Réglage continu/manuel de l'allongement

• Capacité de rouleau de 25 cm (10 po) de diamètre

• Capacité de rouleau de 50 cm (20 po) de largeur

MISE EN GARDE! La commande des moteurs et

les régulateurs électroniques sont branchés à

des tensions dangereuses. Lors de l'entretien

du disque et des régulateurs, des pièces

accessibles avec boîtiers ou saillies peuvent

se trouver au niveau ou au-dessus du potentiel

d'une phase. Faites preuve d'extrême

prudence afin d'assurer une protection contre

les chocs.

L'utilisateur est tenu responsable du respect de

toutes les exigences applicables du code et

des exigences de la mise à la terre. N'utilisez

PAS de rallonges pour utiliser l'équipement.

Coupez l'alimentation d'entrée en c.a. avant

la vérification des pièces, toute opération

d'entretien ou de nettoyage et lorsque la

machine n'est pas en service. NE branchez ou

débranchez PAS les câbles et les connecteurs

tant que le circuit est sous tension.

Seul un personnel qualifié peut effectuer

les travaux de câblage. Il existe un risque

d'électrocution ou d'incendie.

AVERTISSEMENT! NE portez PAS de vêtements

ARRÊT

amples lorsque la machine est en marche.

Tenez-vous à l'écart des pièces mobiles

lorsque la machine fonctionne.

PAGE 19 OF 27 0321 IH-1020

Page 20

DESCRIPTION DU SYSTÈME

Plaque tournante

Tour

Poignée d’allongement

Chariot porte-film

Boîte à moteur

Boîte de commande

Bouton de réglage de tension

Barre de sécurité pour pied

Siège

PAGE 20 OF 27 0321 IH-1020

Page 21

180˚

INSTALLATION DU SYSTÈME

EMPLACEMENT DE LA MACHINE

Placez le distributeur de film étirable automatique

près d'une zone où vous allez emballer vos charges

palettisées. Vérifiez qu'il y a suffisamment d'espace

pour charger/décharger la machine et que vous

n'étirez pas le câble. Vous devez fournir un service

d'électricité à une prise de 120 V c.a., 15 A.

TOLÉRANCE DE ROULEMENT SUR POIDS DU

PLANCHER

Le plancher doit pouvoir supporter le poids de la

machine, le poids de la charge maximale et un

facteur de sécurité. Le plancher doit également être

en mesure de tolérer la tension du fonctionnement de

la machine. Si les chariots à fourche fonctionnent sur la

même surface portante, ajoutez le poids des chariots

aux exigences de tolérance de la tension de la surface

portante.

INSTALLATION DE LA MACHINE

1. Placez la machine sur palettes près de la zone

indiquée pour l'emballage. Enlevez toutes les

attaches d'expédition qui maintiennent la machine

sur la palette. La machine peut être emballée avec

la tour inclinée vers le bas et le rouleau de transport

avant du couvercle moteur peut être retiré pour

l'expédition.

2. Placez les fourches du chariot élévateur dans les

tubes fournis à la base arrière du module, retirez

la machine des palettes et placez-la dans la zone

indiquée pour le banderolage.

3. Si vous avez acheté la rampe OPTIONNELLE (H-1071) :

choisissez une position de la rampe tel qu'illustré

ci-dessous. Vous pouvez placer la rampe partout,

dans une rotation de 180° autour de l'avant

de la plaque tournante. Vous devez laisser un

espacement de 6.3 mm (1/4 po) entre la plaque et

la rampe. La rampe doit être entièrement soutenue

par le plancher. (Voir figure 1)

Figure 1

Espacement

de 6.3 mm

(1/4 po)

PAGE 21 OF 27 0321 IH-1020

Page 22

BOÎTE DE COMMANDE

INFO

MODES

D’EMBALLAGE

SYSTÈME

DE RÉINITIALISATION

TOURNANTE

MANUELLE

CHARIOT MANUEL

DÉMARRER

VITESSE DE LA PLAQUE

TOURNANTE

PLAQUE

VITESSE DU CHARIOT

EMBALLAGES

SUPÉRIEURS

EMBALLAGES

INFÉRIEURS

BANDEROLAGE

PAGE 22 OF 27 0321 IH-1020

Page 23

BOÎTE DE COMMANDE SUITE

AFFICHAGE À DEL

EO État d'arrêt d'urgence

- - Le système est normal

A Mode A sélectionné

B Mode B sélectionné

CO Poursuivre l'opération en appuyant sur le bouton START (DÉMARRER)

S Le système est en manuel

BOUTONS

EMBALLAGE MODE A - ENROULEMENT EN HAUT ET EN BAS

Le voyant DEL dans le coin supérieur gauche du bouton est allumé. En Mode A, l'emballage

commence par la partie inférieure puis se poursuit par la partie supérieure. Le chariot porte-film

revient à sa position initiale à la fin du cycle EMBALLAGE.

EMBALLAGE MODE B - ENROULEMENT EN HAUT UNIQUEMENT

Le voyant DEL dans le coin supérieur gauche est allumé. En Mode B, à la fin de l'emballage de

la partie inférieure vers la partie supérieure, le chariot porte-film reste sur la partie supérieure.

Le bouton START (DÉMARRER) clignote à ce stade. Pour reprendre l'utilisation, appuyez sur START

(DÉMARRER). Lorsque le chariot atteint le bas, le bouton START (DÉMARRER) s'éteint. Appuyez de

nouveau sur le bouton START (DÉMARRER) pour lancer un nouveau cycle.

Le bouton TURNTABLE JOG (PLAQUE TOURNANTE MANUELLE) vous permet d'activer manuellement la

plaque tournante. Lorsque vous appuyez sur ce bouton, le voyant dans le coin supérieur gauche

du bouton s'allume. Appuyez sur le bouton START (DÉMARRER) pour activer la plaque. Si vous

appuyez de nouveau sur le bouton, la plaque tournante s'arrête et le voyant s'éteint. Ce bouton

peut être utilisé avec le bouton CARRIAGE JOG (CHARIOT MANUEL).

Le bouton CARRIAGE JOG (CHARIOT MANUEL) vous permet d'activer manuellement le chariot. Lorsque

vous appuyez sur ce bouton, l'un des voyants dans le coin supérieur droit ou gauche du bouton

s'allume. Le voyant dans le coin supérieur gauche indique que le chariot remonte lorsque vous

appuyez sur le bouton START (DÉMARRER). Inversement, le voyant dans le coin supérieur droit indique

que le chariot descend lorsque vous appuyez sur le bouton START (DÉMARRER). Pour suspendre

l'opération, appuyez simplement de nouveau sur ce bouton. Les deux voyants s'éteignent. Ce bouton

peut être utilisé avec le bouton TURNTABLE JOG (PLAQUE TOURNANTE MANUELLE).

Appuyez sur ce bouton RESET (RÉINITIALISER), puis sur le bouton START (DÉMARRER), pour réinitialiser

le système. La plaque tournante revient à sa position initiale et le chariot s'abaisse.

Appuyez sur le bouton TOP WRAPS (EMBALLAGES SUPÉRIEURS) pour sélectionner le nombre

d'emballages supérieurs souhaité (0 à 9).

PAGE 23 OF 27 0321 IH-1020

Page 24

COMMANDES DE FONCTIONNEMENT SUITE

Appuyez sur le bouton BOTTOM WRAPS (EMBALLAGES INFÉRIEURS) pour sélectionner le nombre

d'emballages inférieurs souhaité (0 à 9).

Tournez le bouton de réglage CARRIAGE SPEED (VITESSE DU CHARIOT) dans le sens horaire pour

augmenter la vitesse du chariot et dans le sens antihoraire pour la diminuer. Cela vous permet

de régler la superposition de votre film.

Tournez le bouton de réglage TURNTABLE SPEED (VITESSE DE LA PLAQUE) dans le sens horaire pour

augmenter la vitesse de la plaque tournante et dans le sens antihoraire pour la diminuer.

Le bouton BANDING (BANDEROLAGE) est utilisé pour appliquer des emballages de renforcement

multicouches en mode automatique ou manuel. Poussez et maintenez ce bouton : le chariot ne

remonte/descend plus. Lorsque le bouton est relâché, le chariot reprend ses mouvements.

Le bouton EMERGENCY STOP (ARRÊT D'URGENCE) arrête la plaque tournante en cas d'urgence.

Cela N'arrête PAS la plaque tournante instantanément. La plaque tournante s'arrête en roue libre,

selon le poids de la charge, lorsque vous appuyez sur ce bouton.

Cela ALLUME ou ÉTEINT l'alimentation principale. Également utilisé pour reprendre l'utilisation après

une coupure d'électricité.

AVERTISSEMENT! La BARRE DE SÉCURITÉ POUR PIED, située sous le chariot porte-film,

ARRÊT

fonctionne uniquement lorsque la machine est allumée. Lorsque la barre est activée,

l'alimentation principale s'éteint. L'alimentation principale se réactive lorsque vous

relâchez la barre. Pour reprendre l'utilisation, appuyez sur START (DÉMARRER).

PAGE 24 OF 27 0321 IH-1020

Page 25

CHARGEMENT DE FILM

d’alimentation

Poignée d’allongement

FONCTIONNEMENT DE LA MACHINE

MISE EN GARDE! Assurez-vous d'enfoncer le

bouton EMERGENCY STOP (ARRÊT D'URGENCE)

avant d'enrouler le film et de tirer sur ce

bouton lorsque le film est enroulé.

1. Placez le film sur le mandrin de film.

2. Mettez la poignée d'allongement sur la position OFF

(Arrêt) pour relâcher la tension du film.

3. Suivez le diagramme d'alimentation du film

et enfilez l'extrémité du film de 1.8 m (70 po)

COMPLÈTEMENT à travers les rouleaux.

4. Mettez la poignée d'allongement du la position OFF

(Arrêt) pour relâcher la tension du film.

5. Tournez le bouton de réglage de la tension

d'allongement dans le sens horaire pour augmenter

la tension du film et dans le sens antihoraire pour la

diminuer.

6. Fixez solidement le film sur la palette. Si vous formez

un nœud avec l'extrémité du film, cela permet

d'attacher le film à la palette.

DÉMARRAGE NORMAL DU SYSTÈME

1. Placez le film sur le mandrin de film.

2. Mettez la poignée d'allongement sur la position OFF

(Arrêt) pour relâcher la tension du film.

(Position arrêt)

MOINS

ALLONGEMENT

Indicateur

de la tension

d'allongement

OFF (Arrêt)

PLUS

500100

Bouton de réglage de la

tension d’allongement

ON (Marche)

Diagramme

du film

APPLICATION DES EMBALLAGES

DE RENFORCEMENT

1. Appuyez comme d'habitude sur le bouton START

(DÉMARRER) pour lancer le cycle.

2. À mesure que le chariot monte, maintenez

enfoncé le bouton BANDING (BANDEROLAGE).

Le chariot monte, maintenez enfoncé le bouton

BANDING (BANDEROLAGE). Le chariot s'arrête et les

emballages de renforcement sont appliqués.

3. Enroulez le film selon les instructions et attachez-le

au produit.

3. Le cycle reprend si vous relâchez le bouton

BANDING (BANDEROLAGE).

4. Déterminez le nombre souhaité d'emballages

supérieurs et inférieurs.

5. Sélectionnez le mode d'emballage A ou B.

6. Appuyez sur le bouton START (DÉMARRER) pour

lancer le cycle.

ÉTAT D'ARRÊT

1. En cas d'urgence, appuyez sur le bouton STOP

(ARRÊTER). Cela annule le cycle d'emballage en

cours et arrête immédiatement le système.

2. Corrigez le problème

3. Tirez sur le bouton STOP (ARRÊTER) et effectuez la

procédure de démarrage normal du système.

REMARQUE : Après avoir appuyé sur le

bouton STOP (ARRÊTER), attendez au moins 60

secondes avant de tirer sur ce même bouton.

Cela permet de désactiver complètement la

carte à microcontrôleur.

PAGE 25 OF 27 0321 IH-1020

Page 26

PROCÉDURE D'AUTO-TEST

A1

E1

D1

A2

C2

Un opérateur peut vérifier l'état de la machine en

exécutant un auto-test. Si la procédure est effectuée

correctement, l'écran INFO indique l'emplacement du ou

des problèmes.

Pour exécuter l'auto-test, suivez la procédure suivante :

1. Tournez les boutons de réglage de vitesse de

la plaque tournante et du chariot à la position

maximale (dans le sens horaire).

2. Mettez une charge sur la plaque tournante (environ

91 cm [36 po] de haut).

3. Allumez le sectionneur principal tout en maintenant

enfoncés les boutons TURNTABLE JOG (PLAQUE

TOURNANTE MANUELLE) et CARRIAGE JOG (CHARIOT

MANUEL).

4. Relâchez les boutons lorsque l'écran affiche « EE ».

5. Appuyez sur le bouton START (DÉMARRER). La

machine effectue le test qui dure environ 2 minutes.

6. L'écran affiche le code d'alarme. Reportezvous au tableau ci-dessous pour obtenir des

renseignements sur le code.

AFFICHAGE EMPLACEMENTS SUSPECTS

A1 Barre de sécurité du chariot porte-film

Bouton EMERGENCY STOP (ARRÊT D'URGENCE)

Interrupteur de sécurité du boîtier électrique

B1 Interrupteur de fin de course maximal supérieur

du boîtier électrique

C1 Interrupteur de fin de course maximal inférieur du

boîtier électrique

D1 Compteur de la plaque tournante/Détecteur de

proximité principal

E1 Bouton-poussoir BANDING (BANDEROLAGE)

F1 Bouton-poussoir START (DÉMARRER)

G1 Détecteur optique de la hauteur du paquet

A2 Voyant START (DÉMARRER)

B2 Moteur de la plaque tournante

C2 Moteur du chariot

F1

B1

B2

G1

C1

PAGE 26 OF 27 0321 IH-1020

Page 27

DÉPANNAGE

1

0

uline.ca

ARRÊT

AVERTISSEMENT! Veillez à ce que seul un

personnel qualifié effectue les inspections, le

dépannage et le remplacement des pièces.

MISE EN GARDE! Coupez toutes les alimentations,

dont celle de la commande externe qui peut

être présente, avant toute opération d'entretien

des variateurs de fréquence. ATTENDEZ trois (3)

minutes que les condensateurs du bus c.c. se

déchargent. L'affichage du variateur de

fréquence et/ou les voyants à DEL ne constituent

pas des indicateurs précis de l'absence de

tension du bus c.c.

PROBLÈME DE FONCTIONNEMENT CAUSES RECOMMANDATIONS

La machine ne s'allume pas sous tension. L'alimentation électrique principale est

coupée.

La machine n'est pas branchée à une

prise de 120 V c.a.

L'alimentation électrique est

défectueuse.

La batterie interne n'est pas chargée.

Le pied du chariot porte-film est

engagé.

Vérifiez que la machine est alimentée en électricité.

Vérifiez que l'interrupteur est en position de marche.

Vérifiez que la tension en direction de la machine

correspond aux étiquettes d'alimentation électrique

apposées au module d'alimentation.

Enlevez l'obstruction du pied du chariot porte-film.

Le chariot porte-film est défectueux. Le bouton FILM CARRIAGE SPEED

(VITESSE DU CHARIOT PORTE-FILM) n'est

pas réglé à un niveau suffisant.

La résistance du potentiomètre ne

correspond pas à 5K_ partout.

Le bras de levier de l'interrupteur de fin

de course du chariot est obstrué.

La carte à microcontrôleur à l'intérieur

du boîtier électrique n'est pas activée.

La plaque tournante est défectueuse. Le bouton du potentiomètre de vitesse

de la plaque tournante n'est pas réglé

à un niveau suffisant.

La résistance du potentiomètre ne

correspond pas à 5K_ partout.

La carte à microcontrôleur à l'intérieur

du boîtier électrique n'est pas activée.

Le moteur de la plaque tournante ne

fonctionne pas.

Réglez le potentiomètre vers 100 % pour définir la

vitesse.

Serrez le câblage, remplacez le cadran au besoin.

Enlevez l'obstruction et/ou nettoyez la tête de

l'interrupteur de fin de course.

Vérifiez et allumez le disjoncteur principal.

Réglez le potentiomètre vers 100 % pour définir la

vitesse.

Serrez le câblage, remplacez le cadran au besoin.

Vérifiez et allumez le disjoncteur principal.

Serrez ou remplacez le câblage du moteur au

besoin.

Vérifiez les contraintes mécaniques de la plaque

tournante.

Remplacez le microcontrôleur ou le relais de sortie

de la plaque tournante.

-800-295-551

PAGE 27 OF 27 0321 IH-1020

Loading...

Loading...