Page 1

π H-3518

GREEN MACHINE

AIR PILLOW MACHINE

1- 80 0-295 -5510

uline.com

SPECIFICATIONS

The Uline Green Machine converts rolls of pre–

perforated and sealed flat tubing into air cushions for

use as void fill packaging.

CAUTION! For safety reasons the cushions are

to be used ONLY as a packaging material and

MUST NOT be used as a flotation aid, a toy or

other unspecified use.

SAFETY INSTRUCTIONS

Operators must never use the machine other than as

specified by the instructions set out in this manual.

1. Do not remove any part of machine casing.

2. Under no circumstances should operators expose or

modify the electrical components of the machine.

3. Keep hands away from all moving parts while

operating machine.

4. The machine will automatically shut down in the

event of a film blockage. To restart the machine,

clear the blockage and press reset. Press the start

button to restart.

TECHNICAL SPECIFICATIONS

Machine Dimensions (L x W x H) 14 x 12 x 11"

Machine Weight 19 lbs.

Power Supply 110V, 60 H z

Film Material Low and high density

polyethylene blend

Roll Length 1640 '

Roll Width 8"

6. In the event of an emergency, press the red

emergency stop button. The machine will no

longer be live. To restart the machine, rotate the

emergency stop button, which will spring out to the

normal operating position.

NOTE: THE EMERGENCY STOP BUTTON IS ONLY TO

BE USED FOR EMERGENCIES. For normal start

and stop, use the start/stop button.

7. If the machine is to remain inactive for longer

periods of time, the machine should be switched

off using the main power switch located where the

power cable enters the machine.

5. Do not place flammable materials over the heat

sealing section.

PAGE 1 OF 3 0812 IH-3518

Page 2

OPERATING INSTRUCTIONS

LOADING THE FILM

1. Place machine on a level, stable surface, leaving

sufficient clearance from the floor to prevent the

cushions backing up into the machine.

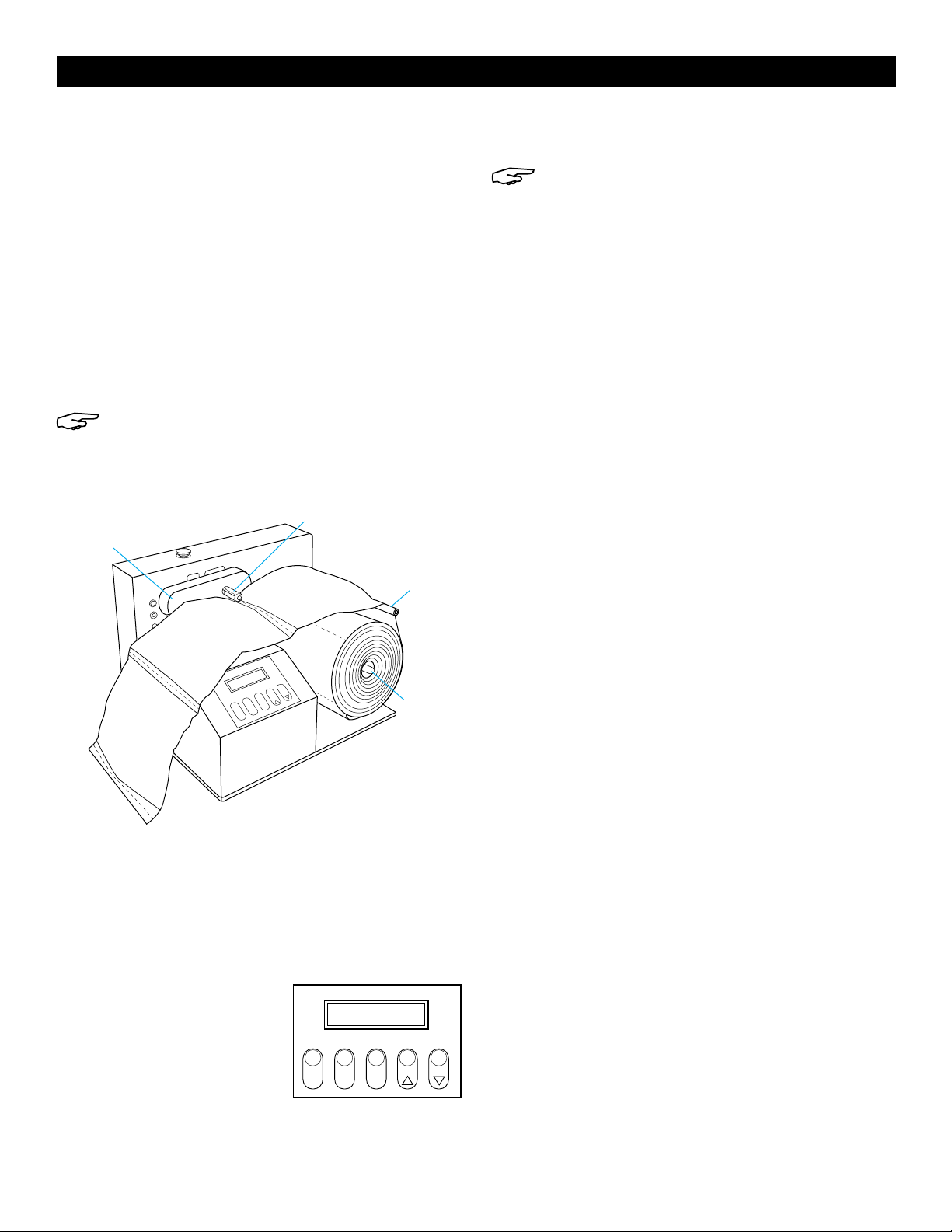

2. Slide the roll onto the axle (A). Ensure that the open

end of the film is closest to the machine. (See Figure 1)

3. Take the film and loop it back over the top roller (B).

4. Open the heat seal mechanism by lifting black

handle (C).

5. Thread the open end of the film onto the guide bar

and pull through the open heat seal mechanism

and through the rubber drive wheel mechanism (D).

NOTE: Ensure that the perforation is NOT on the

drive wheel.

6. The film is now ready to run.

Figure 1

D

C

B

3. Using the Select button scroll through the

parameters on the menu that need to be changed.

NOTE: The only parameters that should be

changed are Heat Seal, Blower and Bag Count

settings.

4. Up or down arrows adjust the value of parameters

as required. To change heat seal settings, it is best

to increase or decrease in increments of 10.

5. Once the required parameters have been set, scroll

through the parameters until 'Exit Engineer Mode' is

displayed. Press the 'UP' key.

ADJUSTING THE OPERATOR SETTINGS

Without entering Engineer Mode, the operator can

adjust the following parameters to give the exact

cushion functionality required:

1. Heat seal setting +/- 10

2. Blower speed +/- 10

3. Number of cushions 1 to 10,000

ADJUSTING THE HEAT SEAL AND BLOWER SETTINGS

The operator is able to adjust these settings up 10 units

and down 10 units using the following procedure:

A

SETTING THE MACHINE SETTING PARAMETERS

(ENGINEERING SETTINGS)

1. Factory default settings are normally ideal for

operation. If machine is not sealing, inflating

or counting properly, settings may need to be

changed.

2. In order to change the

default settings, the

following password needs

to be keyed into the display

panel using the arrow keys:

DDUUUDUD (See Figure 2)

START

STOP

SELECTRESET

1. Press Select to scroll through the menu options until

you get to the parameter that is to be changed

2. Press the UP/DOWN buttons to change the value

ADJUSTING THE NUMBER OF CUSHIONS

The Uline Green Machine can be run in manual mode

or automatic. In manual, the operator presses the Start

button to begin producing air cushions and the Stop

button to finish the production. The Uline Green Machine

will default to produce 10,000 cushions unless instructed

to do otherwise using the automatic operation mode.

To automatically select the number of cushions required,

press the Select button and scroll through the menu

until you see the Select Number of Bags. Press the UP/

DOWN buttons to adjust to the number you require, up

to 10,000 cushions.

The machine will stop when the count quantity as been

reached.

Figure 2

PAGE 2 OF 3 0812 IH-3518

Page 3

OPERATING INSTRUCTIONS CONTINUED

ADJUSTING THE NUMBER OF CUSHIONS

To pause the machine during the run press the start/stop

button.

To restart the machine press start. Machine will resume

and continue to required quantity.

RESTARTING AFTER THE ROLL OF FILM HAS RUN OUT

(CONTINUED)

CUSTOMER ASSISTANCE MESSAGES

In the instance of an error occurring the following

messages may appear on the control panel:

01 Under Voltage 03 Under Current

02 Over Voltage 04 Over Current

If an error message appears please follow the

instructions below:

When the roll has finished, the display on the control

panel will read OUT OF FILM. Reload a new roll and

press the START button.

1. Press the emergency stop button

2. Leave for 30 seconds

3. Retry the machine

TROUBLESHOOTING

OPERATING ISSUE RECOMMENDATIONS

Machine does not start Check that the emergency stop button is not depressed

Check if main power is on

Film comes off guide bar (Fig 1: ‘D’)

(Display will show ‘Out of Film’ message)

Check that the roll has been properly loaded onto the axle

Check that the film has been wound around the rollers in the correct manner

Check bags for overinflation

Check film edge is not dragging against machine chassis

Heat seals are not strong enough Check on overinflation

Change the Operator Settings on the Control Panel

If this does not work, a trained operator can change the Engineering Settings

Heat seals are burning through Reduce the heat

Reduce the Blower as overinflation can cause burning through, particularly on the

smaller cushion size

Cushions deflate Usually due to the incorrect amount of heat in the heat seals. This may occur if too

Film not sealing Check for damaged belts

Film Jam Remove jam and press the START button to restart production

Film winding around heat seal/rollers Check for damaged belts

Recommended: a daily inspection of belts will help prevent the above issues.

much or too little heat is used

Change settings accordingly

Check on overinflation

Check for damaged belts

Reduce temperature

π

CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1- 800 -295- 5 510

PAGE 3 OF 3 0812 IH-3518

uline.com

Loading...

Loading...