Page 1

Service Manual

2010

2115R

2115WC

2115WCOL

2175/2275DWRR

2175R

2175RF

2175WC

2175WCOL

CLR2160

CLRCO2175

CO2175/CO2275DWR

CO2175F

Entertain with U-Line Elegance

2175BEV

2275DWRWS

2275DWRWOL

2275ZWC

2275ZWCOL

1115R

1115WC

1175BEV

1175R

1175WC

ADA24R

www.u-line.com

Page 2

Section 1 - General Information

IMPORTANTIMPORTANT

INTRODUCTION

Three generations of pride and quality manufacturing and design improvements are built into all U-Line products. The result: U-Line leads the market with innovative technology and superior craftsmanship.

This manual contains specific instructions for servicing the U-Line Products which include these models:

ÉCHELON MODELS

2115R

2115WC

2115WCOL

2275DWRR

2175R

2175RF

2175WC

2175WCOL

CLR2160

CLRCO2175

CO2275DWR

CO2175F

2175BEV

2275DWRWS

2275DWRWS

2275ZWC

2275ZWCOL

ORIGINS MODELS

1115R

1115WC

1175BEV

1175R

1175WC

ADA24R

POTENTIAL PROBLEMS WITH HFC-134A

This service manual has been written to cover products

manufactured with HFC-134A. HFC-134A compressors receive a

synthetic based ester oil charge. The hygroscopic (water

attraction) property of ester oil is many times greater than the

mineral oils previously used with CFC-12. High system moisture

causes the formation of acids and alcohol which can damage the

compressor. Systems should not be left open for more than fifteen

(15) minutes at any time as humidity from the air will enter the

system. To ensure system dehydration, the system should be pulled

down to 100 microns and vacuum pump oil (mineral oil) must not

be allowed to enter the system.

Cleanliness of the system is extremely important. The presence of

residues (chlorinated or greasy residues, mineral oil, or impurities)

can lead to capillary tube restrictions, oil return problems and

compressor damage. Do not use flux on brazed joints.

Check for the latest service related information at ULineService.com. The Technical Knowledge base is

continuously updated and can be accessed anytime. Each

U-Line product has a unique method of installation, but it

is consistent with U-Line’s methods and requirement.

Follow the installation guidelines for the U-Line product

you are installing.

1-1

Page 3

Section 1 - General Information

TABLE OF CONTENTS

SECTION 1 - GENERAL INFORMATION

Introduction ..................................................................................................................................................................1-1

Potential Problems With HFC-134A.......................................................................................................................1-1

Safety Precautions .......................................................................................................................................................1-4

Safety Alert Definitions ....................................................................................................................................1-4

General Precautions .........................................................................................................................................1-4

U-Line Corporation Limited Warranty...................................................................................................................1-5

Product Liability Policy................................................................................................................................................1-6

Serial Number Format ................................................................................................................................................1-7

Warranty Claims Procedure......................................................................................................................................1-7

Proof of Purchase.........................................................................................................................................................1-7

Parts Listing....................................................................................................................................................................1-8

SECTION 2 - TROUBLESHOOTING

Customer Call Guide ..................................................................................................................................................2-1

Refrigeration System Diagnosis Guide....................................................................................................................2-3

Thermistor Types.........................................................................................................................................................2-3

Troubleshooting ...........................................................................................................................................................2-4

SECTION 3 - SERVICE AND REPAIR

Operation ......................................................................................................................................................................3-1

CLR2160 .............................................................................................................................................................3-1

CLRCO2175 ......................................................................................................................................................3-4

2175R/2115R/2175WC/2115WC/2175BEV/2175DWRR/2275DWRWS/2275ZWC

(Includes Overlay Models) ............................................................................................................................3-14

CO2175F/2175RF/CO2175DWR ...............................................................................................................3-17

1175R/1115R/1175WC/1115WC/1175BEV/ADA24R ...........................................................................3-27

Operating Environmental/Climate Control Requirements .............................................................................3-29

For All - Except WC, DWRWS, BEV Center, CODWR & 2275ZWC/2275ZWCOL .................3-29

For WC, DWRWS, CODWR, BEV, CLRCO & 2275ZWC/2275ZWCOL .....................................3-29

Échelon Keypad Options ...............................................................................................................................3-29

Échelon Service Menu ....................................................................................................................................3-32

Error Codes .....................................................................................................................................................3-34

Échelon Service Quick Reference Card .....................................................................................................3-36

Échelon Electronic Control Quick Reference Guide .............................................................................3-37

Origins Electronic Control ............................................................................................................................3-38

Origins Keypad Options.................................................................................................................................3-38

Origins Service Menu .....................................................................................................................................3-39

Error Codes .....................................................................................................................................................3-39

Origins Electronic Control Quick Reference Guide ..............................................................................3-40

Refrigeration System Diagnosis Guide .......................................................................................................3-41

Defrost Information - All models ..........................................................................................................................3-41

Specifications ..............................................................................................................................................................3-42

CLR2160 ...........................................................................................................................................................3-42

CLRCO2175 ....................................................................................................................................................3-43

2175R/2115R/2175WC/2115WC/2175BEV2175WRR/2175DWRWS/2275ZWC ........................3-44

CO2175F/2175RF/CO2175DWR ...............................................................................................................3-45

1175R/1115R/1175WC/1115WC/1175BEV/ADA24R ...........................................................................3-46

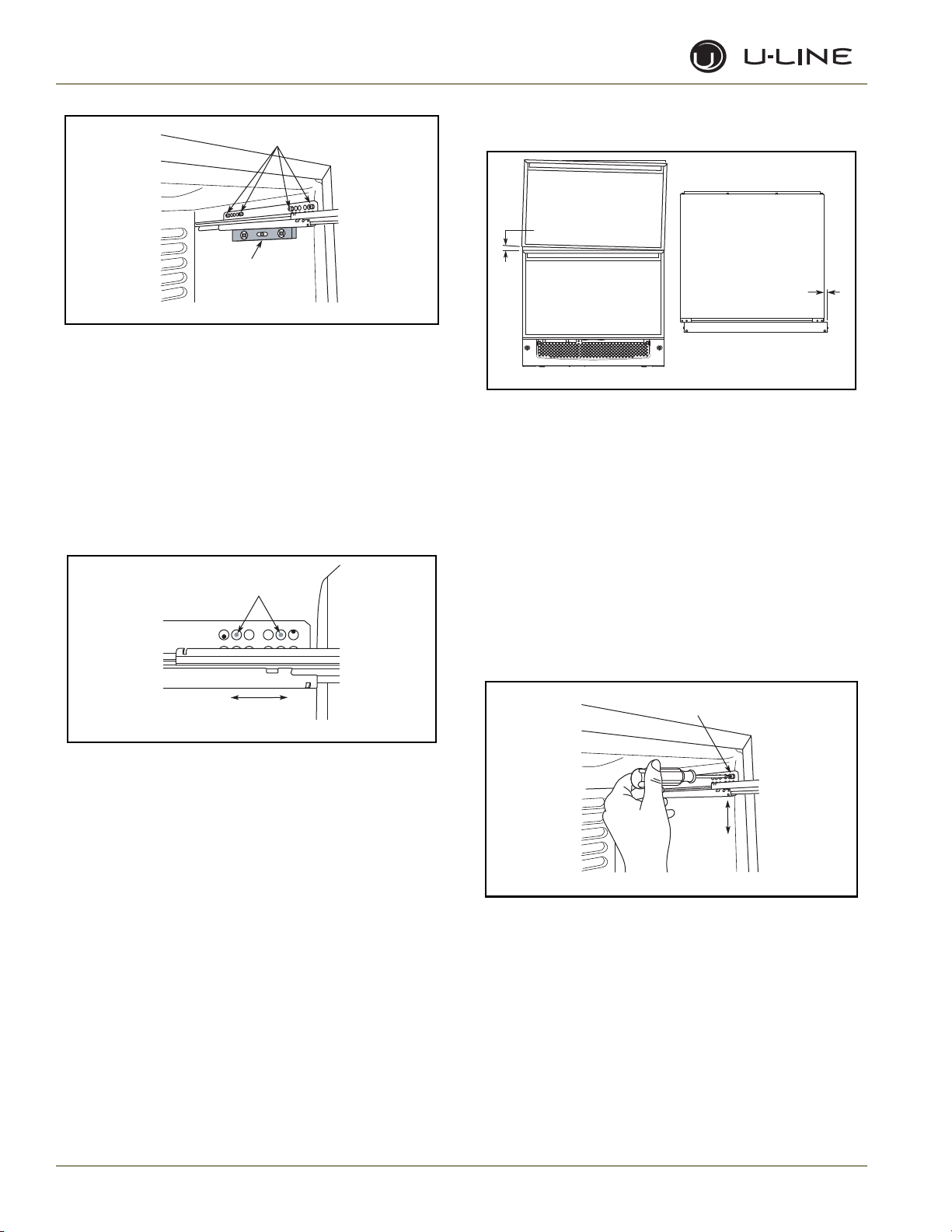

Adjustments and Repair............................................................................................................................................3-47

Leveling ..............................................................................................................................................................3-47

Door Alignment - Échelon Models .............................................................................................................3-47

Door Alignment - Origins Models ..............................................................................................................3-49

Drawer Alignment ..........................................................................................................................................3-49

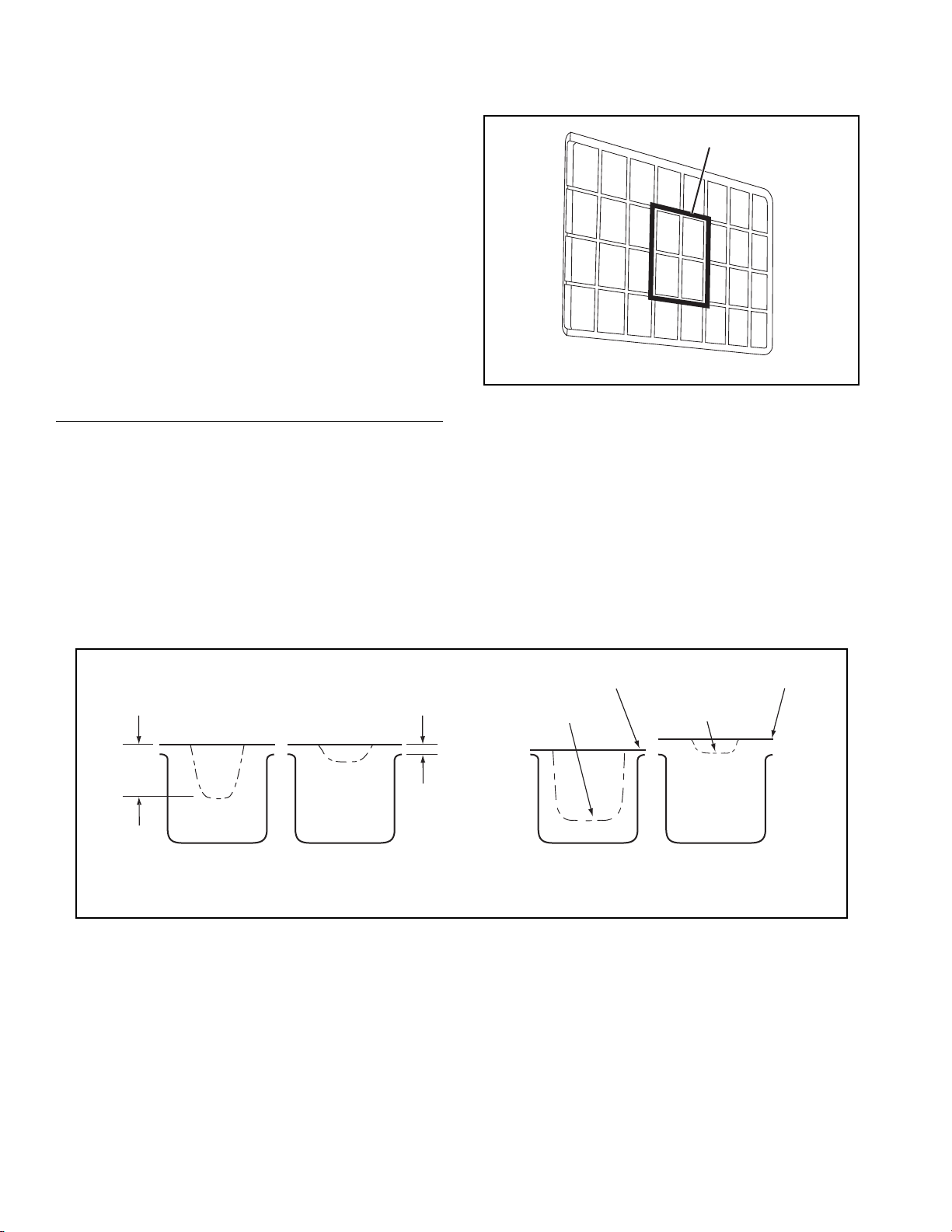

Ice Cube Thickness Adjustment ..................................................................................................................3-53

Parts Replacement ..........................................................................................................................................3-54

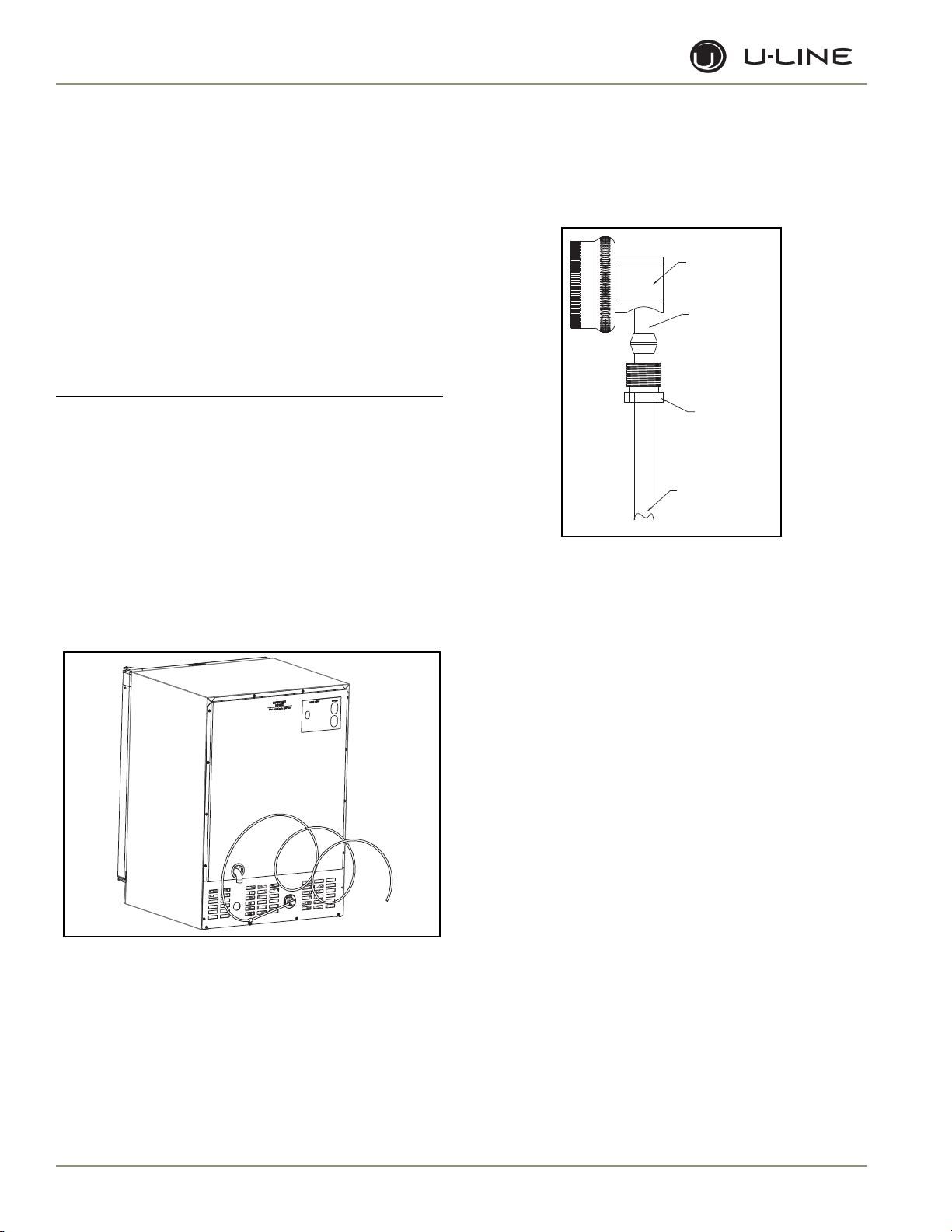

Plumbing - CLR2160 and CLRCO2175 ...............................................................................................................3-57

SECTION 4 - PARTS

Parts Listing .................................................................................................................

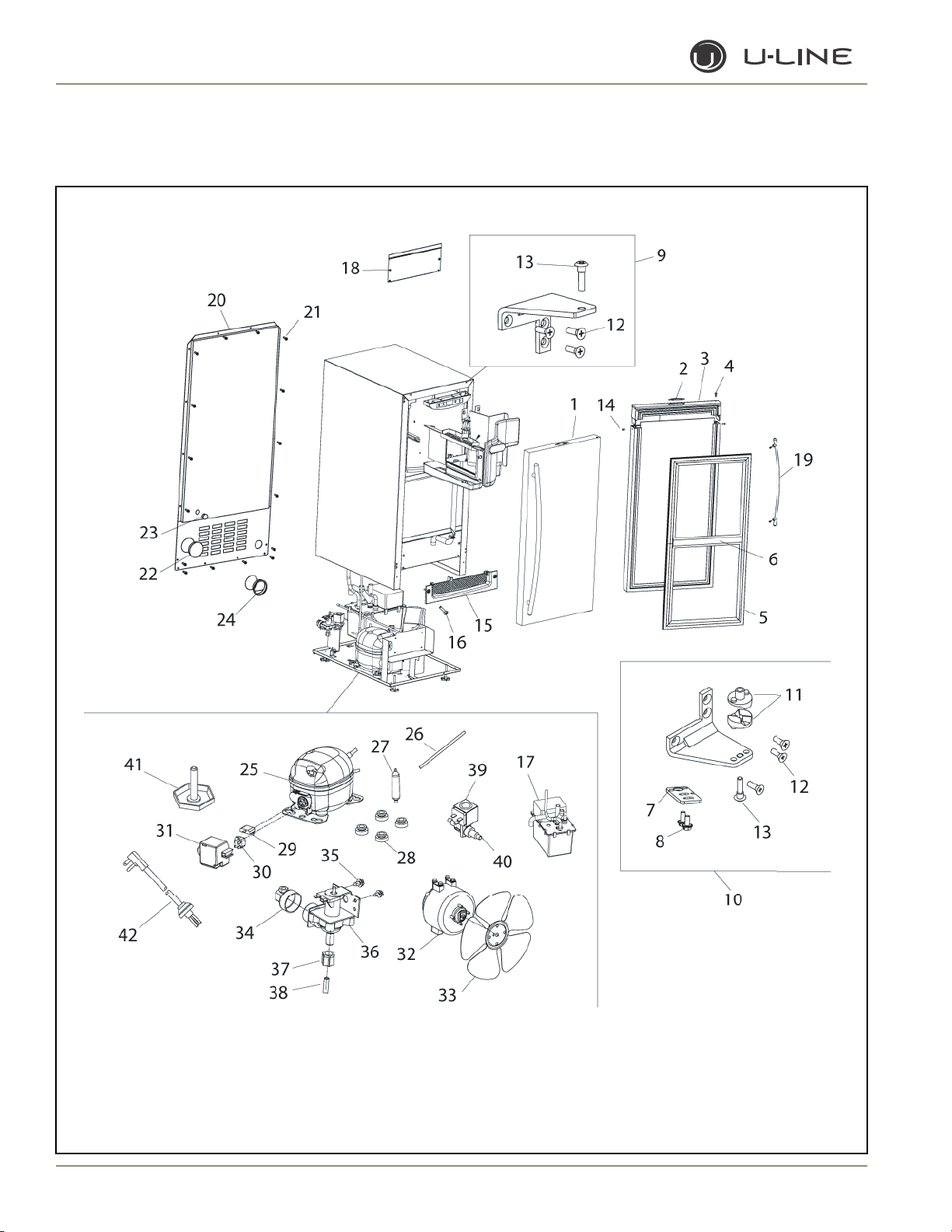

Anti-Tip Kit ...................................................................................................................................................................4-1

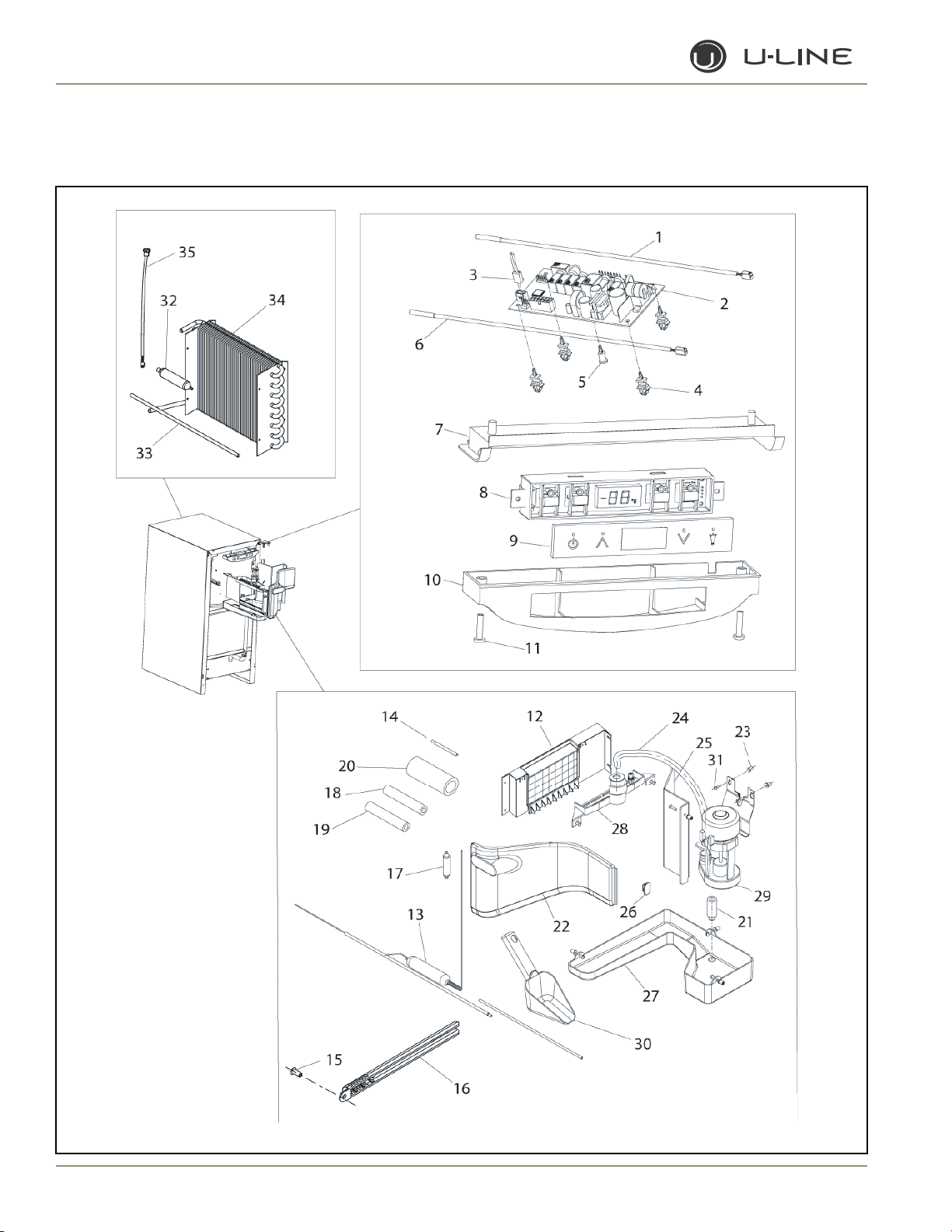

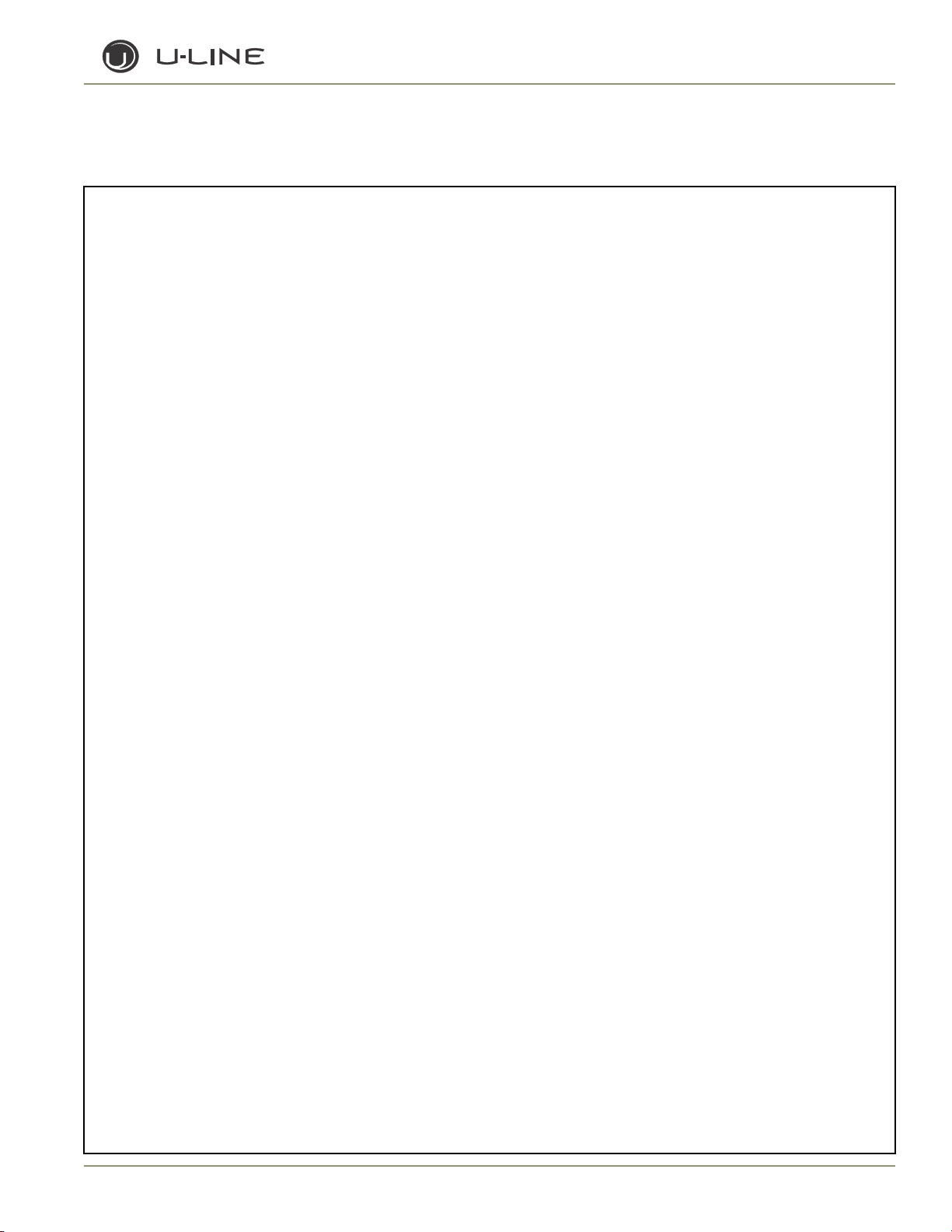

CLR2160 .......................................................................................................................................................................4-2

CLRCO2175..................................................................................................................................................................4-6

.................................................4-1

1-2

Page 4

Section 1 - General Information

2175R............................................................................................................................................................................4-14

2115R............................................................................................................................................................................4-18

2175WC/2175WCOL ..............................................................................................................................................4-22

2115WC/WCOL........................................................................................................................................................4-26

2175BEV .......................................................................................................................................................................4-30

2275DWRR.................................................................................................................................................................4-34

2275DWRWS/2275DWRWOL.............................................................................................................................4-38

CO2175F......................................................................................................................................................................4-42

2175RF..........................................................................................................................................................................4-50

CO2175DWR.............................................................................................................................................................4-56

2275ZWC/2275ZWCOL.........................................................................................................................................4-64

1175R ...........................................................................................................................................................................4-70

1115R............................................................................................................................................................................4-74

1175WC ......................................................................................................................................................................4-78

1115WC ......................................................................................................................................................................4-82

1175BEV .......................................................................................................................................................................4-86

ADA24R.......................................................................................................................................................................4-90

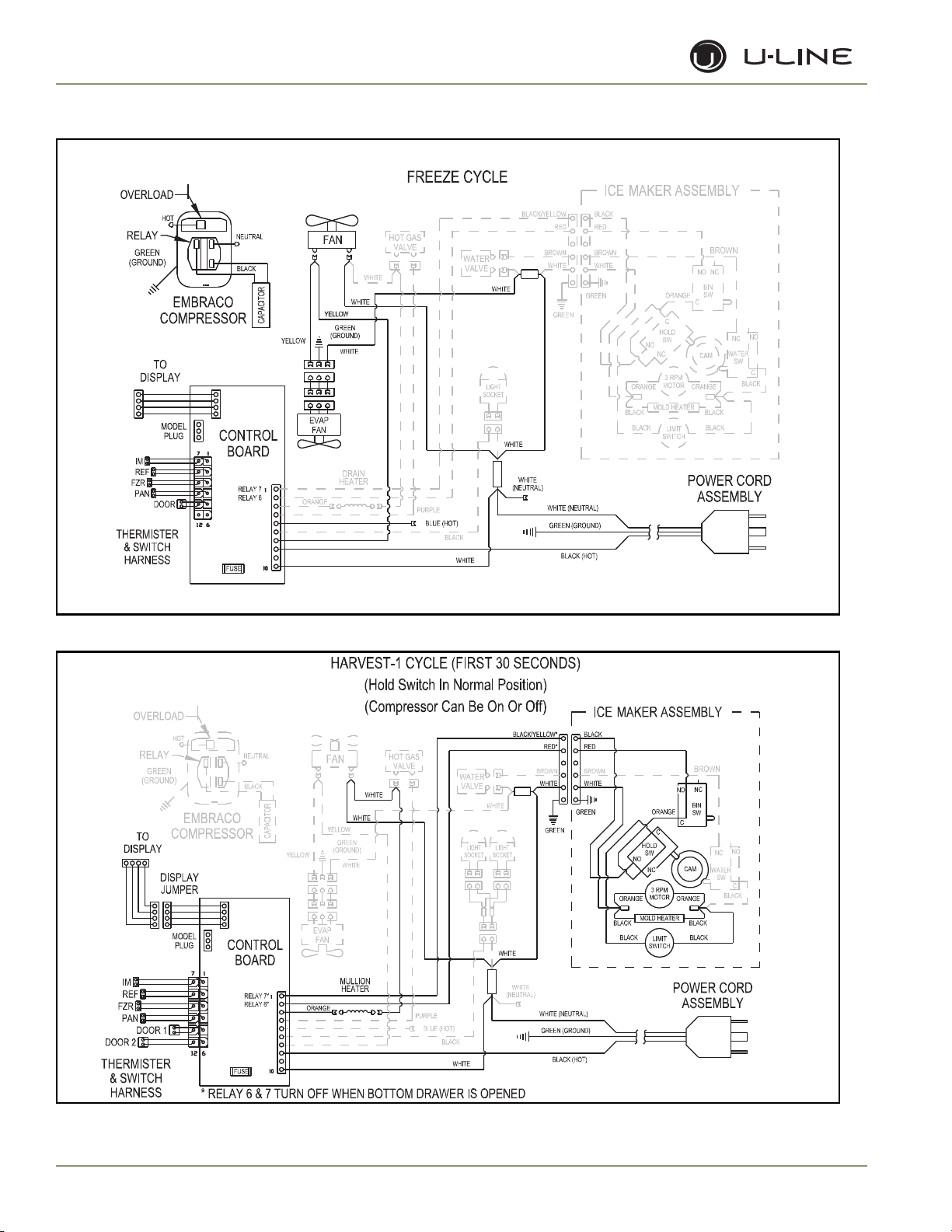

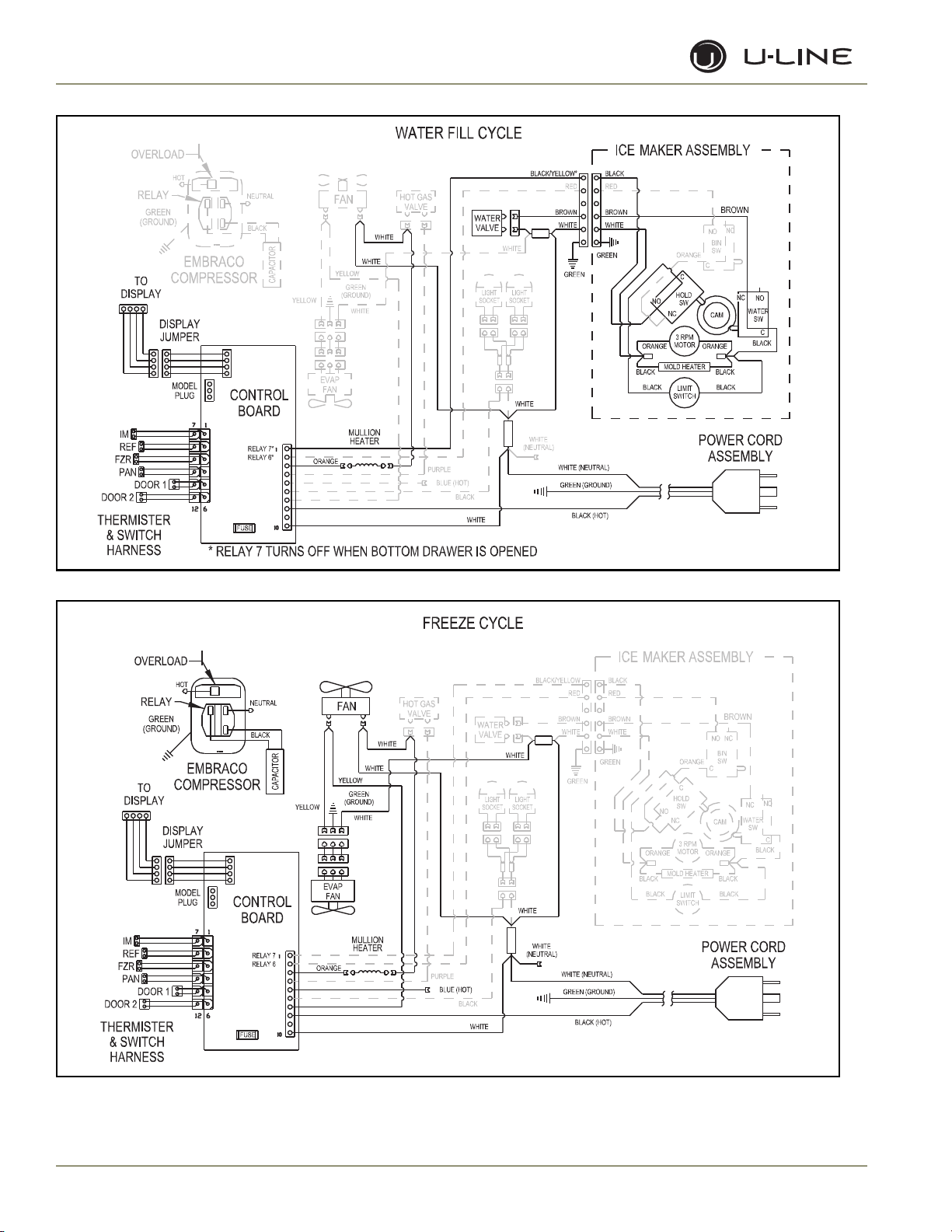

SECTION 5 - WIRING DIAGRAMS

CLR2160 .......................................................................................................................................................................5-1

CLRCO2175 ................................................................................................................................................................5-1

2115R, 2115WC, 2175R, 2175WC ........................................................................................................................5-2

2275DWRWS/2275ZWC ........................................................................................................................................5-2

2175DWRR ..................................................................................................................................................................5-3

2175RF ........................................................................................................................................................................... 5-3

CO2175F ......................................................................................................................................................................5-4

CO2175DWR ..............................................................................................................................................................5-4

1175R/1115R/1175WC/1115WC/1175BEV/ADA24R .......................................................................................5-5

1-3

Page 5

Section 1 - General Information

IMPORTANT

IMPORTANT

DANGER

DANGER

WARNING

CAUTION

DANGER

DANGER

WARNING

WARNING

CAUTION

IMPORTANT

IMPORTANT

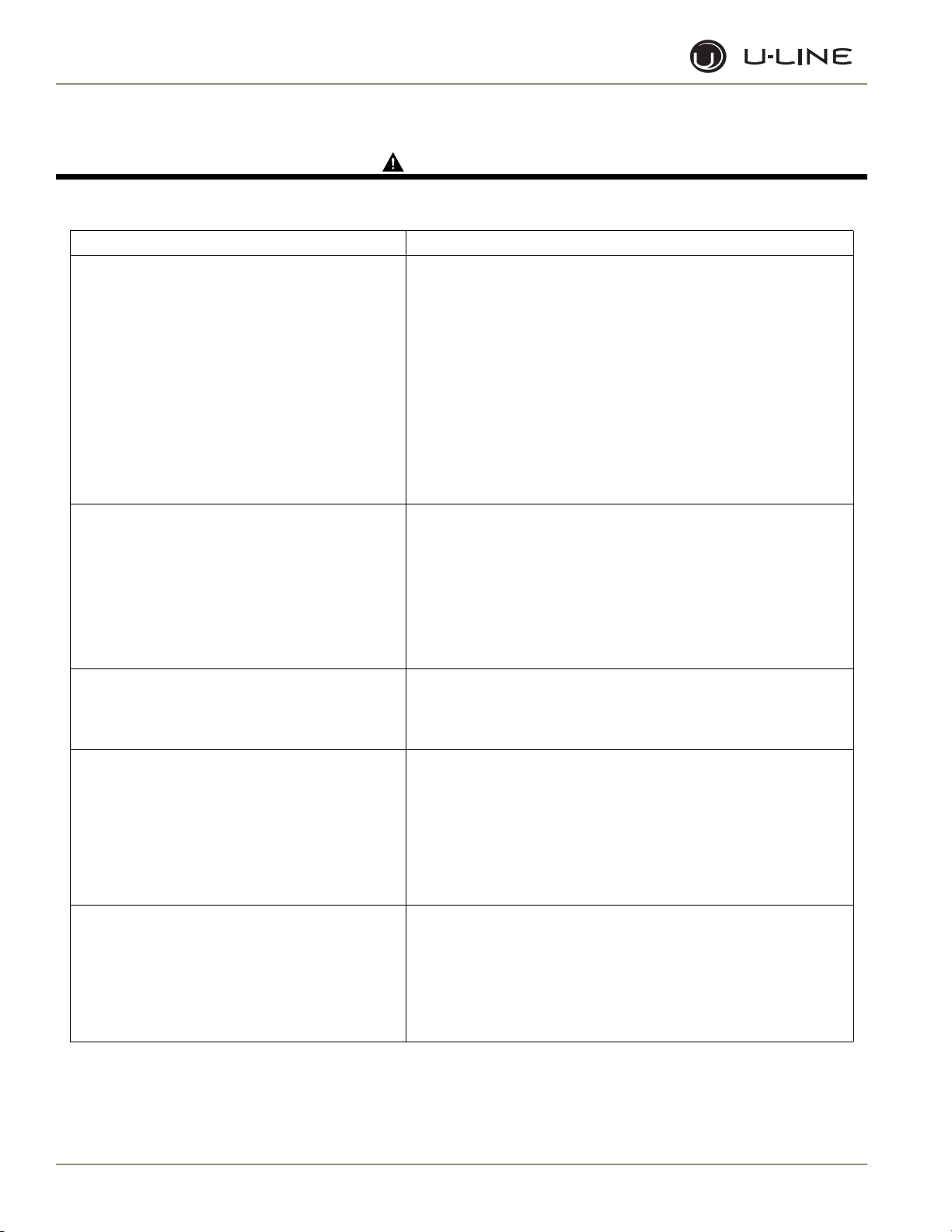

SAFETY PRECAUTIONS

PLEASE READ all instructions completely before

attempting to service the unit.

• Proper installation procedures must be followed if this

unit is being initially installed, or is moved to a new

location after being in service. An INSTALLATION

GUIDE for your unit, providing complete installation

information is available from U-Line Corporation directly,

and must be consulted before any installation is begun. ULine contact information appears on the rear cover of this

guide.

• This unit requires connection to a grounded (threeprong), polarized receptacle that has been placed by a

qualified electrician in accordance with applicable

electrical codes.

Safety Alert Definitions

Safety items throughout this guide are labeled with a Danger, Warning or Caution based on the risk type:

Danger means that failure to follow this safety statement will

result in severe personal injury or death.

Warning means that failure to follow this safety

statement could result in serious personal injury or death.

Caution means that failure to follow this safety statement

may result in minor or moderate personal injury, property

or equipment damage.

General Precautions

Use this appliance for its intended purpose only and follow these general precautions along with those listed throughout this guide:

• Altering, cutting of power cord, removal of power cord,

removal of power plug, or direct wiring can cause

serious injury, fire and/or loss of property and/or life

and will void the warranty.

• Never use an extension cord to connect power to the

unit.

• Always keep your working area dry.

Failure to use the Anti-Tip Kit when it is included with the

product can cause serious personal injury. The Anti-Tip

Kit must be installed before the unit is used.

• Use care when moving and handling the unit. Use gloves

to prevent personal injury from sharp edges.

• If your model requires defrosting, DO NOT use any type

of heater to defrost. Using a heater to speed up defrosting

can cause personal injury and damage to the inner lining.

• Do not lift unit by door handle.

• Never install or operate the unit behind closed doors. Be

sure front grille is free of obstruction. Obstructing free air

flow can cause the unit to malfunction and may void the

warranty.

• Failure to clean the condenser every three months can

cause the unit to malfunction. This could void the

warranty.

• Allow unit temperature to stabilize for 24 hours before

use.

• If your model requires defrosting, never use an ice pick or

other sharp instrument to help speed up defrosting. These

instruments can puncture the inner lining or damage

cooling unit.

• Use only genuine U-Line replacement parts. Imitation

parts can damage the unit, affect its operation or

performance and may void the warranty.

RISK OF CHILD ENTRAPMENT. Before you throw away your

old refrigerator or freezer, take off the doors and leave shelves

in place so that children may not easily climb inside.

SHOCK HAZARD - Electrical Grounding Required.

• Never attempt to repair or perform maintenance on

the unit until the electricity has been disconnected.

• Never remove the round grounding prong from the

plug and never use a two-prong grounding adapter.

1-4

Page 6

Section 1 - General Information

U-LINE CORPORATION LIMITED WARRANTY

U-Line Corporation warrants each U-Line product to be free from defects in materials and workmanship for a period of one year from the date

of purchase; and warrants the sealed system (consisting of the compressor, the condenser, the evaporator, the hot gas bypass valve, the dryer

and the connecting tubing) in each U-Line product to be free from defects in materials and workmanship for a period of five years from the date

of purchase. During the initial one-year warranty period for all U-Line products U-Line shall: (1) at U-Lines option, repair any product or replace

any part of a product that breaches this warranty; and (2) for all Marine, RV and Domestic U-Line products sold and serviced in the United

States (including Alaska and Hawaii) and Canada, U-Line shall cover the labor costs incurred in connection with the replacement of any defective

part. During years two through five of the warranty period for the sealed system, U-Line shall: (1) repair or replace any part of the sealed

system that breaches this warranty; and (2) for all Marine, RV and Domestic U-Line products sold and serviced in the United States (including

Alaska and Hawaii) and Canada, U-Line shall cover the labor costs incurred in connection with the replacement of any defective part of the

sealed system. All other charges, including transportation charges for replacements under this warranty and labor costs not specifically covered

by this warranty, shall be borne by you. This warranty is extended only to the original purchaser of the U-Line product. The Registration Card

included with the product should be promptly completed by you and mailed back to U-Line or you can register on-line at www.ULineService.com.

The following are excluded from this limited warranty: installation charges; damages caused by disasters or acts of God, such as fire, floods, wind

and lightening; damages incurred or resulting from shipping, improper installation, unauthorized modification, or misuse/abuse of the product;

customer education calls; food loss/spoilage; door and water level adjustments (except during the first 90 days from the date of purchase);

defrosting the product; adjusting the controls; door reversal; or cleaning the condenser.

If a product defect is discovered during the applicable warranty period, you must promptly notify either the dealer from whom you purchased

the product or U-Line at P.O. Box 245040, Milwaukee, Wisconsin 53224 or at 414-354-0300. In no event shall such notification be received later

than 30 days after the expiration of the applicable warranty period. U-Line may require that defective parts be returned, at your expense, to ULines factory in Milwaukee, Wisconsin, for inspection. Any action by you for breach of warranty must be commenced within one year after the

expiration of the applicable warranty period.

This limited warranty is in lieu of any other warranty, express or implied, including, but not limited to any implied warranty of

merchantability or fitness for a particular purpose; provided however, that to the extent required by law, implied warranties

are included but do not extend beyond the duration of the express warranty first set forth above. U-Lines sole liability and

your exclusive remedy under this warranty is set forth in the initial paragraph above. U-Line shall have no liability whatsoever

for any incidental, consequential or special damages arising from the sale, use or installation of the product or from any other

cause whatsoever, whether based on warranty (express or implied) or otherwise based on contract, tort or any other theory

of liability.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential

damages, so the above limitations may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

1-5

Page 7

Section 1 - General Information

PRODUCT LIABILITY POLICY

Field service technicians are authorized to make an initial assessment. If in the servicer’s judgment

the damage is the result of a product defect, the product would be removed and returned to U-Line in an

unaltered condition. The dealer would then be authorized to permanently replace the end-user’s product at

no cost to the end-user. Please call U-Line immediately at 800-779-2547 to initiate the RA and product exchange process.

If in the servicer’s judgment the damage is the result of installation issues (water

connection/drain, etc.), the consumer would be so notified and the correction would be made by the servicer

or installer without requiring removal of the product. Any claim for damages should be directed to the

original installer.

Any U-Line unit involved in an alleged property damage claim must remain unaltered and unrepaired,

for evaluation. No service or repairs should be performed on any unit suspected to be involved

in a property damage situation. If a unit has been altered or repaired in the field prior to ULine’s evaluation, any claim for damage may be declined.

If the unit in question is a U-Line CLR or CLRCO with a drain pump, both the unit and the drain pump

(regardless of the manufacturer) must be returned to U-Line Corporation.

To complete the damage claim process for the customer, please obtain the following and forward to U-Line

at onlineservice@U-Line.com, fax to 414-354-5696 or mail to the address below.

Pictures of the unit, installation and any alleged property damage.

Inquire when the problem first appeared, any prior problems with the product and provide a brief

description of the alleged damages.

To expedite the claim process, U-Line will need two damage repair estimates.

Reference the RA number and customer name when providing this information.

If a unit is returned to U-Line, this evaluation will take approximately ten business days. No field service

company is authorized to perform this evaluation. When a Return Authorization Number is issued,

and the unit has been boxed in a U-Line carton, U-Line should be contacted and then will make arrangements

for shipping, or designate a truck line to have the unit shipped freight collect.

If U-Line’s evaluation finds the unit, (or U-Line P60 pump) to be defective, causing the property damage, the

damage claim will be reviewed by the U-Line Customer Assurance Department.

If U-Line’s evaluation finds the unit not to be defective, does not repeat a failure or does not leak any water

from the U-Line unit or U-Line P60 pump, all claims for damage will be declined.

When a product evaluation is needed, it is the customer’s responsibility to assure that the unit is returned

for evaluation. If the customer fails to do so, or has the unit repaired in the field prior to U-Line’s evaluation,

any claim for damage will be declined.

8900 N. 55th St. • P.O. Box 245040

Milwaukee, WI 53224-9540

414/354-0300 • Fax: 414/354-7905

Website: www.u-line.com

1-6

Leaders In Quality Undercounter Refrigeration

Page 8

Section 1 - General Information

IMPORTANT

IMPORTANT

0914997-11-XXXX

Year

Month

Factory Internal

Control Number

Shop

Order

SERIAL NUMBER FORMAT

Starting October 2009 U-Line Corporation went to a

13 digit serial number. Anything before that date will

have 12 digits.

The serial number is divided into four segments. A typical serial number is 0914997-11-0005.

Number

The first two digits of the first segment, 09, represents the year the unit was made.

The next four/five digits of the first segment, 14997, represent the shop order number. Order number 14997 is assigned for the Model CLRCO2175B-40 units.

The next two digit segment, 12, represents the month the unit was made.

The last four digit segment, XXXX, is a factory internal control number used at U-Line Corporation.

WARRANTY CLAIMS PROCEDURE

WHEN SUBMITTING CLAIMS FOR WARRANTY

PAYMENT, PLEASE FOLLOW THESE

GUIDELINES.

You can use any form you would normally use to bill your customer (your own computer generated form, Narda, USA, etc.). Claims can also be filed on-line at www.u-lineservice.com.

The model and serial number MUST be on the claims. Claims will not be paid without a model and serial number.

If you used a part in your repair, you MUST put the part number, the invoice number and where the part came from. Claims will be returned without this information.

If you work on more than one unit per service call please submit a separate claim for each unit.

We track all defects through warranty claims, so please be specific on what the repair was. If it is a system leak, please specify where the leak was.

Please be sure the claim is legible. If the claim form cannot be read, it will be returned, unpaid.

Remember: Door and water level adjustments are 90 day warranties only.

If you are changing out a unit please supply the model and serial number of both units (the unit being replaced and the new unit) and the R.A. number.

Occasionally the customer does not return their warranty cards. In

this case we use the date the unit was shipped to our distributor for

a beginning warranty date. This may cause the claim to be rejected

for a proof of purchase. If you want to check on a purchase date, you

may contact the U-Line Corporation Customer Assurance

Department at 1-800-779-2547. This will allow you to get a proof of

purchase, if needed, before you submit the claim.

At U-Line, parts and labor claims are paid separately. Included in

labor are freon and recovery charges, all other parts are handled by

the parts department. We require that some parts be returned to us,

so we may return them to our vendor. It will be noted on your

packing list if we require you to return the part. If a part is to be

returned please include a copy of the packing list and a copy of your

claim. If the part was purchased at one of our part distributors, you

must handle the part warranty with that company. For labor payment

please send a readable copy of your claim to U-Line Corporation,

P.O. Box 245040, Milwaukee WI, 53224-9540, or fax it to 414-354-

5696. Claims can also be filed on-line at www.u-lineservice.com.

PROOF OF PURCHASE

Proof of Purchase and/or Proof of Install is an important part of the warranty claim process. Sometimes it is difficult to obtain a proper Proof of Purchase/Proof of Install for a number of different reasons:

• The customer does not have a copy (only the original).

• The customer has only their copy of the final Walk Through or

sign-off of new construction.

• Other valid reasons that prevent your technician from leaving the

job site with a suitable Proof of Purchase/ Proof of Install.

We understand the problem and have modified our Proof of Purchase policy to help you in these situations.

Effective immediately, if a copy of the Proof of Purchase/Proof of Install is not available at the site, the technician should record the following information on the Labor Invoice:

• The name of the selling Dealer

• The date of purchase/installation

• The Order or Invoice number (if available)

• The type of document they saw, i.e. Store Receipt, Closing Papers,

Sign-Off of Building Permit, Final Walk Through, etc.

If we have this information on the Labor Invoice, and we have the

other information that is needed (correct Serial Number, type of

repair, time spent on repairs, parts used in the repair,

invoice number for the part, etc.), we will be able to process the

invoice for you in a timely manner.

1-7

Page 9

Section 1 - General Information

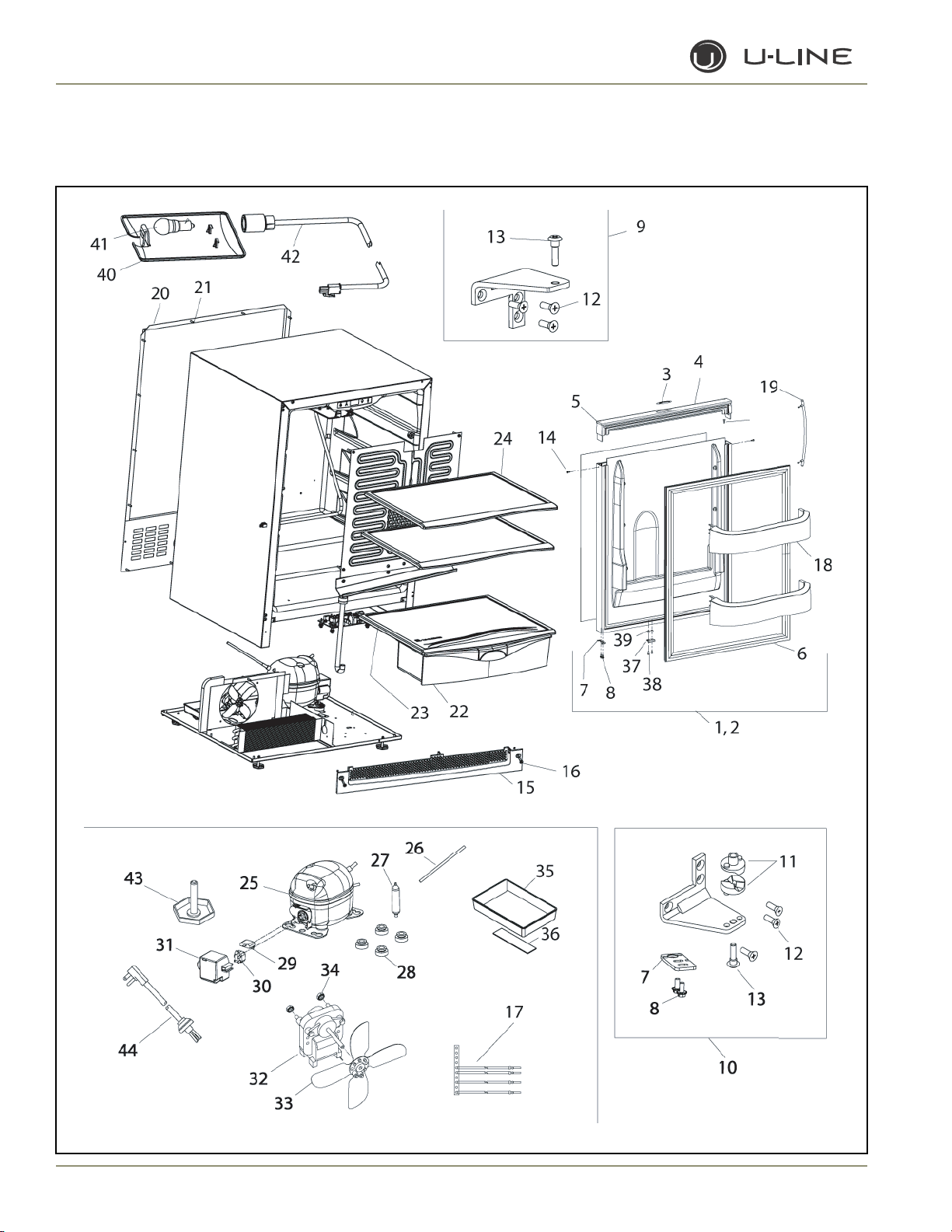

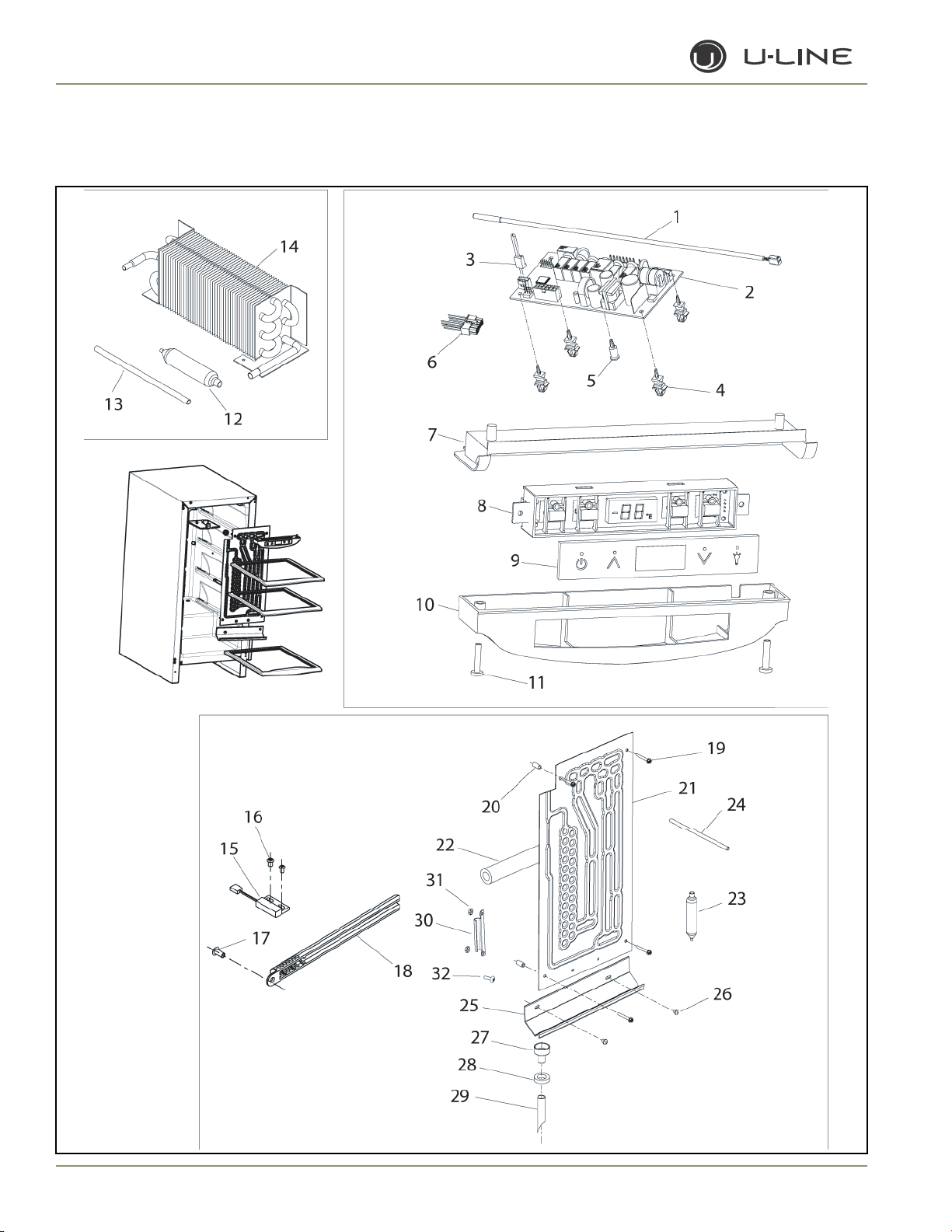

PARTS LISTING

How to Order Replacement Parts

1. Refer to Service Parts and locate the illustration(s) for the model you are servicing.

2. Locate the desired part to be serviced and note the item number assigned to it.

3. Locate the item number within the parts list. Note the full description and the corresponding part number. If this is for a warranty unit, indicate and record the model and serial numbers.

4. When ordering parts, it will be necessary to supply Model Number, Serial Number, Part Number, Part Description and in some cases Color or Voltage.

All warranty parts will be shipped at no charge as long as warranty

status has been confirmed. If we require that a part be returned to Uline, you will be informaed at the time the order is placed. It will be

noted on your packing list if we require you to return a part or if you

may field scrap it. If U-Line requires a defective part to be returned, a

prepaid shipping label will be included with your new replacement

part. When returning parts enclose a copy of your packing list and a

copy of your labor claim, showing the model and serial number, and

tag or label the part with the nature of the defect.

Our warranty records may not match the customer's information. In

this case, a proof of purchase will be required. If you do not have the

proof of purchase at the time the order is placed, the part will be

sent net 15 days, charged to a Visa or MasterCard or COD if you

don't have an open account with U-Line Corporation. When the

proof of purchase is provided, we will credit your account (a check

will be sent if the part was sent COD).

5. Parts may be ordered on-line, by FAX or phone:

www.U-LineService.com

onlineparts@u-line.com

FAX Number (414) 354-7905

Phone Number (414) 354-0300 or (800) 779-2547;

REPLACEMENT PARTS: Use only genuine U-Line replacement

parts. The use of non-U-Line parts can reduce ice rate, cause water

to overflow from ice maker mold, damage the unit, and can void the

warranty.

1-8

Page 10

CUSTOMER CALL GUIDE

Section 2 - Troubleshooting

The following guide has been developed to help answer

frequently asked questions. It can be used by persons

Concern Response

The unit is not cold enough. • Are you familiar with the factory temperature specifications for

• Is the door or drawers sealing properly? If the door or drawer is

• Has the door or drawers been left open?

• Is the condenser clean? U-Line’s warranty does not cover cleaning

• Is the unit behind closed doors or the vent restricted? The front

• Is the unit in an application of heavy usage? Heavy usage or high

• Did you try adjusting the temperature to a colder level? Adjust to

Temperature is too cold. Check actual temperature versus set-point.

The unit is frosting up. • Are you familiar with the defrost technology of your unit?

• Is the door or drawers sealing properly? If the door or drawer

• Has the door or drawers been left open?

• Is the unit in an application of heavy usage? Heavy usage or high

The ice cubes are sticking together. • Is the door or drawers sealing properly? This could cause the ice

• Have you tried to shake the ice bucket? If the ice sits without

• Does the unit need to be defrosted?

Water is leaking out of the unit. Have you checked the water connection to the unit? U-Line’s

warranty does not cover installation adjustments.

No ice or not enough ice. • Are you aware of the factory specifications for ice production?

• Is the ice maker bin arm down? When the arm is up, the ice

• Is the door or drawers sealing properly? U-Line’s warranty is 90

• Has the ice maker been turned off at the display?

scheduling service calls. Things to consider before

scheduling a service call:

your unit? Many factors can cause these temperatures to vary;

ambient temperature, application, amount of use (number of times

and length of time the door or drawers or opened and closed),

etc.

not sealed properly, it allows heat into the unit. U-Line’s warranty

is 90 days for door or drawer adjustments.

the condenser.

grille must be free of obstruction.

ambient temperatures will cause a unit to frost up.

a colder level. Be sure to allow 24 hours between temperature

control adjustments.

is not sealing properly, it allows heat/humidity into the unit.

U-Line’s warranty is 90 days for door or drawer adjustments.

ambient temperatures will cause a unit to frost up.

cubes to stick together.

being used, it will tend to stick together. Shaking the bucket will

usually break the ice cubes apart. If the ice has been sitting for a

long time, you should consider discarding it and make a fresh

batch.

maker will not make ice.

days for door adjustments.

2-1

Page 11

Section 2 - Troubleshooting

CLR2160 Model Only:

Concern Response

The cubes are wet. • The storage bin that holds the ice is not refrigerated. The

cubes in the bin are slowly melting down. The bin will

maintain a temperature of 32°F to 34°F.

The floor is very warm in front of my unit. • The unit is designed for a built-in application, so warm air

will vent through the front grille, below the door. There

is a safety feature built into the control board that will

shut down the unit if warm air can’t vent or is restricted.

No ice, but water pours into the trough and

down into the drain.

When the unit is turned on, all I get is water

fill.

The ice does not come out in a perfect cube

shape.

The cubes do not fall into the bin as

individual cubes.

Not enough ice is stored in the bin. • Make sure unit is level.

• The standpipe needs to be inserted into the drain hole of

the water trough to maintain the proper level of water

inside the trough.

• Once the unit is turned on, there will be a three-minute

water fill. This ensures a fresh batch of water has filled

the trough. If water flows more than three minutes, a

service call will be required.

• When the ice is made, a small hole or “dimple” will

appear on the front or top of the cube. Increasing or

decreasing the time of the freeze cycle will adjust the size

of the dimple.

• This is normal. You can use the scoop to break the cubes

apart.

Drawer Models Only:

Concern Response

There is excessive condensation on the mullion. • The mullion has a heater behind it that should keep the mullion free of

frost and sweat. In extremely humid conditions, some sweat may appear

on the mullion or lower drawer handle/gasket. The heater will not

operate in ambient temperatures over 90°F.

• Drawer units should not be used outdoors or in an area that is not airconditioned.

Drawer will not close properly. • The drawer slides have a self-closing feature which engages when the

drawer is about 1” (25.4mm) from being closed. There may be some

resistance. If the resistance is hard to overcome, try closing the drawers

with more force a couple of times and then try slowly closing the drawers

again.

2175DWRR Model Only:

Concern Response

There is a water leak inside the unit. • Make sure the drain is not blocked. Remove any blockage.

2-2

Page 12

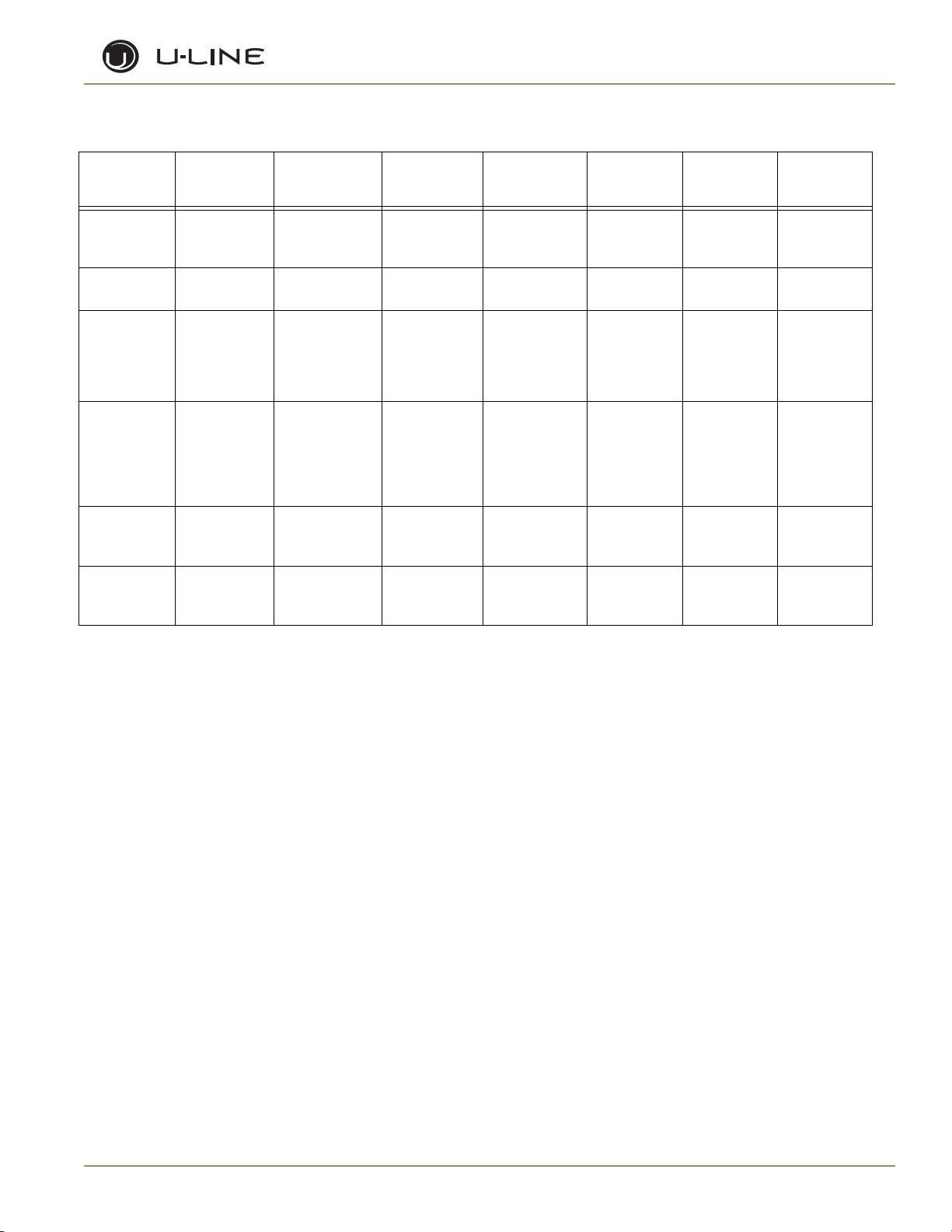

REFRIGERATION SYSTEM DIAGNOSIS GUIDE

Section 2 - Troubleshooting

System

Condition

Normal Normal Slightly below

Overcharge Higher than

Undercharge Lower than

Partial

Restriction

Complete

Restriction

No Gas 0 PSIG to 25” Room

Suction

Pressure

normal

normal

Somewhat

lower than

normal

vacuum

In deep

vacuum

Suction

Line

room

temperature

Very cold may

frost heavily

Warm-near

room

temperature

Warm - near

room

temperature

Room

temperature

(cool)

temperature

(cool)

Compressor

Discharge

Very hot Very hot Warm Cold Normal

Slightly warm

to hot

Hot Warm Warm Extremely

Very hot Top passes

Room

temperature

(cool)

Cool to hot Room

Condenser Capillary

Evaporator Wattage

Tub e

Hot to warm Cool Cold Higher than

Lower than

cold near

inlet - Outlet

below room

temperature

warm - Lower

passes cool

(near room

temperature)

due to liquid

Room

temperature

(cool)

temperature

(cool)

Room

temperature

(cool) or

colder

Room

temperature

(cool)

Room

temperature

(cool)

Extremely

cold near

inlet - Outlet

below room

temperature

backing up

No

refrigeration

No

refrigeration

Lower than

Lower than

Lower than

normal

normal

normal

normal

normal

THERMISTOR TYPES

Type 1 (Black)

Resistance at 77°F = 10,000 Ohms ± 5%.

Operating range is 185,000 to 650 Ohms. Resistance goes

down as temperature increases. Type 1 does not need to be

calibrated and can be changed without changing other wires

or board.

Type 2 (White)

Resistance at 77°F = 5,000 Ohms ± 5%.

Operating range is 180,000 to 550 Ohms. Resistance goes

down as temperature increases. Type 2 does not need to be

calibrated and can be changed without changing other wires

or board.

2-3

Page 13

Section 2 - Troubleshooting

TROUBLESHOOTING

DANGER

Never attempt to repair or perform maintenance on the unit until the main electrical power has been

disconnected from the unit.

Cause Remedy

Will not eject ice (water frozen).

1. Control setting too cold.

2. Control inoperable.

3. Bin switch inoperable.

4. Limit switch defective (open).

5. Ice maker assembly motor stalled.

6. Broken wire in ice maker circuit.

7. Water soaked cabinet insulation.

8. Dirty condenser.

Will not fill with water.

1. Water supply valve closed.

2. Water switch inoperable (open).

3. Solenoid valve inoperable.

4. Fill tube outlet frozen.

5. Broken wire in water fill circuit.

Will not stop making ice.

1. Bin switch inoperable (closed).

2. Bin arm binding.

Water will not stop filling.

1. Adjust control warmer.

2. Replace control.

3. Replace bin switch.

4. Replace limit switch.

5. Replace motor.

6. Repair or replace wiring.

7. Replace foamed cabinet assembly.

8. Clean condenser.

1. Open water supply valve.

2. Replace water switch.

3. Replace solenoid valve.

4. Defrost fill tube.

5. Repair or replace wiring.

1. Replace bin switch.

2. Lubricate bin arm pivot points or loosen bin arm lever screw.

1. Water switch inoperable (closed).

2. Solenoid valve inoperable.

3. Stalled ice maker motor.

4. Temperature control inoperable. Ice maker is in

continuous harvest cycle.

Ejector blades will not stop turning.

1. Control inoperable.

2. Hold switch inoperable.

3. Broken wiring.

4. Short in mold heater.

2-4

1. Replace water switch.

2. Replace solenoid valve.

3. Replace motor.

4. Replace temperature control.

1. Replace control. Replace hold switch.

2. Repair or replace wiring.

3. Replace heater.

4. Replace mold heater.

Page 14

Low ice production.

Section 2 - Troubleshooting

Cause Remedy

1. Control set too cold.

2. Fan motor stalled.

3. Ice cubes too large.

4. Dirty condenser.

5. Bypass valve stuck open (Frost Free units only).

Not freezing (compressor and fan motors

operating).

1. Little or no frost pattern on evaporator.

2. Bypass valve stuck open (Frost Free units only).

Not freezing (compressor not operating - fans

operating).

1. Relay inoperable.

2. Overload inoperable (open).

3. Compressor inoperable.

Not freezing (compressor and fans not operating).

1. Power cord not plugged in.

2. Unit turned off.

3. Control panel inoperable.

4. Hold switch inoperable (open).

5. Control inoperable.

6. Broken wire in freeze circuit.

7. Ejector blades not in freeze position (12:00)

Compressor overheating.

1. Adjust control warmer.

2. Replace fan motor.

3. Lower water fill adjustment.

4. Clean condenser.

5. Replace bypass valve (Frost Free units only).

1. Check for sealed system leak or restriction.

2. Replace bypass valve (Frost Free units only).

1. Replace relay.

2. Replace overload.

3. Replace compressor.

1. Plug in power cord.

2. Press On/Off button to turn unit on.

3. Replace control panel.

4. Replace hold switch.

5. Replace control.

6. Repair or replace wiring.

7. Manually advance ejector blades to the 12:00 position (test ice

maker and limit switch).

1. Condenser air flow restricted.

2. Condenser fan blade obstructed.

3. Condenser fan motor stalled.

4. Compressor inoperable.

Compressor will not stop operating.

1. Temperature set too cold.

2. Control inoperable.

3. Control sensing bulb not sensing mold

temperature.

4. Evaporator fan stalled.

1. Remove restriction (clean condenser and grille).

2. Remove blade restriction.

3. Replace fan motor.

4. Replace compressor.

1. Adjust temperature warmer.

2. Replace control.

3. Fully insert bulb into ice maker tube. Rout bulb away from

compressor discharge tube.

4. Remove obstruction or replace motor.

2-5

Page 15

Section 2 - Troubleshooting

Cause Remedy

Water leak (under unit).

1. Water supply line leaking at solenoid valve inlet.

2. Water line leaking at solenoid valve outlet.

3. Water line leaking at fill tube.

4. Defrost drain line not in drain pan.

5. Crack in water line.

Water leak (inside unit).

1. Ice maker assembly fill cup obstructed.

2. Fill ice cup and fill tube out of alignment.

3. Water level too high.

4. Defrost drain plugged (Frost Free units only).

Excessive frost buildup.

1. Door gasket not sealing properly.

2. Door out of alignment.

3. Water soaked cabinet insulation.

4. Light stays on when door is closed.

Noisy.

1. Tighten or replace fitting.

2. Replace water line and fitting.

3. Tighten clamp or replace fill tube assembly.

4. Position drain line in drain pan.

5. Replace water line.

1. Remove obstruction.

2. Align fill tube and fill cup.

3. Adjust water level.

4. Ice in drain trough (Frost Free units only) (see below).

1. Adjust door hinges or replace door gasket.

2. Adjust door hinges.

3. Replace foamed cabinet assembly.

4. Repair or adjust light bracket.

1. Copper refrigeration tube touching cabinet.

2. Fan blade touching shroud.

3. Fan blade obstruction (wiring, foam insulation,

packaging material).

Ice buildup in drain trough or drainage problem.

1. Obstructed drain cup or tube.

2. Drain trough heater failed (Frost Free units

only).

3. Kinked drain tube.

4. Drain trough spout and drain cup not aligned.

Unit will not defrost (Frost Free units only).

1. Bypass coil inoperable.

2. Defrost timer inoperable.

3. Bypass valve inoperable.

Fresh food temperature too cold.

1. Temperature control set too cold.

2. Bin/Freezer door not closing.

3. Ice bucket not fully inserted.

1. Carefully adjust tubing.

2. Adjust fan mounting or shroud.

3. Remove obstruction.

1. Clear obstruction.

2. Replace drain trough heater (Frost Free units only).

3. Reroute drain tube.

4. Align drain trough and drain cup.

1. Replace bypass valve.

2. Replace defrost timer.

3. Replace bypass valve.

1. Adjust control to warmer setting (counterclockwise).

2. Adjust or replace door.

3. Check for ice behind bucket and push ice bucket in place.

2-6

Page 16

Section 3 - Service and Repair

OPERATION

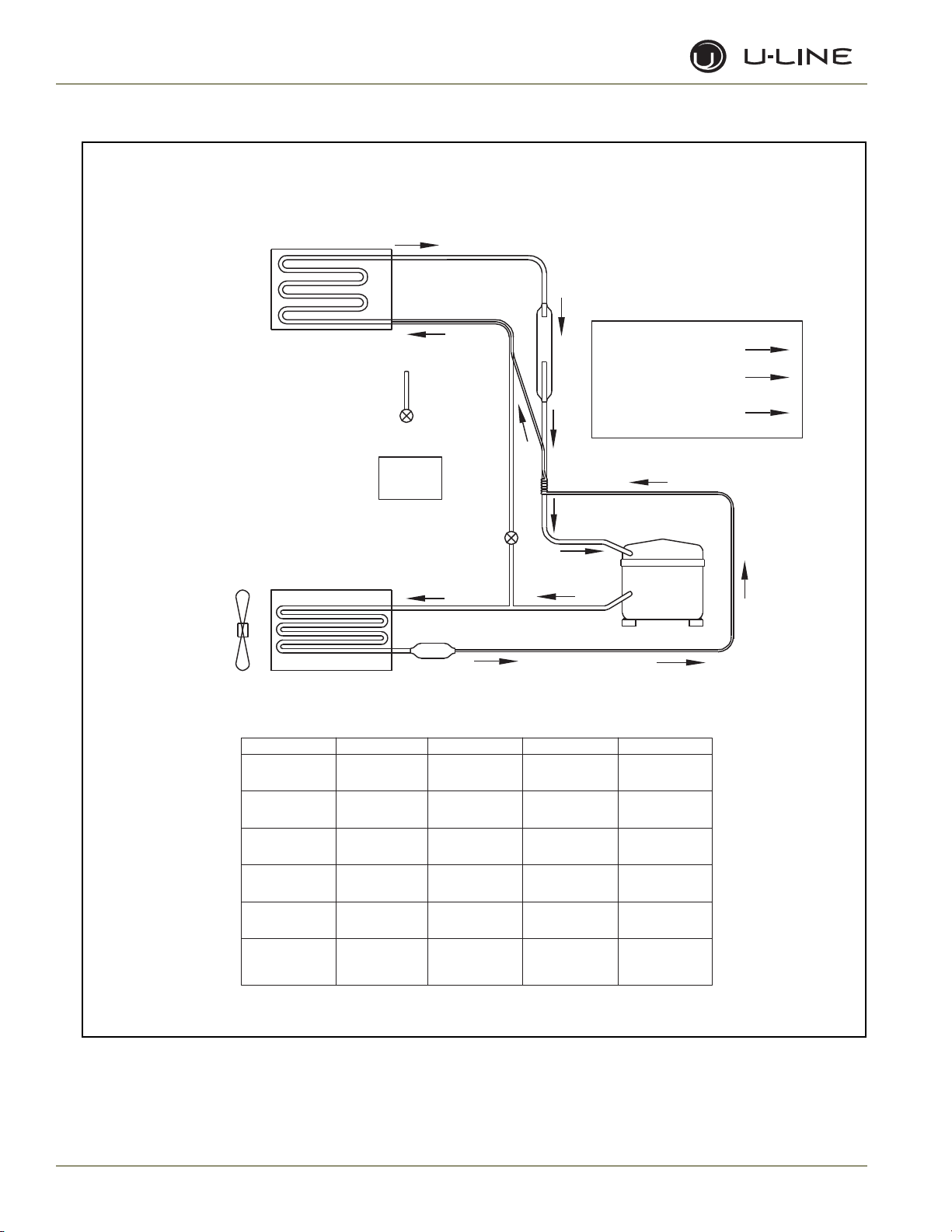

CLR2160

GENERAL

Upon initial startup, this unit will enter mode number 5

which is a three-minute water fill regardless of the

thermistor temperatures. This only occurs when the initial

startup is caused by a power-up of the main board.

Following the three-minute water fill, the unit moves into mode 1

which is the freezing mode. In this mode the water is pumped from

the sump trough over the ice maker grid by the circulation pump.

This mode typically lasts 10-20 minutes and is regulated by the

temperature of the thermistor mounted near the dryer

(thermistor 4).

At the conclusion of the freeze cycle the unit will enter mode 2

which is the ice harvest. This harvest can last up to three minutes.

During this mode the water trough also refills.

Before the next cycle begins, the custom electronic board

determines whether the bin is full. A temperature below 34°F, or a

temperature below 35°F for at least one hour will stop the unit

from producing ice. The ice-making will always stop at the

conclusion of a harvest cycle. It will never stop in the middle of a

cycle.

The custom electronic board continuously monitors the optional

P60 pump to ensure the drain line is not becoming restricted. In

the event of a drain line obstruction, the display interface will show

“P1.” If the drain remains restricted the unit will stop ice

production until the drain clears. In the event of a partially

restricted drain, reduced ice rate will be noticed as the unit

continuously turns on and off to eliminate any chances of overfilling

the unit with water. If no pump is used the pink jumper needs to be

connected to the power cord in its place.

A cleaning mode is available through the user interface by using the

key sequence described in the Controls Section. The cleaning

mode lasts about 45 minutes, at which point the unit will sit idle

for another 15 minutes. During this time the display will show

“CL.” At the conclusion of the cycle the unit will automatically turn

back on.

THERMISTOR OUTAGE

entering the sequence, keep the COLDER key pressed until you

completely release the ON/OFF key for the third time. The display

will cycle through a series of numbers to tell which relays are

energized. For example, if the unit was in ice-making mode the

display would show 11 20 31 40 51 60 70. The first number is the

relay number. In the second number, “1” means on and “0” means

off. The relay information can be found in the Control Section.

Each relay can also be turned on and off individually to determine

whether or not the board and component are operating. If a board

is suspected of not operating correctly you can run through this

sequence to ensure each component is turning on and off through

the board correctly. Go into service mode and choose option #22.

This will cycle every relay on and off showing 10 11 20 21 …. If a

component fails to turn on when the relay does, you can verify if

there is voltage present by using a voltmeter to check the board

output.

To view the actual thermistor readings, hold the WARMER and

COLDER keys for about five seconds. The display will cycle

through the three thermistors and their temperatures. If a

thermistor is unused in a unit it will show a “0” reading. The

CLR2160 uses thermistors 2 and 4. For thermistor 4 the display

will only show up to “99.” In the event the temperature is higher

than this the display will show a flashing “99.”

TROUBLESHOOTING

Error Codes

E1, E2, E9 Bad thermistor errors. Replace thermistor. Check

for thermistor errors by accessing “View thermistor

# status (2,19, 20, or 21).” If the error code is

repeated, the thermistor is open or shorted. If a

temperature is displayed, the thermistor is not

defective.

P1 Pump circuit is detecting a drain problem. Consult a

plumber to resolve the issue. If unit does not have a

P60 installed, then the jumper wire is missing in

place of the pump.

Any other error messages will not affect the operation of the

CLR2160 model.

After checking the errors be sure to clear the error log by

performing service option 12

In the event that a thermistor fails, the unit will stop all functions

and display “ER” on the user interface. The exact error can be

accessed via the service mode.

SERVICE

The CLR2160 model uses four relays and two thermistors. There

is a variety of built-in servicing features to aid in diagnosing the

root problem associated with a unit.

To check to see which relays are currently operating, hold the

COLDER key and press the ON/OFF key three times. When

3-1

Page 17

Section 3 - Service and Repair

HIGH PRESSURE

LOWPRESSURE

TRANSITIONAL PRESSURE

IN CAPILLARY TUBE

H

L

C

L

L

C

C

C

C

C

L

L

H

H

C

L

ICEMAKER EVAPORATOR

2276

R4: WATER

SUPPLY

R5: WATER

CIRCULATION PUMP

R4: HOT GAS

BYPASS

VALV E

R1: CONDENSER

FAN

CONDENSER

R3: COMPRESSOR

RELAY R1 R3 R4 R5

FUNCTION FAN

ON

ON

OFF

OFF

OFF

ON

ON

OFF

OFF

OFF

OFF

ON

OFF

ON/OFF

ON*

ON

OFF

OFF

ON/OFF

OFF

COMP CIRC PUMP

HOT GAS /

WATER IN

Mode 1:

Ice Making

Mode 2:

Ice Harvest

Mode 3:

Off

Mode 4:

Cleaning

Mode 5:

Water Fill &

Initial Start-Up

* Normal Start-Up lasts 3 minutes

Note: R2, R6 and R7 not used

.

3-2

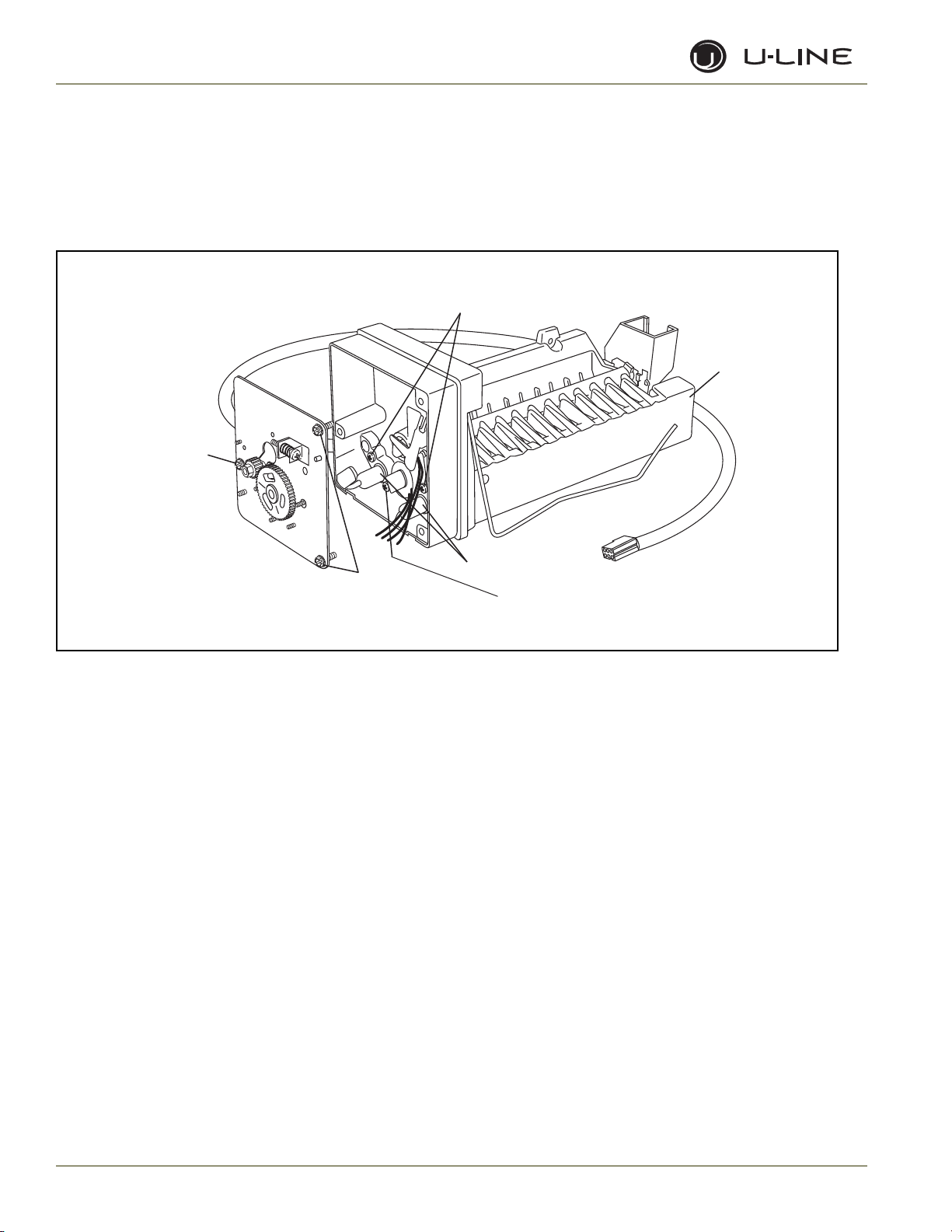

Figure 1. CLR2160

Page 18

Section 3 - Service and Repair

TROUBLESHOOTING (CONTINUED)

No ice

Check the ice bin temperature. If the temperature is in the 3435°F range, the unit is shut down due to low temperature inside.

This could be caused by low ambient temperatures or running the

unit without a water supply attached.

If the ice bin temperature is above 35°F, the unit should be

producing ice. Check to ensure the water trough is full and the

pump is operating.

Too much ice

Ensure there is Permagum around the thermistor hole. If there is,

proceed to the next step.

The control board is equipped with an adjustment to adjust the

level of ice in the bin for customer preference or when used in

abnormal installations. With ice stacked to the desired level, check

the bin temperature by holding WARMER and COLDER for five

seconds. We’ll assume the display showed 38°F for this example.

Go to service mode #24 and adjust the setting to that number.

This will allow the bin to shut off at this ice level. This temperature

needs to be checked after the door has been closed for at least 10

minutes in order for the thermistor temperature to stabilize.

Too little ice

If this is a recurring issue, try adjusting service option #24 colder in

1 or 2° increments until the desired level of ice is achieved.

Ice not sized to customer satisfaction

The thickness of the cubes can be adjusted per the ice thickness

section of the manual.

Noise

Some noise from this unit is normal. You may hear the sound of ice

dropping into the bin, especially when it is empty. The harvesting

processes involves flowing refrigerant and water through valves

which may produce a rushing type sound during the harvest. The

fan and compressor will produce a continuous low motor noise. If

installed, the P60 pump will produce noise at regular intervals as it

empties water from the unit. If any of these is objectionable, the

unit has an Office mode which can be entered for three hours at a

time. During this mode the unit will not produce ice; however, the

drain pump will continue to operate.

This can be caused by poor incoming water quality. The CLR2160

is designed to produce clear ice in most water; however, abnormal

water conditions may result in the need for further filtering.

Water in ice bin

A defect in the drain from the unit will cause water to stop

draining from the unit.

Display is showing something other than “Ice,” “ER”

or “CL.”

Push one of the keys to see if the display is reset.

Turn unit on and off via the display pad.

Unplug unit, wait one minute and plug back in. If any of these steps

return the unit to operation the unit was probably accidently

entered into a service mode.

Display is showing a random snaking of characters

or a degree symbol is flashing.

The unit is in a special showroom mode. Hold the COLDER key

and press the LIGHT key three times to exit.

Display not illuminating but unit operating

First try to plug and unplug the unit. If the display still does not

illuminate, there is a four-wire pin connector running from the

main board in the base to the display board. One of the wires is

disconnected or damaged.

Unit is not operating—no cooling—no fans.

Unplug unit and plug back in. If main board beeps when plugging in

the unit then this is most likely a system problem not a board issue.

If board does not beep when plugging in the unit, check the power

supply to ensure the outlet is working. Also, check the fuse on the

circuit board.

No water in trough

Ensure the standpipe is fully inserted into the trough.

Check the water valve to see if it is filling the unit.

Watch the water flow over the mold to see if excess water is being

splashed out of the trough. This could be the result of improper

leveling.

Ice does not release from evaporator

This could be caused by improper leveling or the unit is in need of

cleaning.

Poor ice quality

3-3

Page 19

Section 3 - Service and Repair

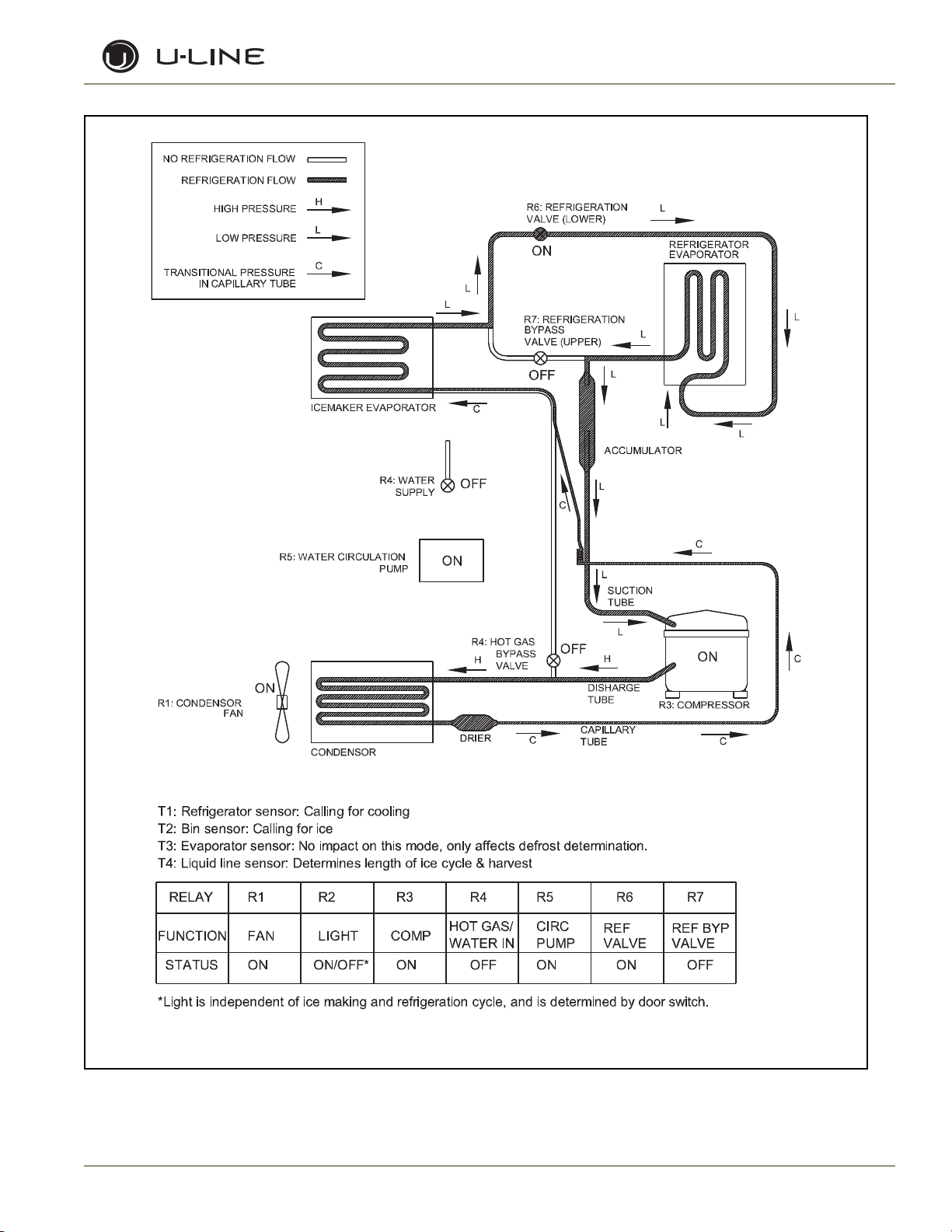

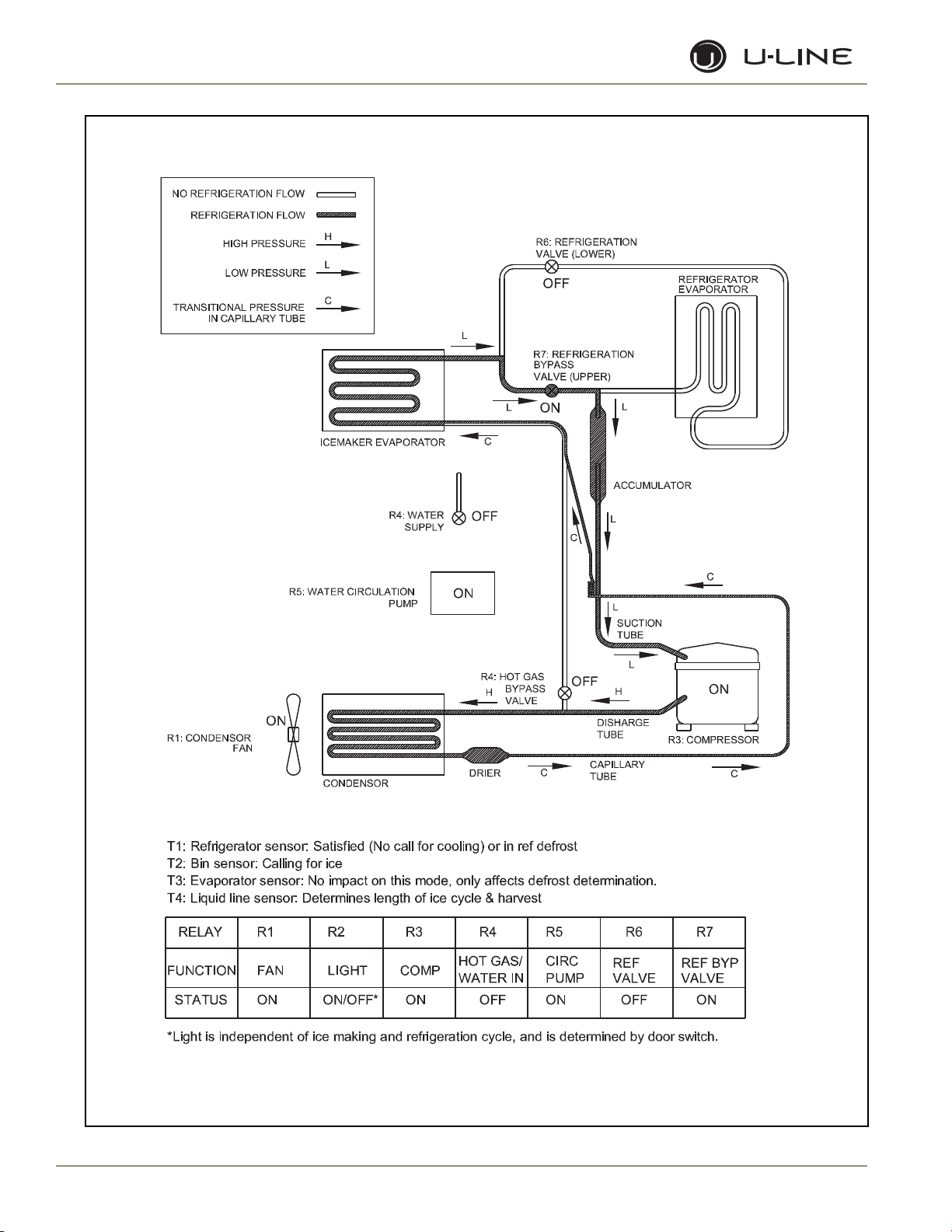

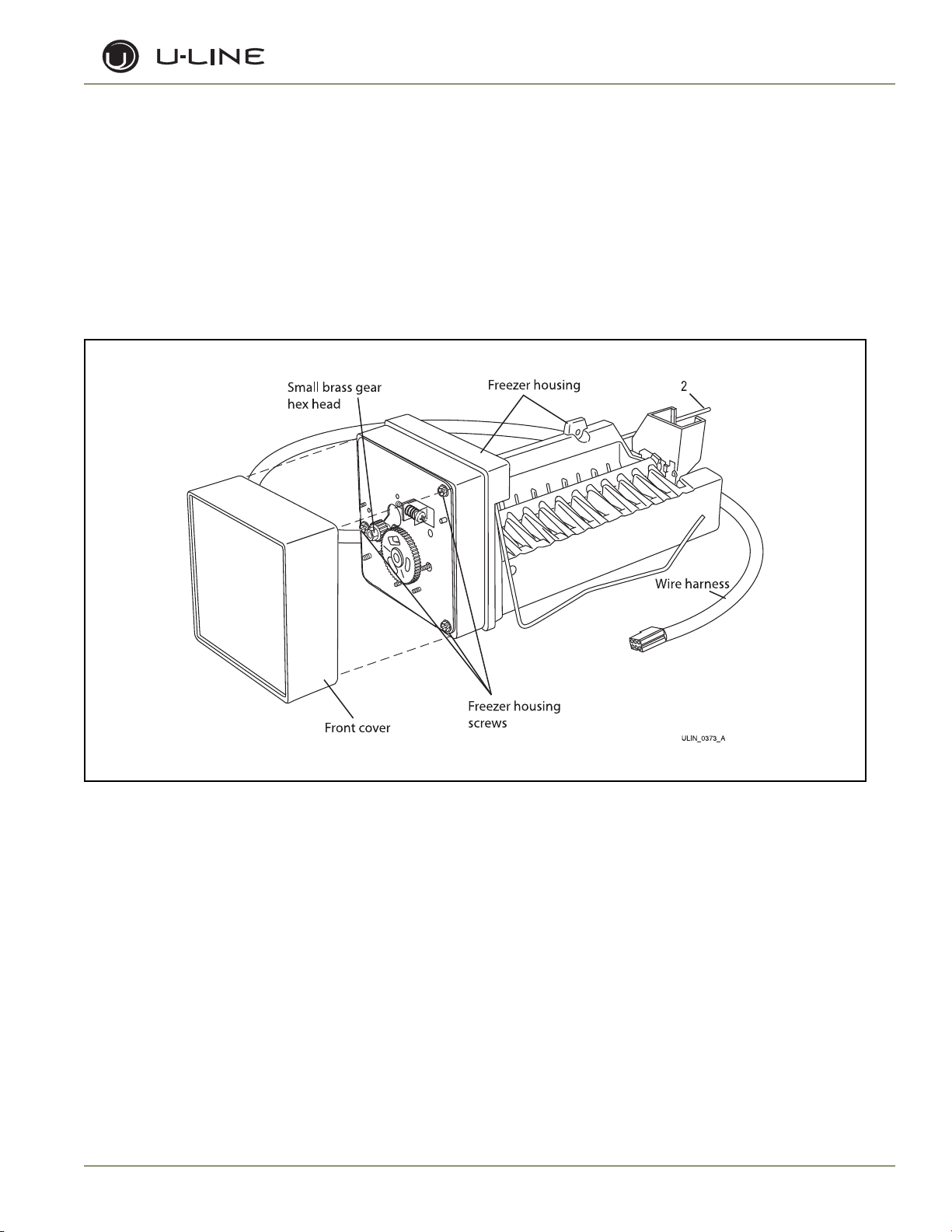

CLRCO2175

GENERAL

The U-Line Model CLRCO2175 combines the best of Échelon

refrigeration and clear ice-making capabilities into a single unit. A

state-of-the-art microprocessor-based controller simplifies

operation and troubleshooting. There are four primary modes of

operation:

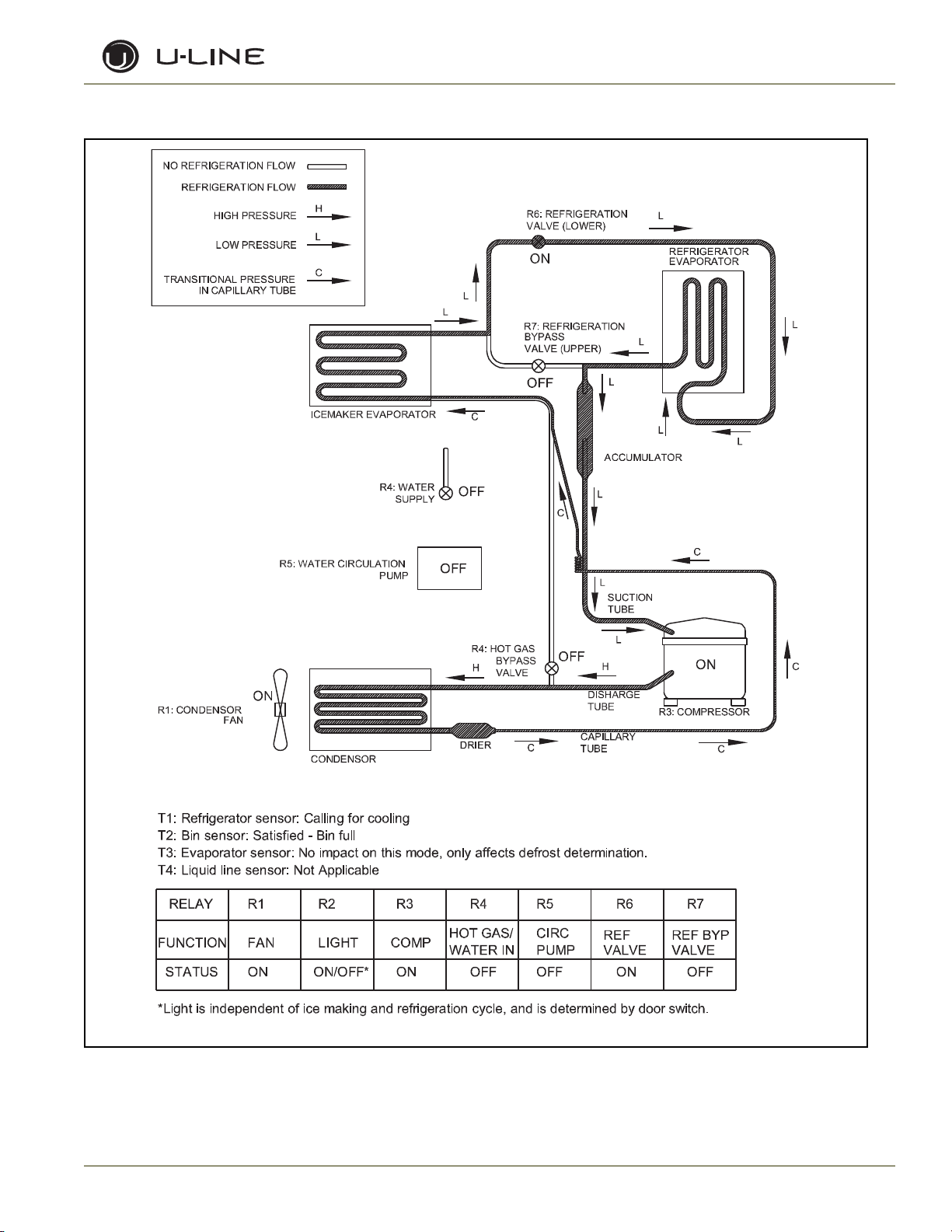

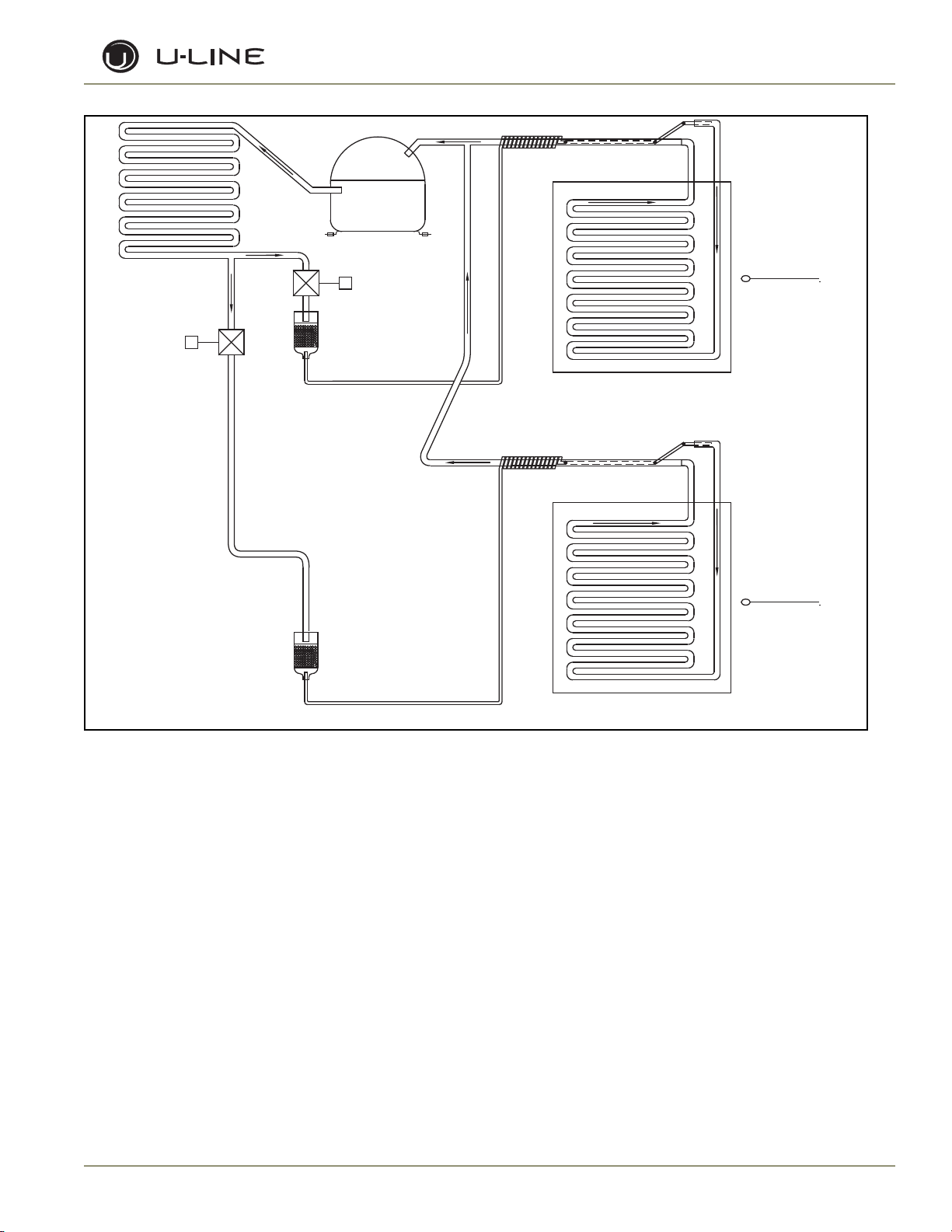

1. Ice Making and Refrigeration (Figure 2).

2. Ice Making and No Refrigeration (

3. Refrigeration and No Ice Making (

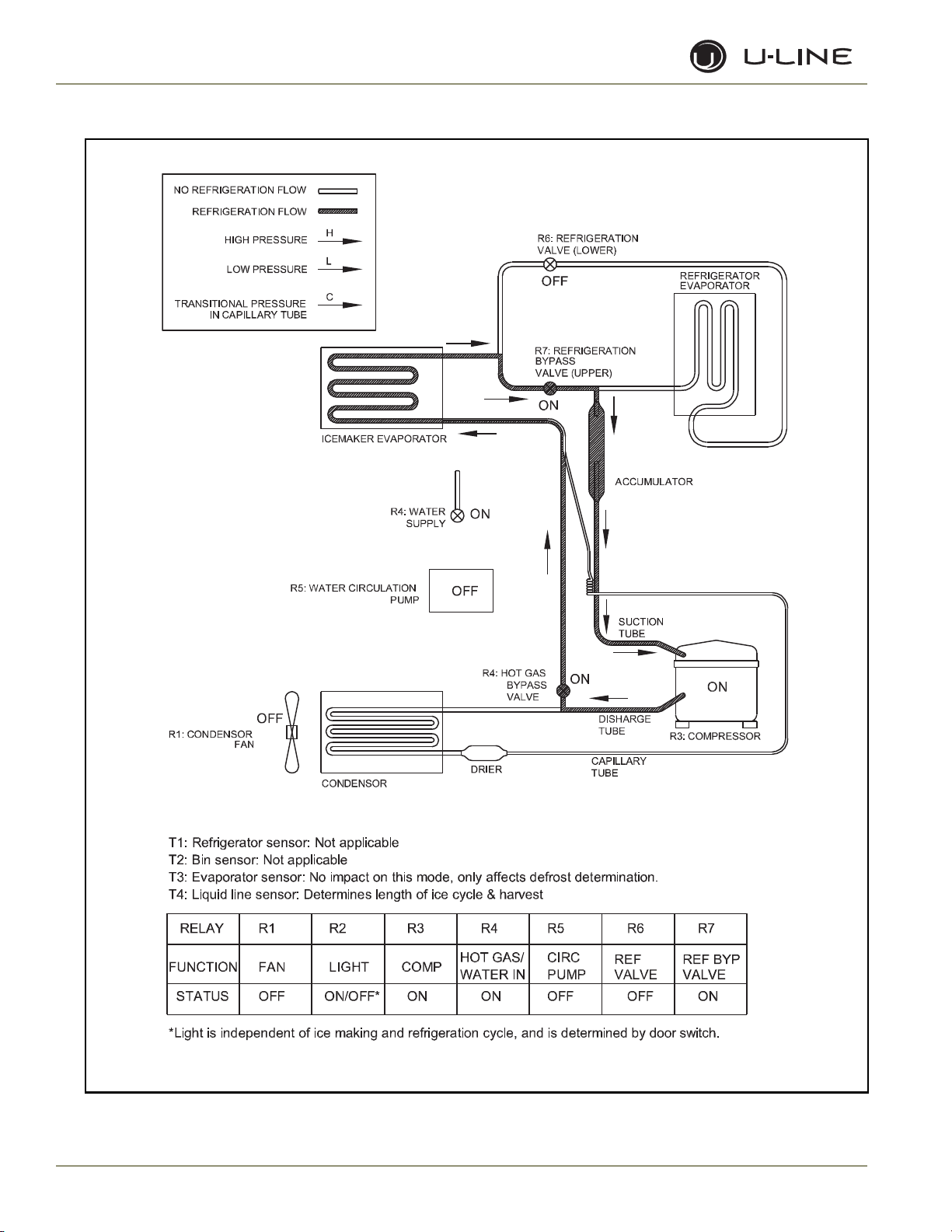

4. Ice Harvest/Water fill (No Refrigeration Possible)

(

Figure 5

In addition, there are three sub modes of operation:

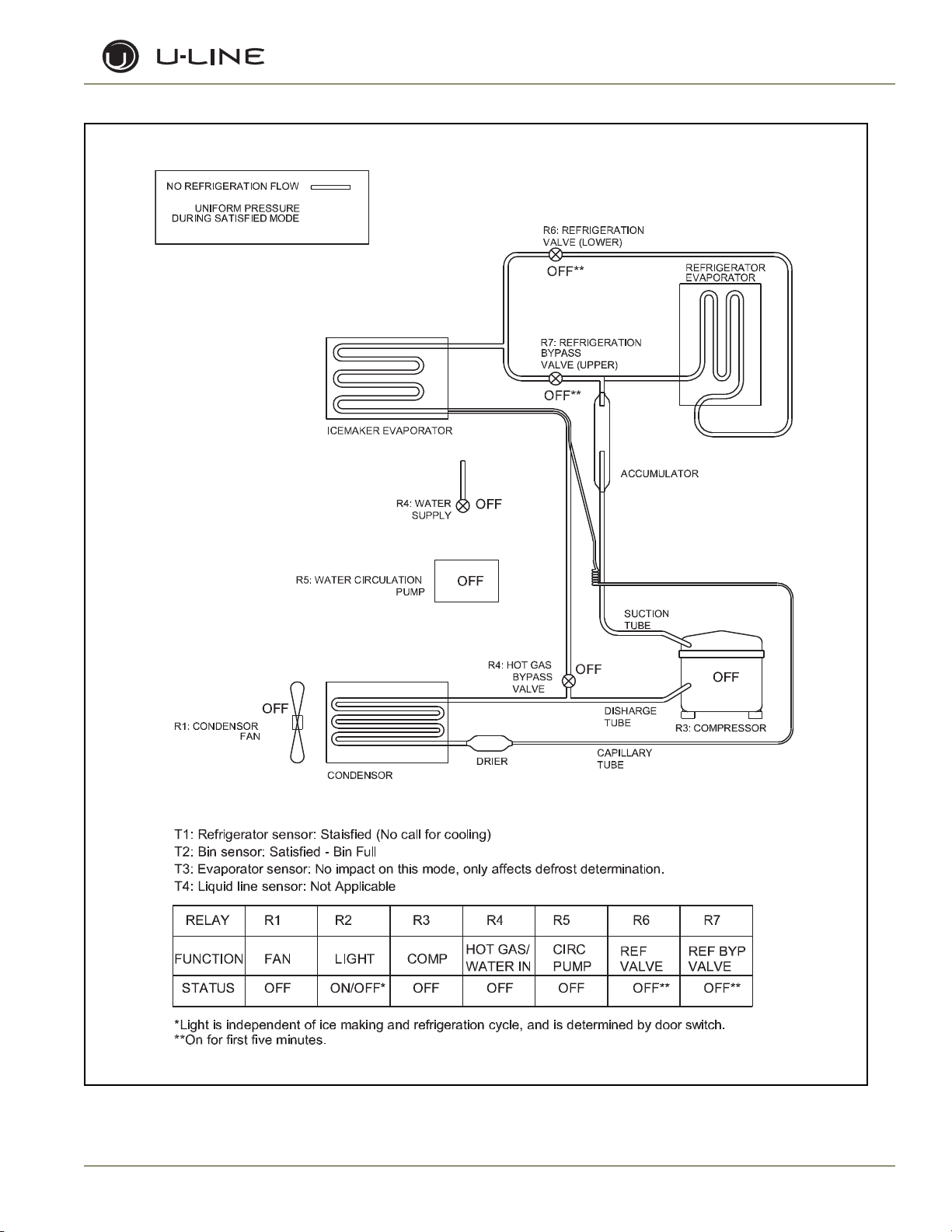

5. Off (

6. Water Fill - No Refrigeration (

7. Cleaning (No Refrigeration Possible) (

Review the following notes for general information before reading

the schematics.

These are some additional general notes and exceptions:

• The controller has a four-minute compressor minimum off-

cycle regardless of thermistor status, for compressor

protection and cycling.

• When making ice, the controller reads liquid line temperature

four minutes into the ice-making cycle to determine the length

of that ice-making cycle and subsequent harvest length.

• Once an ice-making cycle is initiated, it will continue through to

harvest regardless of the bin sensor.

• There is a three-minute water fill cycle when the unit is turned

on. Mode 6.

• In order to maintain adequate refrigerator temperature, the

unit will sometimes run in the refrigeration only mode, as

shown in Mode 3, even if the ice bin sensor is calling for ice. At

the end of each ice harvest, the controller checks the

refrigerator sensor and if it is warmer than the higher of 42°F,

or the set-point, it will go into refrigeration only mode. The

refrigerator must be at 42° or setpoint to make ice

continuously. Example:

Setpoint Temperature

).

Figure 6

).

Figure 3)

Figure 4

Figure 7

Figure 8

.

).

).

).

or below the sensor. However, after the first slab of cubes is

harvested, the controller will follow the logic defined in 5 above

and realizing the refrigerator is too warm, will continue in

refrigeration only mode (3) until the requirement is satisfied.

Thus, upon start-up, the user will see one slab of ice dropped in

about 30 minutes, and then there will be no more ice until the

refrigerator reaches 42°F or set-point. (This may be two to

three hours depending on ambient conditions.)

• There will also be a water fill cycle after the ice bin has been

“full” and then calls to make ice again. This can occur when the

refrigerator side is off as shown in Mode 6, or when it is on,

which is shown in Mode 8. If the refrigerator side is on, when

the fill cycle initiates, it will remain on until the fill cycle is

completed, even if the refrigerator sensor is satisfied.

• The controller has a four-degree differential designed into it for

the refrigerator sensor, such that when it is set to 38°F, the

refrigerator will cool until the refrigerator sensor reads 36°F

and will not re-initiate refrigerator cooling until the sensor

reaches 40°F. So someone monitoring actual temperature (by

pressing WARMER momentarily) may see the refrigerator off

when the temperature is a degree warmer than set-point, or

refrigerator on when it is a degree below set-point. Refer to

Echelon Keypad.

• There is no high limit cut-out on this unit; however, if the liquid

line sensor were to go out of range (approximately 185°F) the

ice maker side of the unit will shut down. The refrigerator will

continue to run. When the temperature of the liquid falls back

in range, the unit will re-initiate operation. The unit will not

normally experience this condition up to 110°F, but conditions

such as door openings, heavy loading, restricted airflow, dirty

condenser or direct sunlight may contribute to reaching this

mode.

• Different from the earlier CLRCO2075, this unit uses two

relays to control the refrigeration valves. This means that the

valves will only be energized when needed.

• There is now a thermistor on the refrigerator evaporator that

will sense the evaporator plate temperature. This will allow the

unit to fully defrost based on temperature of the evaporator

plate during the defrost modes.

38° 42° or lower ice

38° 45° no ice

55° 55° ice

55° 58° no ice

There is no fill cycle when ice-making re-initiates in this case

because the bin sensor has not been satisfied.

• When the initial three-minute fill cycle is complete, the unit will

enter ice making and refrigeration mode (1) if the bin is empty

3-4

Page 20

Section 3 - Service and Repair

ULIN_0328_A

Figure 2. CLRCO2175 Mode 1: Ice Making and Refrigeration

3-5

Page 21

Section 3 - Service and Repair

ULIN_0329_A

3-6

Figure 3. CLRCO2175 Mode 2: Ice Making and No Refrigeration (or Ref Defrost)

Page 22

Section 3 - Service and Repair

ULIN_0330_A

Figure 4. CLRCO2175 Mode 3: Refrigeration and No Ice Making

3-7

Page 23

Section 3 - Service and Repair

3-8

ULIN_0331_A

Figure 5. CLRCO2175 Mode 4: Ice harvest (No Refrigeration Possible)

Page 24

Section 3 - Service and Repair

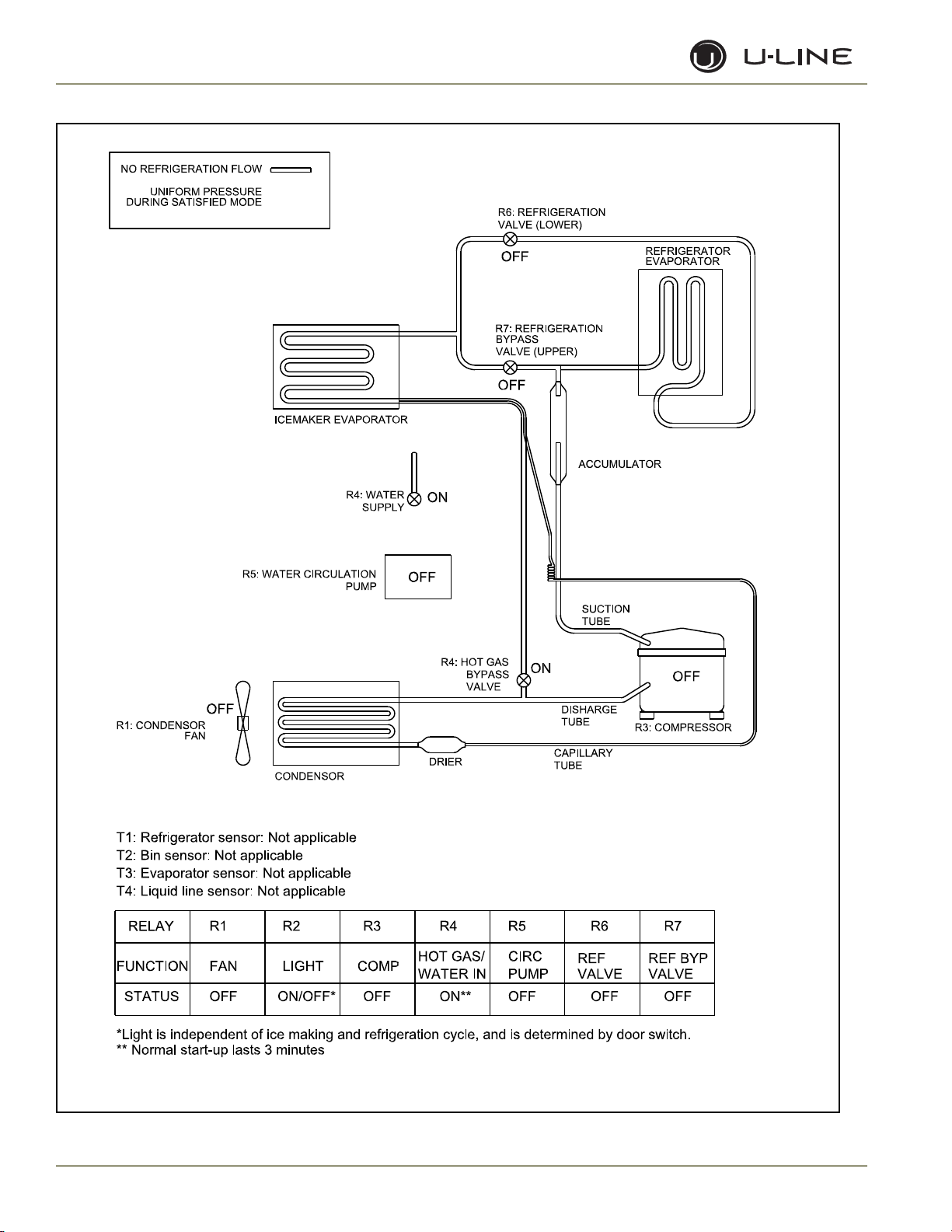

Figure 6. CLRCO2175 Mode 5: Off

ULIN_0332_A

3-9

Page 25

Section 3 - Service and Repair

3-10

Figure 7. CLRCO2175 Mode 6: Water Fill - No Refrigeration Possible (Normal Start-Up)

Page 26

Section 3 - Service and Repair

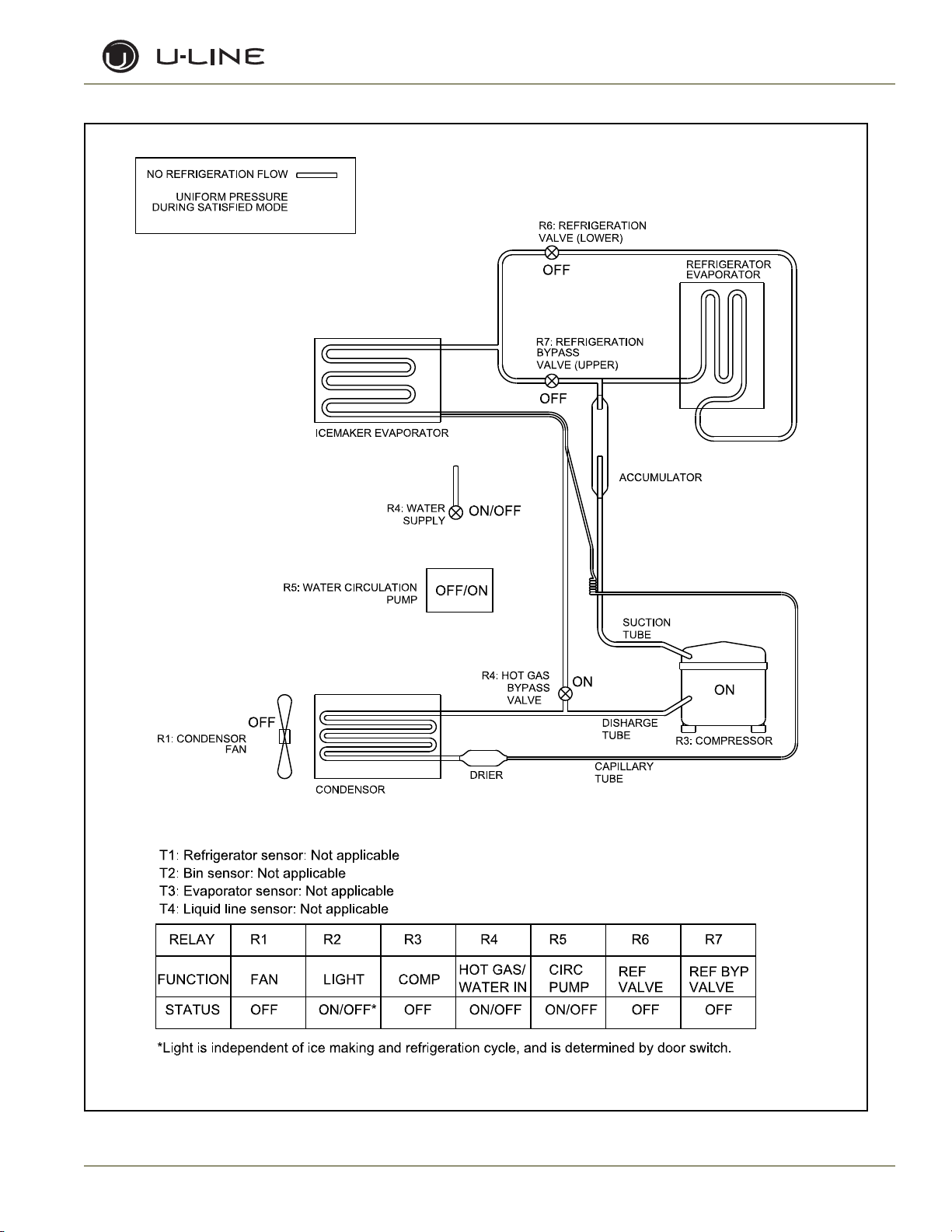

Figure 8. CLRCO2175 Mode 7: Cleaning (No Refrigeration Possible)

3-11

Page 27

Section 3 - Service and Repair

THERMISTOR OUTAGE

In the event that the condenser thermistor (T4) fails, the unit will

stop all functions and display “ER” on the user interface. The exact

error can be accessed via the service mode.

If the refrigerator thermistor (T1) fails, the refrigerator will stop

operation; however, the ice maker will continue to function. The

display will show “ER.” The exact error can be accessed via the

service mode.

If the ice bin thermistor (T2) fails, the ice maker will stop functioning;

however, the refrigerator will continue to work. The display will

show “ER.” The exact error can be accessed via the service mode.

If the refrigerator evaporator thermistor (T3) fails, the unit will

function normally; however, defrosting will occur on a timing interval

instead of timing and temperature. The display will show “ER.” The

exact error can be accessed via the service mode.

SERVICE

The CLRCO2175 model uses seven relays and four thermistors.

There is a variety of built-in servicing features to aid in diagnosing the

root problem associated with a unit.

To check to see which relays are currently operating, hold the

COLDER key and press the ON/OFF key three times. When entering

the sequence keep the COLDER key pressed until you completely

release the ON/OFF key for the third time. The display will cycle

through a series of numbers to tell which relays are energized. For

example, if the unit was in ice-making mode, the display would show

11 20 31 40 51 60 70. The first number is the relay number. In the

second number, 1 means ON and 0 means OFF. The relay

information can be found in the Control Section.

Each relay can also be turned on and off individually to determine

whether or not the board and component are operating. If a board is

suspected of not operating correctly, you can run through this

sequence to ensure each component is turning on and off through

the board correctly. Go into service mode and choose option #22.

This will cycle every relay on and off showing 10 11 20 21 …. If a

component fails to turn on when the relay does, you can verify if

there is voltage present by using a voltmeter to check the board

output.

To view the actual refrigerator (T1) temperature, hold the WARMER

key until the actual temperature is displayed. To view the actual

thermistor readings for 2-4, hold the WARMER and COLDER keys

for about five seconds. The display will cycle through the three

thermistors and their temperatures. If a thermistor is unused in a unit

it will show a “0” reading. For thermistor 4 the display will only show

up to “99.” In the event the temperature is higher than this, the

display will show a flashing “99.”

E1, E2, E7, E8, E9 Bad thermistor errors. Replace thermistor.

Check for thermistor errors by accessing

“View thermistor # status (2, 19, 20, or 21).” If

the error code is repeated, the thermistor is

open or shorted. If a temperature is displayed,

the thermistor is not defective.

E3 This will be accompanied by a beep every

minute. This signals that the door has been left

open for longer than 20 minutes. Close the

door to reset. If the light and display do not go

off when the door is closed, check to make

sure the magnet is positioned properly.

E5 This signals that the unit has been above set-

point for more than twelve hours by at least

10°. If the unit was just plugged in leave for 24

hours to see if the problem is corrected. If it is

not corrected, it is most likely a refrigeration

system issue.

E6 This signals that the refrigerator section has

been at least 10° below set-point for at least

twelve hours. This would most likely be caused

by a bad relay and the circuit board.

P1 Pump circuit is detecting a drain problem.

Consult a plumber to resolve the issue. If unit

does not have a P60 installed, then the jumper

wire is missing in place of the pump.

After checking the errors, be sure to clear the error log by

performing service option 12.

No ice

Check the ice bin temperature. If temperature is in the 34-35°F range

the unit is shut down due to low temperature inside. This could be

caused by low ambient temperatures or running the unit without a

water supply attached.

If the ice bin temperature is above 35°F the unit should be producing

ice. Check to ensure the water trough is full and the pump is

operating. If the components are not operating, see the service

section above.

In the general section the methods to enter some other service

modes are available. For the CLRCO2175 model some useful modes

are the ICE MAKER OFF MODE, FORCED REFRIGERATOR

DEFROST, ICE THICKNESS ADJUST, CLEAN, AND TEMPORARY

SHUTDOWN MODE. These can be useful in servicing the unit.

TROUBLESHOOTING:

Error Codes

3-12

Page 28

Section 3 - Service and Repair

Too much ice

Ensure there is Permagum around the thermistor hole. If there is,

proceed to the next step.

The control board is equipped with adjustment to adjust the level

of ice in the bin for customer preference or when used in

abnormal installations. With ice stacked to the desired level, check

the bin temperature by holding WARMER and COLDER for five

seconds. We’ll assume the display showed 38°F for this example.

Go to service mode #24 and adjust the setting to that number.

This will allow the bin to shut off at this ice level. This temperature

needs to be checked after the door has been closed for at least 10

minutes in order for the thermistor temperature to stabilize.

Too little ice

If this is a recurring issue, try adjusting service option #24 cooler

in 1 or 2° increments until the desired level of ice is achieved.

Ice not sized to customer satisfaction

The thickness of the cubes can be adjusted per the ice thickness

section of the manual.

Noise

Some noise from this unit is normal. You may hear the sound of ice

dropping into the bin, especially when it is empty. The harvesting

process involves flowing refrigerant and water through valves

which may produce a rushing type sound during the harvest. The

fan and compressor will produce a continuous low motor noise. If

equipped, the P60 pump will produce noise at regular intervals as it

empties water from the unit. If any of these is objectionable the

unit has an Office mode which can be entered for three hours at a

time. During this mode the unit will not produce ice; however, the

drain pump will continue to operate.

No water in trough

Ensure the stand pipe is fully inserted into the trough.

Check the water valve to see if it is filling the unit.

Watch the water flow over the mold to see if excess water is being

splashed out of the trough. This could be the result of improper

leveling.

Display is showing something other than “SP (38),”

“ER” or “CL.”

Push one of the keys to see if the display is reset.

Turn unit on and off via the display pad.

Unplug unit, wait one minute and plug back in. If any of these steps

returns the unit to operation the unit was probably accidently

entered into a service mode.

Display is showing a random snaking of characters

or a degree symbol is flashing.

The unit is in a special showroom mode. Hold the COLDER key

and press LIGHT three times to exit.

Display not illuminating but unit operating

First try to plug and unplug the unit. If the display still does not

illuminate there is a four-wire pin connector running from the main

board in the base to the display board. One of the wires is

disconnected or damaged.

Unit is not operating—no cooling—no fans.

Unplug unit and plug back in. If main board beeps when plugging in

the unit then this is most likely a system problem, not a board

issue.

If board does not beep when plugging in the unit, check the power

supply to ensure the outlet is working. Also, check the fuse on the

circuit board.

Refrigerator not cooling but ice maker working

Check to ensure the refrigerator thermistor is working properly.

Ice maker not operating—no water flowing over

mold

The refrigerator needs to be at or below set-point (or 42°F) to

start the ice-making process. If the unit is cool enough there could

be a defective bin thermistor, defective condenser thermistor or

defective solenoid coil.

Ice does not release from evaporator

This could be caused by improper leveling or the unit is in need of

cleaning.

Poor ice quality

This can be caused by poor incoming water quality. The

CLRCO2175 is designed to produce clear ice in most water;

however, abnormal water conditions may result in the need for

further filtering.

Water in ice bin

A defect in the drain from the unit will cause water to stop

draining from the unit.

3-13

Page 29

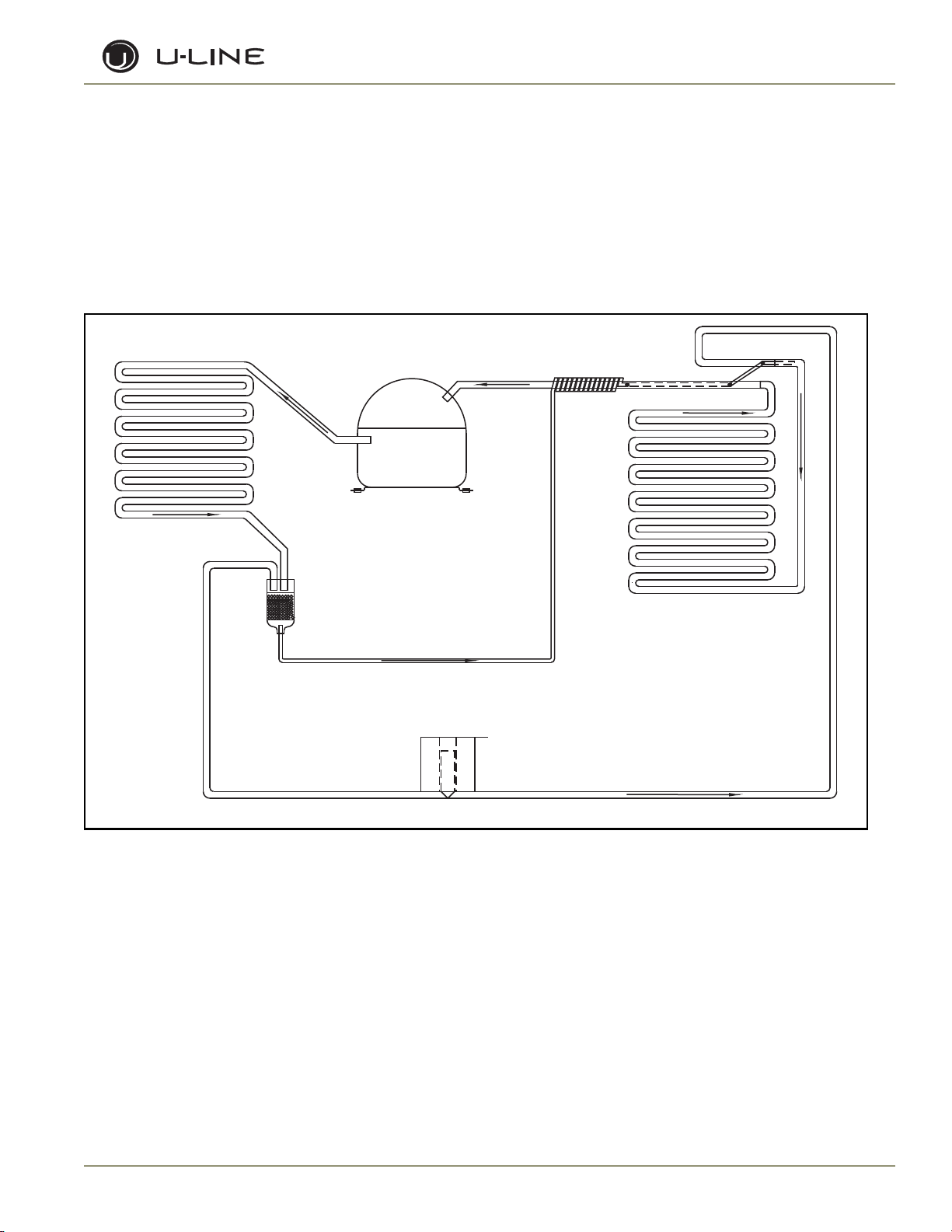

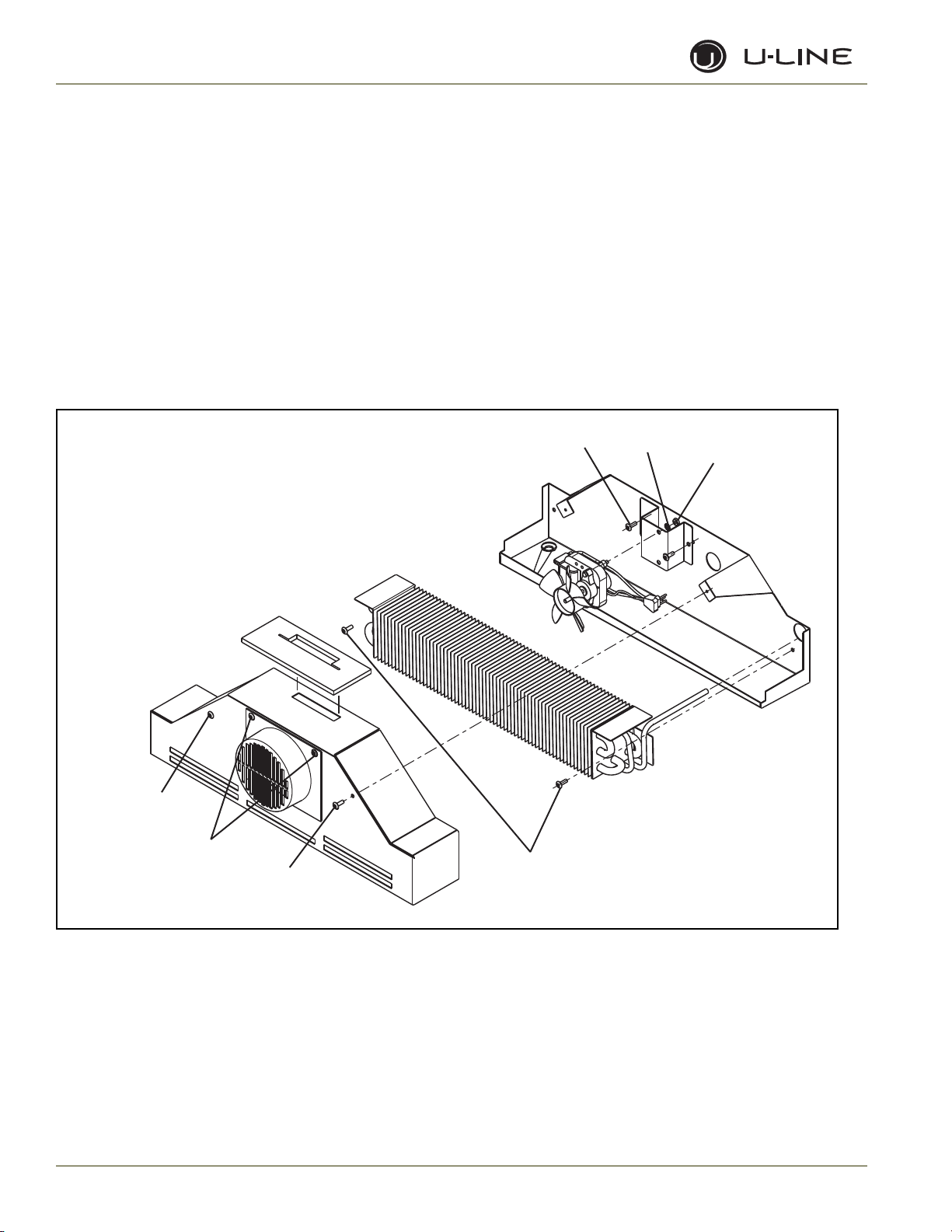

Section 3 - Service and Repair

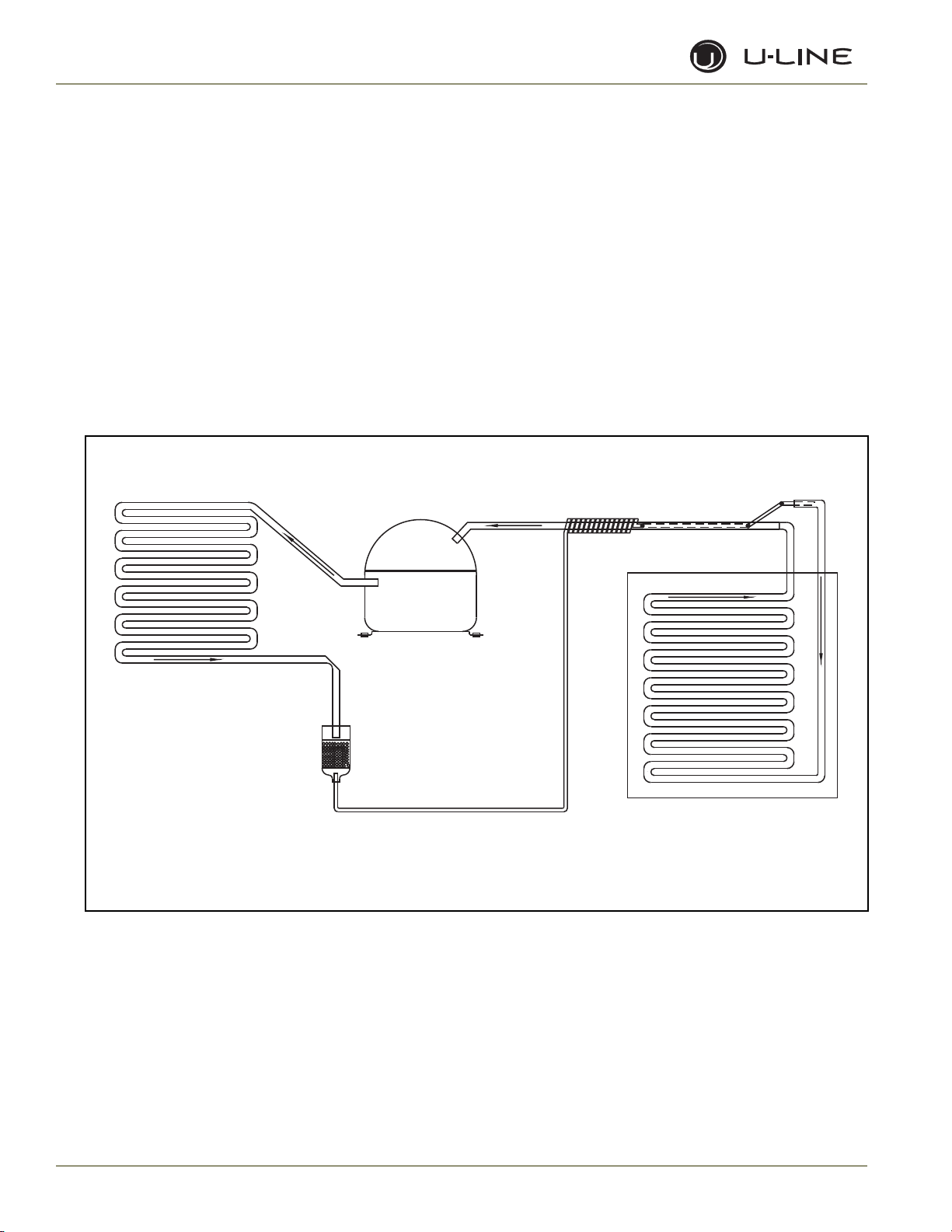

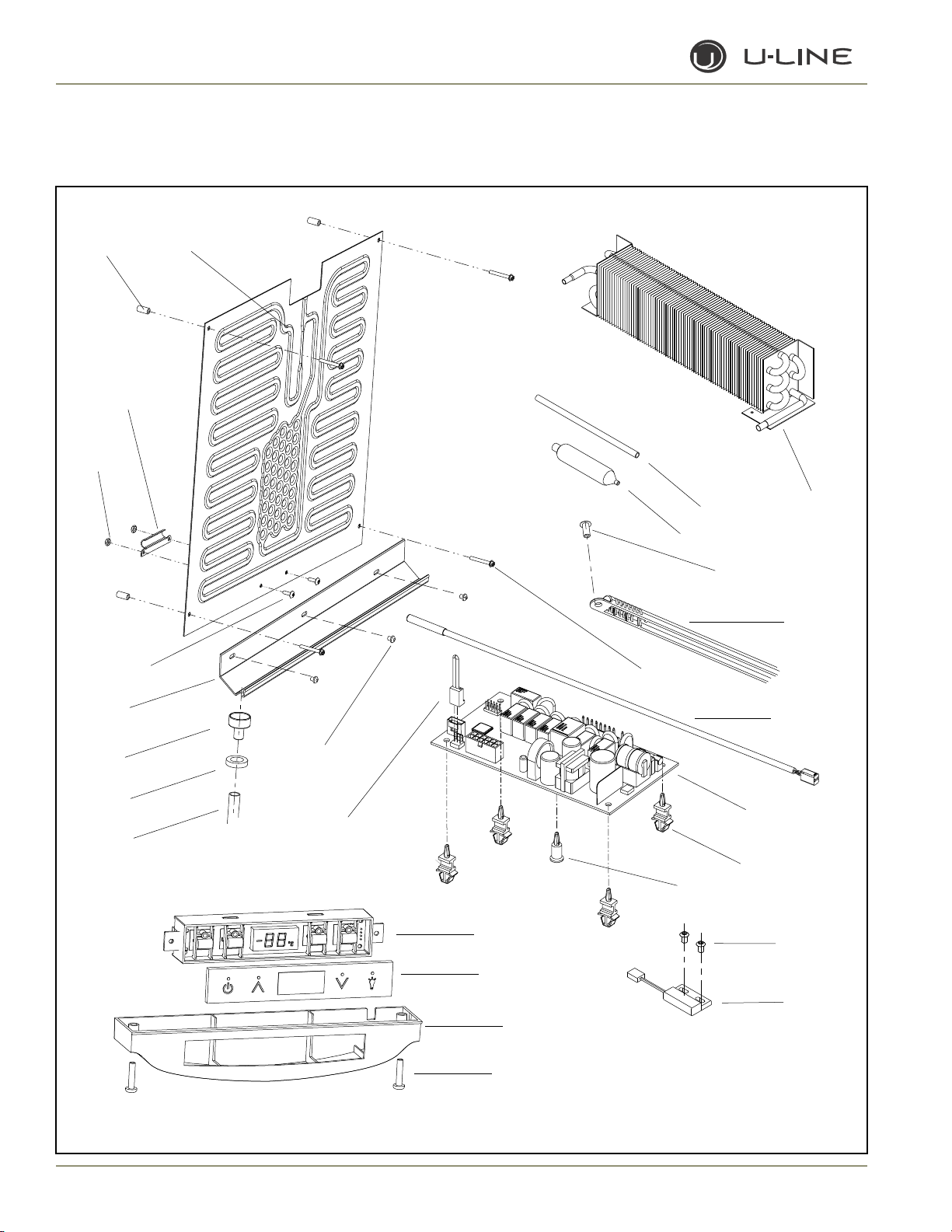

CAPILLARY TUBE

DRYER

CONDENSER

COMPRESSOR

EVAPORATOR

ULIN_0280_A

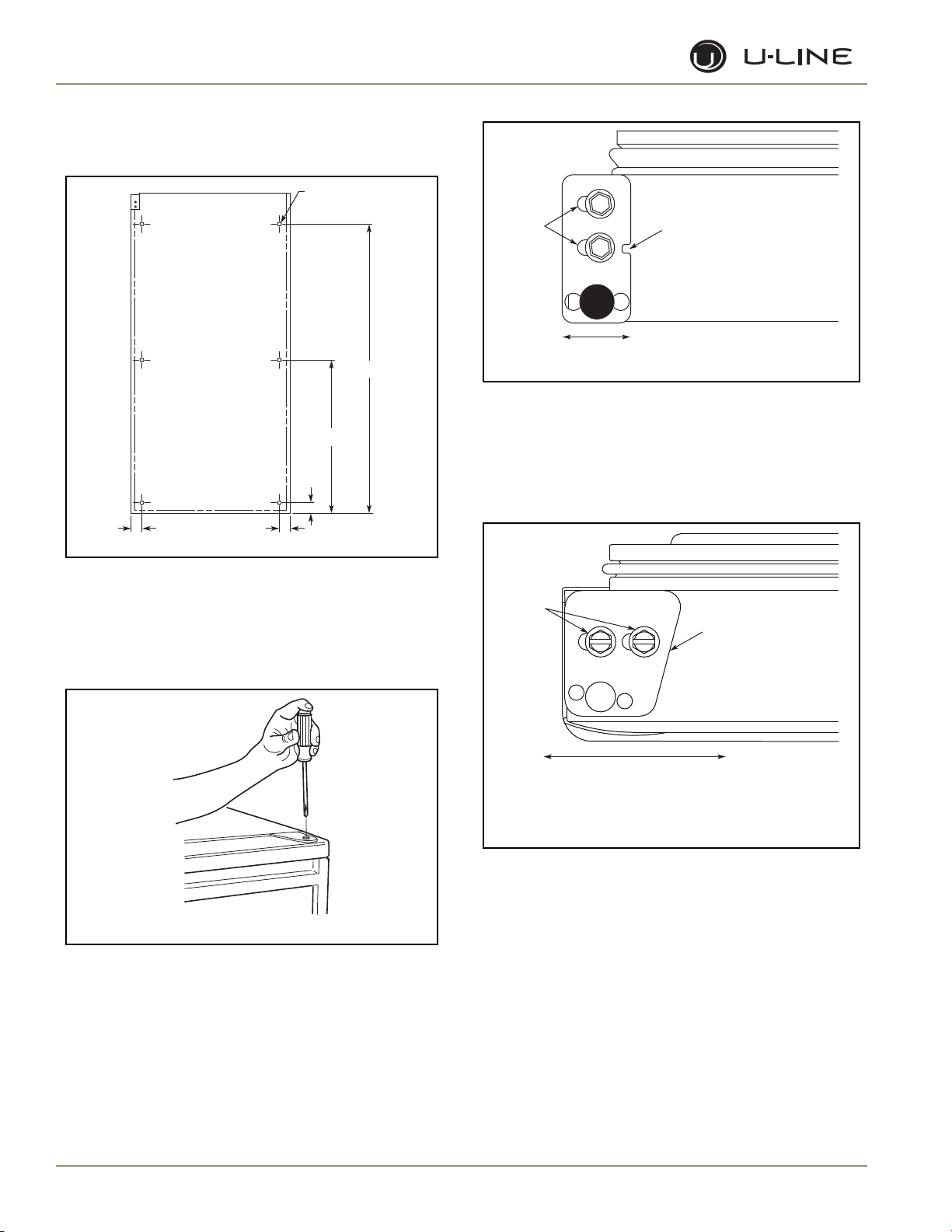

2175R/2115R

2175WC/2115WC

2175BEV

2175DWRR/2275DWRWS

2275ZWC

(Includes Overlay Models)

GENERAL

Refrigerant is pumped from the compressor to the condenser as a

high pressure, high temperature vapor.

As the refrigerant cools in the high pressure condenser, the vapor

condenses to liquid. During this phase change, a great amount of

heat is rejected with the help of the condenser fan.

The liquid then flows to the dryer where it is strained and filtered.

From the dryer, the refrigerant flows through the capillary tube

which meters the liquid refrigerant to the evaporator. The

pressure of the refrigerant is reduced to the evaporating or low

side pressure.

The reduction of pressure on the liquid refrigerant causes it to boil

or vaporize until it reaches saturation temperature. As the low

temperature refrigerant passes through the evaporator coil, it

continues to absorb a lot of heat, causing the boiling action to

continue until the refrigerant is completely vaporized. It is during

this phase that the most heat is absorbed (the cooling takes place)

in the refrigerator.

The refrigerant vapor leaving the evaporator travels through the

suction line to the compressor inlet. The compressor takes the

low pressure vapor and compresses it, increasing both pressure

and temperature. The hot high pressure gas is pumped out the

discharge line and into the condenser. The cycle continues

3-14

Figure 9. 2175R/2115R/2175WC/2175BEV/2275DWRR/2175DWRR

Page 30

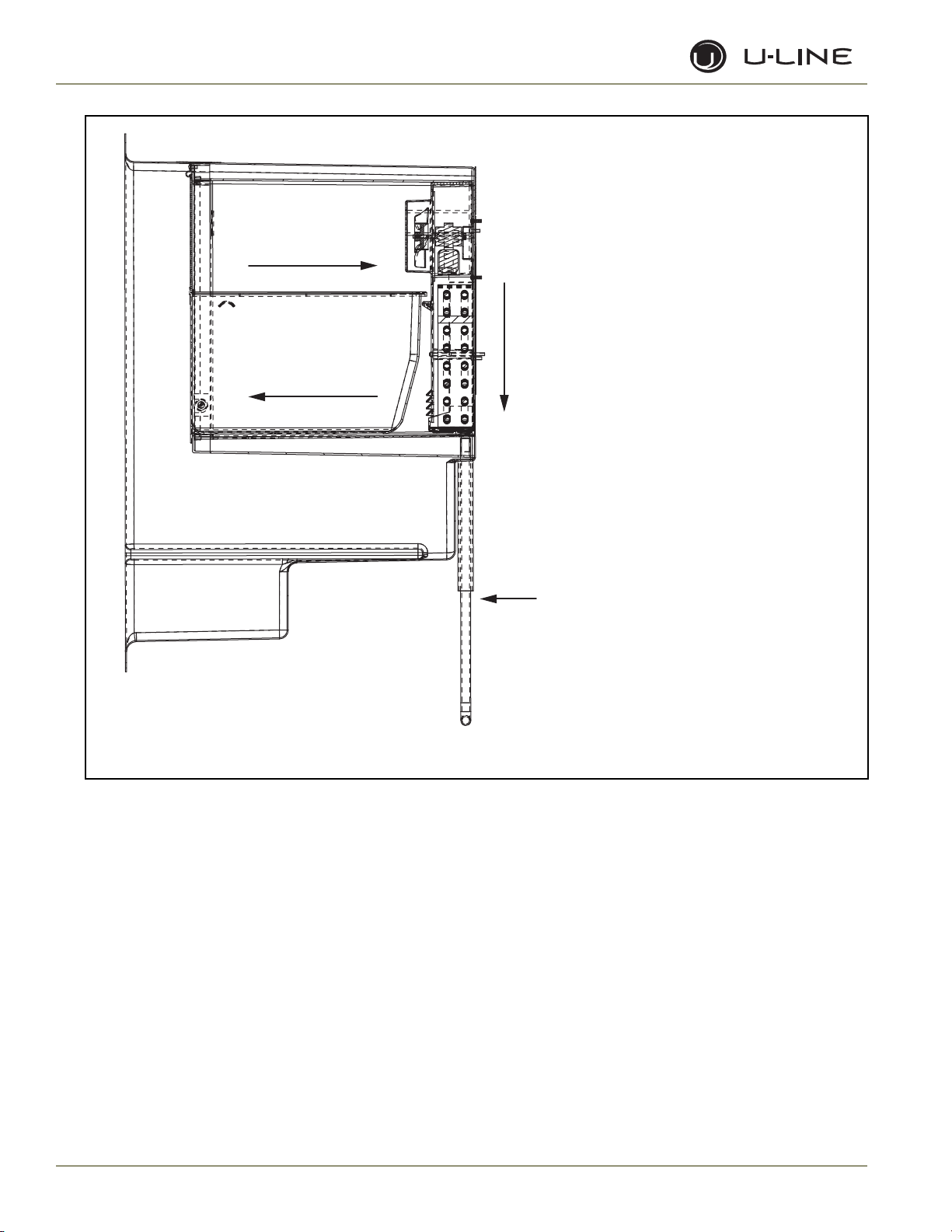

Section 3 - Service and Repair

CAPILLARY TUBE

SOLENOID VALVE

SOLENOID VALVE

DRYER

CONDENSER

COMPRESSOR

EVAPORATOR

TOP

COMPARTMENT

THERMISTOR

CAPILLARY TUBE

DRYER

EVAPORATOR

DWR052

BOTTOM

COMPARTMENT

THERMISTOR

CAPILLARY TUBE

SOLENOID VALVE

SOLENOID VALVE

DRYER

CONDENSER

COMPRESSOR

EVAPORATOR

TOP

COMPARTMENT

THERMISTOR

CAPILLARY TUBE

DRYER

EVAPORATOR

DWR052

BOTTOM

COMPARTMENT

THERMISTOR

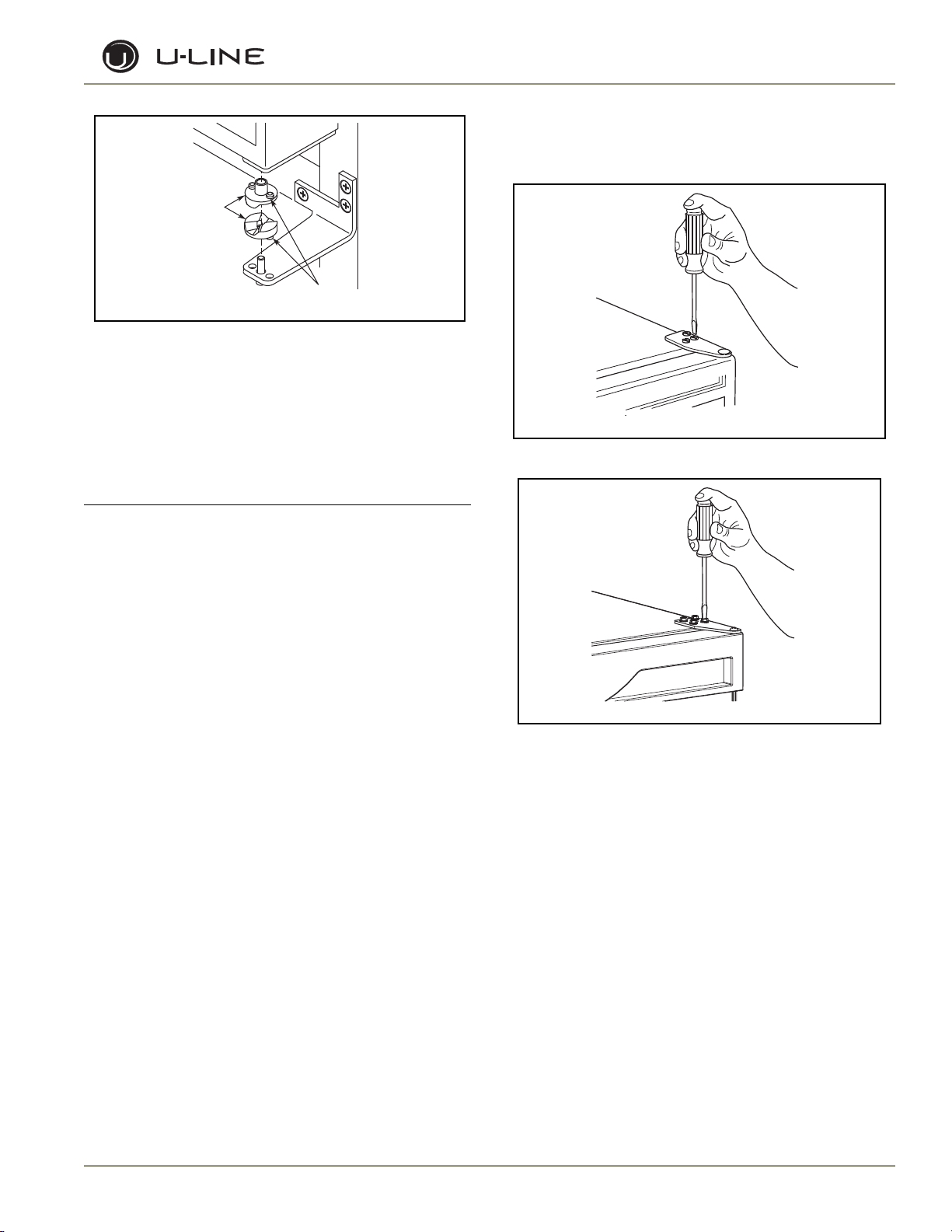

REVIEW THE FOLLOWING NOTES FOR GENERAL

INFORMATION.

• The unit is equipped with a four-minute compressor-off cycle.

• The mullion heater is energized on the 2175DWRR whenever the

Normal defrosting is based on a time and temperature scale. See

chart on page 3-40. Defrost ends if evaporator thermistor reaches

stop point or maximum time, whichever comes first.

THERMISTOR OUTAGE (EXCEPT DWRWS & 2275ZWC):

If the refrigerator thermistor (T1) fails, the unit will continue to

operate based on a preset time interval of 10 minutes on and 30

minutes off. The display will show “ER.”

If the evaporator thermistor (T2) fails, the unit will operate except it

will defrost solely on time and ignore the temperature reading. The

display will show “ER.” If the ambient thermistor (T3) fails, the unit

will always have the mullion heater energized. The display will show

“ER.”

THERMISTOR OUTAGE (DWRWS & 2275ZWC)

T3 temperature falls below 90°F.

Figure 10. 2275DWRWS/2275ZWC

If T1 is not working, unit runs a preset time interval —

10 minutes ON, 60 minutes OFF.

If T2 is not working, unit runs a preset time interval —

10 minutes ON, 60 minutes OFF.

If either T3 or T4 is open, use 90 minutes for defrost length. These

errors do not show on the display; they are only logged on the board.

SERVICE

To check to see which relays are currently operating, hold the