Page 1

Service and Parts Manual

Supplement

For Models

• 2075DWRR • CO2075DWR • 2075DWRWC

U-Line Corporation U-Line Corporation

8900 North 55th Street PO Box 245040

Milwaukee, WI 53223 Milwaukee, WI 53224-9540

www.U-LineService.com

Phone (414) 354-0300 • FAX (414) 354-7905

Service & Parts Tech Lines Phone (800) 779-2547 • FAX (414) 354-5696

M

A

D

E

I

N

T

H

E

U

S

A

Page 2

Page 3

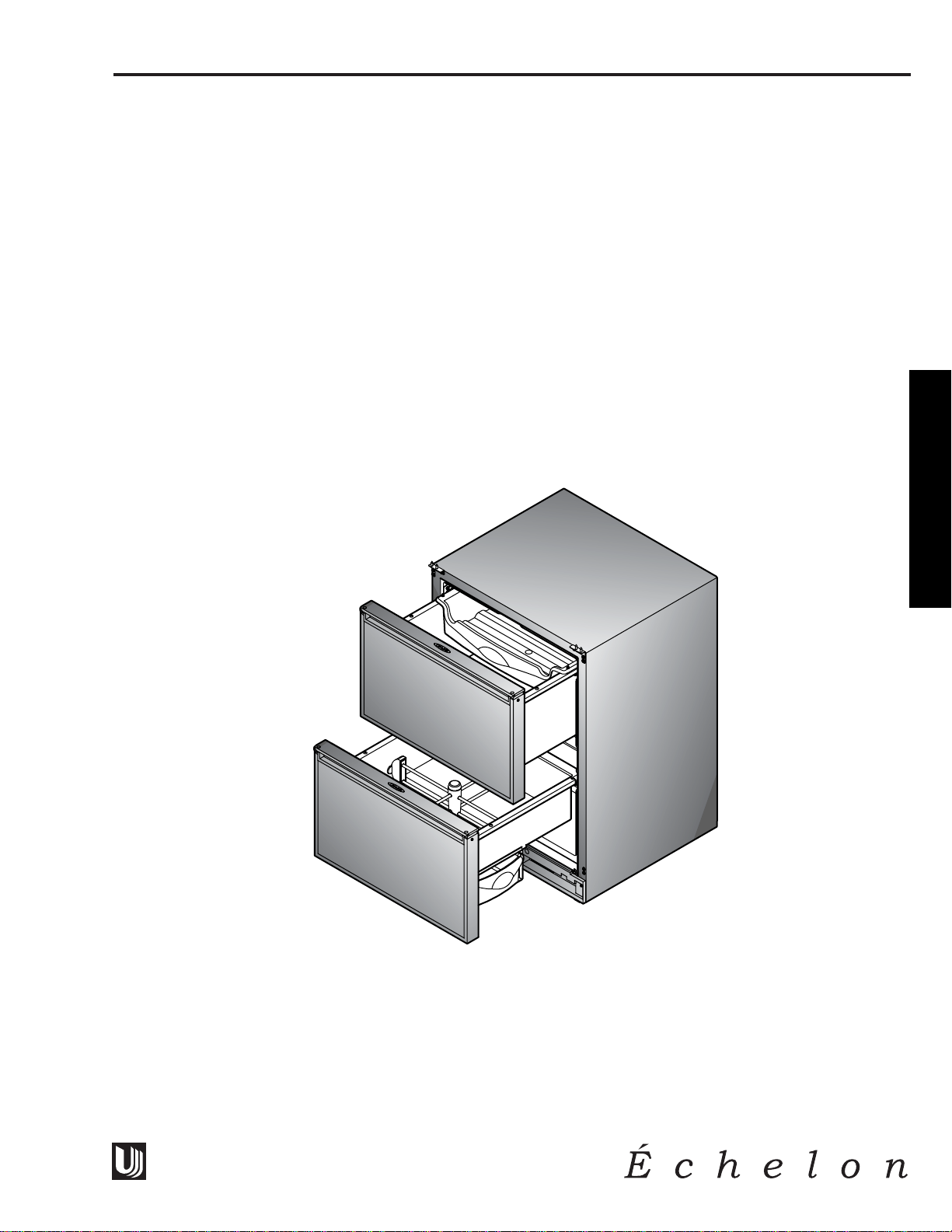

INTRODUCTION

1

Design ■Features ■Performance

General Information

2075DWRR

2075DWRWC

CO2075DWR

Page 4

NOTES

2

Design ■Features ■Performance

Page 5

INTRODUCTION

Three generations of pride and quality manufacturing and design improvements are built into all U-Line

products. The result: U-Line leads the market with innovative technology and superior craftsmanship.

This manual contains specific instructions for servicing the U-Line Échelon 2075DWRR, CO2075DWR and

2075DWRWC.

Potential Problems With HFC-134A

This Service Manual has been written to cover product manufactured with HFC-134a. HFC-134A compressors will be received with a synthetic based ester oil charge. The hygroscopic (water attraction) property of

ester oil is many times greater than that of the mineral oils previously used with CFC-12. High system

moisture causes the formation of acids and alcohol which can damage the compressor. Systems should not

be left open for more than fifteen (15) minutes at any time as humidity from the air will enter system. To

assure system dehydration, the system should be pulled down to 100 microns and vacuum pump oil (mineral oil) must not be allowed to enter the system.

Cleanliness of the system will be extremely important. The presence of residues (chlorinated or greasy

residues, mineral oil, or impurities) can lead to capillary tube restrictions, oil return problems and compressor damage. Flux must not

be used on brazed joints.

INTRODUCTION

3

Design ■Features ■Performance

Page 6

SERIAL NUMBER FORMAT

The serial number is divided into four segments. A typical serial number is 031234-01-5678.

The first two digits of the first segment, 03, represent the year the unit was made.

The next four digits, 1234, represent the shop order number. Every model is assigned a new shop order

number at the beginning of a production run.

The second two digit segment, 01, represents the month the unit was made.

The last four digits, 5678, are an internal control number used at U-Line Corporation.

INTRODUCTION

4

Design ■Features ■Performance

031234-01-5678

Year

Shop

Order

Number

Month

Factory Internal

Control Number

Page 7

General

Information

Page 8

GENERAL INFORMATION

Design ■Features ■Performance

Page 9

LIMITED WARRANTY

U-Line Corporation warrants each U-Line product to be free from defects in materials and workmanship

for a period of one year from the date of purchase; and warrants the sealed system (consisting of the compressor, the condenser, the evaporator, the hot gas bypass valve, the dryer and the connecting tubing) in

each U-Line product to be free from defects in materials and workmanship for a period of five years from

the date of purchase. During the initial one-year warranty period for all U-Line products U-Line shall: (1)

at U-Line’s option, repair any product or replace any part of a product that breaches this warranty; and (2)

for all Marine, RV and Domestic U-Line products sold and serviced in the United States (including Alaska

and Hawaii) and Canada, U-Line shall cover the labor costs incurred in connection with the replacement

of any defective part. During years two through five of the warranty period for the sealed system, U-Line

shall: (1) repair or replace any part of the sealed system that breaches this warranty; and (2) for all

Marine, RV and Domestic U-Line products sold and serviced in the United States (including Alaska and

Hawaii) and Canada, U-Line shall cover the labor costs incurred in connection with the replacement of

any defective part of the sealed system. All other charges, including transportation charges for replacements under this warranty and labor costs not specifically covered by this warranty, shall be borne by you.

This warranty is extended only to the original purchaser of the U-Line product. The Registration Card

included with the product should be promptly completed by you and mailed back to U-Line, or you can

register on-line at www.U-LineService.com.

The following are excluded from this limited warranty: installation charges; damages caused by disasters or

acts of God, such as fire, floods, wind and lightening; damages incurred or resulting from shipping,

improper installation, unauthorized modification, or misuse/abuse of the product; customer education

calls; food loss/spoilage; door and water level adjustments (except during the first 90 days from the date of

purchase); defrosting the product; adjusting the controls; door reversal; or cleaning the condenser.

If a product defect is discovered during the applicable warranty period, you must promptly notify either the

dealer from whom you purchased the product or U-Line at P.O. Box 23220, Milwaukee, Wisconsin 53223

or at 414-354-0300. In no event shall such notification be received later than 30 days after the expiration

of the applicable warranty period. U-Line may require that defective parts be returned, at your expense, to

U-Line’s factory in Milwaukee, Wisconsin, for inspection. Any action by you for breach of warranty must

be commenced within one year after the expiration of the applicable warranty period.

This limited warranty is in lieu of any other warranty, express or implied, including, but not limited to

any implied warranty of merchantability or fitness for a particular purpose; provided however, that to

the extent required by law, implied warranties are included but do not extend beyond the duration of the

express warranty first set forth above. U-Line’s sole liability and your exclusive remedy under this warranty is set forth in the initial paragraph above. U-Line shall have no liability whatsoever for any incidental, consequential or special damages arising from the sale, use or installation of the product or from any

other cause whatsoever, whether based on warranty (express or implied) or otherwise based on contract,

tort or any other theory of liability.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation

of incidental or consequential damages, so the above limitations may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights which vary from state to state.

GENERAL INFORMATION

5

Design ■Features ■Performance

Page 10

WARRANTY CLAIMS PROCEDURE

When submitting claims for warranty payment, please follow these guidelines.

You can use any form you would normally use to bill your customer (your own computer generated form,

Narda, USA, etc.).

The model and serial number MUST be on the claims. Claims will not be paid without a model and serial

number.

If you work on more than one unit per service call please submit a separate claim for each unit.

We track all defects through warranty claims, so please be specific on what the repair was. If it is a system

leak, please specify where the leak was.

Please be sure the claim is legible. If the claim form cannot be read, it will be returned, unpaid.

U-Line will not cover part or labor claims for the replacement of a complete ice maker assembly. All ice

maker parts are available as replacement parts and are stocked in our inventory. Remember: we do not

pay customer education calls. Door and water level adjustments are 90 day warranties only.

If you are changing out a unit please supply the model and serial number of both units (the unit being

replaced and the new unit) and the R.A. number.

If a copy of the Proof of Purchase/Install is not available at the site, the technician should record the

following information on the Labor Invoice:

• The name of the selling Dealer

• The date of purchase/installation

• The Order or Invoice number (if available)

• The type of document they saw i.e. Store Receipt, Closing Papers, Sign-Off of Building Permit,

Final Walk Through, etc.

At U-Line, parts and labor claims are paid separately. Included in labor are freon and recovery charges, all

other parts are handled by the parts department. We require that some parts be returned to us, so we may

return them to our vendor. It will be noted on your packing list if we require you to return the part. If a

part is to be returned please include a copy of the packing list and a copy of your claim. If the part was

purchased at one of our part distributors, you must handle the part warranty with that company. For labor

payment please send a readable copy of your claim to U-Line Corporation, P.O. Box 245040, Milwaukee

WI, 53224-9540, for warranty payment, or fax a legible copy to 414-354-5696.

GENERAL INFORMATION

6

Design ■Features ■Performance

Page 11

PARTS LISTING

How to Order Replacement Parts

1. Locate the illustration(s) for the model you are servicing.

2. Refer to the area where the desired part would be installed, locate the part and note the item number

assigned to it.

3. Locate the item number in the left column of the parts listing which is on the next page from the product illustration. Note the full description and the corresponding part number. If this is for a warranty

unit, please indicate and record the model and serial numbers.

4. When ordering parts, it will be necessary to supply us with Model Number, Serial Number, Part

Number, Part Description and in some cases Color or Voltage.

5. U-Line requires the return of the parts listed below if replaced under warranty.

GENERAL INFORMATION

7

Design ■Features ■Performance

• Fan motors (condenser and evaporator)

•Temperature controls

•Water solenoid valves

• Pumps

•Control boards (with thermistors)

• Ice maker motors

• Bypass solenoids

• Compressors (two years old or less - lines

soldered closed)

All warranty parts will be shipped at no charge as long as warranty status has been confirmed. We require

that some parts be returned to us, so we may return them to our vendor. It will be noted on your packing

list if we require you to return a part or if you may field scrap it. If U-Line requires a defective part to be

returned, a prepaid shipping label will be included with your new replacement part. When returning parts

please enclose a copy of your packing list and a copy of your labor claim, showing the model and serial

number, and tag or label the part with the nature of the defect.

Our warranty records may not match the customer’s information. In this case a proof of purchase will be

required. If you do not have the proof of purchase at the time the order is placed, the part will be sent net

15 days (COD if you don’t have an open account with U-Line Corporation). When the proof of purchase is

provided we will credit your account (a check will be sent if the part was sent COD).

6. Parts may be ordered on-line or by FAX or phone.

On-Line: www.U-LineService.com

FAX Number: (414) 354-7905

Phone Number: (414) 354-0300 or (414) 354-7885; press 3

To expedite parts shipments, on-line ordering is fastest. When placing FAX orders, copy the FAX Parts

Order Form, located in the back of this manual, when placing an order, or order on-line at

www.u-lineservice.com.

7. Effective immediately, U-Line will not pay warranty claims for the replacement of a complete ice

maker assembly. Complete ice maker assembly replacement is not necessary because all ice maker

parts are available as replacement parts and are stocked in our inventory.

REPLACEMENT PARTS: Use only genuine U-Line replacement parts. The use of non-U-Line parts can

reduce ice rate, cause water to overflow from ice maker mold, damage the unit, and may void the

warranty.

Page 12

SAFETY PRECAUTIONS

Do not attempt to service or repair the unit until you have read the entire procedure. Safety items throughout this manual are labeled with Warning or Caution.

Warning means that failure to follow this safety statement may result in extensive product

damage, serious personal injury, or death.

Caution means that failure to follow this safety statement may result in minor or moderate

personal injury, property or equipment damage.

DANGER: Risk of child entrapment. Before you throw away an old refrigerator or freezer:

Take off the doors, leave shelves in place so that children may not easily climb inside.

• Never attempt to repair or perform maintenance on the unit until the electricity has been

disconnected.

• Altering, cutting of power cord, removal of power cord, removal of power plug, or direct

wiring can cause serious injury, fire and/or loss of property and/or life and will void the

warranty.

•Do not lift unit by door handle.

• Never use an ice pick or other sharp instrument to help speed up defrosting. These

instruments can puncture the inner lining or damage the cooling unit.

• Failure to clean the condenser every three months can cause the unit to malfunction. This

could void the warranty.

•Never install the unit behind closed doors. Be sure front grille is free of obstruction.

Obstructing free air flow can cause the unit to malfunction, and may void the warranty.

!

!

WARNING

!

!

WARNING

!

!

!

WARNING

!

GENERAL INFORMATION

8

Design ■Features ■Performance

Page 13

2075DWRR

Page 14

2075DWRR

Design ■Features ■Performance

Page 15

COMPRESSOR/ELECTRICAL SPECIFICATIONS

2075DWRR

COMPRESSOR PINS

To measure start winding resistance, measure across the C-S pins.

To measure run winding resistance, measure across the C-R pins. These pins should never measure any

resistance to ground. This would indicate a shorted compressor.

Specifications

EMU30HSC Start Winding Resistance: 28 OHMS

EMU30HSC Run Winding Resistance: 8 OHMS

115 VOLT Capacitor: 12 µF

115 VOLT Valve Coil Resistance: 380 OHMS

115 VOLT Drain Pan Heater 6900 OHMS

UL183-3C

OVERLOAD PROTECTOR

STARTING RELAY

RELAY COVER

EMU30HSC

C

S

R

2075DWRR

9

Design ■Features ■Performance

Page 16

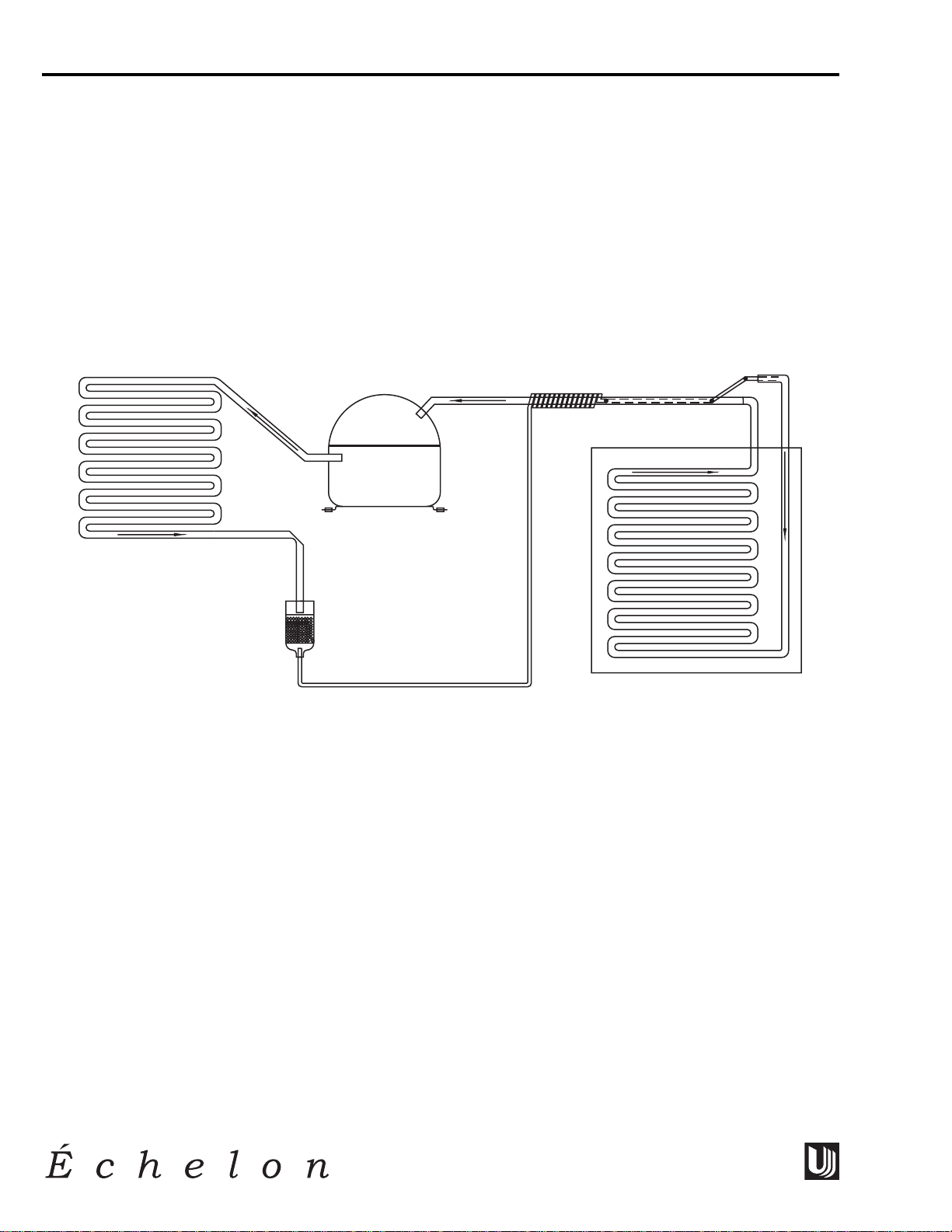

REFRIGERATION SYSTEMS

Normal Vapor/Compression Cycle Refrigeration

• Refrigerant is pumped from the compressor to the condenser as a high pressure, high temperature

vapor.

• As the refrigerant cools in the high pressure condenser, the vapor condenses to liquid. During this

phase change, a great amount of heat is rejected with the help of the condenser fan.

• The liquid then flows to the dryer where it is strained and filtered.

• From the dryer, the refrigerant flows through the capillary tube which meters the liquid refrigerant to

the evaporator. The pressure of the refrigerant is reduced to the evaporating or low side pressure.

• The reduction of pressure on the liquid refrigerant causes it to boil or vaporize until it reaches saturation temperature. As the low temperature refrigerant passes through the evaporator coil, it continues to

absorb a lot of heat, causing the boiling action to continue until the refrigerant is completely vaporized. It is during this phase change that the most heat is absorbed (the cooling takes place) in the refrigerator.

• The refrigerant vapor leaving the evaporator travels through the suction line to the compressor inlet.

The compressor takes the low pressure vapor and compresses it, increasing both pressure and temperature. The hot high pressure gas is pumped out the discharge line and into the condenser. The cycle

continues.

2075DWRR

10

Design ■Features ■Performance

COMPRESSOR

CONDENSER

DRYER

EVAPORATOR

CAPILLARY TUBE

UL183-1

Page 17

THERMISTOR

The thermistor senses the compartment temperature. This is used in conjunction with the control board to

determine the length of the refrigeration cycle.

Thermistors generally fail due to moisture or physical damage.

SERVICE NOTES

2075DWRR

The 2075DWRR has the same basic refrigeration system as the 2075R with a few exceptions.

• The compressor is a high efficiency Embraco EMU30HSC.

• The electro-mechanical gas bulb is replaced with an electronic controller. The controller features a

digital temperature display and control with two LED indicators and three touch pad buttons.

• The mullion between the two drawers has a low wattage “anti sweat” surface heater to prevent condensation on the mullion. Additionally, there is an anti-frost heater on the drain trough.

A thermal cut-out is mounted on the base, where the thermostat is normally mounted. This energy

saving feature cuts-out the “anti-sweat” heater as well as the trough heater in high ambient temperatures, when in most conditions, the mullion would normally be warmed by ambient air.

• There are two interior lights and light switches. The switches are mounted in a switch box in the rear

interior of the cabinet and the lights, in a housing in the top front of the drawers.

2075DWRR

11

Design ■Features ■Performance

Page 18

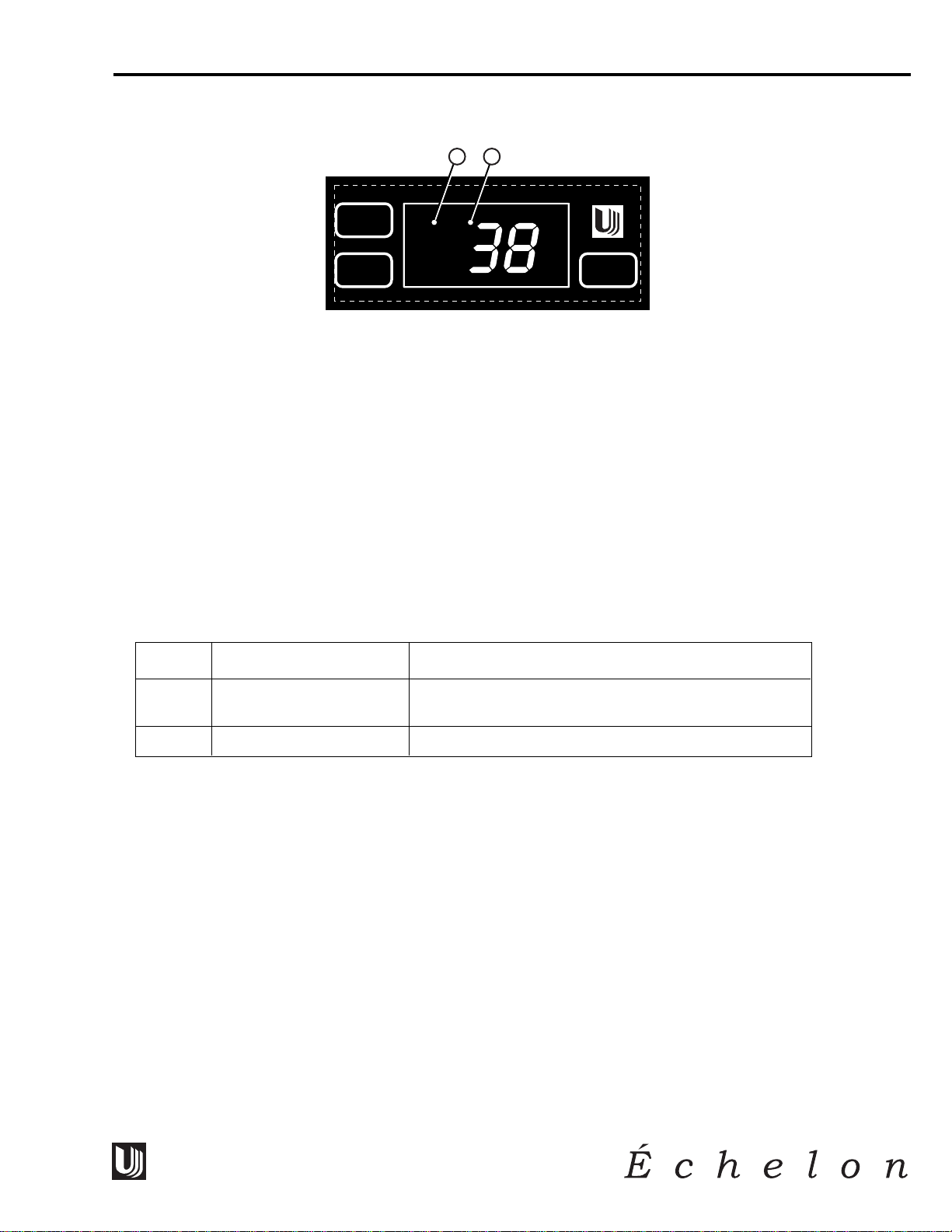

THE ELECTRONIC TEMPERATURE CONTROLLERS

2075DWRR

• The controller has a four minute minimum off-cycle regardless of the thermistor status.

• The controller has a 4° differential built into it for the refrigerator thermistor. When it senses 38°F, the

refrigerator will cool until the thermistor senses 36°F, and will not re-initiate cooling until the thermistor senses 40°F. When monitoring actual temperature, by pressing WARMER temporarily, the refrigeration cycle may be off, when the temperature is a degree warmer than the set point, or the refrigeration

cycle on, when it is a degree below the set point.

• The LED status indicator lights indicate compartment temperature is displayed and open thermistor. A

solid light on, in LED position (1), means compartment temperature is displayed. A flashing light, in

LED position (2), means open thermistor. (The thermistor has failed or has been out of limits.) If a

refrigerator thermistor fails, the refrigerator will shut down. A thermistor would normally fail by opening (no continuity), or by shorting (no resistance).

• Under most conditions, the refrigerator will remain frost-free by clearing itself between refrigeration

cycles. Because there is no thermostat bulb on the evaporator, like other U-Line refrigerators, the controller runs a 45 minute off-cycle for every 12 hours of clock time. The refrigerator will not cool during

this off-cycle even if the refrigerator thermistor is calling for cooling.

• The entire control system is mounted in a single housing in the top drawer.

2075DWRR

12

Design ■Features ■Performance

Page 19

2075DWRR

The temperature controller is located in the top drawer. The LED display shows the temperature set point

and is calibrated in degrees Fahrenheit. The controller is factory programmed for a set point of 38°F which

will show when the unit is first powered-up.

To display actual temperature, press the “WARMER” button momentarily. A solid status indicator light (1)

will show the air temperature reading in the cabinet for approximately 10 seconds.

To adjust the temperature set point, press the “SET TEMP” button momentarily; the display will flash. Press

the “WARMER” or “COOLER” button as desired to change the set point. When the desired set point shows

on the display, wait 10 seconds and the new set point will be saved. Wait 24 hours for the temperature to

stabilize before checking the actual temperature again. The temperature range is 34°F to 45°F.

Indicator light status

LED Status Indicates

1•Solid • Compartment temperature displayed

• Flashing • Not Applicable

2•Flashing • Open Thermistor

SET

TEMP

WARMER

COOLER

2075DWRR

13

Design ■Features ■Performance

1 2

WARMER

COOLER

SET

TEMP

CLRCO011B

Page 20

2075DWRR

14

Design

■

Features

■

Performance

REFRIGERATION SYSTEM DIAGNOSIS GUIDE

SystemSuction Suction Compressor Condenser Capillary Evaporator Wattage

Condition Pressure Line Discharge Tube

Normal Normal Slightly below Very hot Very hot Warm Cold Normal

room

temperature

Overcharge Higher than Very cold Slightly warm Hot to warm Cool Cold Higher than

normal may frost to hot normal

heavily

Undercharge Lower than Warm - near Hot Warm Warm Extremely cold Lower than

normal room near inlet - normal

temperature outlet

below room

temperature

Partial Somewhat Warm - near Very hot Top passes Room Extremely cold Lower than

Restriction lower than room warm - temperature near inlet - normal

normal-in temperature lower passes (cool) or outlet

vacuum cool colder below room

(near room temperature

temperature) backing up

due to liquid

Complete In deep Room Room Room Room No Lower than

Restriction vacuum temperature temperature temperature temperature refrigeration normal

(cool) (cool) (cool) (cool)

No 0 PSIG Room Cool Room Room No Lower than

Gas to temperature to temperature temperature refrigeration normal

25" (cool) hot (cool) (cool)

Page 21

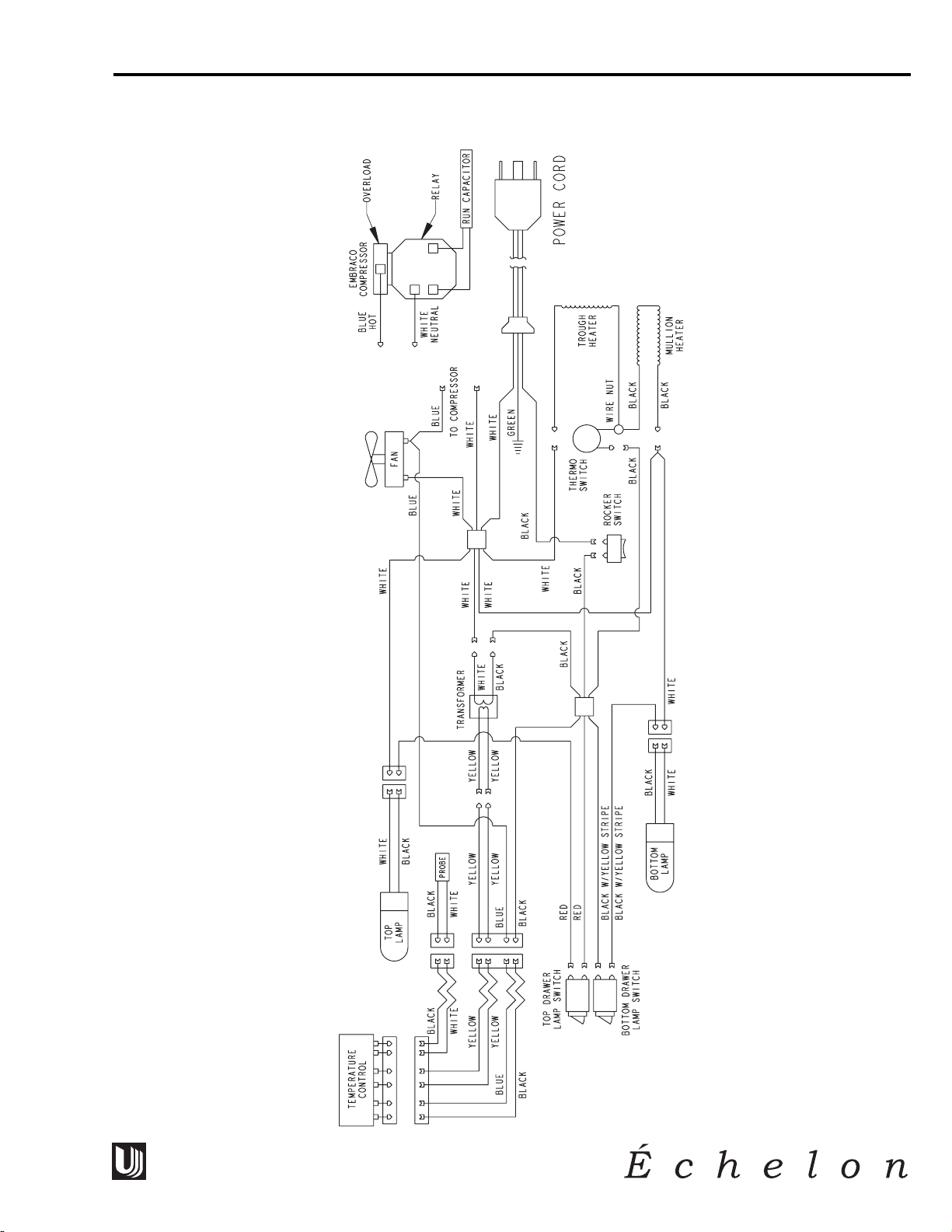

2075DWRR WIRING DIAGRAM

F

2075DWRR

15

Design ■Features ■Performance

42184-

Page 22

2075DWRR

16

Design ■Features ■Performance

DO NOT service the unit until the main electrical power has

been disconnected.

!

WARNING

!

TROUBLESHOOTING

2075DWRR

1 Not refrigerating (compressor and fan are operating)

Cause Remedy

a. Little or no frost pattern on evaporator a. Check for sealed system leak or restriction

2 Not refrigerating (compressor not operating, fan operating)

Cause Remedy

a. Wire off or broken a. Check wiring

b. Defective compressor - check resistence b. Replace compressor

c. Defective overload c. Replace overload

d. Defective relay d. Replace relay

3 Not refrigerating (compressor and fan not operating)

Cause Remedy

a. No power to the unit a. Check that unit is plugged in

b. On/Off switch b. Check that switch is in the on position

c. Display on - check for power in to controller c. None - Check for bad wire

d. Display on - check for power out of controller d. None - Bad controller

e. Display off e. Check transformer

f. Thermistor light flashing f. Bad Thermistor

g. Display on - power in & out of controller g. Broken circuit - check wiring

4 Compressor overheating

Cause Remedy

a. Condenser air flow restricted a. Remove restriction (clean condenser and grille)

b. Condenser fan blade obstructed b. Remove blade restriction

c. Condenser fan motor stalled c. Replace fan motor

d. Defective Compressor - check resistance d. Replace compressor

5 Compressor will not stop operating

Cause Remedy

a. Defective controller a. Replace controller

b. Wiring defect b. Check wiring

6Water leak inside unit

Cause Remedy

a. Blocked drain a. Remove blockage

7 Excessive frost build-up

Cause Remedy

a. Gasket not sealing a. Repair or replace gasket

b. Product too tall for drawer or product not b. Instruct customer

allowing top bin to move forward (2075DWRR)

Page 23

2075DWRR

17

Design ■Features ■Performance

8 Noisy

Cause Remedy

a. Copper refrigeration tube touching cabinet a. Carefully adjust tubing

b. Fan blade touching shroud b. Adjust fan mounting or shroud

c. Fan blade obstruction (wiring, foam insulation, c. Remove obstruction

packaging material)

9 Fresh food or wine temperature too cold

Cause Remedy

a. Controller set too cold a. Adjust controller

b. Defective controller b. Replace controller

c. Wiring defect c. Check wiring

d. Thermistor not pushed all the way into the well d. Check thermistor location

10 Excessive condensation on mullion

Cause Remedy

Mullion heater not operating - check resistance

a. Good resistance a. Bad heater switch

b. No resistance b. Heater wiring

Note: The heater will not operate in ambients over 90° F.

Page 24

2075DWRR (1 OF 2)

2075DWRR

18

Design ■Features ■Performance

4

3

2

1

12

5,6 7 8 9 10 11

22

25

24

23

22

19

19

20

18

17

21

15

16

14

13

7

26

DWR023

Page 25

2075DWRR (1 OF 2)

Item Description Black Stainless Steel

1 Control Housing 26006 26006

2 Control Assembly 68005 68005

3Organizer Assembly 80-48001-00 80-48001-00

4Top Bin 26000 26000

5 Switch Box 26010 26010

6 Light Switch 42179 42179

7Drawer Slides 80-47001-00 80-47001-00

8 Evaporator Assembly 2333-S 2333-S

9 Anti-Tip Components 80-16005-01 80-16005-02

10 Light Cover 11859 11859

11 Light Bulb 31317 31317

12 Back Panel 11969 11969

13 Drain Trough 31391-3 31391-3

14 Control Harness 68015 68015

15 Drain Cup 11508 11508

16 Drain Tube 31726 31726

17 Grille 11902-BLK-01 11902-BLK-01

18 Top Drawer (No Front) 14007-S 14007-S

19 Door Gasket 31493-13-BLK 31493-13-GRY

20 Bottom Drawer (No Front) 14008-S 14008-S

21 Crisper, Bottom 26001 26001

22 Door Assembly 2075DRW-FRNT BLK 2075DRW-FRNT SS

23 Crisper Shelf 40000-02 40000-02

24 Door Handle Bottom 11927-4-BLK 11927-4-BLK

25 Door Handle Top, Modified 11926-7-BLK N/A

26 Drain Trough Heater 66002 66002

Parts Not Shown

Item Description Black Stainless Steel

Full Door Handle 11926-4-BLK N/A

2075DWRR

19

Design ■Features ■Performance

Page 26

2075DWRR (2 OF 2)

2075DWRR

20

Design ■Features ■Performance

12

13

3

2

1

4

10

5

6

7

8

11 14

9

8

DWR024

Page 27

2075DWRR (2 OF 2)

Item Description Black Stainless Steel

1 Rocker Switch 2053 2053

2Transformer 68014 68014

3 Thermo Cutoff Switch 66001 66001

4 Condenser 2303-S 2303-S

5 Fan Blade 5188 5188

6 Fan Motor 5263 5263

7Drain Pan 31550-1-F 31550-1-F

8 Leg Levelers 41319 41319

9 Drier 2694 2694

10 Capacitor 71008 71008

11 Compressor Assembly 70077-S 70077-S

12 Overload 71009 71009

13 Relay 71010 71010

14 Power Cord 2887 2887

2075DWRR

21

Design ■Features ■Performance

Page 28

NOTES

22

Design ■Features ■Performance

Page 29

2075DWRWC

Page 30

2075DWRWC

Design ■Features ■Performance

Page 31

COMPRESSOR/ELECTRICAL SPECIFICATIONS

2075DWRWC

COMPRESSOR PINS

To measure start winding resistance, measure across the C-S pins.

To measure run winding resistance, measure across the C-R pins. These pins should never measure any

resistance to ground. This would indicate a shorted compressor.

Specifications

EMU30HSC Start Winding Resistance: 28 OHMS

EMU30HSC Run Winding Resistance: 8 OHMS

115 VOLT Capacitor: 12 µF

115 VOLT Valve Coil Resistance: 380 OHMS

UL183-3C

OVERLOAD PROTECTOR

STARTING RELAY

RELAY COVER

EMU30HSC

C

S

R

2075DWRWC

23

Design ■Features ■Performance

Page 32

REFRIGERATION SYSTEMS

Normal Vapor/Compression Cycle Refrigeration

• Refrigerant is pumped from the compressor to the condenser as a high pressure, high temperature

vapor.

• As the refrigerant cools in the high pressure condenser, the vapor condenses to liquid. During this

phase change, a great amount of heat is rejected with the help of the condenser fan.

• The liquid then flows to the dryer where it is strained and filtered.

CAPILLARY TUBE

SOLINOID VALVE

SOLINOID VALVE

DRYER

CONDENSER

COMPRESSOR

EVAPORATOR

TOP

COMPARTMENT

THERMISTOR

CAPILLARY TUBE

DRYER

EVAPORATOR

DWR052

BOTTOM

COMPARTMENT

THERMISTOR

2075DWRWC

24

Design ■Features ■Performance

Page 33

• From the dryer, the refrigerant flows through the capillary tube which meters the liquid refrigerant to

the evaporator. The pressure of the refrigerant is reduced to the evaporating or low side pressure.

• The reduction of pressure on the liquid refrigerant causes it to boil or vaporize until it reaches saturation temperature. As the low temperature refrigerant passes through the evaporator coil, it continues to

absorb a lot of heat, causing the boiling action to continue until the refrigerant is completely vaporized. It is during this phase change that the most heat is absorbed (the cooling takes place) in the refrigerator.

• The refrigerant vapor leaving the evaporator travels through the suction line to the compressor inlet.

The compressor takes the low pressure vapor and compresses it, increasing both pressure and temperature. The hot high pressure gas is pumped out the discharge line and into the condenser. The cycle

continues.

THERMISTORS

The two thermistors sense the two compartment temperatures. This is used in conjunction with the control

board to determine the length of the refrigeration cycle.

Thermistors generally fail due to moisture or physical damage.

SERVICE NOTES

2075DWRWC

The 2075DWRWC has the same basic refrigeration system as the 2075R/2075WC with a few exceptions.

• The compressor is a high efficiency Embraco EMU30HSC.

• The electro-mechanical gas bulb is replaced with an electronic controller. The 2075DWRWC features

an LED display and touch sensors for each drawer and a touch sensor to control the lighting.

• There are two interior lights and light switches which can be controlled independently from each

other. The switches are mounted in the liner in the rear interior of the cabinet and the lights, in a

housing in the top front of the drawers.

This unit is operated with a two part electronic control assembly. The main board is located in the base of

the unit behind the grille and the display board is permanently attached to the glass in the upper drawer.

There is a snap in access panel in the drawer to reach the back of the board.

The LED display indicates the set point of both compartments. Holding either the up or down arrow for

three seconds enters into the set point mode. You can adjust the temperature of each compartment

independently from 40-60°F.

Holding both the up and down arrow for either section displays the actual temperature.

When the unit is plugged in the top compartment begins cooling first. After the top set point has been

reached the lower compartment will begin cooling. Only one drawer can cool at a time. One compressor

and condenser are used in this system. Behind the compressor are two valves that switch the refrigerant

from the top system to the bottom system. Each system has a bypass valve, dryer, evaporator and capillary

tube. Only one system can operate at a time.

2075DWRWC

25

Design ■Features ■Performance

Page 34

The top and bottom valve can never be open at the same time. After initial startup whichever compartment

calls for cooling first, will have priority. Once the setpoint is achieved the other compartment will be

cooled if necessary.

When both compartments have reached setpoint and the compressor shuts off, the last bypass valve that

was open will remain open for four minutes. This is done to help the refrigerant pressures stabilize and

reduce hard starting of the compressor.

This unit can be put into a diagnostic mode.

1. Unplug unit

2. Install jumper on pins 9 and 10 on board.

3. Plug unit back in.

Based on the attached chart you can turn on and off each relay individually.

Control pot at 2 – bottom light

Control pot at 0 – top light

Control pot at -2 – bottom bypass valve

Jumper on 1/4" spade terminals – COMPRESSOR

Jump pins on J2 – TOP VALVE

Jump pins on J2 – CONDENSER FAN

2075DWRWC

26

Design ■Features ■Performance

TOP DRAWER

THERMISTOR

9 & 10 PINS

POT

4

3

2

1

COMPRESSOR

0

-1

-2

-3

-4

POWER

TOP

VALVE

BOTTOM

VALVE

TOP

LIGHT

BOTTOM

LIGHT

COND/GAS

FAN

5

-5

POWER ON

123456 78910

DISPLAY BOARD

CONNECTION

J2

1/4" SPADE

TERMINALS

BOTTOM DRAWER

THERMISTOR

CONDENSER

FAN

TOP

VALVE

CLRCO035C

Page 35

THE ELECTRONIC TEMPERATURE CONTROLLERS

2075DWRWC

The temperature controls are integrated in the top, front drawer panel. They consist of an LED display and

touch sensors for each drawer and a touch sensor to control the lighting (“ ”, “ ” and “ ”). The LED

displays show the drawer’s temperature set point, and are calibrated in degrees Fahrenheit. The controls

are factory programmed for a set point of 60°F for the top drawer and 40°F for the bottom drawer. Each

drawer’s display will show its set point when the unit is first powered up.

To display actual temperature of each drawer, press the “ ” and “ ” touch sensors simultaneously for

three seconds. The display indicates the actual temperature. After approximately 10 seconds, the set point

temperature displays.

Both drawers can be controlled independently from 40°F to 60°F.

To adjust the temperature set point, touch and hold either the “ ” or “ ” for that drawer for three seconds. When the LED displays “SP,” lift your finger from the controller and the corresponding LED will

begin to flash the set point. Touch the “ ” or “ ” until the desired set point displays. Wait 10 seconds

for the new set point to be saved. Wait 24 hours for the temperature to stabilize before checking the actual

temperature again. The compartment set point range is 40°F to 60°F.

2075DWRWC

27

Design ■Features ■Performance

DWR034

DWR045

Page 36

2075DWRWC

28

Design ■Features ■Performance

INTERIOR LIGHTING (2075DWRWC)

The interior lighting can be controlled by the controller. Each time the light “ ” symbol is touched, the

lighting is scrolled through the following options:

Touch once – Both compartment lights on.

Touch twice – Top compartment light on.

Touch three times – Bottom compartment light on.

Touch four times – Both compartment lights off.

To enter the “black-out mode,” touch and hold “ ” for approximately 15 seconds, this will turn off both

display temperatures and the cabinet lights. The unit will continue to maintain the compartment set point

temperatures even though they are not displayed. If the light symbol is touched and held for 10 seconds,

the unit will come out of “black-out mode,” the set points will be displayed and the lighting function will

be in one of the four scrolled positions.

Note: When the unit is in “black-out mode,” the light will come on automatically if the drawer is

opened. If you do not want the lights to come on when the drawers are opened, the light bulbs

must be removed. Refer to Light Bulb Replacement.

A solid indicator light (LED dot) indicates a thermistor error in that drawer.

Page 37

REFRIGERATION SYSTEM DIAGNOSIS GUIDE

2075DWRWC

29

Design

■

Features

■

Performance

System Suction Suction Compressor Condenser Capillary Evaporator Wattage

Condition Pressure Line Discharge Tube

Normal Normal Slightly below Very hot Very hot Warm Cold Normal

room

temperature

Overcharge Higher than Very cold Slightly warm Hot to warm Cool Cold Higher than

normal may frost to hot normal

heavily

Undercharge Lower than Warm - near Hot Warm Warm Extremely cold Lower than

normal room near inlet - normal

temperature outlet

below room

temperature

Partial Somewhat Warm - near Very hot Top passes Room Extremely cold Lower than

Restriction lower than room warm - temperature near inlet - normal

normal-in temperature lower passes (cool) or outlet

vacuum cool colder below room

(near room temperature

temperature) backing up

due to liquid

Complete In deep Room Room Room Room No Lower than

Restriction vacuum temperature temperature temperature temperature refrigeration normal

(cool) (cool) (cool) (cool)

No 0 PSIG Room Cool Room Room No Lower than

Gas to temperature to temperature temperature refrigeration normal

25" (cool) hot (cool) (cool)

Page 38

2075DWRWC

30

Design

■

Features

■

Performance

2075DWRWC WIRING DIAGRAM

POWER CORD ASSEMBLY

BLACK-HOT

(SMOOTH)

BLACK-NEUTRAL

(RIBBED)

CONTROL BOARD

GREEN

GROUND

BLACK

WHITE

WHITE

BOT

VALVE

TOP

VALVE

WHITE

BOTTOM

DRAWER

DISPLAY

BOARD

CONNECTOR

DWR038

(WHITE) 9

(BLACK) 8

(BLACK W/YELLOW) 6

12345678910

(RED) 5

(YELLOW) 4

(PURPLE) 3

(BROWN) 2

(BLUE) 1

TOP DRAWER

THERMISTORS

BLACK

7

RED

BLACK

BLACK

WITH

YELLOW

YELLOW

PURPLE

COND

FAN

BROWN

OVERLOAD

BLUE

WHITE

TOP

LAMP

LAMP

BOTTOM

RELAY

EMBRACO

COMPRESSOR

BLACK CAPACITOR

Page 39

2075DWRWC

31

Design ■Features ■Performance

DO NOT service the unit until the main electrical power has

been disconnected.

!

WARNING

!

TROUBLESHOOTING

2075DWRWC

Before servicing this unit, take readings from the electronic control (refer to The Electronic Temperature

Control for checking actual temperatures, if needed). These actual readings are important to take before

having the drawers open for more than 30 seconds to obtain accurate readings.

Top drawer temperature: __________

This temperature should be within a few degrees of the setpoint.

Bottom drawer temperature: _________

This temperature should be within a few degrees of the setpoint.

If there is a dot illuminated above the temperature display, there has been a problem with the thermistor. If

you can read the actual temperatures then the problem has been corrected. If you were unable to read the

temperatures or if you read 99, then the thermistor is not working and the circuit board and thermistors

must be changed. The thermistor harness is matched to the circuit board and these must be changed as an

assembly.

1Temperatures not cold enough

• Check actual temperatures versus setpoint. After 24 hours of runtime, temperatures should be within a few degrees of setpoint.

• Drawers left open or not sealing properly.

• Clean condenser.

2 Temperatures too cold

• Check actual temperatures versus setpoint.

• Ensure thermistors are pushed all the way into the well tube.

• If top drawer is well below setpoint and the lower drawer is not achieving setpoint the thermistors

may be switched.

• If bottom drawer is well below setpoint and the upper drawer is not achieving setpoint the valve

power wires may be switched.

Page 40

3 Drawers will not close properly

• The drawer slides contain a self-closing feature which engages when the drawer is about 1 inch

from being closed. At the point the closers engage, there may be some resistance. If this resistance

is hard to overcome, try closing the drawers with more force a couple times and then try slowly

again. If, during shipment, the unit has been mishandled, the drawer slide closers may become disengaged. Reset by closing the drawers with more force than normal.

• Ensure large bottles are not restricting rack movement.

• Check rail to make sure they are free of contaminents.

4 Cascade parts not operating properly

• The cam on the cascade mechanism should automatically reset as the drawer is moved fully in and

out. If it does not, manually reset cam.

If the drawer will not close, make sure the cascading cams are positioned correctly. The drawer will

not close if the cams are in the A “open” position. Reset the cams manually as shown in position B

“closed.” The drawers should take a minimal amount of effort to close. See illustration on page 33.

5 LED dot lit on display

• This light indicates that a thermistor has gone out of range. If the unit is still working the thermistor

is now operational. Unplug unit and plug back in, to clear light. If unit is still not working, change

board and thermistors.

6 Trouble with lights

• Each light is controlled by a switch that operates when the drawer is opened and by a touchsensor

in the glass.

• Check wiring.

• Check bulb.

7 Display not functioning

• Red LED on rear of display indicates the display has power.

• Flashing green indicates communication with main board.

• If either is not lit, check wiring to main board.

• Could be in Sabbath mode.

8 Not cooling

• Check solenoid valves and connections.

2075DWRWC

32

Design ■Features ■Performance

Page 41

CASCADING PARTS NOT OPERATING PROPERLY

2075DWRWC

33

Design ■Features ■Performance

A - Cascade mechanism in the correct opening position.

DWR065

B - Cascade mechanism in the correct closing position.

Page 42

2075DWRWC (1 OF 2)

2075DWRWC

34

Design ■Features ■Performance

4

8

7

21

6

5

2

1

3

20

3

9,10

11

12

13

DWR067

19

17

22

14

15

16

17

18

Page 43

2075DWRWC (1 OF 2)

Item Description Black Stainless Steel

2 Drawer & Rack Assembly Top 80-17028-01 80-17028-03

3 Cascade Assembly Left Side 26028-02-S 26028-02-S

4 Top Rack Assembly 80-33005-S 80-33005-S

5 Drawer Slide Assembly 80-47001-00 80-47001-00

6 Evaporator Assembly 2649-S 2649-S

7 Anti-Tip Brackets 80-16005-01 80-16005-01

8 Back Panel 11969 11969

9 Lens Cover 11859 11859

10 Light Bulb 31317 31317

11 Drain Trough 31391-6 31391-6

12 Drain Funnel 11508 11508

13 Drain Tube 41967-4 41967-4

14 Grille 11942-BLK-01 11942-BLK-01

15 Cascading Rack Assembly 80-48003-00 80-48003-00

16 Cascade Rack Latch Assembly 26022-S 26022-S

17 Cascade Assembly Right Side 26028-01-S 26028-01-S

18 Drawer Wine Caddy Assembly 80-48002-00 80-48002-00

19 Door Gasket 12094-07-BLK 12094-07-BLK

20 Drawer Handle 11949-blk 11949

21 Interior Slides (White) 42118-S 42118-S

22 Main board jumper wire 2932 2932

2075DWRWC

35

Design ■Features ■Performance

1 Drawer & Rack Assembly Bottom 80-17030-01 80-17030-03

Page 44

2075DWRWC (2 OF 2)

2075DWRWC

36

Design ■Features ■Performance

12

13

11

1

2

3

4

10

9

8

6

7

6

5

DWR068

Page 45

2075DWRWC (2 OF 2)

Item Description Black Stainless Steel

1 Board 68019-S 68019-S

2 Condenser Assembly 2303-S 2303-S

3 Fan Blade 5188 5188

4 Fan Motor 5263 5263

5 Power Cord 2916 2916

6 Valve Coil 73002 73002

7 Valve Assembly 73002-S 73002-S

8 Drier 2694 2694

9 Compressor Assembly 70077-S 70077-S

10 Leveling Leg 41319 41319

11 Capacitor 71008 71008

12 Overload 71009 71009

13 Relay 71010 71010

2075DWRWC

37

Design ■Features ■Performance

Page 46

NOTES

2075DWRWC

38

Design ■Features ■Performance

Page 47

CO2075DWR

Page 48

CO2075DWR

Design ■Features ■Performance

Page 49

COMPRESSOR PINS

To measure start winding resistance, measure across the C-S pins.

To measure run winding resistance, measure across the C-R pins. These pins should never measure any

resistance to ground. This would indicate a shorted compressor.

Specifications

EMI70HER Start Winding Resistance: 8 OHMS

EMI70HER Run Winding Resistance: 3 OHMS

115 VOLT Ice Maker Heater Resistance: 80 OHMS

115 VOLT Water Valve Coil Resistance: 335 OHMS

115 VOLT Bypass Valve Coil Resistance: 380 OHMS

CO2075DWR

39

Design ■Features ■Performance

EMI70HER

OVERLOAD PROTECTOR

STARTING RELAY

RELAY COVER

C

R

S

UL183-3D

Page 50

U-LINE FROST FREE REFRIGERATION SYSTEM

Cooling Mode:

• Bypass solenoid valve closed

• Evaporator fan operating

• Refrigerant flows through capillary tube

• Normal vapor/compression cycle refrigeration

Defrost Mode:

• Bypass solenoid valve open

• Refrigerant flows through bypass system

•Vapor flows from condenser to evaporator without a phase change

THERMISTORS

There are three thermistors to sense the refrigerator, freezer and icemaker temperature. These are used in

conjunction with the control board to control compartment temperatures and initiate ice harvest.

Thermistors generally fail due to moisture or physical damage.

CO2075DWR

40

Design ■Features ■Performance

COMPRESSOR

CONDENSER

DRYER

FLOW WHEN SOLENOID

VALVE IS CLOSED

CAPILLARY TUBE

SOLENOID VALVE

EVAPORATOR

FLOW WHEN SOLENOID

VALVE IS OPEN

UL183-2

Page 51

SERVICE NOTES

CO2075DWR

The CO2075DWR has the same basic refrigeration system as the CO2075F with a few exceptions.

• The compressor is an Embraco EMI70HER.

• The electro-mechanical gas bulb is replaced with an electronic controller which features a digital

temperature display.

• The mullion between the two drawers has a low wattage “anti sweat” surface heater to prevent condensation on the mullion.

• There are two interior lights and light switches. The switches are mounted in the liner in the rear

interior of the cabinet. The lights are in the housing in the top front of the drawers. The bottom light

switch controls the icemaker. When the light switch is on the icemaker stops functioning. If the drawer

is left open, the icemaker will not make ice.

General Operation Notes:

This unit is operated with a two part electronic control assembly. The main board is located in the base of

the unit behind the grille and the display board is located in the upper drawer.

The setpoint button allows the consumer to set a refrigerator temperature. The preset temperature is 38°F.

Based on the design of the mullion and chimney, there is approximately a 38°F difference between freezer

and refrigerator. While the consumer sets the refrigerator temperature the cooling system is actually

controlled by the freezer temperature. When a consumer inputs 38 for the refrigerator, the board subtracts

38 and cools the freezer to 0°F. Use these numbers as reference, but they could be 40°F and 2°F, or 36°F

and -2°F, and so on. The freezer temperature will be maintained at 0°F with a differential of 2°F. In the

event that the refrigerator is warmer than 38°F, but the freezer is 0°F or below, the cooling system will

continue to run to allow the refrigerator to cool to its setpoint. This prevents spoilage of food in the refrigerator. During this time, the freezer may be driven to a lower temperature which will not cause any problems. In the event the refrigerator gets to 32°F it will again override the freezer and cause the cooling system to shut off until the temperature rises above 32°F. This prevents accidental freezing of product in the

refrigerator.

The ice maker setpoint can be reached by holding the “SET TEMP” button down for about 10 seconds. At

first SP1 will be displayed followed by SP2. Release the “SET TEMP” button and 15 should appear. This is

the default ice maker setpoint. Changing this temperature will increase or decrease production. To increase

production raise the setpoint no more than 2°F in 24 hours. Press “SET TEMP” three more times to exit this

menu.

The circuit board has a timing circuit which maintains a minimum compressor off cycle of four minutes. If

the compressor shuts off, no matter what temperature the cabinet rises to, the compressor will remain off

for four minutes to prevent compressor damage.

There is a 30 minute hot gas defrost cycle every 12 hours of clock time. The defrost cycle is automatically

operated by the circuit board. Interrupting power to the unit will reset the clock.

CO2075DWR

41

Design ■Features ■Performance

Page 52

When checking the thermistors to see if they are reading accurately, it is common to place them in an

icebath to see if they read 32°F. Do not place them directly in the water. Use a plastic bag to protect them

from moisture. The freezer and ice maker should read 32°F in icewater, however the refrigerator thermistor should read 36°F. There is a built-in 4°F offset in this reading due to its location in the cabinet. This

sensor is located outside the refrigerator drawer, which is approximately 4°F colder than the inside of the

drawer.

To check the actual temperatures via the display, touch and release the warmer button to view the refrigerator temperature. Hold the colder button, while LED 1 is lit, the freezer temperature will be displayed.

Continue holding the colder button, and the display will cycle from freezer to ice maker until the button is

released.

This unit can be put into a diagnostic mode.

1. Unplug unit

2. Install jumper on pins 9 and 10 on board.

3. Plug unit back in.

Based on the information listed below, you can turn on and off each relay individually.

Control pot at 0 – CONDENSER/EVAPORATOR FANS

Jumper on 1/4" spade terminals – COMPRESSOR

Jump pins on J2 – HOT GAS VALVE

Jump pins on J2 – ICEMAKER

Example (force a defrost cycle):

Set control pot to 0, Jump pins on J2 for hot gas valve and install jumper on 1/4" spade terminals.

CO2075DWR

42

Design ■Features ■Performance

POWER

ICEMAKER

SENSOR

FREEZER

SENSOR

9

10

POT

123456 78910

REFRIGERATOR

4

3

5

2

1

HOT

COND/EVAP

GAS

FAN

ICEMAKER

0

-1

COMPRESSOR

-2

-3

-4

-5

DISPLAY BOARD

CONNECTION

J2

SENSOR

HOT GAS

VALVE

ICEMAKER

POWER ON

1/4" SPADE

TERMINALS

CLRCO035B

Page 53

43

Design ■Features ■Performance

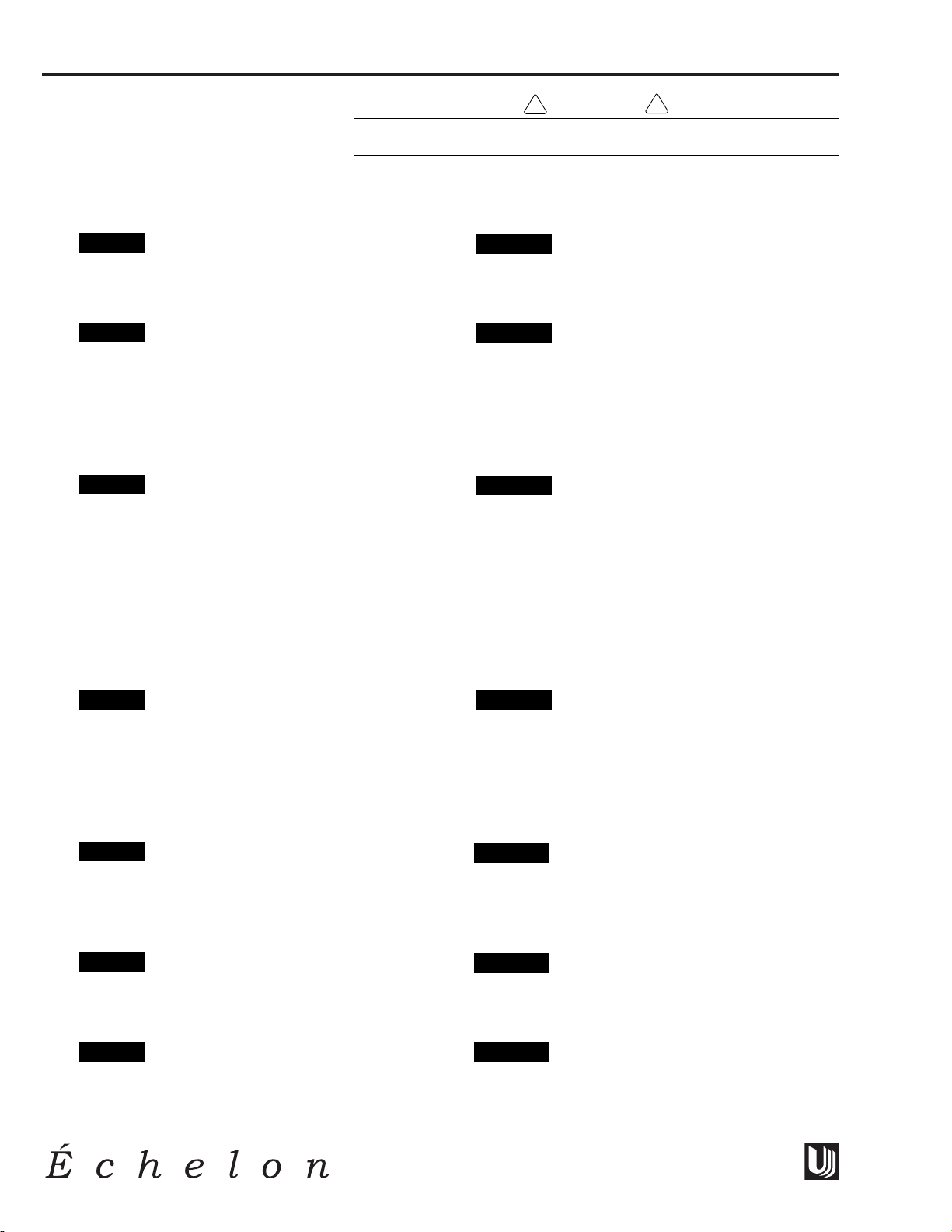

THE ELECTRONIC TEMPERATURE CONTROLLER

The temperature controller is located in the top drawer. It consists of an LED display, two LED status indicator lights and three touch pad buttons. The LED display shows the compartment temperature set point

and is calibrated in degrees Fahrenheit. The controller is factory programmed for a set point of 38°F for the

top drawer which will show when the unit is first powered up. The factory set point for the ice compartment is 0°F.

To display the actual refrigerator compartment temperature, press the “WARMER” button momentarily.

A solid status indicator light (LED 1) will show the air temperature reading in the refrigerator drawer for

approximately 10 seconds.

To adjust the temperature set point, press the “SET TEMP” button momentarily; the display will flash. Press

the “WARMER” or “COOLER” button as desired to change the set point. When the desired set point shows

on the display, you can press the “SET TEMP” again or wait 10 seconds and the new set point will be

saved and the display will stop flashing. Wait 24 hours for the temperature to stabilize before checking the

actual temperature again. The compartment temperature range is 34°F to 45°F.

To check the actual temperatures via the display, touch and release the warmer button to view the

refrigerator (LED 1) temperature. Hold the colder button, while LED 1 is lit, the freezer (LED 2) temperature

will be displayed.

Continue holding the colder button, and the icemaker (LED 3) temperature will be displayed. If you

continue to hold the colder button, the display will cycle from freezer temperature to ice maker

temperature until the button is released.

Indicator light status

LED Status Indicates

1•Solid • Compartment temperature displayed

• Flashing • Not Applicable

2•Solid • Freezer Temperature displayed

• Flashing • Open Thermistor – call for service

3•Solid • Icemaker temperature displayed

SET

TEMP

WARMER

COOLER

CO2075DWR

1 2 3

WARMER

COOLER

SET

TEMP

CLRCO011

Page 54

44

Design

■

Features

■

Performance

CO2075DWR

REFRIGERATION SYSTEM DIAGNOSIS GUIDE

System Suction Suction Compressor Condenser Capillary Evaporator Wattage

Condition Pressure Line Discharge Tube

Normal Normal Slightly below Very hot Very hot Warm Cold Normal

room

temperature

Overcharge Higher than Very cold Slightly warm Hot to warm Cool Cold Higher than

normal may frost to hot normal

heavily

Undercharge Lower than Warm - near Hot Warm Warm Extremely cold Lower than

normal room near inlet - normal

temperature outlet

below room

temperature

Partial Somewhat Warm - near Very hot Top passes Room Extremely cold Lower than

Restriction lower than room warm - temperature near inlet - normal

normal-in temperature lower passes (cool) or outlet

vacuum cool colder below room

(near room temperature

temperature) backing up

due to liquid

Complete In deep Room Room Room Room No Lower than

Restriction vacuum temperature temperature temperature temperature refrigeration normal

(cool) (cool) (cool) (cool)

No 0 PSIG Room Cool Room Room No Lower than

Gas to temperature to temperature temperature refrigeration normal

25" (cool) hot (cool) (cool)

Page 55

45

Design ■Features ■Performance

CO2075DWR WIRING DIAGRAM

CO2075DWR

DWR036

ICEMAKER

SENSOR

REFIGERATOR

SENSOR

SENSOR

FREEZER

Page 56

46

Design ■Features ■Performance

DO NOT service the unit until the main electrical power has

been disconnected.

!

DANGER

!

TROUBLESHOOTING

Before servicing this unit, take readings from the electronic control (refer to The Electronic Temperature

Control for checking actual temperatures if needed). These actual readings are important to take before

having the drawers open for more than 30 seconds to obtain accurate readings.

Refrigerator temperature: __________

This temperature should be approximately 38°F. Slight fluctuations are common during normal

operation.

Freezer temperature: __________

This temperature should be approximately 0°F. If this temperature is between -10°F and +5°F, this

should be considered normal. The temperature can fluctuate in order to maintain an optimum

refrigerator temperature.

Ice maker temperature: _________

The ice maker will harvest when this temperature reaches 15°F. Temperatures may rise to 50°F

during an ice harvest and drop -10°F during ice storage mode.

If there is a dot illuminated above the temperature display, there has been a problem with the thermistor. If

you can read the actual temperatures then the problem has been corrected. If you were unable to read the

temperatures or if you read 159, then the thermistor is not working and the circuit board and thermistors

must be changed. The thermistor harness is matched to the circuit board and these must be changed as an

assembly.

1. Not making ice

• If temperature reading was above 15°F, the unit will not make ice. Possible causes for this could be

a leak in the system or the drawer left open.

• If temperature reading is below 15°F, the unit should produce ice. If there is no ice in the mold,

check the water fill and water connection. If there is ice in the mold and it did not harvest, close

the freezer drawer, unplug the unit and plug it back in. If the temperature is still below 15°F, the

unit should harvest (drawer must be closed). If the freezer drawer opening caused the ice maker

temperature to go above 15°F, wait until it goes below 15°F.

To harvest ice, the bin arm must be in the down position and the drawer must be closed to engage

the ice maker/light switch, mounted in the liner. When the ice maker reaches 15°F, the circuit

board will close a relay for 30 seconds, energizing the ice maker. When the ice maker rotates to

approximately the 2 o’clock position, it will continue the cycle under its own power and break the

circuit to the control board.

If the ice maker does not harvest after unplugging the unit and plugging it back in, try again and

watch the circuit board to verify the relay energizes by checking the green LED on the board (on

this model you can also accomplish this by using the ON/OFF switch). If the ice maker does not

harvest, but the LED illuminates, check the bin arm circuit and the ice/light switch circuits.

• The ice maker relay will only energize a maximum of one time every 75 minutes of operation,

even if the temperature is below the 15°F harvest temperature. To harvest ice you must unplug the

unit and plug it back in (can use the ON/OFF switch) so that the timer on the circuit board is reset.

The timing circuit ensures that proper cubes are formed before allowing the ice harvest.

CO2075DWR

Page 57

47

Design ■Features ■Performance

2. Some cooling

• Clean condenser.

• Check condenser fan.

• Possible system leak.

3. No cooling

• Check compressor/fan operation

• Check refrigeration system pressure

• Check wiring and power at circuit board

4. Noise

• This is a frost free unit with two fans, compressor, and two solenoid valves. Some noise is normal

such as a hum from the fans/compressor. Also, during an ice harvest it is normal to hear water filling the mold and cubes dropping in the bucket.

5. Condensation on mullion

• The mullion has a heater behind it. The heater is always energized and should keep the mullion

free of frost and sweat. In extremely humid conditions some sweat may appear on the mullion or

lower drawer handle/gasket.

6. Excessive frost

• Frost may be visible through the evaporator cover slots.

• Any buildup on the bottom of the liner could be caused by failure to clean up spilled ice cubes.

• If evaporator is not defrosting, the board can be manually entered into a defrost cycle using the

diagnostic feature.

• If evaporator or drain pan does not clear during a defrost, check the bypass valve coil for continuity.

• Drawers not closing properly.

7. Display not operational

• Check four conductor wires from main board to display board. The display board should have red

light and flashing green light on the rear of the board. If these lights are not lit, the wire is not connecting to the main board.

8. Dot flashing on display

• If a thermistor goes out of range it will illuminate a dot on the display board. This dot will remain lit

even if the thermistor goes back into range. It can be cleared by switching the unit off and back on.

9. Drawers will not close properly

• The drawer slides contain a self-closing feature which engages when the drawer is about 1 inch

from being closed. At the point the closers engage, there may be some resistance. If this resistance

is hard to overcome, try closing the drawers with more force a couple times. If, during shipment,

the unit has been mishandled, the drawer slide closers may become disengaged. Reset by closing

the drawers with more force than normal.

10. Evaporator fan not operational

• Ensure fan is not restricted.

CO2075DWR

Page 58

48

Design ■Features ■Performance

Ice maker Operation

1. Freeze cycle

• Ice maker relay is not energized.

• Unit is cooling ice maker down to the 15°F setpoint.

• The unit may cycle on and off as it is pulling ice maker to setpoint in order to maintain ideal

refrigerator and freezer temperatures.

• The minimum ice making cycle time as permitted by the timing circuit in the circuit board is 75

minutes.

7

CO2075DWR

DWR05

Page 59

49

Design ■Features ■Performance

2. Harvest cycle 1

• Ice maker relay on circuit board energizes for 30 seconds. This allows power to the ice maker to

allow the blades rotate.

• Refrigeration system is independent of the ice maker.

• The bin arm must be in the fully lowered position and the drawer must be closed, to initiate this

cycle. The drawer switch must be depressed for the ice maker to cycle.

8

CO2075DWR

DWR05

Page 60

50

Design ■Features ■Performance

3. Harvest cycle 2

• The drawer switch must remain depressed for this cycle to continue.

• The ice maker relay is now de-energized

• This cycle initiates when the blades move to approximately the 2 o’clock position.

• Ejector blades stall on the ice and pulse until the mold heater warms the mold and releases the ice.

• This cycle may last a couple minutes.

CO2075DWR

DWR055

Page 61

51

Design ■Features ■Performance

4. Water fill cycle

• This cycle initiates when the blades move to approximately the 10 o’clock position.

• At this point the ice has moved out of the mold and is dropping into the bucket.

• The ice maker switch is depressed for about seven seconds while the mold fills with water. The

water fill is approximately 120 ml.

• At the end of the fill cycle, the blades stop at the 12 o’clock position and wait for another harvest

cycle to begin.

5. Storage mode

• The bin arm is in the up position, either held by ice in the bin or manually raised.

• The unit will be cycling the compressor on and off in this mode.

The ice maker relay will energize when the ice maker reaches 15°F, but with the bin arm in the raised

position, it will not start an ice making cycle.

CO2075DWR

DWR056

Page 62

52

Design ■Features ■Performance

DISASSEMBLY PROCEDURES

Note: Échelon models do not require removal of the ice maker or freezer housing to access the fan

motor, drain or evaporator.

To replace evaporator fan motor:

1. Disconnect unit from power source.

2. Remove two screws (1) holding evaporator fan cover to evaporator cover.

3. Unplug fan connection.

4. Remove two nuts (4) and two washers (5) holding the fan to the fan bracket.

5. Replace with new fan.

6. Plug-in the fan connection making sure the fan wires are tucked behind the fan bracket.

7. Re-install evaporator cover.

8. Re-install unit and test.

To access evaporator and drain pan:

1. Disconnect unit from power source.

2. Remove two screws (2) holding evaporator cover to drain pan.

3. Remove two screws (6) holding evaporator to drain pan.

4. Remove two screws (3) holding fan bracket to drain pan.

5. Unplug fan connection.

6. Re-install parts in reverse order.

7. Re-install unit and test.

CO2075DWR

3

4

5

2

1

6

2

DWR041

Page 63

53

Design ■Features ■Performance

REPLACING ICE MAKER ASSEMBLY

1. Remove unit from installation.

2. Disconnect water and unplug unit.

3. Disconnect ice maker wire harness at plug in back of unit (1).

4. Remove thermistor from the sensing tube on ice maker assembly (2).

5. Remove water inlet tube.

6. Remove front cover (3).

7. Advance ejector blade to the 3 o’clock position by turning the 5/16" hex head on the small brass gear

counterclockwise (4).

8. Remove two screws from icemaker bracket (5).

9. Remove ice maker assembly.

10. Install new ice maker assembly.

11. Reconnect plug.

12. Insert thermistor ice maker sensing tube.

13. Insert water inlet tube.

14. Apply Permagum

®

to all exit holes.

15. Install back panel.

16. Plug in unit and test.

CO2075DWR

4

2

5

1

5

DWR064

3

Page 64

54

Design ■Features ■Performance

NOTES

CO2075DWR

Page 65

55

Design ■Features ■Performance

REPLACING MOLD AND HEATER

1. Remove ice maker assembly. Refer to REPLACING ICE MAKER ASSEMBLY.

2. Remove one stripper screw (1) and stripper (2).

3. Remove three face plate screws (3) and face plate.

4. Remove one screw (4) and detach limit switch from mold.

5. Detach heater leads (5).

6. Remove two screws (6) and mold from support housing.

7. To assemble, replace parts in reverse order.

8. Install the ice maker assembly.

CO2075DWR

6

1

3

2

5

4

5

3

DWR061

Page 66

56

Design ■Features ■Performance

CO2075DWR (1 OF 3)

CO2075DWR

10

30

5

7

24

6

23

4

2

1

3

25

8

22

9

11, 12

13

21

18

17

20

19

27

28

29

26

25

16

15

14

DWR025

Page 67

57

CO2075DWR (1 OF 3)

Item Description Black Stainless Steel

1 Control Housing 26006 26006

2 Display Board Assembly 68024 68024

3 Control Harness 68025 68025

4 Organizer Assembly 80-48001-00 80-48001-00

5 Top Bin 26000 26000

6 Drawer Slides 80-47002-00 80-47002-00

7 Light Switch Top Drawer 42179 42179

8 Chimney 28002 28002

9 Anti-Tip Components 80-16005-01 80-16005-02

10 Back Panel 11969 11969

11 Light Cover 11859 11859

12 Light Bulb 31317 31317

13 Light Switch Bottom Drawer 66003 66003

14 Evaporator Fan Cover 11952 11952

15 Evaporator Cover 14039 14039

16 Insulator Chimney Panel 35005 35005

17 Evaporator Assembly 74002-S 74002-S

18 Evaporator Fan Blade 31656 31656

19 Evaporator Fan 5434 5434

20 Drain Pan Assembly 14038 14038

21 Drain Tube 31726 31726

22 Grille 11902-BLK-01 11902-BLK-01

23 Ice Maker Assembly 80-39007-00 80-39007-00

24 Top Drawer (No Door) 14007-S 14007-S

25 Door Gasket 12094-07-BLK 12094-07-GRY

26 Ice Bucket 26014 26014

27 Bottom Drawer with Drawer Front 80-17043-01 80-17043-03

28 Door Handle Bottom 11927-4-BLK 11927-4-BLK

29 Door Handle Top, Modified 11926-7-BLK N/A

30 Door Front Assembly 2075DRW-FRNTBLK 2075DRW-FRNTSS

Parts Not Shown

Item Description Black Stainless Steel

Full Door Handle 11926-4-BLK N/A

CO2075DWR

Design ■Features ■Performance

Page 68

58

Design ■Features ■Performance

CO2075DWR (2 OF 3)

CO2075DWR

14

15

16

17

18

2

4

3

2

5

1

8

6

7

9

13

12

11

DWR063

10

Page 69

59

Design ■Features ■Performance

CO2075DWR (2 OF 3)

Item Description Black Stainless Steel

1 Water Line Assembly 404-CO2075DWR 404-CO2075DWR

2 Water Valve 2552A 2552A

3 Plastic Nut & Sleeve 41254 41254

4 Brass Fitting 41826 41826

5 Drier 72018 72018

6 Compressor Assembly 70079-FFS 70079-FFS

7 Overload 71025 71025

8 Relay 71026 71026

9 Power Cord 2915 2915

10 Leg Levelers 41319 41319

11 Rocker Switch 2053 2053

12 Control Board Assembly 68023-S 68023-S

13 Condenser 2303-FFS 2303-FFS

14 Drain Pan 31550-1-F 31550-1-F

15 Hot Gas Bypass Assembly 73002-FFS 73002-FFS

16 Bypass Solenoid Coil Only 73002-1 73002-1

17 Fan Blade 5428 5428

18 Fan Motor 5300 5300

CO2075DWR

Page 70

60

Design ■Features ■Performance

CO2075DWR (3 OF 3)

CO2075DWR

8

6

5

4

3

2

1

36

10

9

7

33

34

35

10

32

11

31

12

30

29

13

28

14

27

15

26

16

25

17

24

18

19

20

21

22

23

DWR060

Page 71

61

Design ■Features ■Performance

CO2075DWR (3 OF 3)

Note: This ice maker is used only on CO2075DWR.

Use only genuine U-Line replacement parts. U-Line ice maker parts are not the same as

standard FSP Whirlpool parts. Using non-U-Line parts can reduce ice rate, cause water to

overflow from ice maker mold, damage the unit, and may void the warranty.

!

CO2075DWR

Item Description Part No.

Ice Maker Assembly 80-39007-00

Faceplate Assembly 150-DWRCO

1 Gear Screw 488957*

2 Gear 628210*

3 Face Plate 11641*

4 Motor 627973*

5 Switch Spacer 625834*

6 Hold Switch 2506*

7 Motor Screw 488622*

8 Long SW Screw 488361*

9 Cam 627302*

10 Spring & Housing Screw 488372*

11 Limit Switch 2917

12 Support Housing 625827

13 Bin Arm Spring 627526

14 Bin Arm 18031

15 Mold Heater 625843

16 Mold & Heater Assembly 628123-DWRCO

17 Ejector 627375

Item Description Part No.

18 Waterline Clip 652604

19 Water Cup 544304

20 Stripper Screw 489128

21 Stripper 31400

22 Sensor Tube 23008

23 Sensor Tube Retainer 14064

24 Wire Harness 2918

25 Bin Switch 2506

26 Bin SW Screw 488360

27 Clamp 625829

28 Arm Lever 625830

29 Arm Lever Screw 627199

30 Short SW Screw 488362*

31 Valve Switch 2506*

32 Insulator 627680*

33 Valve Switch Plate 625836*

34 Spring 627163*

35 Plate Screw 41375

36 Cover 627000

U-Line will not pay warranty claims for the replacement of a complete ice maker assembly. Complete ice

maker assembly replacement is not necessary because all ice maker parts are available as replacement

parts and are stocked in our inventory.

* Parts included in the 150-DWRCO Faceplate assembly

Page 72

62

Design ■Features ■Performance

NOTES

Page 73

INTRODUCTION

63

Design ■Features ■Performance

NOTES

Page 74

INTRODUCTION

64

Design ■Features ■Performance

NOTES

Page 75

65

FAX PARTS ORDER FORM

FAX # 414-354-7905

Account# ____________________________________

Bill to: ______________________________________

____________________________________________

____________________________________________

Date:________________________________________

Phone#______________________________________

Ship to:______________________________________

____________________________________________

____________________________________________

Attention:

P.O. ________________________________________

Fax# ________________________________________

PART#COLOR QTY DESCRIPTION MODEL SERIAL UNIT IN

NUMBER WARRANTY?

SPECIAL INSTRUCTIONS:

All part shipments will be sent ground delivery.

We have air shipment available at an additional cost to you.

Next Day Air 2nd Day Air 3 Day Select

If you do not have an open account with us your order will be shipped C.O.D.

COMMENTS: ________________________________________________________________________________

____________________________________________________________________________________________

Authorized By ________________________________________________

Page 76

P. O. Box 245040

Milwaukee, WI 53224-9540

Phone 414.354.0300

FAX 414.354.7905

Printed in U.S.A.– February 2005 P/N 30017

Loading...

Loading...