Page 1

H

CADDY 5 UL

CADDY 10 UL

ENGLIS

OPERATOR’S MANUAL

Page 2

CADDY

1 TECHNICAL CHARACTERISTICS

5/2

Transparent removable bowls n 1 2 2 3 4

Capacity of each bowl,

approx.

Dimensions:

width cm 23 47 23 35 47

depth cm 34 34 34 34 34

height cm 58 58 58 58 58

Net weight, approx. kg 16 26 17 21 26

Gross weight, approx. kg 17 29 19 24 29

Adjustable thermostats n 1 2 1 1 2

Hermetic compressor

Air-cooled condenser

Overload protector

Noise level lower than 70 dB (A)

10/1

l 10 10 5 5 5

5/3

10/2

IMPORTANT

Read electrical ratings written on the data

plate under the individual units. The serial

number of the unit is preceded by the

symbol #. Data plate specifications will

always supersede the information in this

manual.

Specifications are subject to change without

notice.

2 INTRODUCTION

Please read all sections of this manual

thoroughly to familiarize yourself with all

aspects of the unit.

Like all mechanical products, this machine will

require cleaning and maintenance. Besides,

dispenser working can be compromised by

operator’s mistakes during disassembly and

cleaning. It is strongly recommended that

personnel responsible for the equipment’s daily

operations, disassembly, cleaning, sanitizing

and assembly, go through these procedures in

order to be properly trained and to make sure

that no misunderstandings exist.

3 INSTALLATION

1 - Remove the corrugate container and

packing materials and keep them for

possible future use.

2 - Inspect the uncrated unit for any possible

damage. If damage is found, call the

delivering carrier immediately to file a

claim.

3 - Install the unit on a counter top that will

support the combined weight of dispenser

and product.

4 - A minimum of 15 cm (6”) of free air space

all around the unit should be allowed to

5/4

guarantee adequate ventilation.

5 - Ensure that the legs are screwed tightly

into the base of the machine.

6 - In case of units with gravity faucet, install it

according to this handbook instructions

(chapter 5.3.4 ASSEMBLY).

7 - Before plugging the unit in, check if the

voltage is the same as that indicated on

the data plate. Plug the unit into a

grounded, protected single phase electrical

supply according to the applicable

electrical codes and the specifications of

your machine. When the unit has no plug,

install a proper grounded plug, in

compliance with electrical codes in force in

your area, suitable to at least 10 Amp

250 Volt (220-230 Volts 50-60 Hz areas)

and 20 Amp 250 Volt (100-115 Volts 5060 Hz areas) applications. Should you

prefer to connect the unit directly to the

mains, connect the supply cord to a 2-pole

wall breaker, whose contact opening is at

least 3 mm. Do not use extension cords.

ATTENTION

Failure to provide proper electrical ground

according to applicable electrical codes could

result in serious shock hazard.

8 - The unit doesn’t come presanitized from

the factory. Before serving products, the

dispenser must be disassembled, cleaned

and sanitized according to this handbook

instructions (chapter

5.3 CLEANING AND SANITAZING

PROCEDURES).

4 TO OPERATE SAFELY

1 - Do not operate the dispenser without

reading this operator’s manual.

2 - Do not operate the dispenser unless it is

properly grounded.

3 - Do not use extension cords to connect the

dispenser.

4 - Do not operate the dispenser unless all

panels are restrained with screws.

5 - Do not obstruct air intake and discharge

openings: 15 cm (6”) minimum air space all

around the dispenser.

6 - Do not put objects or fingers in panels

louvers and faucet outlet.

7 - Do not remove bowls, augers and mixers

for cleaning or routine maintenance unless

the dispenser is disconnected from its

power source.

2

Ugolini S.p.A.

Page 3

CADDY

5 OPERATING PROCEDURES

1 - Clean and sanitize the unit according to

the instructions in this manual. See chapter

5.3 CLEANING AND SANITIZING

PROCEDURES.

2 - Fill the bowls with product to the maximum

level mark. Do not overfill.

The exact quantity of product (expressed

as liters and gallons) is shown by marks on

the bowl.

3 - In case of products to be diluted with

water, pour water into bowl first, then add

correct quantity of product. In case of

natural squashes, it is advisable to strain

them, in order to prevent pulps from

obstructing the faucet outlet.

4 - Install the covers and check that they are

correctly placed over the bowls.

5 - Set the control switches as shown in

chapter 5.1 DESCRIPTION OF

CONTROLS.

6 - The dispenser must always run with the

covers installed to prevent a possible

contamination of the product.

7 - Always leave the dispenser on, as the

refrigeration stops automatically when the

beverage reaches the dispensing

temperature. The mixing devices will

continue to turn.

8 - To maintain a high standard of flavour,

keep refrigeration and mixing devices on

during the night when beverage is in the

bowl.

5. 1 DESCRIPTION OF CONTROLS

The dispenser is equipped with the power

switch only. When it is set to position I, the

power is turned on both to mixing devices and

to refregeration.

IMPORTANT

Should despenser be operated without using

all the bowls (left bowl, facing the unit from

dispensing side, must be always used) it is

advisable to remove (see 5.3.1 DISASSEMBLY

paragraph) the pump impeller from the empty

bowls.

If operated without liquid, the impeller would

be seriously damaged.

Beverage temperature adjustment (model

10/1 only): turn the knob, located on the right of

the faucet side of the dispenser, toward right to

decrease temperature or vicevarsa.

increase productivity, it is advisable to prechill the product to be used in the

dispenser.

3 - To shorten product cooling down time and

increase productivity, the bowl should be

refilled after the product level drops lower

than half and at the start of each day.

4 - The dispenser must be able to emit heat.

In case it seems excessive, check that no

heating source is close to the unit and air

flow through the slotted panels is not

obstructed by wall or boxes. Allow at least

15 cm (6”) of free clearance all around the

dispenser.

In any case if the product in the bowls is

cold the unit is running properly.

5. 3 CLEANING AND SANITIZING

PROCEDURES

Cleaning and sanitizing of the dispenser are

recommended to guarantee the conservation of

the best product taste and the highest unit

efficiency. This section is a procedural

guideline only and is subject to the

requirements of the local Health Authorities.

Prior to the disassembly and cleaning, the

machine must be emptied of product.

5. 3. 1 DISASSEMBLY

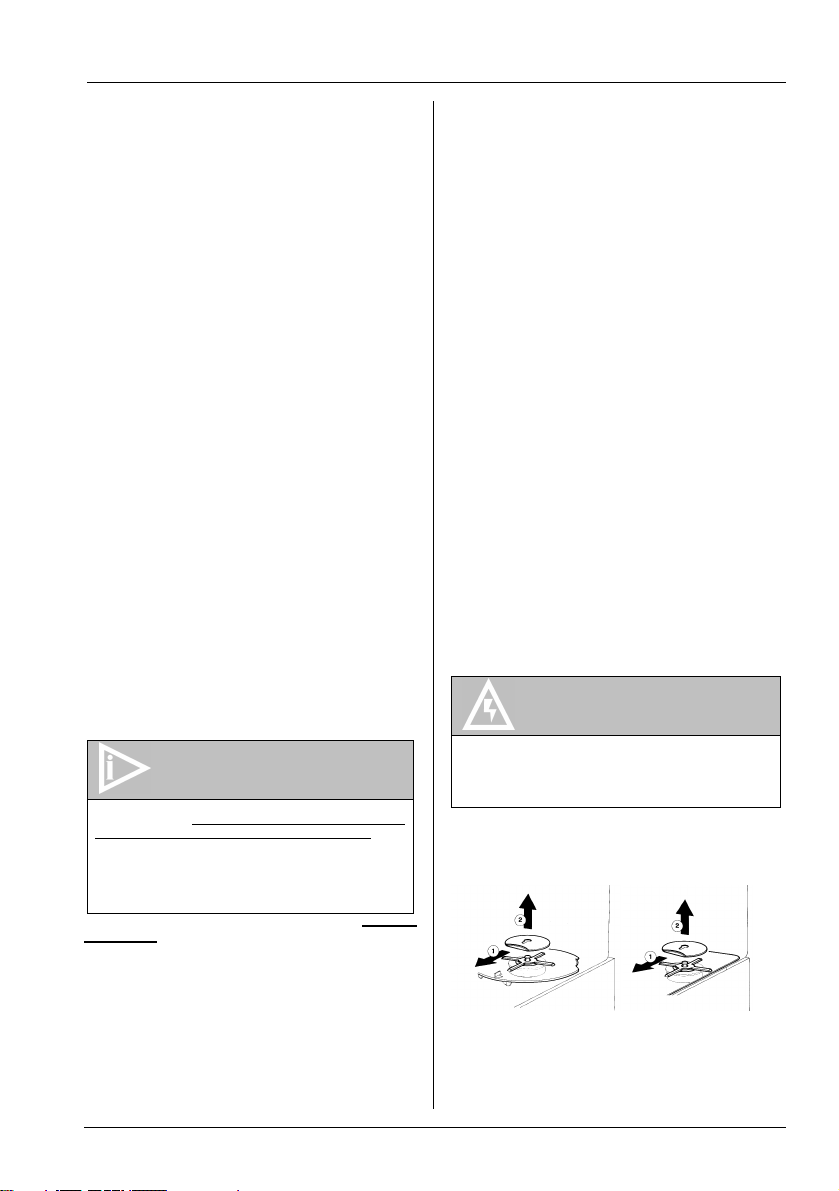

ATTENTION

Before any disassembly and/or cleaning

procedure make sure that the dispenser is

disconnected from its power source by

unplugging it or switching off the 2-pole wall

breaker.

1 - Remove cover from the bowl.

2 - Uncouple (1) the pump cover retainer and

lift it up and out (2) (see figure 1).

5. 2 HELPFUL HINTS

1 - The length of time for cooling down the

product is governed by many variables,

such as ambient temperature and

beverage initial temperature.

2 - To shorten product cooling down time and

Ugolini S.p.A.

figure 1

3 - Remove the pump cover.

4 - Remove the empty bowl by lifting first its

rear side (opposite to faucet side) up

3

Page 4

CADDY

and off bowl gasket (see figure 2).

5 - Remove the bowl gasket.

6 - Remove the pump impeller from its

location.

7 - Pinch tube faucet: push the dispensing

handle (1) and take the pinch tube off from

its seat (2) (see figure 3).

8 - Gravity faucet: extract the piston (1) and

then remove the dispensing handle (2-3)

(see figure 4).

9 - Slide drip tray out and empty it.

figure 2

figure 3

figure 4

5. 3. 2 CLEANING

ATTENTION

Before any disassembly and/or cleaning

procedure make sure that the dispenser is

disconnected from its power source by

unplugging it or switching off the 2-pole wall

breaker.

IMPORTANT

Do not attempt to wash any machine

components in a dishwasher.

1 - Prepare at least two gallons of a mild

cleaning solution of warm (45-60 °C 120140 °F) potable water and dishwashing

detergent. Do not use abrasive detergent.

Important: if present, follow label

directions, as too strong a solution can

cause parts damage, while too mild a

solution will not provide adequate cleaning.

IMPORTANT

In order to prevent any damages to the

dispenser use only a detergent suitable with

plastics parts.

2 - Using a brush, suitable for the purpose,

thoroughly clean all disassembled parts in

the cleaning solution.

ATTENTION

When cleaning the machine, do not allow

excessive amounts of water around the

electrically operated components of the unit.

Electrical shock or damage to the machine

may result.

3 - Rinse all cleaned parts with cool clean

water.

5. 3. 3 SANITIZING

Sanitizing should be performed immediately

prior to starting the machine. Do not allow the

unit to sit for extended periods of time after

sanitization.

1 - Wash hands with a suitable antibacterial

soap.

2 - Prepare at least two gallons of a warm (45-

60 °C 120-140 °F) sanitizing solution (100

PPM available chlorine concentration or 1

spoon of sodium hypoclorite diluted with

half a gallon of water) according to your

local Health Codes and manufacturer’s

specifications.

3 - Place the parts in the sanitizing solution

following manifacture ‘s specifications

(about five minutes).

4 - Place the sanitized parts on a clean dry

surface to air dry.

5 - Wipe clean all exterior surfaces of the unit.

Do not use abrasive cleaner.

5. 3. 4 ASSEMBLY

1 - Slide the drip tray into place.

2 - Pinch tube faucet: push the dispensing

handle (1) and insert the pinch tube into its

vertical seat in the bowl bottom(2). Lightly

pull the pinch tube end downwards til itl is

4

Ugolini S.p.A.

Page 5

CADDY

well arranged (3) (see figure 5).

3 - Gravity faucet: install the faucet handle

(1-2) and the piston with its gasket (3) (see

figure 6).

4 - Fit the bowl gasket to the evaporator. Note:

the largest brim of the gasket must face

against the drip plate (see figure 8).

figure 5

figure 6

sanitizer from the bowl(s). Drain this

solution. Do not rinse out the machine.

5. 4 IN-PLACE SANITIZATION

The In-Place Sanitization prior to starting

the machine may be performed, if needed,

only as further precaution, in addition to the

Disassembled Parts Sanitization described

before, but never in lieu of it.

1 - Prepare two gallons of a warm (45-60°C,

120-140 °F) sanitizing solution (100 PPM

available chlorine concentration or 1 spoon

of sodium hypoclorite diluted with half a

gallon of water) according to your local

Health Codes and manufacturer’s

specifications.

2 - Pour the solution into the bowl(s).

3 - Using a brush suitable for the purpose,

wipe the solution on all surfaces protruding

above the solution-level and on the

underside of the top cover(s).

4 - Install the top cover(s) and operate the

unit. Allow the solution to agitate for about

two minutes. Drain the solution out of the

bowl(s).

5 - Use fresh product to chase any remaining

sanitizer from the bowl(s). Drain this

solution. Do not rinse out the machine.

6 ROUTINE MAINTENANCE

5 - Place bowl on the unit. Wet the gasket for

ease of insertion.

CADDY 5 : be sure first that the faucet top

(1) is under the tooth jutting (2) out of the

drip plate (see figure 8).

6 - Replace the pump impeller and its cover

and hook the retainer.

7 - Use fresh product to chase any remaining

figure 7

figure 8

Ugolini S.p.A.

Daily: inspect the machine for signs of product

leaks past seals and gaskets. If proper

assembly does not stop leaks around seals or

gaskets, check for improper lubrication, worn or

damaged parts. Replace parts as needed with

original spare parts from the supplier.

6. 1 MAINTENANCE (TO BE

CARRIED OUT BY QUALIFIED

SERVICE PERSONNEL ONLY)

Montly: clean all internal components,

primarily the condenser, using compressed air.

To clean these internal parts, unplug the unit or

switch off the 2-pole wall breaker, then remove

front panel (dispensing side).

Condenser fins are very sharp. Use extreme caution

when cleaning.

5

Page 6

2441 V 2.0 01D17

1 Switch

2 Thermostat

3 Compressor

4Fan/Pump motor

21 22081-00001 Bowl gasket

✻✻✻ Please order what printed on piece

22 33800-05401 Impeller for 7 lt bowl

23 22800-19900 Central pivot

24 22040-00000 Central pivot OR

25 10554-45000 Clip

26 21087-00001 Thermostat

27 22800-18301 Cabinet for Caddy 7/1 -10/1

27 22800-18321 Cabinet for Caddy 10/2

28 22800-10000 Leg

29 22800-05500 Terminal block with cable clamp

30 22800-20700 Fan

31 01702-00000 Faucet cover for pinch tube faucet

31 22800-04410 Faucet cover for gravity faucet

33 33800-08900 Faucet assembly

34 33800-05402 Impeller for 10 lt bowl

35 22800-21900 Faucet piston

36 10028-02500 Faucet gasket

37 22800-04410 Faucet cover

38 22800-02303 Push handle

WIRING DIAGRAM

1 21980-00000 Cover

2 21703-00000 Pinch tube

3 22800-18730 10 lt bowl

4 21705-00000 Faucet spring

5 21704-00000 Rubber spring retainer

6 21701-00001 Push handle

7 21983-00000 Pump cover fixing clip

8 33800-05700 Evaporator assembly

9 21125-00000 Switch

10 22800-05100 Switch cap

11 22800-19300 Thermostat knob

12 33800-00803 Magnet

13 22800-04800 Motor bracket

14 22800-18901 Fan/pump motor

15 ✻✻✻ Relay

16 ✻✻✻ Overload protector

17 22800-18400 Caddy 7/1-10/1 dispensing side panel

17 22800-18420 Caddy 10/2 dispensing side panel

18 22800-00500 Drip tray cover

19 22800-00600 Drip tray (grey)

20 22800-18800 Pump cover

CADDY 10 U/UL

SPARE PART LIST

Page 7

2441 V 2.0 01D17

( ) For Caddy 5/3 only

✻✻✻ Please order what printed on piece

21 22800-18810 Pump cover

22 33800-05615 Bowl and faucet asbly for pinch tube faucet

22 33800-05617 Bowl and faucet asbly for gravity faucet

23 22800-17200 Bowl gasket

24 33800-05401 Pump impeller

25 22800-19900 Central pivot

26 22040-00000 Central pivot OR

27 21983-00000 Pump cover retainer

28 10554-45000 Clip

29 22800-18301 Cabinet for Caddy 5/2

29 22800-18311 Cabinet for Caddy 5/3

29 22800-18321 Cabinet for Caddy 5/4

30 22800-10000 Rubber leg

31 22800-05500 Terminal block with cable clamp

34 22800-21900 Faucet piston

35 10028-02500 Faucet gasket

36 22800-04410 Faucet cover

(32) 33800-00803 Motor magnet for Caddy 5/3

37 22800-02303 Push handle

(33) 22800-04706 Pump motor for Caddy 5/3

1Switch

2Thermostat

3 Compressor

4 Fan/Pump motor

5Pump

WIRING DIAGRAM

1 21703-00000 Pinch tube

2 21705-00000 Faucet spring

3 21704-00000 Spring holder

4 01701-00001 Push handle

5 33800-05710 Evaporator assembly

6 21125-00000 Switch

7 22800-05100 Switch cap

8 21087-00000 Thermostat

9 33800-00811 Pulley, magnet an d spacer asbly

10 22800-01800 Belt

11 22800-02201 Driving pulley

12 22800-04800 Motor bracket

13 22800-18911 Fan/pump motor

14 22800-20700 Fan

15 ✻✻✻ Relay

16 ✻✻✻ Overload protector

17 22800-18400 Caddy 5/2 dispensing side panel

17 22800-18410 Caddy 5/3 dispensing side panel

17 22800-18420 Caddy 5/4 dispensing side panel

18 22800-00500 Caddy 5/2, 5/4 drip tray cover

18 22800-00510 Caddy 5/3 drip tray cover

19 22800-00600 Caddy 5/2, 5/4 drip tray

19 22800-00610 Caddy 5/3 drip tray

(5) 33800-05762 Evaporator assembly Caddy 5/3

20 22800-09110 Bowl cover

CADDY 5 U/UL

SPARE PARTS LIST

Page 8

Ugolini S.p.A.

via dei Pioppi, 33

20090 Opera MILANO ITALY

www.ugolinispa.com

tel ++39 2 5300591

fax ++39 2 530059260

E-mail: sales@ugolinispa.com

2441_02 R3.0 02A09

Loading...

Loading...