Ugolini arctic deluxe ul Operator's Manual

OPERATOR’S MANUAL

CARNET D’INSTRUCTIONS

MANUAL DE INSTRUCCIONES

ARCTIC DELUXE UL

ARCTIC DELUXE UL

2

3

4

8

12

4

ARCTIC DELUXE UL

1 TECHNICAL CHARACTERISTICS

Specifications are subject to change without notice.

2 INTRODUCTION

Please read all sections of this manual thoroughly to familiarize

yourself with all aspects of the unit.

Like all mechanical products, this machine will require cleaning

and maintenance. Besides, dispenser working can be

compromised by operator’s mistakes during disassembly and

cleaning. It is strongly recommended that personnel responsible

for the equipment’s daily operations, disassembly, cleaning,

sanitizing and assembly, go through these procedures in order

to be properly trained and to make sure that no

misunderstandings exist.

3 INSTALLATION

1 Remove the corrugate container and packing materials and

keep them for possible future use.

2 Inspect the uncrated unit for any possible damage. If

damage is found, call the delivering carrier immediately to file a

claim.

3 Install the unit on a counter top that will support the combined weight of dispenser and product bearing in mind what is

stated in the preceding point 1 IMPORTANT warning.

4 A minimum of 15 cm (6”) of free air space all around the unit

should be allowed to guarantee adequate ventilation.

5 Ensure that the legs are screwed tightly into the base of the

machine.

Replace the standard legs originally installed with the 100 mm

(4”) legs whenever they are provided with the unit.

6 Before plugging the unit in, check if the voltage is the same

as that indicated on the data plate. Plug the unit into a grounded, protected single phase electrical supply according to the

applicable electrical codes and the specifications of your

machine. When the unit has no plug, install a proper ground ed

plug, in compliance with electrical codes in force in your area,

suitable to at least 10 Amp 250 Volt (220-230 Volts 50-60 Hz

areas) and 20 Amp 250 Volt (100-115 Volts 50-60 Hz areas)

applications. Should you prefer to connect the u nit directly to

the mains, connect the supply cord to a 2-pole wall breaker,

whose contact opening is at least 3 mm. Do not use extension

cords.

7 The unit doesn’t come presanitized from the factory. Before

serving products, the dispenser must be disassembled, cleaned and sanitized according to this handbook instructions

(chapter 5.3 CLEANING AND SANITAZING PROCEDURES).

4 TO OPERATE SAFELY

1 Do not operate the dispenser without reading this opera-

tor’s manual.

2 Do not operate the dispenser unless it is properly groun-

ded.

3 Do not use extension cords to connect the dispenser.

4 Do not operate the dispenser unless all panels are restrai-

ned with screws.

5 Do not obstruct air intake and discharge openings: 15 cm

(6”) minimum air space all around the dispenser.

6 Do not put objects or fingers in panels louvers and faucet

outlet.

7 Do not remove bowls, augers and panels for cleaning or

routine maintenance unless the dispenser is disconnected from

1/12

1/20

2/12

2/20

3/12

3/20

4/12

4/20

Transparent removable bowls

n 1 2 3 4

Capacity of each bowl, approx.

l 12201220122012

20

Dimensions:

width

cm 18 36 54 72

depth

cm 47 47 47 47

height

12 lt

20 lt

cm 57675767576757

67

Net weight, approx.

12 lt

20 lt

kg 20222432364244

55

Gross weight, approx.

12 lt

20 lt

kg 22252836404649

59

Adjustable thermostats

n 1 2 3 4

Hermetic compressor

Air-cooled condenser

Overload protector

Noise level lower than 70 dB (A)

IMPORTANT

Read electrical ratings written on the data plate of the

individual units; the data plate is adhered on the dispensing side panel of the unit, just behind the drip tray (the

right side drip tray in multiple bowl models). The serial

number of the unit (preceded by the symbol #) is adhered

just below the right bowl. Data plate specifications will

always supersede the information in this manual.

IMPORTANT

When handling the machine never grasp it by the bowls

or by the evaporator cylinders. The manufacturer refuses

all responsibilities for possible damages which may

occur through incorrect handling.

ATTENTION

Failure to provide proper electrical ground according to

applicable electrical codes could result in serious shock

hazard.

IMPORTANT

Install the dispenser so that the plug is easily acces sible.

5

its power source.

5 OPERATING PROCEDURES

1 Clean and sanitize the unit according to the instructions in

this manual. See chapter 5.3 CLEANING AND SANITIZING

PROCEDURES.

2 Fill the bowls with product to the maximum level mark. Do

not overfill.

The exact quantity of product (expressed as liters and gallons)

is shown by marks on the bowl.

3 In case of products to be diluted with water, potabl e water,

pour water into bowl first, then add correct quantity of product.

In case of natural squashes, it is advisable to strain them, in

order to prevent pulps from obstructing the faucet outlet.

4 Install the covers and check that they are correctly placed

over the bowls.

5 Set the control switches as shown in chapter

5.1 DESCRIPTION OF CONTROLS.

6 The dispenser must always run with the covers installed to

prevent a possible contamination of the product.

7 Always leave the dispenser on, as the refrigeration stops

automatically when the beverage reaches the dispensing temperature. The mixing devices will continue to turn.

8 To maintain a high standard of flavour, keep refrigeration

and mixing devices on during the night when beverage is in the

bowl.

5. 1 DESCRIPTION OF CONTROLS

The dispenser is equipped with a power switch and each bowl is

operated by a mixing device switch.

Their functions are as follows:

Power switch

Mixing device switch

To operate the dispenser

1 Set power switch to I position.

2 Set mixing device switch(es) to I position.

5. 2 OPERATION HELPFUL HINTS

1 The length of time for cooling down the product is governed

by many variables, such as ambient temperature and beverage

initial temperature.

2 To shorten product cooling down time and increase productivity, it is advisable to pre-chill the product to be used in the

dispenser.

3 To shorten product cooling down time and increase productivity, the bowl should be refilled after the product level drops

lower than half and at the start of each day.

4 The dispenser must be able to emit heat.

In case it seems excessive, check that no heating source is

close to the unit and air flow through the slotted panels is not

obstructed by wall or boxes. Allow at least 15 cm (6”) of free

clearance all around the dispenser.

In any case if the product in the bowls is cold the unit is running

properly.

5 How to reset beverage temperature:to reset beverage temperature please apply to a technician.

The proper temperature is preset at the factory.

5. 3 CLEANING AND SANITIZING

PROCEDURES

Cleaning and sanitizing of the dispenser are recommended to

guarantee the conservation of the best product taste and the

highest unit efficiency. This section is a procedural guideline

only and is subject to the requirements of the local Health

Authorities.

Prior to the disassembly and cleaning, the machine must be

emptied of product.

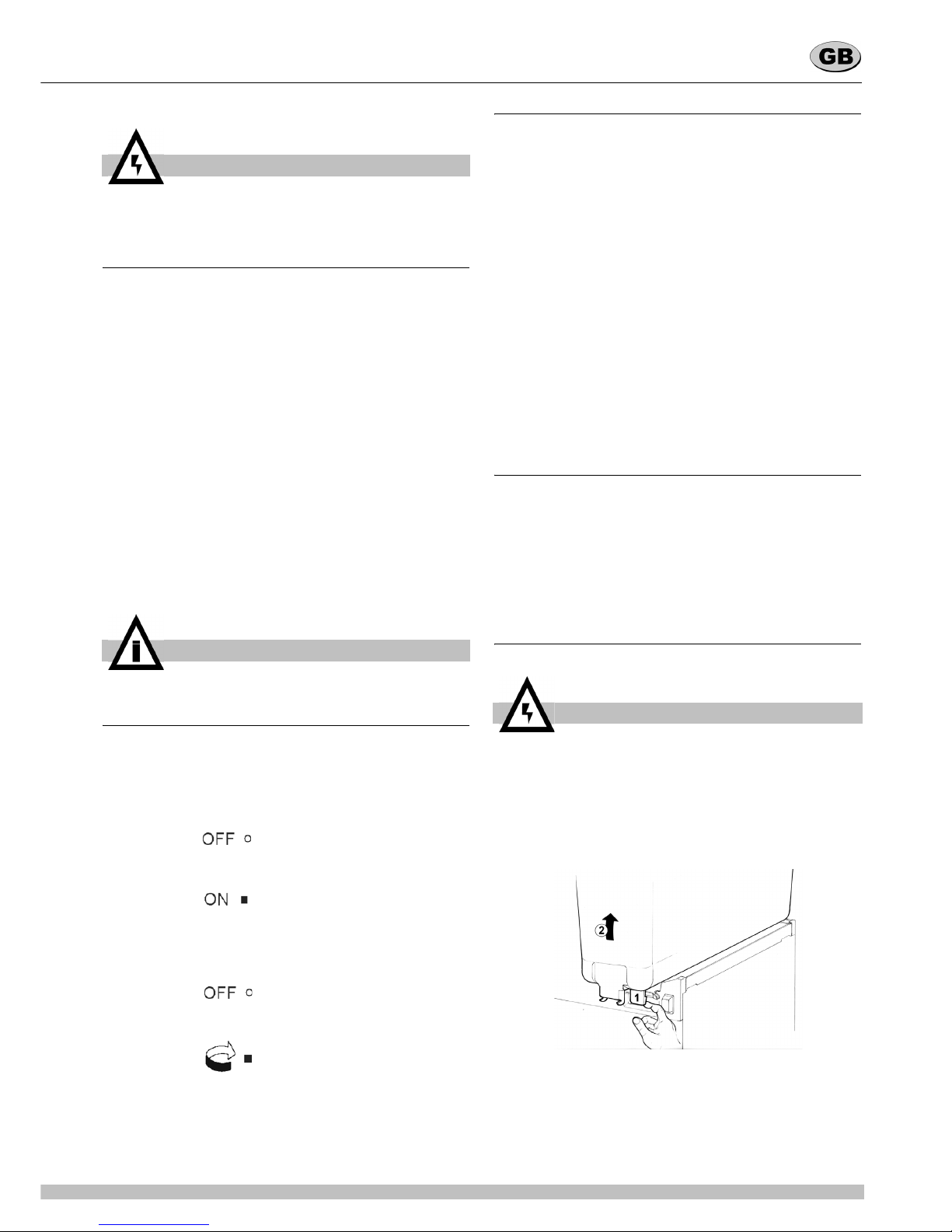

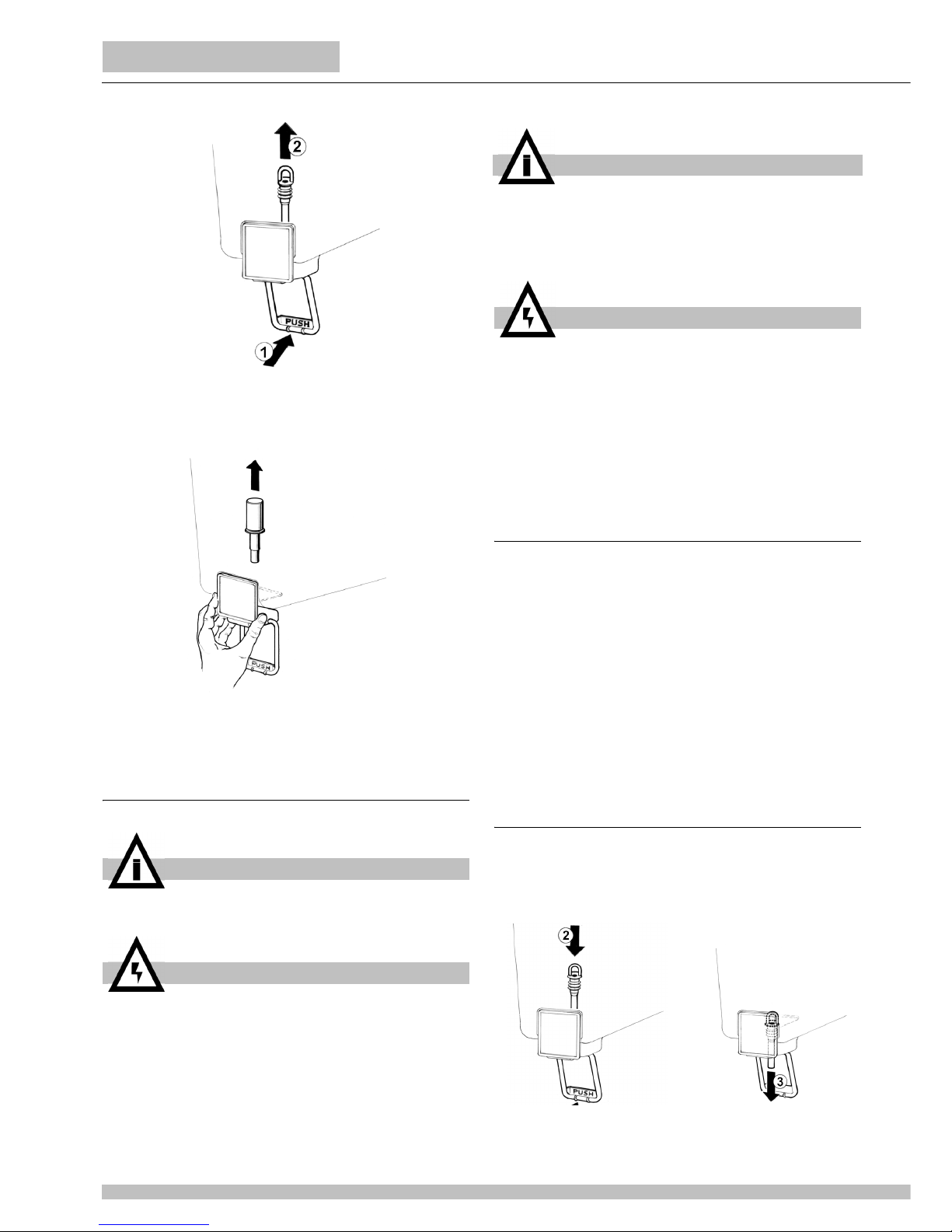

5. 3. 1 DISASSEMBLY

1 Remove cover from the bowl.

2 Remove the empty bowl by lifting first its front side (faucet

side) up and off bowl gasket (see figure 1).

figure 1

3 Remove the bowl gasket.

4 Remove the pump impeller from its location.

5 Pinch tube faucet: push the dispensing handle (1) and

ATTENTION

In case of damages, the power cord must be replaced by

qualified personnel only in order to prevent any shock

hazard.

IMPORTANT

Operate the dispenser with food products only.

0 position : Power is turned OFF to all

functions.

I position :

This position operates the fan

motor and makes the mixing

devices suitable to be turned

on by relevant switches.

0 position : OFF.

I position : Mixing device runs.

ATTENTION

Before any disassembly and/or cleaning proced ure m ake

sure that the dispenser is disconnected from its power

source by unplugging it or switching off the 2-pole wall

breaker.

6

ARCTIC DELUXE UL

take the pinch tube off from its seat (2) (see figure 2).

figure 2

6 Gravity faucet: extract the piston and then remove the

dispensing handle (see figure 3).

figure 3

7 Slide drip tray out and empty it.

5. 3. 2 CLEANING

1 Prepare at least two gallons of a mild cleaning solution of

warm (45-60 °C 120-140 °F) potable water and dishwashing

detergent. Do not use abrasive detergent.

Important: if present, follow label directions, as too strong a

solution can cause parts damage, while too mild a solution will

not provide adequate cleaning.

2 Using a brush, suitable for the purpose, thoroughly clean all

disassembled parts in the cleaning solution.

3 Do not immerse the lighted top covers in liquid. Wash them

apart with the cleaning solution. Carefully clean their undersides.

4 In the same manner clean the evaporator cylinder(s) using

a soft bristle brush.

5 Rinse all cleaned parts with cool clean water.

5. 3. 3 SANITIZING

Sanitizing should be performed immediately prior to

starting the machine. Do not allow the unit to sit for

extended periods of time after sanitization.

1 Wash hands with a suitable antibacterial soap.

2 Prepare at least two gallons of a warm (45-60 °C 120-

140 °F) sanitizing solution (100 PPM available chlorine concentration or 1 spoon of sodium hypoclorite diluted with two litres of

water) according to your local Health Codes and manufacturer’s specifications.

3 Place the parts in the sanitizing solution for five minutes.

4 Do not immerse the lighted top covers in liquid. Carefully

wash their undersides with the sanitizing solution.

5 Place the sanitized parts on a clean dry surface to air dry.

6 Wipe clean all exterior surfaces of the unit. Do not use abra-

sive cleaner.

5. 3. 4 ASSEMBLY

1 Slide the drip tray into place.

2 Pinch tube faucet: push the dispensing handle (1) and

insert the pinch tube into its vertical seat in the bowl bottom(2).

Lightly pull the pinch tube end downwards til itl is well arranged

(3) (see figure 4).

figure 4

3 Gravity faucet: install the faucet handle and the piston with

IMPORTANT

Do not attempt to wash any machine components in a

dishwasher.

ATTENTION

Before any disassembly and/or cleaning procedure make

sure that the dispenser is disconnected from its power

source.

IMPORTANT

In order to prevent any damages to the dispenser use

only a detergent suitable with plastic parts.

ATTENTION

When cleaning the machine, do not allow excessive

amounts of water around the electrically op erated components of the unit. Electrical shock or damage to the

machine may result.

Loading...

Loading...