Ugolini ARCTIC COMPACT, ARCTIC DELUXE Service Manual

SERVICE MANUAL

ARCTIC DELUXE

ARCTIC COMPACT

2

ARCTIC COMPACT & DELUXE

3

SERVICE MANUAL

4

USER MANUAL

10

TROUBLE SHOOTING

16

4

ARCTIC COMPACT & DELUXE

1 INTRODUCTION

Like all mechanical products, this machine will require cleaning

and maintenance.

This Service Manual contains maintenance guideline s

dedicated to qualified service personnel only.

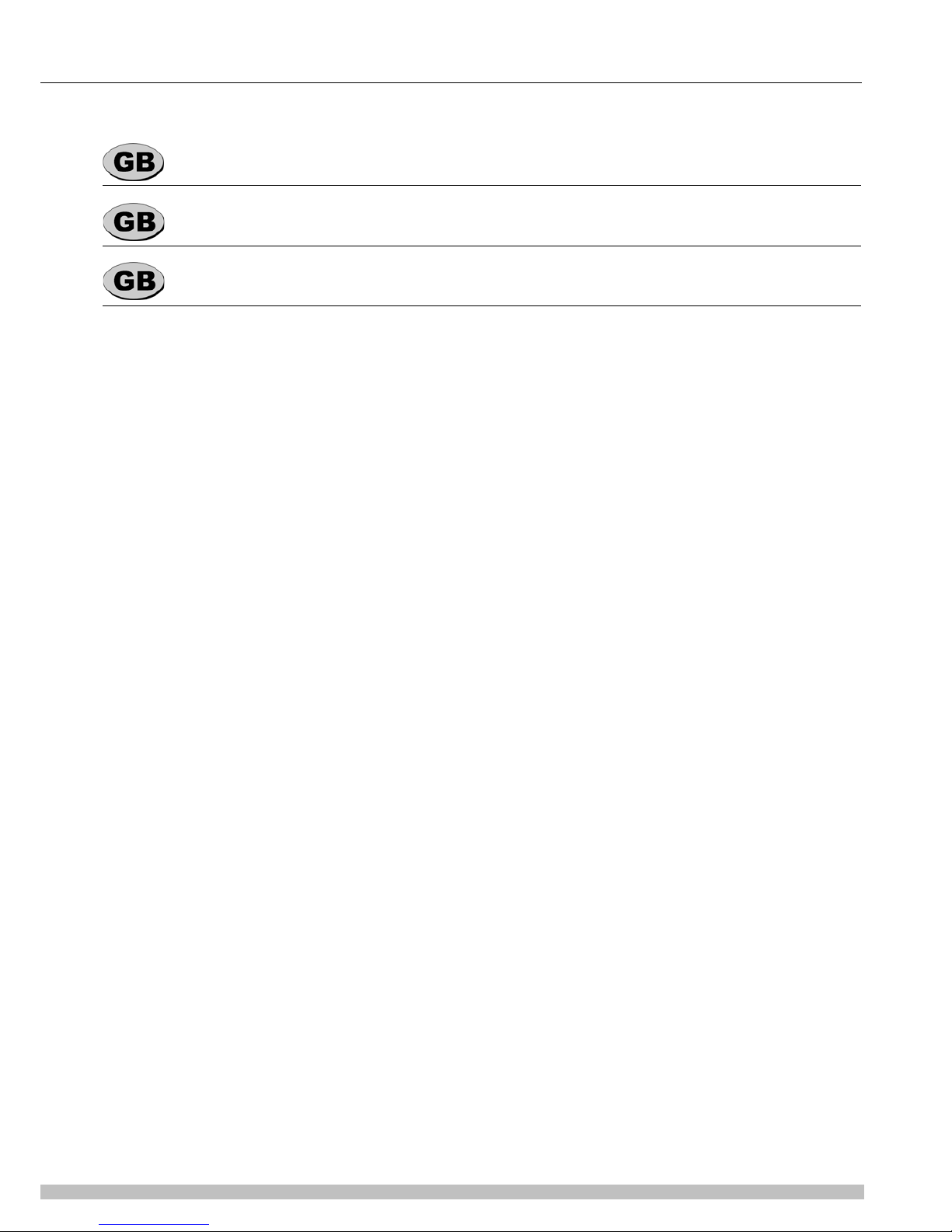

2 TEMPERATURE CONTROLS

All the units with12 or 20 litres bowls, both Deluxe and Compact

series, are equipped with one adjustable thermostat for each

bowl. The thermostats are located behind the panel under each

bowl (see figure 1).

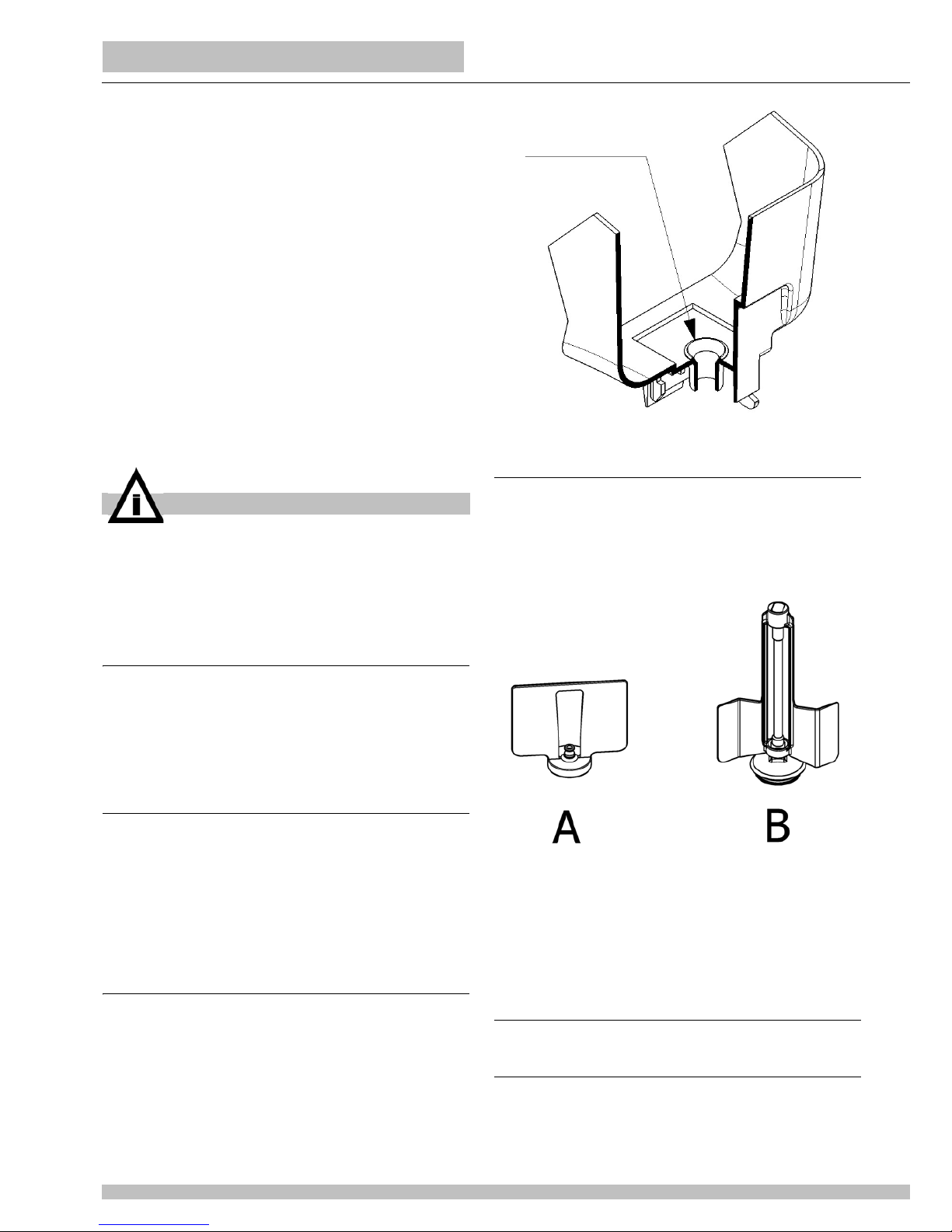

figure 1

It is possible to adjust temperature between 6 °C and 12 °C. On

new machines the temperature is factory preset approx at 8°C.

For temperature adjustment proceed as follows:

- to decrease temperature: rotate the setting screw clockwise.

- to increase temperature: rotate the setting screw

counterclockwise (see figure 2).

figure 2

For Artic Compact 5 and 8 series the situation is the following:

Arctic Compact 5-8/1 are equipped with one thermostat to

control the themperature of the bowl.

Arctic Compact 5-8/2 are equipped only with one thermostat to

control the temperature of the bowl at the right.

Arctic Compact 5-8/3 are equipped only with one thermostat to

control the temperature of the central bow l .

Arctic Compact 5-8/4 are equipped with two thermostats to

control the temperature of the first and the third bowl from right.

The thermostats are always located behind the faucet side

panel under the coresponding bowl.

This means that the refrigeration on and off depend from the

setting of the temperature only of the bowls equipped with the

thermostats.

It is possible to set the temperature between 6 °C and 12 °C. On

new machines the temperature is factory preset approx at 8°C.

For temperature adjustment proceed as follows:

- to decrease temperature: rotate the setting screw clockwise.

- to increase temperature: rotate the setting screw

counterclockwise (see figure 2)

Independent temperature setting for each bowl is not possible.

The following table summarizes the number of thermostats

present on each model:

IMPORTANT

Rotating the setting screw of the thermostats co mple te ly

counterclockwise it is possible to switch off the

thermostat itself. This will stop the refrigeration only on

single bowl units. On multiple bowls units it is necessary

to switch all the thermostats off in order to stop the

refrigeration.

IMPORTANT

On multiple bowls units the thermostats are electrically

wired in parallel and they directly drive the compresso r.

It is necessary that all the bowls reach the set

temperature to stop the refrigeration (all the thermostats

electrically open). It is enough that only in one bowl the

temperature is higher than the setting to start the

refrigeration (only one thermostat electrically closed).

To adjust temperature on multiple bowls machines it is

necessary to adjust all the thermostats together at the

same setting.

On multiple bowls units independent temperature

adjustment for each bowl is not available.

MODEL NUMBER OF

THERMOSTAS

Arctic Compact 5/1 - 8/1 1

Arctic Compact 5/2 - 8/2 1 - RIGHT BOWL

Arctic Compact 5/3 - 8/3 1 - CENTRAL BOWL

Arctic Compact 5/4 - 8/4 2 - FIRST AND THIRD BOWLS

Arctic Compact 12/1 - 20/1 1

Arctic Compact 12/2 - 20/2 2

Arctic Compact 12/3 - 20/3 3

Arctic Compact 12/4 - 20/4 4

Arctic Deluxe 12/1 - 20/1 1

Arctic Deluxe 12/2 - 20/2 2

Arctic Deluxe 12/3 - 20/3 3

Arctic Deluxe 12/4 - 20/4 4

5

3 PUMPS

Arctic Deluxe series dispensers are equipped with spray

pumps. Each pump is magnetically driven by an indepe ndent

electric motor.

These machines are equipped with one Main Switch to power

ON and OFF refrigeration and with one Pump Switch for each

bowl (see user manual for controls details).

Spray pumps are suitable for a large variety of products but it is

better not to spray coffee, tea, natural juices or other beverages

that can foam. To avoid spray on these machines it is necessary

to replace the original impeller with a different one (grey impeller

pn 33900-01201) and to remove the spray tube from the bowl.

In addition the original bowl can be replaced with a dedicated

one (pn 22900-00010 or 22900-04810) to perform even more

gentle agitation.

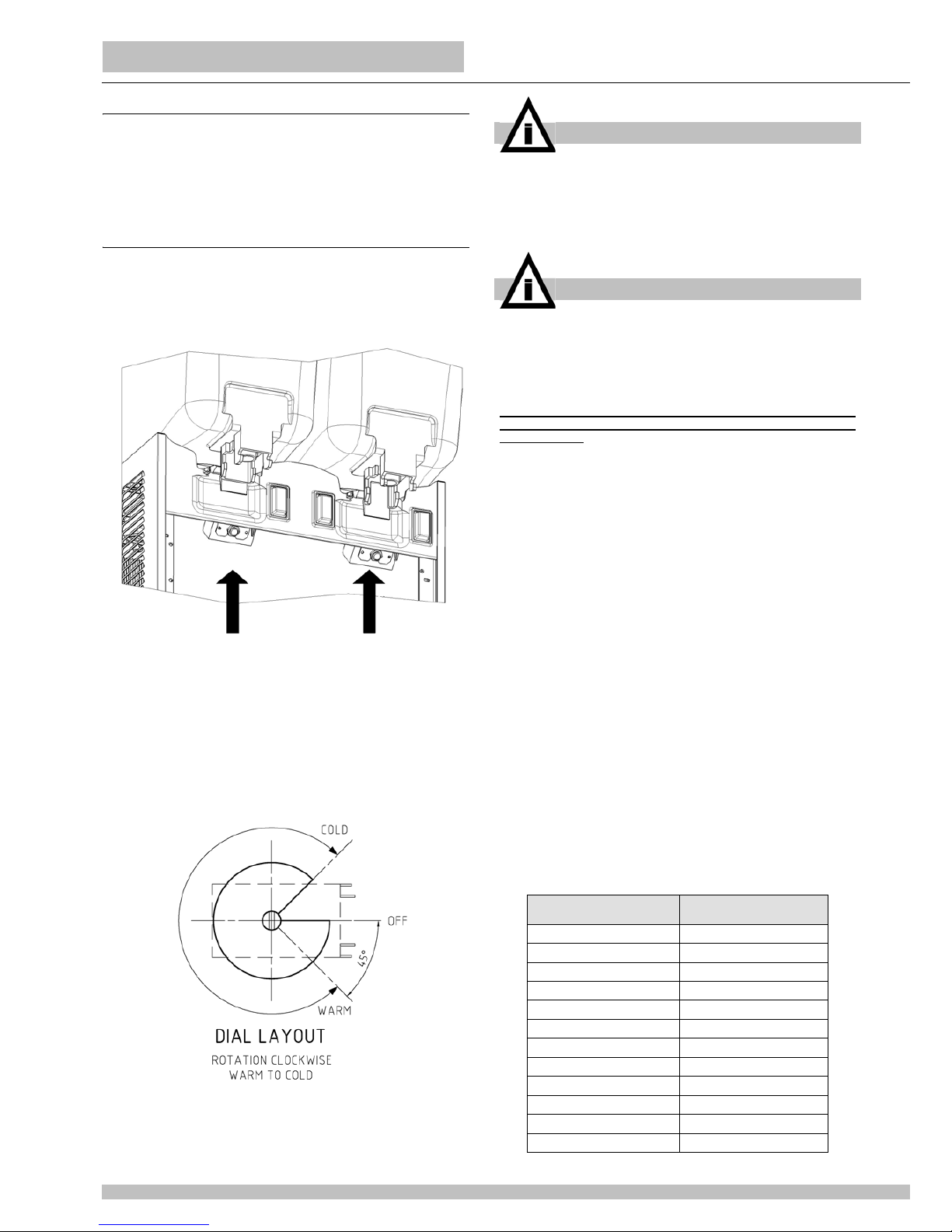

Arctic Compact series dispensers are equipped with

submerged pumps. On double machines the pumps are driven

by only one motor through a transmission belt and three pulleys.

This motor also works as a fan. On triple machines two pumps

are driven by one motor with the same system of double units

and the third is driven by a single motor. On four bowls machies

the pumps are driven by two motors (see figure 3).

figure 3

These machines are equipped only by one Main Switch to

power ON and OFF all the functions, refrigeration and pumps.

Submerged pumps are suitable for almost all kind of beverages

and particularly for coffee, tea, natural juices or other beverages

that can foam. In case of need it is possible to equip Arctic

Compact dispensers with spray pumps replacing the impellers

(pn 33900-01204 or 33900-01205), the bowls (pn 22900-01900,

22900-02000, 22900-00000 and 22900-04800) and installing

the spray tubes.

The following table summarizes all the available impellers:

The following table summarizes all the available bowls:

And the following one specifies all the available spray tubes:

Combined configuration can be realized for particular needings.

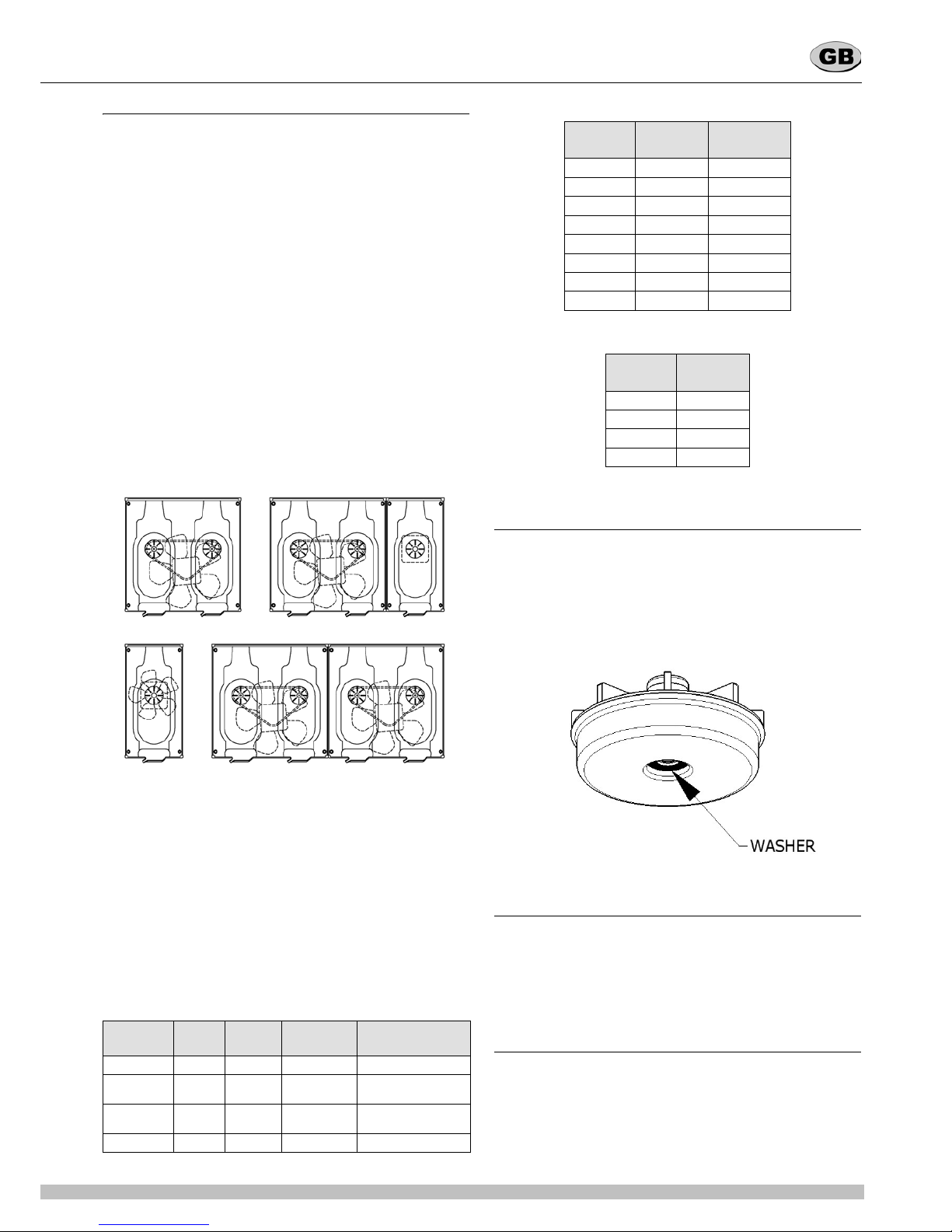

3. 1 IMPELLERS

The impeller must spin freely on its pivot to perform efficient

mixing and cooling. For this purpose keep clean both the

impeller and the pivot from traces of sugar, pulp or other. If

necessary, lube the parts with food grade lubricant.

A self-lubricating washer is moulded into the bottom of the

impeller. Regularly check this part and, if worn, replace the

impeller with a new one (see figure 4).

figure 4

3. 2 MAGNETIC COUPLING

The impellers are magnetic coupled with their respective

motors. The magnetic gap is factory preset and does not require

to be adjusted. In case of loss of magnetic lock, one or more of

the following problems can be present: bent pump motor bracket

due to a transport shock, impeller improper spinning due to

worn, damaged or dirty parts.

3. 3 NOISY IMPELLERS

In case of noisy impellers, it is necessary first of all to remove

them from the pivots and power the unit on. If the noise is still

present it is necessary to power the unit off, unplug it and

remove the panels in order to check the pumps motors

assemblies. Possible causes of noise can be the following:

faulty electric motor, improper magnetic alignment due to a bent

PART

NUMBER

COLOUR

BOWLS

CAPACITY

[litres]

MIXING

SYSTEM

VOLATGE

33900-01200 WHITE 12, 20 SPRAY 230V 50HZ, 240V 50HZ

33900-01201 GREY 5, 8, 12, 20 SUBMERGED 230V 50HZ, 240V 50HZ

115V 60HZ, 220V 60HZ

33900-01204 BLUE 5, 8

12, 20

SPRAY

SPRAY

230V 50HZ, 240V 50HZ

115V 60HZ, 220V 60HZ

33900-01205 RED 5, 8 SPRAY 115V 60HZ, 220V 60HZ

PART

NUMBER

BOWLS

CAPACITY

[litres]

MIXING

SYSTEM

22900-01900 5 SPRAY

22900-01910 5 SUBMERGED

22900-02000 8 SPRAY

22900-02010 8 SUBMERGED

22900-00000 12 SPRAY

22900-00010 12 SUBMERGED

22900-04800 20 SPRAY

22900-04810 20 SUBMERGED

PART

NUMBER

BOWLS

CAPACITY

[litres]

22900-00202 5

22900-00203 8

22900-00201 12

22900-00200 20

6

ARCTIC COMPACT & DELUXE

bracket, fan blade not rotating free from obstacles or some lose

component vibrating during machine working.

On Arctic Compact with multiple bowls it is necessary also to

remove the transmission belt from the pulleys and power on the

unit. If the noise is still present the cause can be the electric

motor once again. Otherwise, if the noise is not present

anymore, it is necessary to remove the magnetic pulleys

assemblies and check for the integrity of their ball bearings. If

necessary replace the entire magnetic pulley assembly.

If, removing the impellers, the noise is not present anymore it

means that the cause of can be in the impellers or in the

magnetic coupling. Check for worn impellers and if necessary

replace them. Clean the impellers and the pivots and if

necessary lubricate them with food grade lubricant. Install the

impellers and put some water into the bowls. If the noise do not

disappear it is necessary to check once again the pump motor

bracket planarity.

4 FAUCETS

Two different faucets are available both for Arctic Deluxe and

Arctic Compact series: pinch tube faucet and stainless steel

gravity faucet.

4. 1 PINCH TUBE FAUCET

This faucet is suitable for all kind of products, liquid or thick, with

or without pulp or other solid particles. In case of dripping, it is

necessary to drain the product out of the bowl, remove the pinch

tube, clean it with fresh water and check for wear on it. If

necessary, replace it with a new one.

4. 2 STAINLESS STEEL GRAVITY FAUCET

This faucet is suitable for liquid prod uct without pulps or other

solid particles. In case of dripping, it is necessary to drain the

product out of the bowl, remove the stainless steel piston, clean

it with fresh water and check for wear of the rubber gasket. If

necessary, replace it with a new one. It is also necessary to

clean the piston housing in the bottom of the bowl and check for

the integrity of the rim around the piston hole (see figure 5).

figure 5

5 SLOW MIXING SYSTEM

The dispensers of Arctic Deluxe series are available also with

slow mixers. Two kind of slow mixers are available: one with

magnetic driving (A) and the other with mechanic driving (B).

The first one is suitable for delicate drinks like tea or coffee while

the other one is suitable also for thick drinks (see figure 6).

figure 6

In case of magnetic slow mixer improper rotation, the cause can

be a faulty drive motor, a magnetic mixer that can’t freely rotate

on its pivot or ice on the evaporator caused by very low level of

product into the bowl.

In case of direct slow mixer improper rotation the cause can be

a foulty motor or an excessive thickness of the drink.

6 REFRIGERANT CIRCUIT SERVICE

6. 1 CHECKING FOR REFRIGERANT LEAKS

The following procedure is the recommended approach to

systematically inspect the entire system for refrigerant leaks

NOTE: when using refrigerant detector, follow along the bottom

IMPORTANT

The impellers are designed to spin always submerged

and wet. It is very important to avoid to have them

spinning dry to prevent worn out. For this reason on

Arctic Deluxe always switch off pump of empty bowls

and on Arctic Compact remove the impeller of empty

bowls or fill them with water.

7

side of the copper tubing since the refrigerant gas is heavier

than air. Where copper tubing is protected by an insulating

jacket, check for leaks at both ends of each jacket section.

.

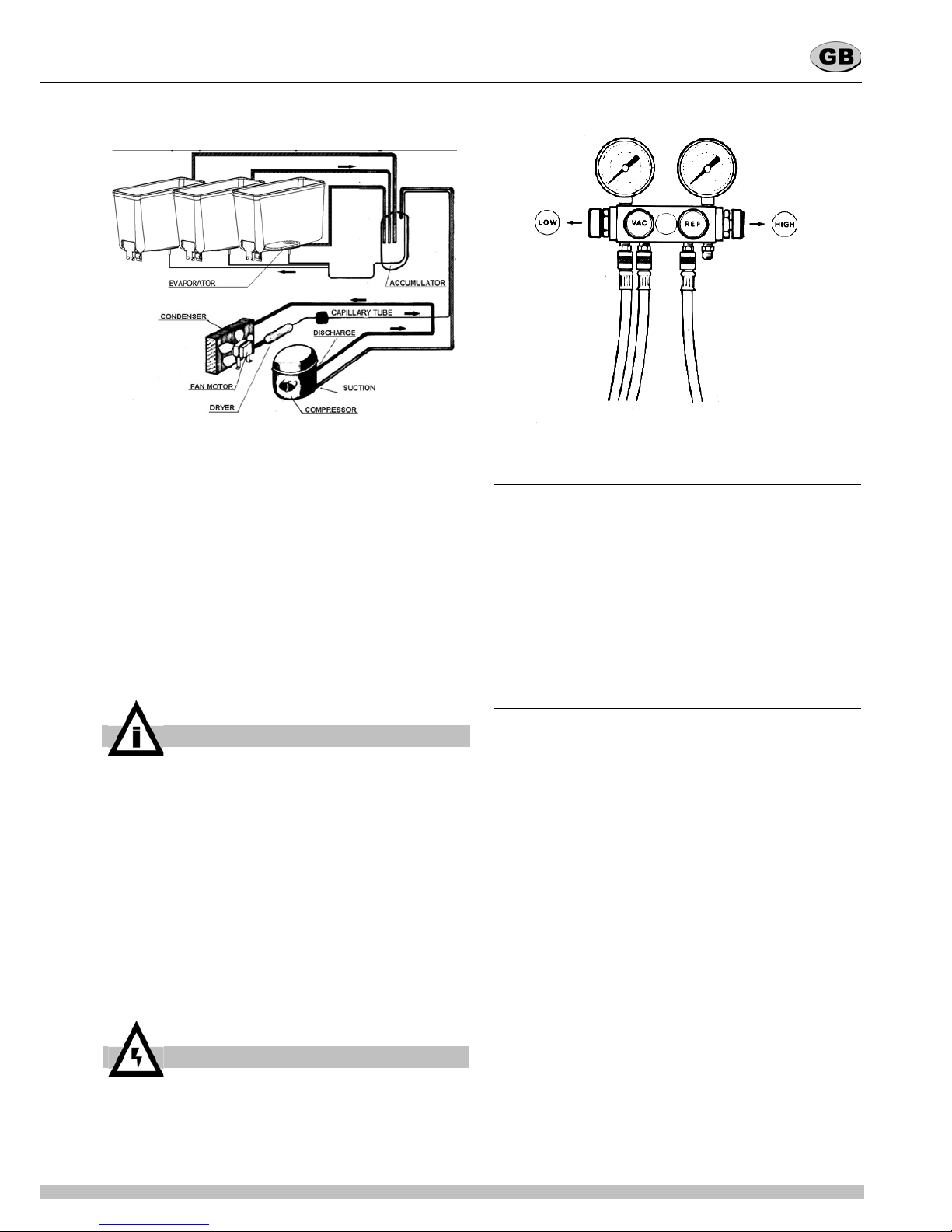

figure 7

Referring to the diagram (see figure 7), perform the following

steps:

1 Start inspection at the high pressure line of the compressor.

Check around the soldered connection.

2 Follow the copper tubing to the condenser and check

around the soldered connections at the top and bottom of the

condenser.

3 Check also along the copper curves on both sides of

condenser.

4 Follow the copper tubing to the evaporators, checking

around the soldered connections of dryer.

5 Remove mixer motors and check the inlet (capillary) and

outlet (suction) tubing.

6 Check the copper tubing all the way back to the

compressor.

7 Check around the low side connections of the compressor

suction and process tubes.

If a leak has been detected, seal it and make a new refrigerant

charge as per instructions in the following paragraphs.

6. 2 DISCHARGING

1 Remove the dispenser panels.

2 If not present install a charging valve on the compressor

process tube.

3 Remove the screw cap from the compressor process tube.

4 Connect the process tube to the LOW part of the gauge set.

5 Connect the VAC port of the gauge set to an adequate

approved gas recovery system.

6 Open the LOW and VAC valves and recover the refrigerant.

7 Once the recovery operation is completed, close the LOW

and VAC valves and disconnect the recovery system.(see

figure 8)

figure 8

6. 3 EVACUATING

Always install a brand new liquid line filter dryer before

evacuating.

1 Connect the REF port of the gauge set to the charging unit.

2 Connect the VAC port of the gauge set to the vacuum pump

and open the VAC valve.

3 Open the line valve of the charging unit and, for a while,

also the REF valve, so as to purge air from the REF hose.

4 Open the LOW valve of the gauge set and turn on the

vacuum pump for a minimum of half an hour.

5 While the pump is running, close the VAC valve once a

vacuum has been established.

6 Turn off the vacuum pump.

6. 4 CHARGING

The gauge set is usually w ith four ports and four valves (se e

figure 8). This is the easiest option to be found in the market

since it allows the charging through both low and high side of the

system. Our refrigeration systems are manufactured so as to be

chargeable through the compressor process tube only (low

side): thus, the HI port is never mentioned nor used in the

following procedure and therefore the HI valve must be kept

closed.

1 Determine how many ounces/grams should be filled by the

charging unit. This information can be found on the dispenser

data plate.

2 Remove bowls and mixers from the dispenser.

3 Plug in the dispenser and turn on the power switch.

4 Open the line valve of the charging unit.

5 Open the REF valve very slowly so as to allow the

refrigerant to be pulled into the system as a gas.

6 When the amount of refrigerant listed on the data plate ha s

been used, the system is charged. Close the REF valve and

the charging unit line valve and allow the compressor to run few

minutes.

7 Ensure that all evaporator plates are covered with frost.

8 Close the LOW valve, disconnect the LOW hose from the

compressor process tube and tighten the screw cap.

The following table reports the suction and discharge pressures

of the machines with the different refrigerants.

They must be verified under the following conditions:

Ambient temperature: 32 °C

Product temperature in the bowls: 5 °C

Evaporation temperature approx -5 °C

Condensation temperature approx 50°C.

IMPORTANT

To check for a leak in the low side of the system, it is

advisable to have the evaporators at least at ambient

temperature.

ATTENTION

The refrigerant gas could be highly acid and toxic.

8

ARCTIC COMPACT & DELUXE

6. 5 COMPRESSOR BURN-OUT

To determine if a burn-out has occurred, perform the following

steps:

1 Disconnect the unit from power source.

2 Remove wiring from the compressor terminals.

3 Using an ohmmeter, check for ground between the

terminals and the compressor housing. If a reading exists, the

compressor has shorted to ground.

In this case compressor must be replaced as per follow ing

steps:

4 Recover the refrigerant using an approved refrigeration

recovery system as per DISCHARGING instructions.

5 Remove the burned-out compressor.

6 Correct the system fault which caused the burn-out. Check

the condition of the capacitor(s) and compressor relay.

7 Install a new compressor and liquid line filter dryer.

8 Evacuate and charge the system as per EVACUATING and

CHARGING instructions.

7 ROUTINE MAINTENANCE

DAILY

Inspect the machine for signs of product leaks past seals and

gaskets. If proper assembly does not stop leaks around seal or

gaskets, check for improper lubrication, worn or damaged parts.

Replace parts as needed with original spare parts from the

supplier.

WEEKLY

Clean and sanitize the machine following the procedures

illustrated on the Operator's Manual of the unit. Check for worn

impellers, bowl gaskets, faucet pinch tubes or stainless steel

piston gaskets. Replace parts as needed with original spare

parts from the supplier.

MONTHLY

Clean all internal components, primarily the condenser, using

compressed air, vacuum or a soft brush.

To clean these internal parts, unplug the unit and remove the

panels. Condenser fins are very sharp. Use extreme caution

when cleaning.

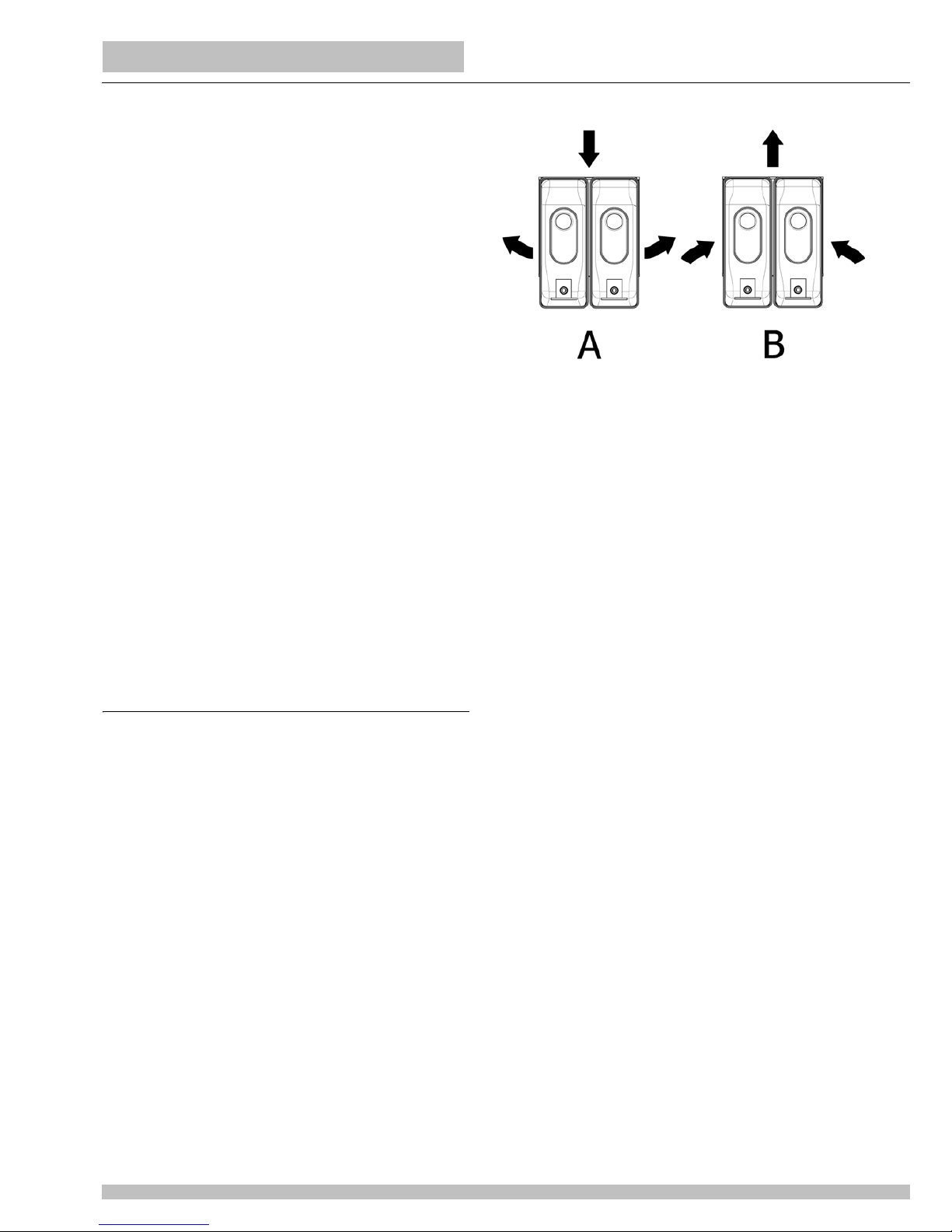

On Arctic Delux e dispensers the condenser is located on the

back of the unit and air flow is from back to sides (A). To clean

the condenser it is necessary to remove the back panel.

On Arctic Compact dispense rs the condenser is always

located on the back of the unit but air flow if from sid es to b ack

(B). To clean the condenser it is necessary to remove the faucet

side panel and to clean it from the inside of the unit (see figure

5).

figure 9

Refrigerant Suction (low)

pressure

Discharge (high)

pressure

R134a 1,43 bar 12,17 bar

R22 3,20 bar 18,39 bar

R404a 4,10 bar 21,93 bar

9

Loading...

Loading...