Page 1

KM900 Plus

Hand-held

Combustion

Analyser

Page 2

1. ANALYSER LAYOUT AND FEATURES

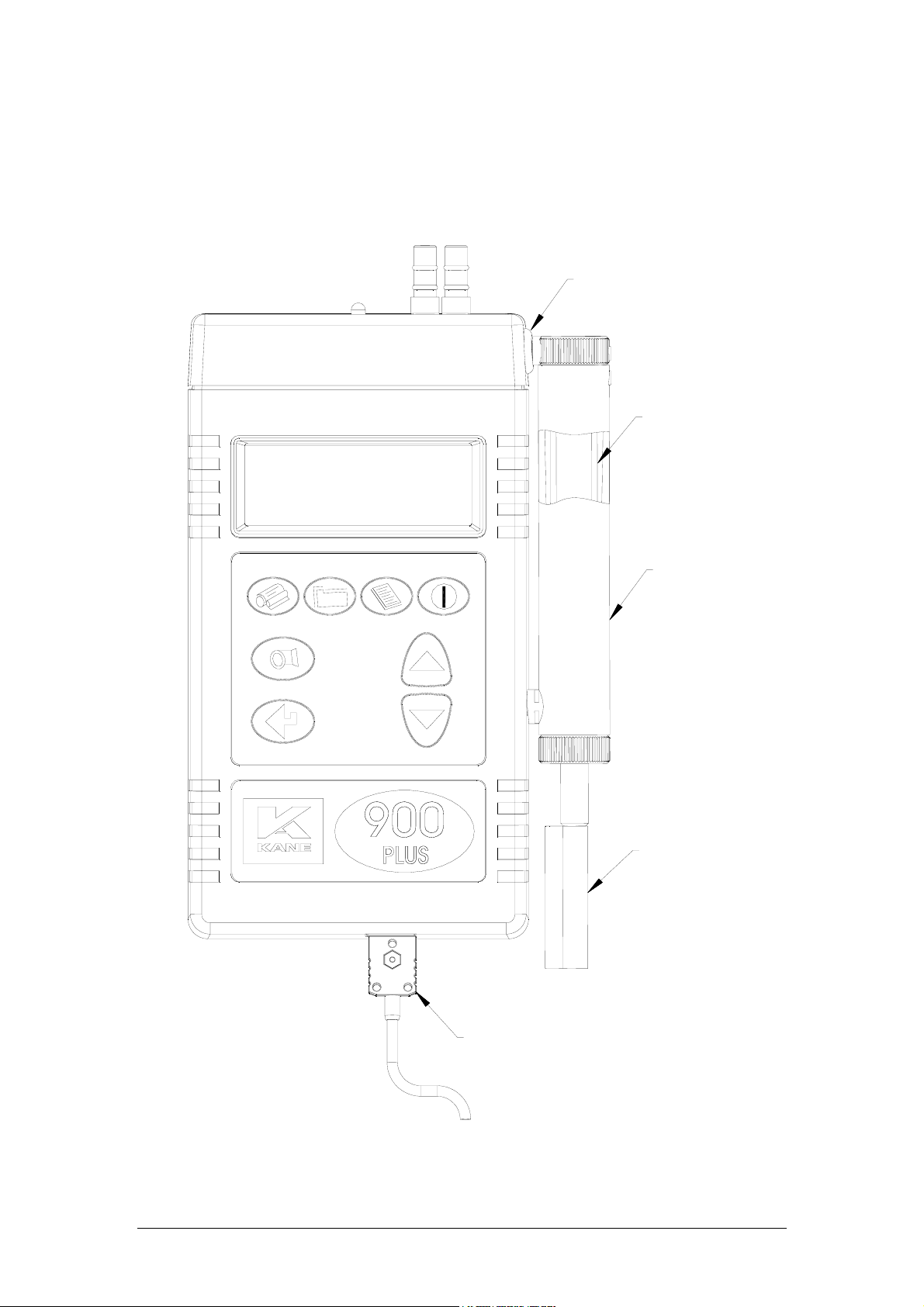

1.1 Instrument Features and Keypad

RS232 (8 pin din)

Charger socket

Store

Print

Pump

Enter

Infra-red emitter

ON/OFF

MENU

Allows access to all menu functions

PUMP

Turns pump on and off

ENTER

Accepts a command ie enters a

menu option

Pressure Inlet

Inlet Port (side)

Menu

On/Off

Up

Down

Keypad

Flue Temperature

Connector (underside)

UP

Scrolls up through options ie Fuel

DOWN

Scrolls down through options

STORE

Enters data storage menu

PRINT

Prints current data

KANE900 Plus Operators Manual Page 1

Page 3

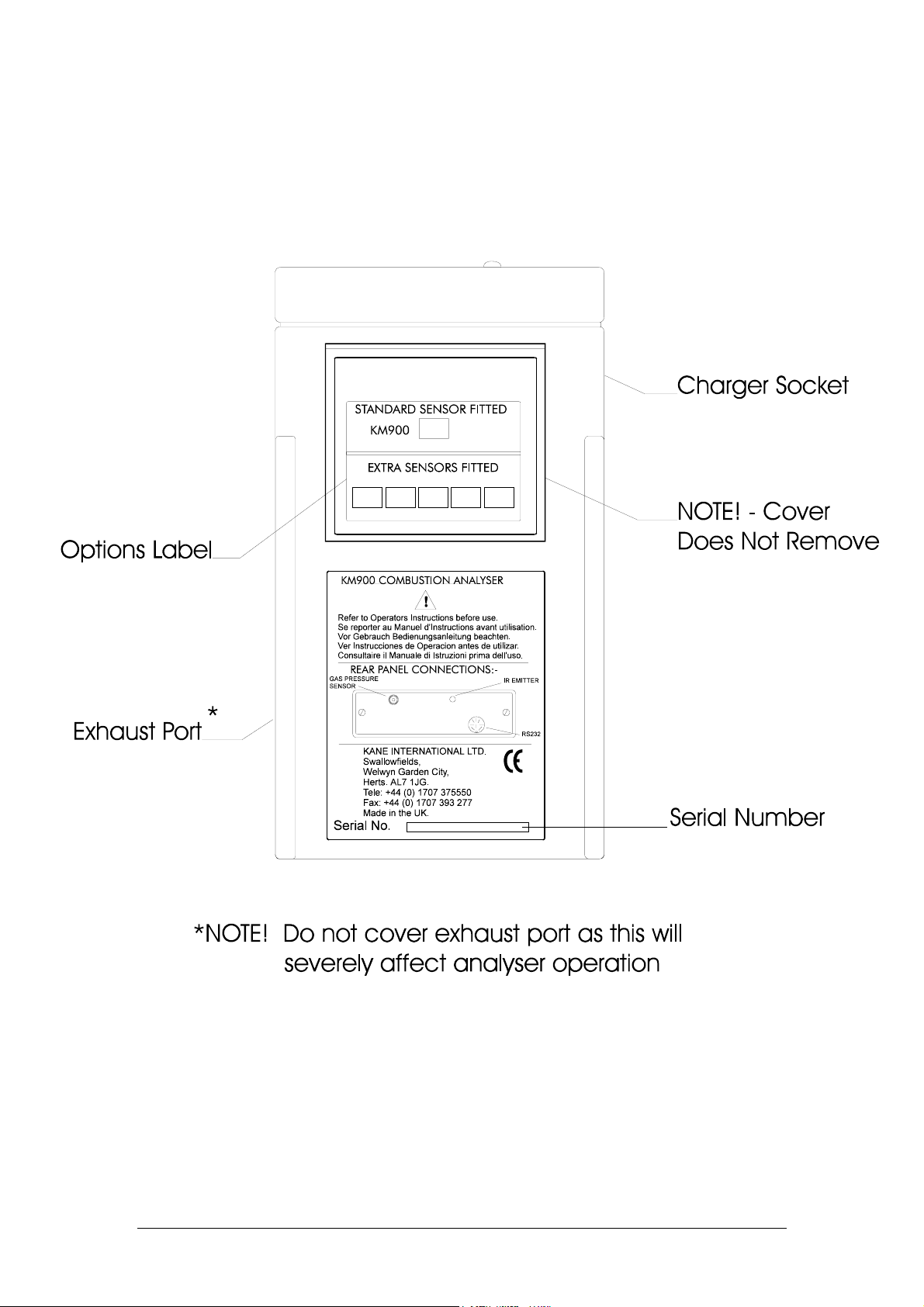

1.2 Instrument Layout (Rear)

KANE900 Plus Operators Manual Page 2

Page 4

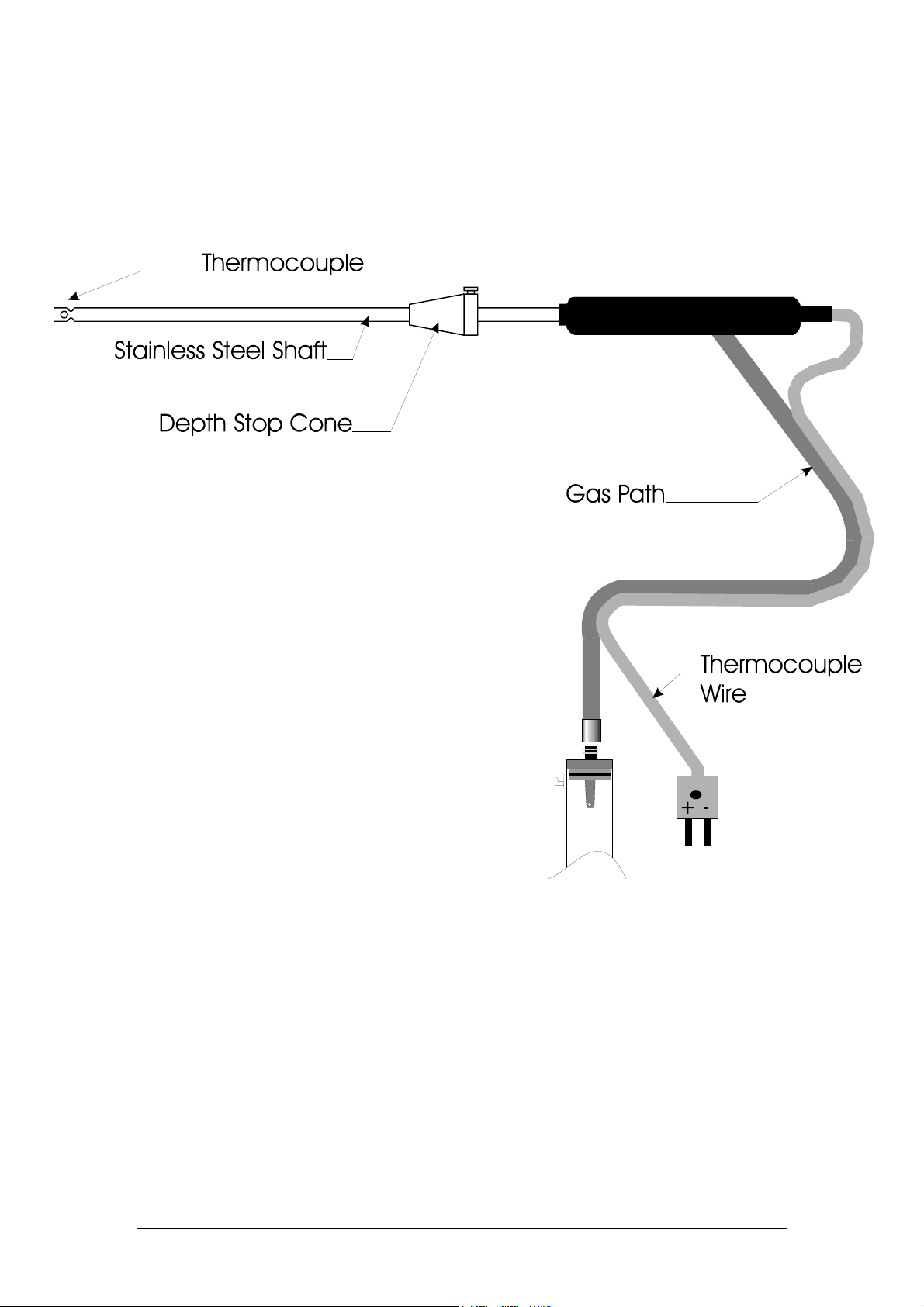

1.3 Standard Probe Configuration

KANE900 Plus Operators Manual Page 3

Page 5

1.4 Analyser Connections

Gas Connection

to Instrument

Particle Filter

In-line Water Trap

Neoprene Hose

Flue Temperature

Connector

KANE900 Plus Operators Manual Page 4

Page 6

2. SAFETY WARNING

This analyser extracts combustion gases that may be toxic in relatively low

concentrations. These gases are exhausted from the side of the instrument. This

instrument must only be used in well ventilated locations. It must only be used by

trained and competent persons after due consideration of all the potential hazards.

Protection Against Electric Shock (in accordance with EN 61010-1 :

1993)

This instrument is designated as Class III equipment and should only be connected to

SELV circuits. The battery charger is designated as:

Class II equipment

Installation category II

Pollution degree 2

Indoor use only

Altitude to 2000m

Ambient temperature 0°C-40°C

Maximum relative humidity 80% for temperatures up to 31°C decreasing linearly to

50%RH at 40°C

Mains supply fluctuations not to exceed 10% of the nominal voltage.

3. FIRST TIME USE

Charge the battery for 12 hours. Following this, an overnight charge should be

sufficient for an average 8 hour day. See Main Parameter displays for Battery

Indicator.

The KANE900 Plus has a rechargeable lead acid battery which uses a different

charger than other Kane analysers. Ensure the correct charger is used or damage

may occur to the instrument.

Check that you have all the items you have ordered.

Take time to read this manual fully. Be aware that the analyser configuration that

you have purchased may not support all the features detailed in this manual.

When using the analyser for the first time you will need to choose from: Language selection

Calibration countdown time

CO gas alarm

NOx percentage for calculation

Time and Date

Printed header name and telephone number

The SET UP MENU (Section 5.2.5) gives details of how to change the above settings.

KANE900 Plus Operators Manual Page 5

Page 7

4. NORMAL START UP SEQUENCE

4.1 Every Time You Use The Analyser

BEFORE SWITCH-ON CHECK THAT:

the particle filter is not dirty

the water trap and probe line are empty of water

all hose connections, etc, are properly made

the probe is sampling CLEAN AMBIENT air

the water trap is correctly fitted and the instrument upright

the flue temperature is connected

Switch ON the instrument by pressing

4.2 Automatic Calibration

During this sequence the analyser pumps fresh air into the sensors to allow toxic

sensors (if fitted) to be set to zero and the Oxygen sensor to be set to 20.9 %.

After switch-on the analyser will briefly display header information :-

Kane International

(44)-1707-375550

And then show the countdown screen :-

ZERO CAL

Time : 180

FRESH AIR PURGE

The calibration time will count down in seconds to zero. Calibration time may be

changed from 2 to 6 minutes. See Set-Up menu section 5.2.5.

Note ! Three minutes is recommended to allow the sensors to stabilise fully. Anything

less than this may result in drift of the toxic and oxygen sensors in clean

ambient air.

To obtain the quoted specification an instrument should be calibrated with clean

ambient air at standard temperature and pressure (STP).

KANE900 Plus Operators Manual Page 6

Page 8

Once the time has reached zero an audible beep will be heard and will show the

selected fuel on the following display:-

NATURAL GAS

∗

PRESS -MENU- KEY

Press

This zeros the toxic sensor and sets Oxygen to 20.9%. The next screen is the MAIN

DISPLAY of the analyser:-

∗

NETT C 0.0

O2 % 20.9

CO ppm 0000

EFF (G) % 0.0

Use and to change the display.

CO2 % 0.0

FLUE C 0.0

INLT NOT FITTED

AMBIENT C 21.5

All parameters are detailed in Appendix A - MAIN DISPLAY PARAMETERS.

KANE900 Plus Operators Manual Page 7

Page 9

4.3 Main Displays

The main display can be changed to show either 4 or 8 parameters at one time. Two

options are available when 4 parameters are selected.

• 4 Page Mode displays 4 lines of data in set format, each page is predefined.

• Line scroll mode allows you to customise the display to show the data you

require.

• 8 Page Mode displays 8 parameters on 4 lines in set format, the bottom two can be

changed.

Changing between the different modes is detailed in Display Menu Section 5.2.4.

4.3.1 4 Page Mode

Use the and keys to change the information that is displayed on the

screen. The following pages are available.

NATURAL GAS

DATE 07-08-96

TIME 12:31:35

BATTERY % 54

This screen only displayed on an

analyser fitted with an NO sensor

NETT C 0.0

O2 % 20.9

CO ppm 0000

EFF (G) % 0.0

CO2 % 0.0

FLUE C 0.0

INLT NOT FITTED

AMBIENT C 21.5

CO/CO2 R 0.0001

P INDEX % 0.01

XAIR % 0.0

Prs mbar 0.00

NO ppm 0000

NOx ppm 0000

NOx calc% 5

O2 ref % 3.0

TIP - In 4 page mode only turns the backlight ON and OFF.

KANE900 Plus Operators Manual Page 8

Page 10

4.3.2 Line Scroll Mode

Line scroll mode allows you to customise the display.

Use the and keys to change the bottom line of the display. Once the

correct line is displayed press to confirm and move the line up. Select the

next parameter and repeat until all lines display the desired parameters.

Change bottom line using

NETT C 0.0

O2 % 20.9

and

CO ppm 0000

CO2 % 0.0

O2 % . . . 20.9

to select and

move parameter up

Select next parameter.

Repeat above until

display reads desired data

CO ppm . . 0000

CO2 % . . . 0.0

CO2 % . . . 0.0

O2 % . . . 20.9

CO ppm . . 0000

CO2 % . . . 0.0

CO/CO2 R . . 0.0001

4.3.3 8 Page Mode

Displays 8 parameters on the screen at one time. Symbols used in this mode are

different from those used in 4 page and line scroll modes and are detailed in Appendix

A - MAIN DISPLAY PARAMETERS.

O2

CO

PI

λ

The bottom line of the display can be changed to display other parameters.

Use the and keys to change this line.

KANE900 Plus Operators Manual Page 9

:20.9 %

: 0ppm

:

:

CO2

Eff

∆T

Tf

:

:

: 0C

: 21C

Page 11

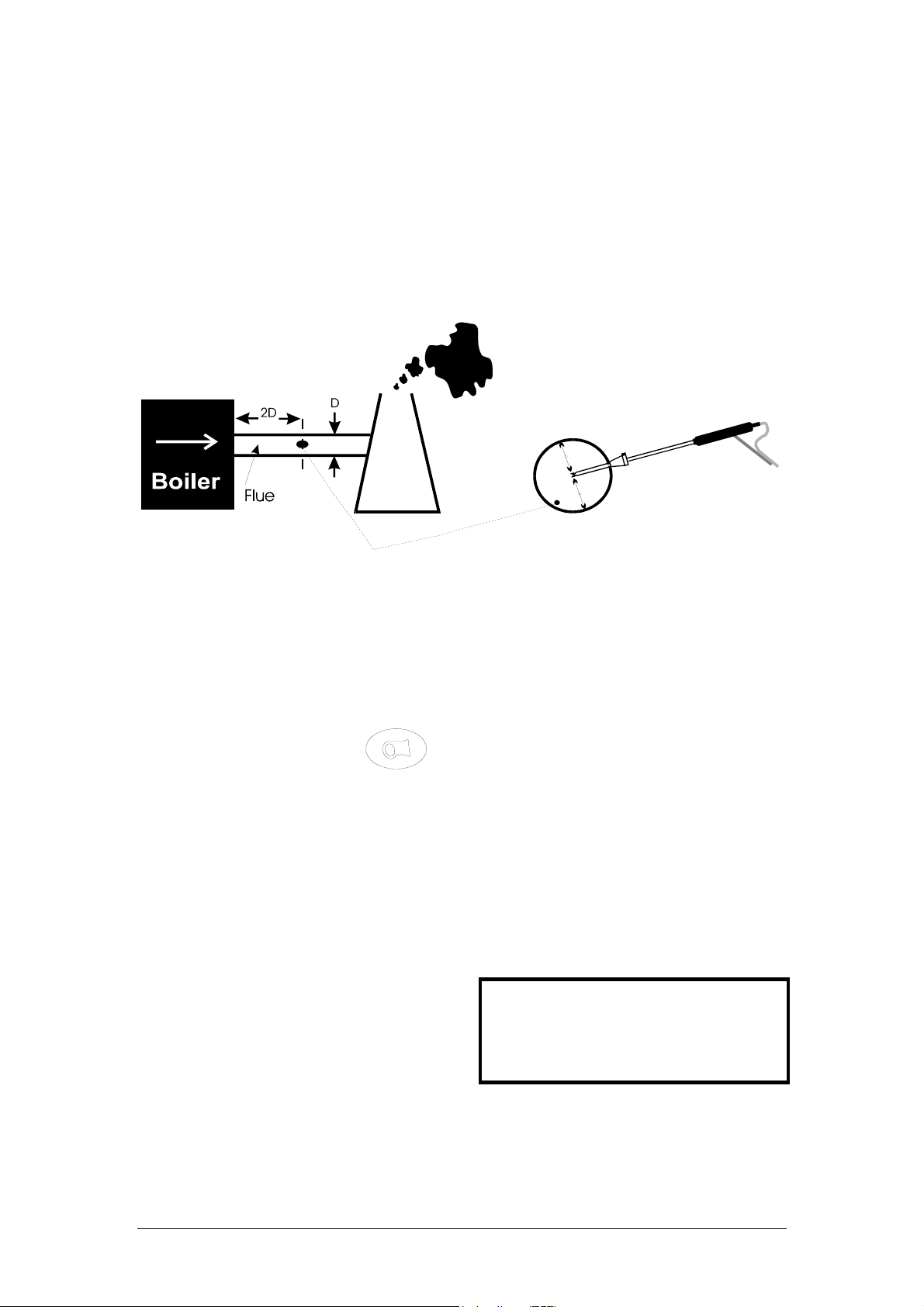

4.4 Sampling the Flue Gas

Once the automatic calibration procedure has been completed and the specific fuel has

been selected (See SELECT menu) the probe can be inserted into the desired

sampling point.

It is recommended that the sampling point be located at least two flue diameters

downstream of any bend and that the probe tip is in the centre of the flue. With

balanced flues and other domestic units the probe should be positioned far enough

into the flue so that no air can ‘back flush’ into the probe. This will be indicated by a

low oxygen reading and/or a low ‘Poison Index’ reading.

The probe depth stop cone provided with the instrument allows the probe to be used

in holes whose diameters range from 8 mm to 21 mm (5/16 to

The standard probe is rated at 650°C (1202oF). Temperatures of up to 1200°C

(2200°F) can be accommodated using an optional high temperature probe.

TIP To conserve battery power, switch off the pump when you are not taking a

measurement. Use the

key to turn ON and OFF the pump.

13

/16 inch).

4.5 Taking a Pressure Reading

With the optional pressure module fitted a flue draught measurement can be made at

any time.

Connect the standard probe to the pressure sensor inlet and the probe in the flue.

The pressure reading will be displayed :-

CO/CO2 R 0.0001

P INDEX % 0.01

XAIR % 0.0

Prs mbar 0.00

To perform a combustion test and display draught pressure at the same time a special

probe is required. Contact Kane International or Authorised Distributor for details.

KANE900 Plus Operators Manual Page 10

Page 12

4.6 Regular Checks During Sampling

Care must be taken at all times not to exceed the analysers operating specifications, in

particular ensure the following :-

• Do not exceed the maximum temperature of the flue probe.

• The analyser internal temperature does not exceed normal operating range,

typically 0-50°C.

• DO NOT PLACE THE INSTRUMENT ON A HOT SURFACE.

• The water trap is vertical at all times. Water condenses in the probe line and can

quickly fill the water trap when the probe is moved. Take care and watch the water

trap closely.

• The in-line particle filter is clean and does not become blocked.

4.7 Normal Shutdown Sequence

DO THIS EVERY TIME YOU USE THE ANALYSER

Remove the probe from the flue - TAKE CARE ! THE PROBE WILL BE HOT -

and allow it to cool naturally. Do not immerse the probe in water as this will be drawn

into the analyser and damage the pump and sensors.

Once the probe is removed from the flue press and the analyser will count

down from 30 to switch off.

OFF 30

MENU TO ESCAPE

If you have not finished but press by mistake, you can press to

return to normal operation and not switch OFF.

KANE900 Plus Operators Manual Page 11

Page 13

4.8 Electromagnetic Compatibility

The European Council Directive 89/336/EEC requires that electronic equipment does

not generate electromagnetic disturbances that exceed defined levels and has an

adequate level of immunity to enable it to be operated as intended. The specific

standards applicable to this product are detailed in the appendices.

Since there are many electrical products in use that pre-date this Directive and may

emit electromagnetic radiation in excess of the standards defined in the Directive

there may be occasions where it would be appropriate to check the analyser prior to

use.

The following procedure should be adopted:

Go through the normal start up sequence in the location where the equipment

is to be used.

Switch on all localised electrical equipment that might be capable of causing

interference.

Check that all readings are as expected. (A level of disturbance in the

readings is acceptable). If not adjust the position of the instrument to

minimise interference or switch off, if possible, the offending equipment for

the duration of the test.

N.B. Maximum cable lengths must be less than 3 metres.

At the time of writing this manual (March 2006) Kane International Ltd is not aware

of any field based situation where such interference has ever occurred and this advice

is only given to satisfy the requirements of the Directive.

KANE900 Plus Operators Manual Page 12

Page 14

5. MOVING THROUGH THE MENUS

5.1 Basic Operation

From the MAIN DISPLAY

Press

to access the MAIN MENU

Press

and to move

cursor up and down

Press to access selected

Menu

NETT C 0.0

O2 % 20.9

CO ppm 0000

EFF (G) % 0.0

MAIN MENU

1. SELECT 3. DISPLAY

2. UNITS 4. SETUP

MAIN MENU

1. SELECT 3. DISPLAY

2. UNITS 4. SETUP

MAIN MENU

1. SELECT 3. DISPLAY

2. UNITS 4. SETUP

Press to select parameter

Use and to change

setting i.e. fuel selected

Press to enter value and

move to next parameter

Press

to save settings and return to the

MAIN MENU

FUEL

O2 Ref

SMOKE

RESET

FUEL

O2 Ref

SMOKE

RESET

FUEL

O2 Ref

SMOKE

RESET

: LIGHT OIL

: OFF

: OFF

: NO

: NATURAL GAS

: OFF

: OFF

: NO

: LIGHT OIL

: OFF

: OFF

: NO

MAIN MENU

1. SELECT 3. DISPLAY

2. UNITS 4. SETUP

Press to return to the MAIN DISPLAY

KANE900 Plus Operators Manual Page 13

Page 15

5.2 Menu Options and Settings

5.2.1 Main Menu

The MAIN MENU consists of 4 sub menus which are shown below and detailed on

the following pages.

MAIN MENU

1. SELECT 3. DISPLAY

2. UNITS 4. SETUP

All sub-menus are accessed using and exited using

The and keys move the cursor within a menu and allow

parameters to be changed.

TIP Holding down one of these keys scrolls through the data quicker.

5.2.2 Select Menu

FUEL

O2 Ref

SMOKE

RESET

This menu allows selections to be made for the parameters detailed below.

FUEL : Select the fuel being used by the boiler from either a standard fuel

stored in the analyser or by entering the user fuel. Once the correct fuel

has been selected press to view the fuel constants.

: NATURAL GAS

: OFF

: OFF

: NO

NATURAL GAS

K1g

K_2

K_4

Calculation of fuel constants are detailed in the Appendix. Fuel constants will have to

be calculated before a user fuel can be entered.

: 0.350

: 11.89

: 32

K1n

K_3

O2r

: 0.390

: 9.83

: 3.0

KANE900 Plus Operators Manual Page 14

Page 16

To enter the user fuel select ‘User Fuel’ and Press

USER FUEL

K1g

K_2

K_4

Use and to select the correct value.

: 0.000

: 0.00

: 00

K1n

K_3

O2r

: 0.000

: 0.00

: 00

USER FUEL

K1g

K_2

K_4

: 0.350

: 0.00

: 0

K1n

K_3

O2r

: 0.000

: 0.00

: 00

Use to move to the next parameter, repeat above until all

parameters are correct. Press

O2 Ref : Toxic gas measurements can be referenced to defined oxygen levels.

Reference values can be set from 1-20%, to AUTO or more normally

to the default value - OFF. Setting to AUTO uses the figure in the

FUEL constants data.

Oxygen referencing is required by some regulations such as TA-LUFT.

If a reference value is selected then toxic gas measurements will be

displayed with the symbol (n) attached to the reading. i.e. CO(n)

What does Oxygen reference mean ?

If 3 % O2 reference is selected and 5 % O2 is measured in the flue then

toxic gas values will be recalculated as if 3 % were measured. The

equation for referencing is detailed in the Appendix.

Oxygen referencing prevents false readings being submitted, e.g.

allowing more air into the boiler will increase the oxygen level in the

flue and hence dilute any toxic gas reading. Oxygen referencing gives

readings as if they were undiluted.

SMOKE: Allows the user to enter a smoke test number from 0-9. This value will

be printed on the standard printout. Default value is OFF.

RESET : Allows the user set the Oxygen to 20.9% and zero the toxic sensors

without turning the analyser off.

to return to SELECT menu.

KANE900 Plus Operators Manual Page 15

Page 17

Selecting YES and will display the following screen.

RESET SENSORS

O2 % : 20.9 CO & NO = 0

PRESS ENTER

MENU TO ESCAPE

After pressing the analyser will count down for 5 seconds and

then return to the main display.

WARNING : The sensors must only be reset if you are sure they

have been sampling fresh air for at least 3 minutes.

Errors in measurement will occur if the sensors are

reset during or just after sampling.

5.2.3 Units Menu

TEMP

GAS

PRESS.

EFF.

Allows all displayed units to be changed.

TEMP : Choose from Centigrade, °C, or Fahrenheit, °F.

GAS : Changes the toxic gas measurement units. Select from volumetric

readings, parts per million (ppm) or mass flow reading milligrams per

cubic meter (mg/m3) .

PRESS. : Flue draught can be displayed in millibar (mbar), hectaPascals (hPa),

millimeters water gauge (mmWG) or inches water gauge (in WG).

EFF. : Efficiency can be selected for gross or net values. Gross efficiency

assumes latent heat of vaporisation is lost in the boiler and hence will

be lower than net efficiency. For natural gas the difference will be

approximately 11%.

Efficiency is displayed as EFF (G) or EFF (N) respectively. Should

the instrument detect that a condensing boiler is under test then it

automatically switches to a third mode that is displayed as EFF (C).

: C

: ppm

: mbar

: GROSS

KANE900 Plus Operators Manual Page 16

Page 18

5.2.4 Display Menu

LIGHT

MODE

CONTRAST

Allows the configuration of the display to be changed.

LIGHT : Choose from ON or OFF.

MODE : Select 4 or 8 Page Mode or Line Scroll Mode as detailed in section 4.3

Main Displays.

CONTRAST :The contrast is set to a DEFAULT value or can be adjusted

↑ LIGHTER or ↓ DARKER. Use the and keys to

adjust.

5.2.5. Set-Up Menu

The set up menu allows the following parameters to be set / altered.

• Language.

• Automatic calibration time

• CO gas alarm

• NOx percentage for calculation

• Date and time

• Printout Header

: OFF

: 8-PAGE

: DEFAULT

LANG

CO AL

CALEN

: ENGLISH

ARM : 400

DAR

ZERO : 3

NOx% : 5

HEADER

Parameter Description Settings

LANG :

ZERO :

CO ALARM :

Changes the analysers displayed and printed

language.

Allows setting of the Autocalibration time in

minutes. Care must be taken when changing this

parameter as sensors may drift from zero if too

short a time is used. Kane International advise 3

minute countdown.

Allows an alarm level to be set on for the CO

reading. This is set as a default at 1000 ppm.

ENGLISH

SPANISH

DUTCH

FRENCH

ITALIAN

2-6 minutes

OFF

0-4000 ppm

KANE900 Plus Operators Manual Page 17

Page 19

Once an alarm has been exceeded the display will flash every two minutes warning

the user of an alarm state and display the gas concentration. A similar display will be

shown during a RECHARGE BATTERY and PUMP OFF alarms.

-- -- -- -- -- -- -- -- -- -- -- -- -- -CO ALARM

1010 ppm

-- -- -- -- -- -- -- -- -- -- -- -- -- --

NO REF:

CALENDAR:

Displayed on the Nitric Oxide unit only. Allows

the percentage P in the following calculation to be

set. The default value set is 5%. Note the

percentage allows for NO2 in a typical boiler.

NOx = NO + P% NO

Allows the user to change the date and time. (24

hour clock).

The following screen will be shown once the

parameter is entered:

OFF

1-9 %

TIME :

FORMAT :

DATE :

FORMAT :

To change the time position the cursor on Time and press . The cursor will

now be to the left of the 13 as shown below:

Changes the date format for display and printing.

TIME :

FORMAT :

DATE :

Using and scroll through the setting options i.e. 0-23.

Once the correct hour is set press to move to the next parameter, the cursor

will move to the left of minutes (53). Move to each parameter until the correct time is

set.

hh

: mm : ss

13

: 53 : 26

dd

: mm : yy

03

: 01 : 96

dd : mm : yy

yy : mm : dd

mm : dd : yy

hh

: mm : ss

13

: 53 : 26

dd

: mm : yy

03

: 01 : 96

Pressing after setting the seconds will return the cursor to the left of the

screen.

Format and Date are set in a similar manner.

KANE900 Plus Operators Manual Page 18

Page 20

Header :

Allows two lines of 20 characters to be

programmed into the analyser. The header appears

on the top of the standard printout. This can be used

to print your company name and/or phone number.

Name/Phone

K

ane International

(44)-1707-375550

‘LEFT’ USE STORE KEY

The screen above shows the standard header setting with the cursor now shown

underlining the K in Kane. By using and any letter or number can be

chosen.

Once the correct character is displayed, use to move right to the next. Move

along until all characters spell the desired name or phone number. If you need to go

back and change a character use to move left.

Press to return to the SET UP menu.

KANE900 Plus Operators Manual Page 19

Page 21

6. PRINTING INFORMATION

Supplied as accessories for the KANE900 Plus are an infra-red thermal printer or a

dot matrix serial printer. Read the manual supplied with each printer prior to

operation. Connections to the KANE900 Plus are detailed below :

• Infra-red thermal printer - this does not require a cable to transmit the data but

uses an infra-red (IR) link similar to a TV remote control. The IR emitter is

positioned on the top of the KANE900 Plus and the bottom of the printer. Ensure

they are pointing at each other and within 300 mm, with no obstructions in the

way. Data may be lost if transmission is interupted. Keep the KANE900 Plus

pointing at the printer until the printout has finished.

• Dot matrix serial printer - requires the supplied serial cable to transmit data.

Connect the cable to the 8 pin DIN socket on the top of the KANE900 Plus and the

25 pin D-connector on the printer.

Data can either be printed from a ‘live’ test or from stored data. Printing of stored data

is detailed in STORING AND RETREIVING DATA.

6.1 Printing a ‘Live’ Test

During a combustion test the KANE900 Plus will print data on request. With the

analyser showing the MAIN DISPLAY press and current data will be sent to

the printer.

The display will show the following until data transmission is complete.

∗∗∗∗∗

Printing

∗∗∗∗∗

KANE900 Plus Operators Manual Page 20

Page 22

6.2 Standard Printout

The standard printout is:-

KANE900 Plus Operators Manual Page 21

Page 23

7. STORING AND RETRIEVING DATA

The KANE900 Plus can store combustion tests. Once stored, the data can be viewed

on the display or downloaded to a PC or printer.

7.1 Storing a ‘Live’ Test

While performing a test and viewing the data on the MAIN display access the STORE

menu as follows :-

MODE

Press

to access the STORE MENU

Mode: Select from the following :-

Location: Automaticaly allocates a location in the memory of the instrument for

To store a test set MODE to STORE and press . The current readings will

be stored in the analysers memory.

Tip : Make a note of the location number for your particular test as it may be

LOCATION

PRESS ‘STORE’ TO LOG

• STORE - Allows data to be stored in memory.

• VIEW / PRINT - Stored data can be viewed or printed.

• DELETE - Clears all data in memory.

the next test. On the display shown above the next location will be 3.

useful when downloading or printing.

7.2 Viewing and Printing a ‘Stored’ Test

Multiple tests can be printed easily with the KANE900 Plus.

Select PRINT under MODE in the STORE menu. This feature is in addition to the

VIEW/PRINT, STORE and DELETE options.

STORE MENU

: STORE

: 3

MODE

Press

to access the STORE

LOCATION

MENU

The cursor will move to the first number, use the

location and start printing.

Press

print.

KANE900 Plus Operators Manual Page 22

to move the cursor to the second number, select the last location to

STORE MENU

: PRINT

: 1 TO 10

PRESS ‘PRINT’

and to select the

Page 24

To print the data press . In the screen shown above locations 1 to 10 will be

printed.

During printing the following will be shown.

PRINT TESTS

1 to 10

PRINTING TEST 1

NOTE While the display above is shown (i.e. the instrument is printing a test) the

keypad is disabled. To exit from printing wait until the current test has finished and

the display below is shown:

PRINT TESTS

Press to exit the print routine. The

instrument will return to main display

1 to 10

PLEASE WAIT

MENU TO ESCAPE

7.3 Deleting Data

To delete the data in stored memory press to obtain the STORE MENU (as

above) :-

Press to access the STORE

MENU

Press to access delete data

screen

Press

screen.

to delete data in memory, press to exit delete data

STORE MENU

MODE

LOCATION

: DELETE

: 3

PRESS ‘ENTER’ TO DELETE

ENTER to ERASE DATA

MENU to ESCAPE

KANE900 Plus Operators Manual Page 23

Page 25

8. AVERAGE OF THREE

8.1 Storing

Ensure the instrument is switched on and in the main screen. In the 4-page mode

below.

When you are ready to store the first reading, go into the STORE menu, use the

and to find the “Ave Store” item. Press . The first sample

has been stored.

The screen appears to go back to the main screen but there is a tiny difference: the

right-most column has just one ‘+’ there. The line that it is on tells you which sample

you have got to in the obvious way. Using the and keys, you can

look at all the usual screens. When you get to the screen with the fuel you will notice

that it is note there. In its place is a countdown (in seconds). (It started at 120

seconds. While it is active another sample cannot be stored. This is there to ensure

users cannot take samples any quicker than once every two minutes.

By and by, the countdown will countdown to zero. Then there is a beep and the

countdown line becomes a message saying you can press when you are

ready to store the next sample. In addition, the ‘+’ is now a ’*’. This is visible even

if the countdown line is not and is there to indicate that the instrument is ready to

accept the next sample. Once you have done this, you have stored the second sample.

Repeat for the third and final sample.

Then the instrument returns to its previous state.

It has stored the three samples together with the average thereof in EEPROM, so it is

available again after switching off and on. Only one such set can be stored at a time.

8.2 Viewing

With the instrument switched on and in the main screen, enter the STORE menu.

Find the “Ave view” item and select if by pressing . You can now look at

the first sample using the and keys. The ‘*’s indicate that you are in

the Average of Three mode and by the position of the ‘*’ which sample you are

currently viewing. Press to pass to the next sample. Eventually you will be

looking at the averages. This is indicated by the bottom ‘*’ being shown. Press

a final time to exit from that mode. (To exit from this mode early, press

, then , then .

8.3 Printing

KANE900 Plus Operators Manual Page 24

Page 26

Get into the average of three viewing mode, “Ave View” as above. Offer a printer to

the instrument in the usual way. Press

flagged as NOT FITTED.

. The print out omits any reading

KANE900 Plus Operators Manual Page 25

Page 27

9. MAINTENANCE

9.1 Emptying and Cleaning the In-line Water Trap

The in-line water trap should be checked and emptied on a regular basis. Water

vapour will condense and gather in the probe line. This may move suddenly to the

trap when the probe is moved. Care should be taken at all times.

Emptying of the water trap is detailed below :-

Carefully remove the end cap from the in-line housing. Dispose of the condensate in a

suitable drain, care must be taken as it could be acidic. If condensate spills onto the

skin or clothing, clean off immediately using fresh water, seek medical advice if

problems occur.

9.2 Changing the Particle Filter

This is a very important part of the analyser and should be changed regularly. It

prevents dust and dirty particles entering the pump and sensors and hence causing

damage. The filter MUST be changed when it is discoloured.

Remove the end cap from the in-line filter housing. Carefully remove the paper filter

element and dispose of it. Clean the inside of the filter housing with a suitable soft

cloth. Insert a new filter element onto the spigot in the filter housing and carefully

replace the end cap.

KANE900 Plus Operators Manual Page 26

Page 28

10. PROBLEM SOLVING

The following is a list of problems that may occur on the instrument through its

operating life. If the cause of the fault is not easy to identify then we advise you

contact Kane International Service Department or an International Distributor for

expert advice.

Fault symptom Causes

• Oxygen too high

• CO2 too low

• Oxygen Error (FAULT)

• Toxic sensor Error (FAULT)

• Analyser not holding charge

• Analyser not charging

• Analyser does not respond to flue

gas

• Flue temperature readings erratic • Temperature plug reversed in socket.

• Analyser automatically switches

off in operation.

• Display shows dark lines and no

response from ON/OFF key.

11. ANNUAL RE-CALIBRATION

• Air leaking into probe, tubing, water trap,

connectors or internal to instrument.

• Oxygen cell needs replacing.

• Calibration time set too short and

instrument not allowed to stabilise

• Instrument has been stored in a cold

environment and is not at normal working

temperature.

• Oxygen cell or toxic sensors needs

replacing.

• Battery exhausted.

• AC charger not giving correct output.

• Fuse blown in charger plug.

• Particle filter blocked.

• Probe or tubing blocked.

• Pump not working or damaged with

contaminants.

• Probe connected to pressure connector.

• Faulty connection or break in cable or plug.

• Battery below alarm level.

• Ambient temperature above 50°C.

• Battery quickly discharging and is faulty.

• Fault has occurred on the instrument

electronics and requires resetting. Contact

Kane International or Distributor.

Whilst the sensors have an expected life of more than two years in normal use it is

recommended that the analyser is re-calibrated at least annually. This is so that long

term drift on the sensors and electronics can be eliminated. Local regulation may

require more frequent re-calibration and users should check with appropriate

authorities to ensure they comply with relevant guidelines.

KANE900 Plus Operators Manual Page 27

Page 29

12. PRODUCT SPECIFICATION

Parameter Resolution Accuracy Range

2

0.1°C/F

0.1°C/F

0.1%

1ppm,mg/m

1ppm,mg/m

1ppm,mg/m

1ppm,mg/m

0.1mbar

0.1%

0.1%

0.1%

0.1%

1.0°C/F

0.0001

0.01%

Temp Measurement

Flue Temperature

Inlet Temperature

Gas Measurement

Oxygen

Carbon Monoxide

Carbon Monoxide, H

compensated

Nitric Oxide

(optional)

Nitrogen Dioxide

(optional)

Pressure (optional)

Carbon Dioxide

*2

Losses

Efficiency

Excess Air

Temp (Nett)

CO/CO

ratio

2

Poison Index *2

*2

*2

*2

*2

*2

Pre-programmed Fuels

Dimensions

Weight

Handset

Probe

Ambient Operating Range

Power Supply (battery charger)

Battery Life

*1

Using dry gases at STP

*2

+2.0°C +0.3% reading

+1°C +0.3% reading

0.2%*1

+

3

20ppm <400ppm*1

+

5% >400ppm

+

3

20ppm <400ppm*1

+

5% <5000ppm

+

10% >5000ppm

+

3

5ppm <100ppm*1

+

5% >100ppm

+

3

5% full scale

+

5.0% full scale

+

0.3% reading

+

1.0% reading

+

1.0% reading

+

0.2%

+

2°C +0.3% reading

+

0.0001

+

0.01

+

0-1200°C/32 -2200°F

with suitable probe

0-50°C/32-122°F

0-25%

0-4000ppm, 0-5000mg/m

0-10,000ppm, 0-12,000mg/m

0-5000ppm, 0-6700mg/m

100ppm, 200mg/m

150 mbar

0-99.9%

0-99.9%

0-99.9%

0-2885.0%

0-1200°C/32-2200°F

0-0.9999

0-99.99

3

Natural gas, Town gas, Gascor, Light Oil, Heavy Oil,

Propane, Butane, Anthracite, Coke, Coal, Kinsale Gas.

1kg

220mm x 55mm x 120mm

L240mm x Dia8mm with 285mm long stainless steel shaft,

type K thermocouple and 1.5m long neoprene hose

-5°C to +50°C/10% to 90% RH non condensing

Input: 110Vac/220 Vac nominal

Output: 12 Vac off load

>8 hours from full charge

Calculated

3

3

3

KANE900 Plus Operators Manual Page 28

Page 30

APPENDICES

A - Main Display Parameters

The parameters and their meanings are detailed as follows : -

DATE : Analyser date. See Set-Up menu section 5.2.5 to change.

TIME : Analyser time. Use Set-Up menu section 5.2.5 to change.

BATTERY : Displays the battery level from 0-100%. The analyser will flash

(BAT) RECHARGE BATTERY at less than 10 % of charge. With the

charger connected the display shows AC ON.

NETT : Nett temperature calculated by deducting the internal AMBIENT

temperature

(∆T) from the measured FLUE temperature. Displays in either °C (C) or

°F (F) and will display NOT FITTED (N/F) if flue probe is not

connected.

If an external INLET probe is used then INLET is deducted from

FLUE.

O2 : Oxygen reading in percentage %.

CO : Carbon Monoxide reading indicated in ppm or mg/m3. If the figures

are referenced to oxygen then the display will show CO(n). See

SELECT menu 5.2.2 for oxygen reference. The display will read

‘O2 > 20%’ if referenced values selected and instrument is in clean

ambient air.

EFF (G) : Combustion Efficiency calculation displayed in percentage. Gross G

or Net N can be set see SELECT menu 5.2.3. The calculation is

determined by fuel type see Appendix B for calculation. The

efficiency is displayed during a combustion test, ‘- -’ is displayed

while in fresh air.

CO2 : Carbon Dioxide calculation determined by the type of fuel. This

only shows a reading when a combustion test is being carried out. ‘-

-’ is displayed while in fresh air.

FLUE : Temperature measured by flue gas probe in Centigrade or

(Tf) Fahrenheit. Will show ambient temperature after fresh air

calibration and NOT FITTED (N/F) or FAULT (FLT) if probe disconnected.

INLET : Temperature measured by the optional inlet air probe. This probe is

(Ti) plugged into the instrument through the RS232 socket. This figure is

used to calculate the NET temperature instead of AMBIENT when

fitted.

KANE900 Plus Operators Manual Page 29

Page 31

AMBIENT : Temperature measured by the internal sensor, used in the NET

(Ta) temperature calculation if an INLET probe is not fitted.

CO/CO2 R : The CO/CO2 ratio, is the ratio of measured CO divided by

calculated CO2.

It gives an indication of the following :-

• How good a gas sample the instrument is reading.

• How clean the boiler is running.

For example : A new or clean domestic boiler will display a ratio of

less than 0.004, a unit in need of cleaning 0.004-0.008 and a unit in

need of major overhaul will show greater than 0.008.

This only shows a reading when a combustion test is being carried

out. ‘- -’ is displayed while in clean ambient air.

P INDEX : The CO/CO2 ratio expressed as a percentage %, called the ‘Poison

(PI) Index’ i.e. P INDEX % = 100 x CO/CO2. ‘- -’ is displayed while in

clean ambient air.

XAIR % : Excess air calculated from the measured oxygen and type of fuel

(λ) used. During a combustion test ‘O2 > 20%’ will be displayed while

in clean ambient air.

Prs : Flue draught pressure reading. Displayed when pressure sensor

fitted. See UNITS menu 5.2.3. for scales.

NO: Nitric Oxide reading in ppm or mg/m3. Displayed when Nitric

Oxide sensor fitted. Also displayed as NO (n) when referenced to

oxygen. The display will read ‘O2 > 20%’ if referenced values

selected and instrument is in clean ambient air.

NOx : Calculated total Nitric oxides displayed in ppm or mg/m3. Where

NOx = NO + P%NO, note P can be set from 0-9%, default = 5%.

See SELECT menu 5.2.2. Also displayed as NOx (n) referenced to

oxygen. The display will read ‘O2 > 20%’ if referenced values are

selected and instrument is sampling clean ambient air.

SO2 : Sulphur Dioxide reading in ppm or mg/m3. Displayed when Sulphur

Dioxide sensor fitted. Also displayed as SO2 (n) referenced to

oxygen. The display will read ‘O2 > 20%’ if referenced values

selected and instrument is in clean ambient air.

O2 ref % : Toxic gas measurements can be referenced to defined oxygen levels.

(O2r) See SELECT menu 5.2.2 for details.

KANE900 Plus Operators Manual Page 30

Page 32

B. COMBUSTION EFFICIENCY CALCULATION

The efficiency calculation is based upon British Standard BS845.

This identifies three sources of loss associated with fuel burning:

Losses due to flue gasses: Dry Flue gas loss,

Moisture and hydrogen

Sensible heat of water vapour

Unburned gas

Losses due to refuse: Combustible in ash

Combustible in riddlings

Combustible in dust

Other losses: radiation

convection

conduction

other unmeasured losses

Net efficiency calculations assume that the energy contained in the water vapour

(formed as a product of combustion and from wet fuel) is recovered and the wet loss

term is zero. Gross efficiency calculations assume that the energy contained in the

water vapour is not recovered.

Since the fuel air mixture is never consistent there is the possibility of

unburned/partially unburned fuel passing through the flue. This is represented by the

unburned carbon loss.

Losses due to combustible matter in ashes, riddlings, dust and grit, radiation,

convection and conduction are not included.

Efficiency Calculation:

Known Data - Fuel: Qgr = Gross Calorific Value (kJ/kg)

Qnet = Net Calorific Value (kJ/kg)

K1 = Constant based on Gross or Net Calorific Value:

K1g = ( 255 x %Carbon in fuel )/Qgr

K1n = ( 255 x %Carbon in fuel )/Q

net

K2 = % max theoretical CO2 (dry basis)

K3 = % Wet Loss

H

H

= % Hydrogen

2

O = % Water

2

Measured Data: Tf = Flue Temperature

Ti = Inlet Temperature

O

O

m = % Oxygen in flue gas

2

r = Oxygen reference %

2

KANE900 Plus Operators Manual Page 31

Page 33

Calculated data: Tnet = Net Temperature

% CO2 content in flue gas

% Dry Flue Gas losses

% Wet losses

% Unburned carbon loss

% Efficiency

Tnet = Flue Temperature - Inlet Temperature

Dry flue gas loss % = 20.9 x K1 x (Tnet) / K2 x (20.9 - O2m)

Wet loss % = 9 x H2 + H2O / Qgr x [2488 + 2.1Tf - 4.2 Ti]

simplified = [(9 x H2 + H2O) / Qgr] x 2425 x [1 + 0.001 Tnet]

Wet loss % = K3(1+0.001xTnet)

Where K3 = [(9 x H2 + H2O) / Qgr] x 2425

Net Efficiency % = 100 - dry flue gas losses

= 100 - 20.9 x K1n x (Tnet) / K2 x (20.9 - O2m)

Gross Efficiency % = 100 - {dry flue gas losses + wet losses}

= 100 – {[20.9 x K1g x (Tnet) / K2 x (20.9 - O2m)]+

[K3 x (1 + 0.001 x Tnett)]}

Excess Air = [(20.9% / (20.9% - 02m%)) – 1] x 100%

CO2% = [(20.9 - O2m) x K2 / 20.9]

Unburned

fuel Loss % = K4 x CO / ( CO + CO2 ) Note: CO scaled in %

Where K4 = 70 for coke

= 65 for anthracite

= 63 for Bituminous coal

= 62 for coal tar fuel

= 48 for liquid petroleum fuel

= 32 for natural gas

The formula for K4 is based on the gross calorific value Qgr. To obtain the loss based

on net calorific value multiply by Qgr/Qnet. Since this loss is usually small this

conversion has been ignored. This loss is subtracted from the efficiency.

Oxygen Reference CO(n) = CO x

(20.9 - O

r)

2

(20.9 - O2m)

KANE900 Plus Operators Manual Page 32

Page 34

C. CALCULATION OF FUEL DATA

For any fuel not specified by Kane International the net calorific value, gross calorific

value and composition should be obtained from the fuel supplier.

The following fuel data has been calculated with reference to the efficiency

calculation.

Example 1:

Chemical composition: C 25%

H

H

Q

Q

Max CO

K1n = (255 x % carbon in fuel) / Q

= (255 x 25) / 8350 = 0.763

K1g = (255 x % carbon in fuel) / Qg (kJ/Kg)

= (255 x 25) / 9300 = 0.685

K2 = Max % CO2 = 20.40

K3 = Wet Loss = [(9 x %H2 + %H2O) / 9300] x 2425

= [(9 x 3 + 50) / 9300] x 2425

= (77 / 9300) x 2425 = 20.08

K4 = 65 (an approximation for wood) *

The fuel values to program into the Analyser are as follows:

3%

2

O 50%

2

8.35 MJ/kg

net

9.3 MJ/kg *

g

20.4%

2

(kJ/Kg)

net

NATURAL GAS

K1g

K_2

K_4

* Assumed values in the absence of supplied data. See previous appendix for other

fuels.

KANE900 Plus Operators Manual Page 33

: 0.763

: 20.4

: 65

K1n

K_3

O2r

: 0.685

: 20.08

: 8.0

Page 35

D. ELECTROMAGNETIC COMPATABILITY (CE)

STATEMENT

This product has been tested for

compliance with the following

generic standards:

EN 61000-6-3

EN 61000-6-1

and is certified to be compliant

Specification

EC/EMC/KI/KANE900 Plus details

the specific test configuration,

performance and conditions of use.

Please Note: Batteries used in this instrument should be disposed of in

accordance with current legislation and local guidelines.

KANE900 Plus Operators Manual Page 34

Page 36

KANE900 Plus Operators Manual Page 35

Page 37

Thank you for buying this

instrument.

Before use,

please register on our

website

www.kane.co.uk

KANE900 Plus Operators Manual Page 36

Page 38

CONTENTS

1. ANALYSER LAYOUT AND FEATURES ................................................................................1-4

1.1 Instrument features and keypad .................................................................................1

1.2 Instrument layout (Rear) ............................................................................................ 2

1.3 Standard Probe Configuration....................................................................................3

1.4 Analyser connections ................................................................................................. 4

2. SAFETY WARNING ...................................................................................................................... 5

3. FIRST TIME USE ...........................................................................................................................5

4. NORMAL START UP SEQUENCE..........................................................................................6-12

4.1 Every Time You Use The Analyser........................................................................... 6

4.2 Automatic Calibration................................................................................................ 6

4.3 Main Displays ........................................................................................................... 8

4.3.1 4 Page Mode..................................................................................................... 8

4.3.2 Line Scroll Mode ............................................................................................. 9

4.3.3 8 Page Mode..................................................................................................... 9

4.4 Sampling the Flue Gas ............................................................................................. 10

4.5 Taking a Pressure Reading....................................................................................... 10

4.6 Regular Checks During Sampling............................................................................ 11

4.7 Normal Shutdown Sequence.................................................................................... 11

4.8 Electromagnetic Compatibility ................................................................................ 12

5. MOVING THROUGH THE MENUS......................................................................................13-19

5.1 Basic Operation....................................................................................................... 13

5.2 Menu Options and Settings ..................................................................................... 14

5.2.1 Main Menu................................................................................................... 14

5.2.2 Select Menu.................................................................................................. 14

5.2.3 Units Menu................................................................................................... 16

5.2.4 Display Menu............................................................................................... 17

5.2.5 Set-Up Menu ................................................................................................ 17

6. PRINTING INFORMATION ...................................................................................................20-21

6.1 Printing a ‘Live’ Test .............................................................................................. 20

6.2 Standard Printout..................................................................................................... 21

7. STORING AND RETRIEVING DATA...................................................................................22-23

7.1 Storing a ‘Live’ Test ............................................................................................... 22

7.2 Viewing and Printing a ‘Stored’ Test ..................................................................... 22

7.3 Deleting Data ..........................................................................................................23

Page No:

Page 39

8. AVERAGE OF THREE...........................................................................................................24-25

8.1 Storing ...................................................................................................................... 24

8.2 Viewing .................................................................................................................... 24

8.2 Printing..................................................................................................................... 25

9. MAINTENANCE ..........................................................................................................................26

9.1 Emptying and Cleaning the in-line water trap ......................................................... 26

9.2 Changing the particle filter ...................................................................................... 26

10. PROBLEM SOLVING ................................................................................................................ 27

11. CALIBRATION........................................................................................................................... 27

12. PRODUCT SPECIFICATION ................................................................................................... 28

APPENDICES:

A. MAIN DISPLAY PARAMETERS ............................................................................ 29

B. COMBUSTION EFFICIENCY CALCULATION ................................................... 31

C. CALCULATION OF FUEL DATA.......................................................................... 33

D. ELECTROMAGNETIC COMPATABILITY STATEMENT ................................. 34

Loading...

Loading...