Page 1

K9206

Quintox Flue Gas Analyzer

INSTRUCTION MANUAL

ENGLISH

BATTERY

ENCLOSURE

AF2

AIR FILTER

Kane

International

SF1

WATER

TRAP

PRESSURE

PRESSURE

FLUE GAS ANALYSER

1-800-547-5740 • Fax: (503) 643-6322

www.ueitest.com • Email: info@ueitest.com

Page 2

TABLE OF CONTENTS

K9206 OVERVIEW ..................................................................................................................... 5

Standard features ............................................................................................................ 5

Handset .......................................................................................................................... 5

Main analyzer unit ......................................................................................................... 5

OPTIONS ................................................................................................................................... 6

Electrochemical sensors ................................................................................................. 6

Other options .................................................................................................................. 6

Probe options .................................................................................................................. 6

Spare parts list ............................................................................................................... 6

K9206 WITH KANE LIVE PC SOFTWARE ............................................................................. 7

ANALYZER LAYOUT AND FEATURES .................................................................................. 8

Handset features ............................................................................................................ 8

Analyzer layout ............................................................................................................... 9

Analyzer layout with KMDM220 gas conditioning

Module fitted ................................................................................................................ 10

Typical probe configuration (KMCSP6) ........................................................................ 11

Analyzer connections ................................................................................................... 12

GETTING STARTED ............................................................................................................... 12

Before taking readings ................................................................................................. 12

Menu: all the options ................................................................................................... 13

STATUS: ESTABLISHING THE ANALYZER’S SET-UP ..................................................... 14

SETUP: CONFIGURING THE ANALYZER’S SET-UP ......................................................... 16

Language ...................................................................................................................... 16

Main purge ................................................................................................................... 17

Printer ........................................................................................................................... 17

Auto set time ................................................................................................................ 18

Set time ........................................................................................................................ 18

Set date ........................................................................................................................ 19

Heater status ................................................................................................................ 19

Select analyzer unit serial number .............................................................................. 19

Bluetooth set up ........................................................................................................... 19

Bluetooth passkey ........................................................................................................ 19

ANALYZER UNITS: CONFIGURES ALL THE DATA SOURCES AND SETTINGS .......... 20

Fuel origin ..................................................................................................................... 20

Fuel type ....................................................................................................................... 20

Efficiency ...................................................................................................................... 20

Gas units ....................................................................................................................... 20

Temperature ................................................................................................................. 20

Pressure ........................................................................................................................ 21

Set percentage reference ............................................................................................ 21

Set NOx calculation ..................................................................................................... 21

Conversion factors ........................................................................................................ 21

2

Page 3

TABLE OF CONTENTS

CO ALARM .............................................................................................................................. 22

CO alarm set ................................................................................................................. 22

CO alarm level .............................................................................................................. 22

SCREEN ................................................................................................................................... 22

Contrast ........................................................................................................................ 22

Back light timer ............................................................................................................. 22

Mode ............................................................................................................................ 22

Lines ............................................................................................................................. 23

REPORTS: CONFIGURES REPORTS .................................................................................... 23

View reports ................................................................................................................. 24

Delete all reports ......................................................................................................... 24

Auto log time ................................................................................................................ 24

Start auto log ............................................................................................................... 24

Start auto printing ........................................................................................................ 24

Header 1 ....................................................................................................................... 24

Header 2 ....................................................................................................................... 24

Form feed ...................................................................................................................... 25

Recertification .............................................................................................................. 25

Manual air zero ............................................................................................................ 25

Manual pressure zero .................................................................................................. 25

BEFORE USING THE ANALYZER FOR THE FIRST TIME .................................................. 25

Safety warning ............................................................................................................. 25

First time use ................................................................................................................ 25

NORMAL START UP SEQUENCE ........................................................................................ 26

Every time you use the analyzer .................................................................................. 26

Automatic calibration ................................................................................................... 26

MAIN MEASUREMENT SCREEN ........................................................................................ 27

In small font mode ....................................................................................................... 27

In large font mode ........................................................................................................ 28

SAMPLING THE FLUE GAS .................................................................................................. 30

LONG TERM MONITORING ................................................................................................. 30

KMDM220 GAS CONDITIONING MODULE ....................................................................... 31

Setting up KMDM220 .................................................................................................. 31

MAINTENANCE ..................................................................................................................... 32

Emptying and cleaning the in-line water trap ............................................................. 32

Changing the particle filter .......................................................................................... 32

Charging the battery .................................................................................................... 33

Changing the paper roll ................................................................................................ 33

To start paper feed ....................................................................................................... 33

Changing the printer ribbon ......................................................................................... 33

PROBLEM SOLVING .............................................................................................................. 34

HOW TO GET EXPERT HELP ................................................................................................ 35

END OF LIFE DISPOSAL ....................................................................................................... 35

3

Page 4

TABLE OF CONTENTS

BATTERY DISPOSAL ............................................................................................................. 35

ANNUAL RECERTIFICATION ............................................................................................... 35

RETURNING YOUR ANALYZER ........................................................................................... 35

Packing your analyzer ................................................................................................... 36

Sending your analyzer .................................................................................................. 36

When we receive your analyzer .................................................................................. 36

PRODUCT SPECIFICATION .................................................................................................. 37

Unit ............................................................................................................................... 37

Optional IR module ....................................................................................................... 38

Handset ........................................................................................................................ 38

Extension cable ............................................................................................................ 38

Main battery and optional heater battery ................................................................... 38

Battery charger ............................................................................................................. 39

Pump ............................................................................................................................. 39

Integral printer .............................................................................................................. 39

Ambient operating range ............................................................................................. 39

Heated line: KMHL3000 ............................................................................................... 39

Heated probe: KMHP1200 ........................................................................................... 39

Gas conditioning module: KMDM220 .......................................................................... 39

Probe ............................................................................................................................. 39

Optional portable printers ............................................................................................ 39

APPENDICES .......................................................................................................................... 40

A. PARAMETER MEANINGS ................................................................................... 40

B. NOx CALCULATIONS ........................................................................................... 42

ONLY AN NO SENSOR FITTED ......................................................................... 42

Working in ppm: NOx referenced to NO ............................................................... 42

Working in mg/m3: NOx referenced to NO or NO2 .............................................. 42

Working in mg/m3: referenced to NO ................................................................... 42

Working in mg/m3: NOx referenced to NO2 ......................................................... 42

Normalizing readings ............................................................................................. 42

BOTH NO AND NO2 SENSORS FITTED ........................................................... 43

Working in ppm: NOx = NO + NO2 ....................................................................... 43

Working in mg/m3 ................................................................................................. 43

NOx = SUM ............................................................................................................ 43

NOx = NO ............................................................................................................... 43

NOx = NO2 ............................................................................................................. 43

Normalizing readings ............................................................................................. 43

ONLY AN NO2 SENSOR FITTED ....................................................................... 43

Normalising readings ............................................................................................. 43

HIGH CO PURGE OPERATION ........................................................................... 44

C. COMBUSTION EFFICIENCY CALCULATION ..................................................... 44

D. CALCULATION OF FUEL DATA ........................................................................... 46

E. ELECTROMAGNETIC COMPATIBILITY (CE) STATEMENT ............................. 47

4

Page 5

K9206 OVERVIEW

The K9206 is broadly based on the KM9106 and while retaining many of its core features has been

significantly enhanced. The most visible difference is the large graphical display on the handset. Up to

15 lines of text/data can be displayed. The handset links to the main analyzer unit using Bluetooth or the

normal cable. It also has a USB connector to link to a PC via a cable and has an infrared output to link to

the portable KMIRP printer.

The main analyzer unit also contains significant enhancements over the previous 9106.

STANDARD FEATURES:

• 19301 Battery charger

• 18277 UK mains lead

• 18276 EU mains lead

• 18275 US mains lead

• 17136 Instruction manual

• KANE LIVE software downloadable at www.ueitest.com website

HANDSET: KBHS

• Bluetooth and cable connectivity to analyzer unit.

• Bluetooth and USB connectivity to PC

• GPS location

• IR connectivity to KMIRP and IRP-2 portable printer

• Large data storage memory (64k records)

• Graphical display with choice of large or small fonts.

• Battery rechargeable via main unit or main charger

MAIN ANALYZER UNIT: AS STANDARD K9206/P

• Measures: Oxygen, Ambient temperature, Atmospheric pressure, Inlet temperature

Flue temperature, Differential pressure

• Features: Main purge, Flow control*, NiMh battery packs, Plain paper printer

*Flow control

To compensate for different suction levels in flues, hose lengths and filter contamination levels,

all of which can affect the flow of sample gases, there is an active flow control system fitted

to the K9206.

It operates as follows:

Every time the instrument is turned on and finishes its first fresh air purge cycle from inside

the analyzer, it measures and records the pump pressure just prior to the sensor manifold while

the pump is at 100% flow rate. During service calibration & normal use, the pump speed is

automatically adjusted to 70% of the purge flow rate to maintain consistent flow.

The flow control can cope with typically 100 mbar suction in a flue and still maintain the same

nominal flow as that present under ambient conditions.

5

Page 6

OPTIONS:

ELECTROCHEMICAL SENSORS : (UP TO 5 SENSORS)

CHOOSE FROM:

• KCO1/Q carbon monoxide (H2 compensated)

• KNO1L/Q Nitric oxide (low range)

• KNO1H/Q Nitric oxide (high Range)

• KNO2/Q Nitrogen dioxide

• KSO2L/Q Sulphur dioxide (low range)

• KSO2H/Q Sulphur dioxide (high range)

• KH2S/Q Hydrogen sulphide

OTHER OPTIONS:

• KHSA Heater for toxic sensors

• KHC/Q IR triple bench (CO, HC, CO2)

• KHPUR/Q High/low CO protection (solenoid and pump)

• WTS9206P Pumped water trap

• KMHL3000 Heated line

• KMHP1200 Heated probe

• KMDM110 Gas conditioning module

SPARE PARTS LIST:

• OS11 Oxygen Sensor

• DP12 Printer ribbon (5) and paper (10)

• DP20 Printer paper (20 rolls)

• SF1 Chemical filter

• KMAF2 Particle filter assembly

• PF2/10 Particle filter ten pack

• WN8 Water trap filter pack

• BP9206 Battery pack

• WTS9106 Water trap assembly

• 19403 Peri pump tubing

PROBE OPTIONS:

• SM10617 Probe handle & hose

• 10051 Standard probe shaft

• 15589 2000˚ 12” Probe shaft

• 15588 36” Standard probe shaft

• 15590 2000˚ 36” Probe shaft

6

Page 7

K9206 WITH KANELIVE PC SOFTWARE

KANELIVE is a free download that runs on Windows based PCs and allows live display and graphing of data.

It can be downloaded from the UEi Test Instruments website www.ueitest.com.

• In the current configuration, the handset needs to be connected to the main unit by a cable and the

Bluetooth setting for the handset needs to be changed to TO PC using MENU, SETUP, BLUETOOTH

SETUP.

• Once this has been selected, go to the PC and select MY BLUETOOTH PLACES.

• Click ADD A BLUETOOTH DEVICE.

• All Bluetooth devices within range will be displayed in icon form. The K9206 handset

will be displayed as: K9206HS

• 999999107 where the 9 digit number is the serial number of the handset.

• Double click on this. Now follow the instructions.

• Then enter the passkey: 1111

• Click on the TICK BOX and then AT SERIAL CONFIGURE and then FINISH.

• Now click on KANELIVE to initiate the program.

• Select your analyzer type by clicking on the analyzer name displayed on the middle of the bottom line

of the screen. If more than one analyzer has been enabled a drop down will appear. Click on the

analyzer of your choice.

• Then click CONNECT and wait for its color to change to green.

• Then click START, which will change to green.

• After a few seconds live data will be displayed.

7

Page 8

ANALYZER LAYOUT AND FEATURES

HANDSET FEATURES

PROTECTIVE COVER

GRAPHICAL DISPLAY

PUMP ON/OFF KEY

PRINT KEY

ENTER KEY

ON/OFF KEY

REMOTE LEAD SOCKET

(8 PIN DIN)

INFRARED LED

BATTERY

COMPARTMENT

(BACK)

MENU KEY

STORE KEY

SERIAL USB CONNECTION

SCROLL UP KEY

SCROLL DOWN KEY

8

Page 9

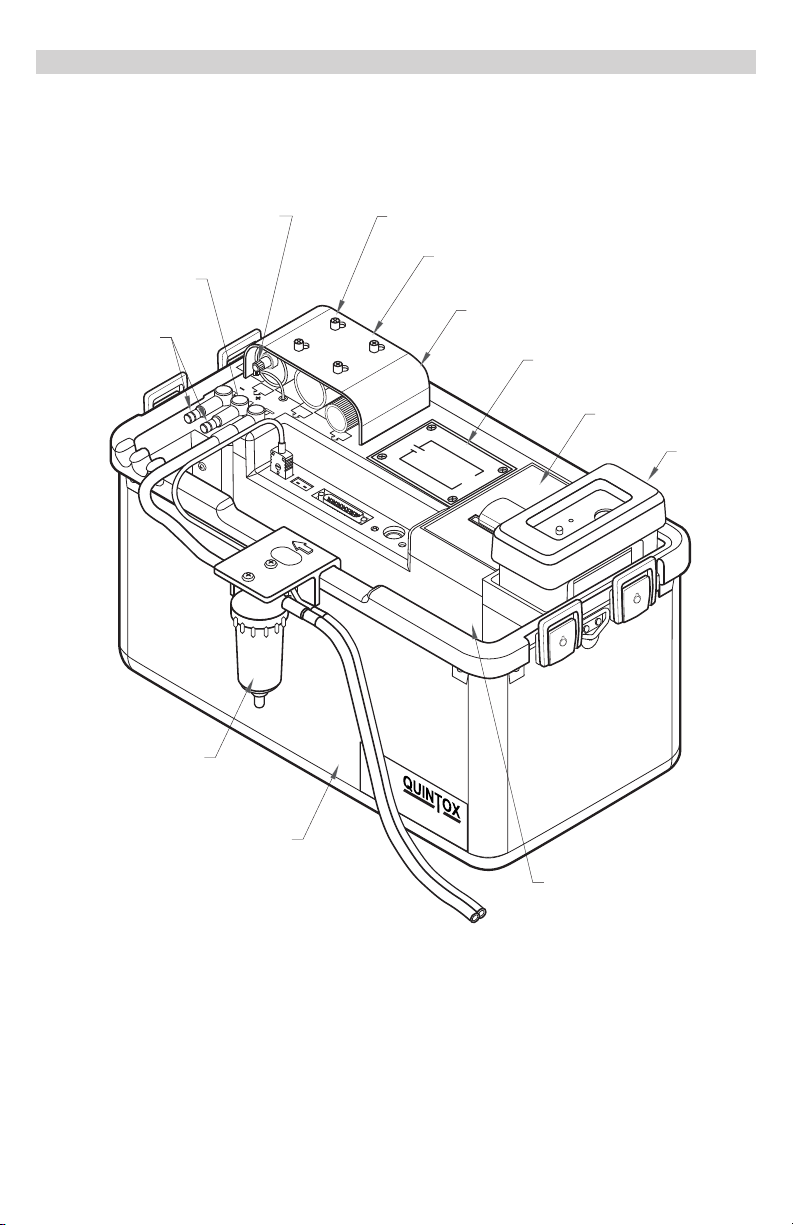

ANALYZER LAYOUT AND FEATURES

ANALYZER LAYOUT

FOR OXYGEN SENSOR

CONNECTION LEAD

FOR OXYGEN SENSOR

PRESSURE / DRAFT

PORTS

WATERTRAP

LOCATED ON SIDE

OF INSTRUMENT

CONNECTION LEAD

PRESSURE PRESSURE

OXYGEN SENSOR

FILTER BRIDGE OR

SULPHUR FILTER

PARTICLE FILTER

Kane

International

SF1

WATER

TRAP

AIR FILTER

AF2

BATTERY

ENCLOSURE

PRINTER UNIT

GAS ANALYSER

BATTERY ENCLOSURE

PRINTER UNIT

HANDSET

(STORED IN

POCKET)

INSTRUMENT CASE

ACCESSORY STORAGE SPACE

(LEADS, WATERTRAP ETC)

9

Page 10

ANALYZER LAYOUT WITH KMDM220 GAS CONDITIONING MODULE FITTED

PARTICLE FILTER

OXYGEN SENSOR

DUAL PRESSURE PORTS

FLUE SOCKET

OXYGEN SENSOR

CONNECTOR

PRINTER UNIT

Kane

International

SF1

WATER

TRAP

PRESSURE

PRESSURE

INLET SOCKET

BATTERY

ENCLOSURE

AF2

AIR FILTER

AUX CONNECTOR

(25 PIN ‘D’)

HEATED LINE

CONNECTION

GAS DRYER

ASSEMBLY

FLUE GAS ANALYSER

INSTRUMENT CASE

WATERTRAP CONNECTION

WATER

TRAP

PRESSUREPRESSURE

ANALYZER ‘ON’ SWITCH

REMOTE HANDSET

CONNECTION

(8 PIN DIN)

BATTERY

ENCLOSURE

CHARGER INPUT SOCKET

RED POWER LED

10

REMOTE HANDSET CONNECTION

(8 PIN DIN)

Page 11

TYPICAL PROBE CONFIGURATION (KMCP6)

THERMOCOUPLE CONNECTION (FLUE)

Kane

PRESSURE PRESSURE

International

SF1

WATER

TRAP

AIR FILTER

AF2

SOCKET FOR

OPTIONAL AIR INLET

TEMPERATURE PROBE

BATTERY

ENCLOSURE

PRINTER UNIT

DEPTH STOP CONE

PROBE HANDLE

11

GAS ANALYSER

WATERTRAP LOCATED

ON SPIGOT IN CASE

PROBE GAS CONNECTION

TO WATERTRAP

Page 12

ANALYZER CONNECTIONS

AUX CONNECTOR (25 PIN ‘D’)

INLET TEMPERATURE SOCKET

FLUE TEMPERATURE SOCKET

OXYGEN SENSOR

CONNECTOR

PRESSUREPRESSURE

DUAL PRESSURE

PORTS

ANALYSER ‘ON’ SWITCH

REMOTE HANDSET CONNECTION

(8 PIN DIN)

RED POWER LED

CHARGER INPUT SOCKET

BATTERY

ENCLOSURE

WATER

TRAP

PRINTER UNIT

HANDSET REMOTE CONNECTION

(8 PIN DIN)

GETTING STARTED

• Check that you have all the items you have ordered.

• Before attempting to use the analyzer to take readings it is recommended that the batteries be fully

charged.

• When the charger is connected to the analyzer and powered up the red LED by the charger socket

will flash until the batteries are fully charged. Once the batteries are fully charged the LED will no

longer be illuminated.

• To charge the handset; connect the handset to the main analyzer unit using its cable.

While switched off, but charging, the display will show the Kane logo and a battery charging icon

in the bottom right hand corner of the handset screen.

Note: The handset battery is charged via the external battery charger and not from the analyzer’s

internal battery. Once the handset battery is fully charged the icon will disappear from the screen.

The handset can also be charged directly using the main charger as used for the analyzer.

12

Page 13

BEFORE TAKING READINGS

You need to establish the current set up of the analyzer and then you can customize to suit your testing

needs.

Press the MENU key and then select STATUS as described below.

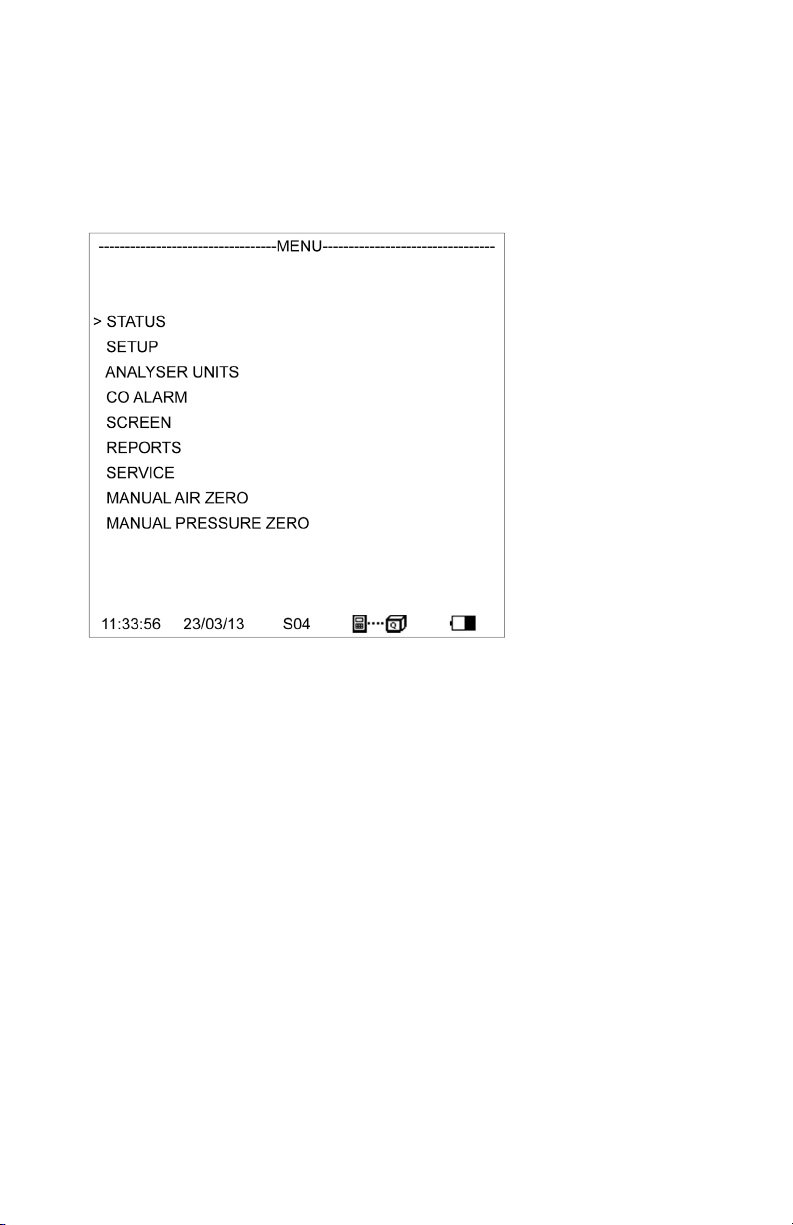

MENU: ALL THE OPTIONS

• Press the MENU key.

The > symbol acts as the cursor. It can be moved up or down by pressing the UP or DOWN keys.

Having made a selection press the ENTER key.

The bottom line of this screen lists:

• the time

• the date

• the number of satellites being received

• the Bluetooth connection status

• the estimated charge in the handset battery

13

Page 14

STATUS: ESTABLISHING THE ANALYZER’S SET-UP

Press MENU and then select STATUS by pressing ENTER.

This screen lists :

• the software version in the handset

• the handset serial number

• the analyzer unit software version number

• the analyzer unit serial number

• the estimated charge in the main battery

• the estimated charge in the heater battery (if fitted)

• the number of days before annual re-calibration is due

14

Page 15

Press DOWN to move to the next screen.

• Press DOWN to move to the next screen.

• Press DOWN to move back to the first screen.

• Press PRINT to print this status on the analyzer’s printer.

• Press MENU to EXIT.

15

Page 16

SETUP: CONFIGURING THE ANALYZER’S SETUP

LANGUAGE:

• Align cursor using UP or DOWN keys, then press ENTER.

• Use UP or DOWN keys to scroll through the selection.

• Press ENTER to select.

16

Page 17

MAIN PURGE:

• AUTO PURGE: Set YES or NO

• AUTO PURGE DURATION TIME: Set fresh air purge duration to between 2 and 30 minutes.

• MAIN PURGE INTERVAL TIME : Set the interval between fresh air purges to between 10 and 120

minutes.

• AUTO ZERO CAL: Set YES or NO to automatically re-zero sensors at the end of a

main purge cycle.

• AUTO PUMP FLOW: Set YES or NO to automatically control the pump flow. This may

be required for some regulatory test protocols.

After switch on, the first purge interval is automatically set to 10 minutes if the optional IR module is

fitted. Changes in the purge interval are implemented after completion of the next purge cycle. To

implement a change immediately perform a “MANUAL AIR ZERO”.

PRINTER:

This sets the destination for outputs from the handset.

The choices of outputs are:

• KMIRP

• IRP-2

• ANALYZER PRINTER

• SERIAL

• BLUETOOTH

Use UP or DOWN keys to scroll through the selection. Press ENTER to select,

17

Page 18

AUTO SET TIME:

This function is locked if reports have been stored. To allow the function to operate, delete the reports. This

allows the time to be set automatically from the GPS signals. Select NO to maintain manual setting.

Use UP or DOWN keys to scroll through the selection. Press ENTER to select,

SET TIME:

This function is locked off if “AUTO SET TIME” is activated or reports have been logged. If this function is

locked, delete the reports.

If manual setting is enabled use UP or DOWN keys to change values.

Press ENTER to select.

18

Page 19

SET DATE:

This function can only be set manually, not by GPS.

If this function is locked, delete the reports.

If manual setting is enabled use UP or DOWN keys to change values.

Press ENTER to select.

HEATER STATUS:

Switch off heaters or operate automatically.

Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

SELECT ANALYZER UNIT SERIAL NUMBER:

If more than one analyzer unit is within Bluetooth range the handset needs to be set to communicate with

the correct unit.

Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

BLUETOOTH SET UP:

The handset can communicate with an analyzer unit or a PC. Bluetooth can also be switched off and a cable

can be used.

Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

BLUETOOTH PASSKEY:

This confirms the Passkey setting.

The Bluetooth Passkey is 1111.

19

Page 20

ANALYZER UNITS:

CONFIGURES ALL THE DATA SOURCES AND SETTINGS

FUEL ORIGIN:

Select from a list of country specific fuel tables.

•

Use UP or DOWN keys to scroll through the selection. Press ENTER to select,

•

FUEL TYPE:

Select from the list of fuel types associated with the chosen origin. The K values for the

•

selected fuel are also shown.

Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

•

There are 5 User Fuels that can be loaded from a PC. The title of these user fuels can be edited

•

using the keypad on the handset.

Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

•

EFFICIENCY:

Select NET or GROSS, condensing net, condensing gross efficiency calculation

•

Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

•

GAS UNITS:

Select ppm or ppmn or mg/m3 or mg/m3n.

•

Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

•

TEMPERATURE:

Allows the selection of Fahrenheit or Celsius.

•

Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

•

20

Page 21

PRESSURE:

Allows the selection of pressure units.

•

Select from: mbar, In H2O, mm H2O, hPa, psi.

•

Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

•

SET PERCENTAGE REFERENCE O2:

Can be set between 0% (equivalent to OFF) and 10%.

•

Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

•

SET NOx CALCULATION:

• Select from: SUM, NO2 or NO

• Set REFERENCE NOx to the percentage required or defined by local regulations.

Typically 5% NO2 is added to an NO reading. The value can be user set.

• SUM adds the readings from an NO sensor and an NO2 sensor when fitted

• NO calculates an NOx reading from the NO reading where NOx = NO x 1.1

NO2 calculates an NOx reading from the NO2 reading where NOx = NO2 x 2.05

• Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

CONVERSION FACTORS:

Display the Propane Equivalency Factor PEF and the Methane Equivalency Factor for the IR module

(if fitted) and the pitot factor – change from 0.10 to 1.00 as determined by the pitot tube being used.

CO ALARM:

21

Page 22

CO ALARM SET:

• Switch the alarm ON or OFF.

• Use UP or DOWN keys to scroll through the selection. Press ENTER to select.

CO ALARM LEVEL:

• Allows a specific CO level in ppm to be set as the alarm trigger point.

• Use UP or DOWN keys to change the digits. Press ENTER to select and move to the next digit.

• The display will show ‘++++’ when the CO alarm is triggered.

SCREEN:

The screen display is fully configurable.

CONTRAST:

• Allows the display to be darkened or lightened. Default value is 14.

• Use UP or DOWN keys to change the digits. Press ENTER to select and move to the next digit.

B’LIGHT:

• The switch off time for the backlight can be set for between 30 and 300 seconds,

• Use UP or DOWN keys to change the digits. Press ENTER to select and move to the next digit.

• During normal measurements press ENTER to switch the backlight on.

MODE:

• The main display can be set for SMALL font or LARGE font.

22

Page 23

LINES:

• This feature allows users to customize the screen display to suit their own requirements.

• Use UP or DOWN keys to change the selection. Press ENTER to select and move to the next digit.

• So for Lines 1-6, the screen shows:

• The parameter to be displayed on each line can be individually selected.

• Use UP or DOWN keys to change the selection. Press ENTER to select and move to the next digit.

REPORTS: CONFIGURES REPORTS

23

Page 24

VIEW REPORTS:

• This selection displays a ‘main screen’ with a LOG number near the top left hand of the display.

• This number can be changed using UP or DOWN and the display automatically changes.

DELETE ALL REPORTS:

• All reports can be deleted. A confirmation YES is required.

• Use UP or DOWN keys to scroll through the selection. Press ENTER to select,

AUTO LOG TIME:

• Automatic logging/printing can be selected for intervals between 10 seconds and 90 minutes.

• Use UP or DOWN keys to scroll through the selection. Press ENTER to select,

START AUTO LOG:

• Select YES or NO.

• Use UP or DOWN keys to scroll through the selection. Press ENTER to select,

START AUTO PRINTING:

• Select YES or NO.

• Use UP or DOWN keys to scroll through the selection. Press ENTER to select,

HEADER 1: 16 CHARACTERS

• Allows the printed header line: YOUR COMPANY to be changed.

• Use UP or DOWN keys to change the characters. Press ENTER to select and move to

the next character.

HEADER 2: 16 CHARACTERS

• Allows the printed header line: NAME & PHONE number to be changed.

• Use UP or DOWN keys to change the characters. Press ENTER to select and move to

the next character.

24

Page 25

FORM FEED:

• Allows remote paper feeding on printers.

RECERTIFICATION:

• CODE: For use by authorized service agents.

• CAL DATE = number of days before annual recertification is due.

MANUAL AIR ZERO:

• Select this and press ENTER to initiate a fresh air purge and sensor zeroing

MANUAL PRESSURE ZERO:

• Select this and press ENTER to re-zero the pressure sensor

BEFORE USING THE ANALYZER FOR THE FIRST TIME.

SAFETY WARNING

This analyzer extracts combustion gases that may be toxic in relatively low concentrations. These gases are

exhausted from the bottom of the instrument. This instrument must only be used in well-ventilated locations.

It must only be used by trained and competent persons after due consideration of all the potential hazards.

FIRST TIME USE

Charge the batteries for 12 hours; following this an overnight charge should be sufficient for an average

8-hour day. There may be three battery packs that need charging, the main battery, the optional heater battery and the handset battery. The handset battery can use the same charger as the analyzer unit or can be

charged via the main unit using a handset lead. All batteries are NiMh.

• While charging the red LED will flash.

• We offer a wide choice of probes, which are not supplied as standard and must be ordered as a

separate item.

• Take time to read this manual fully.

TIP: Take a look at the Spare Parts list and order some replacement filters and paper rolls now.

25

Page 26

NORMAL START UP SEQUENCE

EVERY TIME YOU USE THE ANALYZER

BEFORE SWITCH-ON CHECK THAT:

• the oxygen sensor is connected

• the particle filter is not dirty

• the sulphur filter is fitted for heavy oil or coal

• the water trap and probe line are empty of water

• all hose connections, etc, are properly made

• the paper roll is fitted

• the analyzer unit is in fresh air

• the water trap is vertical

• the flue temperature is connected

• the instrument is placed on a clean, flat, level surface

Switch ON the analyzer by pressing ON/OFF on the handset. You also need to press the ON/OFF

switch on the analyzer main unit.

AUTOMATIC CALIBRATION

• During this sequence the analyzer pumps fresh air into the sensors to allow toxic sensors to be set to

zero and the oxygen sensor to be set to 20.9 %.

• During this sequence the handset display will show the following:

Note: The software version number and serial number are examples only.

26

Page 27

If there is no Bluetooth communication between the handset and the main unit the

following will appear on the screen.

• Press ENTER to continue and follow the instructions.

• Once Bluetooth communication is established the main measurement screen will appear.

MAIN MEASUREMENT SCREEN

IN SMALL FONT MODE

27

Page 28

• TOP LINE: shows status messages

• GASES: O2 and CO2 are shown in % other gases shown in ppm or other user selected

units CO can be shown in % if optional IR bench is fitted

• TEMPERATURES: displayed in C or F. N\F = not fitted

---- occurs for calculations when N\F applies

---- occurs when a calculation cannot be made due to an out of range value (Eg zero)

• Atmospheric pressure (ATM) is always displayed in mbar.

IN LARGE FONT MODE

There are 5 screens that are accessed using the UP or DOWN keys

28

Page 29

29

Page 30

SAMPLING THE FLUE GAS

Once the automatic calibration procedure has been completed and the specific fuel has been selected the

probe can be inserted into the desired sampling point.

It is recommended that the sampling point be located at least two flue diameters downstream of any bend

and that the probe tip is in the center of the flue (this is normally the point of the hottest temperature).

With balanced flues and other industrial units the probe should be positioned far enough into the flue so

that no air can ‘back flush’ into the probe.

The probe depth stop cone provided with the instrument allows the probe to be used in holes whose

diameters range from 8 mm to 21 mm (5/16 to 4/5 inch).

The standard probe is rated at 650°C/1202°F. Temperatures of up to 100°C/2012°F can be accommodated

using an optional high temperature probe.

TIP: To conserve battery power, switch off the pump when you are not taking a measurement. Use the

pump key to turn the pump ON and OFF.

LONG TERM MONITORING

There are a number of things that need to be considered for successful long term

unattended monitoring:

• The provision of enough power for the duration of the test

• The capability to empty the water trap

• Regular fresh air purging of the sensors

• Protection from rain or water spray from the process being monitored.

If a mains power source is being used it is strongly recommended that the supply cable be protected by a suitable Residual Current Device (RCD).

Unless the water trap is to be regularly inspected then a pumped water trap should be fitted.

Electrochemical sensors need regular refreshing with fresh air, preferably at around 50% RH. They also

need a small percentage of oxygen to be present in the sampled gas. If there is zero oxygen the output

from the sensors will decay over time (10 minutes or so). In such circumstances, fresh air purge should be

programmed for a 50% duty cycle every 10 minutes.

The longest sampling time without purging should be limited to 2 hours and then purge for 30 minutes.

When the KHC infrared module is fitted, for maximum accuracy it is recommended that purging occur

every 30 minutes.

30

Page 31

KMDM220 GAS CONDITIONING MODULE

This module is fitted in the front compartment of a standard K9206 carry case and comprises a Peltier fan

cooled chiller assembly, a peristaltic pump to automatically remove condensate, the control electronics

and a power supply module. The module is supported on an aluminum alloy chassis.

The chiller is connected to a flue mounted electrically heated probe (KMHP1200) by a 9.8 foot long heated

line with automatic temperature control (KMHL3000). Because the gas that is extracted from the flue is

maintained at 248°F no condensation occurs in the probe or the hose and so no sample gas is lost in the

condensate. The chiller flash cools the sample gas to below the ambient dew point and any water in the

gas immediately condenses. The condensate is then pumped away using a peristaltic pump. Because the

gas has no chance to remain in contact with the condensate, volatile sample gas is not lost into the condensate. The chilled gas then naturally warms up as it passes through the sampling pump to the sensors

and as it does so its humidity reduces and there is no risk of further condensation.

SETTING UP KMDM220

The heated sample probe must be connected to the top of the heated line and a gas tight connection

be made without over tightening the connections. This joint must then be thermally insulated. Both the

heated probe and the heated line must be connected to a mains power source via a suitable Residual

Current Device (RCD) and be left powered up for 20 minutes to achieve their operating temperature before

attempting to extract sample gas.

When the probe is inserted into the sampling point is must be suitably supported to prevent bending and

unnecessary strain. Likewise the heated line should be carefully supported and never be twisted or kinked

as this may damage the internal heating elements.

The heated line is connected to the chiller by attaching the end of the line to the through bulkhead connection in the K9206 carry case. A short flexible connection then links the hose to the chiller. The chiller

needs to be powered up for at least 10 minutes before it is used.

The peristaltic pump operates automatically. Always check that the drain of the peristaltic pump is clear

and that there are no blockages. The peristaltic pump needs to have its flexible rotor replaced after every

1000 hours of operation.

To operate efficiently the chiller needs to be well ventilated so the case lid must be removed, however

the unit must be protected externally to prevent ingress of water from either the plant being tested or

from rainfall.

31

Page 32

MAINTENANCE

EMPTYING AND CLEANING THE IN-LINE WATER TRAP

The water trap should be checked and emptied on a regular basis. Water vapor will condense in the probe

line, which may cause the water trap to fill beyond the maximum level mark. If this occurs water could be

drawn into the analyzer causing damage. Care should be taken at all times to avoid this risk.

Emptying of the water trap is detailed below:

Carefully remove the end cap from the in-line housing. Dispose of the condensate in a suitable drain; care

must be taken, as it could be acidic. If condensate spills onto the skin or clothing, clean off immediately

using fresh water and seek medical advice if problems occur.

CHANGING THE PARTICLE FILTER

This is a very important part of the analyzer and should be changed regularly. It prevents dust and dirty

particles entering the pump and sensors and hence causing damage. The filter MUST be changed when it

appears discolored.

Remove the end cap from the filter housing. Carefully remove the paper filter element and dispose of it.

Clean the inside of the filter housing with a suitable soft cloth. Insert a new filter element onto the spigot

on the filter end cap and carefully insert it into the filter body.

32

Page 33

CHARGING THE BATTERY

It is important that the battery is charged on a regular basis. The instrument constantly powers the internal sensors and may discharge the battery if left unattended for serveral months. Connect the charger

supplied with the instrument to the correct mains supply.

Note: The correct charger type may be required for your local voltage i.e. 110 or 220volts AC.

Insert the plug in the socket marked CHARGER INPUT SOCKET

The CHARGER ON RED LED will flash showing the instrument is charging.

CHANGING THE PAPER ROLL

To change the paper roll, remove the printer cover by loosening the two screws holding it down. Remove

the old paper roll core and insert the new roll so that it sits as follows:

Feed the free end of paper into the printer through the metal slot beneath the printer ribbon. Start the

paper feed sequence until the paper has emerged from the top of the printer, feed the loose end through

the cover and refit.

TO START PAPER FEED

Go to MENU, REPORTS, FORM FEED

CHANGING THE PRINTER RIBBON

The printer ribbon cartridge will last for approximately two rolls of paper. Remove the printer cover as

detailed above.

Marked on one end of the cartridge is PUSH. Gently press down on this end and the ribbon cartridge will

pop up at the other end. Remove the cartridge and dispose of.

33

Page 34

Fit a new ribbon guiding the paper roll between the exposed ribbon and cartridge body.

PROBLEM SOLVING

The following is a list of problems that may occur on the instrument through its operating life. If the

cause of the fault is not easy to identify then we advise you to contact the Kane International Service

Department or an International Distributor for expert advice.

Fault symptom Causes

Oxygen too high

CO2 too low

Analyzer not holding charge

Analyzer not charging

Analyzer does not respond to flue gas Particle filter blocked.

Flue temperature readings erratic Temperature plug reversed in socket.

Analyzer automatically switches off in operation. Battery below alarm level.

Display is blank. The contrast setting has been lost and requires

Air leaking into probe, tubing, water trap,

connectors or internal to instrument.

Oxygen cell needs replacing.

Battery exhausted.

AC charger not giving correct output.

Fuse blown in charger plug.

Probe or tubing blocked.

Pump not working or damaged with contaminants.

Faulty connection or break in cable or plug.

Battery quickly discharging and is faulty.

resetting. Disconnect handset lead and reconnect.

Set contrast as in MENU : SCREEN : CONTRAST

34

Page 35

HOW TO GET EXPERT HELP

There will be occasions when despite having read the manual there will be problems that you cannot

resolve and so you need external help.

Before calling UEi Test Instruments please check the following first:

Find the serial number of the instrument. It is located on the label close to where the charger and handset

leads plug into the analyzer. Also make a note of which sensors are fitted by observing the tick marks on

the instrument label.

If the handset and analyzer are operating you can also determine the issue of software loaded in the

analyzer and its handset by viewing STATUS. If you can, take a printout of STATUS and a printout of the

measurement screen so that they can be faxed or emailed to your technical support advisor.

END OF LIFE DISPOSAL

The Waste Electrical or Electronic Equipment (WEEE) Directive requires countries in the EU to maximize

collection and environmentally responsible processing of these items.

Products are now labeled with a crossed out wheeled bin symbol to remind you that they can be recycled.

BATTERY DISPOSAL

All the user replaceable batteries used in this product are NiMh and are suitable for recycling through any

local waste portable battery recycling scheme.

ANNUAL RECERTIFICATION

Although sensor life is typically more than five years, the monitor should be re-calibrated and serviced

annually to help prevent any long-term sensor drift or accidental damage.

Local regulations may require more frequent re-calibration.

In the USA, UEi Test Instruments has recertification facilities at Beaverton, OR and Indianapolis, IN.

RETURNING YOUR ANALYZER TO UEi

When returning your K9206, contact customer service at 800-547-5740 or fill out our service request form

at www.ueitest.com.

Please always ensure that you enclose:

• Your full contact details

• A daytime telephone number

• Details of faults you might have experienced

• Any relevant accessories (eg. Probe, printer, adaptor and leak detectors). Any accessories that are

returned will be checked. If an accessory has failed then we will quote you for a repair or a

replacement.

35

Page 36

PACKING YOUR ANALYZER

When returning your analyzer, please pack it appropriately to prevent any damage during transit.

Before sealing your package, please ensure that you have enclosed the items listed above and that it is

clearly marked for the attention of:

WWW.UEITEST.COM

PORTLAND, OR

Headquarters

Recertification Center

1-800-547-5740

info@ueitest.com

SENDING YOUR ANALYZER

Once the analyzer has been securely packed then your package is ready for shipment back to UEi Test

Instruments. If you do not have an account with a courier company you can take your package to your

local Post Office. It is advisable to send the package by Special Delivery so that it is insured and traceable

while in transit.

WHEN WE RECEIVE YOUR ANALYZER

On receipt of your package, our Service Engineers will inspect the analyzer and any accessories and

confirm to you the total service cost. Once you have accepted this, the work will be carried out, and upon

completion the analyzer returned to you.

INDIANAPOLIS, IN

Recertification Center

1-800-547-5740

info@ueitest.com

VANCOUVER, BC

Recertification Center

ISO/IEC 17025:2005

NIST Certification

1-877-475-0648

infocanada@ueitest.com

If you have any questions that we haven’t answered, please contact UEi:

1-800-547-5740 • FAX: (503) 643-6322

www.ueitest.com • Email: info@ueitest.com

36

Page 37

PRODUCT SPECIFICATION

UNIT

Temp Measurement Resolution Accuracy Range

Flue Temperature 0.1° (C/F) 1.0°C ± 0.3% of reading 0 - 1100°C

32 - 2140°F

* Use high temperature probe

for gases >600°C/1112°F

Inlet Temperature 0.1° (C/F) 1.0°C ± 0.3% of reading 0 - 600°C

0 - 999°F

Gas Measurement

*1

Resolution Accuracy Range

Oxygen (02): 0.1% -0.1% +0.2% 02 0- 25%

Carbon monoxide (CO):

(standard: H compensated)

1ppm ± 5ppm < 100ppm

5% of reading < 2000ppm

0 - 10,000ppm

± 10% of reading >2000ppm

Nitric oxide (NO):

(high range)

Nitric oxide (NO):

(low range)

Nitrogen dioxide (NO2): 1ppm ± 5ppm < 100ppm

1ppm ± 5ppm < 100ppm

± 5% of reading > 100ppm

1ppm ± 2ppm < 30ppm

± 5ppm > 30ppm

0 - 5,000ppm

0 - 100ppm

0 - 1,000ppm

± 10ppm < 500ppm

± 5% of reading > 500ppm

Sulphur dioxide (SO2)

(low range):

Sulphur dioxide (SO2)

(high range):

Hydrogen sulphide: 1 ppm ± 5ppm < 100ppm

1ppm ± 2ppm < 30ppm

± 5ppm > 30ppm

1ppm ± 5ppm < 100ppm

± 5% of reading > 100ppm

0 - 100ppm

0 - 5,000ppm

0 - 1,000ppm

± 5% of reading > 100ppm

Pressure: 0.01mbar ± 0.5% Full scale 0 - 150mbar

Carbon dioxide (CO2)

Efficiency

*1

using dry test gases at STP

*2

calculated

*2

: 0.1% ± 1% 0 - 100%

*2

: 0.1% ± 0.3% CO2 0 - Fuel Value

NB: all ppm reading can be displayed in mg/m3 and can be normalized

37

Page 38

OPTIONAL IR MODULE

Hydrocarbons:

Range: Overrange Accuracy Resolution

0-5,000ppm 10,000ppm +5% of reading and + 12ppm vol. 1ppm

CO2:

Range: Overrange Accuracy Resolution

0-20% 40% +5% of reading and + 0.5% vol. 0.1%

CO:

Range: Overrange Accuracy Resolution

0-10% 20% +5% of reading and + 0.2% vol. <30% 0.1%

Response time T90: 30 seconds

Warm up time: 3 minutes

Operating temperature range: 5 to 50 deg. C.

Operating humidity: 10-80% non condensing

Power: Supplied by K9206

Conversion Factors from a Propane Calibration

Propane multiply by 1

Methane multiply by 0.1

Hexane multiply by 2

HANDSET

Dimensions 8.66” long (220mm long)

4.72” high (120mm high)

1.96” wide (50mm wide)

Keypad tactile keys

Display graphical with backlight and contrast control

EXTENSION CABLE

Specification: 8 pin DIN cable

Cable lengths: 16’ Standard 32’-65’-Optional

MAIN BATTERY AND OPTIONAL HEATER BATTERY

Type: NiMH Rechargeable (12V, 2AH)

Life: 8 hours from full charge

Charge time: 12 hours trickle 4 hours fast charge

38

Page 39

BATTERY CHARGER

Input: 100V-240V AC 60 watts

Output: 15V DC @ 4 amps

PUMP

Flow rate: 2 Liters/Minute nominal 500 mbar static suction

INTEGRAL PRINTER

• 16 character dot matrix.

• Plain paper

AMBIENT OPERATING RANGE

• -10°C to + 55°C

• < 85% RH non condensing

• Storage: -10°C to 55°C

HEATED LINE: KMHL3000

• Power supply: 220V ac @ maximum 300 watts

HEATED PROBE: KMHP1200

• Power supply: 220V ac @ maximum 100 watts

• 1200mm insertion length, 8 mm diameter rated to 1000 o C

GAS CONDITIONING MODULE: KMDM220

• Power supply: 220 Vac @ 5 amps peak.

PROBE

• Choose from a range of probe options. See probe website.

OPTIONAL PORTABLE PRINTERS

• Compatible with KMIRP and IRP-2

39

Page 40

APPENDICES

A – PARAMETER MEANINGS

The parameters and their meanings are detailed as follows : -

• DATE : Analyzer date.

• TIME : Analyzer time.

• MAIN BATTERY/ Displays the battery level from 0-100%. The analyzer will flash

HEATER BATTERY: RECHARGE BATTERY at less than 10 % of charge. The analyzer

may show levels greater than 100% when the charger is connected.

• ----- : Displayed when a calculation cannot be performed because a probe is not

fitted or a parameter is out of range.

• FUEL : The fuel used in calculation of efficiency and carbon dioxide.

• K1g: Gross calorific fuel constant. See Appendix for calculation.

• K1n : Gross calorific fuel constant. See Appendix for calculation.

• K2 : Percentage Maximum theoretical CO2 (dry basis).

• K3: Percentage wet loss.

• K4 : Percentage unburnt carbon loss.

• O2r : Toxic gas measurements can be referenced to defined oxygen levels.

Oxygen referencing is required by some regulations such as TALUFT. If a

reference value is selected the toxic gas measurements will be displayed with

the symbol n attached to the units. i.e. ppmn

What does oxygen reference mean?

If 3 % O2 reference is selected and 5 % O2 is measured in the flue then toxic

gas values will be recalculated as if 3 % were measured. The equation for

referencing is detailed in the Appendix. Oxygen referencing prevents false

readings being submitted, e.g. allowing more air into the boiler will increase

the oxygen level in the flue and hence dilute any toxic gas reading. Oxygen

referencing gives readings as if they were undiluted.

• NETT : Nett temperature calculated by deducting the internal AMBIENT temperature

from the measured FLUE temperature. Displays in either Centigrade C or

Fahrenheit F and will display NOT FITTED if flue probe not connected.

If an external INLET probe is used then INLET is deducted from FLUE.

• O2 : Oxygen reading in percentage %.

• CO : Carbon monoxide reading indicated in ppm or mg/m3. If the figures

are referenced to oxygen then the display will show ppmn or mg/m3n. Note

with a high CO sensor fitted the reading will be displayed in percentage %.

EFF (G) : Combustion Efficiency calculation displayed in percentage. Gross (G)

or Net (N) can be set. The calculation is determined by fuel type see

Appendix for calculation. The efficiency is displayed during a combustion test,

00.0 is displayed while in fresh air.

• CO2: Carbon dioxide reading in percentage % when measured, not calculated

• CO2c: Carbon dioxide calculation determined by the type of fuel. This only shows a

reading when a combustion test is being carried out. Zero (0.0) is displayed

while in fresh air.

40

Page 41

• FLUE : Temperature measured by flue gas probe in Centigrade or Fahrenheit. Will

show ambient temperature after fresh air calibration and N\F if probe

disconnected.

• INLET : Temperature measured by the optional inlet air probe or stored using the Flue

probe. The air probe is plugged into the instrument through the INLET socket.

This figure is used to calculate the NET temperature instead of AMBIENT

when fitted. Will show N\F if not fitted.

• AMBIENT : Temperature measured by the internal sensor, used in the NET temperature

• CO/CO2 R : The CO/CO2 ratio, is the ratio of measured CO divided by CO2.

It gives an indication of the following :- How good a gas sample the instrument

is reading. How clean the boiler is running. For example : A new or clean

domestic boiler will display a ratio of less than 0.004, a unit in need of cleaning

0.0040-0.0080 and a unit in need of major overhaul will show greater than

0.008. This only shows a reading when a combustion test is being carried out.

0.0000 is displayed while in fresh air.

• P INDEX : The CO/CO2 ratio expressed as a percentage %, called the ‘Poison Index”

i.e. P INDEX % = 100 x CO/CO2. 0.00 is displayed while in fresh air.

• XAIR % : Excess air calculated from the measured oxygen and type of fuel used.

Displays reading during a combustion test +++ is displayed while in fresh air.

• PRESSURE: Pressure reading. Units can be changed to different scales.

• NO: Nitric oxide reading in ppm or mg/m3. Displayed when nitric oxide sensor

fitted. Reading can also be referenced to oxygen ppmn or mg/m3n.

• NO2: Nitrogen dioxide reading in ppm or mg/m3. Displayed when nitrogen dioxide

sensor fitted. Reading can also be referenced to oxygen ppmn or mg/m3n.

• NOx : Calculated total nitric oxides displayed in ppm or mg/m3.

Reading can also be referenced to oxygen ppmn or mg/m3n.

• SO2 : Sulphur dioxide reading in ppm or mg/m3. Displayed when sulphur dioxide

sensor fitted. Reading can also be referenced to oxygen ppmn or mg/m3n.

• H2S: Hydrogen sulphide reading in ppm or mg/m3. Displayed when Hydrogen

sulphide fitted. Reading can also be referenced to oxygen ppmn or mg/m3n.

• HC : Unburnt Hydrocarbon reading in % of LEL of methane, the sensor is calibrated

with methane. Displayed when a Hydrocarbon sensor fitted.

LEL is the Lower Explosive Limit of a gas when mixed with air, for methane

this has the ratio of 19:1 Air:methane. Below the LEL the mixture can not

ignite and burn. In the Flue an unburnt Hydrocarbons should be well below

this level or there is the potential for an explosion.

• LOSS : Total losses calculated from Combustion Theory. This is the summation of the

next three parameters.

• DRY : Calculated heat lost in turning the carbon in the fuel to carbon dioxide (CO2).

• WET : Calculated heat lost in turning the hydrogen in the fuel into water (H2O).

• CO LOSS % : Calculated loss due to partially burnt carbon. Any carbon monoxide (CO) in the

flue has the potential to be turned into carbon dioxide and release more heat,

hence this heat is lost up the flue.

• GPS (Y): Latitude DDMM.MMM 5148.1060

• GPS (X): Longitude DDDMM.MMM -00011.450

• ATM: Atmospheric pressure in mbar

41

Page 42

B. NOx CALCULATIONS

ONLY AN NO SENSOR FITTED

• WORKING IN PPM: NOx REFERENCED TO NO

The user can select the assumed NO2 percentage and the O2 normalized level then: NOx in ppm = NO in

ppm multiplied by (1 + assumed NO2 percentage) in this setup NOx can only be displayed as NOx = NO

then normalizing:

NO in ppmn = NO in ppm multiplied by (21 minus the O2 norm setting) and then divided by (21 minus the

actual O2 reading)

For a worked example assume:

NO is 1000ppm

NO2 is 5% of NO

O2norm is set to 3%

actual O2 is zero

NOx in ppm = 1000 x (1 +5/100) =1000 x1.05 = 1050 ppm

NO ppmn = 1000 x (21 - 3)/(21-0) = 1000 x 18 / 21 = 857 ppmn

NOx ppmn = 1050 x 18 / 21 = 900 ppmn

or

NOx ppmn = 857 x 1.05 = 900 ppmn

• WORKING IN MG/M3: NOx REFERENCED TO NO OR NO2

The user can select the assumed NO2 percentage, the O2 reference level and whether the NOx reading is

referenced to NO or NO2

• WORKING IN MG/M3: REFERENCED TO NO

NO in mg/m3 = NO in ppm multiplied by 1.34

NOx in mg/m3 = NO in mg/m3 multiplied by (1 + assumed NO2 percentage)

• WORKING IN MG/M3: NOx REFERENCED TO NO2

NOx in mg/m3 = NO in ppm multiplied by 2.05 multiplied by (1 + assumed NO2 percentage)

or

NOx in mg/m3 = NO in mg/m3 divided by 1.34, multiplied by 2.05 and multiplied by (1 +assumed NO2

percentage)

• NORMALIZING READINGS

normalized reading = initial reading multiplied by (21 minus the O2norm setting) and then divided by (21

minus the actual O2 reading)

42

Page 43

BOTH NO AND NO2 SENSORS FITTED

• WORKING IN PPM: NOx = NO + NO2

normalizing readings

ppmn = initial reading in ppm multiplied by (21 minus the O2 norm setting) and then divided by (21 minus

the actual O2 reading)

• WORKING IN MG/M3

The user can select how the readings are referenced.

NOx = SUM

NOx = NO

NOx = NO2

• NOx = SUM

NOx in mg/m3 = NO in ppm multiplied by 1.34 plus NO2 in ppm multiplied by 2.05

• NOx = NO

NOx in mg/m3 = (NO in ppm plus NO2 in ppm) multiplied by 1.34

• NOx = NO2

NOx in mg/m3 = (NO in ppm plus NO2 in ppm) multiplied by 2.05

• NORMALIZING READINGS

ppmn = initial reading in ppm multiplied by (21 minus the O2norm setting) and then divided by (21 minus

the actual O2 reading)

mg/m3n = initial reading in mg/m3 multiplied by (21 minus the O2norm setting) and then divided by (21

minus the actual O2 reading)

ONLY AN NO2 SENSOR FITTED

When there is only an NO2 sensor fitted the NOx function is disabled

NO2 in mg/m3 = NO2 in ppm multiplied by 2.05

• NORMALIZING READINGS

ppmn = initial reading in ppm multiplied by (21 minus the O2norm setting) and then divided by (21 minus

the actual O2 reading)

mg/m3n = initial reading in mg/m3 multiplied by (21 minus the O2norm setting) and then divided by (21

minus the actual O2 reading)

43

Page 44

HIGH CO PURGE OPERATION

If there is a requirement to measure CO to concentrations above 10,000ppm then a High Purge module

should be fitted (this comprises both a purge pump and a solenoid) in addition to the IR triple gas bench.

When the electrochemical sensor’s reading passes 9800ppm the solenoid operates and the high purge

pump switches on and pumps fresh air across the electrochemical CO sensor. The displayed reading

changes at this point from ppm to % as measured by the IR module.

When the reading from the IR module falls below 0.95% the solenoid is deactivated and the high purge

pump stopped. After a short time the displayed reading will revert to ppm. There may be a small perturbation in readings at the point of changeover.

C. COMBUSTION EFFICIENCY CALCULATION

The efficiency calculation is based upon British Standard BS845.

This identifies three sources of loss associated with fuel burning:

• LOSSES DUE TO FLUE GASSES: Dry Flue gas loss,

Moisture and hydrogen

Sensible heat of water vapor

Unburned gas

• LOSSES DUE TO REFUSE: Combustible in ash

Combustible in riddlings

Combustible in dust

• OTHER LOSSES: Radiation

Convection

Conduction

Other unmeasured losses

Net efficiency calculations assume that the energy contained in the water vapor (formed as a product of

combustion and from wet fuel) is recovered and the wet loss term is zero. Gross efficiency calculations

assume that the energy contained in the water vapor is not recovered.

Since the fuel air mixture is never consistent there is the possibility of unburned/partially unburned fuel

passing through the flue. This is represented by the unburned carbon loss.

Losses due to combustible matter in ashes, riddlings, dust and grit, radiation, convection and conduction

are not included.

44

Page 45

EFFICIENCY CALCULATION:

• KNOWN DATA Fuel: Qgr = Gross Calorific Value (kJ/kg)

Qnet = Net Calorific Value (kJ/kg)

K1 = Constant based on Gross or Net Calorific Value:

K1g = ( 255 x %carbon in fuel )/Qgr

K1n = ( 255 x %carbon in fuel )/Qnet

K2 = % max theoretical CO2 (dry basis)

K3 = % Wet Loss

• MEASURED DATA: Tf = Flue Temperature

Ti = Inlet Temperature

O2m = % Oxygen in flue gas

• CALCULATED DATA: Tnet = Net Temperature

% CO2 content in flue gas

% Dry Flue Gas losses

% Wet losses

% Unburned carbon loss

% Efficiency

%CO2 = (20.9 - %O2m) x K2 / 20.9

Tnet = Flue Temperature - Inlet Temperature

Dry flue gas loss = 20.9 x K1n x (Tnet) / K2 x (20.9 - %O2m)

Wet loss = 9 x %H2 + %H2O / Qgr x [2488 + 2.1Tf - 4.2 Ti]

Simplified = [(9 x %H2 + %H2O) / Qgr] x 2425 x [1 + 0.001 Tnet]

Wet loss = K3(1+0.001xTnet)

Where K3 = [(9 x %H2 + %H2O) / Qgr] x 2425

Net Efficiency = 100% - dry flue gas losses

= 100% - 20.9 x K1n x (Tnet) / K2 x (20.9 - % O2m)

Gross Efficiency = 100% - {dry flue gas losses + wet losses}

= 100% - [20.9 x K1g x (Tnet) / K2 x (20.9 - %O2m)] + [K3 x (1 + 0.001 x Tnett)]

Excess Air = [(20.9% / (20.9% - 02m%)) – 1] x 100%

CO2% = [(20.9% - O2m%) x K2% / 20.9%]

Unburned fuel Loss = K4 x CO% / ( CO% + CO2% )

Where K4 = 70 for coke

= 65 for anthracite

= 63 for Bituminous coal

= 62 for coal tar fuel

= 48 for liquid petroleum fuel

= 32 for natural gas

The formula for K4 is based on the gross calorific value Qgr. To obtain the loss based on net calorific

value multiply by Qgr/Qnet. Since this loss is usually small this conversion has been ignored.

45

Page 46

OXYGEN REFERENCE

CO(n) = CO x (20.9 - O2r)

(20.9 - O2m)

D. CALCULATION OF FUEL DATA

For any fuel not specified by Kane International the net calorific value, gross calorific value and composition should be obtained from the fuel supplier.

The following fuel data has been calculated with reference to the efficiency calculation.

Example 1:

Chemical composition: C 25%

H2 3%

H2O 50%

Qnet 8.35 MJ/kg

Qg 9.3 MJ/kg *

Max CO2 20.4%

K1n = (255 x % carbon in fuel) / Qnet (kJ/Kg)

= (255 x 25) / 8350 = 0.763

K1g = (255 x % carbon in fuel) / Qg (kJ/Kg)

= (255 x 25) / 9300 = 0.685

K2 = Max % CO2 = 20.40

K3 = Wet Loss = [(9 x %H2 + %H2O) / 9300] x 2425

= [(9 x 3 + 50) / 9300] x 2425

= (77 / 9300) x 2425 = 20.08

K4 = 65 (an approximation for wood) *

The fuel values to program into the Analyzer are as follows:

NATURAL GAS

K1g : 0.763 K1n : 0.685

K_2 : 20.4 K_3 : 20.08

K_4 : 65 O2r : 8.0

* Assumed values in the absence of supplied data. See previous appendix for other fuels.

46

Page 47

E. ELECTROMAGNETIC COMPATIBILITY (CE) STATEMENT

This product has been tested for compliance with the following

generic standards:

EN 61000-6-3 : 2011

EN 61000-6-1 : 2007

and is certified to be compliant.

Specification

EC/EMC/KI/K9206 details the specific test configuration, performance and conditions of use.

SAFETY STANDARD

This product complies with the EN61010 Safety Standard (Safety requirements for

electrical equipment for measurement, control and laboratory use):

EN61010-1 : 2010

Protection Class 3 (SELV)

47

Page 48

K9206

Quintox Flue Gas Analyzer

Limited Warranty

The K9206 is warranted to be free from defects in materials and workmanship for a period

of one year from the date of purchase. If within the warranty period your instrument should

become inoperative from such defects, the unit will be repaired or replaced at UEi’s option.

This warranty covers normal use and does not cover damage which occurs in shipment or

failure which results from alteration, tampering, accident, misuse, abuse, neglect or improper

maintenance. Batteries and consequential damage resulting from failed batteries are not covered by warranty. Annual calibration is not covered as a warranty item.

Any implied warranties, including but not limited to implied warranties of merchantability and

fitness for a particular purpose, are limited to the express warranty. UEi shall not be liable

for loss of use of the instrument or other incidental or consequential damages, expenses, or

economic loss, or for any claim or claims for such damage, expenses or economic loss. A purchase receipt or other proof of original purchase date will be required before warranty repairs

will be rendered. Instruments out of warranty will be repaired (when repairable) for a service

charge.

For more information on warranty and service:

1-800-547-5740 • FAX: (503) 643-6322

www.ueitest.com • Email: info@ueitest.com

This warranty gives you specific legal rights. You may also have other rights which vary from

state to state.

Para la versión en español de este manual por favor visite www.ueitest.com

Pour une version française du manuel de l'utilisateur s'il vous plaît visitez www.ueitest.com

PLEASE

RECYCLE

Copyright © 2015 UEi. All Rights Reserved

17136 04/15

Loading...

Loading...