TYM

OPERATOR’S MANUAL

FOR

TRACTORS

(T454HST/T554HST)

DaeYong B/D, 7, Eonju-ro 133-gil, Gangnam-gu, Seoul, Korea ■TEL: 82-2-3014-2800, FAX:82-2-3014-2852 ■www.tym.co.kr

1

YANMAR LIMITED WARRANTY

What is Covered by this Warranty?

YANMAR warrants to the original retail purchaser that a new YANMAR T NV common r ail series industrial

engine will be free from defects in material and/or workmanship for the duration of the warranty period.

Note: YANMAR engines may be equipped with external components including, but not limited to: wiring

harnesses, electrical devices, control panels, radiator, air filters, fuel/or exhaust systems that are supplied

and/or installed b y manufac tur e r s other tha n YANM AR. For warranty informatio n on such exte r nal

components, please contact the machine or component manufacturer directly or see your authorized

YANMAR dealer or distributor.

This warranty is provided in lieu of all other warranties, express or implied. YANMAR sp ecifically d isclaims

any implied warranties of merchantability or fitness for a particular purpose, except where such disclaimer

is prohibited by law. If such disclaimer is prohibited by law, then implied warranties shall be limited in

duration to the life of the express warranty.

How Long is the Warranty Period?

The YANMAR standard limited warranty period runs for a period of twenty-four (24) months or

two-thousand(2000) engine operation hours, whichever occurs first. An extended limited warranty of

thirty-six(36) mont hs or thre e t hous and ( 30 0 0 ) e ngine o p e ra ting ho ur s, whiche ver occur s fir st, is pro vid e d

for these specific parts only: the cylinder block, cylinder head, crankshaft forging, connecting rods,

flywheel, flywheel housing, camshaft, timing gear, and gear case. The warranty period for both the

Standard limited warranty and the extended limited warranty (by duration or operation hours) begins on the

date of delivery to the original retail purchaser and is valid only until the applicable warranted duration has

passed or the operation hours are exceeded, whichever comes first.

YANMAR

WARRANTIES

2

YANMAR limited warranty- continued

What the Engine Owner must Do:

If you believe your YANMAR engine has experienced a failure due to a defect in material and/or workmanship, your must contact an authorized

YANMAR industrial engine dealer or distributor within thirty (30) Day s of discov e ri ng the failure, You must provide proof of ownership of the engine ,

proof of the date of the engine purchase and delivery, and documentation of the engine operation hours. Acceptable forms of proof of delivery date

include, but ar e not limited to: the original war ra nt y registrat ion of sales receipts or other docume nt s maintained in the ordinary course of business by

YANMAR dealers and/or dis t r ibut ors , indicating the date of del iv ery of the YANMAR product to the orig ina l r e ta i l purc ha s e r , This information is

necessary to establish whether the YANMAR product is still within the wa r r a nty period. Thus, YANMAR strongly recomm e nds you register your

engine as soon as possible after purchase in order to facilitate any future warranty matters.

You are responsible for the transportation of the engine to and from the repair loca t ion a s des ignated by YANMAR.

To Locate an Authorized YANMAR Industrial Engine Dealer or Distributor:

You can locate your nearest authorized YANMAR industrial engine dealer or distributor by visiting the YANMAR Co,. Ltd. Website at:

http://www.yanmar.co.jp (The Japanese language page will be displayed.) For English lan guage “click” on “English Page.”)

● “click” on “Network” in the website heading to vies the “Yanmar Worldwide Network.”

● Choose and “Click” on the desired product group.

● “Click” on the Icon closest to your region.

● “Click” on the desired country or associate company to locate your nearest authorized YANMAR Industrial engine dealer or distributor.

You may also contac t YANMAR by clicking on “Inquiry” in the w e bs i te heading and typing in your question

or comme nt .

What Y ANMAR will DO:

YANMAR warrants to the original retail purchaser of a new YANMAR engine that YANMAR will make such repairs and/or replacements at

YANMAR ’s option, of any part(s) of the YANMAR product covered by this warranty found to be defective in material and/or w or kmanship. Such

repairs and/or replacements will be made at a location designated by YANMAR at no cost to the purchaser for parts or labor.

3

This warranty does not cover parts affected by or damaged by ant reason other than defective materials or workmanship, including, bur not

limited to, accident, misuse, abuse, “Acts of God,” neglect, improper installation, improper maintenance, improper storage, the use of

unsuitable attachments or parts, the use of contaminated fuels, the use of fuels, oils, lubricants, or fluids other than those recommended in your

YANMAR Operation M a nua l, una ut hori z e d a l terations or modifica t ions , ordina r y wear and tear, and rust or corrosion. This warranty does not

cover the cost of parts a nd/or labor required to perform normal/sc he dule d maintenance on your YANM AR engine. This wa rr a nt y does not

cover consum a ble parts such as, but not limited to, f il te r s , bel ts , hoses, fuel injector, lubricants and cleaning fluids. T hi s warranty

does not cover the cos t of shipping the product to or form the warra nty repair fac i li ty.

Warranty Limitations:

The foregoing is YANMAR’s only obligation to you and your exclusive remedy for breach of Warranty. F ailure to follow the

requirements for sub mitting a claim under this warranty may result in a waiver of all claims for damages and other relief.

In no event shall YA NMAR or any authorized Industrial eng i ne deal er or di st ri butor be liable for i nci dent al , spe ci al o r cons equential

damages.

Such consequential damages may include, but not be limited to, loss of revenue, loan payments, cost of rental of substitute equipment,

insurance cov e r a ge, storage, lodging, transpor ta t ion, fuel mileage, and telephone c os ts . The limitations in this wa r r a nty apply regardless of

whether your clai ms are based on breach of contract, tor t( i nc ludi ng negligence and stric t lia bil it y) or any other theory. Any action arising

hereunder must be brought within one (1) yea r aft e r the cause of ac ti on a c c r ue s or it sha ll be bar r e d. S ome states and countries do not allow

certain limitations on warranties or for breach of warranties.

This warranty gives you specific legal rights, and you may also have other rights which vary form st ate to state and country to country.

Limitations set forth in this paragraph shall not apply to the extent that they are prohibited by law.

Warranty Modifications:

Except as modified in writing and signed by the parties, this warranty is and shall remain the complete and exclusive agreement between the

parties with respect to warranties, superseding all prior agreements, written and oral, and all other communications between the parties relating

to warranties. No person or entity is authorized to give any other warranty or to assume any other obligation on behalf of YANMAR,

either orally or in writing.

Questions:

If you have any questions or concerns regarding this warranty, please call or write to the nearest

authorized Y ANMAR industrial engine deal e r or distri butor or other authorized fa c i li ty.

YANMAR limited warranty- continued

What is no Covered by this Warranty?

EMISSION SYSTEM WARRANTY

YANMAR CO., LTD. LIMITED EMISSION CONTROL SYSTEM

WARRANTY – USA ONLY

Your Warranty Rights and Obligations:

■

California

The California Air Resources Board (CARB), the Environmental Protection Agency (EPA) and YANMAR Co,. Ltd. hereafter referred to as

YANMAR, are pleased to explain the emission control system warranty on your industrial compres sion-ig nition engine. In California,

model year 2000 or later off-road compression-igniti on e ng i ne s m us t be designed, built and equipped to meet the state’s stringent anti-smog

standards. In a ll sta tes, 1998 and later non-road compre ss ion-ig nition e ngi nes mus t be designed, built and equippe d to me et the United States EPA

emissions standa rds . Y ANMAR warrants the emissi on contr ol s ystem on your engine for the periods of time listed below provided there has been no

abuse, neglect or improper maintenance of your engine.

Your emission contr ol s ystem may include parts such as the fuel injection system, the air induction s ystem, the electronic control system ,

EGR(Exhaust Gas Recirculation) system and Diesel Particulate Filter. Also included may be hoses, belts, connectors and other emission-related

assemblies.

Where a warrantable condition exists, YANMAR will repair your non-rod compres sion-ignition engine at no charge to you including

diagnosis, par ts a nd l a bor .

Manufacturer’s Warranty Period:

The model year 1998 or later certified and labeled non-roa d com pr es sion-ignition engines are warranted for the periods listed below.

If any emission-related part on your engine is found to be defective during the applicable warranty period, the part will be replaced by YANMAR.

If your engine i s

certified as

And its maximum

Power is

And its rated speed

is

Then its warranty period is

Variable speed or

Constant speed

kW<19 Any speed 1,500 hours or two (2) years whichever comes first. In the absence of a device to

measure t he hours of use, The eng ine has a warranty period of two( 2) years.

Constant speed 19 ≤ kW < 37 3,000rpm or higher 1,500 hours or two (2) years w hic hever comes fir s t. In the absence of a device to

measure t he hours of use, The eng ine has a warranty period of two( 2) years/

Constant speed 19 ≤ kW <37 Less than 3,000rpm 3,00hours of five (5) years whichever comes first. In the absence of a device to

measure t he hours of use, the Engine has a warranty period of five(5) years.

Variable speed 19 ≤ kW <37 Any speed 3,000 hours or five (5) years whichever comes first. In the absence of a device to

measure the hour s of use, the eng ine has a w arr anty per iod o f five (5) y e ar s.

Variable speed or

Constant spee d

kW ≥ 37 Any speed 3,000 hours or (5) years whichever comes fir s t. In the absence of a device to

measure t he hours of use, The eng ine has a warranty period of five (5) years.

4

5

Limited emission control system warranty – USA only – continued

Warranty Coverage:

This warranty is transferable to each subsequent purchaser for the duration of the warranty period. Repair or replacement of any warranted part

will be performed at an authorized YANMAR industrial engine dealer or distributor.

Warranted parts no t scheduled for replacement as required maintenance in the operation manual shall be warranted for the warranty period.

Warranted parts scheduled for replacement as required maintenance i n the operation manual are warranted for the period of time prior to the first

scheduled replacement. Any part repaired or replaced under warranty shall be warranted for the remaining warranty period.

During the warranty period, YANMAR is liable for damages to other engine components caused by the failure of any warranted part during the

warranty period.

Any replacement part which is functionally identical to the original equipment part in all respects may be used in the maintenance or repair of

your engine, and s ha ll not r e duc e YANMAR’s warranty obligati ons . Add-on or modified parts that are not e x e mpted may not be used, The use of

any non-exempted add-on or modified parts shall be grounds for disallowing a warranty.

Warranted Parts:

This warranty covers engine components that are a part of the emission control system of the engine as Delivered by YANMAR to the original

retail purchase r , S uc h c omponents may include the fol lowing:

● Fuel injection system

● Electronic control system

● Cold start enrichment system

● Intake manifold

●Turbocharger systems

● Exhaust ma ni fold

● EGR system

● Positive crankcase ventilation system

● Hoses, belts, connectors and assemblies associated with emission control systems

● Exhaust gas after treatment (Diesel Par ticu lat e Filter (DPF)

Since emissions-related parts may vary sli ghtly between models, certain models may not cont ain all of These parts and other models may contain

the functional e quivalents.

6

Limited emission control system warranty – USA only – continued

Exclusions:

Failures other tha n t hos e a r is i ng f rom defects in material and/or w orkmanship are not covered by this warranty. The warranty does not extend to

the following: malfunctions caused by abuse, misuse, improper Adjustment, modification, alteration, tampering, disconnection, improper or

inadequate m a i nte nance or use Of non-recommended fuels and lubricating oils; accident-caused damage, and replacement of expendable

Items made in connecti on with scheduled maintena nc e . YA N M AR disclaims any respons i bil it y for Incidental or consequent ial damages such as

loss of time, inconvenience, loss of use of equipment/engine Or commercial loss.

Owner’s Warranty Responsibilities:

As the engine owner, you are responsible for the performance of the required maintenance listed in Your owner’s manual.

YANMAR recommends that you retain all documentation, including receipts, covering maintenance on your non-road compression-ignition

engine, but YA N M AR cannot deny War r a nty solely for the lack of receipts, or f or your f a i lur e to ens ur e the pe r formance of all scheduled

maintenance.

YANMAR may deny your warranty coverage of your non-road compres sion-ignition engine if a part has Faile d due to a bus e , neg l e c t, improper

maintenance or unapproved modifications. Your engine is designed to operate on diesel fuel only. Use of any other fuel may result in your engine

no Longer operati ng i n c ompliance with applicable emissions requirements.

You are responsible for initiating the warranty process. You must present your engine to a YANMAR dealer As soon as a problem exists. The

warranty repairs should be completed by the dealer as expeditiously as Possible. If you have any questions regarding your warranty rights and

responsibilitie s , or would like Informa t ion on the ne a r e s t YA NM AR dealer or authoriz e d s e r vice center, you should contact Y ANMAR

America Corporation.

Website: (www.yanmar.com)

E-mail: CS support@yanmar.com

Toll free telephone number: 1-800-872-2867, 1-855-416-7091

7

FOREWARD

Thank you very much for purchasing our tractor, which, we feel sure, will give you many years of troubling the service.

The introduction in this manual set out the correct manner of operating, maintaining and checking the tractor to ensure long-term durability.

Please ensure correct operation of the tracto r as incorrect operatio n can cause substanti al mechanical damage as well as cau se accidents with the

associated inju r ies.

Please note that in some cases differences can exist between this manual and your tractor due to the manufacture’s policy of constant product

improvement.

In the event that you strike a problem not covered by this manual please contact your nearest dealer who will assist you in resolving your

problem.

WARNING

CALIFORNIA Proposition 65 Warning

The Engine Exhaust from this product contains chemicals known to the state of California to cause cancer,birth

defects or other r e pr oduc ti v e harm

WARNING SIGNS IN THIS MANUAL

The following warning signs in this manual draw additional attention to items of importance for the safe and correct operation of the tractor.

SIGN MEANING OF THE SIGN

Serious hazard with a very high level of risk of either serious injury or death.

Hazard or unsafe practi ce that can lead to severe i njury or death.

Hazard or unsafe practi ce that can lead in inj ury or death.

Instructions for the correct operation of the machine which, if followed, will ensure that it performs at it’s best.

All information,illustrations and specifications in this manual are based on latest information available at the time of publication.The right is

reserved to make changes at any time without notice.

Danger

Warning

Important

Caution

8

CONTENTS

1. Tractor Identification -------------------------------------------------------------------------------------------------------------------

2. About this manual ----------------------------------------------------------------------------------------------------------------------

3. Introduction & Description -------------------------------------------------------------------------------------------------------------

4. Owner assistance ------------------------------------------------------------------------------------------------------------------------

5. ROPS (Roll over protection structures) -----------------------------------------------------------------------------------------------

6. Safety instructions, Do’s & Don’ts ---------------------------------------------------------------------------------------------------

7. Safety signs -------------------------------------------------------------------------------------------------------------------------------

8. Universal symbols -----------------------------------------------------------------------------------------------------------------------

Section A

9. Controls, Instruments & Operations --------------------------------------------------------------------------------------------------

Section B

10. Lubrication & maintenance ----------------------------------------------------------------------------------------------------------

Section C

11. CABIN ------------------------------------------------------------------------------------------------------------------------------

Sr. No. Description Page No.

10

11

12~14

15

16~19

20~35

36~39

40~41

42~77

78~104

105~118

CONTENTS

Section D

12. Specifications -----------------------------------------------------------------------------------------------------------------------

13. Fuel saving Tips ---------------------------------------------------------------------------------------------------------------------

14. Fault tracing ----------------------------------------------------------------------------------------------------------------------

15. Wiring Diagram --------------------------------------------------------------------------------------------------------------------

16. Power train -------------------------------------------------------------------------------------------------------------------------

17. Tractor history card -------------------------------------------------------------------------------------------------------------------

18. Service record -----------------------------------------------------------------------------------------------------------------------

19. Daily operating Log -----------------------------------------------------------------------------------------------------------------

20. Part replacement record -------------------------------------------------------------------------------------------------------------

119~124

125~126

127~130

131~137

138

139

140

141

142

9

All information, illustrations and specifications in this manual are ba sed on latest information a vailable at the time of publication.

The right is reserved to make changes at any time without notice.

Sr. No. Description Page No.

10

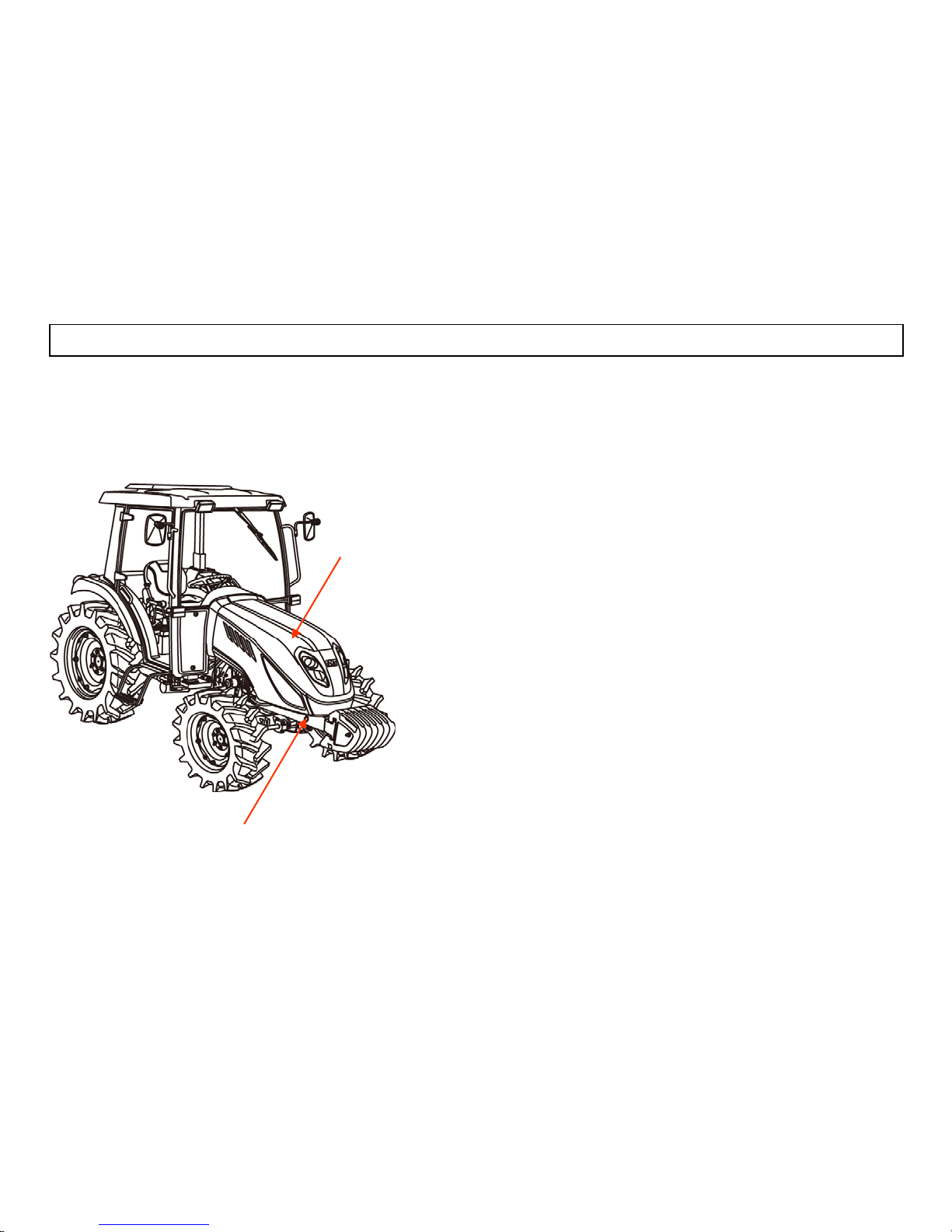

TRACTOR IDENTIFICATIO N

The engine number is stamped on the left hand side of the engine block.

The chassis number is shown on the left hand side of the tractor as shown in the drawing.

Illustration A

WARRANTY OF THE PRODUCT.

The manufacturer warrants this product and full details of

the warranty are provided on a separate

warranty schedule.

SERVICE.

Service is available from any TYM dealer in the country.

PARTS.

To obtain spare parts please contact your nearest dealer

and give him the details listed below.

Tractor model

Tractor serial number

Tractor engine number

Part number and description

Quantity required.

Stamped position of the chassis number

Stamped position

of the Engine type

or Number

11

ABOUT THIS MANUAL

This manual has been prepared to assist you in following/adopting the correct procedure for running-in operation and maintenance

of your new Tong Yang Moolsan CO.,LTD (Here in after refer to TYM) Tractor.

Your Tractor has been designed and built to give maximum performance, with good fuel economy and ease of operation under a

wide variety of operating conditions. Prior to delivery, The tractor was carefully inspected, both at the factory and by your TYM

Dealer/Distributor, to ensure that it reaches you in optimum conditions .To maintain this condition and ensure trouble free

performance. it is important that the routine services, as specified in this manual, are carried out at the recommended intervals.

Read this Manual carefully and keep it in a convenient place for future reference. If at any time you require advice concerning

your Tractor, do not hesitate to contact your Authorized TYM dealer/Distributor. He has trained personnel, genuine parts and

necessary equipments to undertake all your service requirements.

Manufacturer’s policy is one of continuous improvement, and the right to change prices, specifications or equipments at any time

without notice is reserved.

All data given in this book is subject to production variations. Dimensions & weight are approximate only and the illustrations do

not necessarily show Tractors in standard condition. For exact information about any particular Tractor, please consult your TYM

dealer/Distributor.

12

INTRODUCTION & DESCRIPTION

TRACTOR AN INTRODUCTION

The word, ’Tractor’ has been derived from ‘Traction’ which means pulling.

A Tractor is required to pull or haul an equipment, implement or trolley which are coupled to the Tractor body through suitable linkage.

A Tractor can also be used as a prime mover as it has a power outlet source which is also called Power Take or PTO shaft.

In this book the operating, maintenance and storage instructions for all models of TYM Diesel Tractors has been complied.

This material has been prepared in detail to help you in the better understanding of maintenance and efficient operation of the machine.

If you need any information not given in this manual, or require the services of a trained mechanic, please get in touch with the

TYM Dealer/Distributor in your locality. Dealer/Distributors are kept informed of the latest methods of servicing Tractors.

They stock genuine spare parts and are backed by the Company’s full support.

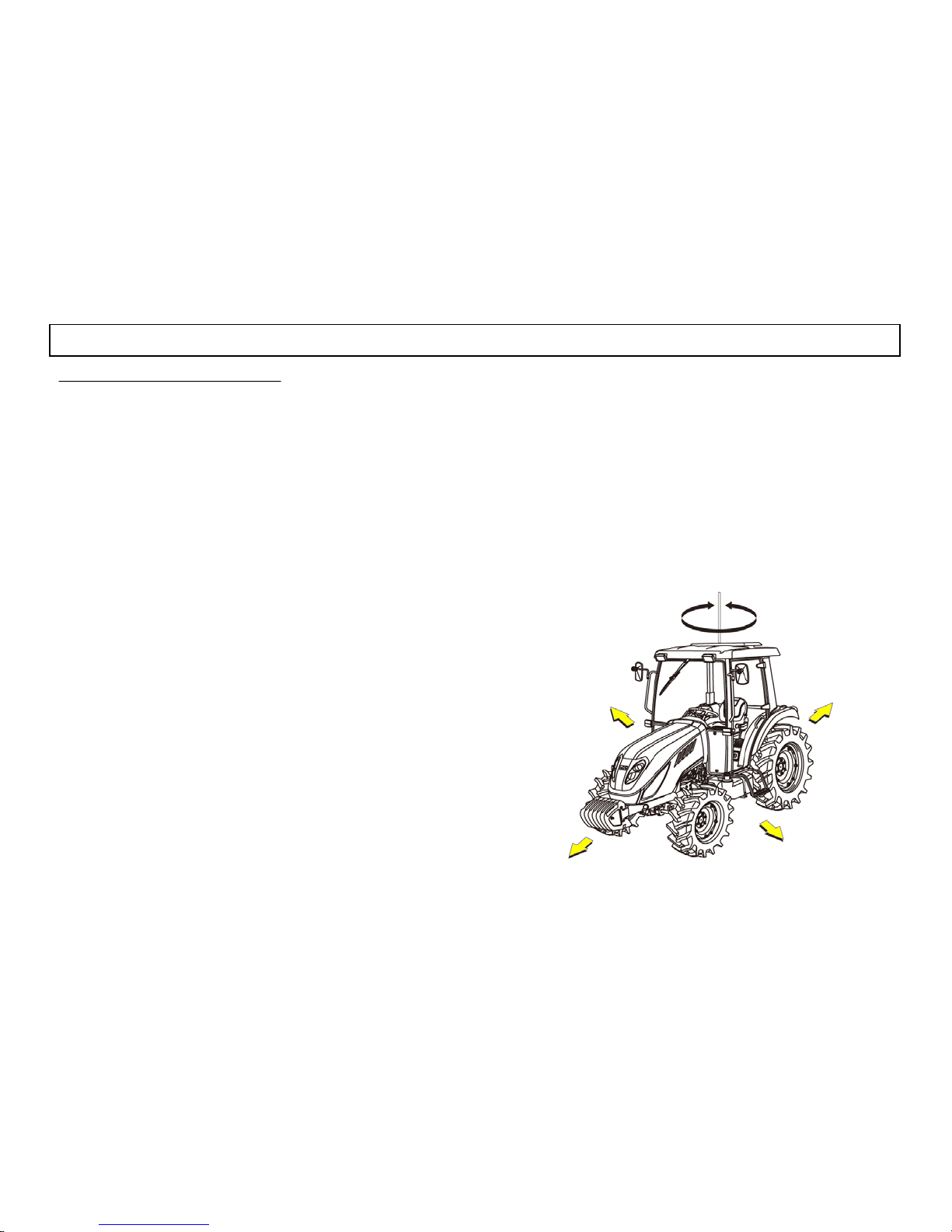

Through thi s manual. The use of the terms LEFT, RIGHT, FRONT

and REAR must be unders tood, to avoid any confusion when

following the intr o d uct io ns. T he LEFT and RIGHT means left and

right sides of the Tractor when facing forward in the driver’s seat,

Reference to the FRONT indicates the radiator end of the Tractor,

while the REAR, indicates the drawbar end ( illustration B)

When spare parts are required, always specify the Tractor and

engine serial number when ordering these parts.(See illustration

A).This will facilitate faster delivery and help ensure that the

correct parts for your particular Tractor is received. The tractor

serial number is punched on a plate attached to the left hand side of

the engine body (illust.A) ,For easy reference, we suggest you to

write the number in the space provided in the owner’s personal

data.

LEFT

RIGHT

FRONT

REAR

RIGHT TURN

(CLOCK WISE)

LEFT TURN

(COUNTER

CLOCK WISE)

illustration B

( Front, Rear,Left,Right Portion)

13

DESCRIPTION

■ General construction

The transmission case, Clutch, Clutch housing, Engine and Front Axle Support are bolted together to form a

rigid unit

■ Front Axle & Wheels

The 4WD front axle is a center-pivot, reverse Eliot t ype. The front wheel drive mechanism is incorporated

as a part of the axle.

The front wheel drive power is taken off the rear transmission and transmitted to the differential in the front

axle where the power is divided into right and left and to the respective final cases.

In the final cases, the transmitted revolution is reduced by the level gears to drive the front wheel. The 4WD

mechanism wit h level gears provides wider s teeri ng and great er durabilit y.

■ Engine

The tractors are fitted with fuel efficient engine with 4 cylinders manufactured by Perkins

■ Hydrostatic Transmission

The Tractor is fitted with servo controlled HST with three ranges and can be selected range by lever. The

tractor has two pedals for speed and forward/reverse control. Tractor with Independent Power Take Off is

fitted with electro – hydraulic clutch Assy .

14

■ Brakes

TYM tractors are provided with independent disc brakes operated by two road travel. A foot brake lever is

fitted for parking.

■ Rear axle & Wheels

This is mounted on ball bearings and is enclosed in removable housi ng which are bolted to the transmission

case. The rim & Disc fitted wi t h Rear ti res are bo lt ed t o the o ut er flan ge o f Rear Axle.

■ Hydraulic system & Linkages.

TYM Tractors are fitted with Live (i.e. system is in operation even when clutch is disengaged.) independent,

very touch of hydraulic System.

Three point Linkages can be used for Category 1 type (USA), or Category 2 type (EU) of implements.

■ Steering

It consists of Hydrostatic Power steering system, which has a hydraulic cylinder and tandem type hydraulic

pump

■ Electrical System

A 12 Volt Lead Acid Propylene Battery is used to activate the Engine through the Starter Motor and the

Electrical system comprising Horn, Head Lamp. Side indicator Lamps, Plough Lamp, Brake Light, Gauge

lamp, Hazard Lamp. Generator or Alternator, Fuse box also from part of the Electrical system.

Warning

When operating the tractor at High speed, Do not attempt to make sharp turns by using the

brakes.This may result in overturning of the Tractor causing serious injury or DEATH.

15

OWNER ASSISTANCE

We at TYM CO.,LTD and your TYM Dealer/Distributor wants you to be completely satisfied with your inv estment.

Normally any problems with your equipment will be handled by your Dealer/Distributor’s Service Departments,

however, misunderstanding can occur. If you feel that your problem has not been handled to your satisfaction, w e

suggest the following.

Contact the owner or General Manager of the Dealership, explain the problem, and request assistance. When additional

assistance is needed, Your Dealer/Distributor has direct access to your office. If you cannot obtain satisfaction by doing

this, contact the TYM CO.,LTD. Office and provide them with;

• Your name, address and telephone number

• Model and Tractor serial number

• Dealer/Distribut or Nam e & Address

• Machine purchase date and Hours used

• Nature of problem

Before contacting TYM CO.,LTD office, be aware that your problem will likely to be resolved in the Dealership using

the Dealer’s/Distributor’s facilities, equipment and personnel. So it is important that your initial contact be with the

Dealer/Distributor.

16

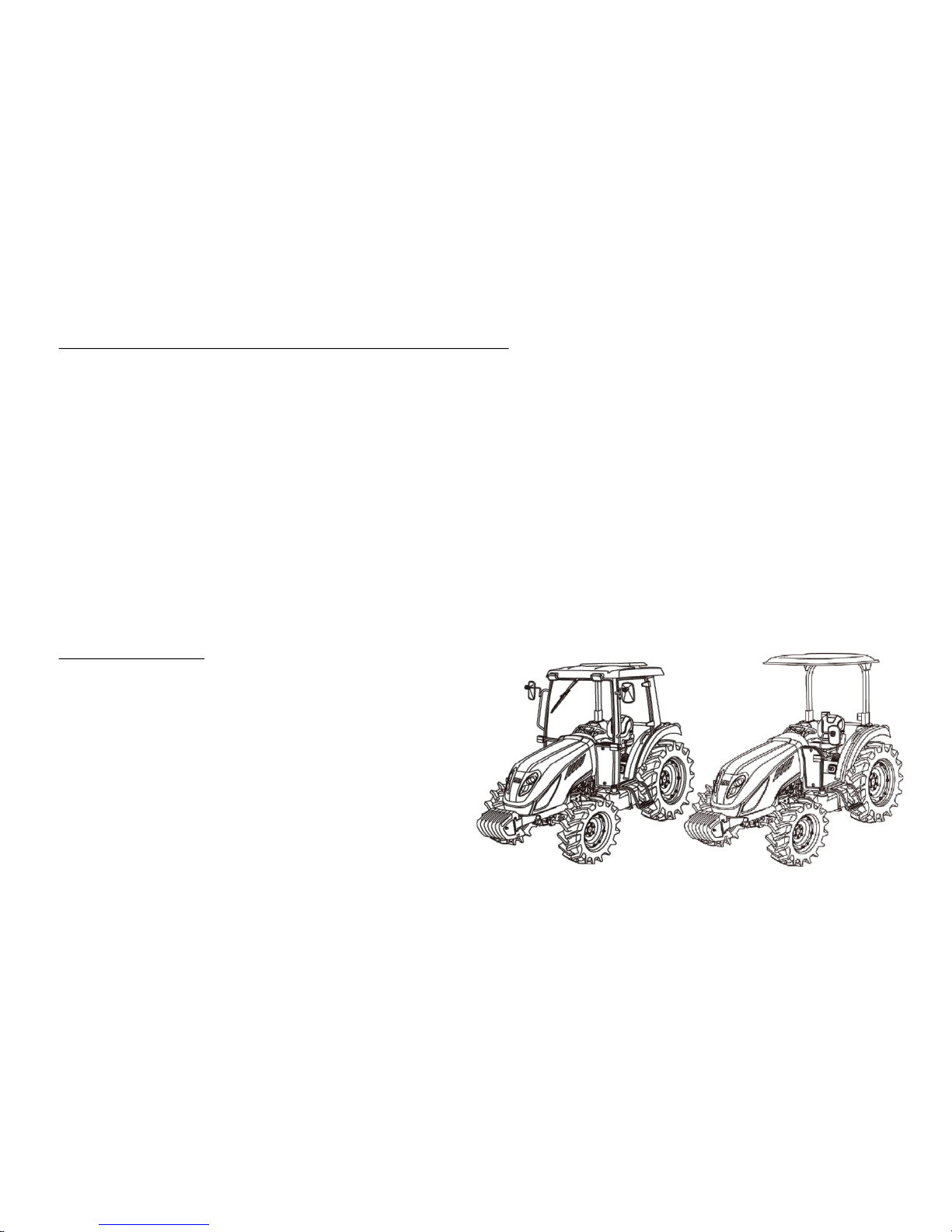

(ROPS) Roll Over Protective Structures

Roll Over Protective Structures (ROPS)

TYM Tractors are equipped with a frame for the protection of operators.

In the case of cab tractors the frame is incorporated in the cab structure.

The objective of the frame or cab structure is to protect the operator in the event of a roll over and they are designed to support

the entire weight of the tractor in that event.

Each TYM ROPS frame or cab structure is designed and has been tested to meet industry and or Government standards.

Included in these tests were all mounting bases and bolts or other fasteners.

DANGER

For ROPS frames to be effective and protect the operato r, t he seat belt prov ided must be worn in order to keep operators

within the ROPS protected area in the event of a roll over.

Failure to use the seat belt can still cause serious injury or death.

On some models the ROPS frame has a fold down feature, which can be used to enter low buildings etc Take care when lowering

the upper section of the ROPS frame and take extreme care while driving the tractor with the ROPS frame lowered.

Do not wear the seat belt with the ROPS lowered and please remember that the fold down facility is for special circumstances

only and must not be lowered for general use.

Use of the tractor with the ROPS lowered can cause fatal injuries.

As the ROPS frame or cab together with the seat belt was designed to meet certain standards, they must be maintained in good

order and condition. To achieve this objective, both the structure and the seat belt should be inspected on a regular basis (every

time the tractor is serviced)

In the event that the seat belt is damaged or frayed, it should be replaced and in the event that the ROPS frame or any part of the

mounting structure is damaged o r cracked, the faulty component must be replaced with a new unit. Such a unit must meet all of

the test criteria of the original unit .Fitment of an inferior item or items affects the certification of the entire ROP S structure and

the effectiveness of the structure in the event of an accident. Drilling or welding of the ROPS struct ure is forbidden.

17

Damage of the ROPS

If the tractor has rolled over or the ROPS has damaged (such

as striking an overhea d ob j ect during transport) , It must be

replaced to provide the original protection. After an accident,

check for damages to the 1.ROPS.2.Seat 3.seat belt & seat

mountings. Before you operate a Tractor, replace all damaged

parts.

(Roll-bar type)

(Cabin type)

18

DO NOT WELD, DRILL OR STRAIGHTEN THE ROPS

Never attach chains, ropes to the ROPS for pulling purposes; this will cause the Tractor to tip backwards.

Always pull from the Tr acto r drawbar . Be careful when d rivi ng thro ugh do or opening o r under lo w overhea d

objects. Make sure there is sufficient overhead clearance for the ROPS fatal injuries

If the ROPS is removed or replaced, make certain that the proper hardware is used to replace the ROPS and the

recommended torque values are applied to the attaching bolts

Always wear your seat belt if the tractor is equipped with ROPS

Warning

Warning

Warning

Fig.1

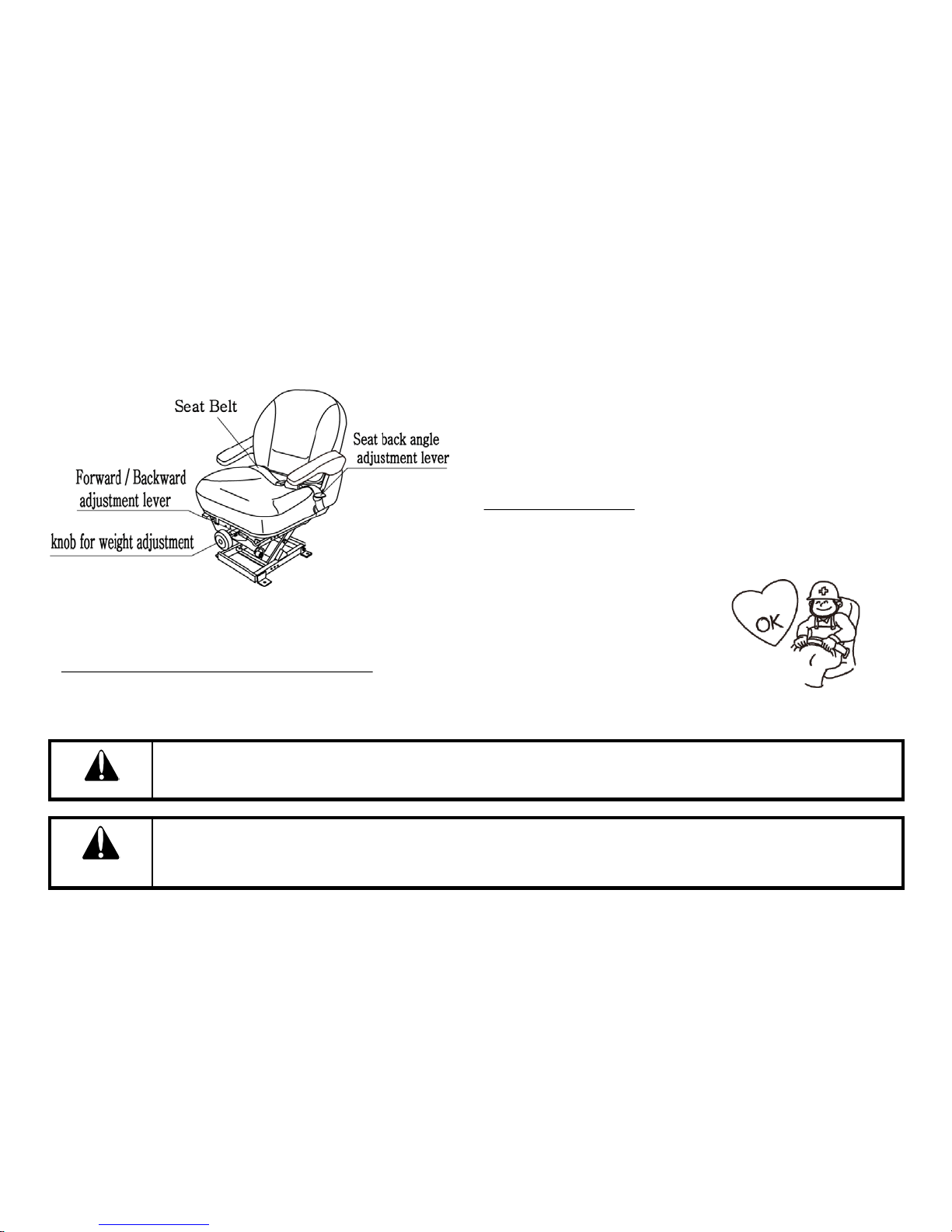

How to adjust the Seat NOTE: Do not use solvents to clean the seat. Use warm water

with a little detergent add e d.

Before operating a Tractor it is important to adjust the seat to

the most comfortable position & check whether it is properly

locked in its position. Figure 1 identifies the seat fitted to your

Tractor.

FOR SLIDING SEAT

To select Seat position, move Adjusting lever and slide Seat

closer to or away from Dash panel and controls.

Check whether the seat proper ly locked in its position before driving the tractor .

Always use the seat belt when the ROPS is installed.Do not use the seat belt if a foldable ROPS is down or there

is no ROPS.Check the seat belt regularly and replace if frayed or damaged.

Danger

Danger

19

SEAT SUSPENSION ADJUSTMENT KNOB

To adjust the seat correctly, turn Weight adjustment knob clockwise or counterclockwise, while seated in the driving position.

20

SAFETY INSTRUCTIONS

SIGNAL WORDS.

A signal word―DANGER, WARNING OR CAUTION―is used with safety aler t symbol.

DANGER identifies the most serious hazards. Safety signs with signal Word ―DANGER OR

WARNING―are typically near specific hazards. General precautions are listed on CAUTION

safety signs.

READ SAFETY INSTRUCTION

Carefully read all safety instructions given in this manual for your safety. Tempering with any of

the safety devices can cause serious injuries or death. Keep all safety signs in good condition.

Replace missing or damaged safety signs.

Keep your tractor in proper condition and do not allow any unauthorized modifications to be

carried out on the Tractor, which may impair the function/safety and affect Tractor life.

RECOGNIZE SAFETY INFORMATION

Thi s symbol means ATTENTION! YOUR SAFETY IS INVOLVED. T he message that follows the

symbol contains important information about safety. Carefully rea d the message

DANGER

WARNING

CAUTION

PROTECTION CHILDR EN

Keep children and others away from the Tractor while operating.

BEFORE YOU REVERSE

- Look behind Tractor for children.

- Do not let children to ride on Tractor or any implement.

USE OF ROPS AND SEAT BELT

The Roll Over Protective Structure(ROPS) has been certified to industry and/or government

standards. Any damage or alternation to the ROPS, mounting hard-ware, or seat belt voids the

certification and will reduce or eliminate pr otec tion for the oper ator in the event of a roll-over . The

ROPS, mounting hardware, and seat belt should be checked after the first 100 hours of Tractor and

every 500 hours thereafter for any evidence of damage, wear or cracks. In the event of damage or

alteration, the ROPS must be replaced prior to further operation of the Tractor.

The seat belt must be worn during machine operation when the machine is equipped with a certified

ROPS.

Failure to do so will reduce or eliminate protection for the operator in the event of a roll over.

PRECAUTION TO AVOID TIPPING

Do not drive where the Tractor could slip or tip.

Stay alert for holes and rocks in the terrain, and other hidden hazards.

Slow down before you make a sharp turn.

Driving forward out of a ditch or mired condition could cause Tractor to tip over backward. Back out of

these situations if possible

21

22

PARK TRACTOR SAFELY

Before working on the Tractor ;

Lower all equipment to the ground.

Stop the engine and remove t he ke y

KEEP RIDERS OFF TRACTOR

Do not allow riders on the Tractor.

Riders on Tractor are subject to injury such as being stuck by

foreign objects and being thrown off of the Tractor

HANDLE FUEL SAFELY-AVOID FIRES

Handle fuel with care; it is highly flammable. Do no t refuel the Tractor while smoking or near

open flame or sparks.

Always stop engine before refueling Tractors.

Always keep your tractor clean of accumulated grease, and debris. Always clean up spilled fuel.

STAY CLEAR OF ROTATING SHAFTS

Entanglement in rotating shaft can cause serious injury or death.

Keep PTO shield in place at all times.

Wear close fitting clothing. Stop the engine and be sure PTO drive is stopped before making

adjustments, co nnectio ns, or cleaning o ut

PTO driven equipment.

23

ALWAYS USE SAFETY LIGHTS AND DEVICES

Use of hazard warning lights a nd tur n signa ls a re re co mmend ed

when towing equipment on public roads unless prohibited by state

or local regulations.

Use slow moving vehicle (SMV) sign when driving on public road

during both day & night time, unless prohibited by law

RACTICE SAFE MAINTENANCE

Understand service procedure before doing work.

Keep the surrounding area of the Tractor clean and dry.

Do not attempt to service Tractor when it is in motion.

Keep body and clothing away from rotating shafts.

Always lower equipment to the ground. Stop the engine.

Remove the key. Allow Tractor to cool before any work repair is caused on it.

Securely support any Tractor elements that must be raised for service work.

Keep all parts in good condition and properly installed.

Replace worn or broken parts. Replace damage/missing decals.

Remove any buildup of grease or oil from the Tractor.

Disconnect battery ground cable(−) before making adjustments on electrical systems or

welding on Tractor

24

AVOID HIGH-PRESSURE FLUIDS

Escaping fluid under pressure can penetrate the skin causing serious injury. Keep hands and body away

from pinholes a nd no zz les , which eject fluids und e r hi gh p r ess ure . I f ANY flui d is inj ec te d into the ski n.

Consult your doctor immediately.

PREVENT BATTERY EX PLO SION S

Keep sparks, lighted matches, and open flame away from the top of battery. Battery gas can explode.

Never check battery charge by placing a metal object across the poles.

PREVENT ACID BURNS

Sulfuric acid in battery electrolyte is poisonous. It is strong enough to burn skin, cause holes

in clothing and cause blindness if found entry into eyes.

For adequate safety always;

1.Fill batteries in a well-ventilated area.

2.Wear eye protection and acid proof hand gloves

3. Avoid breathing direct fumes when electrolyte is added.

4. Do not add water to electrolyte as it may splash off causing severe burns.

If you spill acid on yourself;

1.Flush your skin with water.

2.Flush your eyes with wate r for 10-15 minutes. Get medical attention immediately.

25

SERVICE TRACTOR SAFELY

Do not wear a necktie, scarf or loose clothing when you work near

moving parts. If these items were to get caught, severe injury could result.

Remove rings and other jeweler to prevent electrical shorts and

entanglement in moving parts.

TRACTOR RUNAWAY

1. The tractor can start even if the transmission is engaged position causing Tractor to runaway and serious injury to the people

standing nearby the tractor.

2. For additional safety keep the pull to stop knob (fuel shut off control) in fully pulled o ut position.

Transmission in neutral position, Foot brake engaged and PTO lever in disengaged position while attending to Safety Starter

Switch or any other work on Tractor.

WORK IN VENTILATED AREA

Do not start the Tractor in an enclosed building unless the doors &

windows are open for proper ventilation, as tractor fumes can cause

sickness or death. If it is necessary to run an engine in an enclosed area

remove the exhaust fumes by connecti ng exhaust p ipe extension.

26

Safety Starter Switch is to be replaced after every 2000 hours/4 years, whichever is earlier

SAFETY STARTER SWITCH

1. Clutch operated safety switch is provided on all Tractors which allow the starting system to

become operational only when the Clutch pedal is fully pressed.

2. Do not By-pass this safety starter switch or work on it. Only Authorized Dealers are

recommended to work on safety starter switch.

3. On some models Safety Star te r switch is provided on transmission High-low shifter lever and in

PTO shifter lever.The tractor can be started only if High-low shifter lever is in neutral position.

Caution

27

SAFE OPERATION OF YOUR TRACTOR

The manufacturer of your tractor has made every effort to make it as safe as is humanly possible.

Beyond this point it is the responsibility of the operator to avoid accidents and we ask that you read and implement our

suggestions fo r your sa fety.

Ensure that only trained and competent operators use this tract or and ensure that they are fully conversant with the

machine and aware of all it’s control and safe ty featur es .

Operators should not operate the tractor or associated machinery while tired or untrained.

To avoid accidents please ensure that the op erato r wears clo thing which will not get entangled in the moving parts of the tractor

or machine and protect him or her from the elements.

When spraying or using chemicals, please ensure that clothing and protective equipment is worn which prevents respiratory or

skin problems.

For full details consult the manufacturer of the chemicals.

To avoid lengthy e xp os ure to noise ens ure that ea r pr o te ct io n is worn.

If adjustment to the tractor or machinery need to be made ensure the tractor or machine are turned off beforehand.

Use of certified Roll Over Protection Structure ( ROPS) is a must while operating a tr a c tor.

Use of seat belt is a must while operating a tractor.

In summary, ensure at all times that the safety of the operator and any other worker is paramount.

28

SAFETY TIPS DURING MAINTENANCE

1. At least on a daily basis check all oil levels. Water level in the radiator and electrolyte level in the battery and perform services

according to the service schedule.

2. Ensure tire pressure are even and the correct pressure for the job being done is maintained.

3. Check to ensure that the all controls and preventative mechanisms of the Tractor and implement work correctly and effecti vel y.

4. Ensure that an adequate set of the correct tools is available for maintenance and minor repairs.

5. Ensure that all service work and repairs are carried out on a flat area with a concrete or similar floor.

Do not carry out service work on a tractor until it is switched off, and the parking brake applied and wheels choked.

Where a tractor is started in a confined area, ensure that the area is well ventilated as exhaust gases are very harmful, and can

cause death.

6. Do not work under raised implements.

7. When changing wheels or tires ensure that a suitable wheel stand is placed under the axle prior to removing the wheel and the

wheels are chocked.

8. Where guards or shields need to be removed to perform a service or rep air, ensure that the guard or shield is correctly

reinstalled before starting the Tracto r.

9. Never refuel near an open flame or with an overheated engine. Ensure to turn off Engine before refueling.

10. The cooling system operates under pressure, take care when removing the Radiator cap on a hot engine to prevent being

scalded by steam or hot water. Do not add water in the radiator when the engine is hot. Add water to the radiator only after

the engine cools down completely.

11.To prevent fires keep the tractor including the engine clean and free from inflammable material and well away from fuels and

other inflammable material.

Loading...

Loading...