Page 1

Model RC-1 Retard Chamber

For Variable Pressure Wet Pipe Sprinkler Systems

300 psi (20,7 bar)

Tech ni cal Service s: Tel: (800) 381-9312 / Fax: (800) 791-5500

Page 1 of 4 JULY 2009 TFP920

General

Description

The Tyco® Model RC-1 Retard

Chamber is required in installations

that will be subject to pressure variations, as are generally associated with

public water supplies, in order to help

prevent false alarms. The RC-1 is specifically intended for use as a separately ordered item for the Model AV-1-300

Alarm Check Valve ( TFP910). It can,

however, also be used as a separately

ordered item for changing out older

style Retard Chambers used with the

Central Model F/G, Gem Model A, or

Star Model E/F Alarm Check Valves.

The Model RC-1 Retarding Chamber

is a re-designation for the Gem Model

F211 for use with Gem Model F20/

F200/F2001 Alarm Check Valves, as

well as the Star Model S310 for use

with Star Model S30/S300/S3001

Alarm Check Valves.

NOTICE

The Mode l RC-1 Retard Chamber

described herein must be installed

and maintained in compliance with

this document, as well as with the

applicable standards of the National

Fire Protection Association, in addition

to the standards of any other authorities

having jurisdiction. Failure to do so may

impair the integrity of this device.

The owner is responsible for maintaining

their fire protection system and devices

in proper operating condition. The

insta lli ng co ntr actor o r s pri nkl er

manufacturer should be contacted

relative to any questions.

Technical

Data

Approvals

UL and ULC Listed, as well as

FM Approved for use with the Model

AV-1-300 Alarm Check Valves.

UL and ULC Listed, as well as FM,

LPCB, and VdS Approved for use with

the following Alarm Check Valves:

Model AV-1-175

Gem Model F20/F200/F2001

Gem Model A

Star Model S30/S300/S3001

Working Water Pressure

300 psi (20,7 bar)

Construction

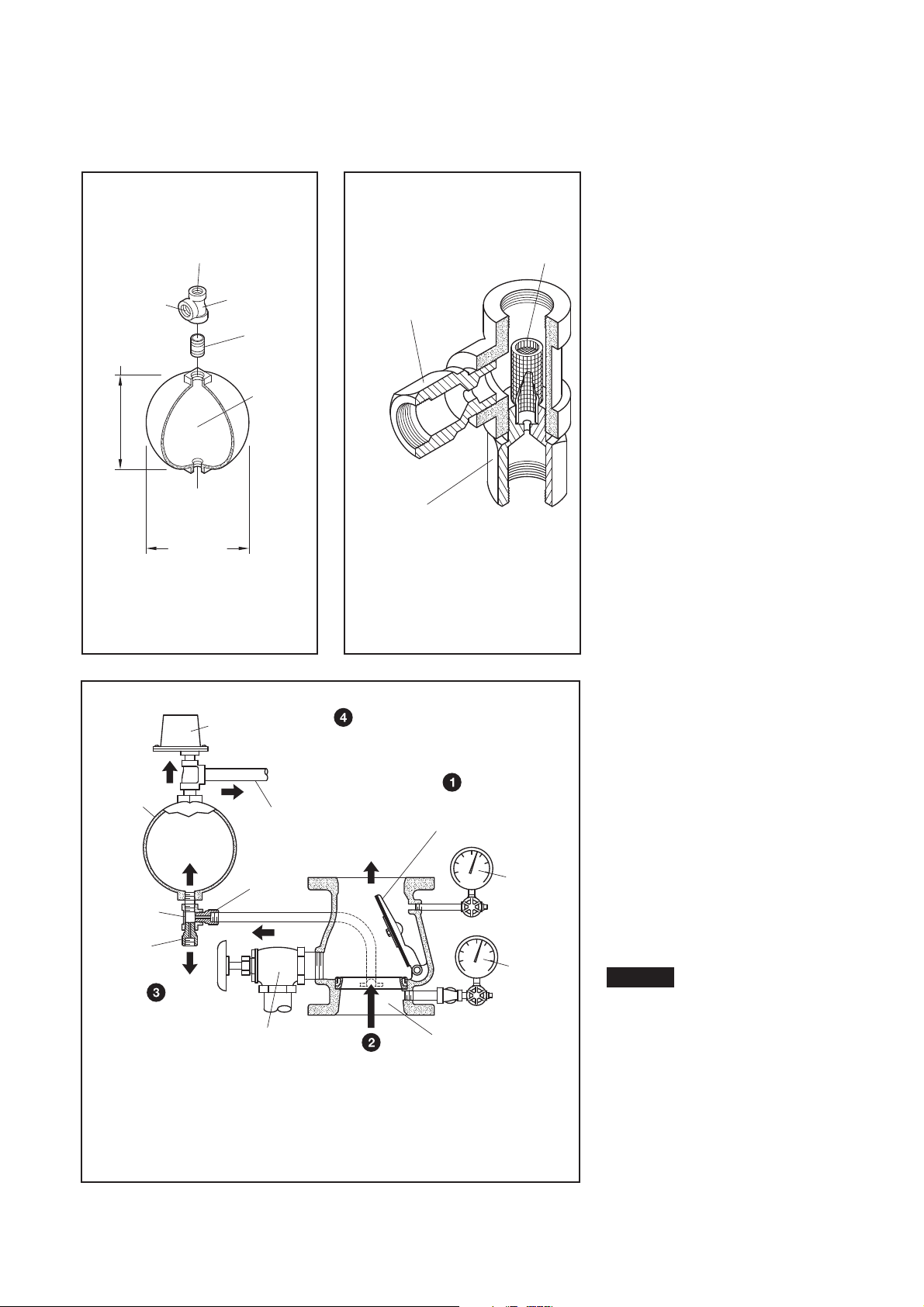

The Model RC-1 Retard Chamber

shown in Figure 1 is cast iron, and a

3/4” x 1/2” x 3/4” Tee is provided at

the outlet (top) for connection of a

pressure alarm switch and/or water

motor alarm. The Restriction Assembly shown in Figure 2 is provided with

the AV-1-300 trim or ordered separately for retrofitting other valves. This

assembly is comprised of brass restrictions assembled to a cast iron or

malleable iron threaded tee fitting. The

screen is stainless steel.

Operation

When water flows steadily into the

sprinkler system due to sprinkler operation, the Waterway Clapper in the

Alarm Check Valve opens as shown

in Figure 3. Water is then permitted to

flow into the centrally located groove

in the Seat Ring and out through the

Alarm Port towards the Restriction Assembly (Figure 2).

When the flow through the Inlet Restriction of the Restriction Assembly

exceeds the flow out through the Outlet Restriction, the Retard Chamber

begins to fill. Subsequently, the Water Motor Alarm and/or the Pressure

Alarm Switch activate. The alarms continue to operate as long as the Waterway Clapper remains open. When the

Clapper closes as a result of discontinued water flow, water in the alarm

lines automatically drains out through

the 1/8 inch (3,2 mm) drain orifice in

the Restriction Assembly ( Figure 2).

In the case of variable pressure systems, a transient surge in supply pressure that is sufficient only to open the

Clapper momentarily will not cause a

false alarm. The volume of the Retard

Chamber is sufficiently large enough

that it will not fill to operate the connected alarm devices. Any water in

the alarm line is then automatically

drained, further reducing the possibility of a false alarm due to a successive

transient surge in supply pressure.

Page 2

3/4" x 1/2" x 3/4"

REDUCING TEE

3/4" x 1-1/2"

END-TO-END

8-1/8"

(206,0 mm)

DIA.

1/2" NPT INLET

CONNECTION

3/4" NPT WATER

CONNECTION

MOTOR ALARM

9-1/8"

(232,0 mm)

WATERFLOW

CONNECTION

PRESSURE

ALARM SWITCH

1/2" NPT

1 GAL.

(3,8 L)

CAPACITY

NOMINAL

NIPPLE

SCREEN

ORIFICE

ORIFICE

WITH 0.125" (3.2 mm)

RESTRICTION FITTING

WITH 0.219" (5.6 mm)

RESTRICTION FITTING

DRAIN

INLET

PRESSURE

WATERFLOW

ALARM SWITCH

MOTOR ALARM

VALVE

RESTRICTION

(3,2 mm)

OUTLET

ORIFICE

RETARD CHAMBER

BEGINS TO FILL

INLET EXCEEDS OUTLET,

RESTRICTION ASSEMBLY

WHEN FLOW THROUGH

ASSEMBLY

1/8"

CHAMBER

RETARD

INLET

ALARM PORT

RING GROOVE AND

THROUGH SEAT

WATERFLOW

MAIN

DRAIN

ALARM ACTUATE

WATERFLOW PRESSURE

CHAMBER OVERFLOWS,

ONCE RETARD

WATER MOTOR

ALARM SWITCH AND

WATERFLOW

TO SYSTEM

WATERFLOW

TO WATER

7/32"

ORIFICE

(5,6 mm)

UPON SPRINKLER

FLOW, WATERWAY

CLAPPER OPENS

GAUGE

GAUGE

SUPPLY

PRESSURE

PRESSURE

SYSTEM

CHECK

VALVE

ALARM

TFP920

Page 2 of 4

Installation

The Tyco® Model RC-1 Retard Chamber must be installed in accordance

with the specific instructions provided

with the Tyco® Model AV-1-300 Alarm

Check Valve (TFP910). The standard

trim for these Alarm Check Valves includes all necessary components including the Restriction Assembly

shown in Figure 2.

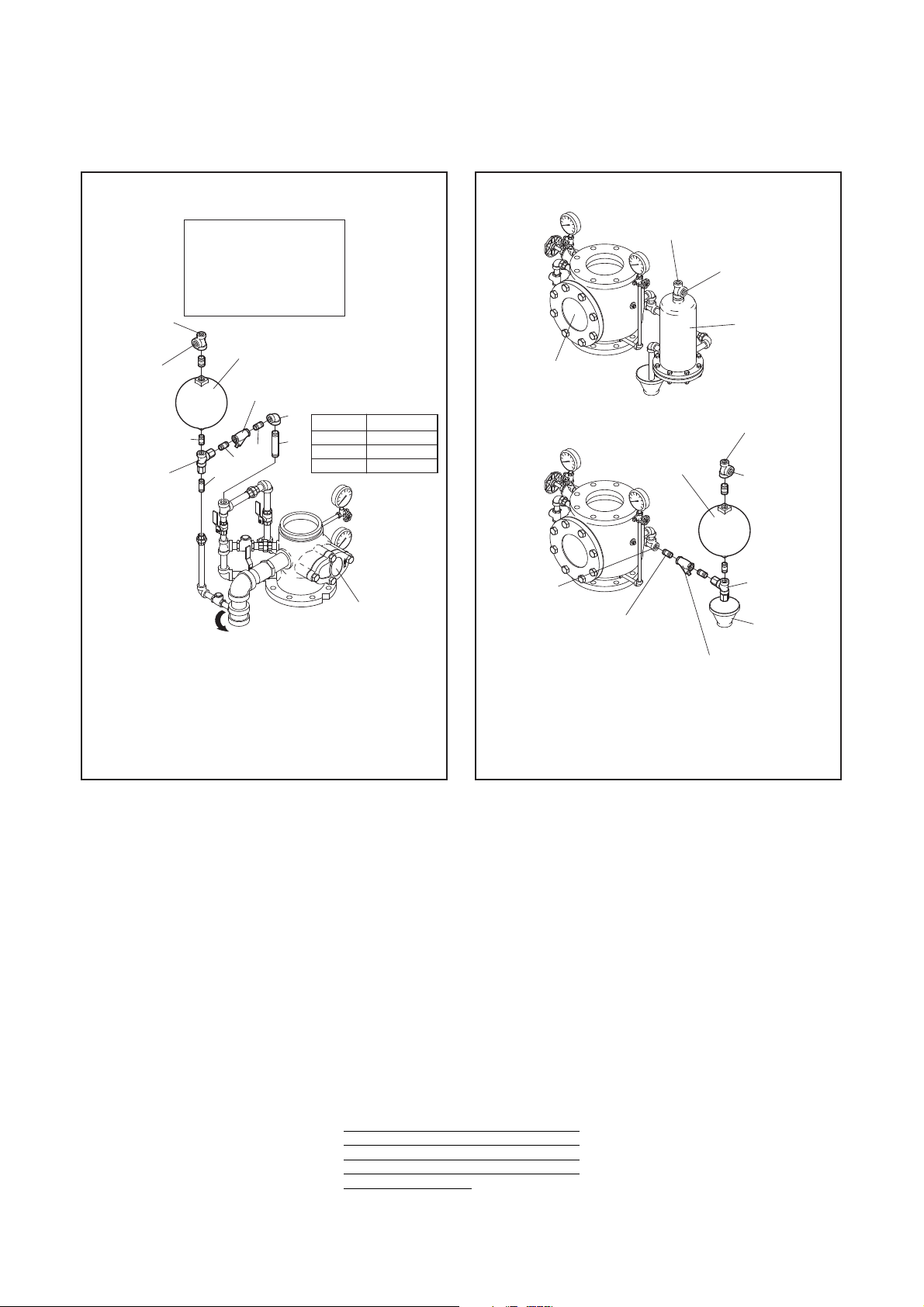

s)NTHECASEOFRETROlTTING#ENTRAL

Model F/G Alarm Check Valves, refer to Figure 4.

s)NTHECASEOFRETROlTTING'EM-OD-

el A Alarm Check Valves, refer to

Figure 5.

s)NTHECASEOFRETROlTTING3TAR-OD-

el E/F Alarm Check Valves, refer to

Figures 6 and 7.

Apply pipe thread sealant sparingly to

male threads only.

Care and

Maintenance

Responsibility lies with the owner for

the inspection, testing, and maintenance of their fire protection system

and devices in compliance with this

document, as well as with the applicable standards of the National Fire

Protection Association (for example,

NFPA 25), in addition to the standards

of any authority having jurisdiction.

Contact the installing contractor or

product manufacturer regarding any

questions.

Automatic sprinkler systems should

be inspected, tested, and maintained

by a qualified Inspection Service in

accordance with local requirements

and/or national codes.

Specific consideration must be given

to cleaning the Screen within the Restriction Assembly, as well as the YStrainer. More frequent cleaning than

that required by NFPA 25 may be necessary as determined after the first inspection and is a function of the water quality with respect to water borne

debris.

NOTICE

Bef ore c los ing a f i re pr ote cti o n

system control valve for inspection

or m aintenanc e wor k o n th e f ire

protection system that it controls, obtain

permission to shut down the affected

fire protection system from the proper

authorities, and notify all personnel who

may be affected by this action.

After placing a fire protection system

in service, notify the proper authorities

an d a dvis e those responsible for

monitoring proprietary and/or central

station alarms.

FIGURE 2

RESTRICTION ASSEMBLY

FIGURE 3

MODEL RC-1 RETARD CHAMBER

OPERATION

FIGURE 1

MODEL RC-1

RETARD CHAMBER

Page 3

1/2" x 2" Nipple

Select per Table

DESCRIPTION

3/4" x 1/2" 90°

Reducing Elbow

NIPPLES & FITTINGS

1/2" x 1-1/2" Nipple

3

4

1

2

NO.

than TFSBP.

Includes nipple and

tee per Figure 1.

Nipples & fittings

from sources other

may be acquired

1. . . . . . . .

. . . . . . .

2

1

1

. . . . . . . .

. . . . .3

1

QTY.

1

P/N 52-353-1-005

1/2" Y-STRAINER

RETARD CHAMBER

P/N 52-211-1-002

RETARD CHAMBER DRAIN TRIM

3

RESTRICTION

ASSEMBLY

P/N 92-210-1-005

TO ACCOMMODATE NEW

RETARD CHAMBER TRIM

(SEE FIGURE 2)

ROTATE EXISTING

WATERFLOW

CONNECTION

PRESSURE

ALARM SWITCH

1/2" NPT

3/4" NPT WATER

CONNECTION

MOTOR ALARM

2

2

WITH ALARM TRIM

REFER TO DATA

SHEET 7-3.0

(6"/DN150 SHOWN)

ALARM CHECK VALVE

CENTRAL MODEL F/G

2

4

1

MODEL RC-1

2

8" (DN200) 3/4" x 1-1/2"

3/4" x 4-1/2"

Nipple 4 SizeValve

4" (DN100)

6" (DN150)

3/4" x 6"

ALARM SWITCH

PRESSURE

CONNECTION

WATERFLOW

1/2" Y-STRAINER

P/N 52-353-1-005

VALVE SIZE & TRIM

LENGTHS TO SUIT

ARRANGEMENT

NIPPLE

WITH BASIC TRIM

ALARM CHECK VALVE

(6"/DN150 SHOWN)

REFER TO DATA

GEM MODEL A

SHEET TD1

MOTOR ALARM

POINT

CONNECTION

DRIP FUNNEL

(IF REQUIRED)

P/N 92-210-1-005

ASSEMBLY

(SEE FIGURE 2)

RESTRICTION

1/2" NPT

ALARM SWITCH

WATERFLOW

CONNECTION

PRESSURE

3/4" NPT WATER

MOTOR ALARM

CONNECTION

3/4" NPT WATER

RETARD CHAMBER

REFER TO DATA

WITH ALARM TRIM

GEM MODEL A-3

SHEET TD1-1

REMOVE

ALARM TRIM

REMOVE

ORIGINAL

TO THIS

1/2" NPT

RETARD CHAMBER

P/N 52-211-1-002

MODEL RC-1

TEE PER FIGURE 1)

(INCLUDES NIPPLE &

TFP920

Page 3 of 4

repaired or replaced, at TFSBP’s sole

option. TFSBP neither assumes, nor

authorizes any person to assume for it,

any other obligation in connection with

the sale of products or parts of products. TFSBP shall not be responsible

for sprinkler system design errors or

inac curate or incomplete information

sup plied by Buyer or Buyer’s representatives.

In no event shall TFSBP be liable, in

contract, tort, strict liability or under

any other legal theory, for incidental, indirect, special or consequential

damages, including but not limited to

labor charges, regardless of whether

TFSBP was informed about the possibility of such damages, and in no

event shall TFSBP’s liability exceed an

amount equal to the sales price.

The foregoing warranty is made in

lieu of any and all other warranties,

express or implied, including warranties of merchantability and fitness for

a particular purpose.

This limited warranty sets forth the

ex clusive remedy for claims based on

failure of or defect in products, materials or components, whether the claim

is made in contract, tort, strict liability

or any other legal theory.

This warranty will apply to the full extent permitted by law. The invalidity,

in whole or part, of any portion of this

warranty will not affect the remainder.

Limited

Warranty

Products manufactured by Tyco Fire

Suppression & Building Products

(TFSBP) are warranted solely to

the original Buyer for ten (10) years

against defects in mate rial and workmanship when paid for and properly

installed and maintained under normal use and service. This warranty

will expire ten (10) years from date

of shipment by TFSBP. No warranty

is given for products or com ponents

manufactured by companies not affiliated by ownership with TFSBP or for

products and components which have

been subject to misuse, improper installation, corrosion, or which have

not been installed, maintained, modified or repaired in accordance with

ap plicable Standards of the National

Fire Protection Association, and/or

the standards of any other Authorities

Having Jurisdiction. Materials found by

TFSBP to be defective shall be either

FIGURE 4

MODEL RC-1 RETARD CHAMBER

WITH CENTRAL MODEL F/G ALARM CHECK VALVES

FIGURE 5

MODEL RC-1 RETARD CHAMBER

WITH GEM MODEL A ALARM CHECK VALVES

Page 4

may be acquired

from sources other

Nipples & fittings

tee per Figure 1.

Includes nipple and

. . . . .13 3/4" x 3-1/2" Nipple

than TFSBP.

2

1

1/2" x 1-1/2" Nipple

NIPPLES & FITTINGS

Reducing Elbow

3/4" x 1/2" 90°

DESCRIPTION

1

2

NO.

. . . . .

. . . . . . . .31

QTY.

1

DISCARD EXISTING

STAR MODEL E

REFER TO DATA

SHEET 2-1.1.20

ALARM CHECK VALVE

WITH ALARM TRIM

(SEE FIGURE 2)

2

SEPARATE

CHAMBER

EXISTING 1/2"

TO FACILITATE

UNION HALVES

ASSEMBLY OF

NEW RETARD

RETARD CHAMBER DRAIN TRIM

TRIM

RETARD CHAMBER TRIM

TO ACCOMMODATE NEW

ROTATE EXISTING

MOTOR ALARM

CONNECTION

3/4" NPT WATER

1/2" NPT

ALARM SWITCH

PRESSURE

CONNECTION

WATERFLOW

P/N 92-210-1-005

ASSEMBLY

RESTRICTION

MODEL RC-1

P/N 52-211-1-002

RETARD CHAMBER

1/2" Y-STRAINER

P/N 52-353-1-005

2

2

3/4" x 2" NIPPLE

REMOVE AND

3

1

2

2

(SEE FIGURE 2)

TO ACCOMMODATE NEW

RETARD CHAMBER TRIM

ROTATE EXISTING

RETARD CHAMBER DRAIN TRIM

(6"/DN150 SHOWN)

REFER TO DATA

SHEET 2-1.1.10

ALARM CHECK VALVE

WITH ALARM TRIM

STAR MODEL F

TO FACILITATE

TRIM

NEW RETARD

ASSEMBLY OF

CHAMBER

UNION HALVES

EXISTING 1/2"

SEPARATE

REMOVE AND

DISCARD EXISTING

3/4" x 2" NIPPLE

1/2" Y-STRAINER

P/N 52-353-1-005

3

1

2

MODEL RC-1

RETARD CHAMBER

P/N 52-211-1-002

2

PRESSURE

MOTOR ALARM

RESTRICTION

ASSEMBLY

CONNECTION

P/N 92-210-1-005

2

CONNECTION

ALARM SWITCH

3/4" NPT WATER

WATERFLOW

1/2" NPT

QTY.

. . . . . . . .

. . . . .

. . . . .3 3/4" x 3-1/2" Nipple

Includes nipple and

tee per Figure 1.

Nipples & fittings

than TFSBP.

from sources other

may be acquired

2

1

NO.

Reducing Elbow

NIPPLES & FITTINGS

DESCRIPTION

3/4" x 1/2" 90°

1/2" x 1-1/2" Nipple

1

2

1

1

3

1

© 2009 TYCO FIRE SUPPRESSION & BUILDING PRODUCTS

, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446

TFP920

Page 4 of 4

FIGURE 6

MODEL RC-1 RETARD CHAMBER

WITH STAR MODEL E ALARM CHECK VALVES

FIGURE 7

MODEL RC-1 RETARD CHAMBER

WITH STAR MODEL F ALARM CHECK VALVES

Ordering

Information

Orders for the Tyco® Model RC-1 and

additional components, as applicable,

must include the description and Part

Number (P/N).

RC-1

Specify: Model RC-1 Retard Chamber

w/galvanized steel fittings,

P/N 52-211-1-002.

Separately Ordered Parts for

Retrofitting Other Valves

When retrofitting according to Figures

4, 5, 6, or 7, the Restriction Assembly,

Y-Strainer, and associated pipe nipples

and fittings must be ordered separately

to complete installation. Pipe nipples

and fittings can be acquired from

sources other than TFSBP.

Specify: 1/2 inch Y-Strainer,

P/N 52-353-1-005.

Specify: Restriction Assembly,

P/N 92-210-1-005.

Loading...

Loading...