Page 1

800-381-9312

Technical Services

+1- 40 1-7 81- 822 0

www.tyco-fi re.com

RAPID RESPONSE Series LFII Residential Sprinklers

4.9 K-factor Flat-Plate Concealed Pendent

Wet Pipe and Dry Pipe Systems

General

Description

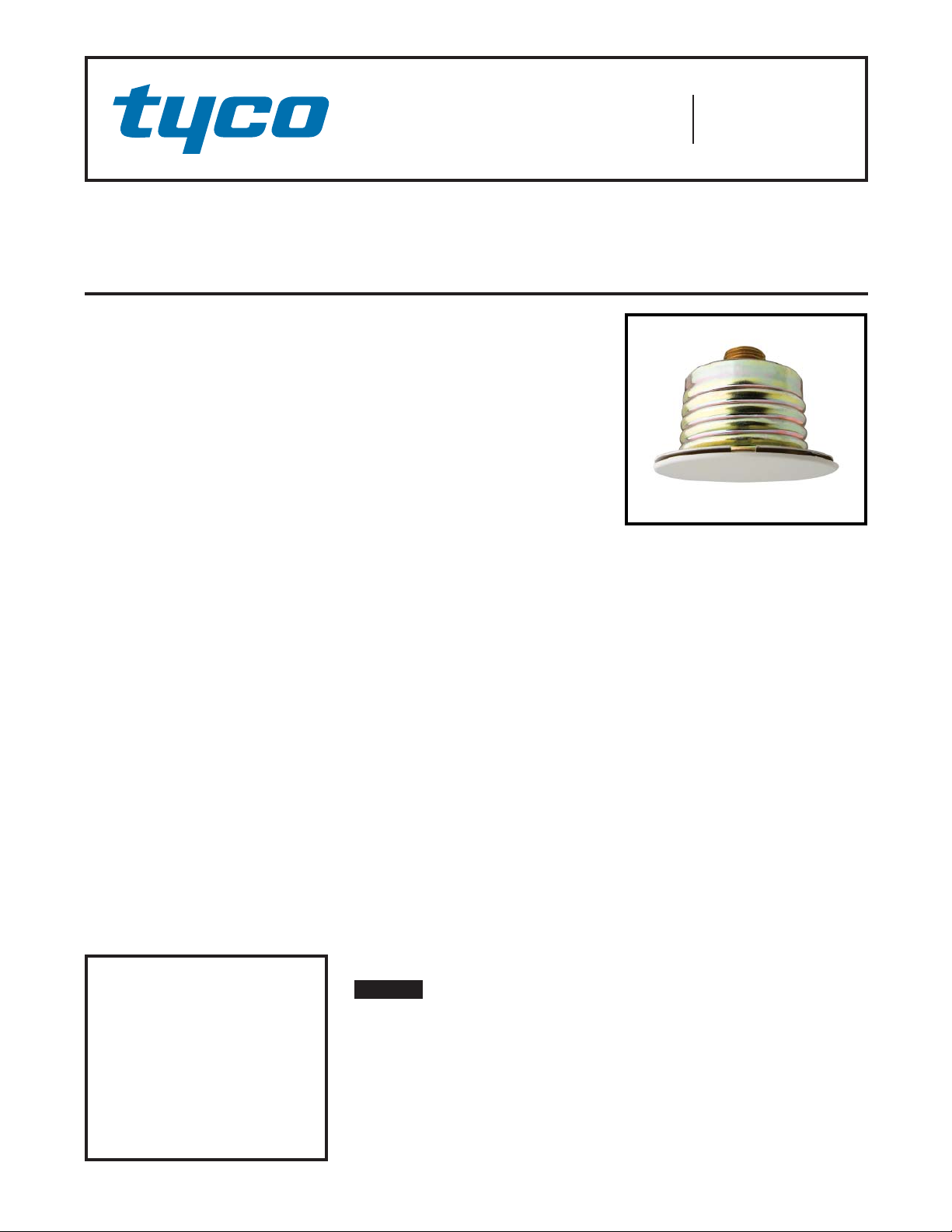

The TYCO RAPID RESPONSE Series

LFII Residential Flat-Plate Concealed

Pendent Sprinklers (TY2524) are decorative, fast response, fusible solder sprinklers designed for use in residential occupancies such as homes, apartments,

dormitories, and hotels.

The Cover Plate/Retainer Assembly conceals the sprinkler operating components above the ceiling. The at pro le

of the Cover Plate provides the optimum

aesthetically appealing sprinkler design.

Additionally, the concealed design of the

Series LFII Residential Flat-Plate Concealed Pendent Sprinklers provides 1/2

inch (12,8 mm) vertical adjustment. This

adjustment provides a measure of exibility when cutting xed sprinkler drops.

The Series LFII Residential Flat-Plate

Concealed Pendent Sprinklers are intended for use in the following systems:

• wet and dry pipe residential sprinkler systems for one- and two-family dwellings and mobile homes per

NFPA 13D

• wet and dry pipe residential sprinkler systems for residential occupancies up to and including four stories in height per NFPA 13R

• wet and dry pipe sprinkler systems

for the residential portions of any

occupancy per NFPA 13.

The Series LFII Residential Sprinklers

have been designed with heat sensitivity and water distribution characteristics

proven to help in the control of residen-

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and installation of sprinkler systems and components. Improper handling and installation can permanently damage

a sprinkler system or its components

and cause the sprinkler to fail to

operate in a fi re situation or cause it

to operate prematurely.

tial res and to improve the chance for

occupants to escape or be evacuated.

The Series LFII Residential Flat-Plate

Concealed Pendent Sprinklers are

shipped with a Disposable Protective

Cap. The Protective Cap protects the

sprinkler during ceiling installation or

nish. After ceiling installation is complete, the Protective Cap is removed

and the Cover Plate/Retainer Assembly is installed. Removing the Protective Cap is required for proper sprinkler

performance.

Dry Pipe System Application

The Series LFII Residential Flat-Plate

Concealed Pendent Sprinkler offers a

laboratory approved option for designing dry pipe residential sprinkler systems, whereas, most residential sprinklers are laboratory approved for wet

systems only.

Through extensive testing and as referenced in U.S. Patent 7,712,543, it has

been determined that the number of design sprinklers (hydraulic design area)

for the Series LFII Residential Flat-Plate

Concealed Sprinklers (TY2524) need not

be increased over the number of design

sprinklers (hydraulic design area) speci ed for wet pipe sprinkler systems, as

is customary for density/area sprinkler

systems designed per NFPA 13, 13D,

or 13R.

Consequently, the Series LFII Residential Flat-Plate Concealed Sprinklers

(TY2524) offer the features of non-water lled pipe in addition to not having to

increase the number of design sprinklers

(hydraulic design area) for systems designed to NFPA 13, 13D, or 13R. Nonwater lled pipe will permit options for

areas sensitive to freezing.

NOTICE

The Series LFII Residential Flat-Plate

Concealed Pendent Sprinklers (TY2524)

described herein must be installed and

maintained in compliance with this document and the applicable standards of

the National Fire Protection Association,

in addition to the standards of any authorities having jurisdiction. Failure to

do so may impair the performance of

these devices.

The owner is responsible for maintaining their fi re protection system and devices in proper operating condition. The

installing contractor or sprinkler manufacturer should be contacted with any

questions.

Sprinkler

Identifi cation

Number (SIN)

TY2524

Page 1 of 6 APRIL 2012 TFP443

Page 2

TFP443

Page 2 of 6

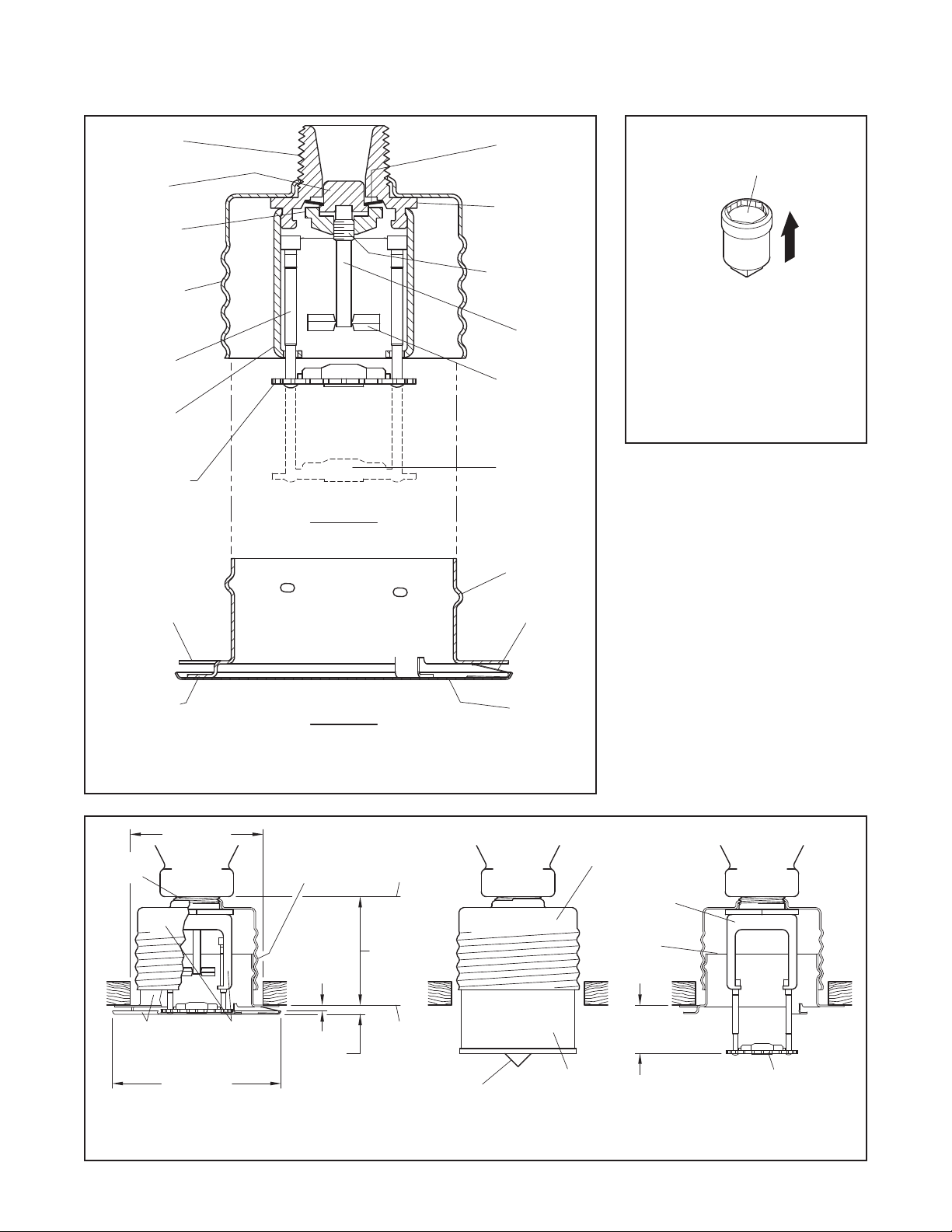

BODY

(1/2" NPT)

CAP

SADDLE

SUPPORT

CUP WITH

ROLL FORMED

THREADS

GUIDE

PIN

GUIDE PIN

HOUSING

DEFLECTOR

THREAD INTO

SUPPORT CUP

UNTIL MOUNTING

SURFACE IS

FLUSH WITH

CEILING

SPRINKLER/SUPPORT CUP

ASSEMBLY

SEALING

ASSEMBLY

SPRINKLER

WRENCHING

AREA

COMPRESSION

SCREW

LEVER

SOLDER LINK

ELEMENT

DEFLECTOR

(OPERATED

POSITION)

RETAINER

WITH THREAD

DIMPLES

EJECTION

SPRING

WRENCH

RECESS

PUSH WRENCH

IN TO ENSURE

ENGAGEMENT

WITH SPRINKLER

WRENCHING AREA

FIGURE 2

W-TYPE 18

— SPRINKLER WRENCH —

SOLDER

TAB

COVER PLATE/RETAINER

ASSEMBLY

COVER

PLATE

FIGURE 1

RAPID RESPONSE SERIES LFII RESIDENTIAL FLAT-PLATE CONCEALED

PENDENT SPRINKLER (TY2524)

— ASSEMBLY —

SPRINKLER-

SUPPORT CUP

ASSEMBLY

DISPOSABLE

1/2"

NPT

COVER-

RETAINER

2-1/2" DIA.

(63,5 mm)

SPRINKLER-

SUPPORT CUP

ASSEMBLYASSEMBLY

3-3/16" DIA.

(81,0 mm)

1/2" (12,7 mm)

THREADED

ADJUSTMENT

1/8" GAP

(3,2 mm)

3/16"

(4,8 mm)

FACE OF

SPRINKLER

FITTING

1-7/8"±1/8"

(47,6 mm

±3,2 mm)

MOUNTING

SURFACE

TIP OPERATED POSITION

PROTECTIVE CAP

FIGURE 3

PROTECTIVE CAP AND ACTIVATED DEFLECTOR

— INSTALLATION DIMENSIONS —

OPERATED

SPRINKLER

COVER

PLATE

RETAINER

7/8" (22,2 mm)

1-1/8" (28,6 mm)

DEFLECTOR IN

Page 3

TFP443

Page 3 of 6

Technical

Data

Approvals

UL and C-UL Listed

The TYCO RAPID RESPONSE Series

LFII Residential Flat-Plate Concealed

Pendent Sprinklers are only listed with

the Series LFII Concealed Cover Plates

having a factory-applied nish.

For details on approvals, refer to the Design Criteria section.

Maximum Working Pressure

175 psi (12,1 bar)

Discharge Coeffi cient

K=4.9 GPM/psi

Temp erat ure Rati ng

Sprinkler: 160°F (71°C)

Cover Plate: 139°F (59°C)

Vertical Adjustment

1/2 inch (12,7 mm)

Finishes

Refer to the Ordering Procedure section.

Physical Characteristics

Cover Plate/Retainer Assembly:

Cover Plate . . . . . . . . . . . . . Copper

Ejection Spring . . . . Stainless Steel

Retainer . . . . . . . . . . . . . . . . Brass

Sprinkler/Support Cup Assembly:

Body . . . . . . . . . . . . . . . . . . . Brass

Cap . . . . . . . . . . . . . . . . . . . Bronze

Saddle . . . . . . . . . . . . . . . . . . Brass

Sealing Assembly . . . . . . .Beryllium

Soldered Link Halves . . . . . . Nickel

Lever . . . . . . . . . . . . . . . . . . Bronze

Compression Screw . . . . . . . Brass

De ector . . . . . . . . . . . . . . . Bronze

Guide Pin Housing. . . . . . . . Bronze

Guide Pins . . . . . . . . . . . . . Bronze

Support Cup . . . . . . . . . . . . . . Steel

1/2

(70,6 LPM/bar

Nickel w/ TEFLON

1/2

)

Operation

When exposed to heat from a re, the

Cover Plate, which is normally soldered

to the Retainer at three points, falls away

to expose the Sprinkler/Support Cup Assembly. At this point, the De ector, supported by the Guide Pins, drops down

to its operated position.

The Solder Link Element of the Sprinkler/

Support Cup Assembly is comprised of

two link halves that are soldered together with a thin layer of solder. When the

rated temperature is reached, the solder melts and the two link halves separate, allowing the sprinkler to activate

and ow water.

Design

Criteria

The TYCO RAPID RESPONSE Series

LFII Residential Flat-Plate Concealed

Pendent Sprinklers (TY2524) are UL

and C-UL Listed for installation in accordance with this section:

Residential Sprinkler Design Guide

When conditions exist that are outside

the scope of the provided criteria, refer to the Residential Sprinkler Design

Guide TFP490 for the manufacturer's

recommendations that may be acceptable to the authority having jurisdiction.

System Type

Per the UL Listing, wet pipe and dry pipe

systems may be utilized. Per the C-UL

Listing, only wet pipe systems may be

utilized.

Refer to Technical Data Sheet TFP485

about the use of Residential Sprinklers

in residential dry pipe systems.

Hydraulic Design

(NFPA 13D and 13R)

For systems designed to NFPA 13D or

NFPA 13R, the minimum required sprinkler ow rate are given in Tables A and

B as a function of temperature rating

and the maximum allowable coverage

areas. The sprinkler ow rate is the minimum required discharge from each of

the total number of “design sprinklers”

as speci ed in NFPA 13D or NFPA 13R.

The number of “design sprinklers” speci ed in NFPA 13D and 13R for wet pipe

systems is to be applied when designing

dry pipe systems.

Hydraulic Design

(NFPA 13)

For systems designed to NFPA 13, the

number of design sprinklers is to be

the four most hydraulically demanding

sprinklers. The minimum required discharge from each of the four sprinklers

is to be the greater of the following:

• The ow rates given in Tables A and

B as a function of temperature rating

and the maximum allowable coverage area.

• A minimum discharge of 0.1 gpm/ft2.

over the “design area” comprised of

the four most hydraulically demanding sprinklers for the actual coverage

areas being protected by the four

sprinklers.

The number of “design sprinklers”

speci ed in NFPA 13 for wet pipe systems is to be applied when designing

dry pipe systems.

Dry Pipe System Water Delivery

When using the Series LFII Residential

Flat-Plate Concealed Pendent Sprinklers

(TY2524) in dry pipe sprinkler systems,

the time for water delivery exceed 15

seconds for the most remote operating sprinkler.

Obstruction to Water Distribution.

Sprinklers are to be located in accordance with the obstruction rules of

NFPA 13D, 13R, an d 13 as ap pl ic able

for residential sprinklers as well as with

the obstruction criteria described within

the Technical Data Sheet TFP490.

Operational Sensitivity

Install sprinklers relative to the ceiling

mounting surface as shown in Figure 3.

The Series LFII Residential Flat-Plate

Concealed Pendent Sprinklers must

not be used in applications where the

air pressure above the ceiling is greater

than that below. Down drafts through

the Support Cup can delay sprinkler operation in a re situation.

Sprinkler Spacing

The minimum spacing between sprinklers is 8 feet (2,4 m). The maximum

spacing between sprinklers cannot exceed the length of the coverage area

(Table A) being hydraulically calculated

(e.g., a maximum of 12 feet for a 12 ft. x

12 ft. coverage area or 20 feet for a 20

ft. x 20 ft. coverage area.)

Page 4

TFP443

Page 4 of 6

(c, d, e)

(b)

Sloped Ceiling

(c, d, e)

(Greater than 4 inch rise

up to maximum 8 inch

rise for 12 inch run)

160°F (71°C)

Sprinkler

17 GPM (64,3 LPM)

12.0 psi (0,83 bar)

17 GPM (64,3 LPM)

12.0 psi (0,83 bar)

17 GPM (64,3 LPM)

12.0 psi (0,83 bar)

22 GPM (83,3 LPM)

20.2 psi (1,39 bar)

24 GPM (90,8 LPM)

24.0 psi (1,65 bar)

Minimum Flow and Residual Pressure

Maximum

Coverage

(a)

Area

Ft. x Ft .

(m x m)

Maximum

Spacing

Ft.

(m)

Horizontal Ceiling

(Maximum 2 inch rise

for 12 inch run)

(c, d, e)

160°F (71°C)

Sprinkler

12 x 12

(3,7 x 3,7)

14 x 14

(4,3 x 4,3)

16 x 16

(4,9 x 4,9)

18 x 18

(5,5 x 5,5)

20 x 20

(6,1 x 6,1)

(a) For coverage area dimensions less than or between those indicated, use the minimum required ow for the next highest coverage area for which

Hydraulic Design section under the Design Criteria are stated.

(b) The Minimum Flow requirement is based on minimum ow in GPM (LPM) from each sprinkler. The associated residual pressures are calculated using

the nominal K-factor. Refer to “Hydraulic Design” in the Design Criteria section for details.

(c) For NFPA 13D 2010 applications, Horizontal Ceiling criteria shall be used for certain sloped ceiling con gurations up to 8:12 pitch.

Refer to TIA 1028R for allowed sloped ceiling limitations when using horizontal ceiling criteria.

(d) For NFPA 13R applications, Horizontal Ceiling criteria may be used for sloped ceiling con gurations up to 8:12 pitch when acceptable to

the local authority having jurisdiction.

(e) For NFPA 13 residential applications, the greater of 0.1 gpm/ft.

this table must be used.

12

(3,7)

14

(4,3)

16

(4,9)

18

(5,5)

20

(6,1)

13 GPM (49,2 LPM)

7.0 psi (0,48 bar)

13 GPM (49,2 LPM)

7.0 psi (0,48 bar)

13 GPM (49,2 LPM)

7.0 psi (0,48 bar)

17 GPM (64,3 LPM)

12.0 psi (0,83 bar)

20 GPM (75,7 LPM)

16.7 psi (1,15 bar)

2

over the design area or the ow in accordance with the criteria in

WET PIPE SYSTEM

Sloped Ceiling

(Greater than 2 inch rise

up to maximum 4 inch

rise for 12 inch run)

160°F (71°C)

Sprinkler

17 GPM (64,3 LPM)

12.0 psi (0,83 bar)

17 GPM (64,3 LPM)

12.0 psi (0,83 bar)

17 GPM (64,3 LPM)

12.0 psi (0,83 bar)

22 GPM (83,3 LPM)

20.2 psi (1,39 bar)

24 GPM (90,8 LPM)

24.0 psi (1,65 bar)

SERIES LFII RESIDENTIAL FL AT-PLATE CONCEALED PENDENT SPRINKLER (TY2524)

TABLE A

NFPA 13D, 13R, AND 13 HYDRAULIC DESIGN CRITERIA

— WET PIPE SYSTEMS —

Maximum

Coverage Area

Ft. x Ft .

(m x m)

(a)

Maximum Spacing

Ft.

Horizontal Ceiling Minimum Flow and Residual Pressure

(m)

Minimum Flow and Residual Pressure

(Maximum 2 Inch Rise for 12 Inch Run)

160°F (71°C) Sprinkler

DRY PIPE SYSTEM

12 x 12

(3,7 x 3,7)

14 x 14

(4,3 x 4,3)

16 x 16

(4,9 x 4,9)

18 x 18

(5,5 x 5,5)

20 x 20

(6,1 x 6,1)

(a) For coverage area dimensions less than or between those indicated, use the minimum required ow for the next highest

coverage area for which Hydraulic Design section under the Design Criteria are stated.

(b) The Minimum Flow requirement is based on minimum ow in GPM (LPM) from each sprinkler. The associated residual pressures

are calculated using the nominal K-factor. Refer to “Hydraulic Design” in the Design Criteria section for details.

(c) For NFPA 13 residential applications, the greater of 0.1 gpm/ft.

this table must be used.

12

(3,7)

14

(4,3)

16

(4,9)

18

(5,5)

20

(6,1)

15 GPM (56,8 LPM)

9.4 psi (0,65 bar)

15 GPM (56,8 LPM)

9.4 psi (0,65 bar)

16 GPM (60,6 LPM)

10,7 psi (0,74 bar)

17 GPM (64,3 LPM)

12.0 psi (0,83 bar)

21 GPM (79,5 LPM)

18,4 psi (1,27 bar)

2

over the design area or the ow in accordance with the criteria in

(b)

(c)

SERIES LFII RESIDENTIAL FL AT-PLATE CONCEALED PENDENT SPRINKLER (TY2524)

TABLE B

NFPA 13D, 13R, AND 13 HYDRAULIC DESIGN CRITERIA

— DRY PIPE SYSTEMS —

Page 5

TFP443

Page 5 of 6

Installation

The TYCO RAPID RESPONSE Series

LFII Residential Flat-Plate Concealed

Pendent Sprinklers must be installed in

accordance with this section:

General Instructions

Damage to the Solder Link Element during installation can be avoided by handling the sprinkler by the Support Cup

only; that is, do not apply pressure to the

Solder Link Element (Figure 1).

A leak-tight 1/2 inch NPT sprinkler joint

should be obtained by applying a minimum-to-maximum torque of 7 to 14

ft.-lbs. (9,5 to 19,0 Nm). Higher levels

of torque can distort the sprinkler inlet

with consequent leakage or impairment

of the sprinkler.

Do not attempt to compensate for insuf cient adjustment in the Cover Plate/

Retainer Assembly by under- or overtightening the sprinkler. Re-adjust the

position of the sprinkler tting to suit.

Step 1. Install pendent sprinklers in

the pendent position, with the centerline of the sprinkler perpendicular to the

mounting surface.

Step 2. Remove the Protective Cap.

Step 3. With pipe-thread sealant ap-

plied to the pipe threads, and using the

W-Type 18 Wrench shown in Figure 2,

install and tighten the Sprinkler/Support Cup Assembly into the tting. The

W-Type 18 Wrench accepts a 1/2 inch

ratchet drive.

Step 4. Replace the Protective Cap by

pushing it upwards until it bottoms out

against the Support Cup. The Protective Cap helps prevent damage to the

De ector and Guide Pins during ceiling

installation and/or during application of

the nish coating of the ceiling.

NOTICE

As long as the protective Cap remains

in place, the system is considered “Out

Of Service”.

Step 5. After the ceiling has been completed with the 2-1/2 inch (63 mm) diameter hole and in preparation for installing the Cover Plate/Retainer Assembly,

remove and discard the Protective Cap,

and verify that the De ector moves up

and down freely.

If the sprinkler has been damaged and

the de ector does not move up and

down freely, replace the entire sprinkler

assembly. Do not attempt to modify or

repair a damaged sprinkler.

Step 6. Screw on the Cover Plate/Retainer Assembly until its ange contacts

the ceiling. Do not continue to screw

on the Cover Plate/Retainer Assembly

such that it lifts a ceiling panel out of

its normal position.

If the Cover Plate/Retainer Assembly

cannot be engaged with the Mounting

Cup or the Cover Plate/Retainer Assembly cannot be engaged suf ciently to

contact the ceiling, the Sprinkler Fitting

must be repositioned.

Care and

Maintenance

The TYCO RAPID RESPONSE Series

LFII Residential Flat-Plate Concealed

Pendent Sprinkler (TY2524) must be

maintained and serviced in accordance

with ths section:

Before closing a re protection system

main control valve for maintenance work

on the re protection system that it controls, obtain permission to shut down the

affected re protection system from the

proper authorities and notify all personnel who may be affected by this action.

Absence of a Cover Plate may delay the

sprinkler operation in a re situation.

The owner must assure that the sprinklers are not used for hanging any objects and that the sprinklers are only

cleaned by means of gently dusting with

a feather duster; otherwise, non-operation in the event of a re or inadvertent

operation may result.

When properly installed, there is a nominal 1/8 inch (3,2 mm) air gap between

the lip of the Cover Plate and the ceiling, as shown in Figure 3. This air gap

is necessary for proper operation of the

sprinkler by allowing heat ow from a

re to pass below and above the Cover

Plate to help assure appropriate release

of the Cover Plate in a re situation. If the

ceiling needs repainting after sprinkler

installation, exercise care to ensure that

the new paint does not seal off any of

the air gap. Failure to do so may impair

sprinkler operation.

Factory painted Cover Plates must not

be repainted. They should be replaced,

if necessary, by factory painted units.

Non-factory applied paint may adversely

delay or prevent sprinkler operation in

the event of a re.

Do not pull the Cover Plate relative to the

Retainer. Separation may result.

Sprinklers which are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or otherwise

altered after leaving the factory. Modi ed or overheated sprinklers must be

replaced.

Care must be exercised to avoid damage to the sprinklers - before, during,

and after installation. Sprinklers damaged by dropping, striking, wrench twist/

slippage, or the like, must be replaced.

The owner is responsible for the inspection, testing, and maintenance of

their re protection system and devices

in compliance with this document, as

well as with the applicable standards of

the National Fire Protection Association

(e.g., NFPA 25), in addition to the standards of any other authorities having jurisdiction. Contact the installing contractor or sprinkler manufacturer regarding

any questions.

Automatic sprinkler systems are recommended to be inspected, tested,

and maintained by a quali ed Inspection Service in accordance with local

requirements and/or national codes

.

Page 6

TFP443

Page 6 of 6

Limited

Warranty

Products manufactured by Tyco Fire

Production Products (TFPP) are warranted solely to the original Buyer for

ten (10) years against defects in material and workmanship when paid for

and properly installed and maintained

under normal use and service. This

warranty will expire ten (10) years from

date of shipment by TFPP. No warranty is given for products or components

manufactured by companies not af liated by ownership with TFPP or for

products and components which have

been subject to misuse, improper installation, corrosion, or which have not

been installed, maintained, modi ed or

repaired in accordance with applicable

Standards of the National Fire Protection Association, and/or the standards of

any other authorities having jurisdiction.

Materials found by TFPP to be defective shall be either repaired or replaced,

at TFPP’s sole option. TFPP neither assumes, nor authorizes any person to

assume for it, any other obligation in

connection with the sale of products

or parts of products. TFPP shall not be

responsible for sprinkler system design

errors or inaccurate or incomplete information supplied by Buyer or Buyer’s

representatives.

In no event shall TFPP be liable, in contract, tort, strict liability or under any

other legal theory, for incidental, indirect, special or consequential damages,

including but not limited to labor charges, regardless of whether TFPP was informed about the possibility of such

damages, and in no event shall TFPP’s

liability exceed an amount equal to the

sales price.

The foregoing warranty is made in lieu

of any and all other warranties, express

or implied, including warranties of merchantability and tness for a particular

purpose.

This limited warranty sets forth the exclusive remedy for claims based on failure of or defect in products, materials or

components, whether the claim is made

in contract, tort, strict liability or any other legal theory.

This warranty will apply to the full extent

permitted by law. The invalidity, in whole

or part, of any portion of this warranty

will not affect the remainder.

Ordering

Procedure

Contact your local distributor for availability. When placing an order, indicate

the full product description and Part

Number (P/N).

Sprinkler/Support Cup Assembly

Specify: Series LFII (TY2524), K=4.9

(70,6), Residential Flat-Plate Concealed

Pendent Sprinkler without Cover Plate/

Ret ain er A s semb ly, P/N 51-114 -1-160 .

Cover Plate/Retainer Assembly for

Horizontal or Sloped Ceiling

Applications

Specify: Series LFII (TY2524), K=4.9

(70,6), Residential Flat-Plate Concealed

Pendent Sprinkler Cover Plate/Retainer Assembly with (specify) nish, P/N

(specify):

Off White . . . . . . . . . . . . . . . . P/N 56-201-0-135

Pure White*

(RAL9010) . . . . . . . . . . . . . . P/N 56-201-3-135

Signal White**

(RAL9003) . . . . . . . . . . . . . . P/N 56-201-4-135

Standard White (Grey White)

(RAL9002) . . . . . . . . . . . . . . P/N 56-201-5-135

Custom . . . . . . . . . . . . . . . . . . .P/N 56-201-X-135

* Eastern Hemisphere sales only

** Previously known as Bright White

Note: All Custom Cover Plates are painted using Sherwin Williams Interior Latex Paint. Contact

TYCO Customer Ser vice with any questions related

to custom orders.

Optional Cover Plate/Retainer Assembly for Horizontal Ceiling

Applications Only

Specify: Series LFII (TY2524), K=4.9

(70,6), Residential Flat-Plate Concealed

Pendent Sprinkler Cover Plate/Retainer Assembly with (specify) nish, P/N

(specify):

Off White . . . . . . . . . . . . . . . . .P/N 56-122-0-135

Pure White*

(RAL9010) . . . . . . . . . . . . . . . . P/N 56-122-3-135

Signal White**

(RAL9003) . . . . . . . . . . . . . . . . P/N 56-122-4-135

Custom . . . . . . . . . . . . . . . . . . . P/N 56-122-X-135

* Eastern Hemisphere sales only

** Previously known as Bright White

Note: All Custom Cover Plates are painted using Sherwin Williams Interior Latex Paint. Contact

TYCO Customer Ser vice with any questions related

to custom orders.

Sprinkler Wrench

Specify: W-Type 18 Sprinkler Wrench,

P/N 56-000-1-265.

Copyright © 2012 Tyco Fire Protection Products. All rights reserved.

TEFLON is trademark of The DuPont Corporation.

Loading...

Loading...