Page 1

PGx312

PowerG2-Way Wireless MagneticCont act Device

with Hard-Wired Input Installation Instructions.

Introduction

The PGx312is a two-way wireless PowerG magnetic

contact device. Thedevice has the following features:

l Weatherproof,water-resistant outdoor transceiver

l Flat and curved surface installation

l Battery pull tab for autoenrollment

l Functions atextreme temperatures( -40°C to

66°C / -40°F to151 °F) and is IP66certified

Note:ULtestingtemperatures:-35°C to 66°C

(-31 °F to151 °F)

l Battery life ofup to5 years (with typical

commerical use)

l Integratedmagnetic sensor

l Maximum magnetic gapof 44.5 mm (1.75 in.) on

woodand 31.8 mm (1.25 in.) on metal

l Magnetic sensor toggle if the auxiliary inputonly is

required

l Separatetransmissions from sensor andauxiliary

inputthat trigger thesame RF transmitter.

l Front and back tamper protection( back tamper not

available in USmarket)

l Automatic periodic supervision atr egular intervals

l PowerGtwo-w ay FHSS TDMA technology

l Anti-maskingprotection, based on panel software

version

l Auxiliary hard-wired input, programmable as

either normally open (NO), normally closed (NC),

endof line (EOL, or double end ofli ne (DEOL) for

usew ithadditional device. DEOLfunctionalityi s

based onpanel version software.

l Supports temperature level reports accordingto

PowerGpanel software version

l Paintableusing non-metallic paint. Recommended

paints includeKrylon 'Fusionfor Plastic', RustOleum 'Plastic', and Dupli-Color 'Vinyl & Fabric

Coating'.

Enrolling thePGx312

1. Enter into the installer menuand select 02: ZONES

/ DEVICES.

2. SelectADD N EW DEVICES.

3. Beginthe auto-enrollment process by pulling the

tab,inserting the batteries,or enteringthe device

ID.

4. Selectthe desiredzone number.

5. Configure thelocation,zone type, and chime parameters.

6. Configure thedetector.

Note:

l If the magnetic contactdevice is already enrolled,

configure the magnetic contactdevice parameters

usingthe ModifyD evices option– see step 2.

l To configurethe device parameters, select the

Device Settingsoptionand refer to Configuringthe

Device Parameters.

l To enroll thedevice, power onthe device bypulling

thebattery tab or insert thebatteries. Both methods

will activatethe auto-enrollment process. Alternatively,enter theID:107-XXXX (thenumber of the

deviceprinted on the label).

l If the device was not automatically enrolled, press

theenrollment buttonas seenin Figure 1B.

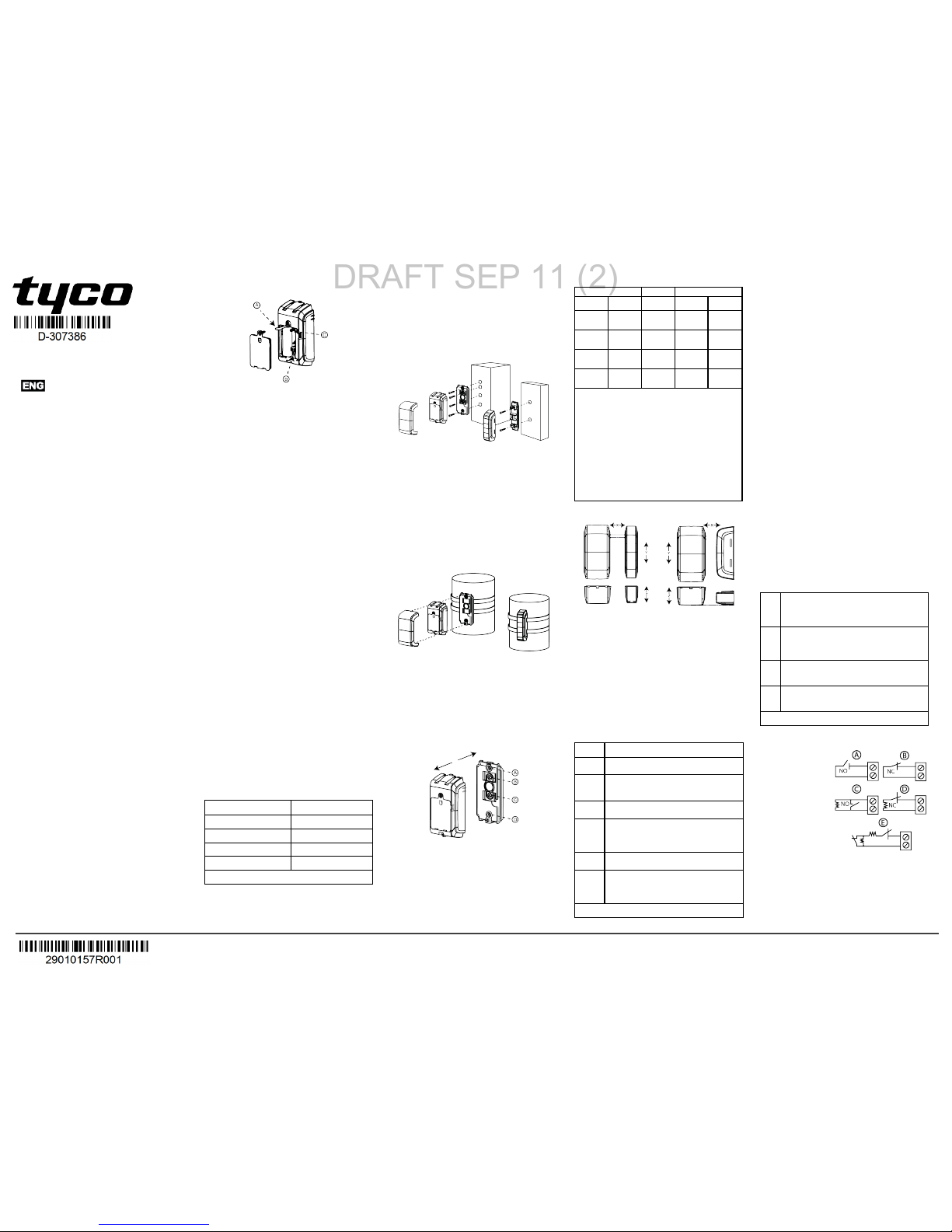

A:Enrollment tab B:Enrollment button

C:Ta mperswitch

Figure 1: Enrollment options

Installation

This equipmentis designed tobe installed byqualified

service persons only. Placethe device abovethe door

or window on the fixed frameand the magnet on the

movablepart ofthe door or window. Do not place the

magnet more than44.5 mm (1.75 in) from the marked

side of thedevice.

To monitor outdoor areas, you can mount the PGx312

ona curved surface,such as afence pole or simil ar.

Note:

l Oncethe battery cover is removed, a tamper mes-

sageis transmittedto thepanel. Subsequent

removal ofthe battery prevents transmissionof the

TAMPER RESTOREalert, leavingthe receiver in

permanent alert. Toavoid this,press thetamper

switch whenyou removethe battery.

l It is recommendedto wait about1 minuteafter bat-

tery removal before insertingthe new batteries.

Caution! Risk of explosion ifthe battery is replacedby

ani ncorrect type. Dispose ofthe used battery according

to the manufacturer’s instructions.

Attention! Some modelshave aback tamper switch

behind the device. As longas thedevice is seatedfir mly

within the bracket, the switchl ever will be pressed

against aspecial break-away bracket segment that is

looselyconnected tothe bracket. Be sureto fasten the

break-away segment tothe wall. Ifthe detector uniti s

forcibly removed from the wall, this segment will break

away from the bracket,causing the tamper switch to

open.

Locald iagnosticst est

A local diagnostic test establishesthe signal strength of

a device ini tscurrent position during the installationprocess. Toperform this mandatory test,complete the following:

1. Separate the decorativecover from thedevice and

unscrew the battery cover. See steps 1to 3 of

Mounting the PGx312.

2. Press thetamper switch onceand release it.

3. Openthe door or window andverify thatdetection

is indicated by a redLED flash.

After two seconds,the LEDflashes three times in

oneof threecolors to indicatethe signal strength.

LEDresponse Reception

Green LEDflashes Strong

Yellow LED flashes Good

Red LEDflashes Poor

No flashes No communication

Table1: LEDreceptionresponse

Important! Reliable receptionmust beassured. There-

fore," poor" signal strengthi snot acceptable. Ifyou

receive a"poor" signal from thedetector, relocate it and

re-test until a "good" or "strong" signalstr engthis

received(i nregions requiring UL-compliant installation,

only “strong” signal strength is permitted).

Note:

l For UL, only strong signal strength is acceptable.

l For detailed diagnostics testinstructions,r efer to

thecontrol panel Installer Guide.

l After this step, reattachthe battery cover.

l The LED lighti soff in normal conditions.

Mounting th ePGx312

Figure 2: Mounting on a flat surface

1. Insert aflat-headscrewdriver into the slotprovided

andpush upward to removethe decorativecover.

2. Unscrew thelower screw from thedevice cover.

3. Separate the device from the bracket.

4. Mark anddril l the required number of holes in the

mounting surface.

5. Screw in the bracket with four screws provided.

6. Reattach thedevice to thebracket.

7. Mountthe magnet base withtwo suppliedscrews

to an adjacent surfaceand attachthe magnetto the

magnet bracket.

Figure 3: Mounting on a curved sur face with straps

To mount the device ona curvedsurface, use straps

(not included)as seen in Figure 3.

Note:

l Use holes A andD i nFigure 4 for standard mount-

ing.Add holes B and C inFigure 4 for tamper protection.

l Align the device and magnetaccordingto thespe-

cificationsin RangeCoverage Directions.

A:Stan dardmo unting

C:Ta mperprot ection

B:Ta mperprot ection

D:Stan dardmo unting

Figure 4: Devic e and bracket separ ation

Range coveragedirections

Non-metallic surface Supports Metallic surface

Open Close Direction Open Close

71 mm

(2.8 in.)

52 mm

(2.0 in.)

X

48 mm

(1.9 in.)

35 mm

(1.4 in.)

40 mm

(1.6 in.)

33 mm

(1.3 in.)

Y (up)

32 mm

(1.3 in.)

25 mm

(1.0 in.)

22 mm

(0.9 in.)

17 mm

(0.7 in.)

Y(down)

17 mm

(0.7 in.)

8 mm

(0.3 in.)

85 mm

(3.3 in.)

55 mm

(2.2 in.)

Z

80 mm

(3.1 in.)

60 mm

(2.4 in.)

Table2 - Range coverage directions

Note:

l The values statedabovem ay vary byup to

10%.For steel installations, the gaps cannot be

less than 3.2 mm (0.1in.).

l For roller shutter assembly, themagnetneedsto

bem ounted 25mm to 35m m (1.0in. to1.4 in.)

from thedevices (onthe Xplane). For all other

installations, ami nimum gapof 5 mm (0.2i n.) is

needed.

l Whenm ountingon asli de door, refer to X. When

mounting on ar oller shutter, refer toY. When

mounting on anormal door, refer toZ .

Parallelmagne t Perpendicularm agnet

Figure 5: Range cove rage directions

Note:

l For UL commercial installations, themaximum

openingto activateis 50.8m m (2i n.).

l Y (up) refers tothe upper half ofthe Y plane.Y

(down) refers to the bottom half of thedevice on

theY plane.

l Whenm ountingthe magnetperpendicular tothe

device,align themagnetwi th the faceof the device

as seen inthe perpendicular magnet image.

Configuring the device parameters

Enter thecontrol panel DEVICE SETTINGSmenu and

follow the configuration instructions for thePGx312magneticcontact device as described in Table 3.

Option Configuration instructions

Magnetic

sensor

Determine whether toenable or disable the

magnetic sensor.

Optional settings :Enable (default) or Dis-

abled.

Input #1

Define the external input according to the

install er's requirements.

Optional settings :Disabled(default), NO,

NC,EOL, or DEOL.

Note:DEOL support is dependent onpanel

software version.

Antimask

Determine whether toenable or disable the

anti-masking.

Optional settings :D isabled (default)or

Enabled(default).

Note: This feature is dependenton panel soft-

warev ersion.

Table3 - Magnetic device parameters

Wiring the auxiliaryinput

Note:

l For UL installations,the device connected tothe ini-

tiatingcir cuit must be locatedi nthe same room as

thetransmitter.

l For UL installations,connectto UL listedres-

idential burglar alarm accessories only.

l For ULC installations,connectU LC listed products

only tothe auxiliary wiring input.

l An alarm messagetransmits oncethe loop is

openedor short circuited.

To connectthis devicew ithanother nearby device by

auxiliary input, completethe followingsteps:

1. Remove the jacket atthe end ofthe cable to

expose the wires within.

2. Perforatethe silicongasket witha 0.8m m

(1/32in.) pin.

3. Pass each wire throughan entry holeand out the

opposite side.

4. Remove the insulationfrom the end of eachwir e.

5. Connect each wire tothe relevant terminal, ref-

erencing Auxiliary Wir ingOptions.

6. Screw theterminal closedusing aflat headscrew-

driver.

Note:

l Use a22 AWG AUX cable (3.0 mm, 0.12 in.jacket

diameter) for this installation.

l Use acable shorter than3 m (10 ft) for theAUX

connection.

l Seal theauxiliary wir ing gasket withR TVSilicone

adhesive sealant.

Auxiliary wiring options

Youcan add more devices tothe circuit of the PGx312

for NC, NO, EOL, or DEOL applications. Each applicationtype is as follows:

NC Excl usiv ely use series connected NCs ensorcon-

tacts if the auxili ary input of the PGx312 is

defined as a normally c losed (NC) type.A nEO L

resistor is not required.

NO Exclusi vely use parallel connected NO sensor

contacts if the auxili ary input of the PGx312 is

defined as NO type. An EOL resis toris not

required.

EOL For EOL supervision, NCor NOsensorc ontacts

can be used. A 5.6kΩEO Lresi stormust be wired

at the farend of the zone loop.

DEOL For DEOL supervision, only N.C. contacts should

be used. A 5.6kΩEO Lresi stormust be wired at

the farend of the zone loop.

Table4:Auxiliary wiringoptions

Note:Figure 6 Eill ustratesa DEOL resistor setupthat

is available dependenton panel software version.

A: N.O. switch

B: N.C. switch

C: EOL ;N.O. switch ;

use5.6 kΩ resistor

D: EOL ;N.C. switch ;

use5.6 kΩ resistor

E: DEOL; N.C. switch

only ;use 5.6kΩ

resistor

Figure 6:Auxi liary wiring options

Calibrating theanti-mask

The anti-mask featureenablesthe detectionof attemptedsabotage, for example, sensor obstruction.

Note:

©2018 Tyco Security Products,Toronto,C anada www.dsc.com

Tech.Support:1-800-387-3630

D-307386 Rev.0 (09/18)

DRAFT SEP 11 (2)

Page 2

l This feature is dependent on panel software ver-

sion.

l Begin theanti-mask calibration process whenthe

deviceand magnetare in thefinal installation position.T his must bethe shortestdistance between

them agnet and the device.

l For theproper operation ofthe AM function, align

them agnet with the sensor decorativecover during

calibration. See Figure5 for parallel andperpendicular magneti nstallation.

Pre-requisites:

l To receivean alert for magnet interference, enable

theanti-masking configuration on the device settingsm enu.

l Completethe anti-masking learning process after

enrollment(see Enrollingthe PGx312) andw iththe

deviceand magneti nthe final installation position.

To enablethe anti-mask feature, completethe following

steps:

1. Positionthe device and magnet pointers to face

eachother withr eference toRange CoverageDi r-

ections.

2. Ensurethe device and magnet are placed nomore

than5 mm apart on the Z plane. SeeRangeC over-

ageDir ections.

Note: During theanti-mask learning process, the

sensor andthe magnet mustbe stable for 10

seconds.

3. Press and hold theenroll buttonfor 6-8 secondsto

start the anti-mask learning process.

Note: Do notrelease the enrollment button while

theyellow LED is lit. Release the buttonafter the

greenLED lightsat 6 secondsand before 8

seconds.

If successful, the greenLED flashesthree times.If

unsuccessful,the redLED flashesthree times.

Note: If thedoor is openwhile the enroll buttonis

pressed, theanti-mask learning process is ignored.

Miscellaneouscomments

DSC wireless systems are very reliableand are tested

to high standards. However, dueto low transmitting

power andl imitedrange (required by FCC andother

regulatory authorities), there are somel imitations tobe

considered as follows:

A. Receivers may beblocked byr adio signals occurring onor near their operatingfrequencies, regardless of

thedigital codeused.

B. A receiver responds only toone transmitted signal at

a time.

C. Wireless devices should betestedr egularly to

determine whether there aresources ofinterferenceand

to protectagainst faults.

Specifications

FrequencyBand (MH z):Europeand rest of world:

433-434,868-869. USA:912-919

MaximumT xPower:

10dBm (10mW)@433MHz

14dBm (25mW) @868MHz

15dBm (30mW) @915MHz

Alarm input:Oneinternal and one auxiliary

Supervision:Signalling at4-mi nutei ntervals

Tamperalert:Report when atamper event occurs

Communication protocol:PowerG

Powersupply: Tyce C

Battery type: 2 x 1.5 VAA Ultimate Lithium Energizer

battery only

Battery life expectancy: 5 years with typical commercial transmissionsper day (not tested by UL)

Low batteryt hreshold: 3.0V

Battery supervision: Automatic transmissionof bat-

tery conditiondata as partof theperiodic status report

andim mediately uponlow battery detection.

Operating Temperature:-40°C to 66°C (- 40°F to

151°F)

Note:UL testingtemperatures: -35°C to 66°C

(-31 °F to151 °F)

Relative Humidity (RH):Averagerelative humidity of

approximately 75% non-condensing. For 30 days per

year relative humidity may vary between85% and 95%

noncondensing.

Note:For UL installations, relative humidity is 93%.

Dimensions(LxW xD): 105 mm x 52 mm x 35mm

(4.1 in. x 2.0 in.x 1.4 in.)

Device weight (including battery): 154 g( 5.4 oz)

Color: Dark grey

UL/ULC notes

TheP G9312has beenlistedby UL for commerciala ndresidentialburglary applicationsand byU LCforre sidentialburglar yapplications in accordance withthe

requirementsin theStandardsUL 634and ULC/ORDC634for Doorand Window

Contact.For UL/ULC installationsuse thisdevic eonly in conjunctionwithcompatibleDSC wireless receivers: HSM2HOST9,HS2LCDRF(P )9,HS2ICNRF(P)

9,PG9920, WS900-19,and WS900-29.

Europe: CE/EN(E N50131-2-6GRA DE2, CLASS IV,

EN50131-6 TypeC) listedPG8312: 868MHz PG4312:433

MHz.According toEN 50131-1,this equipmentcan beapplied in

installedsys temsup toand includingSecu rity Grade2,E nvironmentalClass IV.UK:The PG8312 is suitable for usein systemsinstalledto conformtoPD6 662atGrade 2and

environmentalclass IVB S8243.

SIMPLIFIED EU DECLARATION OF CONFORMITY

Hereby, Tyco SafetyPr oductsCanada Ltddeclares thattheradio equipmenttype

isin compliancewith Directive2014/53/EU .Thefulltextof the EUdeclaration of

conformityis availableatthe followinginterneta ddress:www.dsc.com

PG4312:http://dsc.com/pdf/1808001

PG8312:http://dsc.com/pdf/1808002

Frequency Bands Maximum Power

868.0MHz -868.6 MHz 14dBm (25mW)

868.7MHz -869.2MHz 14dBm (25mW)

433.22MHz -434.64MHz 10dBm (10mW)

European singlepoint ofcontact:Tyco Safety Products,Voltaweg 20,6101 XK

Echt,Netherlands.

FCC COMPLIANCE STATEMENT

WARNING!Changes ormodificationsto this unitnotexpress lyapproved bythe

party responsiblefor compliance couldvoid theuser’s authoritytooper atethe

equipment.

Thisdev icehas beentestedand foundto comply with thelimitsfor aClass B digital

device,p ursuanttoPa rt15of theFCC Rules.These limitsar edesigned to provide

reasonable protectionagainstharmfulinterference inresidential installations.This

equipmentgenerates usesand can radiater adiofrequency energyand, ifnot

installedand usedin accordance withtheinstructions, may causehar mfulinterference tor adio andtelevisionr eception.

However, there isno guaranteethatinterference willnot occur inapar ticular installation.Ifthisdevic edoes causes uchinterference,whic hcan beverifiedb yturning

thedevice offando n,theuser isencour agedtoeliminatetheinterference byone

or more ofthefollowingmeasures:

–R e-orientorr e-locatetherec eivingantenna.

–Incre asethedistance betweenthe deviceand thereceiver .

–C onnectthedevice toan outleton acirc uitdifferentfromthe onethatsupplies

power to ther eceiver.

–C onsultthedealer oran experienced radio/TV technician.

FCCID: F5318PG9312

Innovation Science and Economic Dev elopment Canada

(ISED)Statement

Thisequipmentc omplies withFCC andISE DCanada RFradiationexpo surelimits

setforth for anuncontrolledenv ironment.

Thisdev icecomplies withFCC RulesP art15 andwithISED Canada licenceex emptRSS standard(s). Operation issubject tothe followingtwo conditions:

(1) This devicemay notcause harmfulinterference,and (2)this devicemust

accept anyinterference thatmay bereceiv edor thatmay causeunde siredoperation.

Lepr esentappareiles tconformeaux CNRd 'ISED Canadaapplicab les aux

appareils radioexemptsd elicence.L'ex ploitationestautorisee aux deuxconditionssuiva ntes :(1) l'appareilned oitpas produire debrouillage,et( 2)l'utilisateur

del'appar eildo itacc epter toutbrouillage radioelectriquesubi, memesi lebrouillagees tsusceptibled'en compromettre lefonctionnement.

War ranty

(a) NOWARRA NTY- DSC PROVIDES THESOFTWARE “AS IS” WITHOUT

WARRA NTY. DSCDOE SNOT WARRANTTHA TTHE SOFTWARE WILL

MEET YOURRE QUIREMENTS ORTHAT OPERATIONOF THE

SOFTWAREWILL BEU NINTERRUP TED ORER ROR-FREE.

(b) CHANGES INOPER ATING ENVIRONMENT- DSC shallnotbe responsible

forproblems caused bychanges inthe operatingcharacteristics ofthe

HARDWA RE,or for problemsinthe interaction oftheSOFTWARE PRODUCT

withnon-DS C-SOFTWARE orHAR DWAREP RODUCTS.

(c) LIMITATIONOFLIAB ILITY;WARRA NTYREFLE CTSALLOCA TIONOF

RISK -IN ANYE VENT,IFA NYSTA TUTE IMPLIES WARRANTIES OR

CONDITIONSNOT STATEDIN THISLICENSE AGRE EMENT,DSC’S ENTIRE

LIABILITYUND ERANY PROV ISIONOF THIS LICENSE AGREEMENT

SHALL BE LIMITEDTO THEGREA TEROF THE AMOUNTACTUA LLYP AID

BY YOUTO LICENSE THES OFTWARE PRODUCT ANDFIVE CANADIAN

DOLLARS (CAD$5.00). BECAUSE SOME JURISDICTIONSDO NOTALLOW

THE EXCLUSION ORLIMITATIONOF LIABILITY FORC ONSEQUENTIAL OR

INCIDENTAL DAMAGES,THE ABOV ELIMITATIONMAY NOTA PPLY TO

YOU.

(d) DISCLAIMEROF WARRANTIES -THIS WARRANTY CONTAINSTHE

ENTIRE WARRANTY AND SHALLB EIN LIEU OFANY AND ALLOTHE R

WARRA NTIES, WHETHERE XPRES SEDOR IMPLIED (INCLUDINGALL

IMPLIEDWAR RANTIESOF MERCHANTABILITY ORFITNESS FORA

PARTICULAR PURP OSE) AND OFALL OTHEROB LIGATIONSOR

LIABILITIES ONTHE PART OFDSC. DSCMAK ESN OOTHER

WARRA NTIES. DSCNE ITHER ASSUMES NOR AUTHORIZES ANY OTHER

PERS ONPURP ORTINGTO ACTON ITS BEHALF TOMODIFY ORTO

CHANGE THISWA RRANTY,NOR TOASS UMEFOR ITAN YOTHER

WARRA NTY ORLIABILITY CONCERNINGTHIS SOFTWAREP RODUCT.

(e) EXCLUSIVE REMEDY AND LIMITATIONOFWA RRANTY- UNDER NO

CIRCUMSTANCES SHA LLDSC BE LIABLE FOR ANYS PECIAL,

INCIDENTAL,CONS EQUENTIALOR INDIRECTDA MAGES BAS EDUP ON

BREA CHOF WARRANTY,B REACH OFCONTRACT,NE GLIGENCE,

STRICTLIAB ILITY,OR ANYOTHE RLEGAL THEORY.S UCHDA MAGES

INCLUDE,B UTARE NOTLIMITEDTO,LOS SOFP ROFITS,LOSS OFTHE

SOFTWARE PRODUCT ORANY ASS OCIATED EQUIPMENT,COST OF

CAPITAL, COSTOFS UBSTITUTEOR REPLACE MENT EQUIPMENT,

FACILITIES ORS ERVICES, DOWNTIME,PURCHA SERS TIME,THE

CLAIMS OFTHIRD PARTIES, INCLUDINGC USTOMERS ,AND INJURY TO

PROPE RTY.WARNING:

DSC recommendsthatthe entire systembe completelytested ona regularbasis.

However, despitefrequenttesting,and dueto,butnot limitedto,criminaltampering

or electrical disruption,itispo ssibleforthis SOFTWARE PRODUCTto failto performas expected.The termIC before the radiocertificationnumbers ignifiesthat the

IndustryC anadatechnicals pecifications weremet.ThisC lass B digitalapparatus

complieswith CanadianICES- 003.Thisdevice complieswith RSS-247 of

IndustryC anada.Operationis subjecttothe followingtwo conditions:(1) this

device maynotc auseinterference,and (2)this device mustac ceptany interference,including interference thatmaycaus eundesired operationofthe device.

Cetappareil numériquede laclasse Bes tconformeà lanormeN MB- 003du

Canada.Ce dispositifsatisfaitaux exigences d’IndustrieCanada, prescrites dans

ledoc umentCNR- 247.sonutilisationes tautoriséeseulementaux conditions

suivantes:( 1)ilne doitpas produirede brouillageet( 2)l’utilisateur dudispositifdoit

êtreprêt àacce pter toutbrouillage radioélectriquereçu, mêmesi cebr ouillagees t

susceptible decompromettrele fonctionnementdudis positif.

©2018 Tyco Security Products,Toronto,C anada www.dsc.com

Tech.Support:1-800-387-3630

D-307386 Rev.0 (09/18)

DRAFT SEP 11 (2)

Loading...

Loading...