Page 1

PG8WLSHW8 and PG9WLSHW8 IQ

Hardwire PowerG Wired to Wireless

Converter Installation Manual

*29010878R004*

29010878R004

Page 2

2 PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 3

Contents

Contents

Safety instructions.......................................................................................................................................... 5

Introduction.................................................................................................................................................... 6

Technical Specifications................................................................................................................................. 7

Installing the equipment............................................................................................................................. 10

Mounting the equipment................................................................................................................. 11

Mounting the enclosure.......................................................................................................................... 11

Mounting the power adapter................................................................................................................. 11

Wiring the zones................................................................................................................................ 13

Normally open and normally closed wiring......................................................................................... 14

Single end-of-line resistors..................................................................................................................... 14

Double end-of-line resistors................................................................................................................... 16

Wiring programmable outputs........................................................................................................ 17

Wiring a fire zone to the PGM2 configured as a 2-wire loop.............................................................. 18

Wiring a 4-wire smoke, heat, or CO detector....................................................................................... 20

Wiring auxiliary power...................................................................................................................... 21

Wiring the bell output....................................................................................................................... 21

Installing the battery......................................................................................................................... 22

Wiring the equipment....................................................................................................................... 23

Wiring the power supply......................................................................................................................... 23

Wiring the battery.................................................................................................................................... 23

Wiring a keypad....................................................................................................................................... 23

Enrolling the module................................................................................................................................... 26

Testing the module placement........................................................................................................ 26

Enrolling wired zones automatically.......................................................................................................... 27

Enrolling a keypad........................................................................................................................................ 28

Attaching the cover...................................................................................................................................... 29

Status LEDs................................................................................................................................................... 30

Troubleshooting........................................................................................................................................... 31

Wiring diagram............................................................................................................................................. 32

FCC and ISED Canada Information............................................................................................................ 33

Modification statement..................................................................................................................... 33

Interference statement..................................................................................................................... 33

Wireless notice................................................................................................................................... 33

FCC class B digital device notice................................................................................................................. 34

UL and ULC notes......................................................................................................................................... 35

UL commercial and residential installation requirements and considerations......................... 35

UL commercial, UL household, and ULC security level I and II burglar alarm unit................... 35

UL and ULC household fire warning system.................................................................................. 35

European CE Compliance and CERTALARM Certification........................................................................ 36

Simplified EU declaration of conformity......................................................................................... 36

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual 3

Page 4

EULA............................................................................................................................................................... 37

SOFTWARE PRODUCT LICENSE........................................................................................................ 37

Limited warranty.......................................................................................................................................... 40

International Warranty..................................................................................................................... 40

Warranty Procedure.......................................................................................................................... 40

Conditions to Void Warranty............................................................................................................ 40

Items Not Covered by Warranty...................................................................................................... 40

Disclaimer of Warranties.................................................................................................................. 41

Out of Warranty Repairs................................................................................................................... 41

Trademark..................................................................................................................................................... 42

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual4

Page 5

Safety instructions

Read the safety information before you install the equipment.

Important: This equipment must be installed by a skilled person only. A skilled person is an

installer with appropriate technical training. The installer must be aware of potential hazards

during installation and measures available to minimize risks to the installer and other people.

• Before you install this equipment, disconnect all power sources (for example mains, battery,

and telephone line) connected to the alarm panel.

• Install the equipment indoors in a non-hazardous environment where the following

conditions are met:

- Pollution degree - Maximum 2

- Over voltages - Category II

• Internal wiring must be routed to prevent strain on wire and terminal connections, loose

terminal connections, and damage to conductor insulation.

• Instruct the user that there are no user serviceable parts in this equipment. All equipment

must be serviced by a skilled person.

• Skilled persons are persons who have training or experience in the equipment technology,

particularly the various energies and energy magnitudes used in the equipment. Skilled

persons are expected to use their training and experience to recognize energy sources

capable of causing pain or injury and to take action for protection from injury. Skilled

persons are persons who have training or experience in the equipment technology,

particularly the various energies and energy magnitudes used in the equipment. Skilled

persons are expected to use their training and experience to recognize energy sources

capable of causing pain or injury and to take action for protection from injury.

5PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 6

Introduction

The IQ Hardwire PowerG Wired to Wireless Converter converts existing hardwired zones to PowerG

wireless zones.

There are two models, the PG8WLSHW8 and PG9WLSHW8, and each provide eight hardwired zones

and four programmable outputs. This document describes how to mount the enclosure, wire zones,

connect the battery, enroll devices, and troubleshoot.

Note: Only PG9WLSHW8 is UL and ULC listed. For UL and ULC installations, use this device only

in conjunction with compatible wireless receiver and control panel combinations, model Qolsys

IQPanel2.

Before you begin, make sure that the kit contains the following items:

• The plastic enclosure containing the IQ Hardwire PowerG Wired to Wireless Converter

• The transformer

• The hardware pack

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual6

Page 7

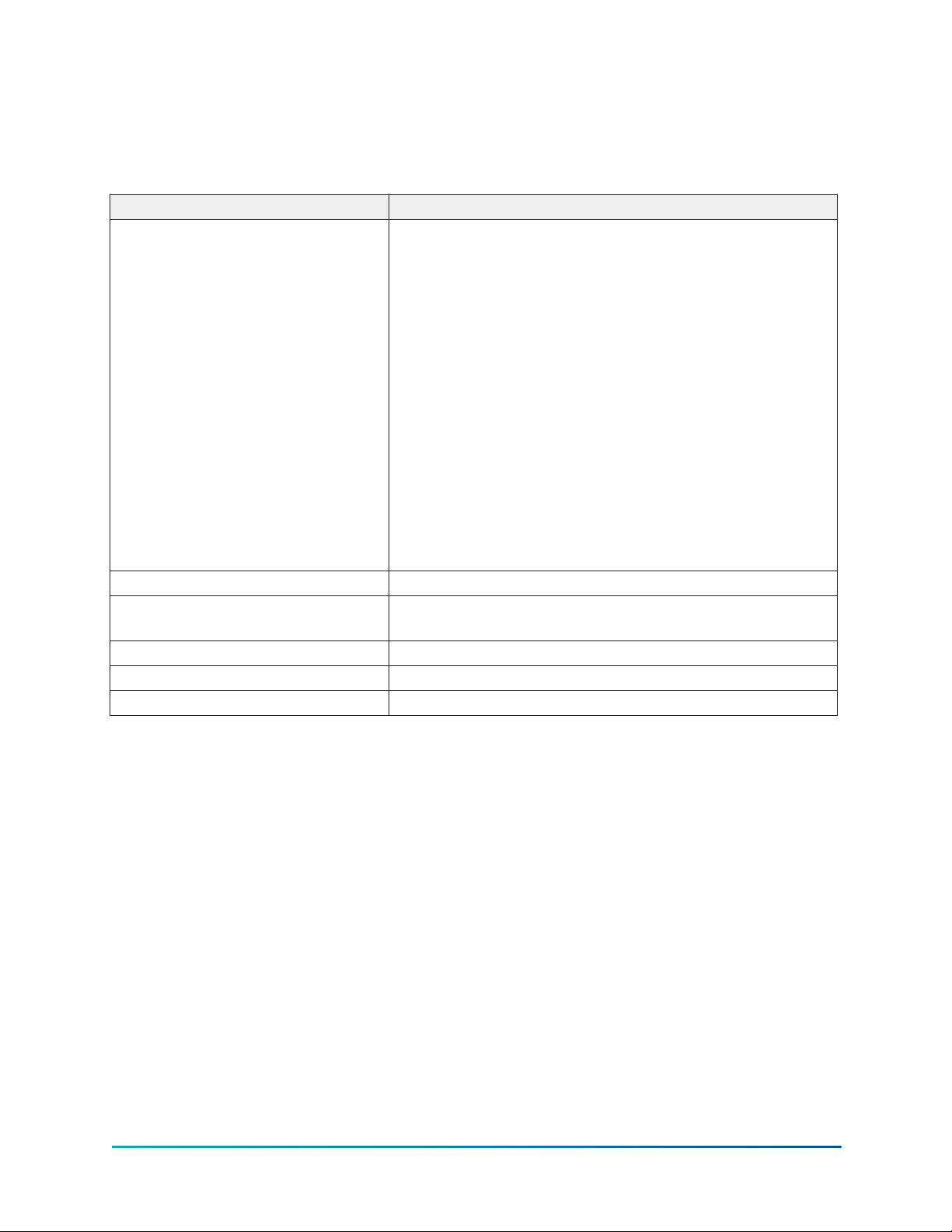

Technical Specifications

The following table outlines the electrical ratings of the components of the IQ Hardwire PowerG

Wired to Wireless Converter.

Table 1: Technical specifications

Type Description

DC input voltage and current Use the provided external power adapter with the following

ratings.

Input for UL and ULC applications: 120 VAC, 60 Hz, 1.2A

Input for EN50131 applications: 240 VAC (+10%, -15%), 50

Hz, 1.2 A

Output: 18 VDC, 2.22 A

Manufacturer: ShenZhen SOY Technology Co. Ltd.

UL and ULC Model: SOY-1800222-NA

EN model: SOY-1800222-EU

DSC UL and ULC part number: PGWLSH40A

DSC EN part number: PGWLSH40C

Battery type Sealed, rechargeable lead acid

Battery charging voltage and

current

Low battery threshold 11.4 VDC

Battery cutoff level 9.6 VDC ± 2%

PCB assembly current consumption 70 mA

13.7 VDC, 360 mA

7PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 8

Table 1: Technical specifications

Type Description

Standby battery Only use the battery rated 12 VDC/ 7 Ah

The energy level of the battery when it is charged is 100%

24-hour standby time and 5-minute alarm time for UL and

ULC residential fire applications and ULC Security Level II

applications.

Note: The AUX current must not exceed 180 mA.

24-hour standby time and 5-minute alarm time for UL and

ULC residential fire applications and 12-hour CO alarm.

Note: The AUX current must not exceed 110 mA.

4-hour standby time and 5-minute alarm time for UL and

ULC residential burglary applications.

Note: The AUX current must not exceed 700 mA.

4-hour standby time and 15-minute alarm time for UL

commerical burglary applications.

Note: The AUX current must not exceed 700 mA.

Note: For EN50131 Grade 2 applications, the devices

provide 12 hours of standby time and recharge in 72

hours. The AUX current load must not exceed 430 mA.

Bell circuit voltage and current 11.3 VDC to 12.5 VDC, maximum current 700 mA

continuous. For EN50131 Grade 2 applications, the voltage

rating is 9.6 VDC to 13.75 VDC.

Note: The bell output supports continuous burglary

alarms, T3 fire alarms, and T4 CO alarms. Alarms sound

in the following priority: fire alarm, CO alarm, burglary

alarm, and other alarms.

Auxiliary power voltage and current.

Note: AUX1 is used only for

burglary alarm initiating

devices. AUX2 is used only for

fire alarm initiating devices

such as smoke, heat, and CO

detectors.

11.3 VDC to 12.5 VDC, maximum current 700 mA shared

between the AUX1 and AUX2, CORBUS RED and BLK

terminals and PGM outputs. Ripple: 50 mVpp.

Note: For EN50131 Grade 2 applications, the voltage

rating is 9.6 VDC to 13.75 VDC and the maximum

current load is 430 mA.

PGM 1, 3, and 4 voltage and current 11.3 VDC to 12.5 VDC, 50 mA

PGM 2 voltage and current 11.3 VDC to 12.5 VDC, 300 mA

PG9WLSHW8 Frequency band: 912.75 MHz to 919.106 MHz

Maximum power: 0.0447 W

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual8

Page 9

Table 1: Technical specifications

Type Description

Operating temperature -10°C to 55°C (14°F to 131°F)

Note: UL and ULC only verified operation for the range

0°C to 49°C (32°F to 120°F).

Note: The Converter and power supply are suitable for

use only inside the supervised premises.

Humidity 5% to 93% RH non-condensing.

Note: UL and ULC only verified operation for a

maximum of 93% RH.

Dimension 250 mm x 225 mm x 80 mm (9.8" x 8.9" x 3.1")

Weight 2.85 kg (6.28 lb) including the battery

Note: The PGM outputs are shared with the CORBUS RED and BLK terminals and the AUX

terminals.

9PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 10

Installing the equipment

This section describes how to mount the enclosure, install the battery, and wire the system.

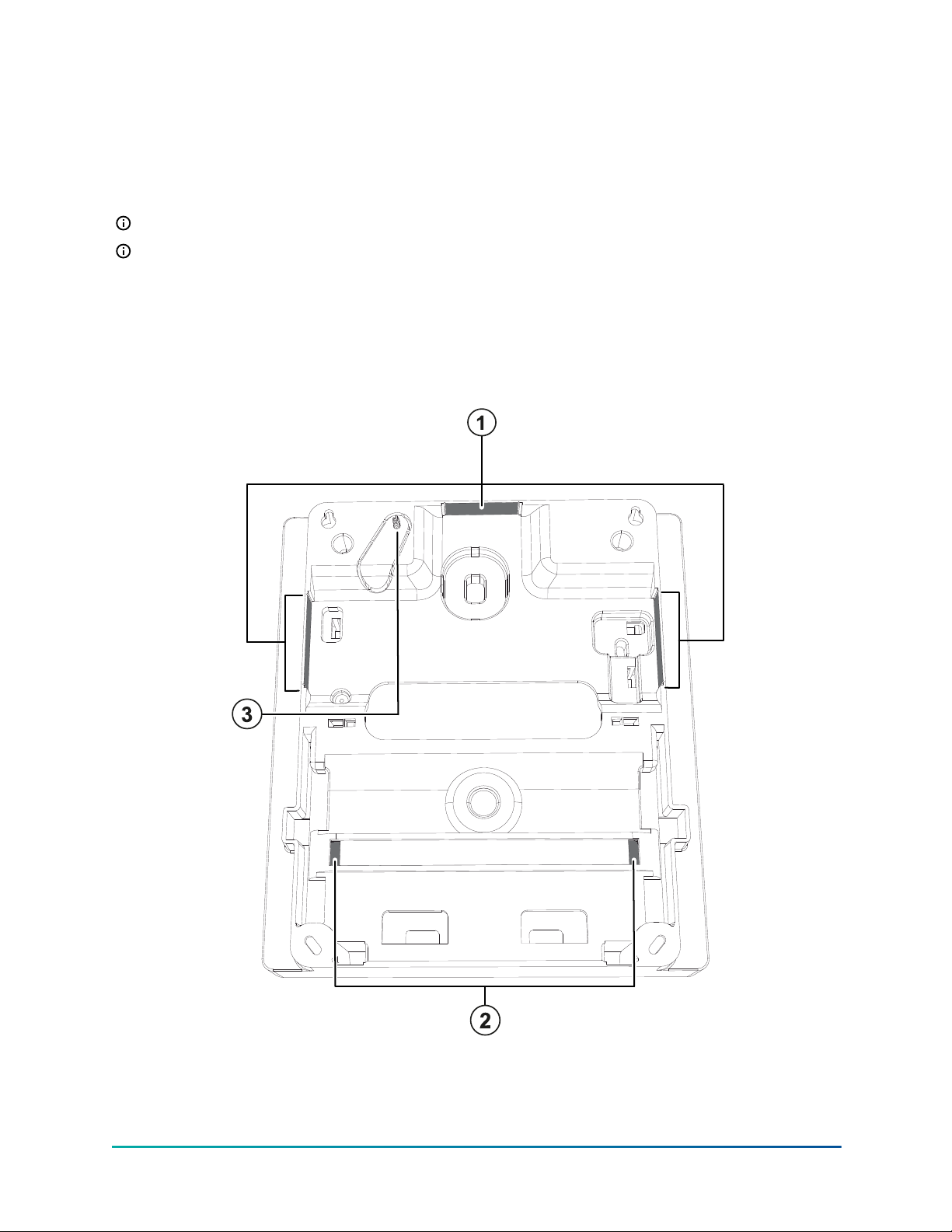

The enclosure has three breakaway tabs that you can use for wiring access during installation.

There are also two slots for the battery strap to pass through. For more information, see the

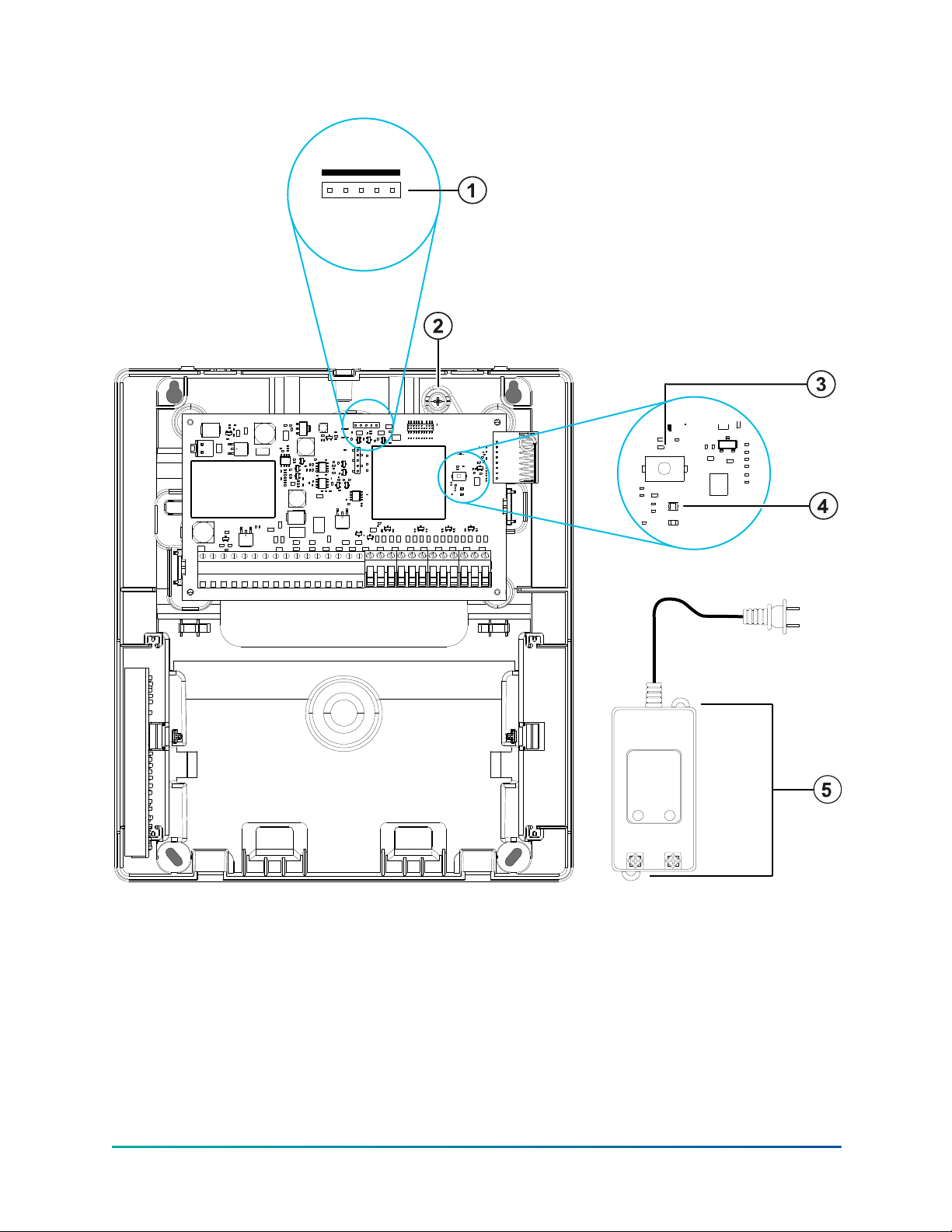

highlighted areas in Figure 1.

Note: Remove the breakaway tabs only if required.

Note: Install the equipment in the protected area of the protected premises. The wiring

methods shall be in accordance with ULC-S302, NFPA72, the National Electrical Code, ANSI/

NFPA 70, the Standard for Installation and Classification of Burglar and Holdup Alarm Systems,

UL 681, and the Standard for Central Station Alarm Services, UL 827. This equipment should be

installed in accordance with Chapter 29 of the National Fire Alarm and Signaling Code, ANSI/

NFPA 72, (National Fire Protection Association, Batterymarch Park, Quincy, MA 02269).

Figure 1: Breakaway tabs and battery strap slots

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual10

Page 11

Callout Description

1 Breakaway tabs

Slots for the battery strap

2

3 Wall tamper screw

Note: Securing the battery in the enclosure with the battery strap is

optional. The battery strap is sold separately.

Mounting the equipment

This section describes how to mount the enclosure and the external power adapter.

Mounting the enclosure

To mount the enclosure, complete the following steps:

1. Use the four screws provided to secure the enclosure to the wall. For more information, see

the highlighted areas in Figure 2.

Note: Screws are provided only for the model PG9WLSHW8.

2. To enable the wall tamper, secure the tamper screw to the wall. For more information, see

Figure 2.

Mounting the power adapter

You must mount the power adapter outside the PGXWLSHW8 enclosure. To mount the power

adapter, complete the following step:

• Use two screws to secure the power adapter to the wall. For more information, see Callout 5

in Figure 2.

Note: Mount the power adapter close to an AC power outlet so there is no strain on the

power cable. Do not connect the power adapter to a receptacle controlled by a switch.

11PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 12

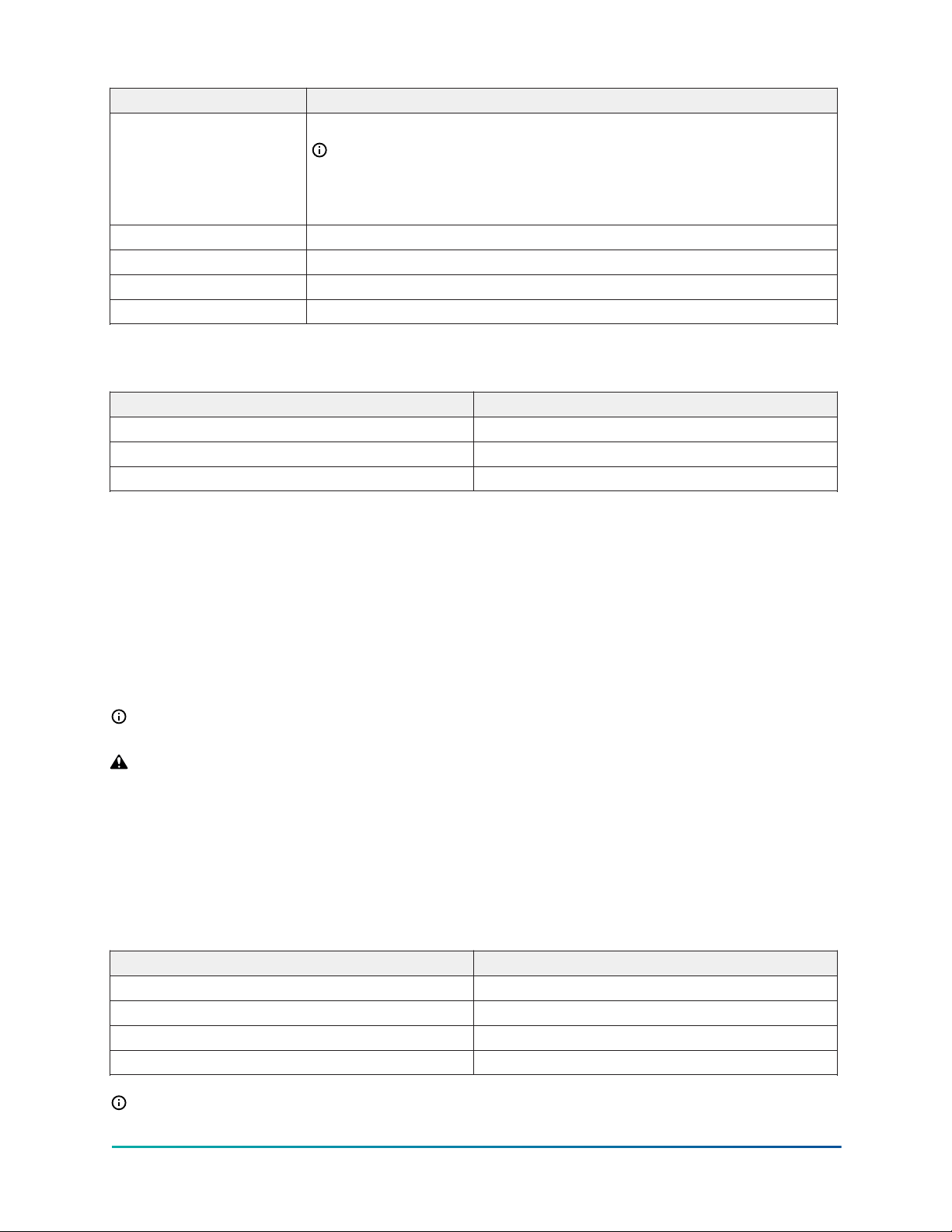

Figure 2: Mounting locations

+

-

1

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual12

Page 13

Callout Description

1 PC Link connection.

Note: Pin one is on the right. When you connect to the PC Link,

make sure that the PCB side of the PC Link connector aligns with

the white line on the module PCB, and use only the four pins on

the right.

2 Wall tamper screw

3 Enrollment button

4 Status LED

5 Power adapter mounting tabs

Use the following table to determine the distance and gauge for the secondary wiring.

Table 2: Wiring distance and gauge

Distance (m/ ft) Gauge (AWG)

2/ 6.5 22

3/ 10 20

4/ 13 18

For UL and ULC installations, use a primary input with ratings of 120 VAC, 60 Hz, and 1.2 A.

For CE and EN50131 Grade 2 installations, use a primary input with ratings 230 VAC (+10%, -15%), 50

Hz, and 1.2 A.

For all installations, the output rating of the power adapter is 18 VDC and 2.22 A.

Wiring the zones

You can wire zones to supervise normally open devices, for example smoke detectors or

heat detectors, or normally closed devices, for example door contacts. You can program the

PGXWLSHW8 for single end-of-line (SEOL) resistors, or double end-of-line (DEOL) resistors.

Note: For UL and ULC installations, use only UL and ULC listed initiating devices that are

compatible with the auxiliary output power range provided by the converter.

CAUTION: Ensure the alarm controller is turned off before you wire the equipment.

When you wire zones, observe the following guidelines:

• For UL and ULC listed installations, only use SEOL or DEOL connections.

• Use a minimum wire size of 22 AWG and a maximum wire size of 18 AWG.

• Do not use shielded wires.

• Do not exceed a wire resistance of 100 Ω. For more information, see the following table.

Table 3: Wiring chart

Wire gauge (AWG) Maximum distance to EOL resistor (m/ ft)

22 914/ 3000

20 1493/ 4900

19 1889/ 6200

18 2377/ 7800

Note: Distances are based on a maximum wiring resistance of 100 Ω.

13PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 14

Normally open and normally closed wiring

Wire normally closed devices in series and normally open devices in parallel. To wire hardwired

devices, complete the following steps:

1. Wire the device to any Zone terminal.

2. Wire the device to any COM terminal.

Note: For UL and ULC installations, do not use normally open or normally closed loops.

The following figure shows you how to wire normally closed loops. The image on the left shows

two normally closed contacts with no end-of-line resistor, and the image on the right shows one

normally closed contact with no end-of-line resistor.

Figure 3: Normally closed loops

Callout Description

1 Zone terminal

2 COM terminal

3 Normally closed contact

Note: Do not exceed a wire resistance of 100 Ω. For more information, see Table 3.

The following table shows the zone status for a given resistance value.

Table 4: Normally closed zone status

Resistance Description Zone status

0 Ω Shorted wire, loop shorted Secure

Infinite Broken wire, loop open Alarm

Single end-of-line resistors

You can use SEOL resistors to detect if a circuit is secure, open, or shorted. Use this option if you

use either normally closed or normally open devices.

You can configure SEOL supervision through zone programming on the control panel.

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual14

Page 15

The following figure shows the different wiring configurations for SEOL resistors. The image on the

left shows one normally closed contact with an SEOL resistor, and the image on the right shows one

normally open contact with an SEOL resistor.

Note: SEOL resistors can have a resistance between 1 kΩ and 10 kΩ. You must install the

SEOL resistor at the end of the loop. UL and ULC verified functionality only with a 5.6 kΩ SEOL

resistor.

For ULC Security Level I burglary installations, use the wiring configurations in Figure 4.

For fire detection installations that use smoke detectors, powered or non-powered heat detectors,

or CO detectors, use the wiring configuration on the right hand side of Figure 4. These devices

use separate AUX2 output for power. Make sure that the voltage range of the AUX2 output is

compatible with the input voltage range of the detector you are using.

Figure 4: SEOL wiring

Callout Description

1 Zone terminal

2 COM terminal

3 Normally open contact

4 End-of-line resistor

5 Normally closed contact

Note: Do not exceed a wire resistance of 100 Ω. For more information, see Table 3.

The following table shows the zone status for a given resistance value.

15PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 16

Table 5: SEOL zone status

Resistance Description Status

0 Ω Shorted wire, loop shorted Alarm

1 kΩ to 10 kΩ Contact closed Secure

Infinite Broken wire, loop open

Alarm for burglary zones and

Trouble for fire zones

Double end-of-line resistors

If you use DEOL resistors at the end of a zone loop, the second resistor detects if a zone is in alarm,

tampered, or faulted. You can select DEOL supervision only if you are using normally closed devices

or contacts. You can use only one normally closed contact in each zone.

Note: Any zone programmed for fire or 24 hour supervisory must be wired with a SEOL

resistor regardless of the type of zone wiring supervision selected for the panel. If you change

the zone supervision from DEOL to SEOL, or from NC to DEOL, turn off the system completely

and then turn on the system for correct operation.

You can configure DEOL supervision through zone programming on the control panel.

For ULC Security Level II installations, use the wiring configuration in the following figure.

Figure 5: DEOL wiring

Callout Description

1 Zone terminal

2 COM terminal

3 5600 Ω end-of-line resistor

4 Normally closed contact

Note: Do not exceed a wire resistance of 100 Ω. For more information, see Table 3.

Note: DEOL wiring is only for burglary use.

The following table shows the zone status for a given resistance value:

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual16

Page 17

Table 6: DEOL zone status

Resistance Description Status

0 Ω Shorted wire, loop shorted Trouble

5600 Ω Contact closed Secure

Infinite Broken wire, loop open Tamper

11200 Ω Contact open Alarm

Wiring programmable outputs

You can use the programmable (PGM) outputs to activate devices such as LEDs and buzzers. To

wire an output to the PGM, complete the following steps:

1. Connect the positive wire from the device to the AUX+ terminal.

2. Connect the negative wire from the device to the PGM terminal.

Note: If the device requires a current greater than the rated value of the PGM output, a

relay and an approved power supply are required.

To wire the LED indicator, see Figure 6.

Figure 6: LED indicator wiring

17PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 18

Callout Description

1 AUX terminals

2 PGM terminals

3 LED indicator

4 680 Ω resistor (typical value)

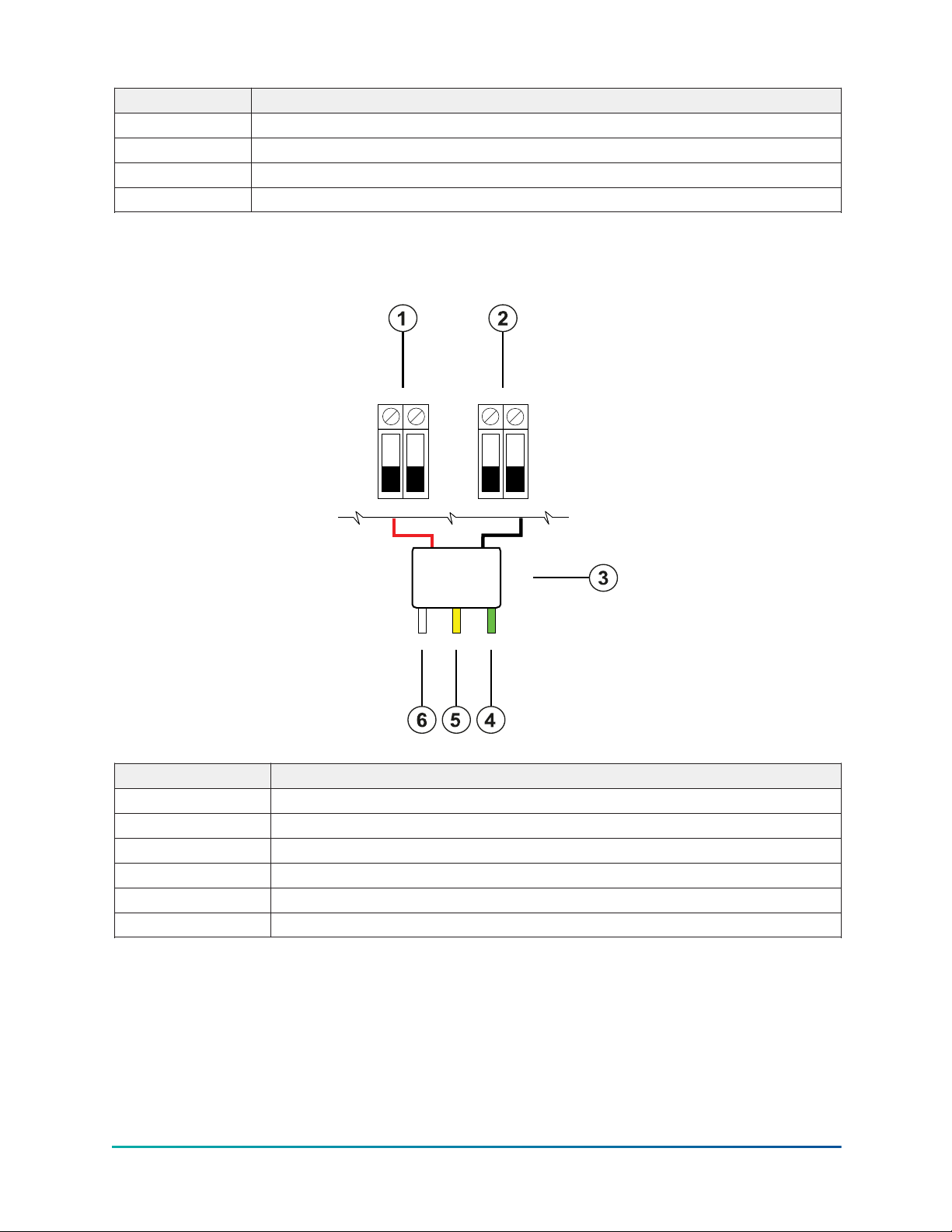

To wire the relay output, see Figure 7.

Figure 7: Relay output wiring

Callout Description

1 AUX terminals

2 PGM terminals

3 Relay (RM-1 and RM-2)

4 To normally open connection

5 To normally closed connection

6 To COM terminal

Wiring a fire zone to the PGM2 configured as a 2-wire loop

When you wire a 2-wire smoke detector, observe the following guidelines:

• You must connect 2-wire smoke detectors in parallel.

• You can wire a maximum of 18 smoke detectors on a 2-wire loop.

• Do not exceed a wire resistance of 24 Ω across the entire loop.

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual18

Page 19

• Do not use smoke detectors from different manufacturers on the same circuit as their

AUX2

1

PGM

3 4

-

+

2

+

-

+

-

operation may be impaired. Refer to the smoke detector installation sheet when you position

detectors.

• For UL and ULC residential fire applications, use only the AUX2 output to provide power to

smoke and CO detectors.

If you program PGM2 for use with a 2-wire smoke detector, you must wire it according to the

following figure:

Figure 8: 2-wire smoke detector wiring

Callout Description

1 2200 Ω end-of-line resistor

The following table lists compatible 2-wire smoke detectors:

Table 7: 2-wire smoke detectors

Detector name

FSA-210X FSA-210XLST FSA-210XRST C2WTA-BA (ULC)

FSA-210XT FSA-210XR FSA-210XLRST 2W-B (UL)

FSA-210XS FSA-210XRT C2W-BA (ULC) 2WT-B (UL)

FSA-210XST FSA-210XRS C2WT-BA (ULC) 2WTA-B (UL)

Note: For the DSC FS210 series, X in the detector name represents A for ULC and B for UL

listed models.

Note: If you use System Sensor detectors on a 2-wire loop, do not combine UL and ULC

detectors. For more information, refer to the System Sensor installation manual.

Note: Do not connect accessories, such as a PRM-2W or any other polarity reversal module, to

2-wire smoke detectors.

The UL compatibility ID for the FSA-210B series is FS200, and for the System Sensor models is A.

Note: For ULC listed installations, use FSA-210A series detectors or FSA-410A series detectors.

Note: You must calculate and test the current draw.

19PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 20

Table 8: 2-wire smoke detector initiation circuit

Item Specification

Class, supervised, power limited Class B IDC. 2-wire smoke detector interface

Compatibility identifier PG9WLSHW8-1

DC output voltage 10.0 VDC to 13.8 VDC

Detector load 2 mA maximum

SEOL 2200 Ω

Maximum capacitance 10 μF

Maximum number of detectors per loop 18 without sounders

Maximum ripple 45 mV

Resting voltage and time 0.2 VDC/ 5 seconds

Loop resistance 24 Ω maximum

Minimum standby impedance 1250 Ω nominal

Maximum alarm impedance 707 Ω maximum

Alarm current 102 mA maximum

Wiring a 4-wire smoke, heat, or CO detector

The following table lists the maximum current rating at 12 VDC of the hardwired CO detectors that

are compatible with the PG9WLSHW8 converter.

Table 9: CO detector ratings

Device Manufacturer UL file number Rating

CO-12/24 Potter E321434 40 mA

12-24SIR Quantum E186246 75 mA

Note: If you wire multiple CO detectors on the same loop, you must break the leads between

each CO detector. You must power the supervision relay from the last detector in the loop.

If you use a non-powered heat detector, such as a fixed temperature or rate of rise type, no

supervision relay is required and you should not wire the detector to AUX2 or PGM2.

To wire a 4-wire smoke, heat, or CO detector, see the following figures:

Note: Do not exceed a wire resistance of 100 Ω. For more information, see Table 3.

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual20

Page 21

Figure 9: CO detector wiring

NC NO

-

+

C NC NOC

-+

+

-

COM

Z

AUX

NC NO

-

+

C NC NOC

-+

+

COM Z

AUX2 PGM

2

Figure 10: 4-wire smoke and heat detector

wiring

Callout Description

1 4-wire smoke, heat, or CO detector power terminals

2 4-wire smoke, heat, or CO detector alarm terminals

3 4-wire smoke, heat, or CO trouble terminals, if provided

4 5600 Ω single end-of-line resistor

5 100 Ω alarm initiating loop

6 RM-1 or RM-2 power loop supervisory relay, 12 VDC, 35 mA.

7 Module zone input

Note: You can manually configure PGM2 as a 2-wire smoke loop in panel programming. If you

configure any zone input as a fire zone, PGM2 is automatically set as a 4-wire smoke detector,

and acts as a power reset. You cannot combine 2-wire detectors and 4-wire smoke or heat

detectors at the same time on the converter.

Wiring auxiliary power

You can use the auxiliary power terminals to power devices such as motion detectors and glass

break detectors. The AUX1 and AUX2 terminals provide a combined current of 700 mA.

Note: For UL and ULC combination fire and CO and burglary applications, the fire and CO

initiating devices, such as smoke detectors, heat detectors, and CO detectors, must be

powered from a separate output (AUX2) than the burglary initiating devices (AUX1).

Note: For UL and ULC installations that require 24-hour backup capacity, the maximum AUX

power load cannot exceed a current of 180 mA when using a 7 Ah battery.

Wiring the bell output

You can use the BELL terminals to power a bell, siren, or other device which requires a steady

output voltage when the system is in alarm. The panel provides a current of up to 700 mA.

Note: A 1 kΩ resistor is required across the BELL+ and BELL- terminals, or the system detects a

trouble condition.

21PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 22

Installing the battery

To install the 12 VDC/ 7 Ah battery in the enclosure, complete the following steps:

Note: The battery is sold separately.

1. Place the battery on the two plasic supports on the bottom of the enclosure. For more

information, see Figure 11.

2. Clip the battery in place.

3. Optional: The battery can also be secured in place using a battery strap. To secure the

battery using the battery strap, complete the following steps:

Note: The battery strap is sold separately.

a. Place the battery on the two plasic supports on the bottom of the enclosure.

b. Insert the battery strap through one of the slots.

c. Wrap the strap around the front of the battery.

d. Insert the strap through the second slot.

Figure 11: Installing the battery

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual22

Page 23

Wiring the equipment

+

-

-

+

-

+

This section describes how to wire the external power supply and battery. For more information,

see Figure 12.

Wiring the power supply

To wire the external power supply, complete the follow steps:

1. On the power supply, secure the wires to the terminals.

2. Insert the cable through the back of the enclosure.

3. Connect the wires to the 18 VDC terminals on the PCB.

Wiring the battery

To wire the battery, complete the following steps:

1. Connect the red battery lead to the positive terminals on the PCB and the battery.

2. Connect the black battery lead to the negative terminals on the PCB and the battery.

Figure 12: Wiring the battery

Important: You must maintain a minimum separation of 6.4 mm (0.25 in.) at all points

between non-power limited battery wiring and all other power limited wiring connections. Do

not route any wiring over circuit boards. You must maintain a minimum separation of 25.4 mm

(1 in.) between all wiring and the PCB.

Wiring a keypad

For v1.1 and higher, you can wire a maximum of four keypads to the PG8WLSHW8 or PG9WLSHW8.

23PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 24

Note: For UL and ULC compliant installations, make sure that the maximum current draw

for the AUX outputs, CORBUS RED and BLK, and any PGM outputs do not exceed the limits in

Table 1. The keypad is only for supplementary use in addition to the panel's user interface. For

information on how to enroll a keypad, see Enrolling a keypad. For information on how to use

the keypad, refer to the keypad user manual.

The PG8WLSHW8 or PG9WLSHW8 supports the following keypads:

- HS2ICON

- HS2ICONP

- HS2LCD

- HS2LCDP

- HS2LCDENG

Note: Proximity tags are not supported on the PG8WLSHW8 or PG9WLSHW8.

You can use the keypad to perform the following operations:

- To arm and disarm the system.

- To view zone status.

- To view partition status.

- To use the keypad function keys.

- The * menus are not supported, except for buzzer frequency, keypad contrast, and keypad

brightness settings in the * 6 menu.

For more information on how to install the keypad, refer to the keypad's installation manual.

To wire a keypad to the PGxWLSHW8, complete the following steps:

1. Remove the keypad backplate. For information on how to remove the keypad backplate, refer

to the keypad installation manual.

2. Connect the R, B, Y, and G terminals to the Corbus terminals on the PGxWLSHW8.

Note: The PGxWLSHW8 does not support the keypad zone/PGM input terminal.

Note: The Corbus should be run with minimum 22 wire gauge quad. two pair twisted

preferred. Devices can be home run to the panel, connected in series, or T-tapped.

Devices cannot be more than 1000 ft (305 m) in wire length from the panel. Do not use

shielded wire for Corbus wiring.

Figure 13: Keypad terminals

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual24

Page 25

Callout Description

1 R terminal

2 B terminal

3 Y terminal

4 G terminal

5 Not supported

Note: When you install multiple keypads and modules, wire keypads using the same

partition on the same module to improve keypad performance. For example, wire

keypads on partition one into module one, and wire keypads on partition two into

module two.

25PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 26

Enrolling the module

Before you enroll the module, ensure that all hardwired zones, PGM, AUX, and BELL are wired to the

module.

To enroll the module, complete the following steps:

1. Enable enrollment through panel programming. For more information, refer to the Qolsys

IQPanel2 Installation Manual.

2. Press the Enroll button on the PCB and release when the LED lights solid orange.

3. Confirm the correct module ID in panel programming.

Note: The module ID is on the module label. It is a seven digit number that identifies the

device being enrolled. It has the format 460-XXXX.

Testing the module placement

To test the signal strength between the module and the alarm panel, complete the following steps:

• Press the Enroll button on the module.

After the placement test is complete, the color of the LED indicates the signal strength. For more

information, see Table 10.

Table 10: Device signal strength

LED color Signal strength

Three red flashes Poor

Three orange flashes Medium

Three green flashes Strong

Note: For UL and ULC installations, only a strong signal strength is acceptable.

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual26

Page 27

Enrolling wired zones automatically

When you successfully enroll the module to the control panel, eight hardwired zones are added to

the control panel. The zones display on the control panel with the same ID as the module and zone

label as the corresponding hardwired input. Enable and configure each zone input and PGM using

the zone configuration options on the control panel.

27PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 28

Enrolling a keypad

To enroll a keypad on to the module, complete the following steps:

1. Select Settings > Advanced Settings > Installation > Devices > Security Sensors.

a. To automatically enroll all keypads that are correctly wired to the module, select Auto

Learn.

b. To manually enroll a keypad that is correctly wired to the module, select Add Sensor.

Enter the module serial number, 460-XXXX, then select Corbus from the Hardwired Input

drop-down menu and enter the keypad serial number.

Note: You must confirm and accept the keypad enrollment on the IQ Panel 2.

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual28

Page 29

Attaching the cover

To attach the front cover to the enclosure, follow the numbered steps in Figure 14.

Figure 14: Attaching the cover

29PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 30

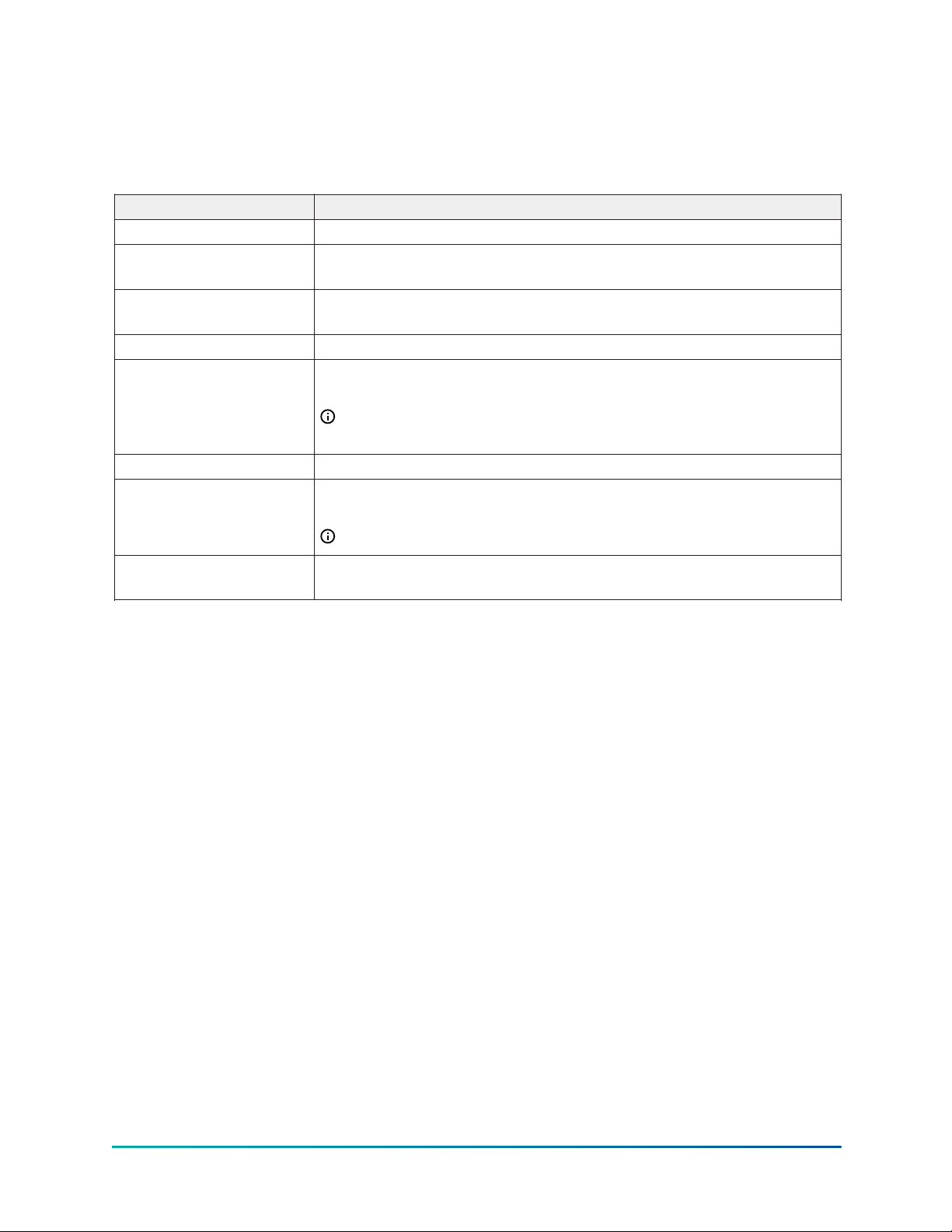

Status LEDs

There is one multicolored LED on the module. The following table describes the status of the

module based on the color of the LED.

Table 11: Status LEDs

Mode Description

Turn on The red LED is on while the module turns on.

Placement test The color of the LED shows the signal strength of the enrolled device.

For more information, see Table 10.

Firmware upgrade in

progress

Firmware upgrade failed The red LED flashes every 120 ms if the firmware update fails.

Trouble The orange LED flashes twice every 10 seconds if any troubles are

Device enrollment The orange LED turns on when the enrollment button is pressed.

Device defaulting The red LED turns on if the enrollment button is pressed and held for

The red LED flashes every 800 ms while the system firmware updates.

detected, excluding a tamper trouble.

Note: For detailed information on device troubles, see the control

panel.

10 seconds.

Note: This defaults all module programming to factory settings.

Normal operation The green LED flashes once every 10 seconds. The module is operating

normally, with no troubles detected.

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual30

Page 31

Troubleshooting

To perform a local update of the firmware, use DLS 5 or higher.

The status LED indicates if a trouble condition is present. You can view the trouble conditions in

detail on the alarm panel.

The following table describes the trouble states that the module can detect.

Table 12: Troubleshooting

Trouble Description

Loss of AC Ensure that there is power to the module, and that the voltage is within the 16

VDC to 20 VDC range at the transformer output.

Module tamper Ensure that the back tamper plastic is in place and that the front cover of the

enclosure is correctly secured.

Zone fault Ensure that the zone is correctly wired and ensure that the zone EOL is

correctly programmed.

Aux Short or overload: There is a short or overload on the AUX terminals.

Low voltage: The output voltage is below 9.8 VDC.

Low battery The battery voltage is below the low battery threshold of 11.5 VDC.

No battery There is no current detected on the battery terminals.

Fail to Enroll Press and hold the Enroll push button for 10 seconds to default the module,

then attempt to enroll again.

Bell circuit The bell circuit is open. The load is less than 1 kΩ.

Note: When you configure PGM2 for use with a 2-wire smoke detector, any troubles detected

show on the panel as a fire trouble.

31PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 32

Wiring diagram

Applicable standards

UL985 Household Fire Warning System Units

UL1023 Househole Burglar Alarm System Units

UL1610 Standard for Central-Station Burglar-Alarm Units

ULC-S545 Standard for Residential Fire Warning System Control Units

CAN/ULC-S304 Standard for Control Units, Accessories and Receiving

Equipment for Intrusion Alarm Systems, Security Level I - II

Install the equipment in the protected area of the protected

premises. The wiring methods shall be in accordance with

NFPA72, the National Electrical Code, ANSI/NFPA 70, the

Standard for Installation and Classification of Burglar and

Holdup Alarm Systems, UL 681, ULC-S302, and the

Standard for Central Station Alarm Services, UL 827. This

equipment should be installed in accordance with Chapter 29

of the National Fire Alarm and Signaling Code, ANSI/NFPA

72, (National Fire Protection Association, Batterymarch Park,

Quincy, MA 02269).

This device complies with Part 15 of the FCC Rules and

ISED Canada licence-exempt RSS standard(s). Operation is

subject to the following two conditions: (1) this device may

not cause interference, and (2) this device must accept any

interference, including interference that may cause undesired

operation of the device.

FCC ID: F5320PG9WLSHW8

PGM connections

LED indicator

AUX1

PGM

LED indicator

660 Ω resistor,

typical value

Relay output

AUX1

PGM

COM NC

NO

RM-1 or

RM-2 relay

Typical zone circuits

Z

COM

Z

COM

Z

COM

NC contact

with SEOL

resistor

NO contact

with SEOL

resistor

NC contact with

5600 Ω DEOL

resistors

1 8765432 COMCOMCOMCOM

4

PGM

1 2 3

AUX2AUX1

+ +

--

R B Y G

CORBUS

ZONE ZONEZONEZONE

BELL

+

-

+

-

18VDC

To AUX+. PGM4 50 mA maximum

To AUX+. PGM1 50 mA maximum

To AUX+. PGM2 300 mA maximum

To AUX+. PGM3 50 mA maximum

700 mA maximum.

Observe polarity

12 V, 7 Ah

battery.

360 mA

charging

current

UL and ULC installations:

120 VAC, 60 Hz, 1.2 A.

CE installations: 230

VAC, 50 Hz, 1.2 A

DSC part number:

PGWLSH40A

Note: Do not connect the

power adapter to a

receptacle controlled by

a switch.

Warning: High voltage. Disconnect DC power before servicing.

Incorrect connections may result in PTC failure or improper

operation. Inspect wiring and ensure connections are correct

before turning on the power. Do not route any wiring over

circuit boards. Maintain at least 25.1 mm (1 in) separation.

All circuits are classified for UL installations as power limited or

class II power limited, except for the battery leads, which are not

power limited. A minimum separation of 6.4 mm (0.25 in) must be

maintained at all points between power limited and non-power

limited wiring.

Resistor identification

2-wire smoke detector

RED

RED

RED

GOLD

2200 Ω

5%

Bell circuit

RED

GOLD

BLK

BRWN

5%

1000 Ω

Single zone EOL

RED

GOLD

GRN

BLUE

5%

5600 Ω

Corbus:

Power for the

keypad.

4-wire smoke detectors

NC

NO

-

+

C

NCNOC

-+

+

COM Z

AUX2 PGM

2

The type of smoke detector must be latching. To

reset the smoke detector, refer to the panel

installation manual

Note: To locate smoke detectors, refer to the panel

installation manual and smoke detector installation

manual.

5600 Ω

100 Ω

alarm

initiating

loop

RM-1 or RM-2 power loop

supervisory relay, 12 VDC,

35 mA.

Power

terminals

Alarm

terminals

Trouble

terminals

AUX2

1

PGM

3 4-+ 2

+

-

+

-

2-wire smoke detectors

Compatiblity idendtifyer: PG9WLSHW8-1

Maximum operating voltage: 13.8 VDC

Maximum circuit resistance: 100 Ω

Maximum number of detectors: 18

Note: Do not use smoke detectors from different

manufacturers on the same circuit as their operation

may be impaired.

2200 Ω

FSA-210X FSA-210XRST

FSA-210XT FSA-210XLRST

FSA-210XS C2W-BA (ULC)

FSA-210XST C2WT-BA (ULC)

FSA-210XLST C2WTA-BA (ULC)

FSA-210XR 2W-B (UL)

FSA-210XRT 2WT-B (UL)

FSA-210XRS 2WTA-B (UL)

Compatible 2-wire smoke detectors

AUX1: Power for intrusion detectors.

AUX2: Power for smoke, heat, and CO detectors.

For an overview of how to wire the system, see the following figure.

Figure 15: Wiring diagram

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual32

Page 33

FCC and ISED Canada Information

This information applies to model PG9WLSHW8.

Modification statement

Tyco Safety Products Canada Ltd. has not approved any changes or modifications to this device by

the user. Any changes or modifications could void the user’s authority to operate the equipment.

Tyco Safety Products Canada Ltd. n’approuve aucune modification apportée à l’appareil par

l’utilisateur, quelle qu’en soit la nature. Tout changement ou modification peuvent annuler le droit

d’utilisation de l’appareil par l’utilisateur.

Interference statement

This device complies with Part 15 of the FCC Rules and ISED Canada licence-exempt RSS

standard(s). Operation is subject to the following two conditions: (1) this device may not cause

interference, and (2) this device must accept any interference, including interference that may

cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'ISED Canada applicables aux appareils radio exempts

de licence. L'exploitation est autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas

produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique

subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

Wireless notice

This equipment complies with FCC and IC radiation exposure limits set forth for an uncontrolled

environment. The antenna should be installed and operated with minimum distance of 20 cm

between the radiator and your body. This transmitter must not be co-located or operating in

conjunction with any other antenna or transmitter.

Cet appareil est conforme aux limites d'exposition aux rayonnements de la IC pour un

environnement non contrôlé. L'antenne doit être installé de façon à garder une distance minimale

de 20 centimètres entre la source de rayonnements et votre corps. L'émetteur ne doit pas être

colocalisé ni fonctionner conjointement avec à autre antenne ou autre émetteur.

33PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 34

FCC class B digital device notice

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This equipment generates uses and can

radiate radio frequency energy and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by turning the equipment

off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003du Canada.

WARNING: To satisfy FCC RF exposure requirements for transmitting devices, a separation

distance of 20cm or more must be maintained between the antenna of this device and persons

during device operation.

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual34

Page 35

UL and ULC notes

The model PG9WLSHW8 has been listed by UL and ULC for commercial burglary and residential

fire/burglary applications in accordance with the requirements in the Standards UL1610/UL1023/

UL985 and ULC-S304/ULC-S545. For UL/ULC installations, use this device only in conjunction with

compatible wireless receivers/control panels combination, model Qolsys IQPanel2.

Test the system weekly. Replace the standby battery every three to five years.

UL commercial and residential installation requirements and considerations

UL commercial, UL household, and ULC security level I and II burglar alarm unit

• Power supply model SOY-1800222-NA (PGWLSHW40A) shall be employed.

• One optional UL or ULC listed audible device rated to operate over the voltage range of 11.3

VDC to 12.5 VDC and rated 85 dB minimum.

• One compatible Qolsys IQPanel2 with PowerG modem card.

• All input zones shall be programmed as end of line supervised. For ULC Level II use DEOL

supervision.

• Burglary initiating devices rated to operate over the voltage range of 11.3 VDC to 12.5 VDC.

• All intrusion zones shall be programmed as audible.

• The battery shall be used to provide a minimum back up power of four hours as per specific

application requirements

UL and ULC household fire warning system

• Power supply model SOY-1800222-NA (PGWLSHW40A) shall be employed.

• 24 hour standby shall be provided.

• At least one UL or ULC listed 4-wire latching type smoke detector rated to operate over the

voltage range 11.3 VDC to 12.5 VDC. A maximum smoke detector alarm load of 102 mA may

be employed on the 2-wire smoke detector circuit.

• One DSC model RM-1 or RM-2 end of line supervision relay module.

• One optional UL or ULC listed audible device, rated to operate over the voltage range 11.3

VDC to 12.5 VDC, with a maximum current rating of 700 mA and rated 85 dB minimum

as required for this application. The required bell cutoff time shall be a minimum of four

minutes for UL and five minutes for ULC. The local audible devices shall be programmed to

sound in a Temporal 3 pattern.

• Model EOLR-2, for 4-wire smoke detectors, heat detectors, and CO detectors, and EOLR-3, for

2-wire smoke interface, end of line resistors shall be used.

• For UL and ULC household fire warning systems, the fire alarm and CO detection devices shall

not be powered from the same AUX output as burglary alarm initiating devices.

35PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 36

European CE Compliance and CERTALARM Certification

This information applies to model PG8WLSHW8.

According to EN50131-1,this equipment can be applied in installed systems up to and including

Security Grade 2, Environmental Class II.

UK: The PG8WLSHW8 is suitable for use in systems installed to conform to PD6662:2017 at Grade 2

and environmental class II. BS8243:2010 + A1:2014.

The PowerG peripheral devices have two-way communication functionality, providing additional

benefits as described in the technical brochure. This functionality has not been tested to comply

with the respective technical requirements and should therefore be considered outside the scope

of the product’s certification.

The Model PG8WLSHW8 Wired to Wireless Converter has been certified by Telefication according

to EN50131-1:2006+ A1:2009, EN50131-3:2009, EN50131-5-3:2017, and EN50131-6:2017 Type A for

Grade2, Class II.

Simplified EU declaration of conformity

Hereby, Tyco Safety Products Canada Ltd declares that the radio equipment type is in compliance

with Directive 2014/53/EU. The full text of the EU declaration of conformity is available at the

following internetaddress: www.dsc.com

868 MHz model: http://dsc.com/pdf/2001001

Frequency band (MHz) Maximum power (dBm/ mW)

868.0 to 868.6 12/ 15

868.7 to 869.2 12/ 15

European single point of contact: Tyco Safety Products, Voltaweg 20,6101 XK Echt, Netherlands.

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual36

Page 37

EULA

IMPORTANT - READ CAREFULLY

DSC Software purchased with or without Products and Components is copyrighted and is

purchased under the following license terms:

• This End- User License Agreement (“EULA”) is a legal agreement between You (the company,

individual or entity who acquired the Software and any related Hardware) and Digital Security

Controls, a division of Tyco Safety Products Canada Ltd. (“DSC”), the manufacturer of the

integrated security systems and the developer of the software and any related products or

components (“HARDWARE”) which You acquired.

• If the DSC software product (“SOFTWARE PRODUCT” or “SOFTWARE”) is intended to be

accompanied by HARDWARE, and is NOT accompanied by new HARDWARE, You may not

use, copy or install the SOFTWARE PRODUCT. The SOFTWARE PRODUCT includes computer

software, and may include associated media, printed materials, and “online” or electronic

documentation.

• Any software provided along with the SOFTWARE PRODUCT that is associated with a separate

end- user license agreement is licensed to You under the terms of that license agreement.

• By installing, copying, downloading, storing, accessing or otherwise using the SOFTWARE

PRODUCT, You agree unconditionally to be bound by the terms of this EULA, even if this EULA

is deemed to be a modification of any previous arrangement or contract. If You do not agree

to the terms of this EULA, DSC is unwilling to license the SOFTWARE PRODUCT to You, and

You have no right to use it.

SOFTWARE PRODUCT LICENSE

The SOFTWARE PRODUCT is protected by copyright laws and international copyright treaties, as

well as other intellectual property laws and treaties. The SOFTWARE PRODUCT is licensed, not sold.

1. GRANT OF LICENSE This EULA grants You the following rights:

• Software Installation and Use - For each license You acquire, You may have only one copy of

the SOFTWARE PRODUCT installed.

• Storage/Network Use - The SOFTWARE PRODUCT may not be installed, accessed, displayed,

run, shared or used concurrently on or from different computers, including a workstation,

terminal or other digital electronic device (“Device”). In other words, if You have several

workstations, You will have to acquire a license for each workstation where the SOFTWARE

will be used.

• Backup Copy - You may make back-up copies of the SOFTWARE PRODUCT, but You may only

have one copy per license installed at any given time. You may use the back-up copy solely

for archival purposes. Except as expressly provided in this EULA, You may not otherwise

make copies of the SOFTWARE PRODUCT, including the printed materials accompanying the

SOFTWARE.

37PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 38

2. DESCRIPTION OF OTHER RIGHTS AND LIMITATIONS

• Limitations on Reverse Engineering, Decompilation and Disassembly - You may not reverse

engineer, decompile, or disassemble the SOFTWARE PRODUCT, except and only to the extent

that such activity is expressly permitted by applicable law notwithstanding this limitation. You

may not make any changes or modifications to the Software, without the written permission

of an officer of DSC. You may not remove any proprietary notices, marks or labels from the

Software Product. You shall institute reasonable measures to ensure compliance with the

terms and conditions of this EULA.

• Separation of Components - The SOFTWARE PRODUCT is licensed as a single product. Its

component parts may not be separated for use on more than one HARDWARE unit.

• Single INTEGRATED PRODUCT - If You acquired this SOFTWARE with HARDWARE, then the

SOFTWARE PRODUCT is licensed with the HARDWARE as a single integrated product. In this

case, the SOFTWARE PRODUCT may only be used with the HARDWARE as set forth in this

EULA.

• Rental - You may not rent, lease or lend the SOFTWARE PRODUCT. You may not make it

available to others or post it on a server or web site.

• Software Product Transfer - You may transfer all of Your rights under this EULA only as part of

a permanent sale or transfer of the HARDWARE, provided You retain no copies, You transfer

all of the SOFTWARE PRODUCT (including all component parts, the media and printed

materials, any upgrades and this EULA), and provided the recipient agrees to the terms of

this EULA. If the SOFTWARE PRODUCT is an upgrade, any transfer must also include all prior

versions of the SOFTWARE PRODUCT.

• Termination - Without prejudice to any other rights, DSC may terminate this EULA if You fail

to comply with the terms and conditions of this EULA. In such event, You must destroy all

copies of the SOFTWARE PRODUCT and all of its component parts.

• Trademarks - This EULA does not grant You any rights in connection with any trademarks or

service marks of DSC or its suppliers.

3. COPYRIGHT - All title and intellectual property rights in and to the SOFTWARE PRODUCT

(including but not limited to any images, photographs, and text incorporated into the SOFTWARE

PRODUCT), the accompanying printed materials, and any copies of the SOFTWARE PRODUCT,

are owned by DSC or its suppliers. You may not copy the printed materials accompanying the

SOFTWARE PRODUCT. All title and intellectual property rights in and to the content which may be

accessed through use of the SOFTWARE PRODUCT are the property of the respective content owner

and may be protected by applicable copyright or other intellectual property laws and treaties. This

EULA grants You no rights to use such content. All rights not expressly granted under this EULA are

reserved by DSC and its suppliers.

4. EXPORT RESTRICTIONS - You agree that You will not export or re-export the SOFTWARE

PRODUCT to any country, person, or entity subject to Canadian export restrictions.

5. CHOICE OF LAW - This Software License Agreement is governed by the laws of the Province of

Ontario, Canada.

6. ARBITRATION - All disputes arising in connection with this Agreement shall be determined by

final and binding arbitration in accordance with the Arbitration Act, and the parties agree to be

bound by the arbitrator’s decision. The place of arbitration shall be Toronto, Canada, and the

installation manual of the arbitration shall be English.

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual38

Page 39

7. LIMITED WARRANTY

• NO WARRANTY - DSC PROVIDES THE SOFTWARE “AS IS” WITHOUT WARRANTY. DSC DOES

NOT WARRANT THAT THE SOFTWARE WILL MEET YOUR REQUIREMENTS OR THAT OPERATION

OF THE SOFTWARE WILL BE UNINTERRUPTED OR ERROR-FREE.

• CHANGES IN OPERATING ENVIRONMENT - DSC shall not be responsible for problems

caused by changes in the operating characteristics of the HARDWARE, or for problems in the

interaction of the SOFTWARE PRODUCT with non-DSC-SOFTWARE or HARDWARE PRODUCTS.

• LIMITATION OF LIABILITY; WARRANTY REFLECTS ALLOCATION OF RISK - IN ANY EVENT,

IF ANY STATUTE IMPLIES WARRANTIES OR CONDITIONS NOT STATED IN THIS LICENSE

AGREEMENT, DSC’S ENTIRE LIABILITY UNDER ANY PROVISION OF THIS LICENSE AGREEMENT

SHALL BE LIMITED TO THE GREATER OF THE AMOUNT ACTUALLY PAID BY YOU TO LICENSE

THE SOFTWARE PRODUCT AND FIVE CANADIAN DOLLARS (CAD$5.00). BECAUSE SOME

JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF LIABILITY FOR

CONSEQUENTIAL OR INCIDENTAL DAMAGES, THE ABOVE LIMITATION MAY NOT APPLY TO

YOU.

• DISCLAIMER OF WARRANTIES - THIS WARRANTY CONTAINS THE ENTIRE WARRANTY

AND SHALL BE IN LIEU OF ANY AND ALL OTHER WARRANTIES, WHETHER EXPRESSED OR

IMPLIED (INCLUDING ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE) AND OF ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART

OF DSC. DSC MAKES NO OTHER WARRANTIES. DSC NEITHER ASSUMES NOR AUTHORIZES

ANY OTHER PERSON PURPORTING TO ACT ON ITS BEHALF TO MODIFY OR TO CHANGE THIS

WARRANTY, NOR TO ASSUME FOR IT ANY OTHER WARRANTY OR LIABILITY CONCERNING

THIS SOFTWARE PRODUCT.

• EXCLUSIVE REMEDY AND LIMITATION OF WARRANTY - UNDER NO CIRCUMSTANCES SHALL

DSC BE LIABLE FOR ANY SPECIAL, INCIDENTAL, CONSEQUENTIAL OR INDIRECT DAMAGES

BASED UPON BREACH OF WARRANTY, BREACH OF CONTRACT, NEGLIGENCE, STRICT

LIABILITY, OR ANY OTHER LEGAL THEORY. SUCH DAMAGES INCLUDE, BUT ARE NOT LIMITED

TO, LOSS OF PROFITS, LOSS OF THE SOFTWARE PRODUCT OR ANY ASSOCIATED EQUIPMENT,

COST OF CAPITAL, COST OF SUBSTITUTE OR REPLACEMENT EQUIPMENT, FACILITIES OR

SERVICES, DOWN TIME, PURCHASERS TIME, THE CLAIMS OF THIRD PARTIES, INCLUDING

CUSTOMERS, AND INJURY TO PROPERTY. WARNING: DSC recommends that the entire system

be completely tested on a regular basis. However, despite frequent testing, and due to, but

not limited to, criminal tampering or electrical disruption, it is possible for this SOFTWARE

PRODUCT to fail to perform as expected.

39PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 40

Limited warranty

Digital Security Controls warrants the original purchaser that for a period of twelve months from

the date of purchase, the product shall be free of defects in materials and workmanship under

normal use. During the warranty period, Digital Security Controls shall, at its option, repair or

replace any defective product upon return of the product to its factory, at no charge for labour and

materials. Any replacement and/or repaired parts are warranted for the remainder of the original

warranty or ninety (90) days, whichever is longer. The original purchaser must promptly notify

Digital Security Controls in writing that there is defect in material or workmanship, such written

notice to be received in all events prior to expiration of the warranty period. There is absolutely no

warranty on software and all software products are sold as a user license under the terms of the

software license agreement included with the product. The Customer assumes all responsibility for

the proper selection, installation, operation and maintenance of any products purchased from DSC.

Custom products are only warranted to the extent that they do not function upon delivery. In such

cases, DSC can replace or credit at its option.

International Warranty

The warranty for international customers is the same as for any customer within Canada and the

United States, with the exception that Digital Security Controls shall not be responsible for any

customs fees, taxes, or VAT that may be due.

Warranty Procedure

To obtain service under this warranty, please return the item(s) in question to the point of

purchase. All authorized distributors and dealers have a warranty program. Anyone returning

goods to Digital Security Controls must first obtain an authorization number. Digital Security

Controls will not accept any shipment whatsoever for which prior authorization has not been

obtained.

Conditions to Void Warranty

This warranty applies only to defects in parts and workmanship relating to normal use. It does not

cover:

• damage incurred in shipping or handling;

• damage caused by disaster such as fire, flood, wind, earthquake or lightning;

• damage due to causes beyond the control of Digital Security Controls such as excessive

voltage, mechanical shock or water damage;

• damage caused by unauthorized attachment, alterations, modifications or foreign objects;

• damage caused by peripherals (unless such peripherals were supplied by Digital Security

Controls);

• defects caused by failure to provide a suitable installation environment for the products;

• damage caused by use of the products for purposes other than those for which it was

designed;

• damage from improper maintenance;

• damage arising out of any other abuse, mishandling or improper application of the products.

Items Not Covered by Warranty

In addition to the items which void the Warranty, the following items shall not be covered by

Warranty: (i) freight cost to the repair centre; (ii) products which are not identified with DSC's

PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual40

Page 41

product label and lot number or serial number; (iii) products disassembled or repaired in such

a manner as to adversely affect performance or prevent adequate inspection or testing to verify

any warranty claim. Access cards or tags returned for replacement under warranty will be credited

or replaced at DSC's option. Products not covered by this warranty, or otherwise out of warranty

due to age, misuse, or damage shall be evaluated, and a repair estimate shall be provided. No

repair work will be performed until a valid purchase order is received from the Customer and a

Return Merchandise Authorisation number (RMA) is issued by DSC's Customer Service. Digital

Security Controls’ liability for failure to repair the product under this warranty after a reasonable

number of attempts will be limited to a replacement of the product, as the exclusive remedy

for breach of warranty. Under no circumstances shall Digital Security Controls be liable for any

special, incidental, or consequential damages based upon breach of warranty, breach of contract,

negligence, strict liability, or any other legal theory. Such damages include, but are not limited to,

loss of profits, loss of the product or any associated equipment, cost of capital, cost of substitute

or replacement equipment, facilities or services, down time, purchaser’s time, the claims of third

parties, including customers, and injury to property. The laws of some jurisdictions limit or do

not allow the disclaimer of consequential damages. If the laws of such a jurisdiction apply to any

claim by or against DSC, the limitations and disclaimers contained here shall be to the greatest

extent permitted by law. Some states do not allow the exclusion or limitation of incidental or

consequential damages, so that the above may not apply to you.

Disclaimer of Warranties

This warranty contains the entire warranty and shall be in lieu of any and all other warranties,

whether expressed or implied (including all implied warranties of merchantability or fitness for a

particular purpose) and of all other obligations or liabilities on the part of Digital Security Controls

Digital Security Controls neither assumes responsibility for nor authorizes any other person

purporting to act on its behalf to modify or to change this warranty, nor to assume for it any other

warranty or liability concerning this product. This disclaimer of warranties and limited warranty are

governed by the laws of the province of Ontario, Canada.

WARNING: Digital Security Controls recommends that the entire system be completely tested

on a regular basis. However, despite frequent testing, and due to, but not limited to, criminal

tampering or electrical disruption, it is possible for this product to fail to perform as expected.

Out of Warranty Repairs

Digital Security Controls will at its option repair or replace out-of-warranty products which are

returned to its factory according to the following conditions. Anyone returning goods to Digital

Security Controls must first obtain an authorization number. Digital Security Controls will not

accept any shipment whatsoever for which prior authorization has not been obtained.

Products which Digital Security Controls determines to be repairable will be repaired and returned.

A set fee which Digital Security Controls has predetermined and which may be revised from time to

time, will be charged for each unit repaired.

41PG8WLSHW8 and PG9WLSHW8 IQ Hardwire PowerG Wired to Wireless Converter Installation Manual

Page 42

Trademark

The trademarks, logos, and service marks displayed on this document are registered in the United

States [or other countries]. Any misuse of the trademarks is strictly prohibited and Tyco will

aggressively enforce its intellectual property rights to the fullest extent of the law, including pursuit

of criminal prosecution wherever necessary. All trademarks not owned by Tyco are the property of

their respective owners, and are used with permission or allowed under applicable laws.

Product offerings and specifications are subject to change without notice. Actual products may vary

from photos. Not all products include all features. Availability varies by region; contact your sales

representative.

© 2020 Johnson Controls. All rights reserved. JOHNSON CONTROLS, TYCO and DSC are trademarks

of Johnson Controls.

Toronto, Canada ∙ www.dsc.com

Tech support: 1-900-3630 (Canada and U.S), or 1-905-760-3000 (International)

Loading...

Loading...