Page 1

MX4428

MXP ENGINEERING / TECHNICAL MANUAL

MX4428 PRODUCT MANUAL

VOLUME 11

Document Number: LT0273

Issue 1.5; 24 March 2006

- APPROVALS -

AUSTRALIAN STANDARD AS4428.1

- SSL Listing Number ....................................................................................... afp1446

NEW ZEALAND STANDARD NZS4512-1997 (INCL AMDT 1 & 2)

- FPA (NZ) Listing number ................................................................................. VF/117

AS/NZS 3548 1995 CLASS A

The 4100MXP is a product of

Tyco Safety Products

211 Maces Road

Christchurch 8030

NEW ZEALAND

Phone +64-3-389 5096

Fax +64-3-389 5938

COPYRIGHT (C) 2003,2004

Information contained in this document is subject to copyright, and shall not be reproduced in any

form whatsoever, without the written consent of Tyco Services Fire & Safety.

Information contained in this document is believed to be accurate and reliable, however Tyco

Services Fire & Safety reserves the right to change the content without prior notice.

Page 2

MX4428 MXP Engineering /Technical Manual Document: LT0273

NON-DISCLOSURE AGREEMENT

Tyco (THE COMPANY) and the User of this/these document(s) desire to share proprietary technical information

concerning electronic systems.

For this reason the company is disclosing to the User information in the form of this/these document(s). In as

much as the company considers this information to be proprietary and desires that it be maintained in confidence,

it is hereby agreed by the User that such information shall be maintained in confidence by the User for a period of

TEN YEARS after the issue date and only be used for the purpose for which it was supplied.

During this period, the User shall not divulge such information to any third party without the prior written consent

of the company and shall take reasonable efforts to prevent any unauthorised disclosure by its employees.

However, the User shall not be required to keep such information in confidence if it was in their possession prior

to its receipt from the company; if it is or becomes public knowledge without the fault of the User; or the

information becomes available on an unrestricted basis from a third party having a lega l right to disclose such

information.

The User's receipt and retention of this information constitutes acceptance of these terms.

This information is copyright and shall not be reproduced in any form whatsoever.

END USER LIABILITY DISCLAIMER

The MX4428 Fire Indicator Panel provides a configuration programming facility, which may be accessed via a

programming terminal using a password. Because this programming facility allows the user to define in detail the

operation of the MX4428 System being customised, changes may be made by the user that prevent this

installation from meeting statutory requirements.

The Company, therefore cannot accept any responsibility as to the suitability of the functions generated by the

user using this programming facility.

AMENDMENT LOG

21 March 01 Issue 1.0 Original

24 April 03 Issue 1.1 Updated DIM800 Compatibility, added VLC800, LPS800, Alarm

Tests

11 March 04 Issue 1.2 DIM800 with s/c fault option. Added "specs", noted source of

MXPPROG, updated MXP software version history.

28 January 05 Issue 1.3 Added requirements for AS1670.1. Noted DIM800 supply

supervision threshold is not adjustable. Added MIM800 max cable

length on inputs to its specs. Updated

replaced 814IB with 5BI.

Noted MkII Sounder Base has AS2220 and ISO tones. Added note

re acceptable type mismatches. Added reference to software

version 1.12.

28 October 05 Issue 1.4 Added 614CH, 614I, 614P, System Sensor 885WP-B detectors to

Table 3-4.

24 March 06 Issue 1.5 Added 614T Section 3.20.3. Added 814P Section 3.9, etc. Added

Loop Filter Board, Chapter 10.

Table 3-2. Added 5B,

TRADEMARKS

VESDA is a registered trademark of Vision Systems.

Page ii 24 March 2006 Issue 1.5

Page 3

Document: LT0273 MX4428 MXP Engineering / Technical Manual

TABLE OF CONTENTS

NON-DISCLOSURE AGREEMENT....................................................................................................... II

END USER LIABILITY DISCLAIMER.................................................................................................... II

AMENDMENT LOG .............................................................................................................................. II

TRADEMARKS ..................................................................................................................................... II

CHAPTER 1 INTRODUCTION ...............................................................................1-1

1.1 ABOUT THIS MANUAL......................................................................................................... 1-2

1.2 ASSOCIATED DOCUMENTATION.......................................................................................1-2

1.2.1 PRODUCT RELATED.................................................................................................... 1-2

1.2.2 STANDARD RELATED..................................................................................................1-3

1.3 SPECIFICATIONS.................................................................................................................1-3

1.4 TERMINOLOGY.....................................................................................................................1-4

CHAPTER 2 RESPONDER LOOP DESIGN CONSIDERATIONS.........................2-1

2.1 MXP APPLICATION CONSIDERATIONS ............................................................................2-2

2.2 "LOGICAL" RESPONDERS .................................................................................................2-3

2.2.1 THEORY.........................................................................................................................2-3

2.2.2 LOGICAL RESPONDERS..............................................................................................2-3

2.2.3 POINT TO CIRCUIT TO ZONE MAPPING....................................................................2-5

2.3 IMPLICATIONS TO SYSTEM DESIGN.................................................................................2-6

CHAPTER 3 DEVICE INFORMATION AND PROGRAMMING..............................3-1

3.1 DEVICE TYPES..................................................................................................................... 3-2

3.1.1 MX DEVICES..................................................................................................................3-2

3.2 DEVICE HANDLING CAPABILITY.......................................................................................3-7

3.2.1 OVERVIEW ....................................................................................................................3-7

3.2.2 DC LOAD........................................................................................................................3-8

3.2.3 AC LOADING..................................................................................................................3-8

3.2.4 ISOLATOR BASE LOADING..........................................................................................3-9

3.2.5 EXAMPLE.......................................................................................................................3-9

3.3 OUTPUT CONTROL............................................................................................................ 3-10

3.3.1 PROGRAMMING..........................................................................................................3-11

3.3.2 OUTPUT STATE UNDER EXCEPTIONAL CIRCUMSTANCES .................................3-11

3.4 DETECTOR PARAMETER SETTINGS SUMMARY...........................................................3-12

3.5 DEVICE INSTALLATION.....................................................................................................3-13

3.5.1 PRECAUTIONS............................................................................................................3-13

3.5.2 MOUNTING..................................................................................................................3-13

3.5.3 ADDRESS & LED BLINK PROGRAMMING................................................................3-13

3.6 MX4428 PROGRAMMING................................................................................................... 3-14

3.7 814H HEAT DETECTOR.....................................................................................................3-15

3.7.1 GENERAL.....................................................................................................................3-15

3.7.2 814H SPECIFICATIONS.............................................................................................. 3-15

3.7.3 MX4428 PROGRAMMING OPTIONS - 814H..............................................................3-15

3.8 814I IONISATION SMOKE DETECTOR.............................................................................3-17

3.8.1 GENERAL.....................................................................................................................3-17

3.8.2 814I SPECIFICATIONS................................................................................................3-17

3.8.3 MX4428 PROGRAMMING OPTIONS - 814I................................................................3-17

3.9 814PH PHOTOELECTRIC SMOKE & HEAT DETECTOR & 814P PHOTOELECTRIC

SMOKE ONLY DETECTOR............................................................................................................

3.9.1 GENERAL.....................................................................................................................3-19

3.9.2 814PH & 814P SPECIFICATIONS............................................................................... 3-19

3.9.3 MX4428 PROGRAMMING OPTIONS - 814PH/814P..................................................3-19

3.10 814CH CARBON MONOXIDE + HEAT DETECTOR..........................................................3-23

3.10.1 GENERAL.....................................................................................................................3-23

3.10.2 814CH SPECIFICATIONS ...........................................................................................3-23

3.10.3 MX4428 PROGRAMMING OPTIONS - 814CH ...........................................................3-23

3-19

Issue 1.5 24 March 2006 Page iii

Page 4

MX4428 MXP Engineering /Technical Manual Document: LT0273

3.11 MUB UNIVERSAL BASE .................................................................................................... 3-25

3.11.1 GENERAL.....................................................................................................................3-25

3.11.2 MUB AND 5B WIRING.................................................................................................3-25

3.11.3 REMOTE INDICATOR WIRING...................................................................................3-25

3.12 5BI ISOLATOR BASE.........................................................................................................3-26

3.12.1 GENERAL.....................................................................................................................3-26

3.12.2 SPECIFICATIONS........................................................................................................3-26

3.12.3 WIRING ........................................................................................................................3-26

3.13 814RB RELAY BASE..........................................................................................................3-28

3.13.1 GENERAL.....................................................................................................................3-28

3.13.2 SPECIFICATIONS........................................................................................................3-28

3.13.3 WIRING ........................................................................................................................3-28

3.14 814SB SOUNDER BASE .................................................................................................... 3-30

3.14.1 GENERAL.....................................................................................................................3-30

3.14.2 SPECIFICATIONS........................................................................................................3-30

3.14.3 WIRING ........................................................................................................................3-30

3.15 MKII SOUNDER BASE........................................................................................................ 3-31

3.15.1 GENERAL.....................................................................................................................3-31

3.15.2 SPECIFICATIONS........................................................................................................3-31

3.15.3 WIRING ........................................................................................................................3-31

3.16 MIM800 AND MIM801 MINI INPUT MODULES..................................................................3-32

3.16.1 GENERAL.....................................................................................................................3-32

3.16.2 MIM800 / MIM801 SPECIFICATIONS .........................................................................3-32

3.16.3 FIELD WIRING.............................................................................................................3-33

3.16.4 MX4428 PROGRAMMING OPTIONS - MIM800 / MIM801 .........................................3-33

3.16.5 MX4428 PROGRAMMING OPTIONS - MIM801..........................................................3-34

3.17 CIM800 CONTACT INPUT MODULE..................................................................................3-35

3.17.1 GENERAL.....................................................................................................................3-35

3.17.2 CIM800 SPECIFICATIONS.......................................................................................... 3-35

3.17.3 FIELD WIRING.............................................................................................................3-36

3.17.4 MX4428 PROGRAMMING OPTIONS - CIM800.......................................................... 3-36

3.18 CP820 MANUAL CALL POINT........................................................................................... 3-38

3.18.1 GENERAL.....................................................................................................................3-38

3.18.2 MX4428 PROGRAMMING OPTIONS - CP820............................................................3-38

3.19 FP0838 / FP0839 MANUAL CALL POINTS .......................................................................3-39

3.19.1 GENERAL.....................................................................................................................3-39

3.19.2 MX4428 PROGRAMMING OPTIONS - FP0838 / FP0839.......................................... 3-39

3.20 DIM800 DETECTOR INPUT MONITOR.............................................................................. 3-40

3.20.1 GENERAL.....................................................................................................................3-40

3.20.2 DIM800 SPECIFICATIONS.......................................................................................... 3-41

3.20.3 DIM800 DETECTOR COMPATIBILITY........................................................................3-42

3.20.4 MX4428 PROGRAMMING OPTIONS - DIM800.......................................................... 3-42

3.21 RIM800 RELAY INTERFACE MODULE.............................................................................3-43

3.21.1 GENERAL.....................................................................................................................3-43

3.21.2 RIM800 SPECIFICATIONS.......................................................................................... 3-43

3.21.3 RIM800 FIELD WIRING ...............................................................................................3-43

3.21.4 MX4428 PROGRAMMING OPTIONS - RIM800.......................................................... 3-44

3.22 SNM800 SOUNDER NOTIFICATION MODULE.................................................................3-45

3.22.1 GENERAL.....................................................................................................................3-45

3.22.2 SNM800 SPECIFICATIONS.........................................................................................3-45

3.22.3 SNM800 FIELD WIRING..............................................................................................3-46

3.22.4 MX4428 PROGRAMMING OPTIONS - SNM800.........................................................3-46

3.23 LPS800 LOOP POWERED SOUNDER MODULE..............................................................3-47

3.23.1 GENERAL.....................................................................................................................3-47

3.23.2 LPS800 SPECIFICATIONS..........................................................................................3-47

3.23.3 MX4428 PROGRAMMING OPTIONS - LPS800..........................................................3-47

3.24 VLC-800MX VESDA LASERCOMPACT.............................................................................3-49

3.24.1 GENERAL.....................................................................................................................3-49

3.24.2 VLC800 SPECIFICATIONS..........................................................................................3-49

3.24.3 MX4428 PROGRAMMING OPTIONS - VLC800..........................................................3-50

3.25 AVF / RAD / SAD / FLOWSWITCH DELAYS.....................................................................3-51

3.25.1 AVF/RAD......................................................................................................................3-51

Page iv 24 March 2006 Issue 1.5

Page 5

Document: LT0273 MX4428 MXP Engineering / Technical Manual

3.25.2 SAD ..............................................................................................................................3-51

3.25.3 AVF/SAD ......................................................................................................................3-51

3.25.4 FLOWSWITCH.............................................................................................................3-51

CHAPTER 4 ANALOGUE LOOP DESIGN CONSIDERATIONS ...........................4-1

4.1 ANALOGUE LOOP CONFIGURATION SELECTION.......................................................... 4-2

4.1.1 LINES & LOOPS ............................................................................................................4-2

4.1.2 LOOP FAULT TOLERANCE..........................................................................................4-2

4.1.3 AS1670.1 DESIGN REQUIREMENTS...........................................................................4-2

4.1.4 NZS4512 DESIGN REQUIREMENTS ...........................................................................4-2

4.2 ANALOGUE LOOP/LINE LAYOUTS.................................................................................... 4-3

4.2.1 LINE MODE....................................................................................................................4-3

4.2.2 LOOP DESIGN WITH SHORT CIRCUIT ISOLATORS..................................................4-3

4.2.3 STAR CONNECTION OF ANALOGUE LINES..............................................................4-5

4.2.4 SPURS ...........................................................................................................................4-5

4.3 CABLE SELECTION CONSIDERATIONS............................................................................4-6

4.4 AC REQUIREMENTS............................................................................................................4-7

4.4.1 GENERAL.......................................................................................................................4-7

4.5 DC CONSIDERATIONS.........................................................................................................4-7

4.5.1 GENERAL.......................................................................................................................4-7

4.6 MECHANICAL CONSIDERATIONS .....................................................................................4-7

4.7 NOISE CONSIDERATIONS .................................................................................................. 4-8

CHAPTER 5 MXP CURRENT CONSUMPTION.....................................................5-1

5.1 THEORY ................................................................................................................................5-2

5.1.1 ALARM CURRENT.........................................................................................................5-2

5.1.2 QUIESCENT CURRENT................................................................................................ 5-3

5.1.3 HEAT LOSS....................................................................................................................5-3

CHAPTER 6 EVENT LOG AND STATUS AT MX4428..........................................6-1

6.1 RETURNED ANALOG VALUES...........................................................................................6-2

6.2 FAULT AND ALARM EVENT LOG.......................................................................................6-3

CHAPTER 7 MXP TECHNICAL DESCRIPTION....................................................7-1

7.1 GENERAL..............................................................................................................................7-2

7.2 CIRCUIT DESCRIPTION.......................................................................................................7-3

7.2.1 BLOCK DIAGRAM..........................................................................................................7-3

7.2.2 MICROPROCESSOR & LOGIC CIRCUITRY................................................................7-3

7.2.3 MXP POWER SUPPLY..................................................................................................7-4

7.2.4 MX4428 LOOP INTERFACE..........................................................................................7-6

7.2.5 ANALOGUE LOOP INTERFACE...................................................................................7-7

7.3 MXP ADJUSTMENTS..........................................................................................................7-10

7.3.1 40V ISO SUPPLY VOLTAGE ADJUSTMENT .............................................................7-10

7.3.2 TX DATA VOLTAGE ADJUSTMENT...........................................................................7-10

7.3.3 40V ISO SUPPLY CURRENT LIMIT ADJUSTMENT...................................................7-10

7.4 MXP LED INDICATIONS.....................................................................................................7-11

7.5 PARTS LIST ........................................................................................................................7-12

CHAPTER 8 MXP DIAGNOSTIC TERMINAL ........................................................8-1

8.1 MXP DIAGNOSTIC TERMINAL OPERATION...................................................................... 8-2

8.1.1 INTRODUCTION............................................................................................................8-2

8.1.2 MENU OF COMMANDS.................................................................................................8-2

8.1.3 SELECTING POINTS FOR MONITORING....................................................................8-2

8.1.4 DISPLAYING DEVICE ANALOGUE VALUES - CV, TV, ETC.......................................8-3

8.1.5 ST (STATUS COMMAND) .............................................................................................8-5

8.1.6 ANALOG LOOP DIAGNOSTICS.................................................................................... 8-6

8.1.7 ADVANCED COMMANDS.............................................................................................8-8

8.1.8 MX4428 DIAGNOSTICS ................................................................................................8-8

Issue 1.5 24 March 2006 Page v

Page 6

MX4428 MXP Engineering /Technical Manual Document: LT0273

8.1.9 MXP EVENT LOG..........................................................................................................8-9

8.2 FLASH PROGRAMMING....................................................................................................8-10

8.2.1 FILES REQUIRED........................................................................................................8-10

8.2.2 PROCEDURE...............................................................................................................8-10

CHAPTER 9 DEVICE PROCESSING.....................................................................9-1

9.1 EXPONENTIAL FILTER........................................................................................................9-2

9.2 STEP LIMITING FILTER........................................................................................................9-2

9.3 HEAT PROCESSING.............................................................................................................9-4

9.3.1 CONVERSION OF DETECTOR READING TO °C........................................................9-4

9.4 PHOTO PROCESSING..........................................................................................................9-6

9.4.1 SMARTSENSE PROCESSING......................................................................................9-6

9.4.2 SMARTSENSE ENHANCEMENT..................................................................................9-6

9.4.3 FASTLOGIC PROCESSING..........................................................................................9-7

9.5 CO PROCESSING................................................................................................................. 9-8

9.5.1 CALIBRATION AND TEMPERATURE COMPENSATION............................................ 9-8

9.5.2 “ENHANCEMENT” .........................................................................................................9-8

9.5.3 CO PROCESSING......................................................................................................... 9-8

9.6 IONISATION PROCESSING ................................................................................................. 9-9

9.7 MIM800 / CIM800 / MIM801 PROCESSING........................................................................9-10

9.7.1 ALGORITHM - MIM800, CIM800................................................................................. 9-11

9.7.2 ALGORITHM - MIM801................................................................................................9-11

9.8 DIM PROCESSING..............................................................................................................9-12

9.8.1 LOAD GRAPH..............................................................................................................9-12

9.8.2 DIM MODEL .................................................................................................................9-12

9.8.3 ALGORITHM - DIM800 ................................................................................................9-12

9.8.4 SUPPLY MONITORING - DIM800...............................................................................9-13

9.9 RIM PROCESSING..............................................................................................................9-13

9.9.1 POSITION MONITORING............................................................................................9-13

9.10 SNM PROCESSING ............................................................................................................9-13

9.10.1 PROGRAMMING..........................................................................................................9-13

9.10.2 SUPPLY FAULT DETERMINATION............................................................................9-13

9.10.3 EOL AND POSITION MONITORING...........................................................................9-13

9.11 LPS PROCESSING .............................................................................................................9-14

9.11.1 ELD AND POSITION MONITORING ...........................................................................9-14

9.12 VLC800 PROCESSING.......................................................................................................9-14

9.12.1 GENERAL.....................................................................................................................9-14

9.13 FILTER STEP LIMITS..........................................................................................................9-15

9.14 ZONE ALARM TEST...........................................................................................................9-15

9.15 ZONE FAULT TEST ............................................................................................................9-15

9.16 AUTOTEST AND SYSTEM TEST.......................................................................................9-15

9.17 NON LATCHING TEST MODE............................................................................................9-16

9.18 COMMISSION MODE.......................................................................................................... 9-16

9.19 FAST POINT TEST..............................................................................................................9-16

9.20 SLOW POINT TEST ............................................................................................................9-16

9.21 SUMMARY OF ALL TEST MODES .................................................................................... 9-16

9.22 ANCILLARY FILTERING.....................................................................................................9-17

9.23 RESET ................................................................................................................................. 9-18

9.23.1 RESET OF ADDRESSABLE DETECTOR...................................................................9-18

9.23.2 RESET OF DIM MODULE............................................................................................9-18

9.23.3 RESET OF ANCILLARY INPUT DEVICE.................................................................... 9-18

9.23.4 RESET OF ANCILLARY OUTPUT DEVICE................................................................9-18

9.24 DEVICE INITIALISATION AND POLLING.......................................................................... 9-19

9.25 SOFTWARE VERSIONS.....................................................................................................9-20

CHAPTER 10 MXP LOOP FILTER BOARD ........................................................

10.1 USE OF MXP LOOP FILTER BOARD................................................................................ 10-2

10.2 FITTING ...............................................................................................................................10-2

10.3 DIAGNOSTICS ....................................................................................................................10-3

10-1

Page vi 24 March 2006 Issue 1.5

Page 7

Document: LT0273 MX4428 MXP Engineering / Technical Manual

Introduction

CHAPTER 1

INTRODUCTION

Issue 1.5 24 March 2006 Page 1-1

Page 8

MX4428 MXP Engineering / Technical Manual Document: LT0273

Introduction

1.1 ABOUT THIS MANUAL

This manual (MX4428 Product Manual Volume 11) is intended to provide all information and

procedures required to incorporate one or more MXPs within an MX4428 system. It

predominantly covers the function and engineering associated with the MXP itself, its impact

on the MX4428 Responder Loop and the analogue loop/line(s) to which the compatible

devices are connected. It does not duplicate basic MX4428 system engineering information,

except at the point of interface (i.e. at the MX4428 Responder Loop), or for clarification as

required. It is therefore a supplement to the F4000 Engineering Manual (F4000 Product

Manual, Vol 3), to which the reader is referred for further information.

1.2 ASSOCIATED DOCUMENTATION

1.2.1 PRODUCT RELATED

The following MX4428/F4000 product manuals are available:

Volume 1, F4000 Operator's Manual, provides a complete guide to the operation and

maintenance of the F4000 FIP and

Australian Standards AS1603 Part 4. This manual is provided as standard with non-LCD

F4000 FIP panels (LT0057). See Volume 10 for AS4428.1 compliant systems.

Volume 2, F4000 Technical Manual, provides complete technical details on the F4000

system and Hardware/Software components, according to Australian Standards AS1603

Part 4, for servicing purposes (LT0069).

Volume 3, F4000 Engineering Manual, provides complete design details for correctly

engineering the F4000/MX4428 system to meet customer and standard specifications

(LT0071).

Volume 4, F4000 Installation Manual, provides complete details for correctly installing

and placing into operation the F4000/MX4428 system (LT0070).

Volume 5, F4000 Programming Manual, provides details for correctly programming the

F4000/MX4428 system to meet the system engineering specifications (LT0072).

Volume 6, F4000 AAR Technical & Engineering Manuals, Volume 6-1 provides

Technical details on the AAR and Addressable Devices, and Volume 6-2 provides

Engineering Design information for correctly engineering the AAR loop (LT0095/LT0096).

Volume 7, F4000 LCD Operator's Manual, provides a complete guide to the operation

and maintenance of F4000 LCD FIP panels with Version 2.X software, according to

Australian Standards AS1603 Part 4, AS4050(INT), and New Zealand Standard NZS4512.

From Issue 2.35A onwards LT0117 includes networked operation, previously covered in a

separate manual LT0150 (LT0117/LT0118). See Volume 10 for AS4428.1 compliant

systems.

Volume 8, F4000 NZ Fire Indicator Panel Technical Manual, provides additional

installation and technical information regarding the application of F4000/MX4428 Analogue

Addressable Fire Alarm Systems in New Zealand (LT0126).

RDU panels, with Version 1.X software, according to

Page 1-2 24 March 2006 Issue 1.5

Page 9

Document: LT0273 MX4428 MXP Engineering / Technical Manual

Introduction

Volume 9, F4000 MPR Technical & Engineering Manuals, Volume 9-1 provides

technical details on the MPR and Addressable devices, and Volume 9-2 provides

Engineering Design information for correctly engineering the MPR loop (LT0139/LT0140).

Volume 10, MX4428 AS4428.1 LCD Operator’s Manual, provides a guide to the

operation and maintenance of MX4428 AS4428.1 LCD FIP panels with Version 3.10

software, according to Australian Standard AS4428.1, and New Zealand Standard NZS4512.

This manual (LT0249) is provided as standard with MX4428 panels.

Volume 11, MX4428 MXP Technical / Engineering Manual, (LT0273) provides technical

details on the MXP and its addressable devices, and provides engineering design

information for correctly engineering the MXP loop.

F4000 Point Text Installation & Operation Manual (LT0228) provides details of the Point

Text expansion option.

SmartConfig User Manual (LT0332) provides details on programming an MX4428

database using the SmartConfig program.

1.2.2 STANDARD RELATED

This manual makes reference to the following Australian Standards –

AS1603.4 Automatic Fire Detection and Alarm Systems

Part 4 - Control and Indicating Equipment

AS1670.1 Automatic Fire Detection and Alarm Systems-

System Design, Installation, and Commissioning.

AS1851.8 Maintenance of Fire Protection Equipment

Part 8 - Automatic Fire Detection and Alarm Systems.

AS4428.1 Automatic Fire Detection and Alarm Systems. Control and Indication

Equipment.

This manual makes reference to the following New Zealand Standard –

NZS4512 Automatic Fire Alarm Systems in Buildings.

1.3 SPECIFICATIONS

Inputs / Outputs 1. Standard F4000 / MX4428 Responder Loop.

2. Analogue Loop for up to 200 MX devices, with a

maximum output current = 400mA.

3. RS232 Diagnostics Port.

Card Size 194mm * 140mm * 35mm.

Supply Voltage 17.0VDC to 30.0VDC.

Current Consumption 50mA to 1.3A depending on the number and type of

devices connected. Refer to section

Operating Temperature Range -5°C to +50°C, 10% to 93% RH non condensing.

5.1.

Issue 1.5 24 March 2006 Page 1-3

Page 10

MX4428 MXP Engineering / Technical Manual Document: LT0273

Introduction

1.4 TERMINOLOGY

AAR Analogue Addressable Responder.

AC Alternating Current.

ACZ Ancillary Control Zone.

ADR Advanced Detector Responder.

Analogue Loop The wiring that allows an MXP to communicate with and

supply power to the addressable devices it is to monitor.

ARR Advanced Relay (and Detector) Responder, which is an ADR

fitted with an RRM.

AVF Alarm Verification Facility, or alarm check.

AZF Alarm Zone Facility, previously referred to as "GROUP".

CO Carbon Monoxide

CV Current Value (Filtered reading from detector)

DC Direct Current.

Detector Addressable device used to detect fires that interfaces to the

MXP via the Analogue Loop. It contains one or more sensors.

EOL End of Line device.

Evacuation Device Sounder for warning of evacuation.

FIP Fire Indicator Panel, as defined by standards.

GLOBAL A function that may affect more than one zone.

HH History High - the highest value a variable has reached

HL History Low - the lowest value a variable has reached.

LCD Liquid Crystal Display (usually alphanumeric)

LED Light Emitting Diode (Visual Indicator).

MAF FIP Master Alarm Facility.

MIC X Measure of smoke density used with ionisation smoke

detectors.

MPR Multi Protocol Responder.

MXP MX Protocol Responder

MCP Manual Call Point (break glass switch).

Module Addressable I/O device that interfaces to the MXP via the

Analogue Loop.

NA Not Applicable.

NC Normally Closed.

NLR Number of logical responders.

NO Normally Open.

PCB Printed Circuit Board.

Point Any addressable device (detector or module) with a unique

address that is connected to the analogue addressable loop.

PSU Power Supp ly Unit.

Responder A general term for all responder types, e.g. ADR, ARR, MPR,

MXP, AAR and IOR that may be connected to the MX4428

Loop.

Responder Loop A 4 core cable for communication and power to all responders

connected to an MX4428 FIP.

ROR Rate of Rise.

RF Radio Frequency.

RRM Responder Relay Module.

RZDU Remote Zone Display Unit.

Sensor Part of a detector which senses the environment - smoke or

temperature or CO.

SLV Step limited (or slope limited) value.

Zone Fire searchable area of Building.

Page 1-4 24 March 2006 Issue 1.5

Page 11

Document: LT0273 MX4428 MXP Engineering / Technical Manual

Responder Loop Design Considerations

CHAPTER 2 RESPONDER LOOP DESIGN CONSIDERATIONS

Issue 1.5 24 March 2006 Page 2-1

Page 12

MX4428 MXP Engineering / Technical Manual Document: LT0273

Responder Loop Design Considerations

2.1 MXP APPLICATION CONSIDERATIONS

The inclusion of one or more MXPs in an MX4428 system requires consideration of .....

(i) The definition of zones throughout the area to be protected.

(ii) Assessment of the detectors and other addressable device types and positions

required to monitor each zone and interface to external equipment. This will indicate

if and where the MXP's addressable devices are most appropriate, for purely

functional reasons or for reducing system cost through reduced wiring.

The Design Engineer should be fully familiar with the concept of logical responders,

as described in Section

zones.

This process should result in an initial system design defining .....

- Number and location of all Responders including MXPs.

- Number and location of all addressable devices.

- Planned cable route for MX4428 Responder Loop.

- Planned cable route(s) for MXP Analogue Loop(s).

(iii) Using the design rules given in this manual, analyse each MXP Analogue Loop/Line

to confirm .....

- the MXP's current capability is adequate for the proposed devices (see

Section 3.2).

- the proposed cable has the correct AC characteristics (see Section

- the proposed cable has the correct DC characteristics (see Section

(iv) Using Section 5 of this manual, in conjunction with the MX4428 Engineering Manual

(LT0071), analyse the MX4428 responder Loop. This should result in.....

- the type and size of cable to be used for the power and signal portions of the

MX4428 Responder Loop.

- the number and position of Loop Boosters required (if necessary).

(v) The results of (iii) and (iv) indicate whether or not the proposed system design is

practical and/or cost-effective. If not, analyse what factors have contributed to the

design being impractical, re-design these areas or consider the use of loop boosters

and return to step (i).

(vi) Assess and document the programming of the MX4428 Master to support the system

design. Programming of the MX4428 is covered in the MX4428 Programming Manual

LT0072, with additional details of using SmartConfig in the SmartConfig user manual

LT0332. The following data must be entered to support MXPs.

- information which, when downloaded to the MXP, defines how the MXP is to

process the data received from addressable devices on the Analogue

Loop/Line(s),

- information retained at the Master which defines how it is to process data

received from configured MXPs on the MX4428 Loop.

2.2, before allocating an MXP to monitor multiple alarm

4.4).

4.5).

Page 2-2 24 March 2006 Issue 1.5

Page 13

Document: LT0273 MX4428 MXP Engineering / Technical Manual

Responder Loop Design Considerations

2.2 "LOGICAL" RESPONDERS

2.2.1 THEORY

The MX4428 Master Panel can transfer data to and from up to 127 uniquely addressed

Responders distributed around the MX4428 Responder Loop. Its database is structured to

support the 4 circuit inputs and 4 relay outputs associated with the most common responder

type, the ADR. Incorporating an MXP, which supports up to 200 input, output, or input /

output points, represents a departure from the original ADR / AAR structure, but it is similar

to that used for the MPR multiprotocol responder.

To incorporate the MXP, while still preserving the original 1 x MX4428 LOOP ADDRESS

SUPPORTS 4 INPUTS (“CIRCUITS”) AND 4 OUTPUTS (“RELAYS”) database assumption,

the concept of "logical responders" is used. A logical responder refers to a single responder

loop number, supporting 4 inputs and 4 outputs. An ADR/ARR therefore represents a single

logical responder. A responder that supports more than 4 inputs and outputs, such as the

MXP, must therefore occupy multiple responder loop numbers. That is, it is a "multiple

logical responder" unit. One MXP may in fact be configured at the MX4428 FIP to be

between 1 and 50 logical responders.

Since an MXP can support up to 200 points irrespective of how many logical responders it

has been configured to represent, it may be necessary to allocate multiple points to each

logical responder circuit input or relay output. This has certain implications described below,

the most significant being that it is a logical responder “circuit” which is mapped to a zone,

not a point, and it is a logical responder “relay” which is mapped to an ACZ, not a single

output point. Thus if multiple devices are allocated to a circuit, they must all be in the same

zone, and if multiple outputs are allocated to a relay, they will generally be controlled as one.

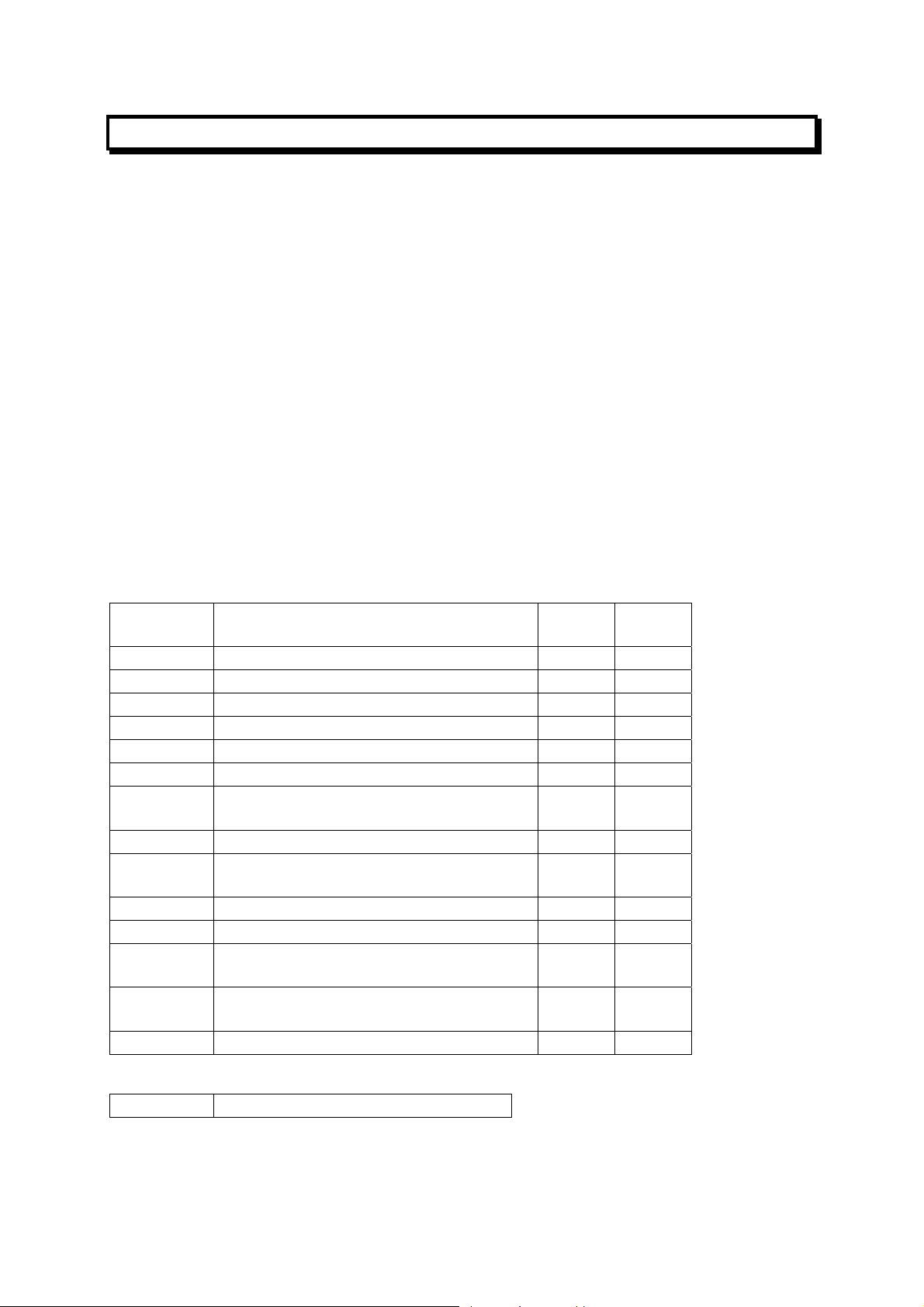

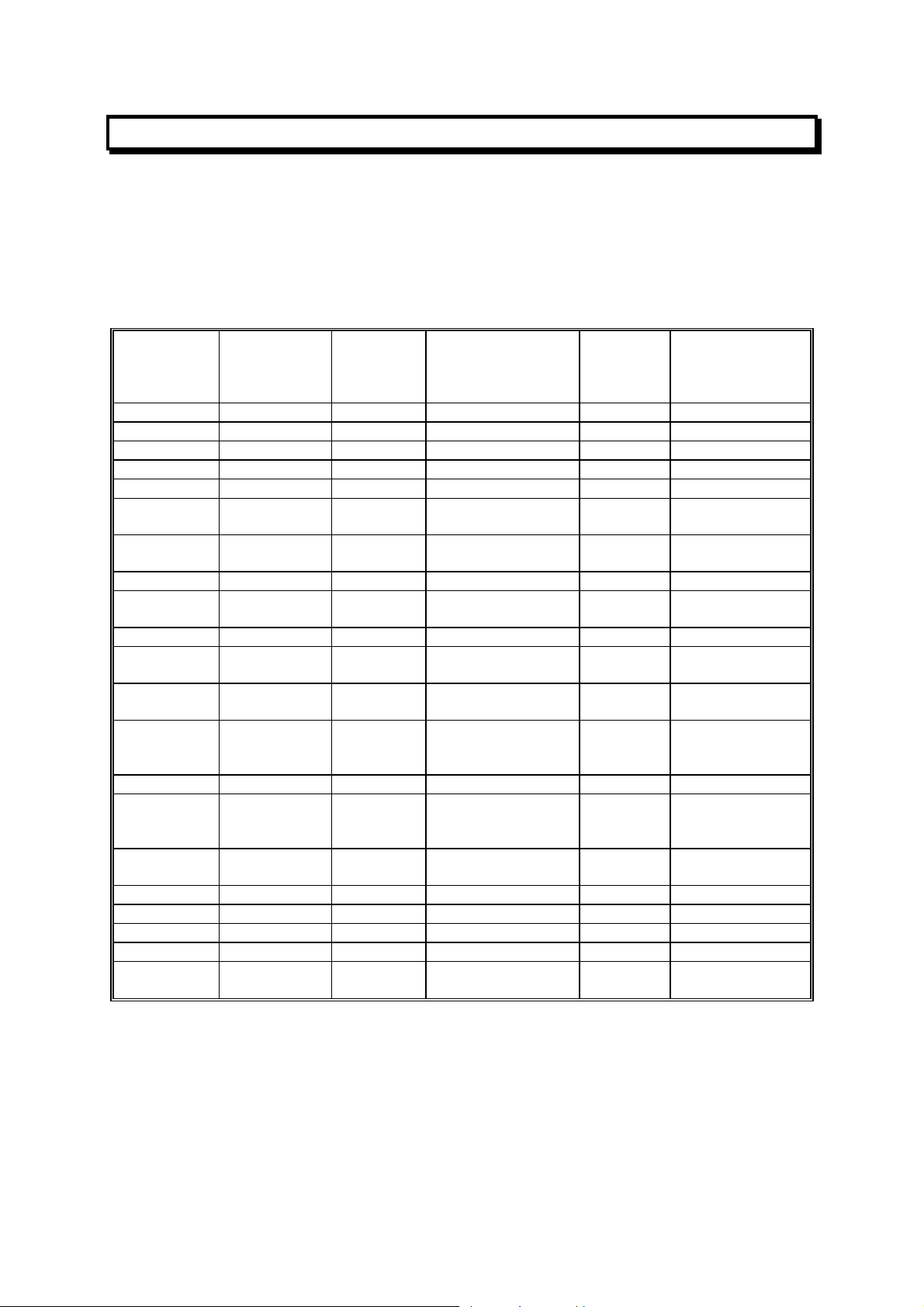

2.2.2 LOGICAL RESPONDERS

Points map to logical responder circuits and relays as shown in Table 2-1 for different

numbers of logical responders.

Basically the 200 points are evenly distributed across the number of logical responder

circuits/relays (= number of logical responders * 4), with the remainder allocated to the last

circuit.

Input devices are map to the circuit. Output devices usually map to the relay, but may map to

the circuit by programming.

The 50 logical responder option is the only one that allows unique monitoring and full front

panel indication of all 200 individual points without using the MX4428 Point Text expansion

option. The 50 logical responder option however, uses 50 of the 127 available MX4428

responder loop addresses and therefore limits the remainder of the MX4428 system.

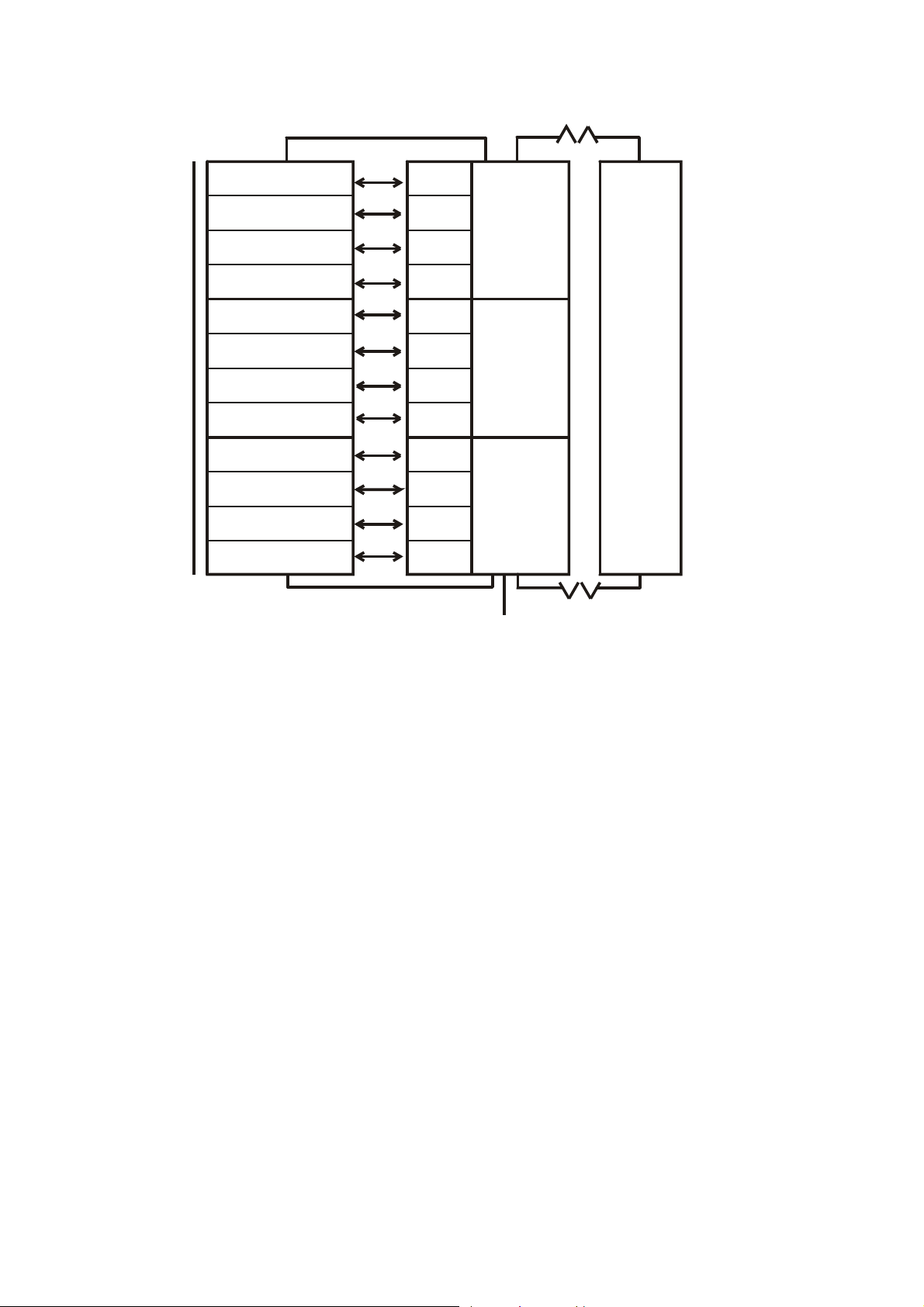

Figure 2.1 shows an example 3 logical responder MXP, which has a capability of 3 X 4 = 12

circuits (C1/1-1/4, C2/1-2/4, C3/1-3/4) and 12 relays (R1/1-1/4 ..... R3/4).

Splitting up the possible 200 addressable devices equally among the 12 circuits results in

each circuit being able to service 200/12 = 16 devices, with 8 left over. Thus devices 1-16

are associated with circuit C1/1, devices 17-32 are associated with C1/2, etc, up to C3/4,

which not only handles its own 16 points but also the extra 8 device addresses (193-200)

otherwise not catered for. Input devices are mapped to circuits, and output devices are

usually mapped to relays but may alternatively be mapped to the circuit.

Issue 1.5 24 March 2006 Page 2-3

Page 14

MX4428 MXP Engineering / Technical Manual Document: LT0273

Responder Loop Design Considerations

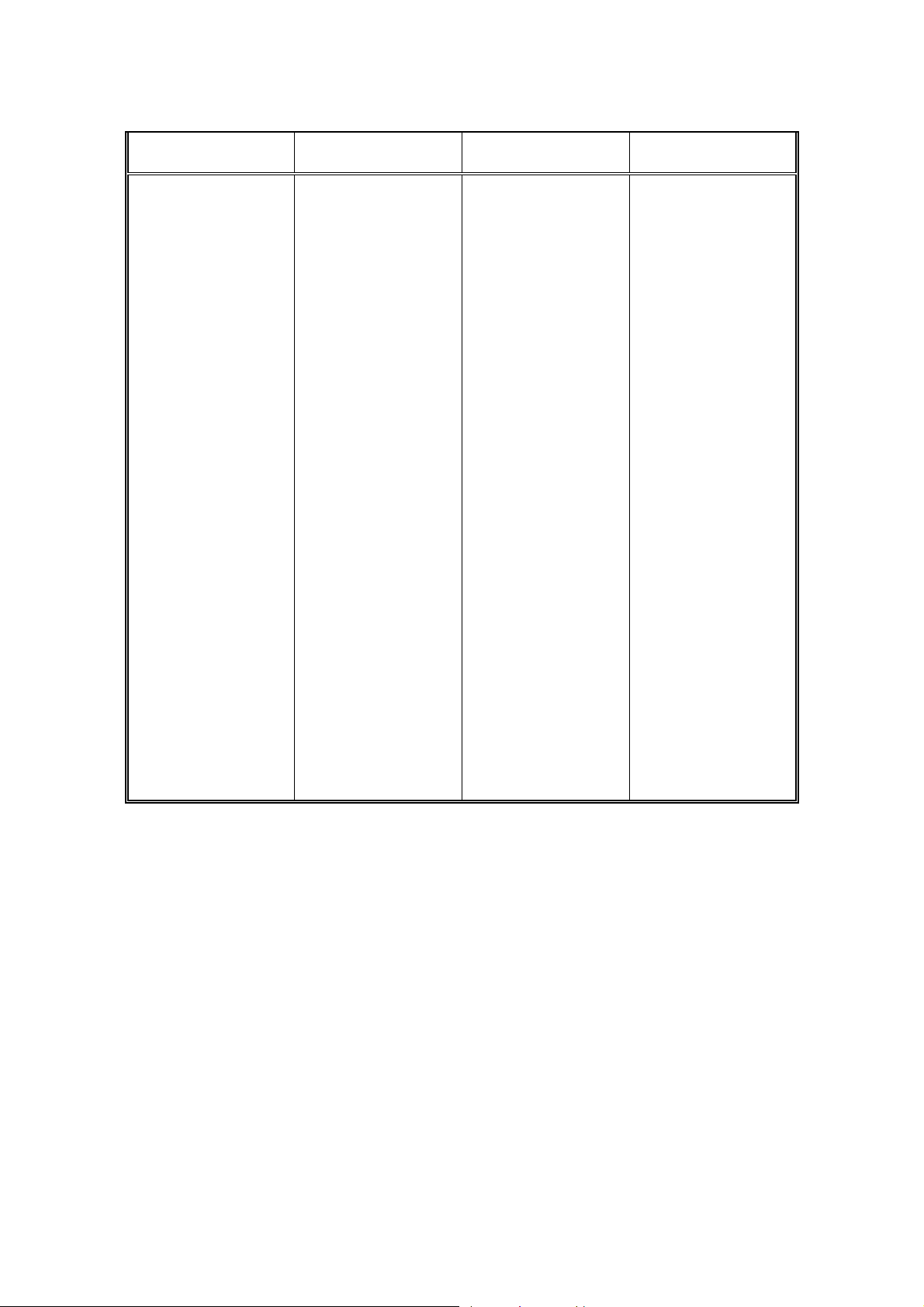

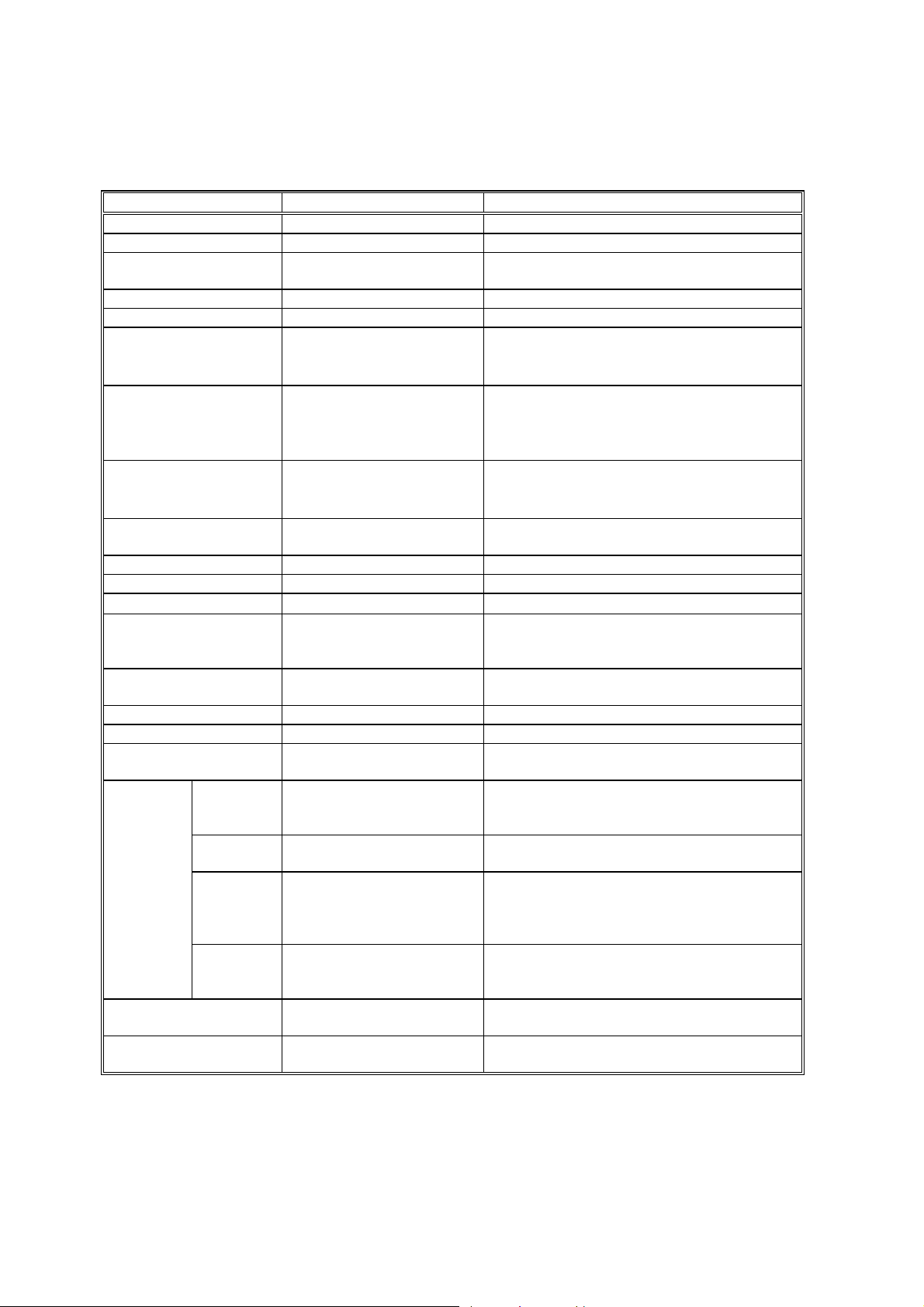

Number of Logical

Responders

(NLR)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

Number of Circuits (Relays)

available

(NC = 4 * NLR)

4

8

12

16

20

24

28

32

36

40

44

48

52

56

60

64

68

72

76

80

84

88

92

96

100

104

108

112

116

120

124

128

132

136

140

144

148

152

156

160

164

168

172

176

180

184

188

192

196

200

Number of Points per circuit

(relay)

PC = 200/NC

50

25

16

12

10

8

7

6

5

5

4

4

3

3

3

3

2

2

2

2

2

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Total Quantity of Points

in Last Circuit

50

25

24

20

10

16

11

14

25

5

28

12

47

35

23

11

66

58

50

42

34

26

18

10

2

97

93

89

85

81

77

73

69

65

61

57

53

49

45

41

37

33

29

25

21

17

13

9

5

1

Table 2-1 Point Allocation For Various Numbers of Logical Responders

Page 2-4 24 March 2006 Issue 1.5

Page 15

Document: LT0273 MX4428 MXP Engineering / Technical Manual

OOP

Responder Loop Design Considerations

TOTAL OF

200 DEVICES

DEVICE 1-16

DEVICE 17-32

DEVICE 33-48

DEVICE 49-64

DEVICE 65-80

DEVICE 81-96

DEVICE 97-112

DEVICE 113-128

DEVICE 129-144

DEVICE 145-160

DEVICE 161-176

DEVICE 177-200

ANALOG LOOP

MAPPED

TO

C1/1 R1/1

C1/2 R1/2

C1/3 R1/3

C1/4 R1/4

C2/1 R2/1

C2/2 R2/2

C2/3 R2/3

C2/4 R2/4

C3/1 R3/1

C3/2 R3/2

C3/3 R3/3

C3/4 R3/4

LOGICAL

RESPONDER

#1

LOGICAL

RESPONDER

#2

LOGICAL

RESPONDER

#3

F4000 L

F4000

MASTER

ANALOG LOOP

3 LOGICAL RESPONDER MXR

F4000 LOOP

Figure 2.1 Device To Circuit Mapping For 3 Logical Responder MXP

2.2.3 POINT TO CIRCUIT TO ZONE MAPPING

Taking the 3 logical responder example in the previous sections, assume that of the 16

possible device addresses that belong to C1/1, only 10 of these are in fact used, and that 7

are input devices, and the remaining 3 are output devices. Further, assume that the

MX4428 FIP is configured to map C1/1 to ZONE 1.

In this case, an alarm sensed by any of the 7 input devices would put C1/1 into alarm, which

in turn would put ZONE 1 into alarm, a condition indicated on the MX4428 Master front

panel. However, the MXP also generates what is referred to as an extended event,

indicating precisely which of the 7 input devices caused the alarm. This is transmitted to the

MX4428 Master where it is presented on the front panel LCD, entered in the history log and

printed on the logging printer (if programmed).

If, for instance, in this example it was input device 6 that caused the ALARM then the

extended event would take the form .....

"P1/6 ALARM" where .....

..... P = POINT

1 = BASE ADDRESS OF RESPONDER

6 = DEVICE NUMBER

If the Point Text expansion option is fitted at the MX4428 Master, the event will be

associated with a text description of the point.

Issue 1.5 24 March 2006 Page 2-5

Page 16

MX4428 MXP Engineering / Technical Manual Document: LT0273

Responder Loop Design Considerations

So far only input devices have been considered. To continue our example for output

devices, if the MX4428 Master generated an output command, via output logic, to turn on

R1/1, then the MXP would activate all output devices associated with that relay, that is, in

this case, all 3.

2.3 IMPLICATIONS TO SYSTEM DESIGN

The System Designer should be aware of the following MX4428 characteristics before

proceeding with the design .....

(i) While the MX4428 with MXP capability can support up to 16 x 200 (3,200) points (i.e.

addressable devices), the Master unit has a maximum of 528 zones with which to

indicate the status of the system.

The 528 zones may be used to display the status of either an "alarm zone",

representing the status of a particular sub-section of the area to be monitored, or an

"ancillary control zone" (ACZ), representing the status of an output controlled by the

MX4428 system.

The Point Text expansion option can be used to extend this capability. Refer to the

F4000 Point Text Installation and Operation Manual (LT0228) for further information.

(ii) FIP zone indicators are controlled according to the zone’s status, which is generated

from the mapped circuit status. That is, the 4 circuits monitored by each of the 127

logical responders can control a maximum of 4 x 127 = 508 unique zones.

The point handling capability of an MX4428 system requiring individual LED

indicators per monitored point is therefore reduced to 508.

Therefore, the more individual LED indications that the FIP must show for each MXP

the more logical responders that MXP must represent.

Every additional 4 zones that must be indicated for the addressable devices on an

MXP incurs a cost of 1 additional logical responder (i.e. MX4428 responder loop

address).

(iii) For the same reasons as given in (ii) above, the more individually controllable output

devices the MXP must drive and control from logic, the more logical responders the

MXP must represent.

Page 2-6 24 March 2006 Issue 1.5

Page 17

Document: LT0273 MX4428 MXP Engineering / Technical Manual

Device Information and Programming

CHAPTER 3

DEVICE INFORMATION AND PROGRAMMING

Issue 1.5 24 March 2006 Page 3-1

Page 18

MX4428 MXP Engineering / Technical Manual Document: LT0273

Device Information and Programming

3.1 DEVICE TYPES

The MXP can communicate with a mix of up to 200 addressable devices, within limits

defined by loop size.

3.1.1 MX DEVICES

MX devices fall into three basic types:

(a) Sensors - Detectors (814PH, 814CH, 814I, 814H, VLC800)

(b) Ancillaries - Input (Monitor) (MIM800, MIM801, CIM800, DIM800)

- MCP (CP820, FP0838, FP0839)

- Output (Control) (RIM800, SNM800, LPS800)

(c) Bases - Standard Base (MUB, 5B)

- Short Circuit Isolator (5BI)

- Relay Base (814RB)

- Sounder Base (814SB, MkII Sounder Base)

In addition non-addressable smoke, thermal or flame detectors may be connected to the

MXP loop by means of the DIM800 Detector Input Module.

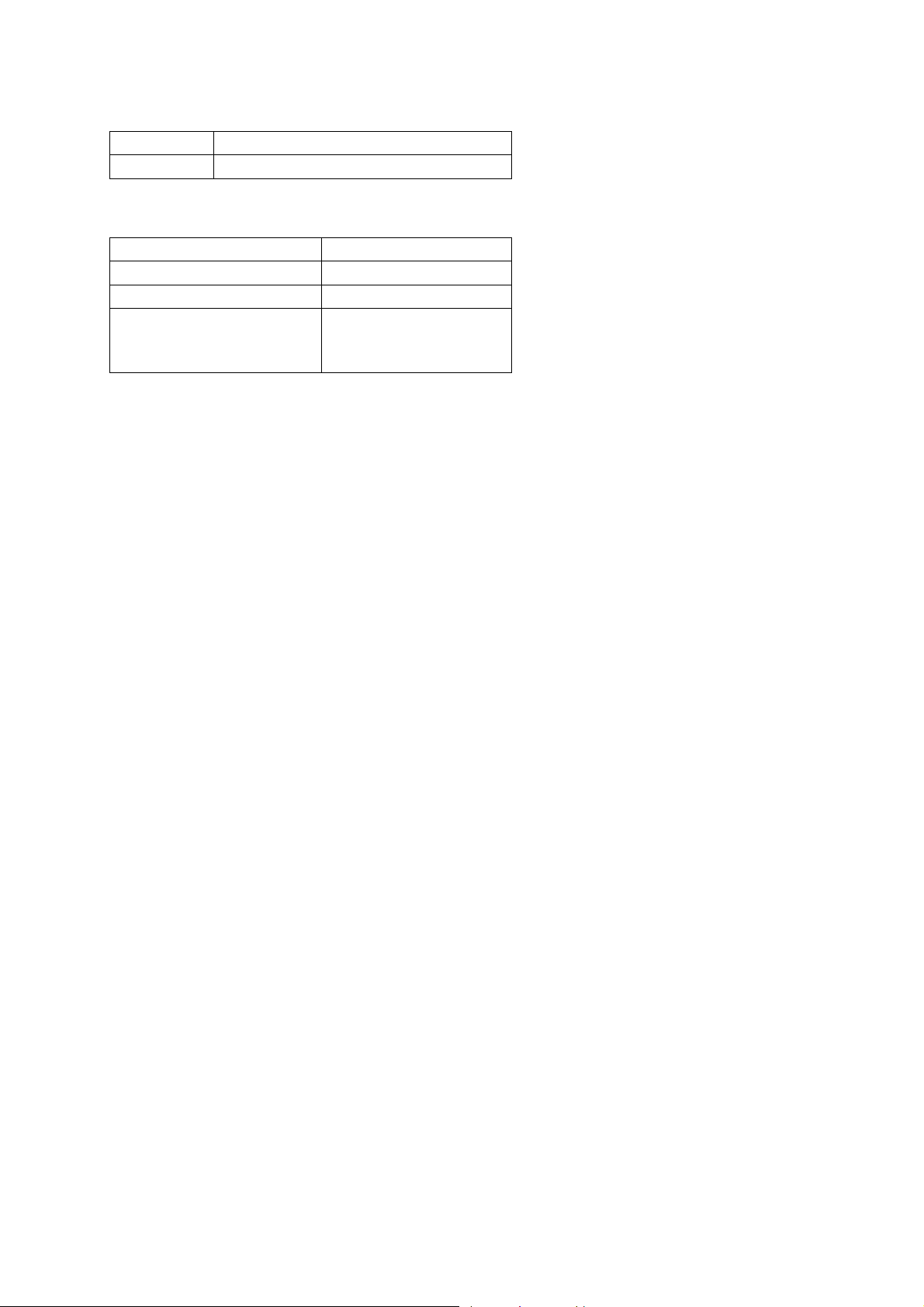

Code Description Input /

Output

814PH Photoelectric Smoke + Heat Detector I/O Y

814CH Carbon Monoxide + Heat Detector I/O Y

814I Ionisation Smoke Detector I/O Y

814H Heat Detector I/O Y

VLC800 Vesda Aspirating smoke detector I/O Y

MIM800 Mini Input Module Input

MIM801 Mini Input Module normally closed

Input

interrupt (FP0837)

CP820 Manual Call Point Input

FP0838

NZ Manual Call Point Input

FP0839

CIM800 Contact Input Module Input

DIM800 Detector Input Module Input

RIM800 Relay Interface Module (unsupervised

Output

load wiring)

SNM800 Sounder Notification Module (relay

Output

output with supervised load wiring)

LPS800 Loop Powered Sounder Output

The devices above are addressed by the

801AP Service Tool

or by command from the diagnostics terminal of an MXP.

Remote

LED

Page 3-2 24 March 2006 Issue 1.5

Page 19

Document: LT0273 MX4428 MXP Engineering / Technical Manual

Device Information and Programming

The standard base for use with the 814 detectors is:

MUB Minerva Universal Base (4”)

5B Minerva Universal Base (5”)

The following special purpose bases may also be used.

5BI Isolator Base

814RB Relay Base

814SB Sounder Base

MkII Sounder Base

Sounder Base

(802SB, 812SB, 901SB,

and 912SB)

The 814RB and 814SB may be plugged into an MUB, 5B or a 5BI, or mounted directly on a

wall / ceiling.

Note that none of the bases are addressable devices. The functional bases (814RB, 814SB,

and MkII Sounder Base) are controlled by the MXP via the detector which is plugged into

them.

The devices above marked as “Input/Output” are always inputs, but may also be used as

outputs via the Remote Indicator output and the signal to the 814RB, 814SB, and MkII

Sounder Base functional bases. The output functionality is programmable and not

necessarily related to the input status.

The devices which have a remote LED output may drive a Tyco E500Mk2 remote LED. The

functionality of this LED is programmable and it does not necessarily follow the local LED.

A brief description of the capabilities of each device follows:

a) 814I Analogue Ionisation Smoke Detector

This unit uses an ionisation chamber (with a small radioactive source) to detect airborne

particles of combustion products.

b) 814H Analogue Heat Detector

This detector incorporates a temperature sensor. The temperature sensor processing may

be programmed as Type A (rate of rise plus fixed temperature = 63°C), Type B (fixed

temperature only = 63°C), Type C (rate of rise plus fixed temperature = 93°C), or Type D

(fixed temperature only = 93°C). Type A, B, C or D operation is programmable at the

MX4428 panel.

c) 814PH Analogue Photoelectric Smoke Detector + Heat Detector

This unit uses light scattering to detect airborne particles of combustion products, and in

addition incorporates a temperature sensor. The heat function may be programmed in the

same way as for the 814H detector.

d) 814P Analogue Photoelectric Smoke Detector

This unit uses light scattering to detect airborne particles of combustion products.

Issue 1.5 24 March 2006 Page 3-3

Page 20

MX4428 MXP Engineering / Technical Manual Document: LT0273

Device Information and Programming

e) 814CH Analogue CO (Carbon monoxide) Detector + Heat Detector

This unit uses a special sensor to detect carbon monoxide, and in addition incorporates a

temperature sensor. The heat function may be programmed in the same way as for the

814H detector.

f) Mini Input Module MIM800

This unit has a single input for monitoring clean contacts (e.g. MCPs, flow switches

conventional detectors with hard contact outputs, relay contacts, switches). As well as

monitoring the state of the contacts the MIM800 can supervise the wiring for open circuit

fault and (optionally) short circuit fault.

g) Mini Input Module MIM801

This unit has a single input for monitoring clean contacts (e.g. MCPs, flow switches,

conventional detectors with hard contact outputs, relay contacts, switches). As well as

monitoring the state of the contacts the MIM801 can supervise the wiring for short circuit

fault and (optionally) open circuit fault. The MIM801 is very similar to the MIM800, however it

is optimised for normally closed applications and can generate an interrupt on an open

circuit. (Interrupt is only used when a fast response is required.) (The MIM800 and CIM800

can also generate interrupts, but only in response to closing contacts.)

h) Contact Input Module CIM800

This unit has two separate inputs for monitoring switch or relay contacts (e.g. MCPs, flow

switches, conventional detectors with hard contact outputs, relay contacts, switches). As well

as monitoring the state of the contacts the CIM800 can supervise the wiring for open circuit

fault and (optionally) short circuit fault. Although there are two separate inputs, both belong

to the same point. Either input in alarm will put the point into alarm, and either input in fault

will put the point into fault. Unused inputs must be terminated with a 200Ω resistor.

i) Detector Input Module DIM800

This unit has two separate inputs for monitoring conventional detectors. As well as

monitoring the state of the detectors they can supervise the wiring for open circuit faults.

Although there are two separate inputs, both belong to the same point. Either input in alarm

will put the point into alarm, and either input in fault will put the point into fault. An external

power supply is required. The voltage requirements for some conventional detector types

are very specific. (Refer to section

j) Australian Call Point Module CP820

This unit consists of a MIM800 complete with a call point switch and break-glass housing.

k) New Zealand Call Point Module FP0838, FP0839

This unit consists of a MIM801 complete with a call point switch and break-glass housing.

FP0838 is flush mounting while FP0839 is surface mounting.

l) Relay Interface Module RIM800

This unit has voltage free changeover relay contacts rated at 2A 30Vdc for external loads.

No supervision of load wiring is provided. However the relay position is supervised and a

“relay checkback fail” fault will be generated if it does not operate.

3.20).

Page 3-4 24 March 2006 Issue 1.5

Page 21

Document: LT0273 MX4428 MXP Engineering / Technical Manual

Device Information and Programming

m) Sounder Notification Module SNM800

This unit has a relay rated at 2A 30Vdc for switching external loads. Supervision of load

wiring and the load supply is provided. The relay position is supervised and a “relay

checkback” fault will be generated if it does not operate.

n) Short Circuit Isolator 5BI

This detector base is designed for isolating short circuited sections of the analog loop. For

instance it can be used where the loop wiring crosses zone boundaries and it will prevent a

short circuit from affecting more than one zone. As well as housing a detector it can be used

with no detector inserted.

o) Sounder Base 814SB and MkII Sounder Base

These detector bases are designed as low cost warning devices. The MkII Sounder Base is

a newer version of the 814SB. Some variants are loop powered while others are powered by

an external supply. The sounder is controlled by the detector which is plugged into the base,

but the operation of the sounder can be quite separate from the operation of the detector.

The 814SB can be setup to generate a number of tones (none of which are AS2220 or

ISO8201 compliant), and three sound levels are selectable.

The MkII Sounder Base models can be setup to generate a number of tones including

AS2220 and ISO8201 compliant evacuation tones, and on some models the sound level is

continuously adjustable. Currently none of the MkII Sounder Base models are SSL listed.

Note that the current taken by a loop powered sounder base is very much higher than any of

the other loop devices (except the LPS800), and the number of sounder bases on a loop is

limited by the available current.

p) Relay Base 814RB

This detector base is designed for a low cost output device. It is controlled by the detector

which is plugged into it, but the operation of the relay can be quite separate from the

operation of the detector. A voltage two pole changeover relay is provided, rated at 1A 30V

dc.

q) Loop Powered Sounder LPS800

This device is similar to the SNM800, in that it drives one or more external sounders,

however the sounder power comes from the loop rather than an external power supply. The

available output current is much lower than that of a SNM800, and as all this current comes

from the loop, the number of LPS800s and their load is limited by the available loop current.

r) Vesda VLC800

The Vision Systems VLC800-MX VESDA Laser COMPACT is an aspirating smoke detector.

It samples the smoke from air which is extracted via piping from a large area of a building.

The sensitivity is adjustable over a wide range at the VLC800 by PC software programme.

The VLC800 requires a 24V power supply.

A summary of the electrical specifications of the various devices is shown in

Table 3-1.

Issue 1.5 24 March 2006 Page 3-5

Page 22

MX4428 MXP Engineering / Technical Manual Document: LT0273

Device Information and Programming

All loop devices are rated at a loop voltage of 20Vdc - 40Vdc and a signalling voltage of 2V

p-p – 6V p-p. Alarm Currents specified do not include remote indicators. Add 7mA for each

remote indicator.

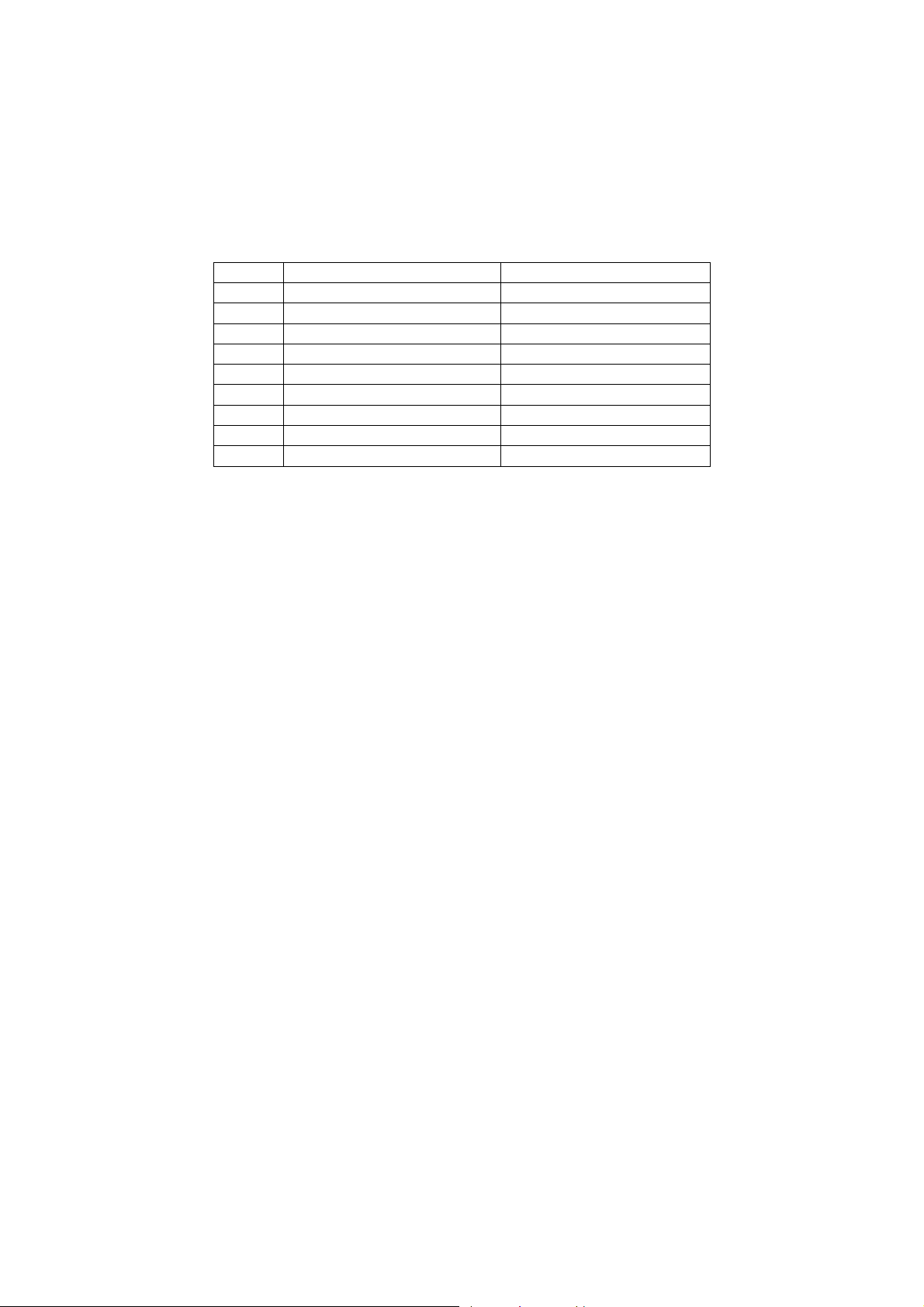

DEVICE FUNCTION Comments

814I

814H

814PH

814P

814CH

MIM800

MIM801

CIM800

DIM800

CP820

FP0838, FP0839

RIM800

SNM800

LPS800

MUB

5BI

814SB

MkII

Sounder

Bases

814RB

VLC800

802SB

812SB

901SB

912SB

Ionisation Smoke Detector Requires base

Heat Detector Requires base

Photo Smoke + Heat

Detector

Photo Smoke Detector Requires base

CO + Heat Detector Requires base

Mini Input Module

Mini Input Module

(normally closed interrupt)

Contact Input Module

(Conventional) Detector

Interface Monitor

Call Point

NZ Call Point

Relay Interface Module

Sounder Notification

Module (Supervised relay

output)

Loop Powered Sounder

Module

Standard Base

Isolator Base

Loop Powered Sounder

Base

Loop Powered Sounder

Base

Loop Powered Sounder

Base

Externally Powered

Sounder Base

Externally Powered

Sounder Base

Relay Base 1A 30Vdc

Vesda aspirating smoke

detector

Requires base

EOL 200Ω

Alarm R (if used) 100Ω

Max Wiring R 10Ω

N/O mode - as MIM800

N/C EOL 200Ω

Max wiring R 50Ω

EOL 200Ω

Alarm R (if used) 100Ω

Max Wiring R 10Ω

EOL 4k7

Requires separate supply.

2A 30Vdc

2A 30Vdc.

Requires external supply.

Provides 24V at up to 75mA

Selectable tone (not AS2220 or ISO8201)

Adjustable sound level

Selectable tone (Including AS2220 and ISO

8201 Evacuation tone)

Adjustable sound level

Selectable tone (Including AS2220 and ISO

8201 Evacuation tone)

Selectable tone (Including AS2220 and ISO

8201 Evacuation tone)

Adjustable Sound Level.

Requires external 24V

Selectable tone (Including AS2220 and ISO

8201 Evacuation tone)

Requires external 24V

2 pole changeover

Requires external supply. Requires PC to

set up.

Table 3-1 Compatible Device Summary

The MXP will allow some alternative devices to be used without generating a fault, where the

inserted device can provide all the features of the configured device. This includes an 814PH

or 814CH used where an 814H was programmed, a CIM800 used where a MIM800 was

programmed, and an 814PH used where an 814P was programmed.

Page 3-6 24 March 2006 Issue 1.5

Page 23

Document: LT0273 MX4428 MXP Engineering / Technical Manual

Device Information and Programming

3.2 DEVICE HANDLING CAPABILITY

3.2.1 OVERVIEW

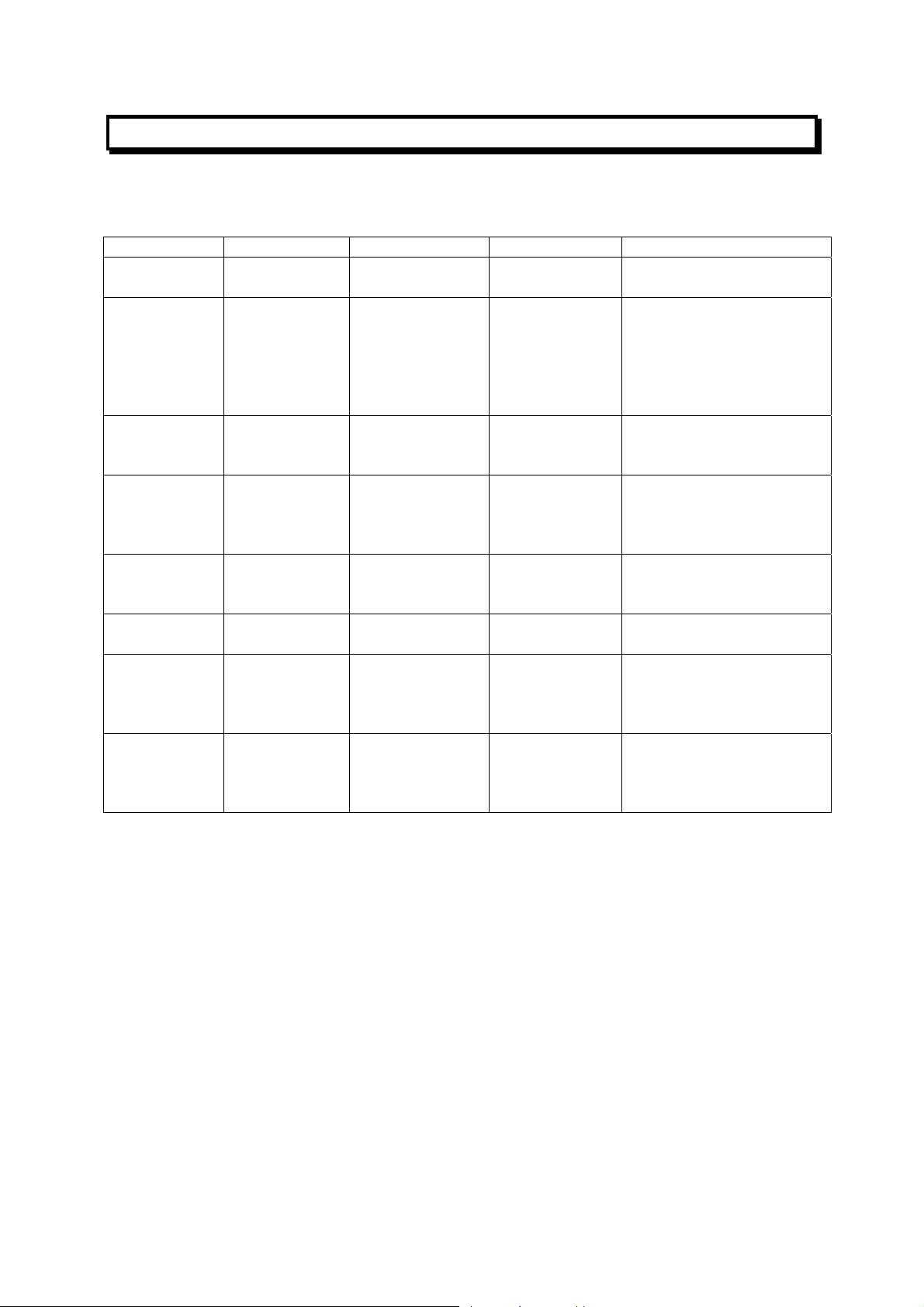

The parameters which determine the maximum number of each device type that can be put

on a loop are as follows. The column “MAX NO. DEVICES” assumes that all devices are of

the same type. If this is not the case, it is necessary to perform the calculations described

below.

DEVICE MAX NO.

DEVICES

814I 200 330uA 3.0mA 1 1.4

814H 200 250uA 3.0mA 1 1

814PH 200 275uA 3.0mA 1 1.2

814P 200 275uA 3.0mA 1 1.2

814CH 200 275uA 3.0mA 1 1

MIM800 200 275uA 2.8mA (with LED)

MIM801 200 275uA 2.8mA (with LED)

CIM800 200 275uA 2.8mA 1 1

DIM800 200 100uA

CP820 200 275uA 2.8mA 1 1.5

RIM800 200 285uA 2.8mA (with LED)

SNM800 200 450uA 3.0mA (with LED)

LPS800 33 or less,

depends on

load

5BI N/A 80uA 0.2 N/A

814SB 40(Quiet)

30(Medium)

24(Loud)

802SB* 200(Quiet)

50 (Loud)

812SB* 18 200uA 21mA 0.5 2.5

901SB* 200 200uA 200uA (Loop) 0.5 2.5

912SB* 200 200uA 200uA( Loop) 0.5 2.5

814RB 200 50uA 100uA 0.3 1.6

VLC800 125 300uA 300uA (no LE D)

Quiescent

Current

(Loop)

450uA Load current +

400uA 9mA(Quiet)

200uA 1.2mA (Quiet)

*Models of MkII Sounder Base

Table 3-2 Device Quantities and Loading

The particular combination of device types, external loads, cable length and type may limit

the total number of devices. This is calculated in the following sections.

There are two types of load which must be considered - DC and AC. Also if isolator bases

are used, the loading between each isolator base must be considered.

Alarm

Current

275uA (no LED)

275uA (no LED)

100uA (Loop) 1 1

285uA (no LED)

450uA (no LED)

4mA, with

minimum of 12mA

12mA(Medium)

15mA(Loud)

6.8mA (Loud)

2.8mA (with LED)

AC Units

(max 250

total)

1 1.5

1 1.5

1 5

1 5

1.5 1

2.4 2.5

0.5 2.5

2 1

IB Units

(max 100 IB

units between

Isolator Bases)

Issue 1.5 24 March 2006 Page 3-7

Page 24

MX4428 MXP Engineering / Technical Manual Document: LT0273

Device Information and Programming

It is recommended that the PC program F4000CAL is used for conducting the loop loading

calculations. However note that it does not include the isolator base loading, this must be

done manually.

3.2.2 DC LOAD

The total current available from the MX Loop terminals on the MXP is 400mA DC.

This must supply operating current to all addressable devices an the loop. This not only

includes the quiescent current required to power the device electronics, but also the

additional current drawn by devices in the ALARM state or by associated ALARM LEDs and

other loop powered outputs.

The sum of currents for all devices connected to the loop is calculated using the “alarm

current” values shown in

1) The MXP limits the number of Alarm LEDs turned on at any one time to 5

(programmable at MX4428).

2) Remote LEDs must be allowed for at 7mA each. Remote LEDs programmed to follow

the detector LED will be limited by the number of alarm LEDs. However remote LEDs

programmed to operate on “Circuit Alarm” or “Relay” will not be limited in any way.

3) LEDs on relay output devices (SNM800, RIM800, LPS800) will operate when the

relay is activated, if the MXP is configured at the MX4428 to flash the LED on Poll

“Global Blink Mode”.

4) The 814RB, RIM800 and SNM800 relay load current must not be supplied from the

analogue loop.

The sum of all currents must not exceed 400mA.

Furthermore, the voltage drop in the cable must not exceed 16.0V, regardless of which end

of the loop the cable is driven from. This is in order to ensure that with the minimum 36V

voltage available from the MX Loop terminals on the MXP, the minimum voltage at any

device will be at least 20V.

If you have any LPS800 devices on the loop, you may need to design for a higher minimum

loop voltage and a lower voltage drop. Refer to section

Table 3-2. Note –

3.23.2.

3.2.3 AC LOADING

Calculate the total of the “AC Units” shown in Table 3-2. The total must not exceed 250.

Also ensure that the cable length does not exceed the values in

Cable type Cable length

MICC 2L1.5, 2L2.5, 1H1.5, 2H2.5 1.8 km*

Steel Wire Armour (SWA) 1.8 km*

Fire resistant ‘foil and drain wire’, e.g.

Radox FR3013, FP200, Lifeline, Firetuff

BS6883 marine cable 2 km

Table 3-3 Maximum Cable Lengths

* Up to 2km of these cable types may be used on condition that the maximum AC loading is

restricted to less than 220 AC units per loop.

Page 3-8 24 March 2006 Issue 1.5

2 km

Table 3-3.

Page 25

Document: LT0273 MX4428 MXP Engineering / Technical Manual

Device Information and Programming

3.2.4 ISOLATOR BASE LOADING

If isolator bases are being used, calculate the sum of the “IB Units” from Table 3-2 for each

section of cable between isolator bases (or between the last isolator base and the end of a

cable spur). Include only one of the detectors at the ends of the section. The sum for any

section must not exceed 100.

See also section

4.1.3 for details of AS1670 requirements and section 4.1.4 for details of

NZS4512 requirements.

3.2.5 EXAMPLE

Consider an MXP monitoring 200 * 814PH detectors with 10 814SB Sounder Bases set to

High, on a 1300 metre long loop, using 1.5mm

2

wire. The cable is divided (with 9 Isolator

Bases) into 10 segments with 1 Sounder Base and 20 detectors on each segment.

(i) Calculate DC Load

IA = 195 x 275uA (No. of detectors in NORMAL)

+ 5 x 3.0mA (No. of detectors with Alarm LEDs turned on, assume limited to

5 max by MXP)

+ 10 x 15mA (Number of 814SB Sounder Bases)

+ 9 x 80uA (Number of Isolator Bases)

(Ref

Table 3-2. Note 1mA = 1000uA)

= 220mA which is well under 400mA

For the voltage drop calculation, assume the worst case in the first instance, i.e. that

all devices are at the far end of 1300 metres. The loop resistance of 1.5mm

2

wire is

25Ω per 1000m and the isolator base resistance is 0.25Ω.

Total R = 25Ω x 1.3 + 9 x 0.25Ω

= 34.75Ω.

Voltage drop = 34.75 x 0.220 = 7.7V, which is well under the maximum allowable of

16V.

(ii) Calculate AC Load

AC Units = 200 x 1 (detectors)

+ 10 x 2.4 (Sounder Bases)

+ 10 x 0.1 (Isolator Bases)

= 225 which is less than the maximum allowable of 250.

Cable length is well under the limits specified in

Table 3-3.

(iii) Calculate IB Load

IB Units for each section = 20 * 1.2 (814PH) + 1 * 2.5 (814SB)

= 26.5 which is less than 100.

As all parameters are within the specified limits, the design is satisfactory.

Issue 1.5 24 March 2006 Page 3-9

Page 26

MX4428 MXP Engineering / Technical Manual Document: LT0273

Device Information and Programming

3.3 OUTPUT CONTROL

The following “outputs” are available on the Analogue loop –

• Output modules – RIM800, SNM800, and LPS800

• Functional Base outputs of detectors (controlling 814SB, MkII Sounder Base or 814RB)

• Remote LED output of detectors.

Each of these is programmable at the MX4428 for which of 3 sources controls the output.

In all cases the outputs are turned off if the point is isolated.

The 3 selectable sources are as follows –

1. Relay output

The output is controlled by the state of the corresponding relay output as sent to the

responder. The relay output state can be controlled directly with a logic equation, be

controlled by the state of the ACZ that the relay is mapped to (this also allows supervision

fault states on the SNM800 and LPS800 output to be indicated), or be controlled by the test

state of the flow switch zone it is mapped to.

The functional bases and remote LED outputs for detectors mapped to circuit X of logical

responder R will be controlled by the state of relay X of logical responder R, i.e. the relay

with the same number as the detector circuit.

2. Circuit alarm

The output will turn on when the corresponding circuit goes into alarm. If the circuit maps to

a latching zone then the output will turn off when the zone alarm is reset. If the circuit does

not map to a latching zone the output will turn off when the circuit goes out of alarm. The

circuit alarm state is determined by the MXP and so can’t include other responder circuits,

nor the state of the zone(s) the circuit maps to. (Use “relay output” if these are needed.)

The functional bases and remote LED outputs for detectors will be controlled by the circuit

the detector is mapped to. Output modules mapped to relay X of logical responder R will be

controlled by circuit X of logical responder R, i.e. the circuit with the same number as the

relay.

WARNING - the output will not be disabled by zone isolate.

3. Point alarm

The output will turn on when that point goes into alarm. If the point maps to a latching zone

then the output will stay on until the zone alarm is reset. If the point does not map to a

latching zone the output will turn off when the point goes out of alarm.

This option is not available on output modules (RIM800, SNM800, and LPS800).

WARNING - the output will not be disabled by zone isolate.

Page 3-10 24 March 2006 Issue 1.5

Page 27

Document: LT0273 MX4428 MXP Engineering / Technical Manual

Device Information and Programming

3.3.1 PROGRAMMING