Page 1

Worldwide

Contacts

www.tyco-fire.com

Model MC-1 (MC-2) Manual Control Station

For Deluge And Preaction Systems

Manual Release Service

Assembly

General

The box and cover in Figure 1 are thermoplastic. The elastomer water seal is TEFLON.

Description

The TYCO Model MC-1 (MC-2) Manual

Control Station provides a tamper

resistant means for emergency release

(that is, operation) of TYCO Automatic

Water Control Valves. Interconnection with the valves may be direct via

hydraulic (wet) pilot line or indirect via

pneumatic (dry) pilot line to a Model

DP-1 Dry Pilot Actuator.

The MC-2 Manual Control Station is a

modified MC-1 designed for use as a

trim component for the Model DV-5a

Automatic Water Control Valve.

NOTICE

The Model MC-1 Manual Control

Station described herein must be

installed and maintained in compliance

with this document, as well as with the

applicable standards of the NATIONAL

FIRE PROTECTION ASSOCIATION, in

addition to the standards of any other

authorities having jurisdiction. Failure

to do so may impair the performance

of these devices.

The owner is responsible for maintaining their fire protection system and

devices in proper operating condition.

The installing contractor or sprinkler

manufacturer should be contacted with

any questions.

Technical

Data

Approvals

UL and UL Listed

FM Approved

Working Water Pressure

20 to 300 psi (1,4 to 20,7 bar)

Minimum Ambient Temperature

Dry Pilot Lines: −50°F (−46°C)

Wet Pilot Lines: 40°F (4°C)

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Operation

Operating instructions are imprinted on

the Cover, and the Cover is hinged to

the Box and is held up in its normally

closed position by a polystyrene Break

Rod. The Break Rod is inserted through

corresponding holes in the top of the

Cover and interior of the Box, and the

Break Rod does not extend above the

top of the Cover so as to prevent unnoticed tampering (that is, the Cover can

only be opened by breaking the Break

Rod).

After actuation of the MC-1, interference between a boss on the interior

of the Cover and the Operating Lever

prevents closing of the Cover, before

the Operating Lever is raised. As an

added precaution, the Cover has been

weighted such that it will not remain

closed unless a Break Rod has been

placed in position.

Opening of the Model MC-1 Manual

Control Station relieves hydraulic or

pneumatic pressure, as applicable,

which permits the automatic water

control valve to open and allow a flow

of water into the system piping.

Installation

When the TYCO Model MC-1 (MC-2)

Manual Control Station is provided as

a trim component for TYCO Automatic

Water Control Valves, MC-1 (MC-2)

must be installed in accordance with

the specific instructions provided with

the TYCO Automatic Water Control

Valve Technical Data Sheets.

When the MC-1 is utilized for remote

locations on either wet or dry pilot lines,

the following instructions apply:

Step 1. The piping to the MC-1 is to

be securely mounted, and the MC-1 is

to be located 4-1/2 ft to 6 ft above the

floor/ground level.

Step 2. The MC-1 is to be installed vertically (so that the Cover will fall open

when the Break Rod is not in place), in

plain view, and in a readily accessible

location.

Step 3. When used with a wet pilot line,

piping from the outlet of the MC-1 is

to be directed to a suitable drain such

that there will be no accidental damage

to property or danger to persons when

the MC-1 is operated. When used on

dry pilot lines, the outlet piping is to be

directed towards the rear of the MC-1

and away from the operator.

Design

Criteria

The TYCO Model MC-1 (MC-2) Manual

Control Station located at the TYCO

Automatic Water Control Valve is to be

reset in accordance with the specific

instructions provided with the TYCO

Automatic Water Control Valve Technical Data Sheets.

When the MC-1 is utilized for remote

locations on either wet or dry pilot

lines, it is reset by raising the Operating Lever, closing the Cover, and inserting a replacement Break Rod.

NOTICE

In order to ensure the proper maximum

pull open force for the Cover, use only

P/N 92-289-1-008 replacement Break

Rods.

It is recommended that a supply of

spare Break Rods be maintained on

hand.

Page 1 of 2 AUGUST 2018 TFP1382

Page 2

TFP13 82

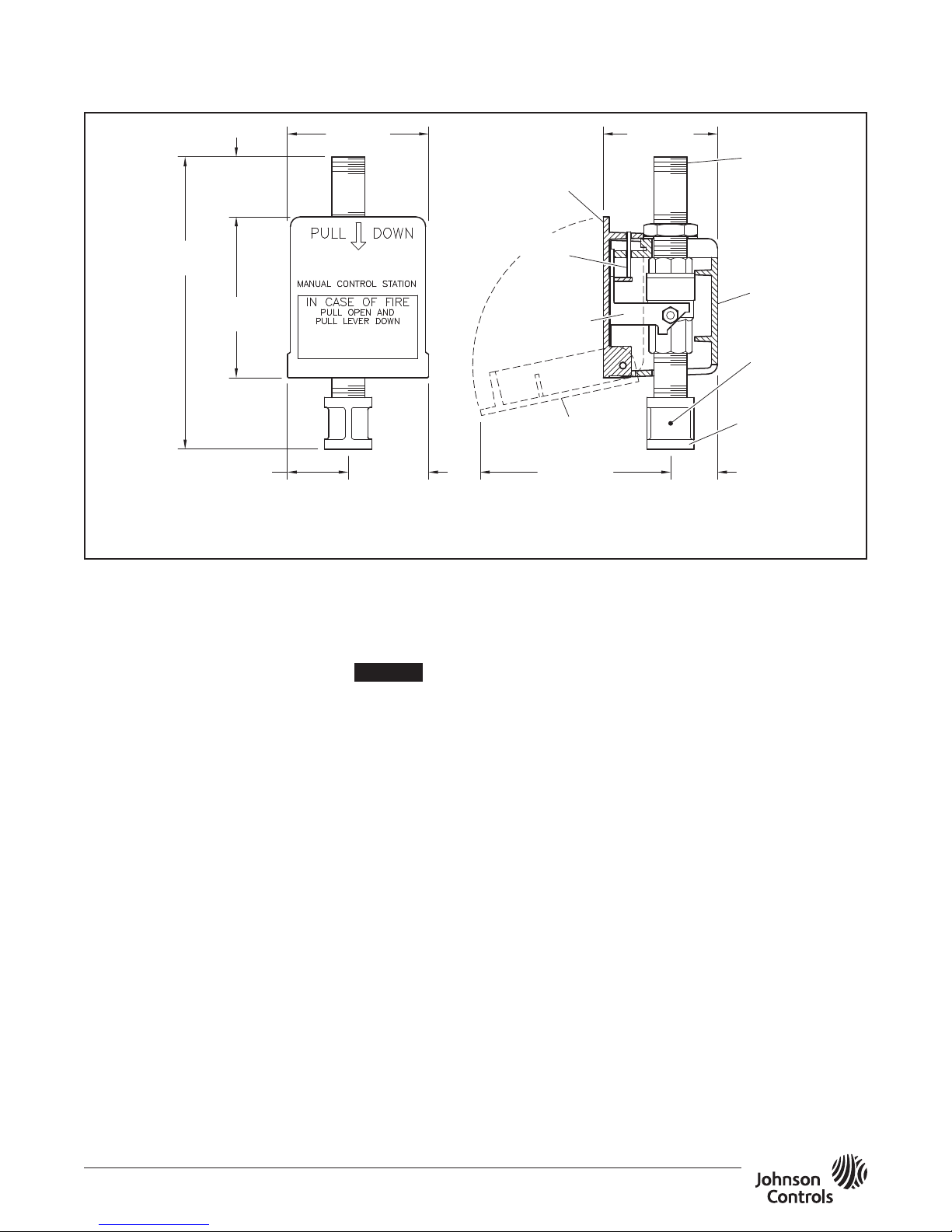

3-9/16"

2-7/8"

(30,2 mm)

(123,8 mm)

(52,4 mm)

(38,4 mm)

(188,7 mm)

Page 2 of 2

1-1/2"

(38,4 mm)

7-7/16"

4-1/8"

(104,8 mm)

1-1/2"

Note: When the MC-1 is ordered as a MC-2 repair trim component for the Model DV-5a

Automatic Water Control Valve, the assembly is provided without the drain coupling.

MODEL MC-1 (MC-2) MANUAL CONTROL STATION

Care and

Maintenance

The following inspection procedure

must be performed as indicated, in

addition to any specific requirements

of the NFPA, and any impairment must

be immediately corrected.

Before closing a fire protection system

control valve for inspection or maintenance work on the fire protection

system that it controls, permission to

shut down the effected fire protection

system must first be obtained from

the proper authorities and all personnel who may be affected by this action

must be notified.

The owner is responsible for the

inspection, testing, and maintenance of

their fire protection system and devices

in compliance with this document, as

well as with the applicable standards

of the NATIONAL FIRE PROTECTION

ASSOCIATION (e.g., NFPA 25), in addition to the standards of any authority

having jurisdiction. The installing contractor or product manufacturer should

be contacted relative to any questions.

Automatic sprinkler systems are recommended to be inspected, tested,

and maintained by a qualified Inspection Service.

(90,5 mm)

COVER

HANDLE

BREAK

ROD

OPERATING

LEVER

2-1/16"

FIGURE 1

After placing a fire protection system

in service, notify the proper authorities

and advise those responsible for monitoring proprietary and/or central station

alarms.

NOTICE

Unless appropriate precautions are

taken, operation of the MC-1 (MC-2)

when performing an inspection will

result in operation of the deluge or preaction systems and/or alarms.

Notify the owner and the fire department, central station, or other signal

station to which the system serves or

alarms are connected before performing inspections.

The Model MC-1 (MC-2) Manual

Control Station must be inspected

quarterly in accordance with this

section.

Step 1. Verify that the MC-1 (MC-2)

opens with ease when operated.

Step 2. Verify that flow out of the MC-1

(MC-2)increases to a rate which will trip

the deluge or preaction valve.

Step 3. Inspect the drain for evidence of continued leakage past the

MC-1 (MC-2). Determine and correct

the cause of the leakage problem, as

applicable.

Step 4. Verify that the MC-1 (MC-2)

is reset properly using only a

P/N 92-289-1008 Break Rod.

COVER

(OPEN)

4-7/8"

(73,0 mm)

1/2" NPT

INLET

BOX

SEE

NOTE

1/2" NPT

OUTLET

(DRAIN)

1-3/16"

Limited

Warranty

For warranty terms and conditions, visit

www.tyco-fire.com.

Ordering

Procedure

Contact your local distributor for availability. When placing an order, indicate

the full product name and Part Number

(P/N).

MC -1

Specify: Model MC-1 Manual Control

Station with galvanized steel fittings,

P/N 52-289-2-001

MC-2

Specify: Model MC-1 (MC-2) Manual

Control Station with galvanized steel

fittings for use with DV-5a Valve,

P/N 54-500-2-000

Note: Contact your local distributor

for MC-1 and MC-2 with black steel

fittings.

Replacement Break Rod

Specify: Replacement Break Rod for

Model MC-1 Manual Control Station,

P/ N 92- 289 -1-0 0 8

1400 Pennbr ook Pa rkwa y, Lans dale, PA 1944 6 | Teleph one +1-215- 362-070 0

© 2018 John son Control s. All right s reserved. A ll specifica tions and ot her informa tion shown wer e current as o f document rev ision date an d are subject t o change wit hout notice.

NATIONAL FIRE P ROTECTION ASSOCIATIO N and NFPA are register ed trademarks of N ational Fire Protec tion Associati on;

TEFLON is a regi stered tradema rk of DuPont

Loading...

Loading...